Method for preparing synthetic gas through microwave pyrolysis and gasification of biomass

A technology of pyrolysis gasification and biomass, applied in fixed bed gasification, chemical modification of combustible gas, purification/transformation of combustible gas, etc., can solve the problems of fast gas flow rate, easy to carry a large amount of particles, etc., and achieve effective conversion rate Improve, avoid structural changes inactivation, reduce the effect of tar content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation of the catalyst used in the embodiment

[0043] According to the ratio of nickel nitrate, magnesium nitrate and lanthanum nitrate molar ratio 1:10:0.1, weigh 0.8mol nickel nitrate, 8mol magnesium nitrate and 0.08mol lanthanum nitrate to make 8L solution, and mix the mixed solution with 2kg silicon carbide powder evenly , and then an equal volume of urea solution (35.52 mol) was mixed and stirred by dropwise addition, while keeping the constant temperature of the reaction system at 90°C. During this process, a precipitate was gradually formed. After the reaction was complete, the precipitate was separated by centrifugation, and the precipitate was filtered and washed with deionized water to neutrality. The precipitate was dried at 90°C for 6h, and then burned at 950°C for 20h. After natural cooling, extrude into strips, the size is φ6mm×10mm, and dry for later use. The resulting catalyst is defined as Ni 0.8 Mg 8 La 0.08 o 8.85 / SiC, in which the met...

Embodiment

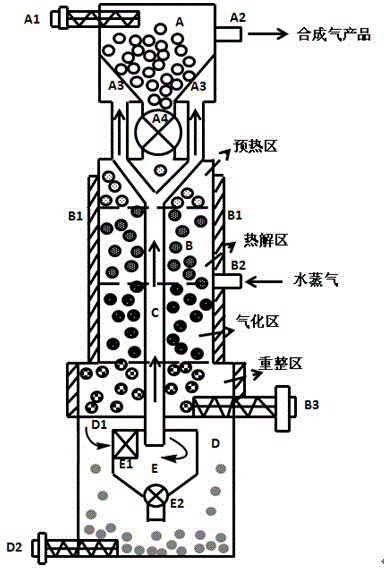

[0045] Biomass raw material and microwave catalyst Ni 0.8 Mg 8 La 0.08 o 8.85 / SiC is fed into the bin A through the screw feeder A1 according to the ratio of 1:1, and then the star valve A4 is opened, and the raw material falls into the microwave pyrolysis reactor B by gravity, and the microwave pyrolysis reactor is filled with the raw material first and then opened Microwave generator B1, set the temperature of preheating zone, pyrolysis zone, gasification zone and reforming zone to 160°C, 550°C, 700°C and 1000°C respectively, and the corresponding microwave power is 1×10 5 W / m 3 , 4×10 5 W / m 3 , 6×10 5 W / m 3 , 8×10 5 W / m 3 . When the reactor reaches the set temperature, adjust the feed rate to 0.5kg / h. First, the raw material is dehydrated and activated in the preheating zone for 5 minutes, and then enters the pyrolysis zone for 5 minutes to react. The semi-coke in the formed gas-liquid-solid product is 15%. , The pyrolysis volatile fraction is 85%, and the pyrol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com