A kind of biomass pyrolysis gasification method

A technology for pyrolysis, gasification and biomass, which is applied in the manufacture of combustible gas and petroleum industry. , Improve the heating effect and shorten the conveying distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

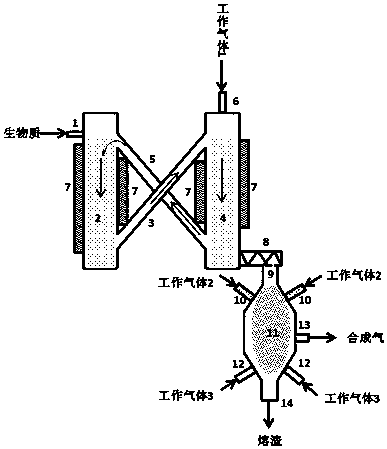

[0038] Enter the biomass raw material with a size of 20mm into the microwave pyrolysis reaction section 2 through the feed port 1, and start the screw propeller 3 at the same time to send part of the biomass raw material to the microwave directional gasification section 4. When the raw material filling reaches the microwave generator 7 irradiation Stop feeding and close the screw propeller 3 within the range, then turn on the microwave generator 7, and set the microwave pyrolysis reaction section 3 power 3 × 10 5 W / m 3 and microwave directional gasification section 4 power 4×10 5 W / m 3 . When the temperatures of the microwave pyrolysis reaction section 2 and the microwave directional gasification section 4 reach 600°C and 800°C respectively, the biomass raw material (10kg / h) is re-introduced and the screw propeller 3 and the screw feeder 5 are started to control the flow from the screw Bio-coke returned by feeder 5 (specific surface area 686m 2 / g, pore volume 0.21cm 3 / g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com