Rapid thin layer deep analysis method based on laser sputtering ionization

An analysis method and laser sputtering technology, which are applied in the direction of material analysis, material analysis, and measurement devices by electromagnetic means, which can solve the problem of time-consuming SIMS analysis, serious matrix effects, powerlessness in non-metal analysis, and limitation of thin-layer industrial development, etc. problems, to achieve the effect of reducing matrix effects, reducing sample damage, and relaxing the requirements of sample shape and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

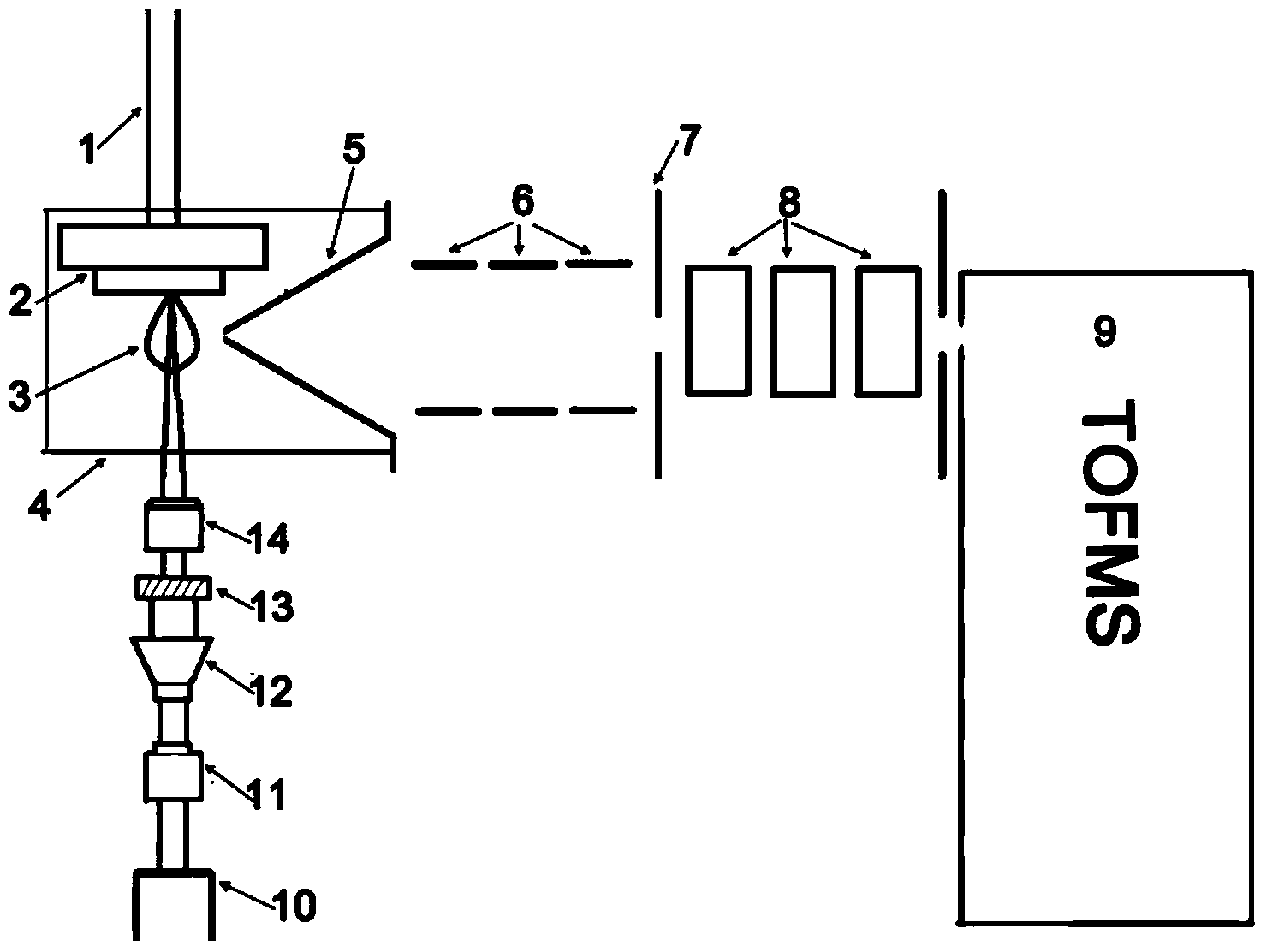

Method used

Image

Examples

Embodiment 1

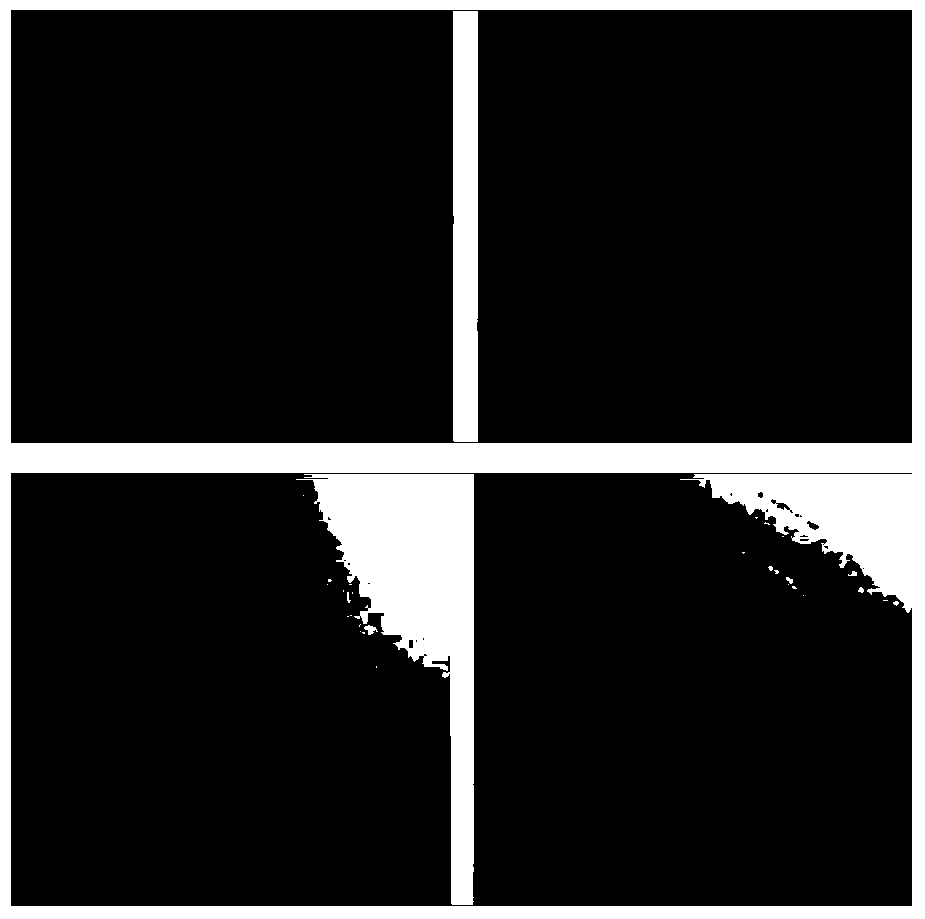

[0040] see figure 2 , discloses the metallographic microscope images of the crater after the nanosecond laser and the femtosecond laser act on the multilayer sample of the copper substrate respectively, in which (a) nanosecond laser sputtering 2 times, (b) nanosecond laser sputtering 10 times, (c ) 8 times of femtosecond laser sputtering and (d) 40 times of femtosecond laser sputtering. Among them, the nanosecond laser power is 9.0×109W / cm2, and the femtosecond laser is 4.4×1012W / cm2. It can be seen from the figure that nanosecond laser sputtering has obvious melting, while femtosecond laser sputtering has no melting phenomenon and is very uniform. So femtosecond laser is more suitable for thin layer analysis.

Embodiment 2

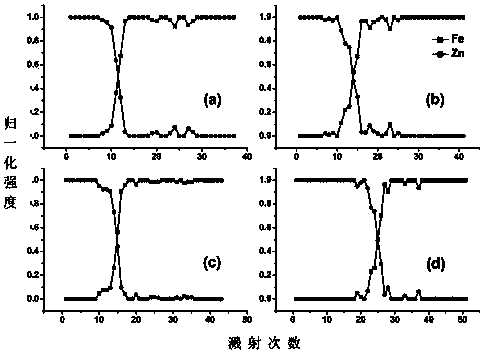

[0042] see image 3 , discloses the depth analysis diagrams of Zn layers at different depths by nanosecond laser ionization vertical time-of-flight mass spectrometry, wherein the thicknesses of Zn are 11.4, 15.5, 17.1, and 28.6 μm, respectively. from figure 2 Using the method of the present invention to analyze single-coated thin-layer samples can obtain obvious steps between the coating and the substrate, thus illustrating that the invention is suitable for single-coated sample analysis.

[0043] Further, at Figure 4 right image 3 The calibration curves of the thickness of the coating and the number of drilling pulses in the four different galvanized iron samples, the calibration curve shows that the number of laser drilling pulses increases linearly with the increase of the coating thickness, which shows that the laser sputtering rate is relatively Uniform, the coating thickness can be converted by the number of pulses.

Embodiment 3

[0045] See Figure 5, which compares femtosecond and nanosecond laser ionization vertical time-of-flight mass spectrometry and analyzes the spectra obtained by different material multilayer conductor coating conductor substrates, specifically: Rh160nm / Au20nm / Pd1100nm three-layer Cu plating. It can be seen from the results that a nanosecond laser is used in Figure 5(a), and a femtosecond laser is used in Figure 5(b). It can be seen from Fig. 5(a) that due to the high sputtering rate of the nanosecond laser, the signals of the first three layers all appear after the first laser action. Therefore, nanosecond pulsed lasers cannot analyze the first three coating layers. While in Fig. 5(b) the femtosecond laser can realize the analysis of the first three layers, because the depth resolution of the femtosecond laser is higher.

[0046] Further, taking Pd as an example to calculate, it can be concluded that the nanosecond laser ionization vertical time-of-flight mass spectrometry can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com