Patents

Literature

65results about How to "Improve effective conversion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing synthetic gas through microwave pyrolysis and gasification of biomass

ActiveCN105524662ARelaxed size requirementsReduce preprocessing power consumptionCombustible gas chemical modificationFixed-bed gasificationHigh carbonLiquid fuel

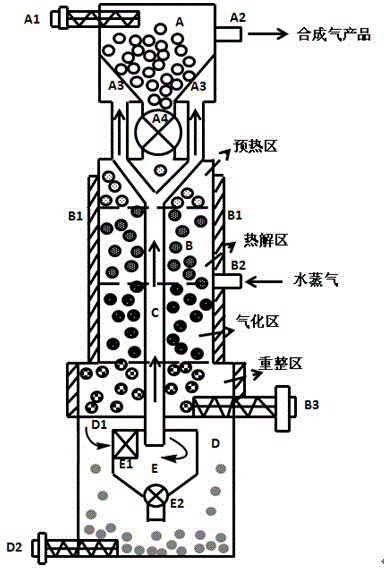

The invention discloses a method for preparing synthetic gas through microwave pyrolysis and gasification of biomass. The method comprises the following steps: a biomass raw material sent to a bunker and a catalyst are introduced into a microwave pyrolysis reactor, and passes through a preheating zone, a pyrolysis zone, a gasification zone and a reforming zone in order for reactions of dehydration, cracking, gasification and reforming, the reformed product is performed with gas-solid separation, gas and a few of carried tar and coke are subjected to a cracking reaction in a gas lifting pipe again, synthetic gas is released from an outlet, and the coke and ash obtained by gas-solid separation can be discharged from a reactor. The method has the advantages of high biomass gasification rate and high carbon conversion rate, the obtained synthetic gas product has high quality, can satisfy synthesis requirement of a liquid fuel, and has good application prospect.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEMICALS CO LTD +1

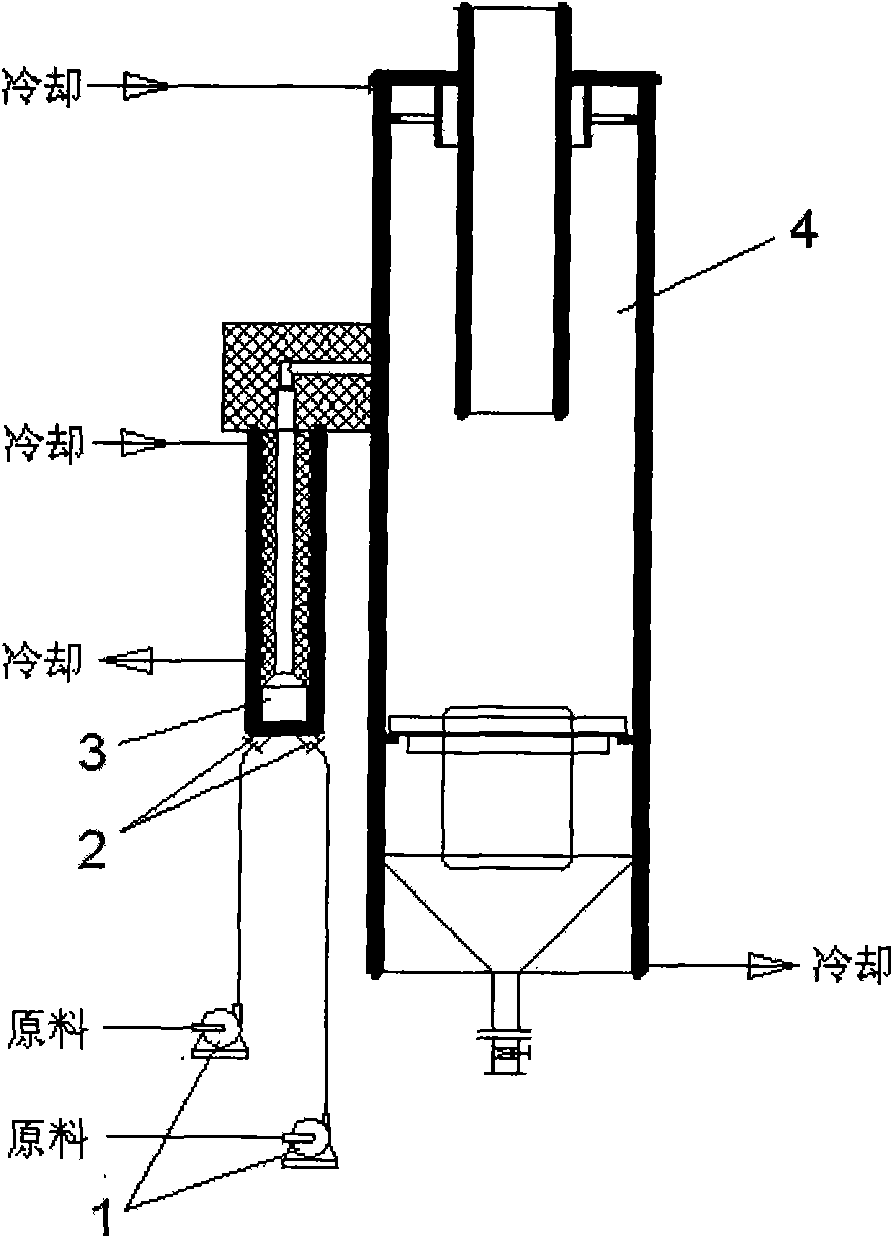

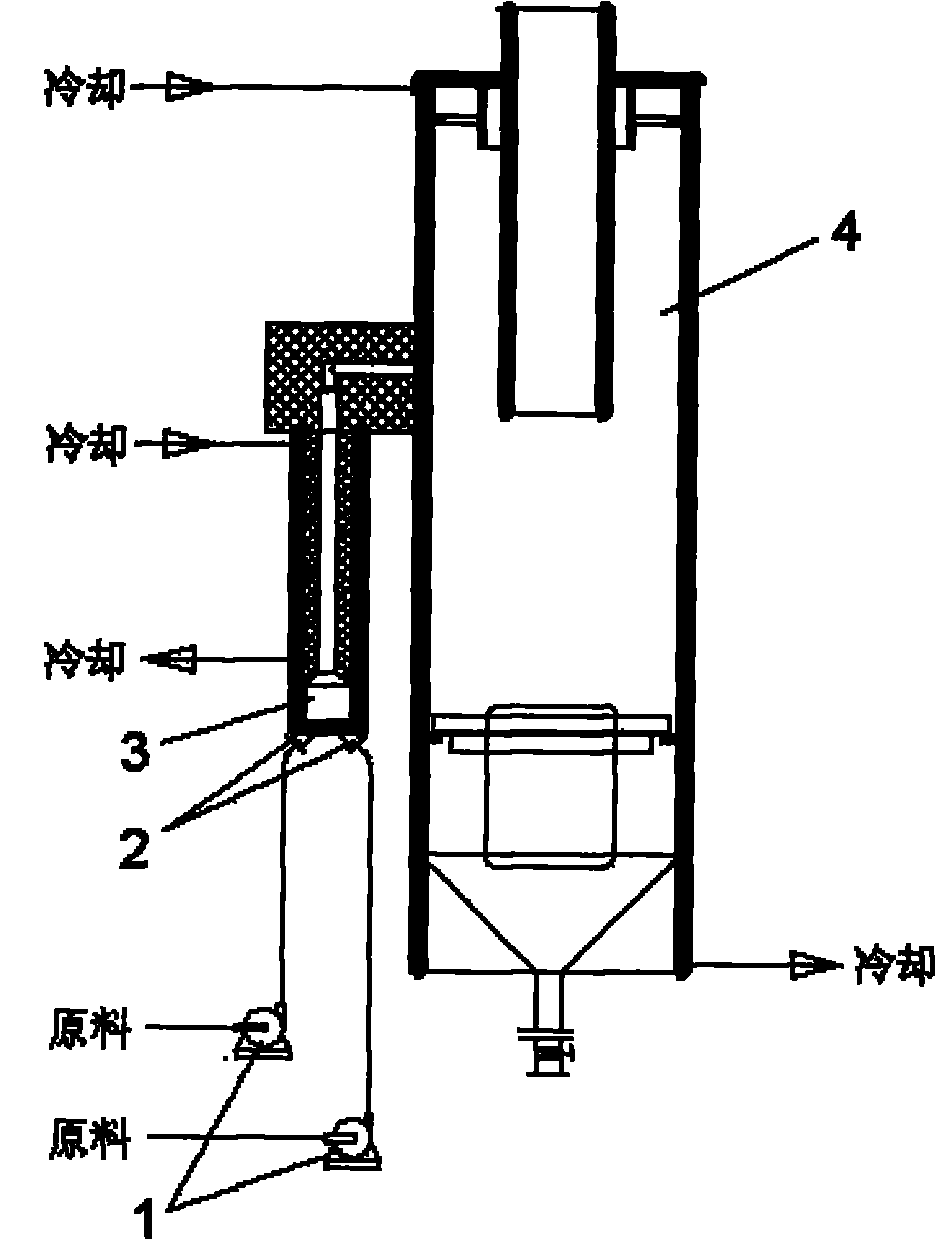

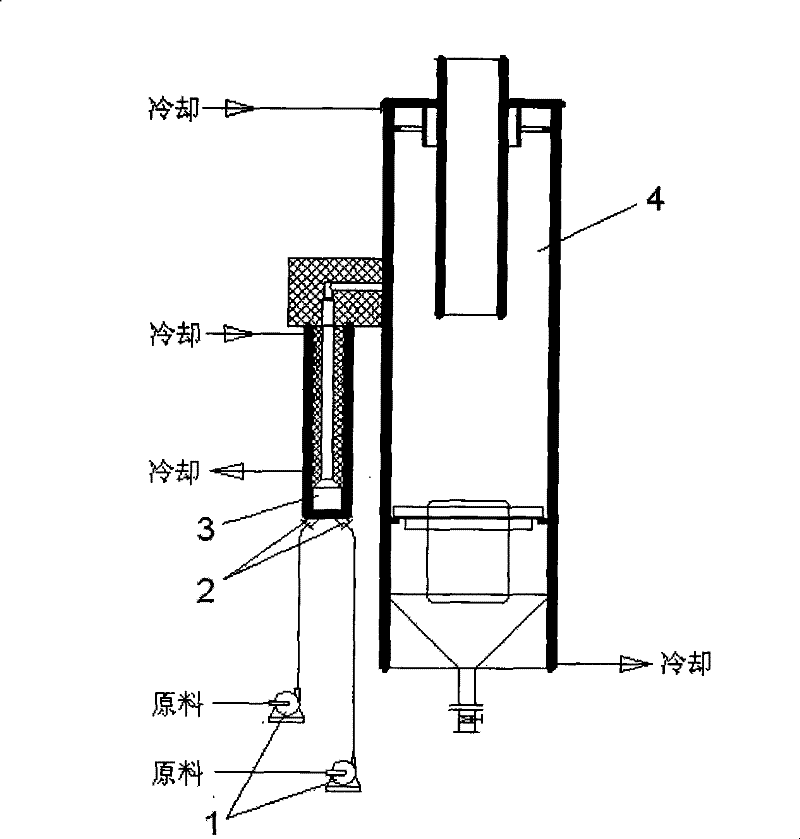

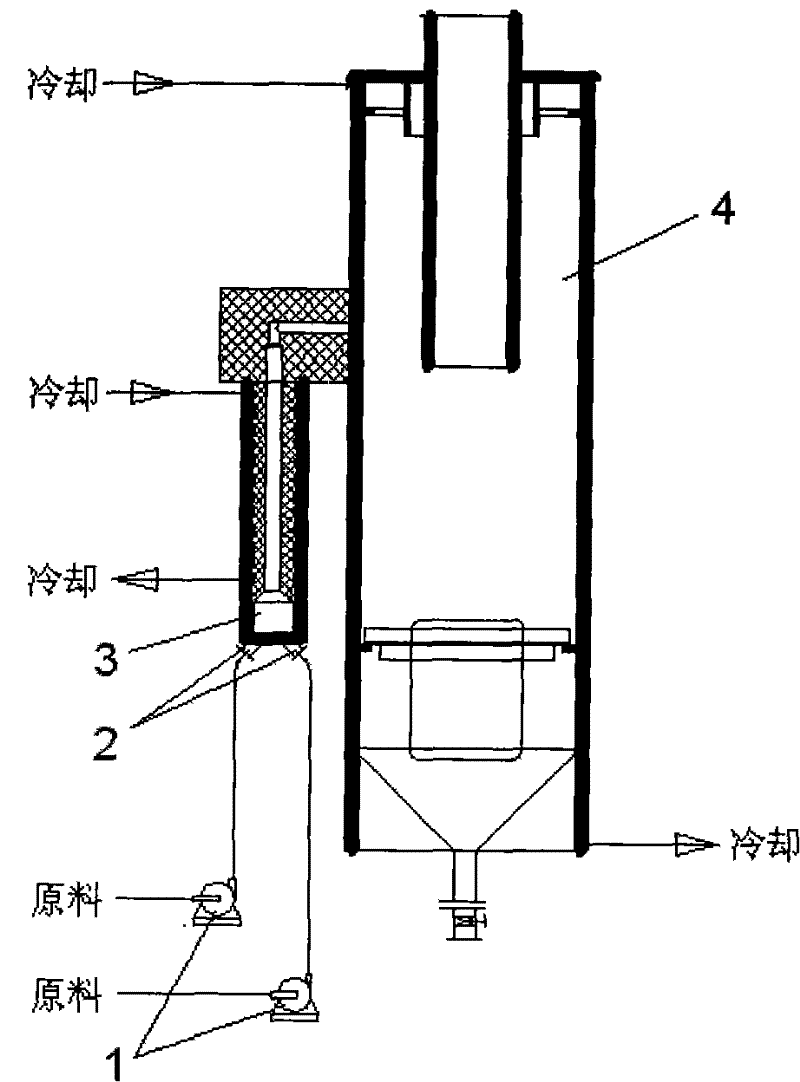

Method for continuous pyrolysis and gasification of material

ActiveCN106675661ASmall footprintExtended stayCombustible gas productionMicrowave pyrolysisWater vapor

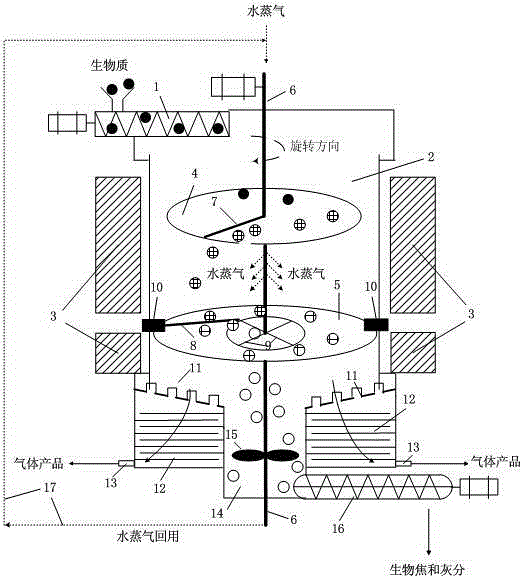

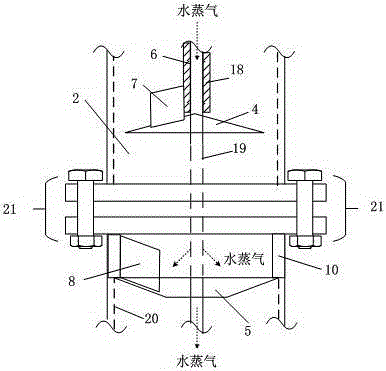

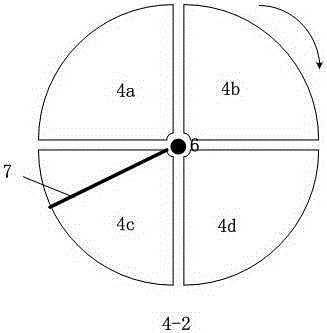

The invention discloses a method for continuous pyrolysis and gasification of a material. The method comprises the following steps: 1, a raw material and a catalyst enter a microwave pyrolysis and gasification system, fall to a first-stage rotating disc of a microwave reaction chamber, and sequentially undergo drying, activating and pyrolysis treatment with rotating; 2, a pyrolysis treated material falls to a second-stage rotating disc of the microwave reaction chamber, and the pyrolysis treated material and a pyrolysis volatile compound undergo a gasification and reforming reaction under the action of water vapor; and 3, a solid product obtained in step 2 falls to a residue storage tank below the microwave reaction chamber from middle holes of the second-stage rotating disc through a second-stage pushing baffle plate, and is discharged from a reaction system under stirring and screw dual action, and a gas product enters a settlement chamber from an annular sieve plate at the bottom of the microwave reaction chamber, and undergoes settlement treatment to obtain the gasification product. The method has the advantages of fast cracking speed, high gasification efficiency, high quality of the gas product, meeting of liquid fuel synthesis requirements, and good application prospect.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEMICALS CO LTD +1

ZSM-5 molecular sieve catalyst for catalytic preparation of xylene from coked benzene and methanol and use thereof

ActiveCN104874418AHigh catalytic activity and stabilityImprove effective conversion rateMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationCoalMethanol

The invention provides a ZSM-5 molecular sieve catalyst for catalytic preparation of xylene from coked benzene and methanol and a use thereof. A preparation method of the ZSM-5 molecular sieve catalyst comprises blending 45-90wt% of a hydrogen-type ZSM-5 molecular sieve, 10-50wt% of a binder, 1-20wt% of sesbania cannabina powder and a dilute nitric acid solution as an assistant by stirring to obtain a uniform mixture, drying and roasting the mixture, extruding the mixture to obtain a strip, immersing the strip in a solution containing one or two of Mg, Zn, Gd, P, La, Ce, Mo and Ni, and carrying out drying and roasting so that the strip is loaded with the metals. In catalytic alkylation reaction preparation of xylene from coked benzene and methanol, the ZSM-5 molecular sieve catalyst has high catalytic activity, high stability, a high raw material effective conversion rate and high desired product xylene selectivity, improves the existing xylene production technology, improves a coal-derived coked benzene utilization rate and realizes change of waster into valuables.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Production method of dimethyl phosphite

ActiveCN101870712AAvoid acidolysis side effectsImprove effective conversion rateGroup 5/15 element organic compoundsChemical/physical/physico-chemical nozzle-type rreactorsLiquid productCyclone

The invention relates to a production method of dimethyl phosphate, which takes phosphorus trichloride and methyl alcohol as raw materials for reaction. The method comprises the steps of: in a reaction chamber space having cross injection angle and the injection structures of the raw materials, respectively and continuously injecting and sending the phosphorus trichloride and the methyl alcohol which are based on the molar ratio of 1: (3.0-3.1) into the reaction chamber space through respective injection structures by corresponding pumping mechanisms for mixing together and reaction; then, introducing reaction material into a centrifugal cyclone separator with the pressure lower than that of the reaction chamber space along the tangential direction, and leading noncondensable gas and condensing liquid product to have centrifugal cyclone separation; and collecting the liquid dimethyl phosphate product descending along the inner wall of the centrifugal cyclone separator. The method can rapidly complete the reaction and the separation for products, effectively reduces the contact between HCl and the dimethyl phosphate, inhibits the occurrence of side reaction, improves the yield and the quality of the product, and greatly reduces the energy consumption.

Owner:SICHUAN LESHAN FUHUA TONGDA AGRO-CHEM TECH CO LTD +1

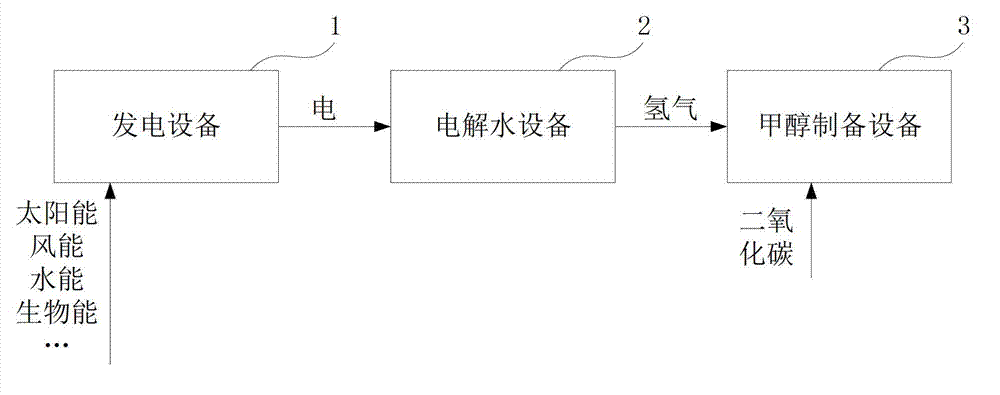

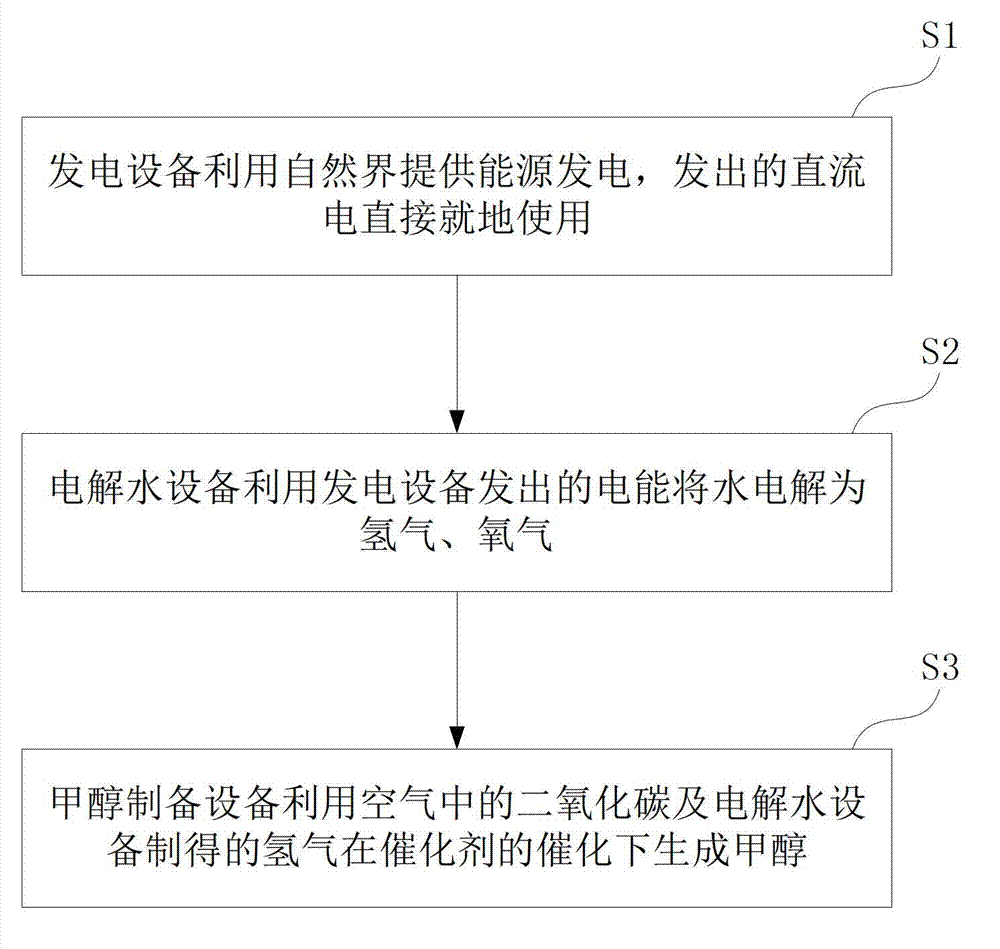

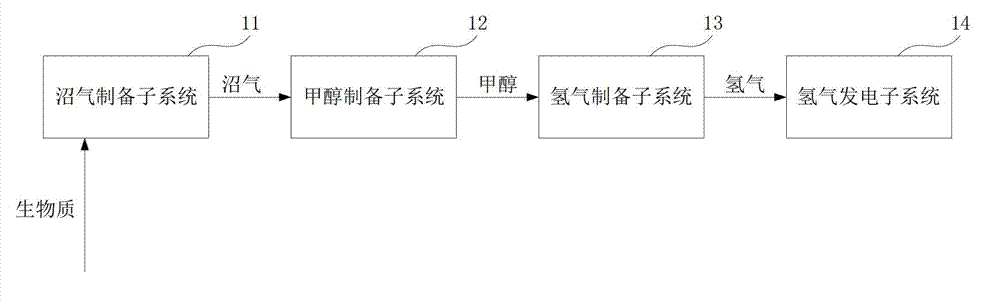

Power generation and supply system and method

InactiveCN102787993AImprove effective conversion rateNo transport requiredMachines/enginesMechanical power devicesElectrolysisEngineering

The invention discloses a power generation and supply system and a method. The power generation and supply system comprises a power generating set which makes use of natural energy to generate electric power, and the direct current power generated by the power generating set can be used at the site. The power generation and supply system further comprises a water electrolyzing device and a carbinol preparation device. The water electrolyzing device makes use of the electric energy generated by the power generating set to electrolyze water into hydrogen and oxygen. The carbinol preparation device makes use of the carbon dioxide in the air and the hydrogen prepared by the water electrolyzing device to produce carbinol under the catalysis of catalyst. According to the power generation and supply system and the method, the direct current power generated by the power generating set by making use of the natural energy is directly used without being converted to alternating current power or being transported, so the effective conversion ratio of the electric energy can be improved. Meanwhile, the power generation and supply system specifically can store the generated electric energy, that is, the electric energy is used to prepare carbinol through carbon dioxide and hydrogen; the carbinol can be stored as an energy source and energy can be obtained from the carbinol combustion; and the carbinol and water can also be used to prepare hydrogen for generation.

Owner:广州市移电科技有限公司

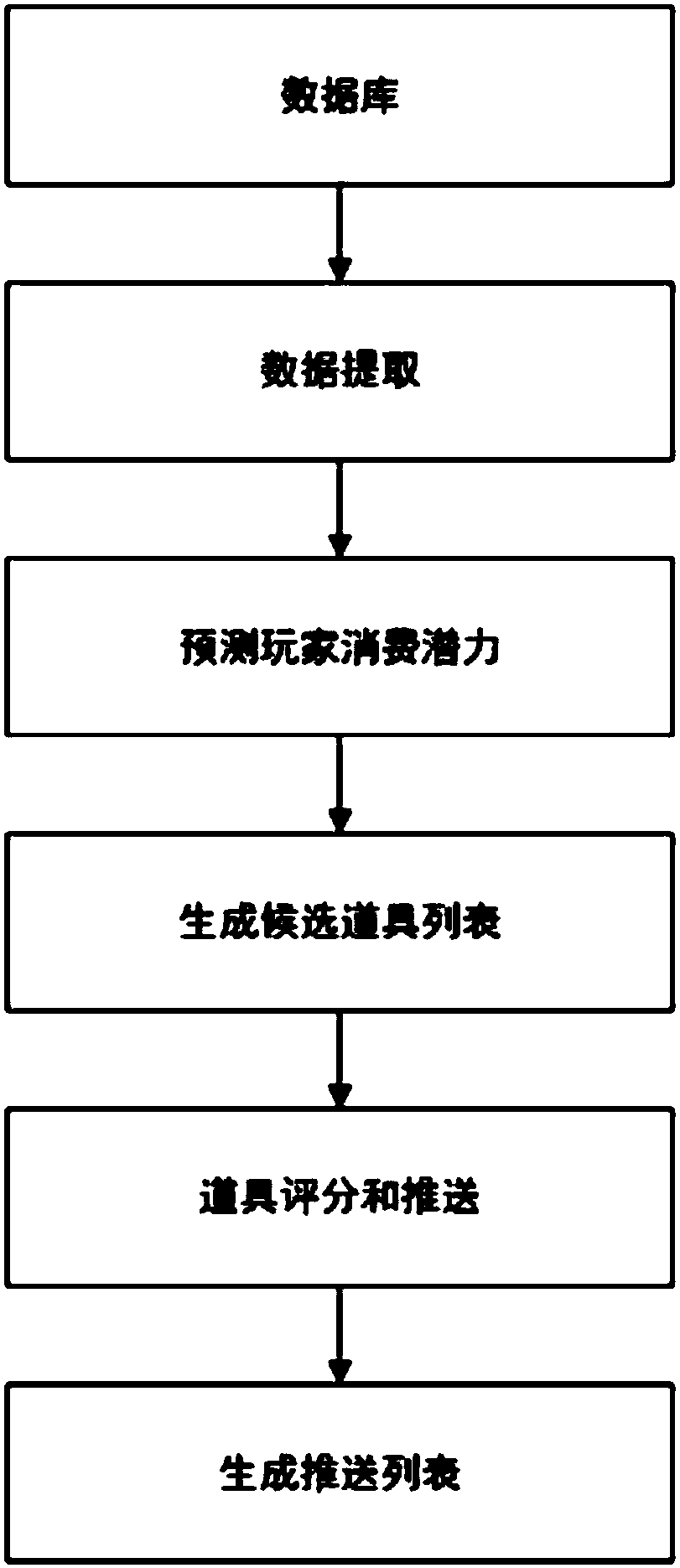

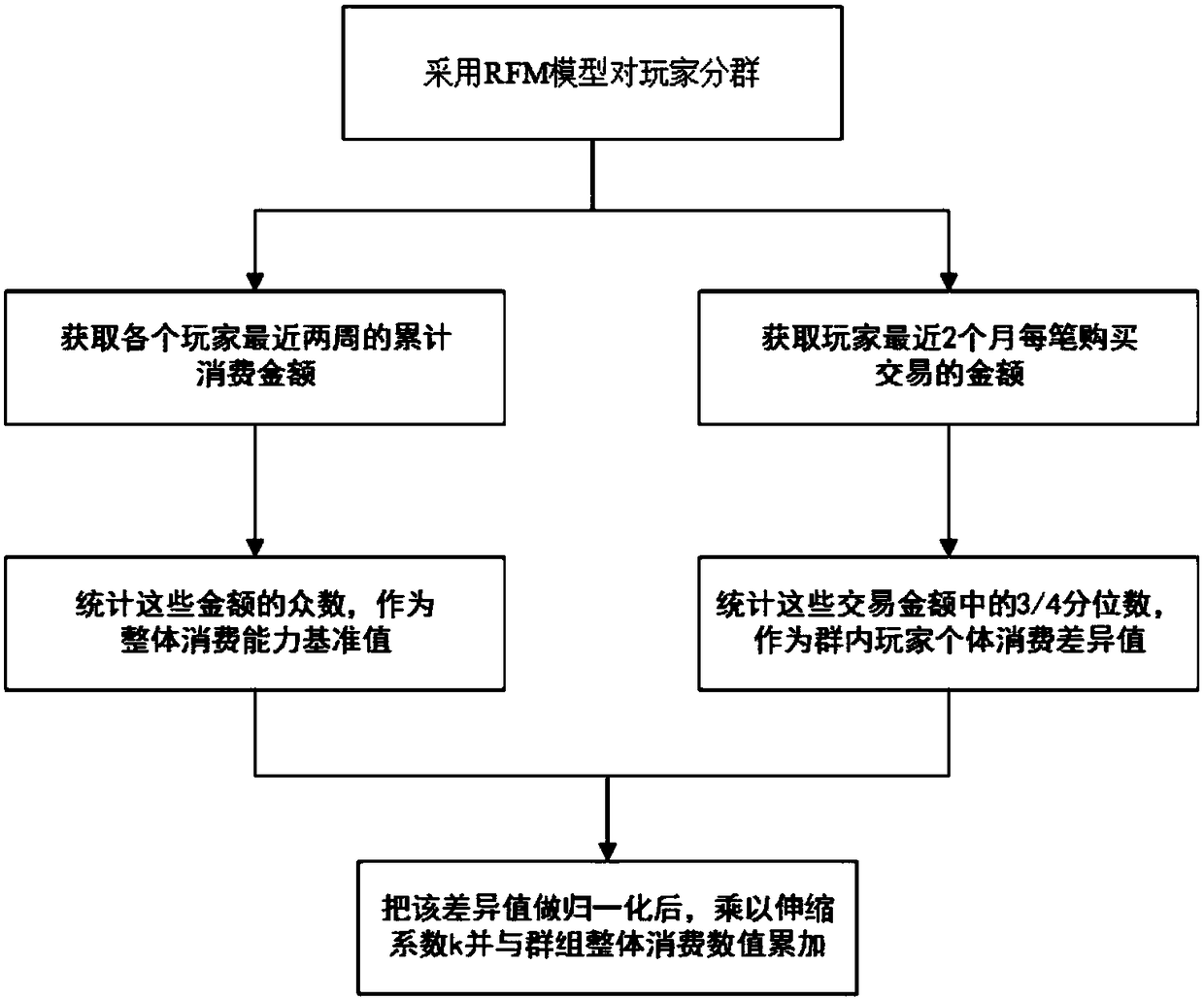

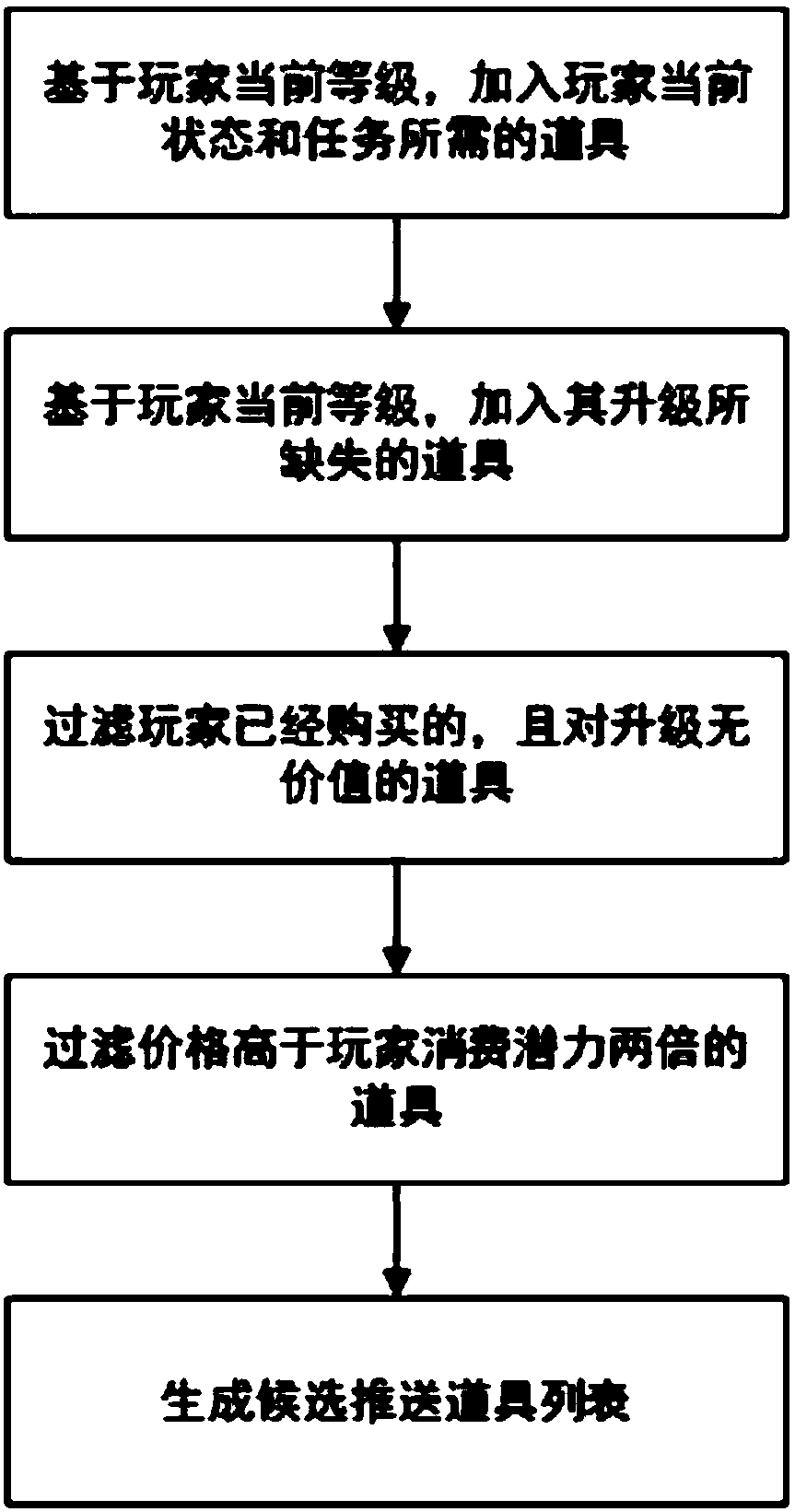

Player consumption potential-based game prop pushing method and device

ActiveCN108090800AImprove effective conversion rateSolve industry problemsBuying/selling/leasing transactionsVideo gamesData scienceOperations research

The invention provides a player consumption potential-based game prop pushing method and device. The method comprises the following steps that: the consumption data of players are extracted from a database; the players are grouped, the consumption ability of each player in each group is predicted; props matched with the consumption ability of the players are selected, and a prop candidate list isgenerated; and candidate props are sorted and pushed to the corresponding players. According to the player consumption potential-based game prop pushing method and device of the invention, the pushinglist of the game props is sorted and outputted on the basis of a plurality of factors; the game props that are matched with the consumption expectation of the players are pushed to the players; the effective conversion rate of conversion from pushing to transaction is significantly improved; and industrial problems are solved.

Owner:ZHUHAI KINGSOFT ONLINE GAME TECH CO LTD +1

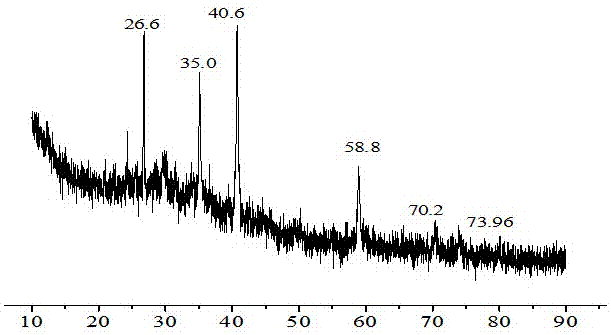

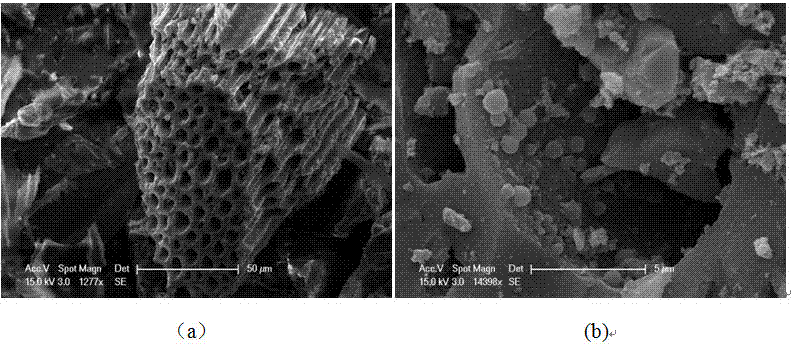

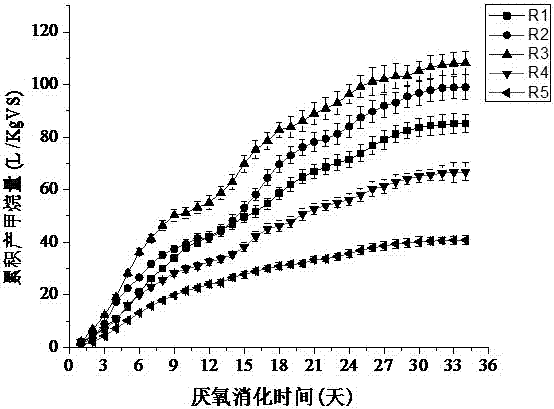

Method capable of improving methane yield in sludge anaerobic digestion process and enhancing heavy metal stabilization process

InactiveCN107117789AEvenly distributedWide range of materialsOther chemical processesWater treatment compoundsActivated carbonAnaerobic digestion

The invention relates to a method capable of improving methane yield in a sludge anaerobic digestion process and enhancing heavy metal stabilization process. According to the method, corn stalk is utilized as a raw material to prepare stalk activated carbon under nitrogen protection and pyrolysis temperature of 550 DEG C; the stalk activated carbon is utilized as a carrier to react with a KMnO4 solution to finally obtain a nano MnO loaded activated carbon function material; in a sludge anaerobic digestion acid production stage, the nano MnO loaded activated carbon function material is added into an anaerobic reaction detection according to a proportion, cumulative gas production of methane in the sludge anaerobic digestion process is obviously improved, free-state heavy metal in the sludge can be effectively adsorbed and processed in a complexation mode at the same time, biological validity and mobility of the heavy metal are reduced, and the heavy metal stabilization process is enhanced. The method disclosed by the invention can be applied to residual sludge anaerobic digestion of urban sewage treatment plants, effectively improves the cumulative gas production of the methane, reduces biological validity of the heavy metal in the sludge anaerobic digestion process and enhances the heavy metal stabilization process.

Owner:TONGJI UNIV

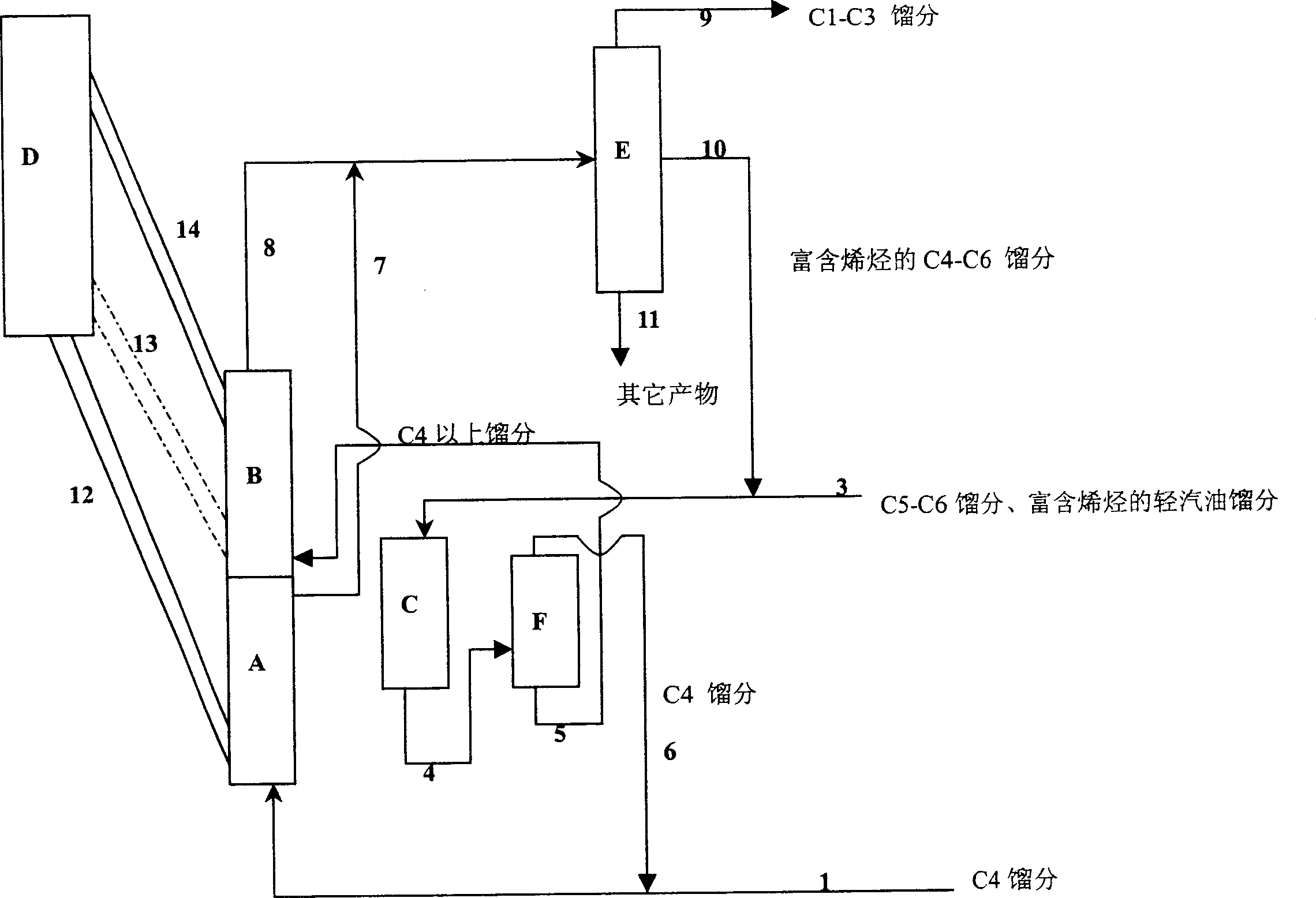

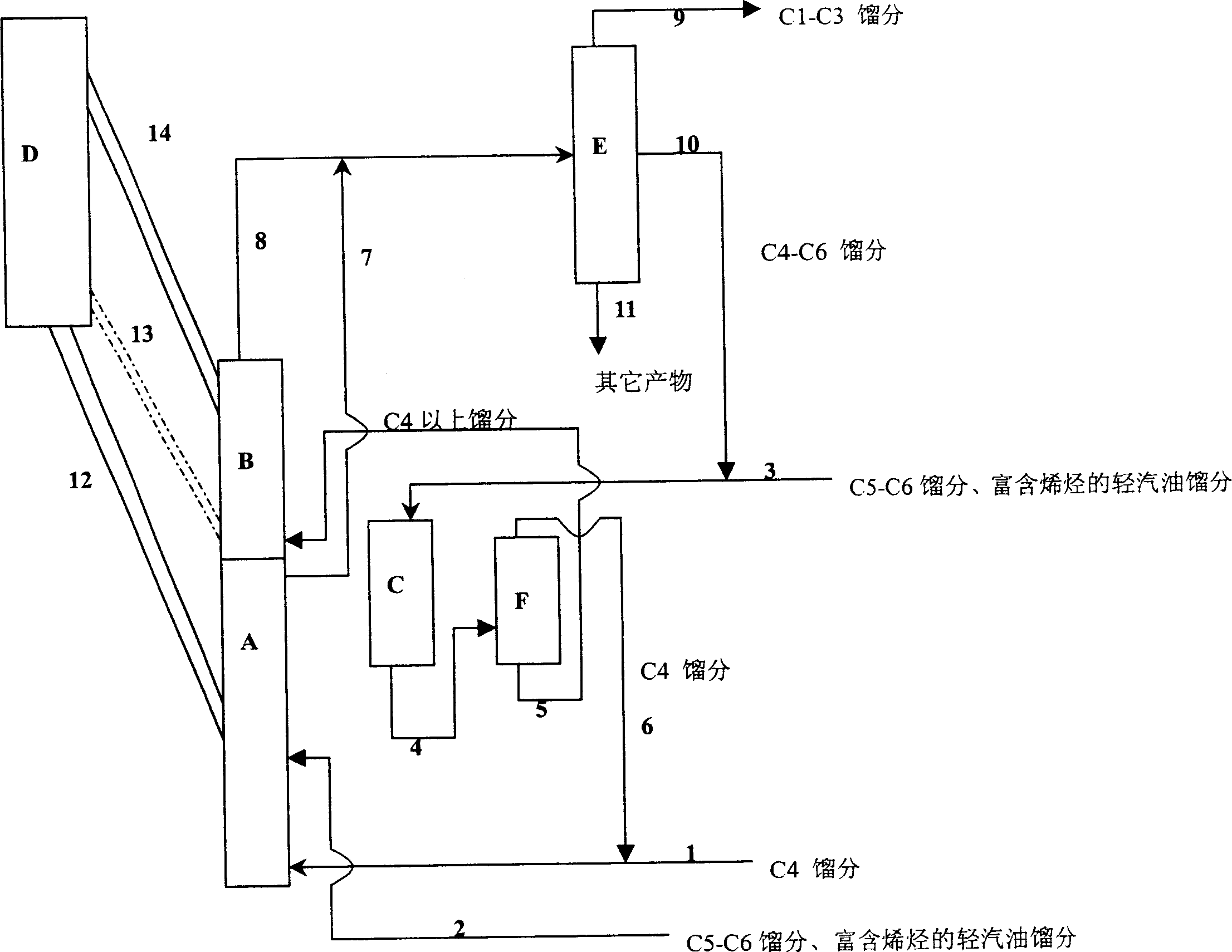

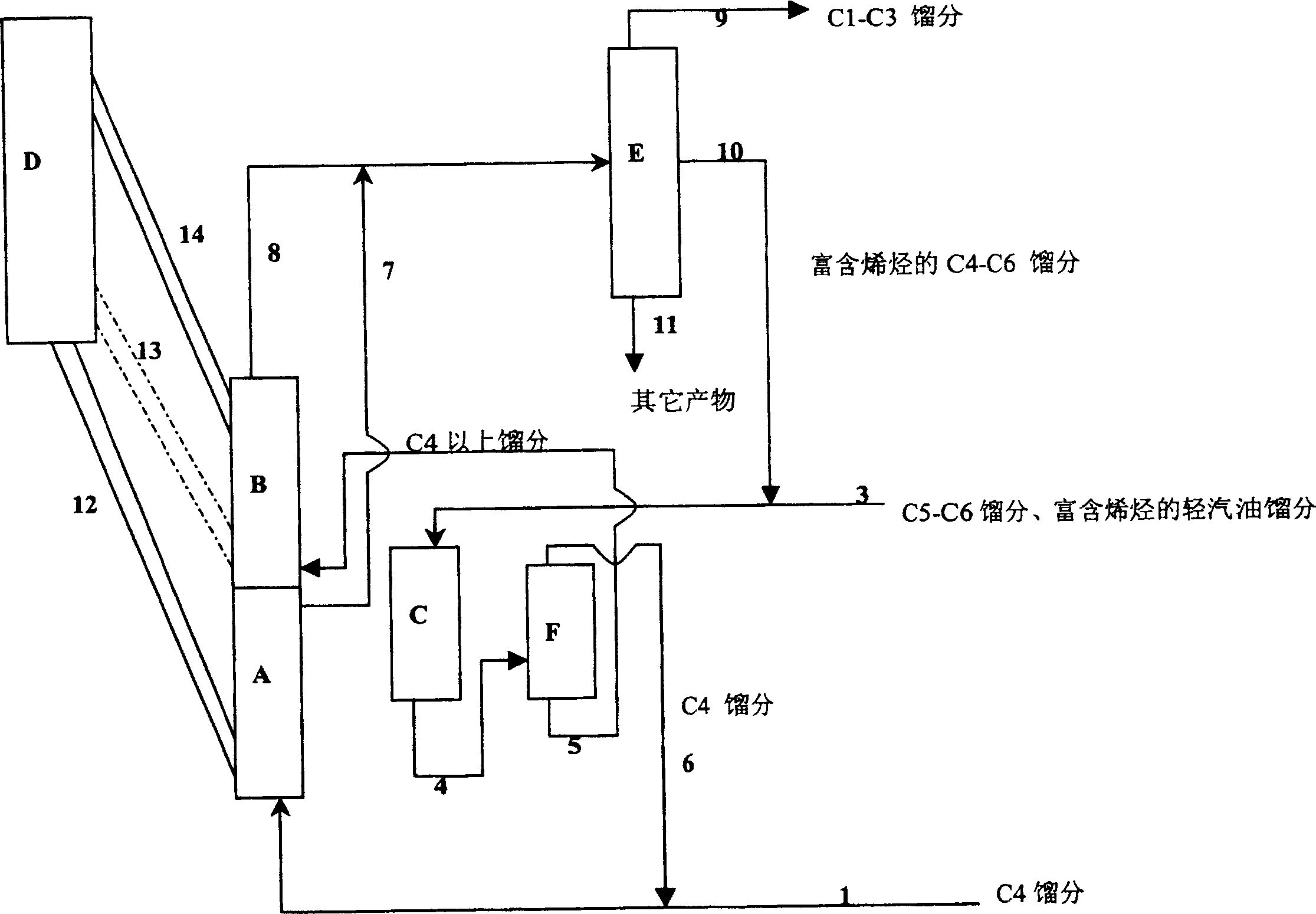

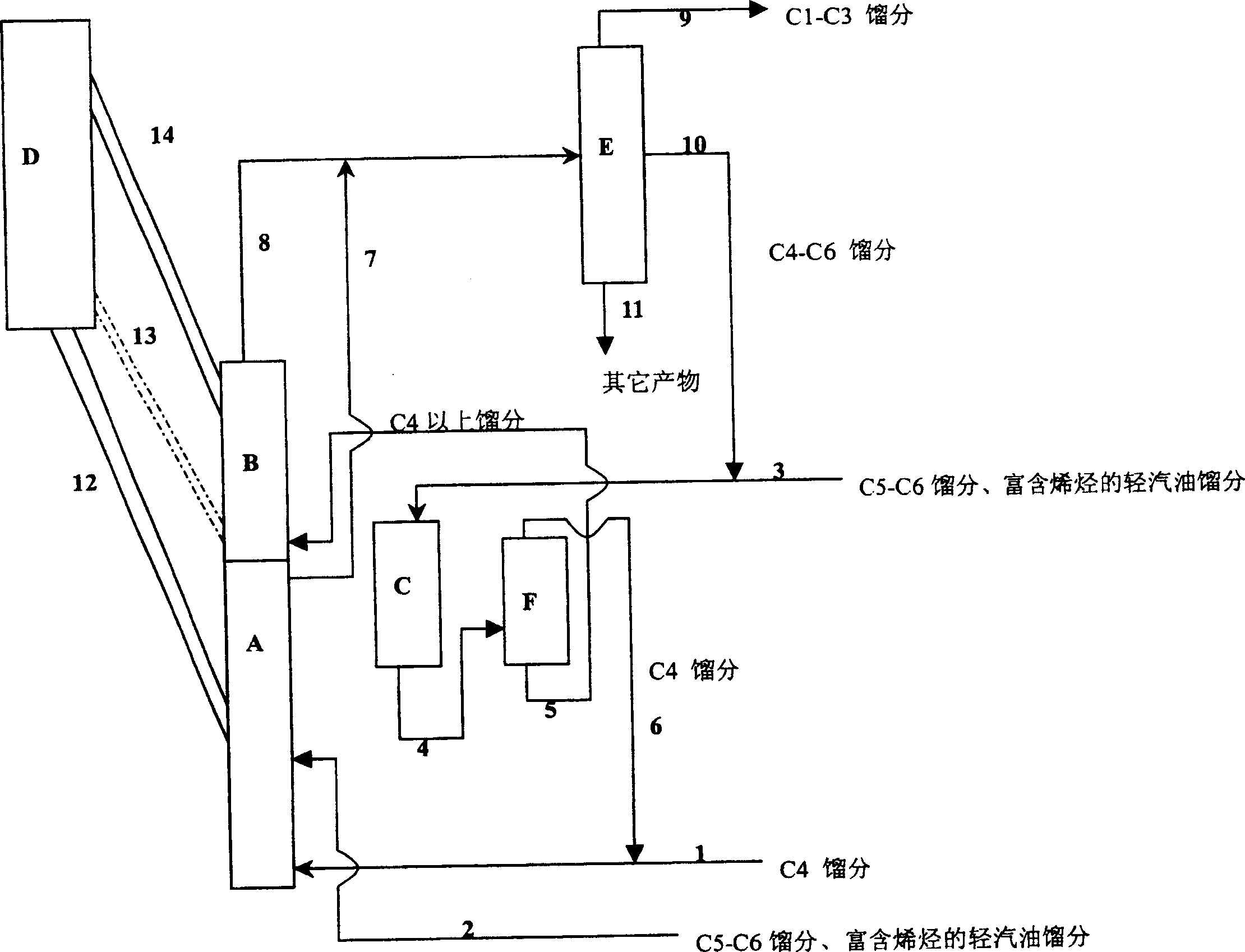

Catalytic conversion method for preparing light olefins by using C4-C6 distillates

ActiveCN1670133AImproved feed characteristicsImprove cracking conversion efficiencyTreatment with plural serial cracking stages onlyGasolineAlkene

A catalytic conversion method for producing light alkene with C4-C6 distillate. Inject the C4-rich gaseous hydrocarbon into the first cracking case or with the light gasoline distillate, it contact and react with catalyst and separate the resultant and catalyst; Inject C4 into the oligomerization reactor or mixed with light gasoline distillate, contact and react with oligomerization catalyst; separate the alkane-rich C4 and the higher distillate from the oligomerization resultant. C4 returns to the said first cracking reactor and the distillate higher than C4 is injected into the second cracking reactor, contact and react with the catalyst, separate the produced resultant and releasing agent, the said resultant can be separated fatherly for many goal products. The releasing agent can be reused after steam stripping.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for synthesizing R-(+)-2-(4-hydroxyphenoxy)propionic acid through gas phase catalysis

ActiveCN111187155AHigh catalytic activityStrong acidOrganic compound preparationOrganic chemistry methodsPropanoic acidPtru catalyst

The invention discloses a method for synthesizing R-(+)-2-(4-hydroxyphenoxy)propionic acid through gas phase catalysis, and belongs to the field of organic synthesis. Hydroquinone and D-lactic acid are used as raw materials, and nitrogen is used as a carrier gas. The hydroquinone and the D-lactic acid are completely gasified and then enter a fixed bed reactor, and the R-(+)-2-(4-hydroxyphenoxy)propionic acid is continuously synthesized in a gas phase under the catalysis of a supported heteropolyacid catalyst. The method has the advantages of mild reaction conditions, simple reaction process, high effective conversion rate of hydroquinone and high selectivity of the R-(+)-2-(4-hydroxyphenoxy) propionic acid, and is completely suitable for industrial production, and the self-made supported heteropolyacid solid catalyst has excellent catalytic activity, strong acidity, good stability and no pollution to the environment, and is a green catalyst.

Owner:JIANGSU SANJILI CHEM

Catalytic cracking addition agent for heavy hydrocarbon oil and preparation method thereof

ActiveCN101439303AHigh molecular cracking capacityHigh porosityCatalytic crackingCatalyst protectionWear resistantGasoline

The invention relates to a heavy hydrocarbon oil catalytic cracking addition agent and a preparation method which belongs to the field of catalytic cracking catalyst of hydrocarbon oil, in particular to an optimized addition agent of a hydrocarbon oil catalytic cracking catalyst. The invention is characterized by comprising the following components (weight percent): 10 to 65 percent of Al2O3, 2 to 13 percent of P (counted in P element), 1 to 15 percent of SiO2 as well as 10 to 65 percent of clay. The addition agent of the invention can be compounded and used with various catalytic cracking catalysts to improve the effective conversion rate of the heavy hydrocarbon oil and the selectivity of a cracking reaction is good, thereby improving the yield of gasoline and liquid gas, improving the gasoline octane number, reducing the olefin content in the gasoline, endowing the catalyst with the performance for resisting the pollution of heavy metals, providing and maintaining the continuous high activity and aquathermal stability of the catalyst, enhancing the wear-resistant intensity performance of the catalyst, and prolonging the service life of the catalyst. The addition agent is an ideal heavy hydrocarbon oil catalytic cracking addition agent.

Owner:青岛鼎诺化工技术有限公司

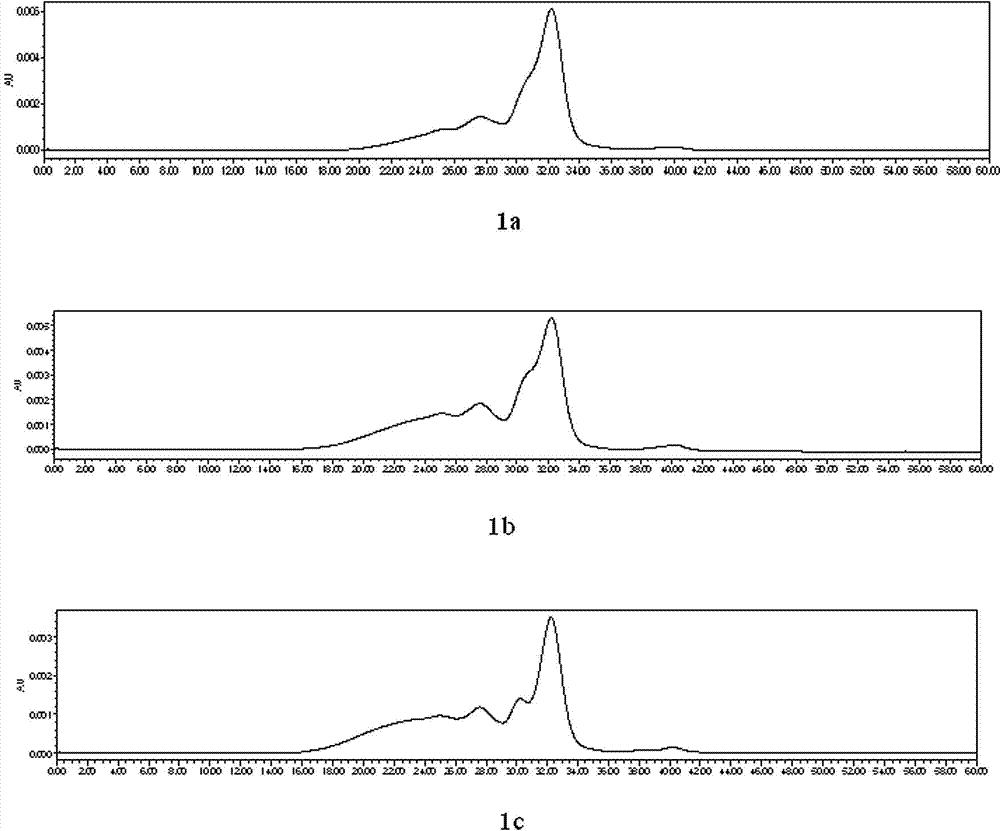

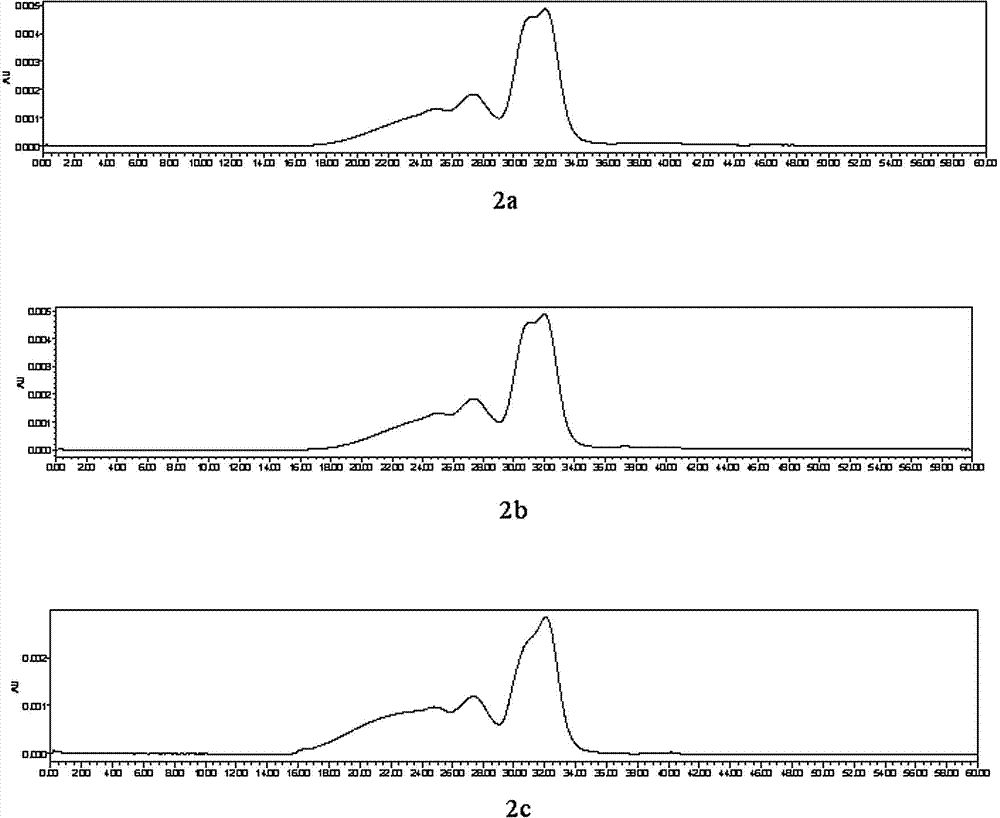

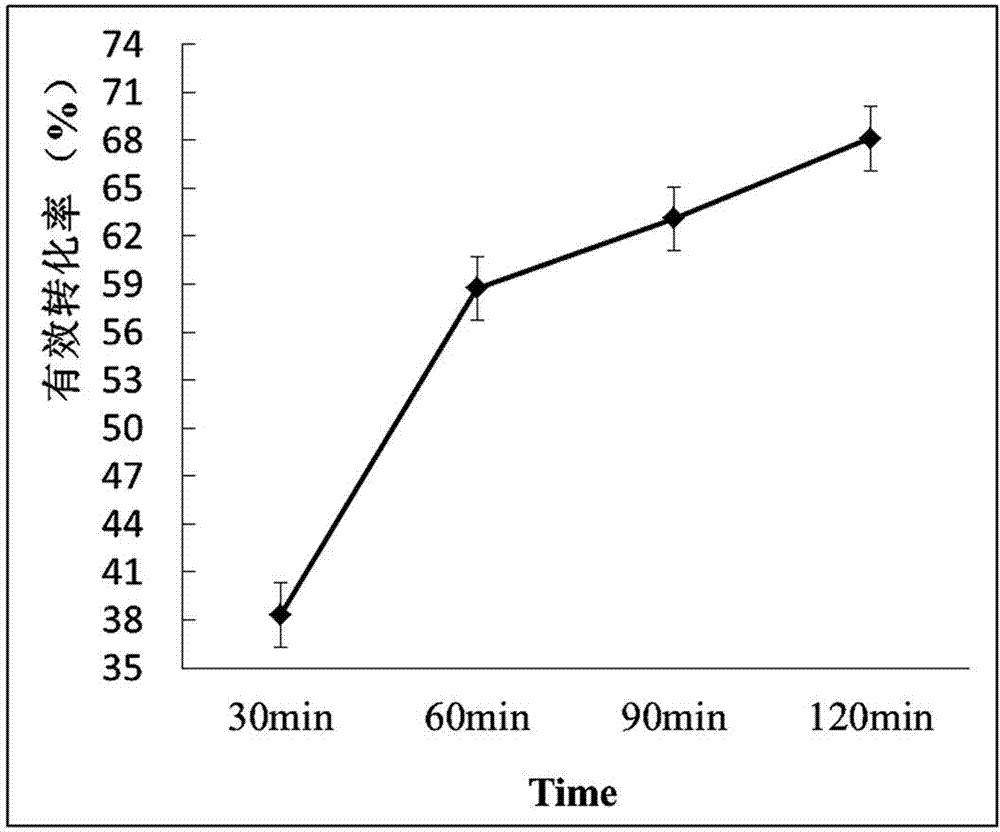

Improved polymerized hemoglobin preparation method

InactiveCN103524614ALow average molecular weightImprove effective conversion rateHaemoglobins/myoglobinsPolymer scienceHemoglobin hb

The invention relates to an improved polymerized hemoglobin preparation method. According to the invention, a hemoglobin aqueous solution with matrix-free human deoxyhemoglobin weight / volume content of 4-14% is adopted as a raw material. Under an inert gas environment and a stirring condition, an aldehyde-type bi-functional crosslinking agent is delivered into the raw material solution through a titanium rod; a polymerization reaction is carried out under a temperature of 0-10 DEG C, such that polymerized hemoglobin with an average molecular weight of 100-210kD and a preferable molecular weight of 110-170kD is obtained. A molar ratio of hemoglobin to the aldehyde-type bi-functional crosslinking agent is 4-8:1. With the method, the polymerized hemoglobin product with relatively low average molecular weight, relatively narrow molecular weight distribution, and effective conversion rate reaching 69% can be prepared, such that a problem of non-uniform molecular weight distribution in product of current polymerized hemoglobin preparation is effectively avoided. The operation is simple, and equipment cost is low.

Owner:BLOOD TRASFUSION INST CHINESE ACAD OF MEDICAL SCI

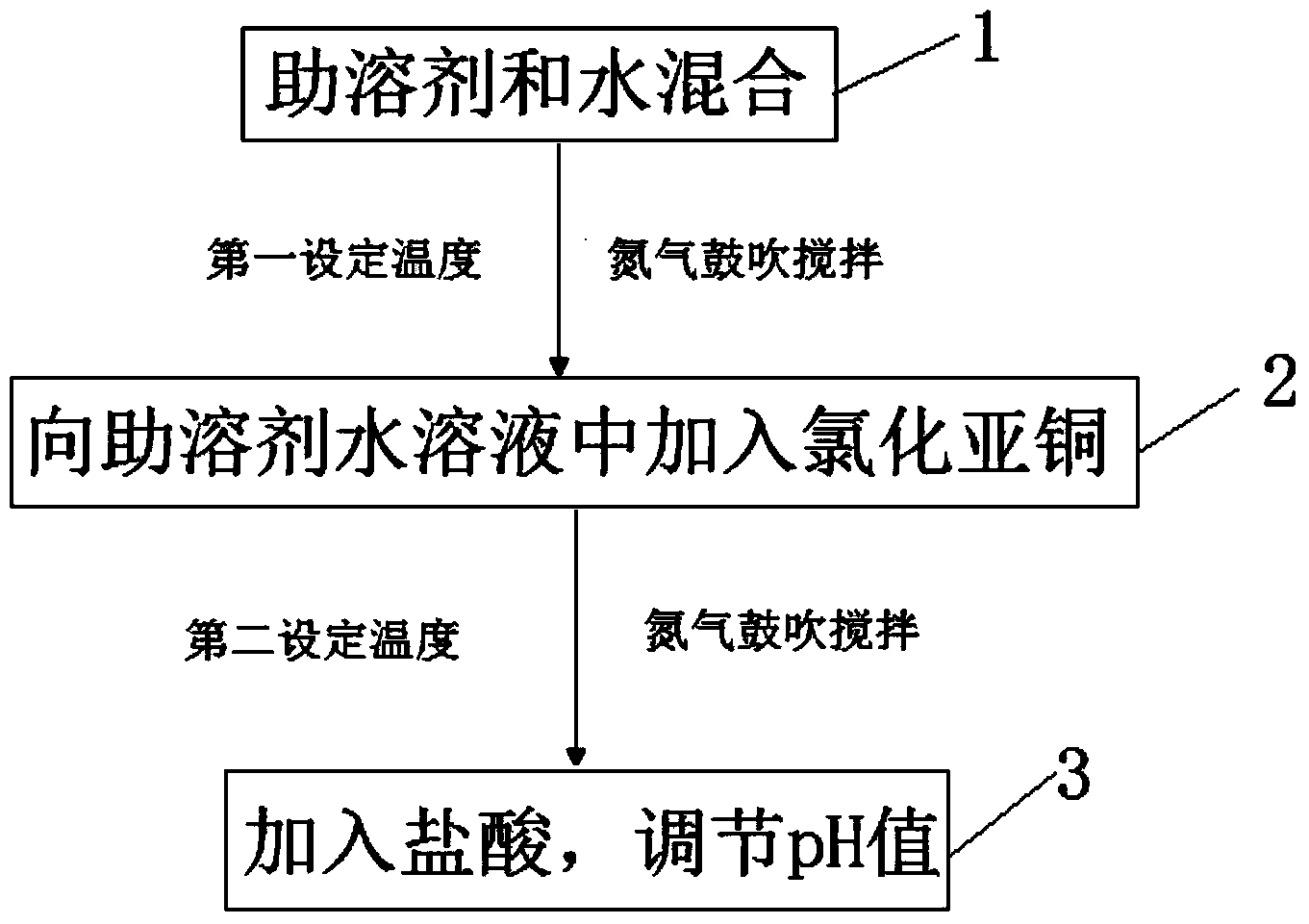

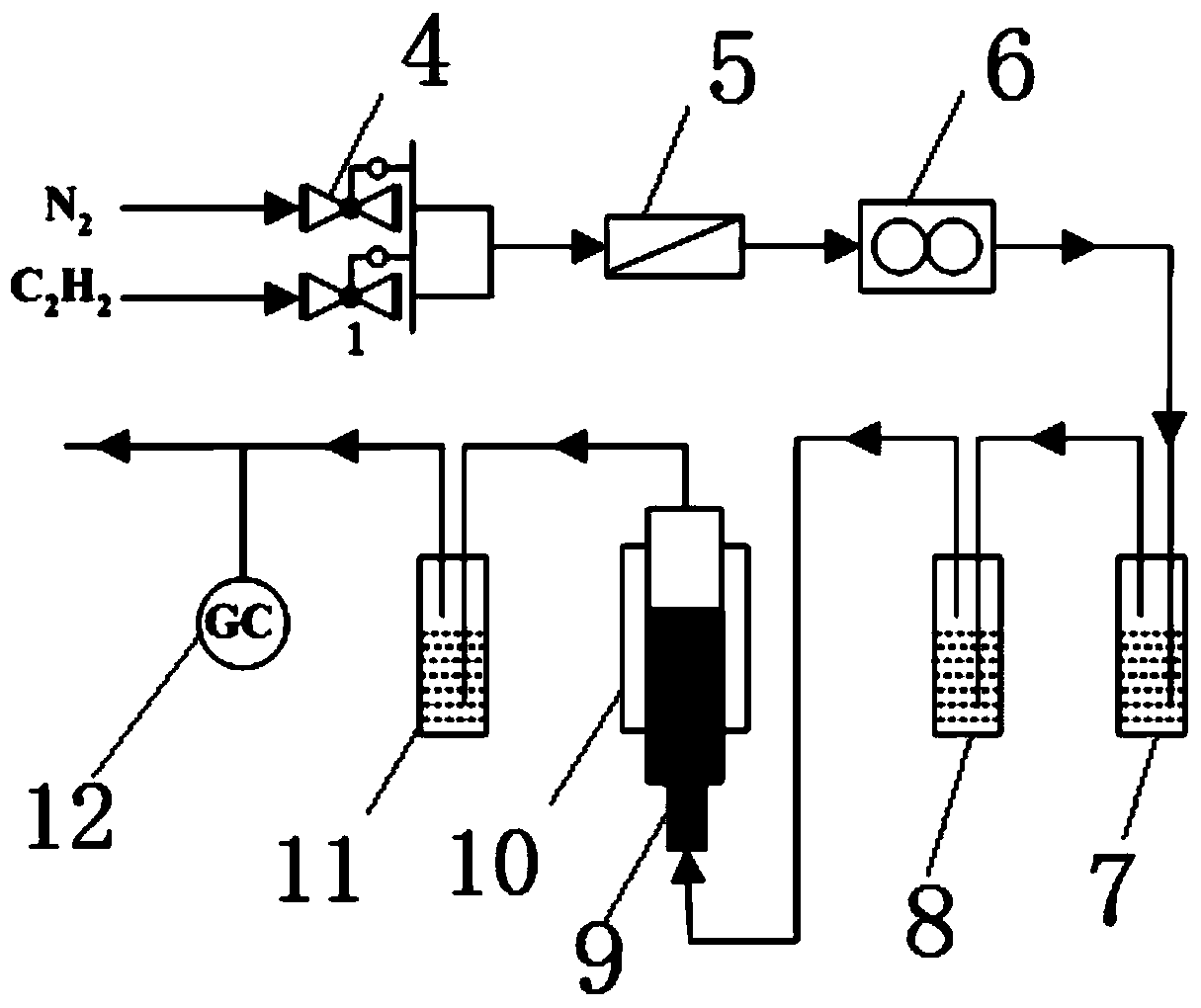

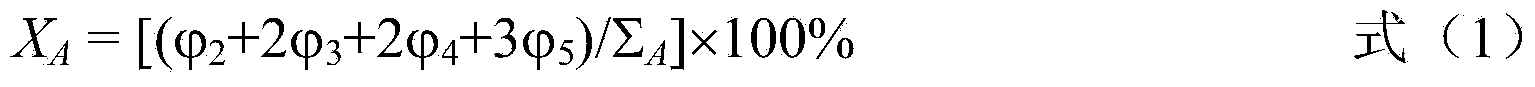

Catalytic system, preparation method thereof, and preparation method of vinyl acetylene by the same

ActiveCN104209144AImprove effective conversion rateHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsChemical industryVinylacetylene

The invention discloses a catalytic system, a preparation method thereof, and a preparation method of vinyl acetylene by the same, relates to the field of chemical industry, and solves the problems of large quantity of generated by-products and polymers and low selectivity of vinyl acetylene in vinyl acetylene production by using acetylene dimerization method in the prior art. A main technical scheme of the invention is as below: the catalytic system is used for catalyzing acetylene dimerization to produce vinyl acetylene. The preparation method of the catalytic system mainly comprises the following steps: adding a cosolvent and water into a reactor with nitrogen, and stirring under a first set temperature to thoroughly dissolve the cosolvent to obtain a cosolvent aqueous solution; and under a second set temperature, adding a main catalyst of cuprous chloride and a ligand polyethylene glycol solvent in the cosolvent aqueous solution to cuprous chloride, thoroughly dissolving cuprous chloride, and adding an acid solution to obtain the catalytic system. The invention is mainly used to improve the selectivity of vinyl acetylene and effective conversion rate of acetylene in the production process of acetylene dimerization method for preparation of vinyl acetylene.

Owner:SHIHEZI UNIVERSITY

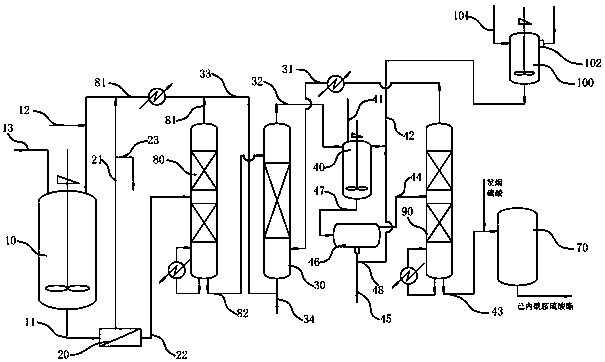

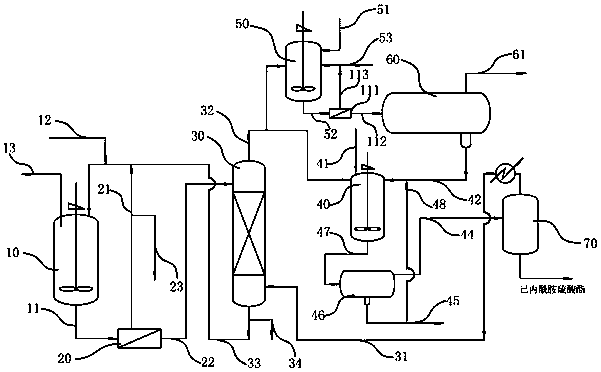

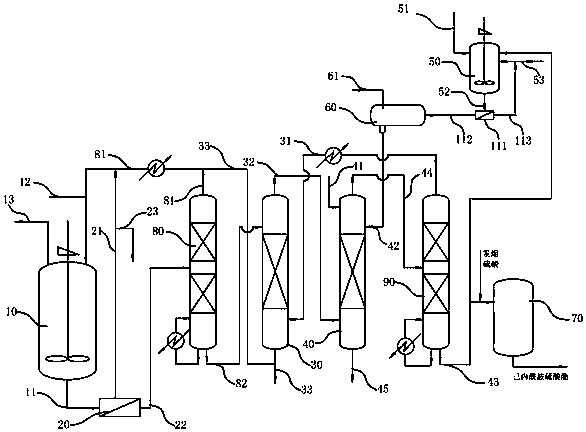

Production technology and equipment system for improving quality and yield of cyclohexanone oxime

PendingCN110803999AImprove effective conversion rateReduce unit consumptionOximes preparationImino compound preparationProcess engineeringOrganosolv

The invention discloses a production technology and equipment system for improving the quality and yield of cyclohexanone oxime. According to the production technology, special ammoximation conditionsare adopted, under the assistance of secondary oximation, the cyclohexanone oximation conversion rate is effectively increased without increasing the consumption amount of hydrogen peroxide, and theyield and quality of cyclohexanone oxime are improved. The equipment system comprises following components communicated by pipelines: a direct ammoximation reactor, a membrane separator, an organic solvent extraction column, and a secondary oximation reactor. The production technology and the structure of the equipment system are simple; the operation is safe; high quality cyclohexanone oxime canbe prepared, and the yield is high.

Owner:长沙兴和新材料有限公司

Synthesis process of glyphosate intermediate dimethyl phosphite

InactiveCN107501318AAvoid acidolysis side effectsImprove effective conversion rateGroup 5/15 element organic compoundsDimethyl phosphiteGlyphosate

The present invention relates to a synthesis process of glyphosate intermediate dimethyl phosphite, the steps are as follows: methanol is metered through a methanol metering tank and enters an esterification reactor, phosphorus dichloride is metered through a metering tank and enters the esterification reactor, materials enter the esterification reactor simultaneously in ratio, after esterification reaction, a material liquid flows into a deacidification kettle via an inner liquid seal tube, a gas generated by the esterification reaction returns back to the esterification reactor via a first condenser and a secondary condenser, hydrogen chloride is removed form the material liquid in the deacidification kettle under high vacuum and steam heating conditions, and after deacidification by the deacidification kettle, the material liquid enters a rectifying kettle for rectifying. Continuous production of the dimethyl phosphite can be achieved, a great development space is provided for production capacity improvement and further significant reduction of operating cost, and purity is increased to 99.0% or more.

Owner:ANHUI DONGZHI GUANGXIN AGROCHEMICAL CO LTD

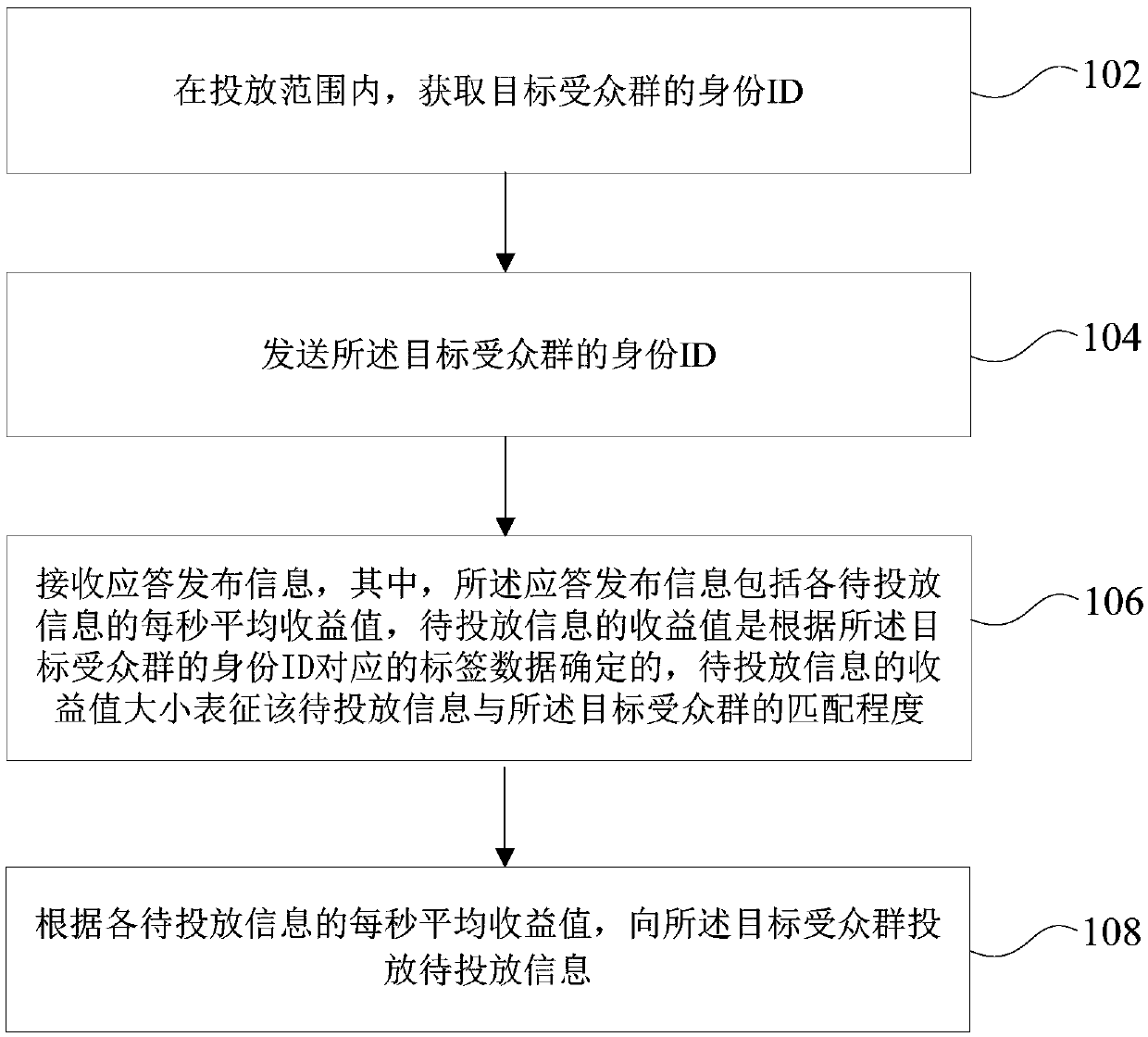

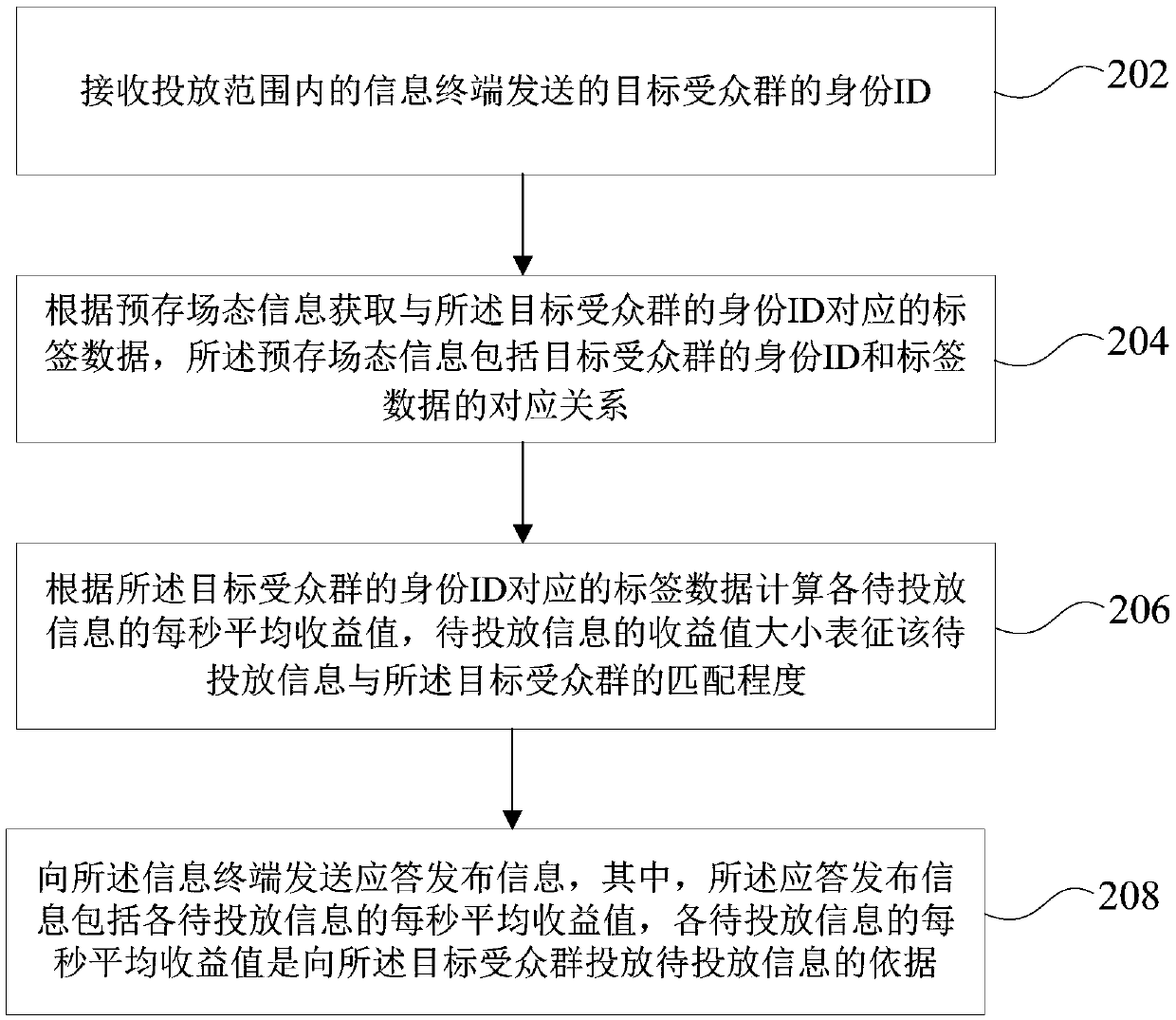

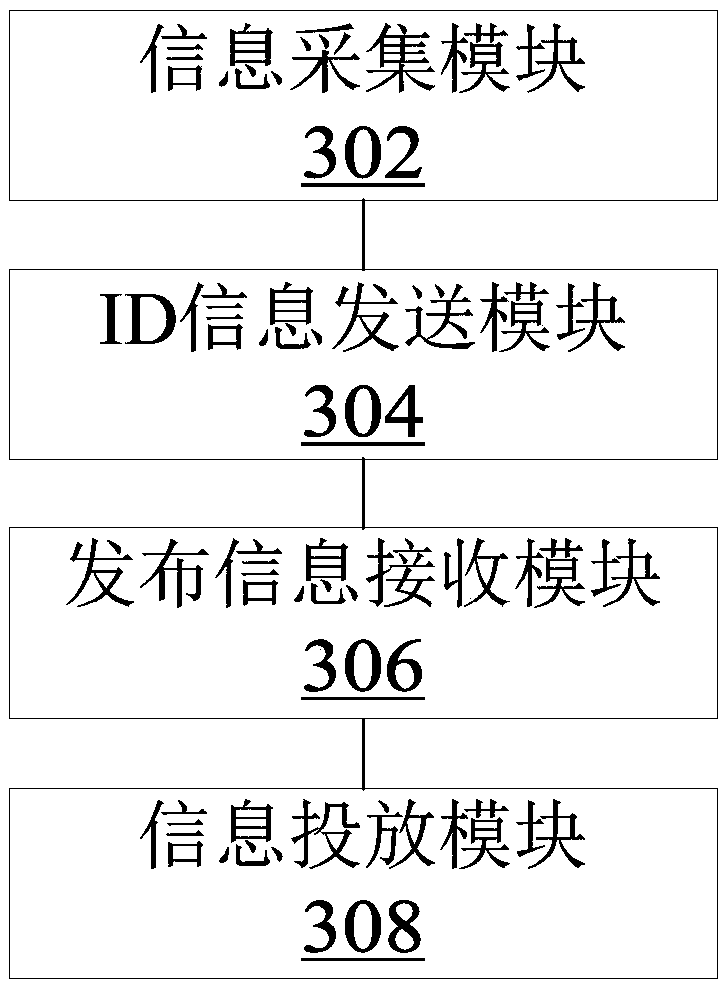

Information directional delivery method, terminal and server

The embodiment of the invention provides an information directional delivery method, a terminal and a server, and the method comprises the steps: obtaining the identity ID of a target audience group in a delivery range; Sending the identity ID of the target audience group; receiving Response release information, wherein the response release information comprises an average earning value per secondof each piece of to-be-released information, determining the earning value of the to-be-released information according to label data corresponding to the identity ID of the target audience group, andenabling the earning value of the to-be-released information represent the matching degree of the to-be-released information and the target audience group; And according to the average benefit valueper second of each piece of to-be-released information, releasing the to-be-released information to the target audience group. According to the scheme, the to-be-released information is released to the target audience group according to the matching degree of the to-be-released information and the target audience group, the target audience group is accurately positioned, the user interest degree is improved, and the released information has a target; The accuracy of delivery is greatly improved, and the user interest degree is improved.

Owner:BEIJING SHUZHI TECHNOLOGY CO LTD

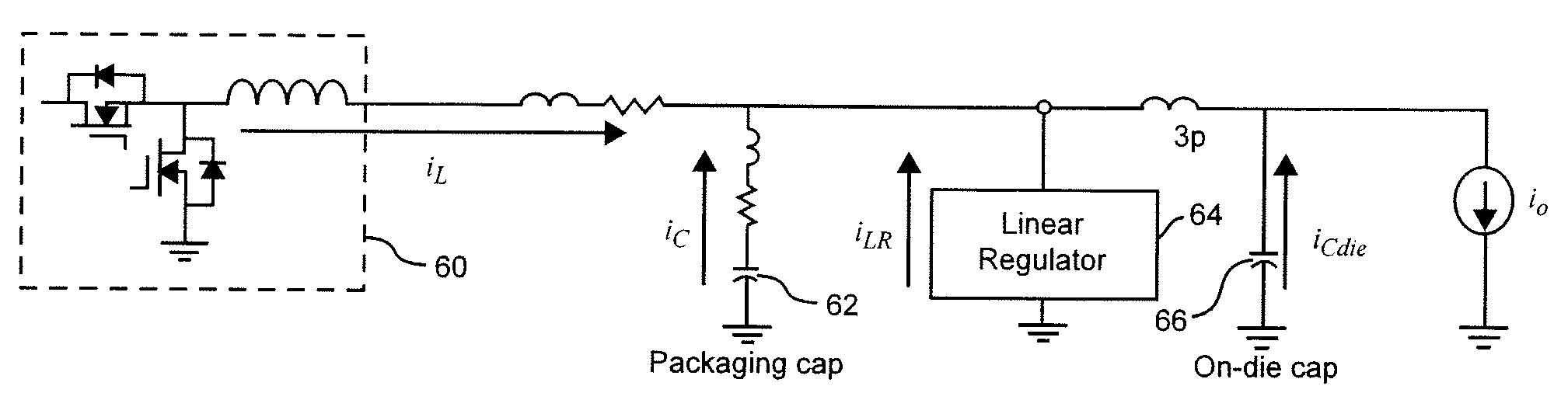

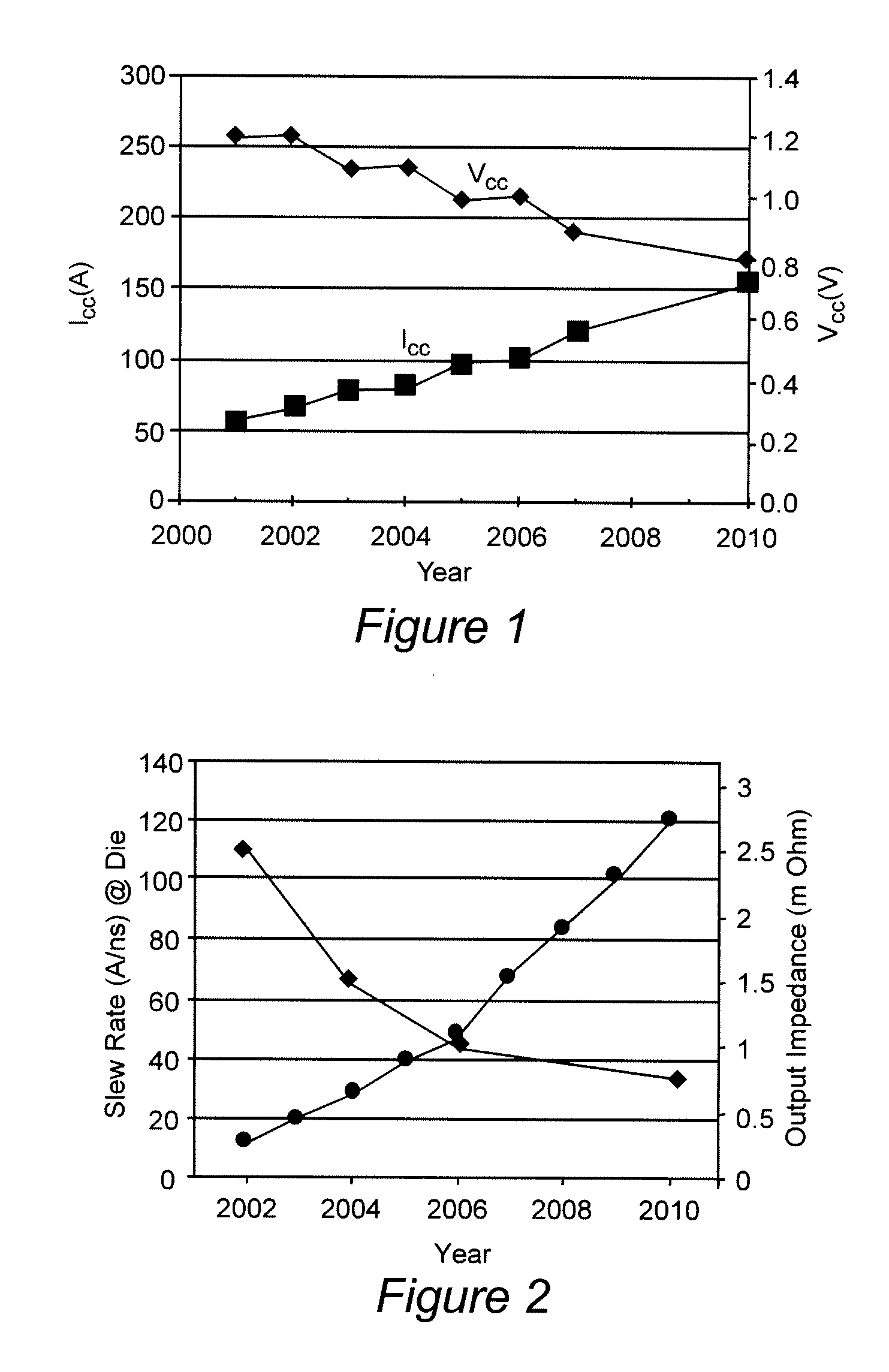

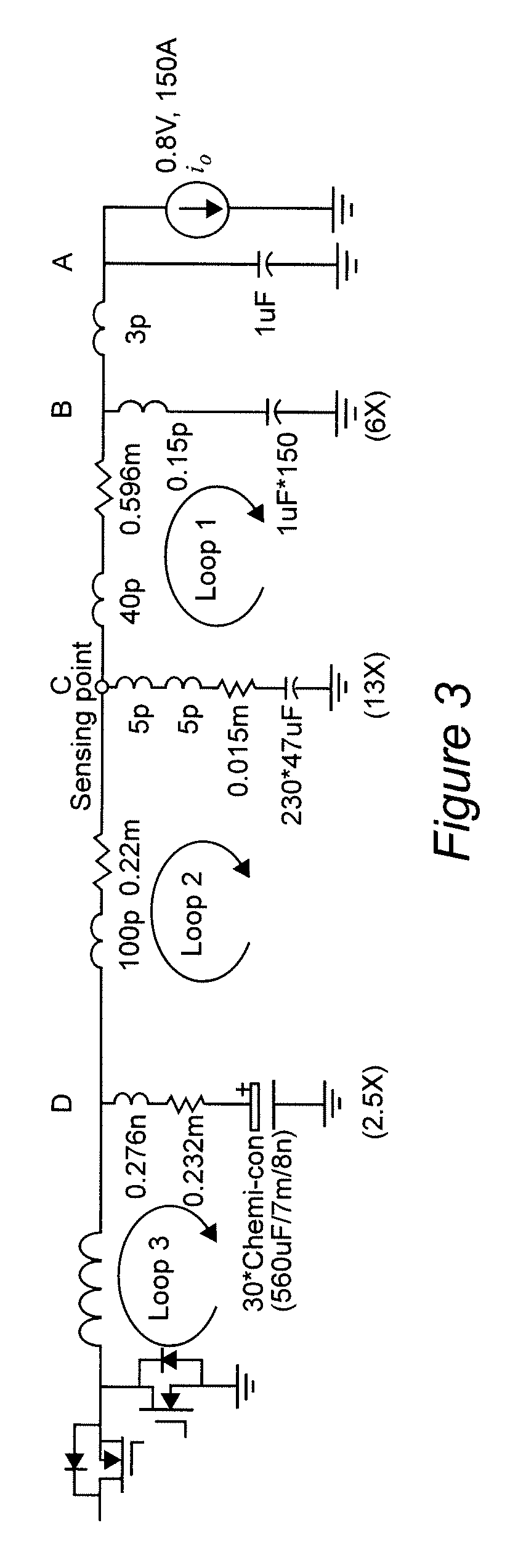

Hybrid Filter for High Slew Rate Output Current Application

InactiveUS20090174378A1High bandwidthIncrease conversion rateDc-dc conversionElectric variable regulationLinear regulatorCapacitance

An active linear regulator circuit in parallel with a filter capacitor of a switching voltage regulator injects current to a load only when the switching regulator and capacitor cannot supply adequate current to follow high frequency load transients in a manner which is compatible with adaptive voltage positioning (AVP) requirements. control of current injection and determination of the insufficiency of current from the switching regulator and capacitors is achieved by impedance matching of the linear regulator to the switching regulator. The linear regulator thus operates at relatively low current and duty cycle to limit power dissipation therein. By matching impedances and increasing the bandwidth of the switching regulator, filter capacitor requirements can be reduced to the point of being met entirely by packaging and / or on-die capacitors which may be placed close to or at the point of load to reduce parasitic inductance, as can the linear regulator.

Owner:VIRGINIA TECH INTPROP INC

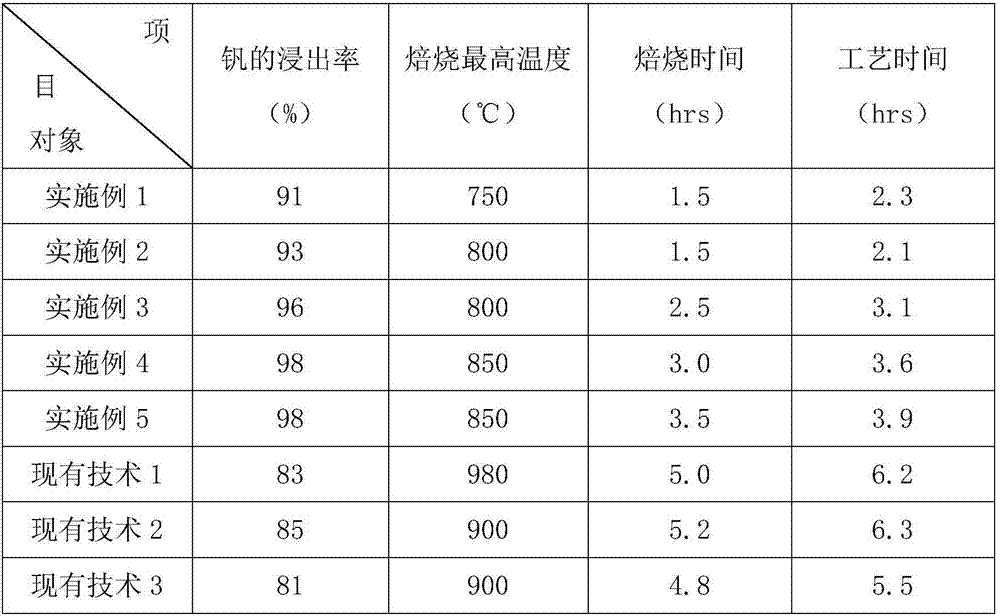

Composite additive used for roasting vanadium extracting and use method of additive

ActiveCN107287410AIncrease conversion rateEasy to extract vanadiumHazardous substanceMixed materials

The invention relates to the technical field of metallurgy, and provides a composite additive used for roasting vanadium extracting. The additive is formed through the step that four materials including, by mass part, 35 parts to 55 parts of sodium materials, 15 parts to 25 parts of calcium materials, 0.5 part to 1 part of vanadium materials and 1 part to 5 parts of titanium materials are mixed and ground to 80 meshes to 100 meshes; the invention further provides a use method of the composite additive used for roasting vanadium extracting. The use method comprises following steps: A, mixing, wherein screened vanadium containing raw materials are selected, and a mixed material with the evenly-mixed composite additive is added; B, roasting, wherein the mixed material is subject to two-time roasting. According to the composite additive and the use method of the additive, the vanadium-contained ore is not likely to generate a liquid phase in the roasting process, the phenomenon of equipment bonding is avoided, toxic and harmful substances are not likely to be generated, the conversion rate and the purity of vanadium can be effectively improved, the roasting time is shortened, the roasting process is simplified, production cost is reduced, and process efficiency is improved.

Owner:CHONGQING KOOPPER CHEM IND

Catalyzed coking benzene and methanol to prepare zsm-5 molecular sieve catalyst of xylene and its application

ActiveCN104874418BImprove effective conversion rateHigh selectivityMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationCoalAlkylation

The invention provides a ZSM-5 molecular sieve catalyst for catalytic preparation of xylene from coked benzene and methanol and a use thereof. A preparation method of the ZSM-5 molecular sieve catalyst comprises blending 45-90wt% of a hydrogen-type ZSM-5 molecular sieve, 10-50wt% of a binder, 1-20wt% of sesbania cannabina powder and a dilute nitric acid solution as an assistant by stirring to obtain a uniform mixture, drying and roasting the mixture, extruding the mixture to obtain a strip, immersing the strip in a solution containing one or two of Mg, Zn, Gd, P, La, Ce, Mo and Ni, and carrying out drying and roasting so that the strip is loaded with the metals. In catalytic alkylation reaction preparation of xylene from coked benzene and methanol, the ZSM-5 molecular sieve catalyst has high catalytic activity, high stability, a high raw material effective conversion rate and high desired product xylene selectivity, improves the existing xylene production technology, improves a coal-derived coked benzene utilization rate and realizes change of waster into valuables.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Production method of dimethyl phosphite

ActiveCN101870712BAvoid acidolysis side effectsImprove effective conversion rateGroup 5/15 element organic compoundsChemical/physical/physico-chemical nozzle-type rreactorsLiquid productCyclone

The invention relates to a production method of dimethyl phosphate, which takes phosphorus trichloride and methyl alcohol as raw materials for reaction. The method comprises the steps of: in a reaction chamber space having cross injection angle and the injection structures of the raw materials, respectively and continuously injecting and sending the phosphorus trichloride and the methyl alcohol which are based on the molar ratio of 1: (3.0-3.1) into the reaction chamber space through respective injection structures by corresponding pumping mechanisms for mixing together and reaction; then, introducing reaction material into a centrifugal cyclone separator with the pressure lower than that of the reaction chamber space along the tangential direction, and leading noncondensable gas and condensing liquid product to have centrifugal cyclone separation; and collecting the liquid dimethyl phosphate product descending along the inner wall of the centrifugal cyclone separator. The method canrapidly complete the reaction and the separation for products, effectively reduces the contact between HCl and the dimethyl phosphate, inhibits the occurrence of side reaction, improves the yield andthe quality of the product, and greatly reduces the energy consumption.

Owner:SICHUAN LESHAN FUHUA TONGDA AGRO-CHEM TECH CO LTD +1

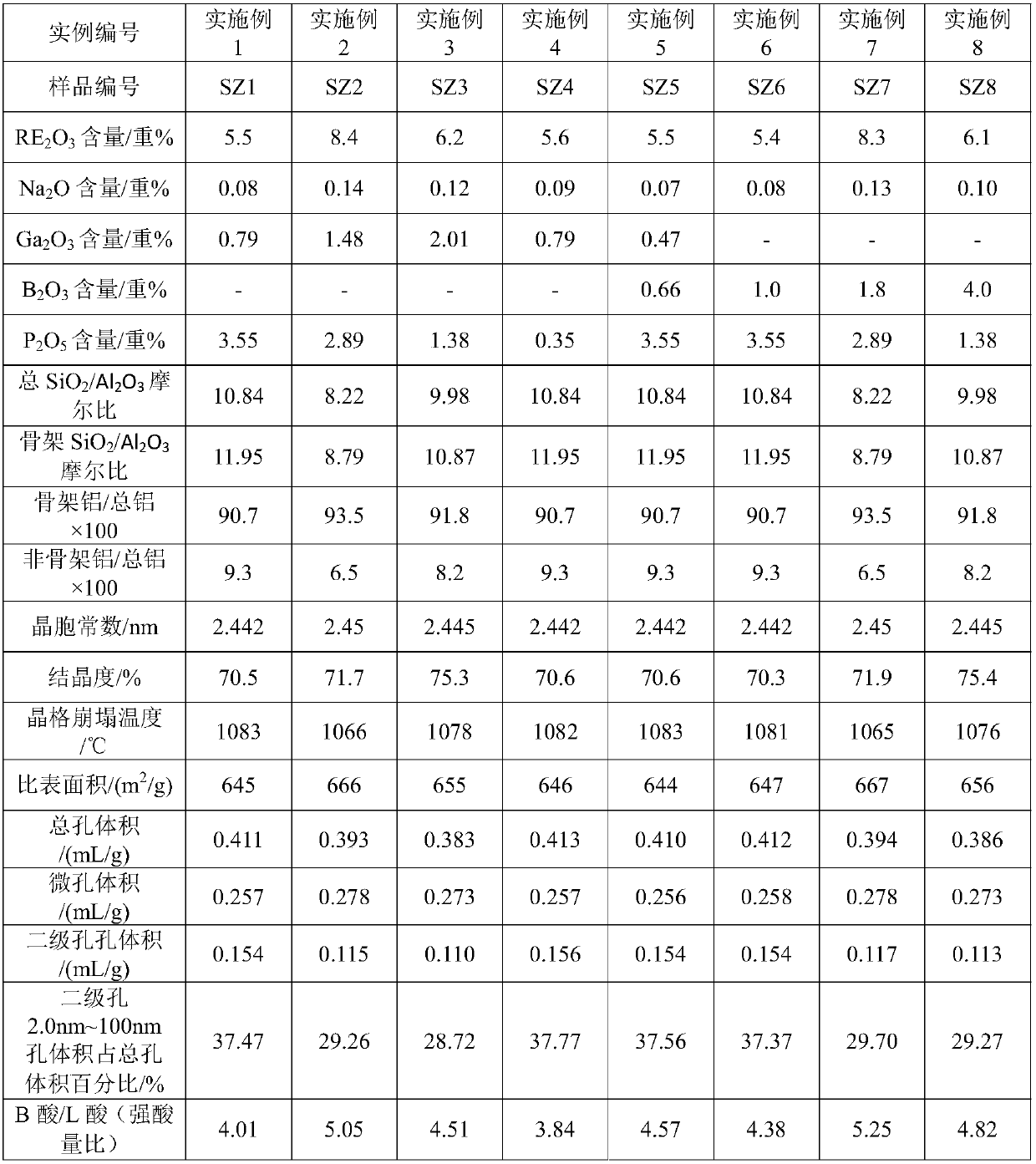

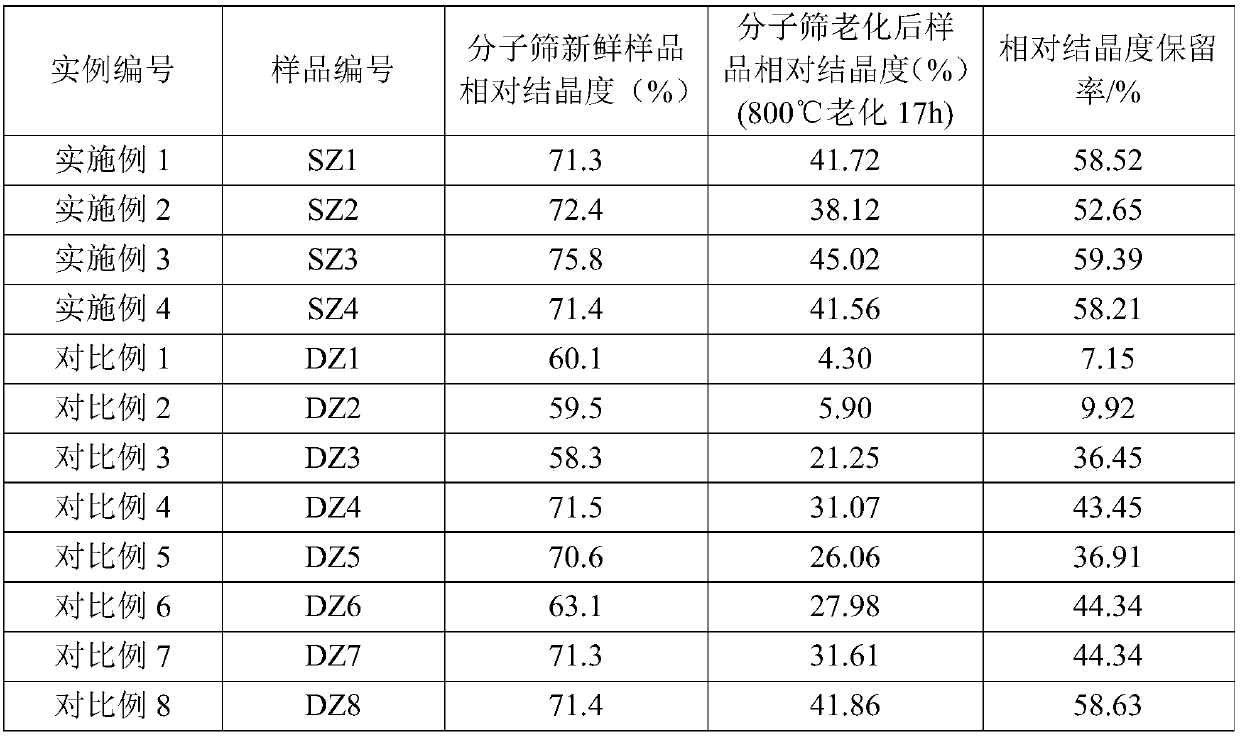

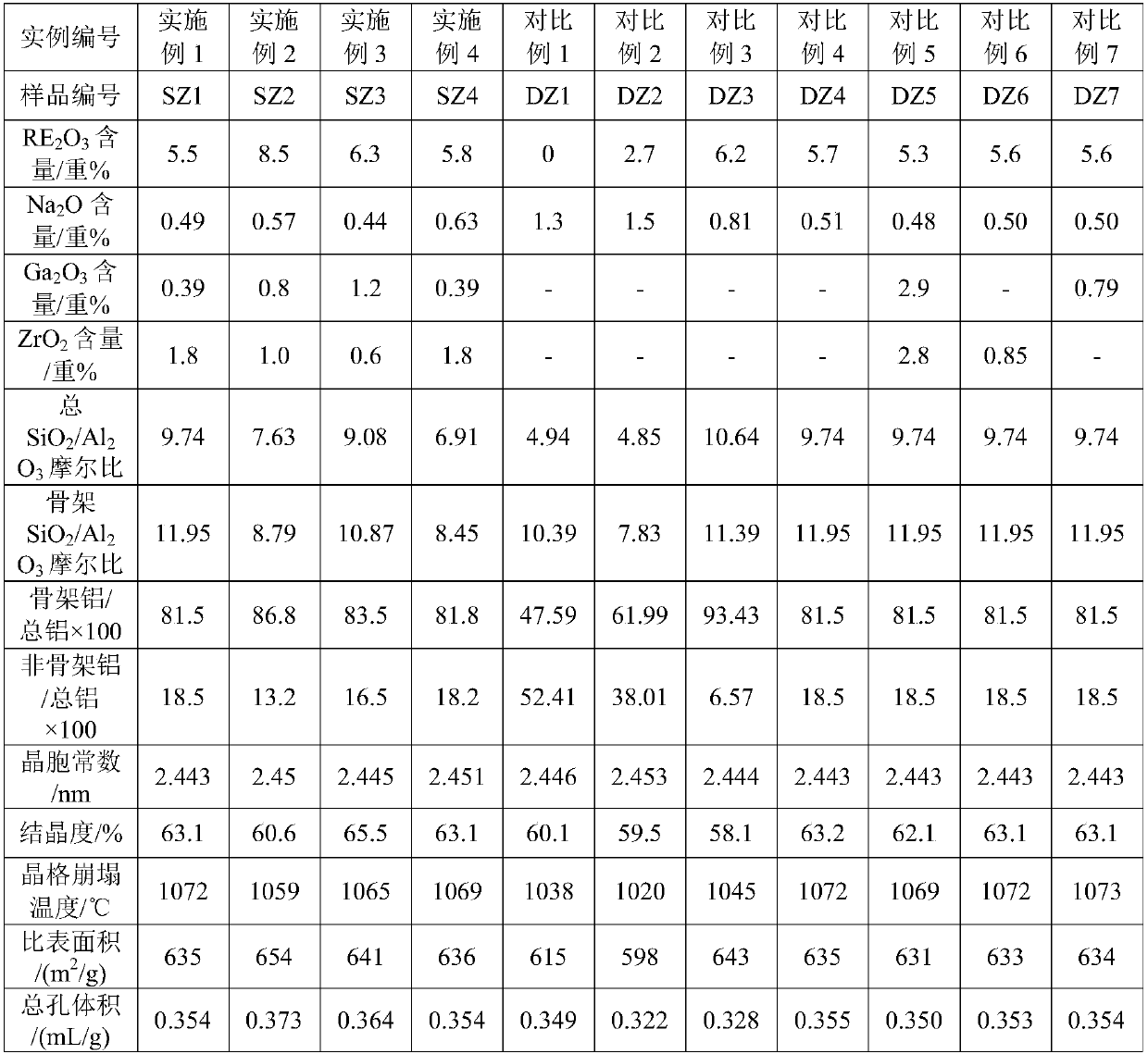

Catalytic cracking catalyst, preparation method and applications thereof

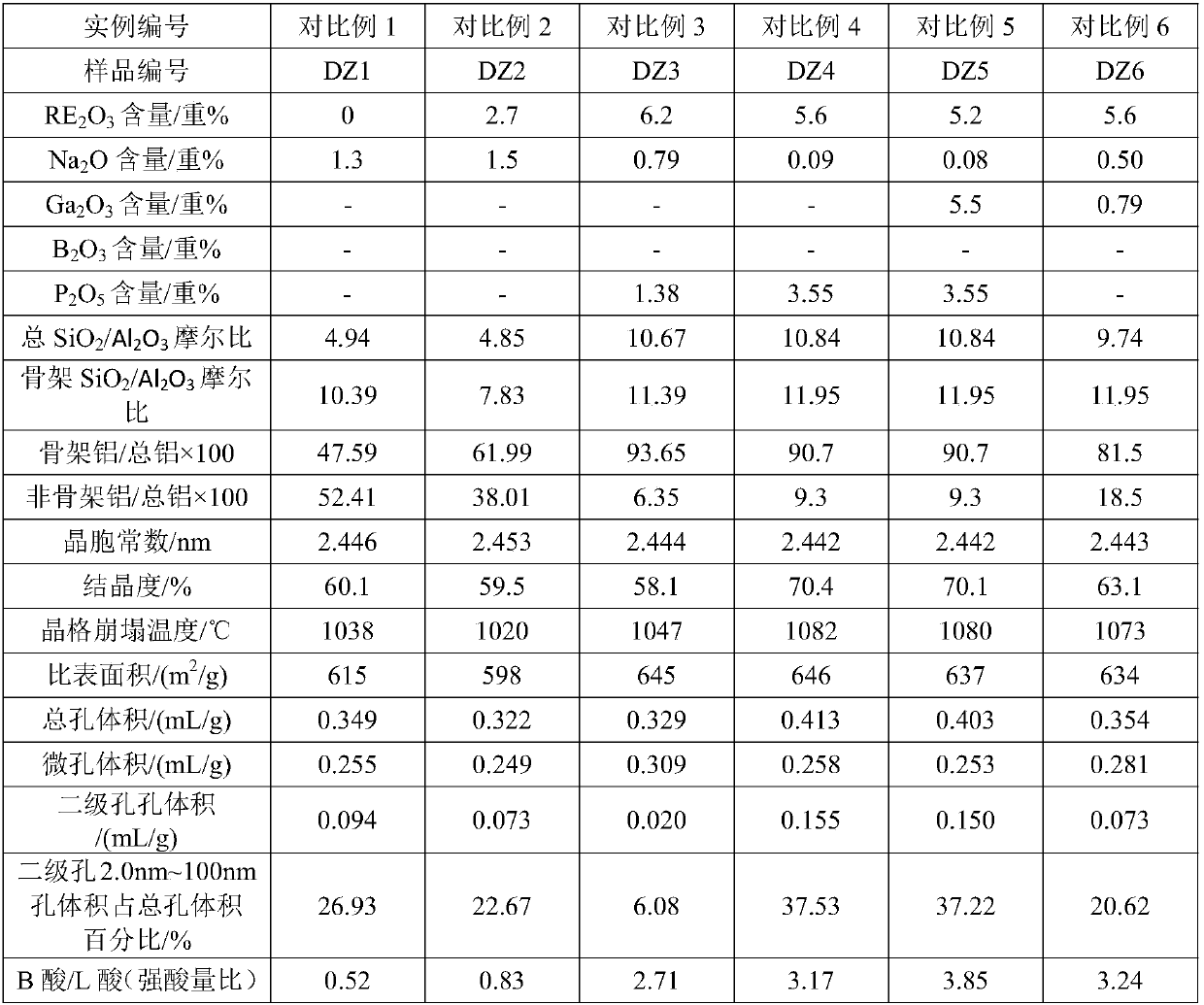

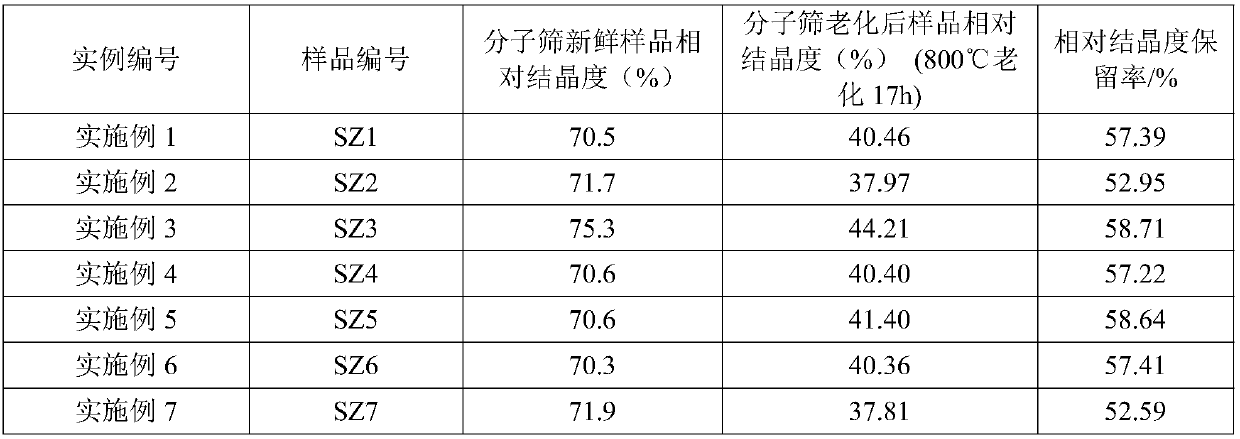

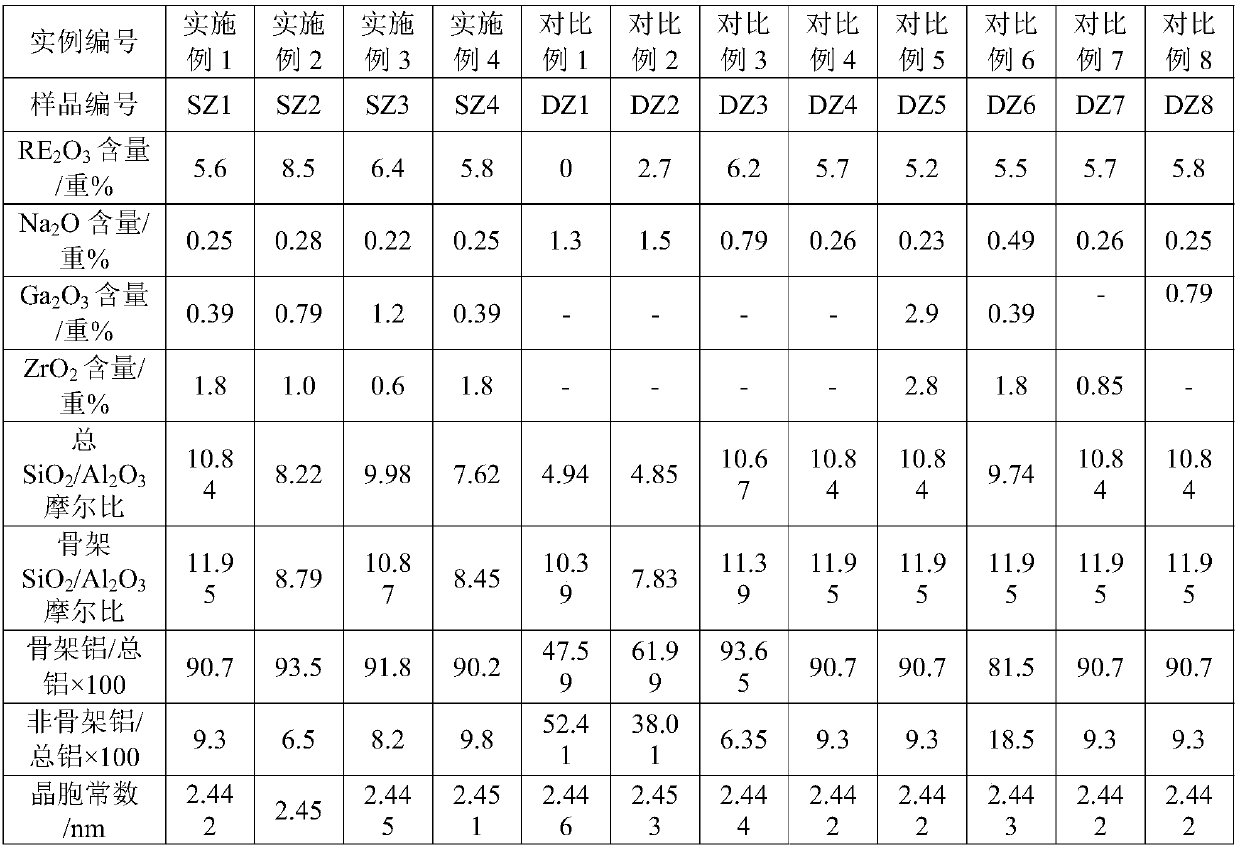

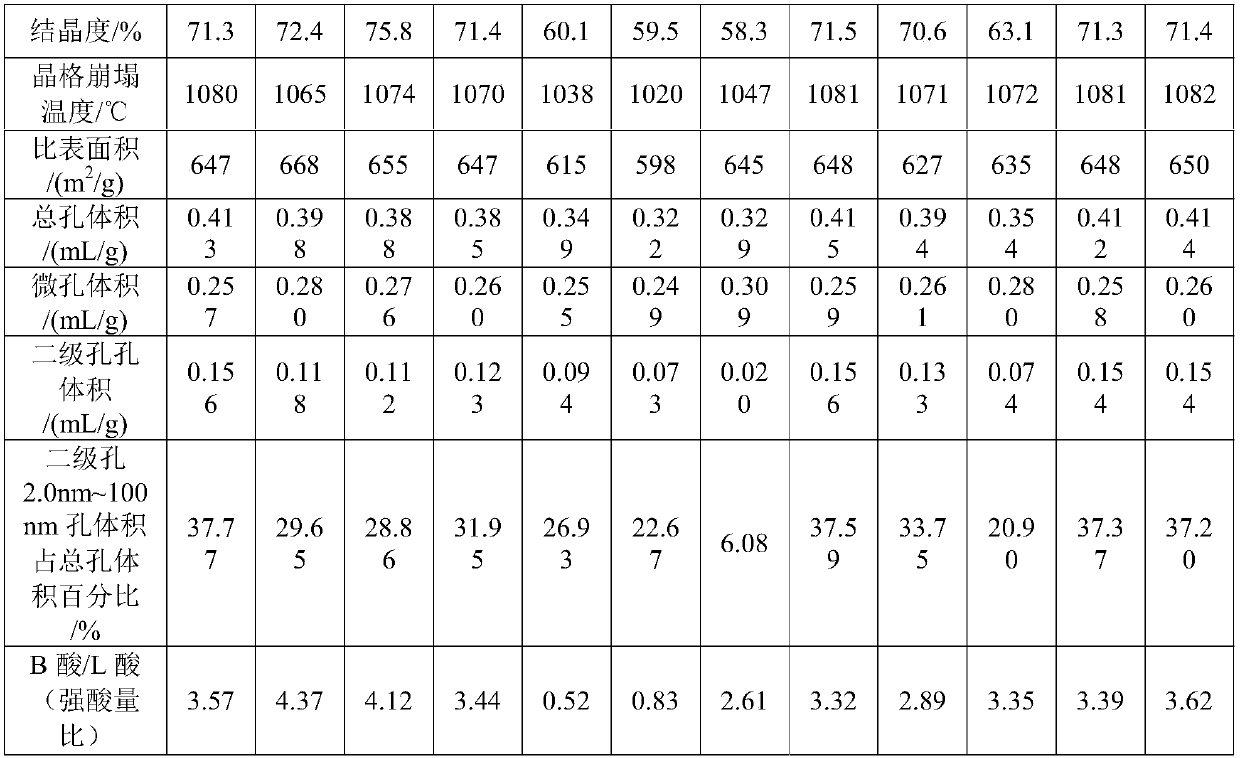

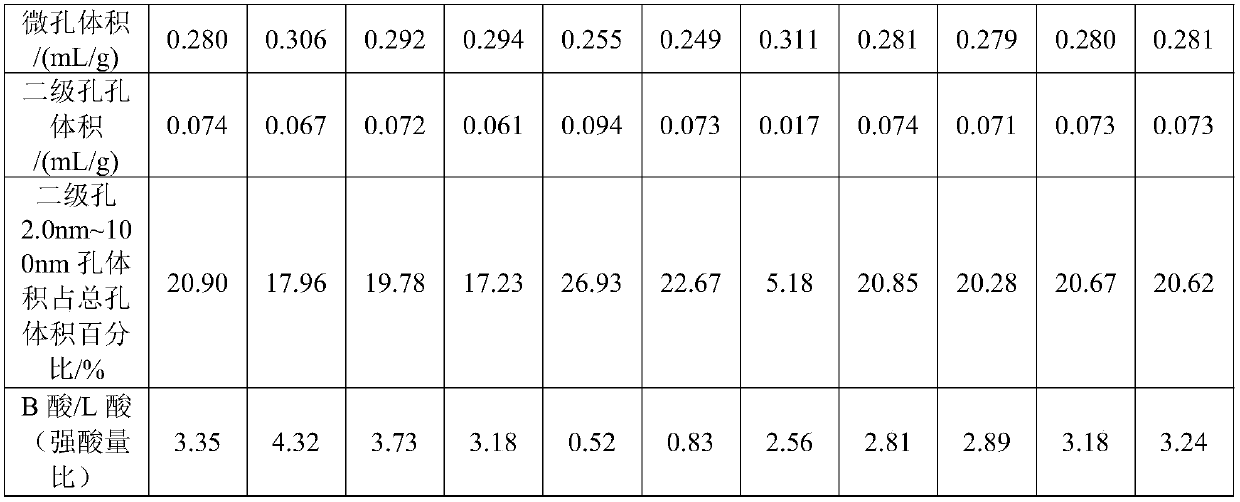

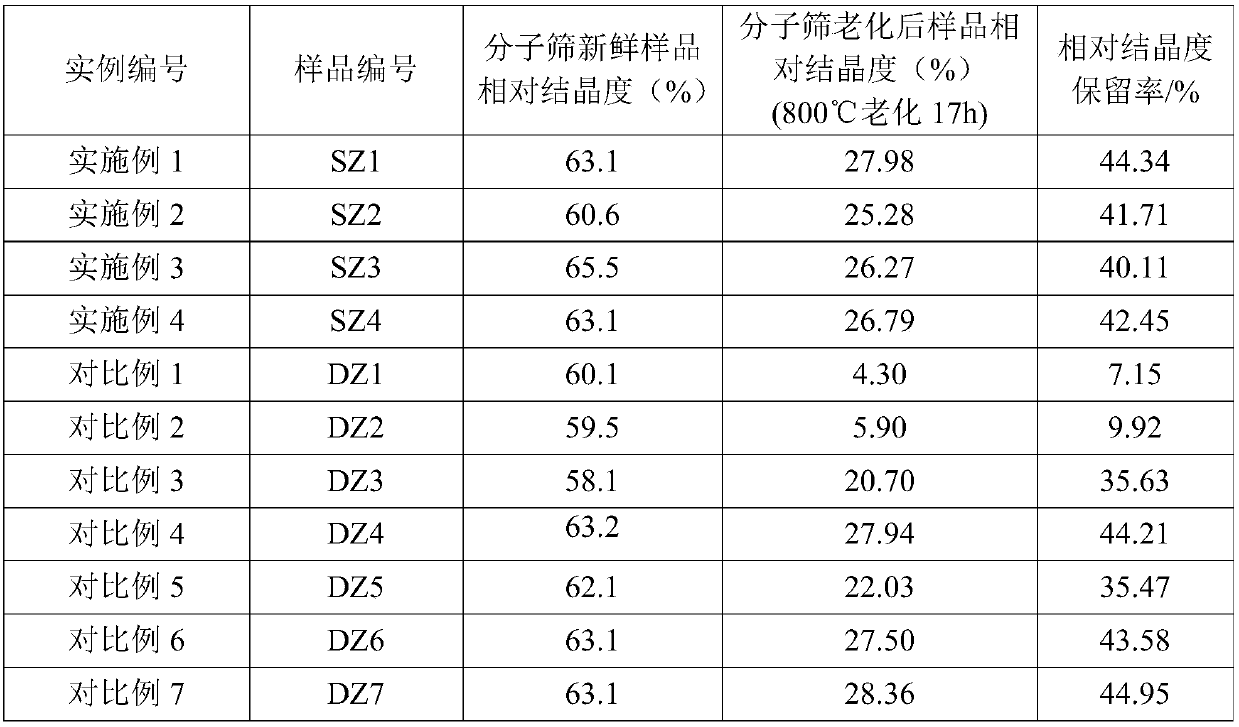

ActiveCN110833851AHigh crystallinityImprove thermal stabilityMolecular sieve catalystsCatalyst activation/preparationMolecular sievePtru catalyst

The invention relates to a catalytic cracking catalyst, a preparation method and applications thereof, wherein the catalyst comprises 10-50 wt% of a modified Y-type molecular sieve, 10-40 wt% of an alumina binder (calculated as alumina), and 10-80 wt% of clay (calculated as dry base), wherein the modified Y-type molecular sieve comprises 4-11 wt% of rare earth elements (calculated as oxide), 0.05-10 wt% of phosphorus (calculated as P2O5), not more than 0.5 wt% of sodium oxide and 0.1-5 wt% of an active element oxide, the active element is gallium and / or boron, the total pore volume of the modified Y-type molecular sieve is 0.36-0.48 mL / g, the pore volume of the secondary pores with a pore size of 2-100 nm accounts for 20-40% of the total pore volume, the cell constant is 2.440-2.455 nm, the lattice collapse temperature is not lower than 1060 DEG C, the non-skeleton aluminum accounts for not more than 10% of the total aluminum content, and a ratio of the amount of the acid B to the amount of the acid L in the amount of the strong acid of the modified Y-type molecular sieve is not less than 3.5. According to the invention, with the application of the catalyst in processing hydrogenation of LCO, the catalyst has high LCO conversion efficiency, low coke selectivity and high yield of gasoline rich in aromatic hydrocarbon.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst, preparation method and applications thereof

ActiveCN110833857AHigh crystallinityImprove thermal stabilityCatalytic crackingMolecular sieve catalystsRare-earth elementMolecular sieve

The invention relates to a catalytic cracking catalyst, a preparation method and applications thereof, wherein the catalyst comprises 10-50 wt% of a modified Y-type molecular sieve, 10-40 wt% of an alumina binder (calculated as alumina), and 10-80 wt% of clay (calculated as dry base), wherein the modified Y-type molecular sieve comprises (calculated as the weight of the dry base of the modified Y-type molecular sieve) 5-12 wt% of rare earth elements (calculated as oxide), not more than 0.5 wt% of sodium oxide, 0.1-2.5 wt% of gallium oxide, and 0.1-2.5 wt% of zirconium oxide, the total pore volume of the modified Y-type molecular sieve is 0.36-0.48 mL / g, the pore volume of the secondary pores with a pore size of 2-100 nm accounts for 20-38% of the total pore volume, the cell constant is 2.440-2.455 nm, the lattice collapse temperature is not lower than 1060 DEG C, the non-skeleton aluminum accounts for not more than 10% of the total aluminum content, and a ratio of the amount of the acid B to the amount of the acid L in the amount of the strong acid is not less than 3.0. According to the invention, with the application of the catalyst in processing hydrogenation of LCO, the LCO conversion efficiency is high, the coke selectivity is low, the yield of gasoline rich in BTX aromatic hydrocarbon and the yield of propylene are high, and the concentration of propylene in liquefied gasis high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic conversion method for preparing light olefins by using C4-C6 distillates

ActiveCN1281722CImproved feed characteristicsImprove cracking conversion efficiencyTreatment with plural serial cracking stages onlyAlkaneGasoline

A catalytic conversion method for producing light olefins from C4-C6 fractions, which is to inject gaseous hydrocarbons rich in C4 fractions into the first cracking reactor alone or together with light gasoline fractions, contact with the catalyst therein, react, and separate the reaction The product and the reacted catalyst, the C4 fraction or C4 fraction in the product and the light gasoline fraction are injected into the oligomerization reactor to contact and react with the oligomerization catalyst inside; the C4 fraction and C4 fraction rich in alkanes are separated from the oligomerization product The above fractions, C4 fractions are returned to the above-mentioned first cracking reactor, and the fractions above C4 are injected into the second cracking reactor, contact and react with the catalyst therein, and separate the obtained reaction product and spent agent, the reaction product It is further separated into various purpose products, and the standby agent is recycled after being stripped and regenerated. The method provides a feasible technical scheme for effectively utilizing the C4 fraction to increase the production of light olefins.

Owner:CHINA PETROLEUM & CHEM CORP +1

Compound feed for improving thickness of head, neck, back and tail meat of Lepomis gulosus and preparation process thereof

InactiveCN110338310AImprove utilization efficiencyIncrease deposition rateFood processingClimate change adaptationBody shapePhosphate

The invention relates to a compound feed for improving thickness of head, neck, back and tail meat of Lepomis gulosus and a preparation process thereof. The compound feed comprises the following components by mass ratio: 12-15% of fish meal, 12-18% of chicken powder, 20-25% of soybean meal, 7-10% of soy protein concentrate, 4-9% of rapeseed meal, 20-23% of flour, 2-5% of squid visceral ointment, 1-3% of fish oil, 3-5% of soybean oil, 0.8-1.2% of dihydrogen phosphate, 0.1-0.2% of multivitamin, 0.1-0.2% of composite minerals, 0.03-0.05% of bile acid and 0.5-1% of taurine. According to the growthand nutrient requirement of the Lepomis gulosus, the process ensures the feed protein addition amount through the reasonable combination of the animal and vegetable protein raw materials, and uses the oil source and the sugar source to reasonably improve the feed protein and energy ratio, and more protein is saved for fish growth, which effectively improves feed protein utilization efficiency anddeposition rate; the growth performance of the Lepomis gulosus and the body shape are improved, so that the head and neck meat of the Lepomis gulosus is convex, the back meat and the tail meat are thick.

Owner:佛山市顺德区旺海饲料实业有限公司

Catalytic cracking catalyst, preparation method and applications thereof

ActiveCN110833854AEven distribution of aluminumLow non-framework aluminum contentMolecular sieve catalystsCatalyst activation/preparationRare-earth elementMolecular sieve

The invention relates to a catalytic cracking catalyst, a preparation method and applications thereof, wherein the catalyst comprises 10-50 wt% of a modified Y-type molecular sieve, 10-40 wt% of an alumina binder (calculated as alumina), and 10-80 wt% of clay (calculated as dry base), wherein the modified Y-type molecular sieve comprises (calculated as the weight of the dry base of the modified Y-type molecular sieve) 5-12 wt% of rare earth elements (calculated as oxide), 0.1-0.7 wt% of sodium oxide, 0.1-2.5 wt% of gallium oxide, and 0.1-2.5 wt% of zirconium oxide, the total pore volume of themodified Y-type molecular sieve is 0.33-0.39 mL / g, the pore volume of the secondary pores with a pore size of 2-100 nm accounts for 10-25% of the total pore volume, the cell constant is 2.440-2.455 nm, the lattice collapse temperature is not lower than 1050 DEG C, the non-skeleton aluminum accounts for not more than 20% of the total aluminum content, and a ratio of the amount of the acid B to theamount of the acid L in the amount of the strong acid is not less than 3.0. According to the invention, with the application of the catalyst in processing hydrogenation of LCO, the LCO conversion efficiency is high, the coke selectivity is low, the yield of gasoline rich in aromatic hydrocarbon and the yield of propylene are high, and the concentration of propylene in liquefied gas is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

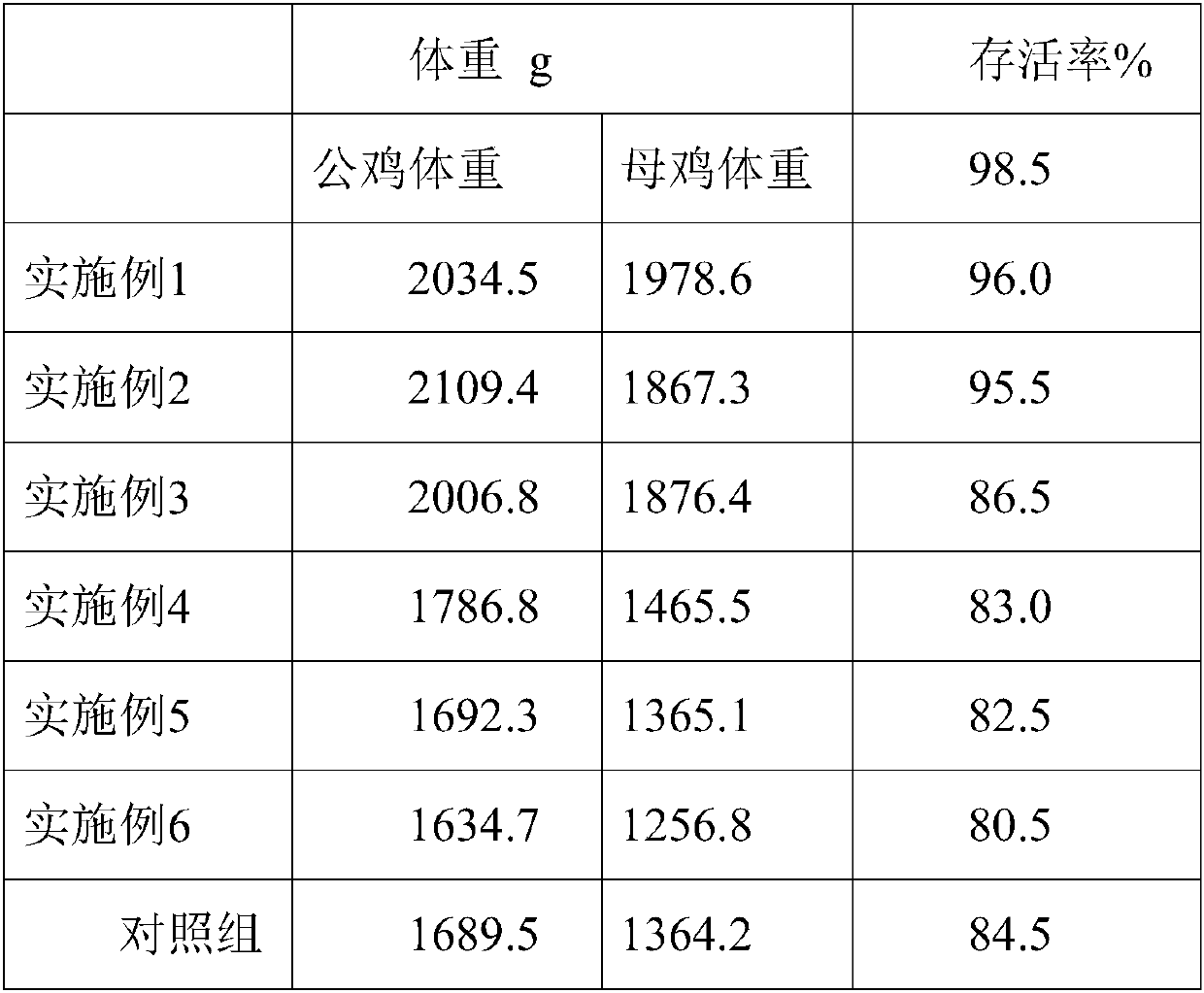

Free-range chicken feed and preparation method thereof

InactiveCN107594202AImprove immunityImprove survival rateFood processingAnimal feeding stuffAnimal scienceCorn flour

The invention relates to the technical field of a poultry feed, in particular to a free-range chicken feed. The free-range chicken feed comprises the following raw materials of rice bran, corn flour,wheat bran, rice bran, bamboo shoots, corn straw, a traditional Chinese medicine extract, a feed additive and a mineral mixture. According to the prepared free-range chicken feed, the traditional Chinese medicine extract and the feed additive are added to the free-range chicken feed, so that the free-range chicken feed has the effects of resisting bacteria, clearing internal free radicals, and regulating the metabolism of fat and protein in bodies, the immunity of free-range chickens can be improved, the survival rate of the free-range chickens can be increased, and the survival rate is as high as 98.5%.

Owner:石阡裕和原生态农牧发展有限公司

Puffed aphrodisiac feed for boars and preparation method thereof

InactiveCN109221713APromote digestion and absorptionImprove palatabilityFood processingAnimal feeding stuffMedicinal herbsAnimal science

The invention provides puffed aphrodisiac feed for boars and a preparation method thereof. The preparation method comprises the following steps: weighing 2 to 5 parts of a traditional Chinese medicineaphrodisiac syrup preparation; weighing 80 to 90 parts of powdered foundation pig feed and extruding and puffing to obtain aphrodisiac puffed feed pellets; spraying 1 to 3 pats of nutritional additive powder composed of 1 to 3 parts of probiotics and pig multivitamins on the surfaces of the pellets to prepare a puffed aphrodisiac pig feed finished product for the boars. The traditional Chinese medicine aphrodisiac syrup preparation is prepared by boiling 3 to 7 parts of ambergris, 15 to 20 parts of rhizoma polygonati, 15 to 20 parts of tuber salep, 10 to 15 parts of frankincense, 3 to 5 partsof nutmeg, 8 to 10 parts of radix aristolochiae, 20 to 25 parts of fructus crataegi, 10 to 15 parts of a liquorice root wall-breaking powdering and medicine preparation bag and 90 to 100 parts of sucrose in 500 to 700 parts of purified water for a plurality of hours and cooling. By adopting the puffed aphrodisiac feed, the utilization rate of valuable medicines is remarkably improved; the semen quantity, semen density and semen survival rate of the boars are remarkably improved and the medicine effect is remarkable; the safe and efficient feed has good palatability and is easy to digest and absorb; the life of the boars is remarkably prolonged; the utilization cost of the boars is correspondingly and effectively reduced and the economic benefits of culturing are increased.

Owner:宝鸡神农农业科技有限公司

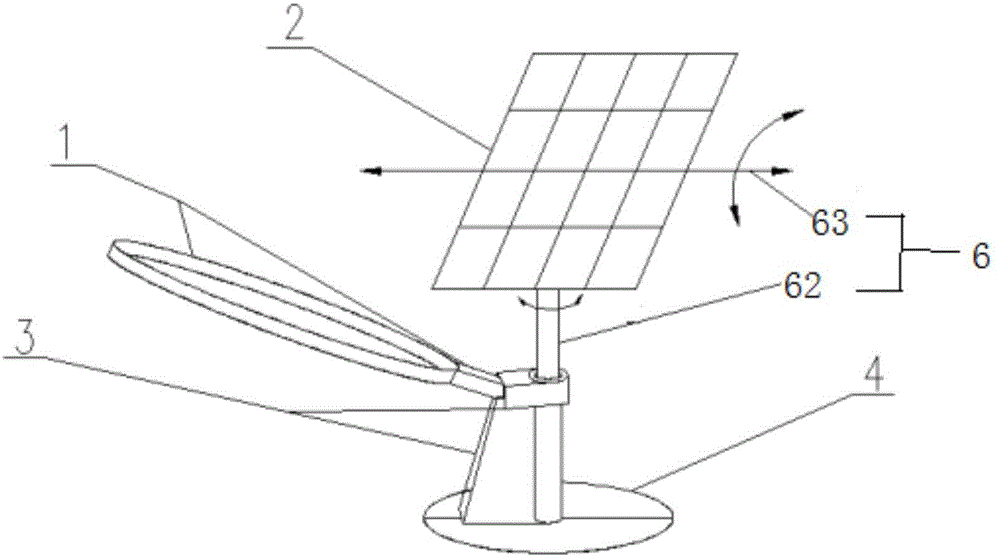

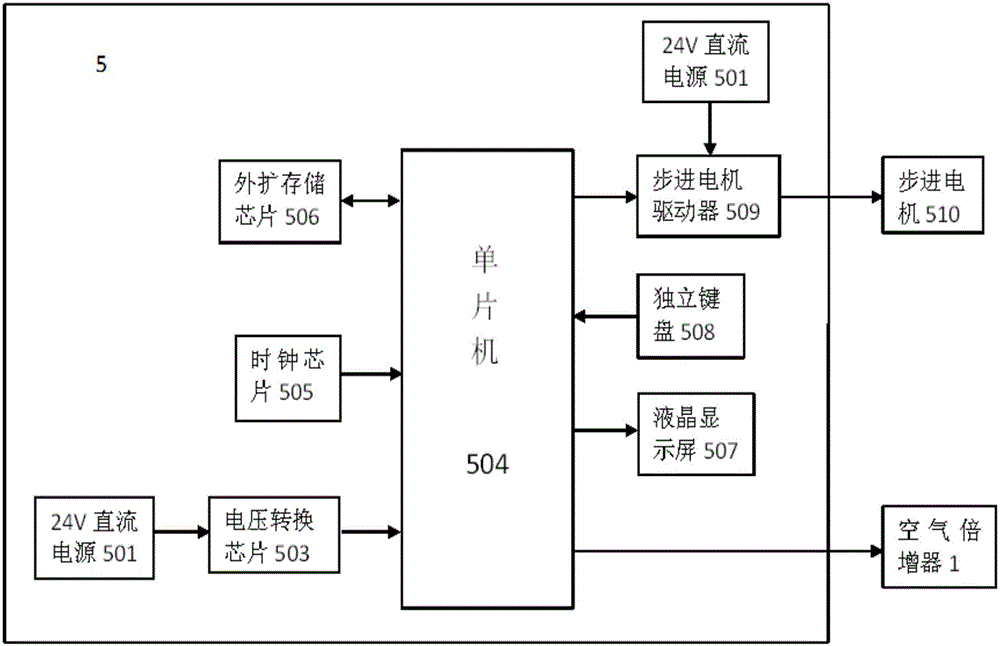

Solar panel power generating device de-dusted based on air multiplier

ActiveCN106598085AStrong windImprove effective conversion rateControl using feedbackCleaning using gasesMicrocontrollerMicrocomputer

The invention relates to a solar panel power generating device de-dusted based on an air multiplier. The device comprises a solar cell panel, a rotating shaft, and a base. The solar cell panel is fixed on the base through the rotating shaft. The rotating shaft consists of a vertical shaft and a horizontal shaft. The device is characterized by further comprising an air multiplier, a support piece, and a control module. The air multiplier sleeves the vertical shaft through the support piece and is fixed above the base, and the air outlet of the air multiplier faces the solar cell panel. The control module controls work of the device. The control module includes a 24V DC power supply, a voltage conversion chip, a single chip microcomputer, a clock chip, an external expanding memory chip, a liquid crystal display, an independent keyboard, and a stepper motor driver. The 24V DC power supply is responsible for supplying power to the stepper motor driver. A 24V voltage is converted by the voltage conversion chip into a 5V voltage for power supply to the single chip microcomputer.

Owner:HEBEI UNIV OF TECH

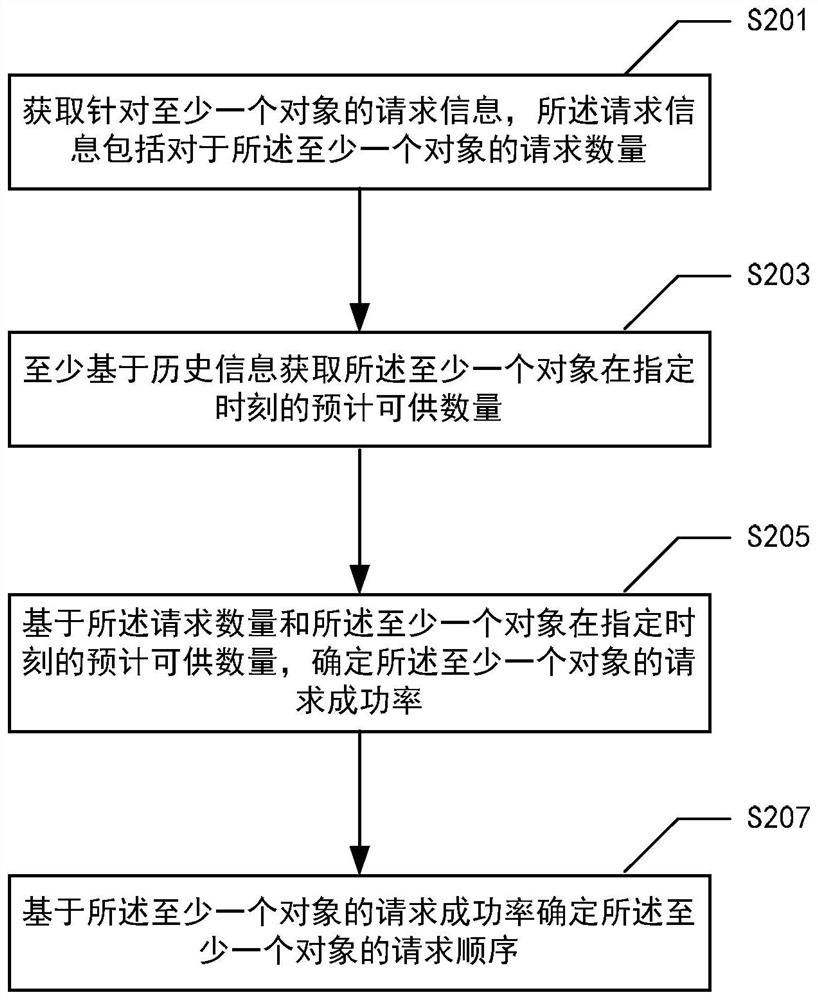

Data processing method, data processing device, computer system and medium

PendingCN111738468AImprove experienceImprove effective conversion rateReservationsForecastingObject basedSoftware engineering

The invention provides a data processing method, a data processing device, a computer system and a medium, and the data processing method comprises the steps: obtaining request information for at least one object, and the request information comprises the number of requests for the at least one object; obtaining a predicted available quantity of the at least one object at a specified moment at least based on historical information; determining a request success rate of the at least one object based on the request number and the predicted available number of the at least one object at the specified moment; and determining a request sequence of the at least one object based on the request success rate of the at least one object.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

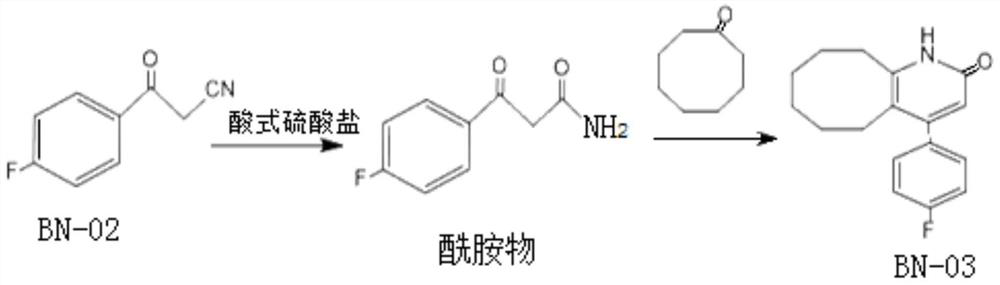

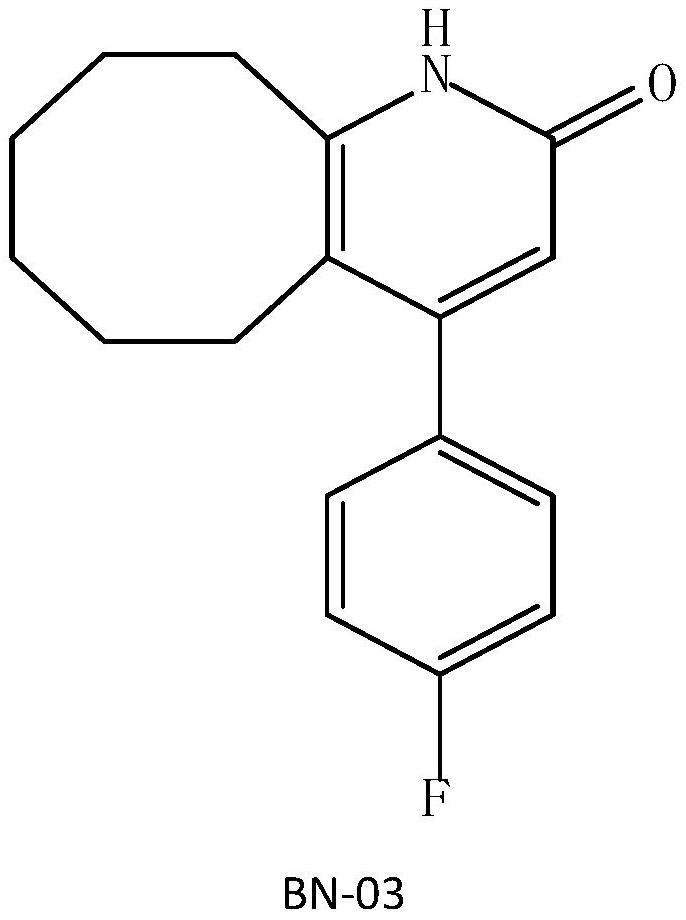

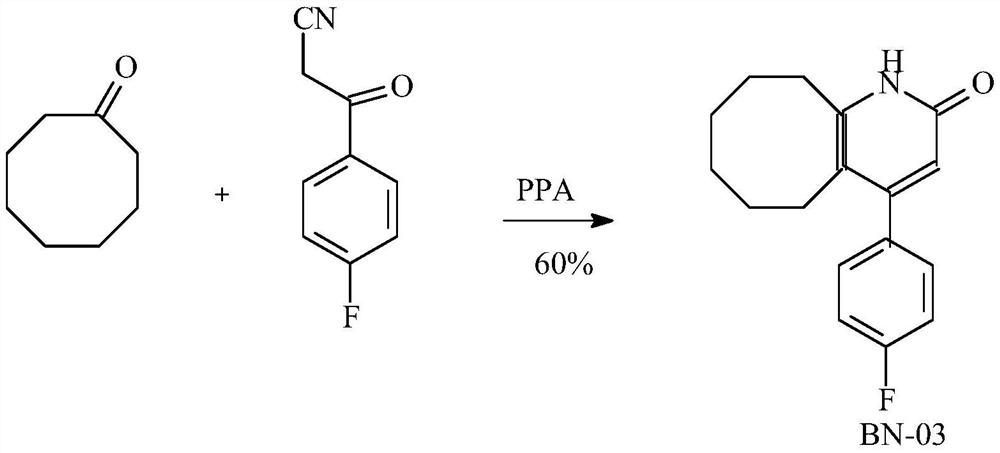

Preparation method of blonanserin intermediate

The invention relates to a preparation method of a blonanserin intermediate, which comprises the following steps: hydrolyzing p-fluorobenzoyl acetonitrile in an aqueous solution in the presence of acid sulfate, then neutralizing with ammonia water until the pH value is 8-9, filtering and drying to obtain 3-(4-fluorophenyl)-3-oxopropanamide; and reacting 3-(4-fluorophenyl)-3-oxopropanamide with cyclooctanone in the presence of polyphosphoric acid and a catalyst, which is pyridine or a pyridine derivative, crystallizing in alkaline water, and pulping with methyl tert-butyl ether to obtain the blonanserin intermediate. The preparation method has the advantages of high product yield and few impurities, also has the advantage of high yield during large-scale production, and is suitable for industrial production.

Owner:湖南省湘中制药有限公司

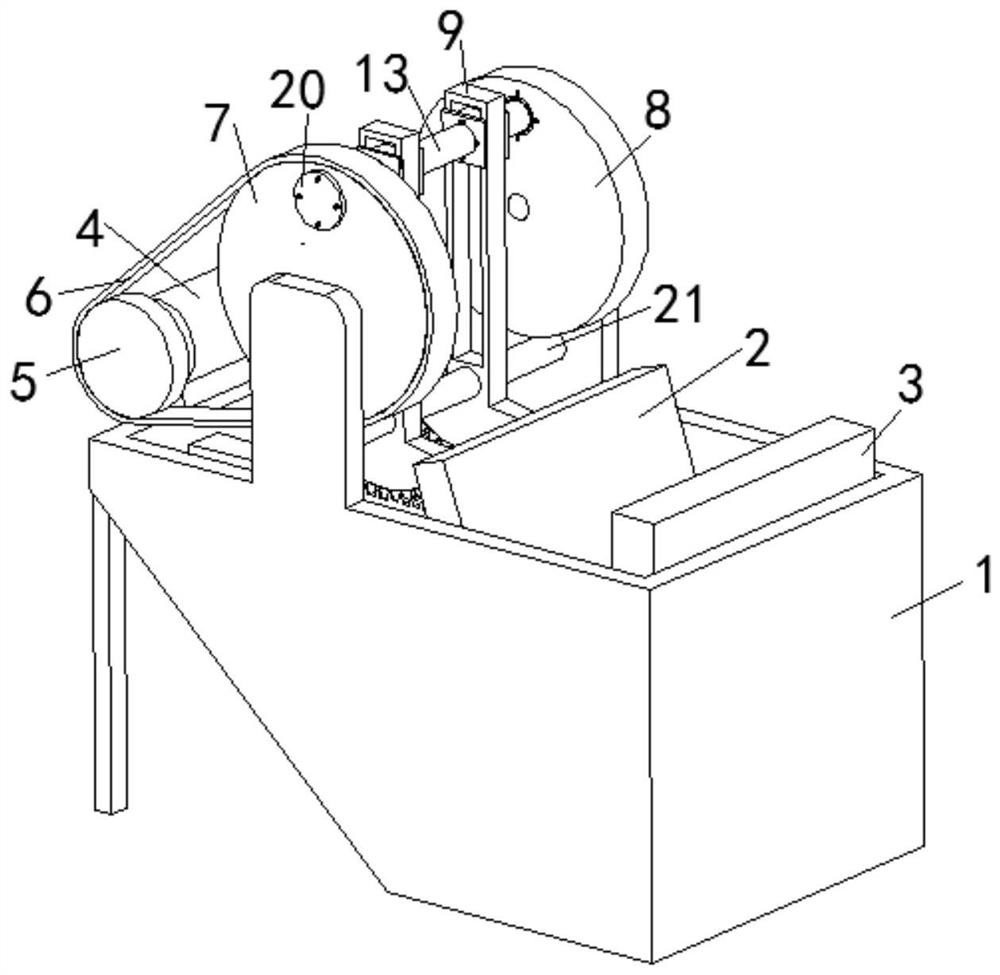

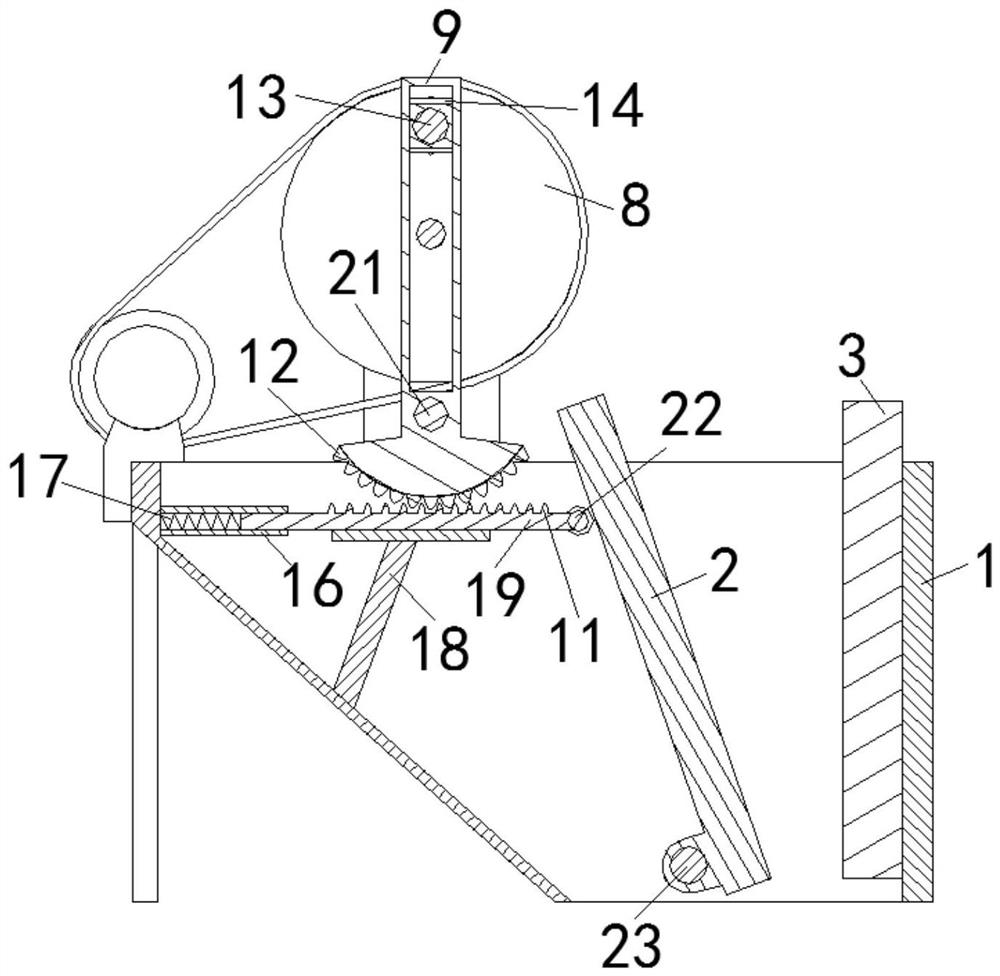

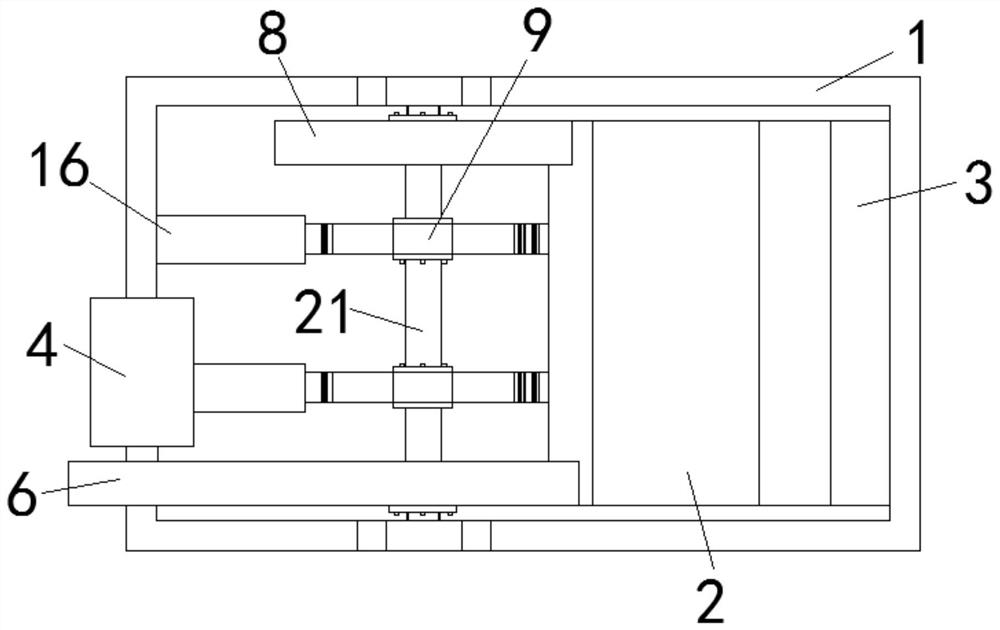

Jaw crusher

The invention discloses a jaw crusher. The jaw crusher comprises a movable jaw body, a static jaw body, a shell, a driving flywheel, a driven flywheel, an eccentric shaft, a fixed shaft, a transmission mechanism and a driving device, wherein the shell is provided with a cavity with an upward opening, the movable jaw body is obliquely arranged in the cavity, the bottom of the movable jaw body is rotatably connected with the shell, the two sides in the cavity are rotatably connected with the driving flywheel and the driven flywheel correspondingly, the eccentric shaft is arranged between the driving flywheel and the driven flywheel, the two ends of the eccentric shaft are connected with the driving flywheel and the driven flywheel correspondingly, the driving device is connected with the driving flywheel and used for driving the driving flywheel to rotate, the rotating axis of the driving flywheel is parallel to the rotating axis of the movable jaw body, and the transmission mechanism isused for enabling the driving flywheel to drive the movable jaw body to crush materials, so that the technical problems in the prior art, for example, the structure is unstable due to recoil and pulling force generated by irregular movement of the movable jaw are solved.

Owner:SICHUAN JIANGYOU XINCHUAN MINE MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com