Patents

Literature

33results about How to "Reduce condensation energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

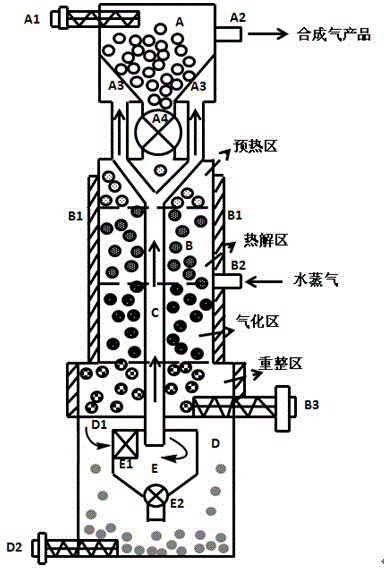

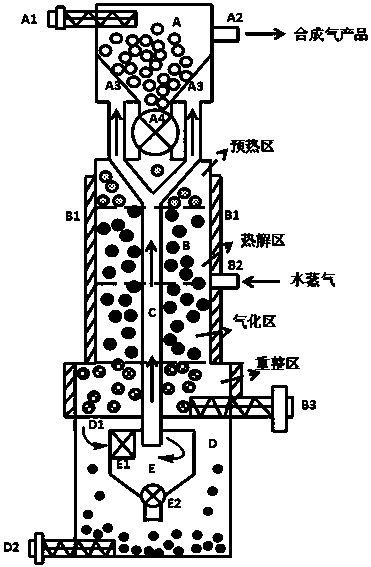

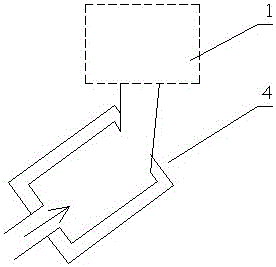

Method for preparing synthetic gas through microwave pyrolysis and gasification of biomass

ActiveCN105524662ARelaxed size requirementsReduce preprocessing power consumptionCombustible gas chemical modificationFixed-bed gasificationHigh carbonLiquid fuel

The invention discloses a method for preparing synthetic gas through microwave pyrolysis and gasification of biomass. The method comprises the following steps: a biomass raw material sent to a bunker and a catalyst are introduced into a microwave pyrolysis reactor, and passes through a preheating zone, a pyrolysis zone, a gasification zone and a reforming zone in order for reactions of dehydration, cracking, gasification and reforming, the reformed product is performed with gas-solid separation, gas and a few of carried tar and coke are subjected to a cracking reaction in a gas lifting pipe again, synthetic gas is released from an outlet, and the coke and ash obtained by gas-solid separation can be discharged from a reactor. The method has the advantages of high biomass gasification rate and high carbon conversion rate, the obtained synthetic gas product has high quality, can satisfy synthesis requirement of a liquid fuel, and has good application prospect.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEMICALS CO LTD +1

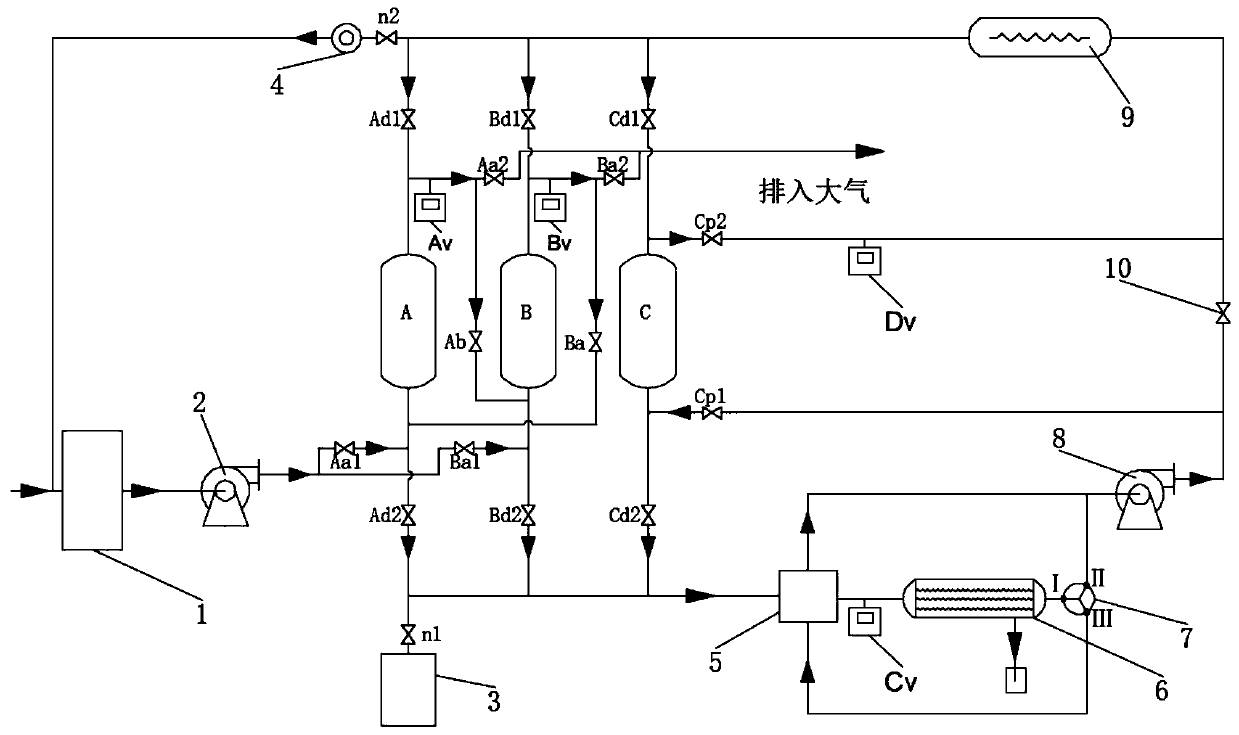

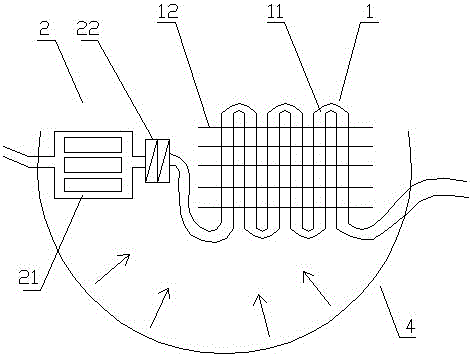

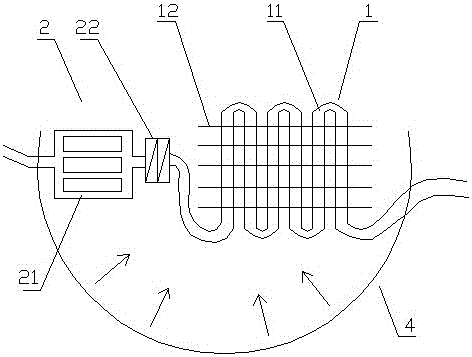

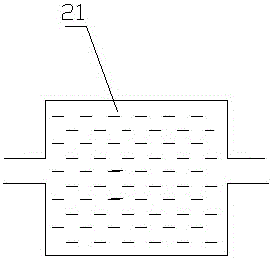

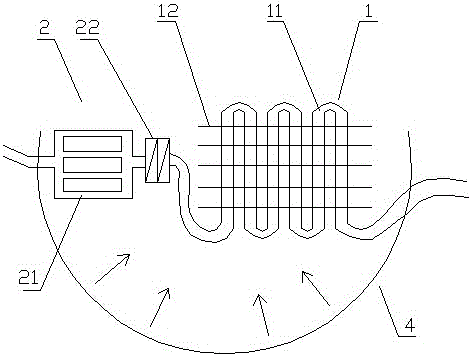

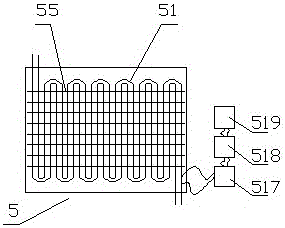

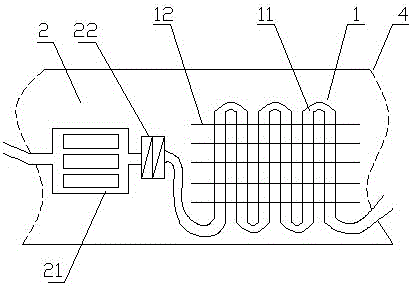

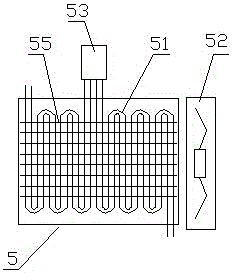

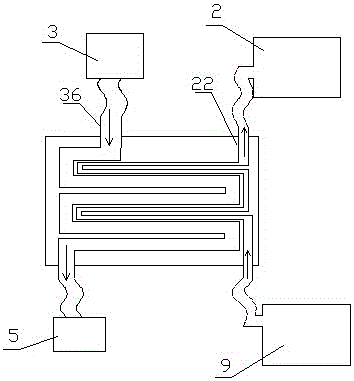

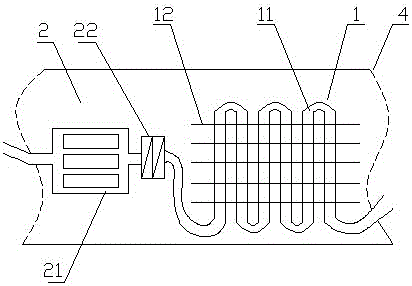

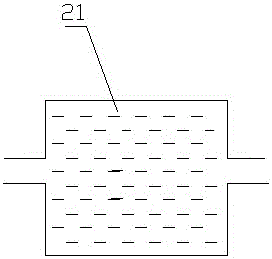

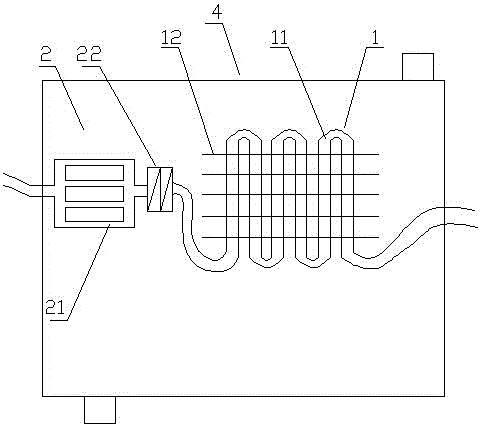

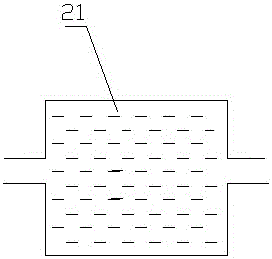

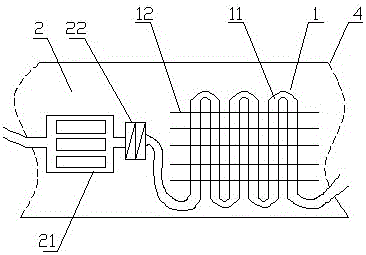

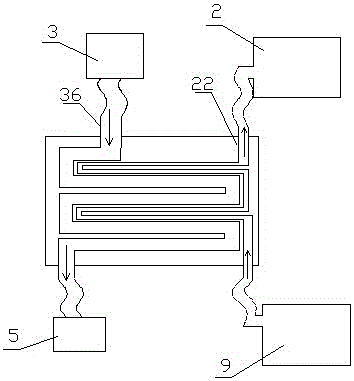

VOC normal-temperature condensation treatment system and method utilizing static activity of activated carbon

PendingCN111013318ALow costReduce system power consumptionGas treatmentDispersed particle separationActivated carbonOrganosolv

The invention discloses a VOC normal-temperature condensation treatment system and a method utilizing static activity of activated carbon, and relates to the technical field of industrial emission VOCs treatment. The VOC normal-temperature condensation treatment system comprises a VOCs pretreatment system, a desorption condensation system, an auxiliary adsorption bed C, an adsorption bed A and anadsorption bed B; the adsorption beds A and B are connected with an adsorption fan through an adsorption air inlet valve; the adsorption fan is connected with the VOCs pretreatment system; the adsorption beds A and B are connected with the atmosphere through adsorption air outlet valves; the adsorption beds A and B are in serial closed connection through series valves Ab and Ba; and two ends of the adsorption bed A, the adsorption bed B and the auxiliary adsorption bed C are respectively connected with two ends of a desorption condensation system through desorption condensation valves. By adopting the treatment method of the system, the static activity of the activated carbon is fully utilized, the cost of the activated carbon is reduced, the service life is prolonged, and the recovered organic solvent is higher in purity and high in recovery efficiency; and a 2 + 1 mode is adopted, so that the control strategy is simpler, and the operation is more reliable.

Owner:TONGJI UNIV

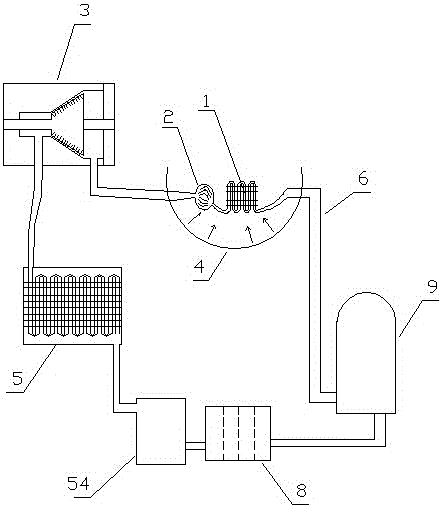

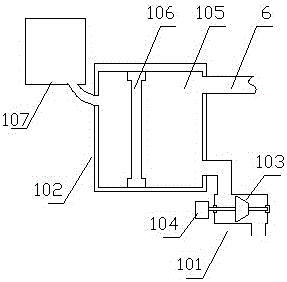

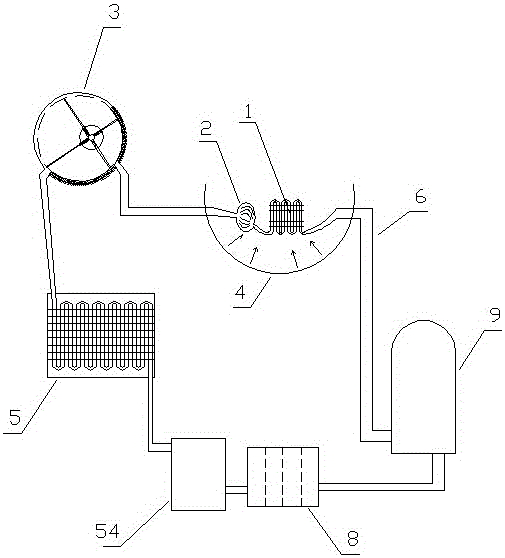

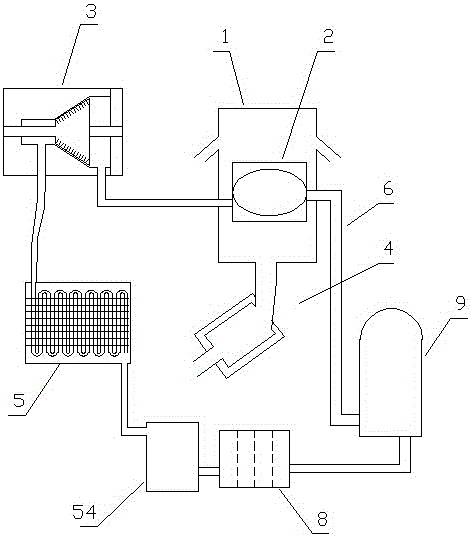

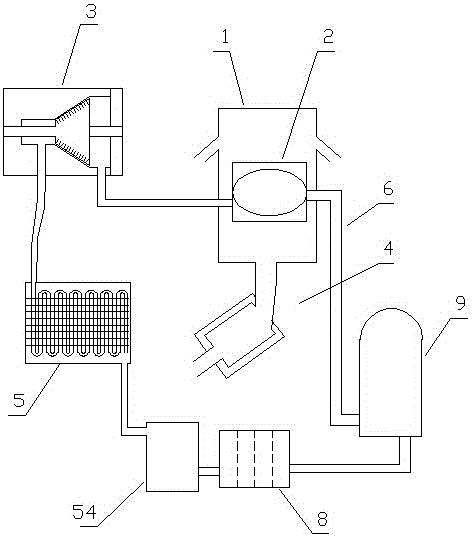

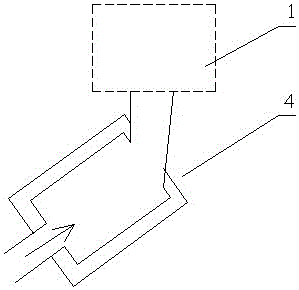

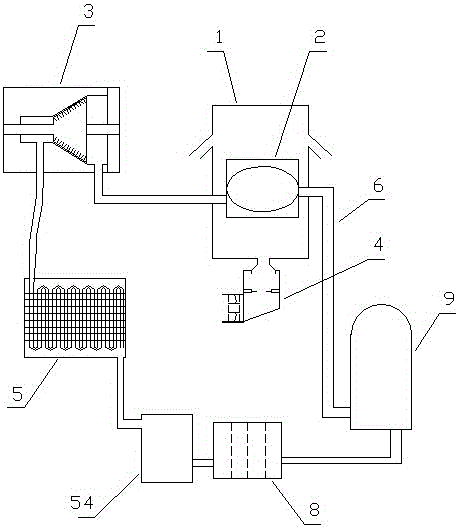

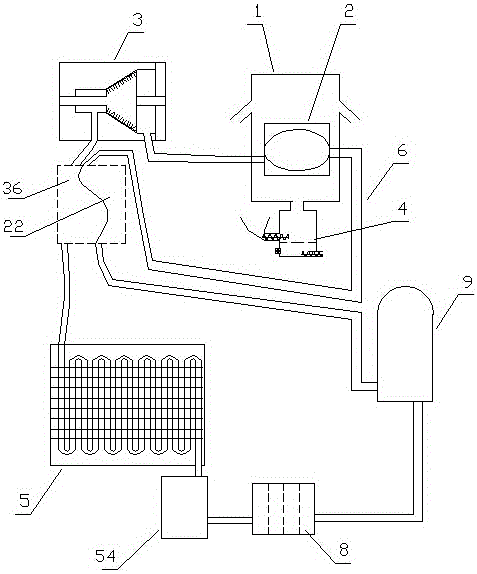

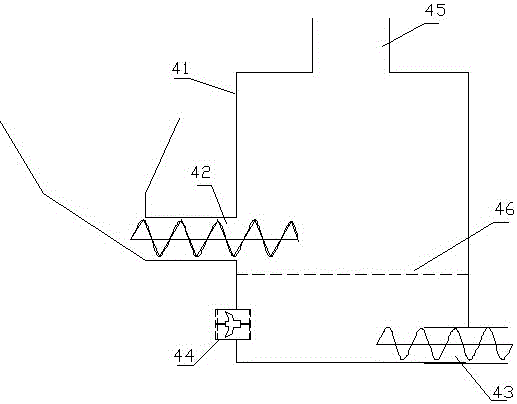

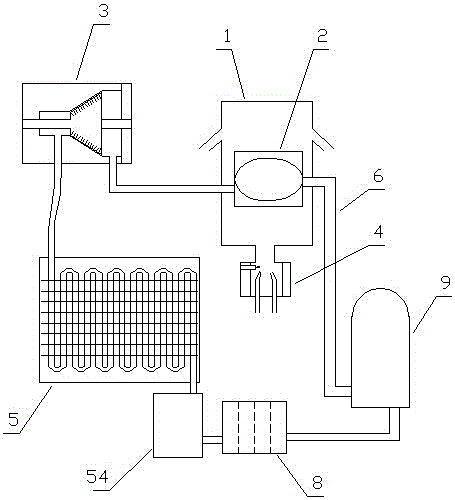

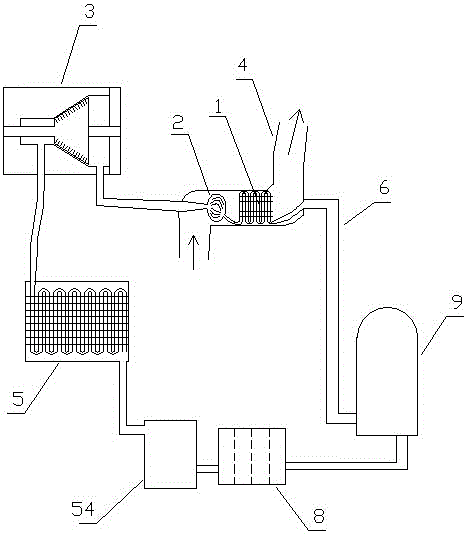

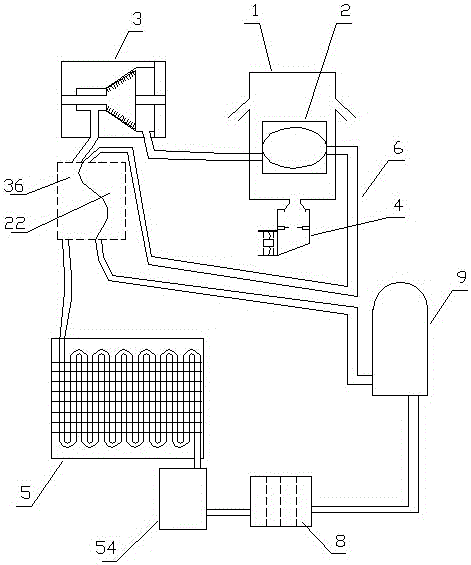

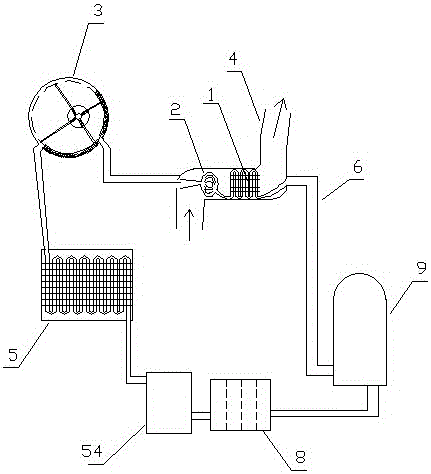

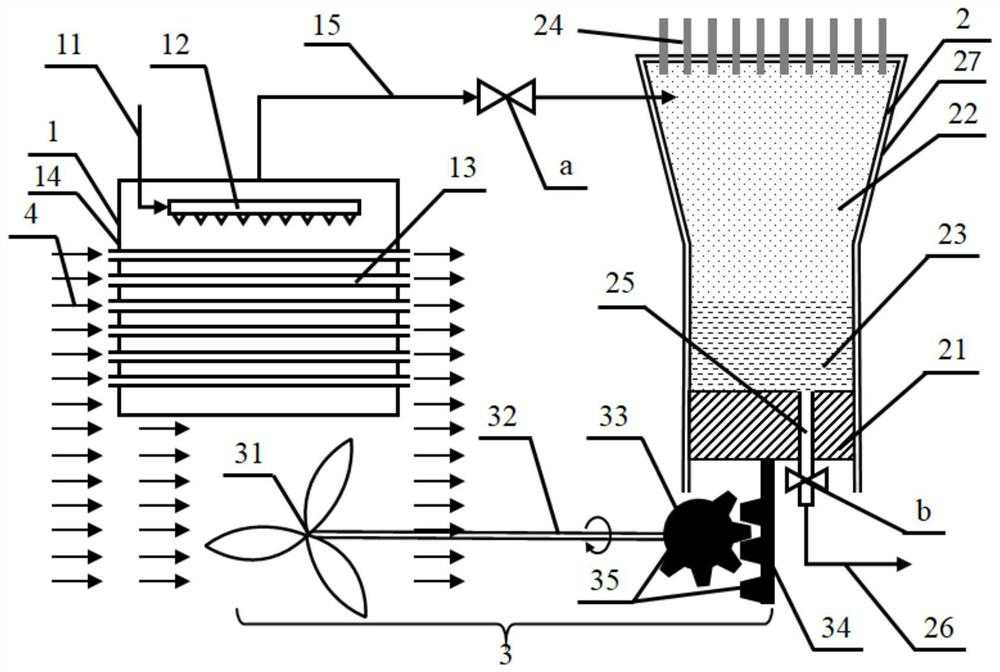

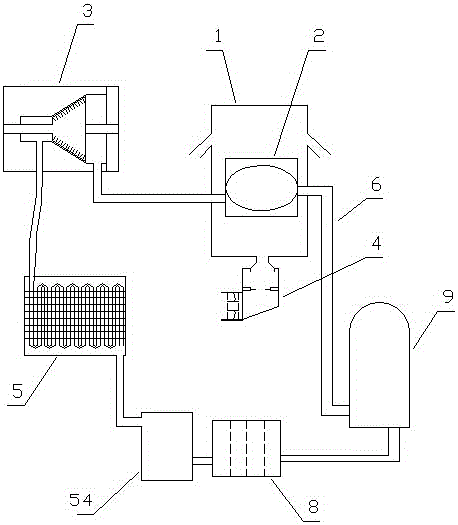

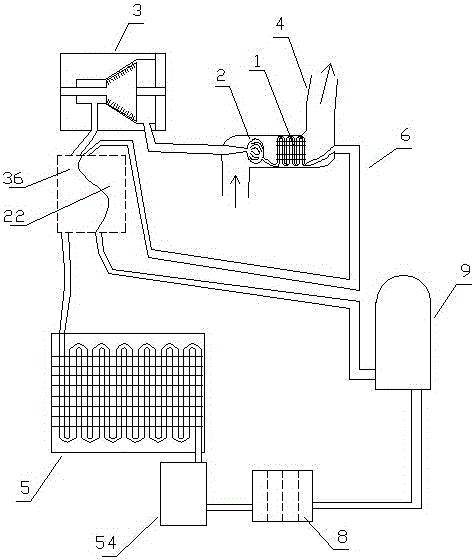

Solar heat energy power system based on multistage pressurization condensation

InactiveCN106438239AImprove heat conversion rateReduce pressureFrom solar energySteam engine plantsThermal energySolar light

The invention discloses a solar heat energy power system based on multistage pressurization condensation. The solar heat energy power system based on multistage pressurization condensation comprises a heat collecting device, a gasifying device, a turbine, a condensing device and a one-way hydraulic pump for realizing circulating communication through circulating pipes; circulating working mediums are filled in the circulating pipes; the heat collecting device and the gasifying device are mounted in a solar light collecting cover; the condensing device is mounted out of the solar light collecting cover, and includes a condensing pipe, a cooling fan and multiple pressurization mechanisms; the cooling fan is mounted above or below the condensing pipe; and the pressurization mechanisms are uniformly distributed at the middle part of the condensing pipe stage by stage. The solar heat energy power system based on multistage pressurization condensation is quicker in condensing speed, can reduce the condensation energy discharge and improve the heat energy conversion efficiency, and is stable in operation and adjustable in power.

Owner:郭远军

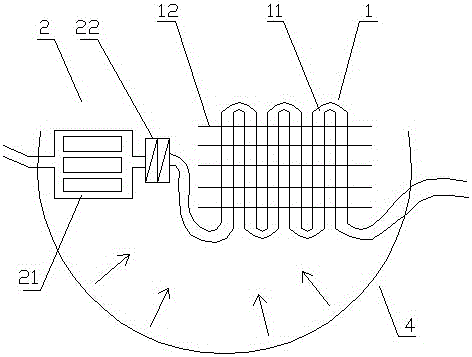

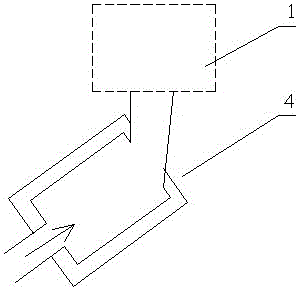

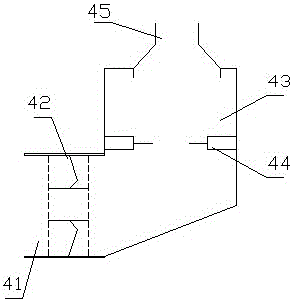

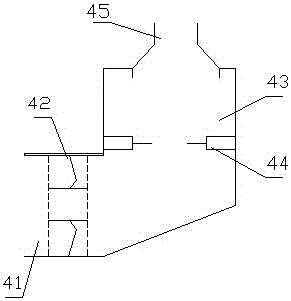

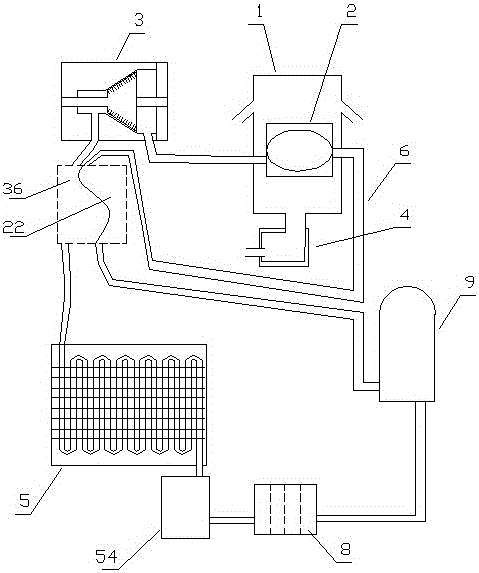

Internal combustion engine tail gas utilization heat energy power system based on adjustable-pressure and stable-pressure condensation

InactiveCN106224032APrevent backflowLarge deformationSteam engine plantsHydraulic pumpInternal combustion engine

The invention discloses an internal combustion engine tail gas utilization heat energy power system based on adjustable-pressure and stable-pressure condensation. The system comprises a gasifying device, a turbine, a condensation device and a one-way hydraulic pump for realizing circular communication through circulating pipes in sequence; circulating working mediums are in the circulating pipes; a heat collecting device is mounted at the external of the gasifying device, and is communicated with an internal combustion engine tail gas pipe; a working medium adjuster is arranged between the turbine and the condensation device, and includes a turbine current limiter and a pressure stabilizing and controlling machine; the pressure stabilizing and controlling machine includes a slow pressure current storage cylinder, a slow pressure piston and an air pressure adjuster; the top end of the slow pressure current storage cylinder is communicated with the circulating pipes, and the bottom end of the slow pressure current storage cylinder is communicated with the air pressure adjuster; and the slow pressure piston is mounted in the slow pressure current storage cylinder. The internal combustion engine tail gas utilization heat energy power system based on adjustable-pressure and stable-pressure condensation has such advantages as high heat energy conversion efficiency, stable operation and adjustable power.

Owner:郭远军

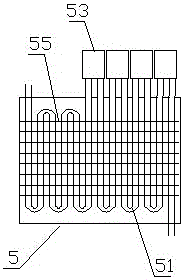

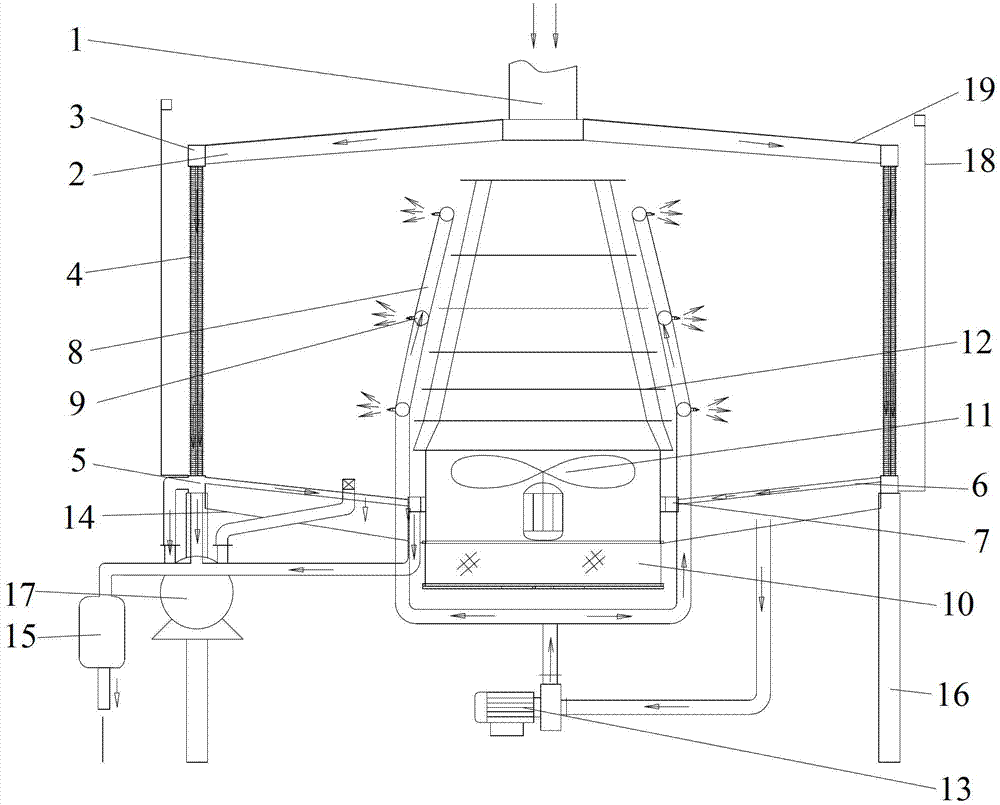

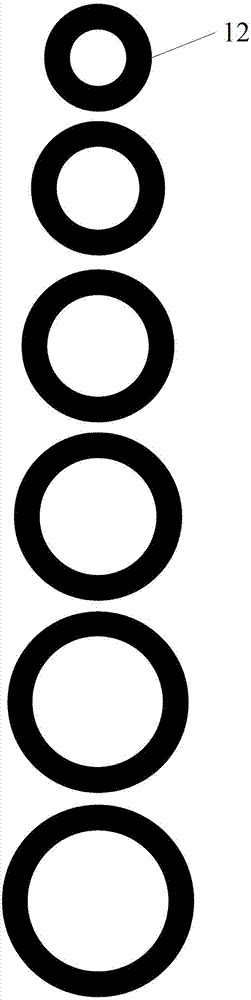

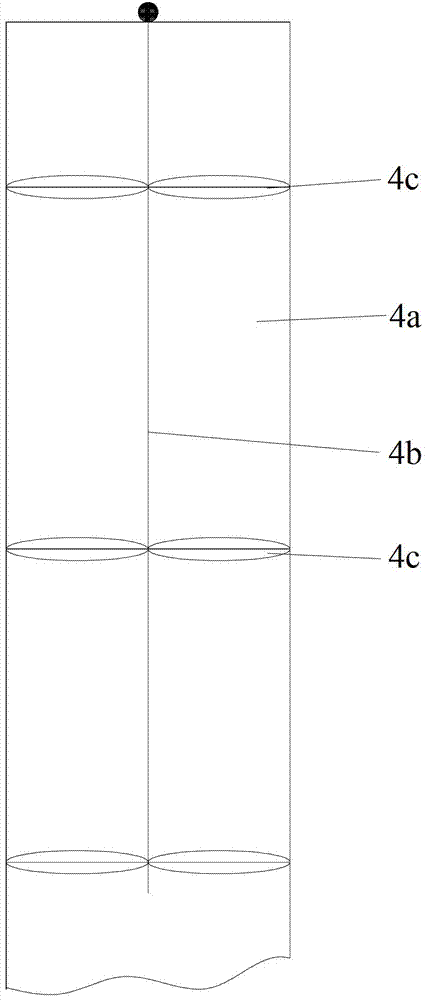

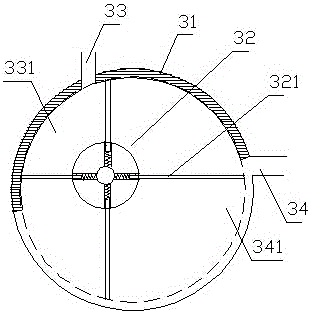

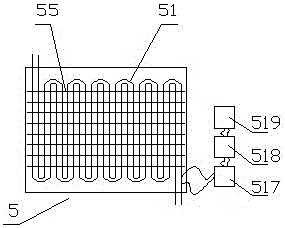

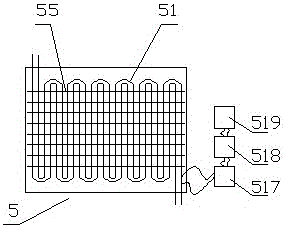

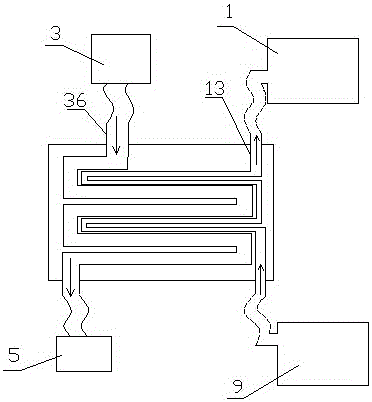

A spray mass transfer condenser

ActiveCN102865753BReduce consumptionAvoid condensationEvaporators/condensersSteam/vapor condensersEngineeringPhase change

The invention discloses a spraying mass transfer type condenser. The condenser comprises a plurality of finned condensing tubes, a water collecting disk and a fan, wherein the plurality of finned condensing tubes are distributed in a circular shape, the water collecting disk is arranged below finned condensing tubes, a secondary steam header pipe is connected above finned condensing tubes, spraying pipes which are distributed in a circular shape are arranged inside the plurality of finned condensing tubes which are distributed in a circular shape, and atomizing nozzles are arranged on spraying pipes. The spraying mass transfer type condenser atomizes water through atomizing nozzles, sprays the water to surfaces of finned condensing tubes for heat absorption and evaporates the water. By the aid of the convective heat transfer having phase changes, the heat exchange coefficient is greatly improved, the condensing energy consumption is greatly saved, besides, the secondary steam header pipe is located above finned condensing tubes, so that the direction of high-speed steam is consistent with the direction of condensed water, the film condensation inside tubes can be prevented effectively, and the heat transfer coefficient is improved.

Owner:FOSHAN DEZHONG PHARMA MACHINERY

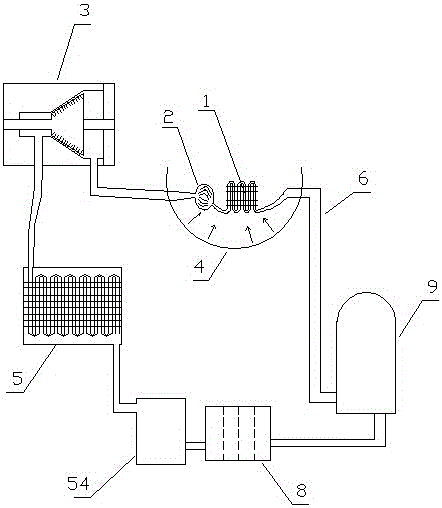

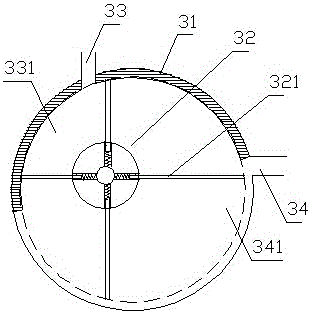

Solar heat energy power system based on eccentric turbine

InactiveCN106437891AAvoid speed instabilityAvoid working fluid leakageSteam/vapor condensersSteam engine plantsSolar lightHydraulic pump

The invention discloses a solar heat energy power system based on an eccentric turbine. The solar heat energy power system comprises a heat collection device, a gasifying device, the turbine, a condensation device and a one-way hydraulic pump, all of which are in circular communication sequentially through a circulation pipeline; circular working media are contained in the circulation pipeline, the heat collection device and the gasifying device are mounted in a solar light condensing cover, the condensation device is arranged outside the solar light condensation cover, the eccentric turbine comprises a turbine main case, a rotating turbine structure, an air inlet and an exhaust opening, a rotating shaft of the rotating turbine structure is eccentrically mounted in the turbine main case, and the air inlet and the exhaust opening are distributed in the two radial sides of the turbine main case. The solar heat energy power system based on the eccentric turbine has the beneficial effects of being high in heat energy conversion efficiency, large in turbine torque, adjustable in power and the like.

Owner:郭远军

Internal combustion engine exhaust utilizing thermal energy power system based on semiconductor condensation

PendingCN106224037AImprove conversion efficiencyIncrease conduction rateSteam engine plantsGenerators/motorsThermal energyExternal combustion engine

The invention discloses an internal combustion engine exhaust utilizing thermal energy power system based on semiconductor condensation. The internal combustion engine exhaust utilizing thermal energy power system comprises a gasifying device, a turbine, a condensing device and a one-way hydraulic pump, wherein the gasifying device, the turbine, the condensing device and the one-way hydraulic pump communicate circularly in sequence through a circulating pipeline. Circulating working media are contained in the circulating pipeline. A heat collecting device is mounted outside the gasifying device and communicates with an internal combustion engine exhaust tube which comprises a gas inlet, an air inlet, a mixed gas combustion cavity and an igniter. The condensing device comprises a condensing pipe and a cooling fan, and the condensing pipe is made of thermoelectric power generation pieces. The internal combustion engine exhaust utilizing thermal energy power system based on semiconductor condensation has a high condensing rate and can reduce condensation energy discharge and improve thermal energy conversion efficiency, operation is stable, and power is adjustable.

Owner:郭远军

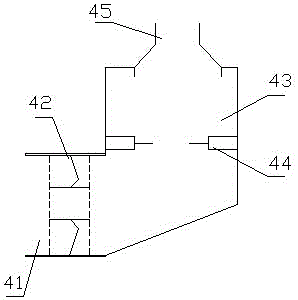

Internal combustion engine tail gas utilization heat energy power system based on multistage pressurization condensation

InactiveCN106437908AIncrease the amount of workIncrease the differential pressureSteam/vapor condensersStationary conduit assembliesHydraulic pumpEngineering

The invention discloses an internal combustion engine tail gas utilization heat energy power system based on multistage pressurization condensation. The system comprises a gasifying device, a turbine, a condensing device and a one-way hydraulic pump for realizing circular communication through circulating pipes in sequence; circulating working mediums are filled in the circulating pipes; a heat collecting device is mounted at the external of the gasifying device, and is communicated with an internal combustion engine tail gas pipe; the condensing device includes a condensing pipe, a cooling fan and multiple pressurization mechanisms; the cooling fan is mounted above or below the condensing pipe; and the pressurization mechanisms are uniformly distributed at the middle part of the condensing pipe stage by stage. The internal combustion engine tail gas utilization heat energy power system based on multistage pressurization condensation has the advantages of quicker condensing speed, capability of reducing the condensation energy discharge and improving the heat energy conversion efficiency, stable operation and power adjustability.

Owner:郭远军

Oil field exhaust gas thermal energy power system based on semiconductor condensation

InactiveCN106246259AImprove conversion efficiencyPrevent backflowSteam engine plantsThermal energyCombustion chamber

The invention discloses an oil field exhaust gas thermal energy power system based on semiconductor condensation. The oil field exhaust gas thermal energy power system comprises a gasification device, a turbine, a condensation device and a one-way hydraulic pump, wherein the gasification device, the turbine, the condensation device and the one-way hydraulic pump are connected in a circulating manner through a circulating pipeline. A circulating working medium is contained in the circulating pipeline. A heat collection device is installed on the exterior of the gasification device and is connected with an oil field exhaust gas combustion device. The oil field exhaust gas combustion device comprises an exhaust gas inlet, an oil field exhaust gas induced draft fan, an exhaust gas combustion chamber, a continuous fire guide device and a hot gas discharge pipe. The condensation device comprises condensation pipes and a cooling fan. The condensation pipes are formed by thermoelectric power generation pieces. The oil field exhaust gas thermal energy power system based on semiconductor condensation has a high condensation speed, can reduce condensation energy discharge and improve the thermal energy conversion efficiency, and is stable in operation and adjustable in power.

Owner:郭远军

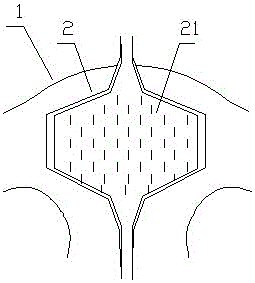

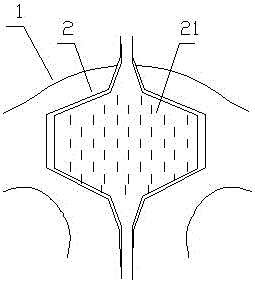

Solar heat energy power system based on honeycomb cavity gasification

InactiveCN106224029AFast thermal conductivityImprove efficiencySteam engine plantsSolar lightHydraulic pump

The invention discloses a solar heat energy power system based on honeycomb cavity gasification. The solar heat energy power system comprises a heat collection device, a gasification device, a turbine, a condensing device and a one-way hydraulic pump, all of which sequentially communicate with one another through a circulation pipeline. A circulation working medium is contained in the circulation pipeline. The heat collection device and the gasification device are installed in a solar light collecting cover. The condensing device is installed outside the solar light collecting cover. The gasification device comprises a solar gasification heat absorption cavity which is a cavity for gasifying the working medium in the gasification device. The gasification device is located in a heat collection cavity. The solar gasification heat absorption cavity is in a honeycomb cavity shape. The solar heat energy power system based on honeycomb cavity gasification has the beneficial effects of being high in gasification efficiency, high in heat energy conversion efficiency, adjustable in power and the like.

Owner:郭远军

Solar heat energy power system based on semiconductor condensation

InactiveCN106246484ARealize power outputIncrease conduction rateFrom solar energySteam engine plantsThermal energyHydraulic pump

The invention discloses a solar heat energy power system based on semiconductor condensation. The solar heat energy power system comprises a heat collection device, a gasification device, a turbine, a condensation device and a unidirectional hydraulic pump which cyclically communicate with one another in sequence through a circulating pipeline, wherein a circulating working medium is accommodated in the circulating pipeline; the heat collection device and the gasification device are mounted in a solar concentration hood; the condensation device is mounted outside the solar concentration hood and comprises a condensation pipe and a heat dissipation fan; and the condensation pipe consists of temperature difference power generation sheets. The solar heat energy power system based on semiconductor condensation is relatively high in condensation rate, can reduce condensation energy discharging and improve the heat energy conversion efficiency, and is stable in operation and adjustable in power.

Owner:郭远军

Internal combustion engine tail gas utilization heat energy power system based on honeycomb cavity gasification

InactiveCN106437972AFast thermal conductivityImprove efficiencyInternal combustion piston enginesExhaust apparatusHoneycombHydraulic pump

The invention discloses an internal combustion engine tail gas utilization heat energy power system based on honeycomb cavity gasification. The system comprises a gasifying device, a turbine, a condensing device and a one-way hydraulic pump, wherein the gasifying device, the turbine, the condensing device and the one-way hydraulic pump communicate in a circulating mode in sequence through circulating pipes; the circulating pipes are filled with circulating working mediums; a heat collecting device is mounted at the external of the gasifying device, and is communicated with an internal combustion engine tail gas pipe; the gasifying device includes a gasification cavity; the gasification cavity is a cavity for realizing gasification of a working medium in the gasifying device; the gasifying device is positioned in a heat collecting cavity; and the gasification cavity takes the shape of a honeycomb cavity. The internal combustion engine tail gas utilization heat energy power system based on honeycomb cavity gasification has such advantages as high gasification efficiency, high heat energy conversion efficiency and power adjustability.

Owner:郭远军

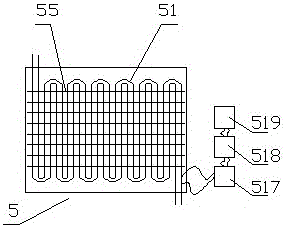

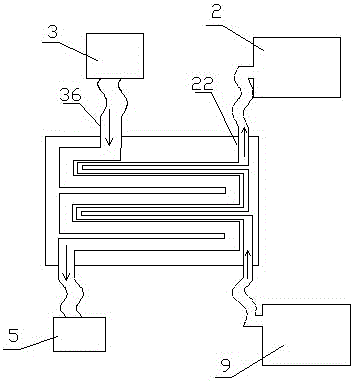

Biomass heat energy power system based on working medium circulation condensation

InactiveCN106437896AReduce the temperatureReduce pressureSteam/vapor condensersStationary conduit assembliesThermal energyHydraulic pump

The invention discloses a biomass heat energy power system based on working medium circulation condensation. The biomass heat energy power system comprises a gasification device, a turbine, a condensing unit and a one-way hydraulic pump which circularly communicate with one another sequentially through circulating pipelines. The circulating pipelines internally contain a circulating working medium. A heat collection device is installed outside the gasification device and communicates with a biomass furnace. The gasification device comprises a gasification cavity and a preheating cavity pipe. A pre-condensation cavity is arranged at the exhaust port position of the turbine, and the preheating cavity pipe makes parallel contact with the pre-condensation cavity. The biomass heat energy power system based on working medium circulation condensation can accelerate condensation, improve the efficiency of the turbine and reduce the heat energy exhaust amount, and therefore the heat energy conversion efficiency is improved.

Owner:郭远军

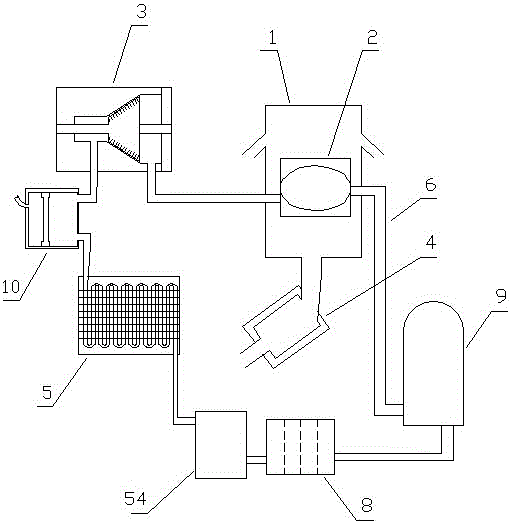

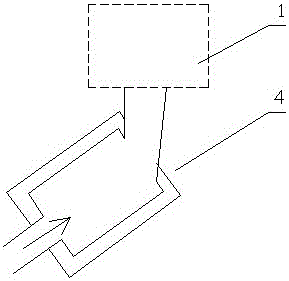

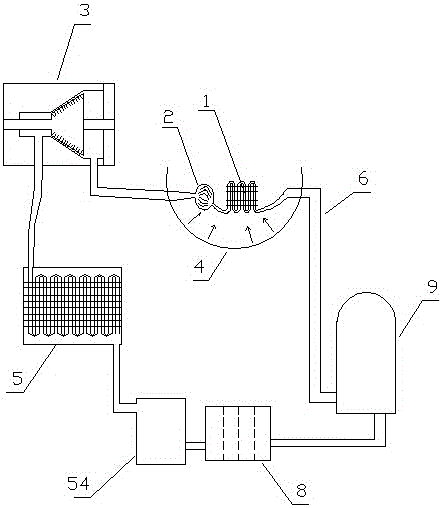

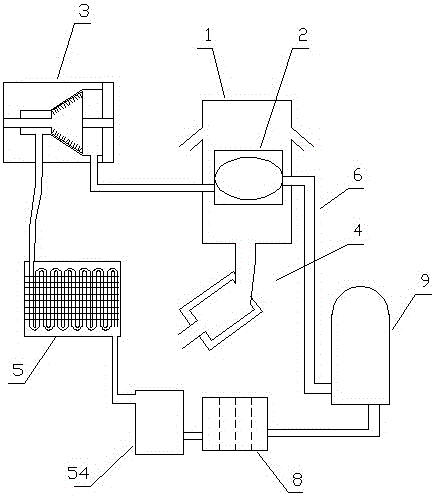

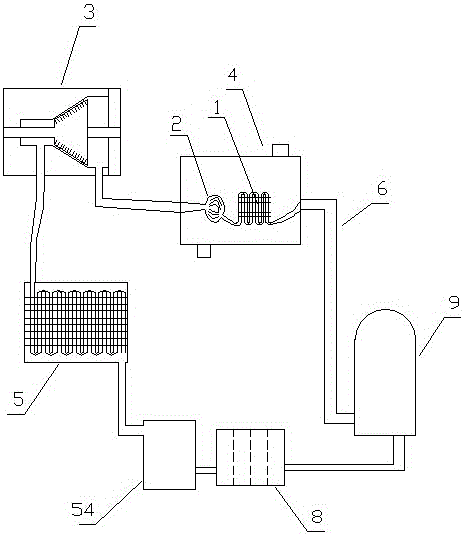

Fuel gas heat energy power system based on multilevel pressurizing condensation

InactiveCN106437890AIncrease condensation rateReduce condensation energy consumptionSteam/vapor condensersStationary conduit assembliesCombustion chamberEngineering

The invention discloses a fuel gas heat energy power system based on multilevel pressurizing condensation. The fuel gas heat energy power system comprises a gasification device, a turbine, a condensing unit and a one-way hydraulic pump which circularly communicate with one another sequentially through circulating pipelines. The circulating pipelines internally contain a circulating working medium. A heat collection device is installed outside the gasification device and communicates with a fuel gas heat supplying furnace. The fuel gas heat supplying furnace comprises a fuel gas inlet, an air inlet, a mixed gas combustion chamber and an igniter. The condensing unit comprises a condenser pipe, a heat dissipation fan and a plurality of pressurizing mechanisms. The heat dissipation fan is installed above or below the condenser pipe, and the pressurizing mechanisms are evenly distributed in the middle portion of the condenser pipe in a step-by-step manner. The fuel gas heat energy power system based on multilevel pressurizing condensation has a high condensing rate, can reduce the condensing exhaust energy and improve the heat energy conversion efficiency and is stable in running and adjustable in power.

Owner:郭远军

Biological fermentation thermal energy power system based on condensation of semiconductor

InactiveCN106246273ARealize power generationIncrease temperatureSteam engine plantsThermal energyHydraulic pump

The invention discloses a biological fermentation thermal energy power system based on condensation of a semiconductor. The system comprises a heat collecting device, a gasifying device, a turbine, a condensing device and a one-way hydraulic pump which circularly communicate through a circulating pipeline; the circulating pipeline contains a circulating working medium, the heat collecting device and the gasifying device are mounted in a biological fermentation pond, and the condensing device is mounted on the outer side of the biological fermentation pond; the condensing device comprises a condensing pipe and a heat dissipation fan, and the condensing pipe is manufactured by a temperature difference power generating piece. The biological fermentation thermal energy power system based on condensation of the semiconductor disclosed by the invention has a relatively great condensing rate, can reduce energy discharge of condensation and improve the heat energy conversation efficiency, and is stable to operate and adjustable in power.

Owner:郭远军

Pressurization and condensation thermal energy power system utilizing thermal drained water of nuclear power station

InactiveCN106224042AImprove heat conversion rateReduce pressureSteam engine plantsThermal energyNuclear power

The invention discloses a pressurization and condensation thermal energy power system utilizing thermal drained water of a nuclear power station. The pressurization and condensation thermal energy power system comprises a heat collecting device, a gasifying device, a turbine, a condensing device and a one-way hydraulic pump, wherein the heat collecting device, the gasifying device, the turbine, the condensing device and the one-way hydraulic pump circularly communicate in sequence through a circulating pipeline. Circulating working media are contained in the circulating pipeline. The heat collecting device and the gasifying device are mounted in a thermal drained water channel of the nuclear power station. The condensing device is mounted in a low-temperature deep-water zone and comprises a condensing pipe, a cooling fan and a pressurization mechanism, wherein the pressurization mechanism is mounted at the middle end of the condensing pipe and comprises a pressurization turbine and a turbine pressure regulator, and the turbine pressure regulator is connected with the pressurization turbine in a controlling mode. The pressurization and condensation thermal energy power system utilizing thermal drained water of the nuclear power station has a high condensing rate and can reduce condensation energy discharge and improve thermal energy conversion efficiency, operation is stable, and power is adjustable.

Owner:郭远军

A method for preparing synthesis gas by microwave pyrolysis gasification of biomass

ActiveCN105524662BRelaxed size requirementsReduce preprocessing power consumptionCombustible gas chemical modificationFixed-bed gasificationMicrowave pyrolysisTar

The invention discloses a method for preparing synthetic gas through microwave pyrolysis and gasification of biomass. The method comprises the following steps: a biomass raw material sent to a bunker and a catalyst are introduced into a microwave pyrolysis reactor, and passes through a preheating zone, a pyrolysis zone, a gasification zone and a reforming zone in order for reactions of dehydration, cracking, gasification and reforming, the reformed product is performed with gas-solid separation, gas and a few of carried tar and coke are subjected to a cracking reaction in a gas lifting pipe again, synthetic gas is released from an outlet, and the coke and ash obtained by gas-solid separation can be discharged from a reactor. The method has the advantages of high biomass gasification rate and high carbon conversion rate, the obtained synthetic gas product has high quality, can satisfy synthesis requirement of a liquid fuel, and has good application prospect.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEMICALS CO LTD +1

Thermal energy dynamic system of oil field exhaust gas based on cyclic condensation of working medium

InactiveCN106246256AReduce the temperatureReduce pressureSteam engine plantsThermal energyCombustion chamber

The invention discloses a thermal energy dynamic system of oil field exhaust gas based on cyclic condensation of working medium comprising a gasification device, a turbine, a condensation device and a one-way hydraulic pump which are successively cycled and communicated through a circulating pipeline; circulating work medium is contained in the circulating pipeline; a thermal-arrest device which is installed outside the gasification device is communicated with an oil field exhaust gas burner comprising an exhaust gas inlet, an oil field exhaust gas induced draught fan, an exhaust gas combustion chamber, a continuous fire guider and a hot gas discharge pipe; the gasification device comprises a gasification chamber and a preheating chamber; an exhaust port of the turbine is provided with a pre-condensing chamber which is in touch with the preheating chamber in parallel. The thermal energy dynamic system of oil field exhaust gas based on cyclic condensation of working medium can accelerate the condensation, improve the efficiency of the turbine, reduce the heat expelled outside, and thereby enhance the heat energy conversion efficiency.

Owner:郭远军

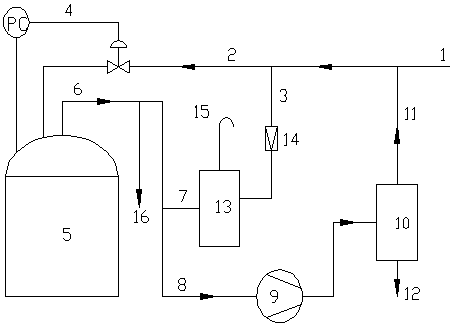

A method and device for purifying exhaust gas from an oil storage tank

ActiveCN105737517BGuaranteed safe operationRelieve pressureSolidificationLiquefactionPurification methodsGas phase

The invention relates to a method and device for purifying exhaust gas from an oil storage tank. The purification device includes an oil storage tank, a water seal tank, a gas compressor, and a condensation system. The exhaust gas outlet on the top of the oil storage tank is divided into three routes. After passing through the gas compressor, it is connected to the condensing system, the second is connected to the exhalation port of the water-sealed tank, and the third is connected to the exhaust gas discharge port; the gas phase discharge port of the condensing system is connected to the low-pressure gas pipe network through pipelines, and the condensing system is Set the condensate discharge pipeline. The outlet of the low-pressure gas pipe network is divided into two routes. The first route is connected to the suction port of the water seal tank through the pressure reducing valve, and the second route is connected to the protective gas inlet of the oil storage tank. Gas flow control facilities are installed on the connecting pipeline between the gas pipeline network and the protective gas inlet of the oil storage tank, which together with the pressure detection facilities on the top of the oil storage tank constitute a pressure control and adjustment system. The method and device for purifying the exhaust gas of the oil storage tank of the present invention have the characteristics of safety, reliability, simple equipment, low investment and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Gas heat energy power system based on honeycomb cavity gasification

PendingCN106438044AFast thermal conductivityImprove efficiencyGas turbine plantsTurbine/propulsion fuel controlHoneycombHydraulic pump

The invention discloses a gas heat energy power system based on honeycomb cavity gasification. The gas heat energy power system based on honeycomb cavity gasification comprises a gasifying device, a turbine, a condensing device and a one-way hydraulic pump for realizing circulating communication through circulating pipes; circulating working mediums are filled in the circulating pipes; the heat collecting device is mounted at the external of the gasifying device, and is communicated with a gas heating furnace; the gas heating furnace includes a gas inlet, an air inlet, a mixed gas combustion cavity and an igniter; the gasifying device includes a gasification cavity; the gasification cavity is a cavity for realizing gasification of a working medium in the gasifying device; the gasifying device is positioned in a heat collecting cavity; and the gasification cavity takes the shape of a honeycomb cavity. The gas heat energy power system based on honeycomb cavity gasification has such advantages as high gasification efficiency, high heat energy conversion efficiency and power adjustability.

Owner:郭远军

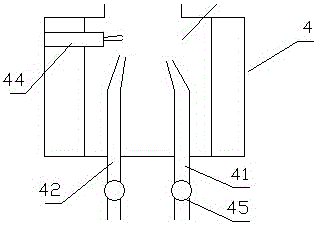

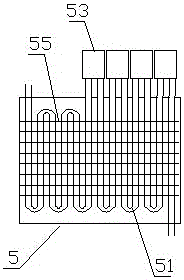

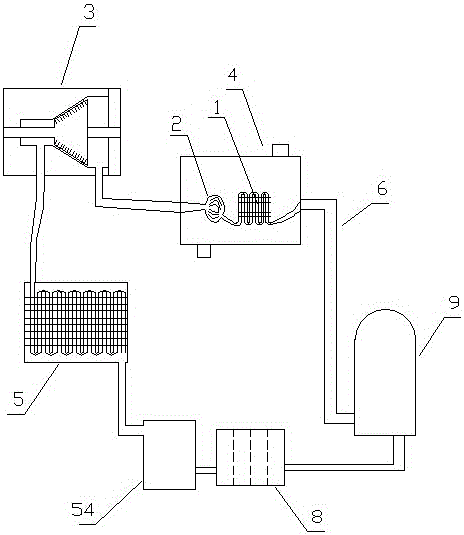

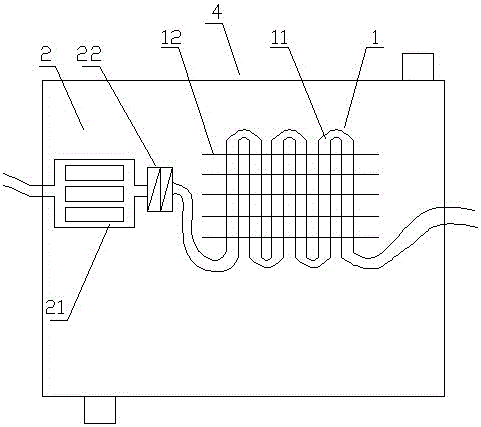

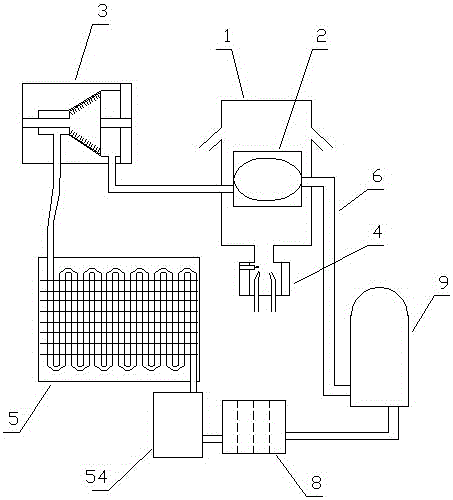

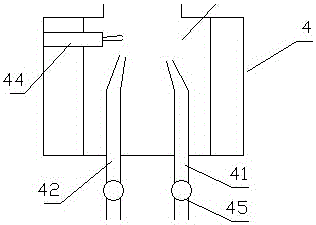

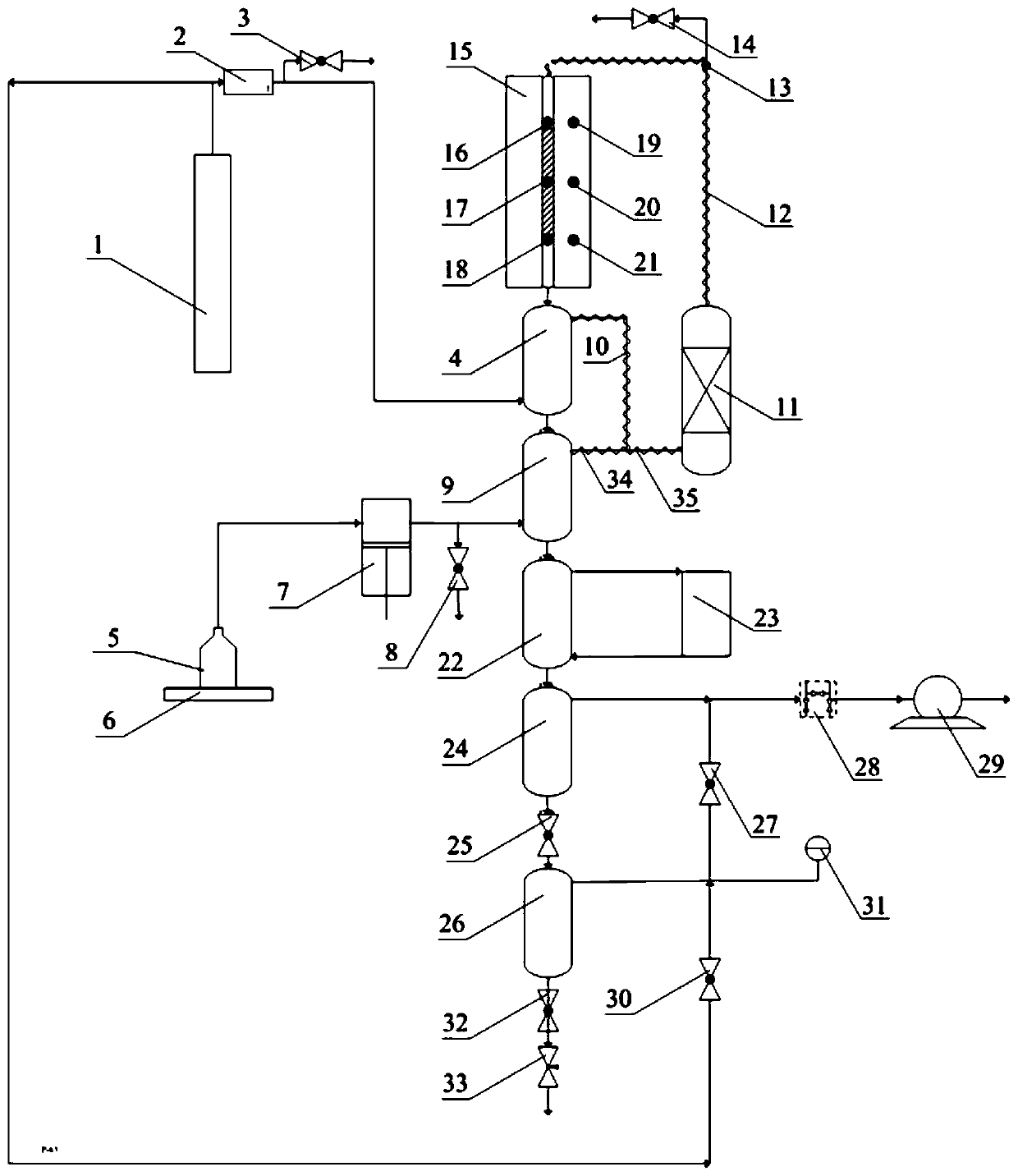

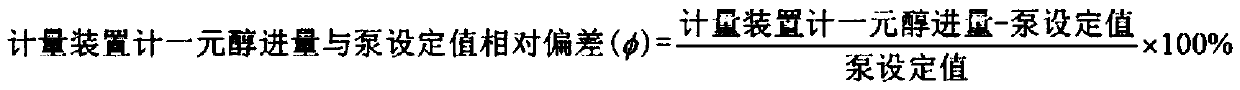

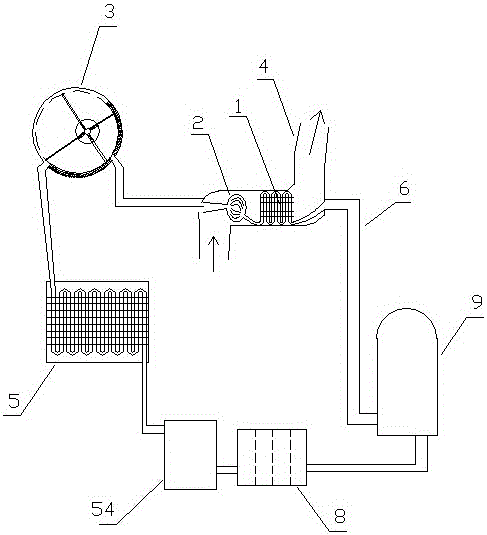

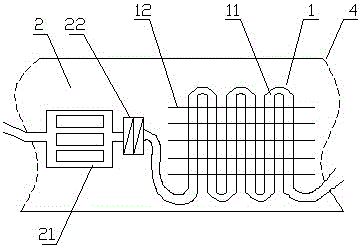

A kind of process device and method for preparing acetal by monoalcohol-air catalytic conversion

ActiveCN107867980BSimple structureDesign scienceOrganic chemistryOrganic compound preparationLiquid productFixed bed

Disclosed by the present invention are a processing system and method for preparing an acetal by using monohydric alcohol-air catalytic conversion, which solves the problems in the existing technology wherein costs are high, safety and environmental protection risks are high, conversion efficiency is low, fast and precise control of production conditions is not possible, and continuous industrial chemical production is not possible. The feeding system of the present invention comprises a raw material tank, a reciprocating metering pump, an air generating device, and a mass flow meter; a heating mixing system comprises a gas pre-heater, a liquid pre-heater, a gas pre-heating pipe, a liquid pre-heating pipe, a gas-liquid mixed pre-heating pipe, a vaporization mixer, and a overheating pipe; a catalytic conversion system comprises a fixed bed catalytic reactor; a condensing system comprises a deep cooler and a circulating refrigerator; a gas-liquid separation system comprises a gas-liquid separation tower, a product tank and a wet flow meter. A monohydric alcohol and air enter the heating mixing system by means of the feeding system and are heated and mixed, then entering the catalytic conversion system to react, a reaction tail gas being condensed by means of the condensing system and being separated by means of the gas-liquid separation system to obtain a liquid product containing the acetal.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Honeycomb cavity gasification heat energy power system using nuclear power plant hot drained water

InactiveCN106437901AImprove conversion efficiencyFast thermal conductivitySteam engine plantsThermal energyNuclear engineering

The invention discloses a honeycomb cavity gasification heat energy power system using nuclear power plant hot drained water. The system comprises a heat collecting device, a gasifying device, a turbine, a condensing device and a one-way hydraulic pump, wherein the heat collecting device, the gasifying device, the turbine, the condensing device and the one-way hydraulic pump communicate in a circulating mode in sequence through circulating pipes; the circulating pipes are filled with circulating working mediums; the heat collecting device and the gasifying device are mounted in a nuclear power plant hot drainage way; the condensing device is mounted in a deep water low-temperature area; the gasifying device includes a gasification heat sucking cavity; the gasification heat sucking cavity is a cavity for realizing gasification of a working medium in the gasifying device; the gasifying device is positioned in a heat collecting cavity; and the gasification heat sucking cavity takes the shape of a honeycomb cavity. The honeycomb cavity gasification heat energy power system using nuclear power plant hot drained water has such advantages as high gasification efficiency, high heat energy conservation efficiency and power adjustability.

Owner:郭远军

Biological fermentation heat energy power system based on honeycomb cavity gasification

InactiveCN106437897AImprove conversion efficiencyFast thermal conductivitySteam engine plantsHoneycombHydraulic pump

The invention discloses a biological fermentation heat energy power system based on honeycomb cavity gasification. The biological fermentation heat energy power system comprises a heat collection device, a gasification device, a turbine, a condensing unit and a one-way hydraulic pump which circularly communicate with one another sequentially through circulation pipelines. The circulation pipelines internally contain a circulation working medium. The heat collection device and the gasification device are installed in a biological fermentation pool, and the condensing unit is installed outside the biological fermentation pool. The gasification device comprises a gasification heat absorbing cavity which is a cavity where a working medium in the gasification device achieves gasification, the gasification device is located in a heat collection cavity, and the gasification heat absorbing cavity is in a honeycomb cavity shape. The biological fermentation heat energy power system based on honeycomb cavity gasification has the beneficial effects that the gasification efficiency is high, the heat energy conversion efficiency is high, and the power is adjustable.

Owner:郭远军

Eccentric type turbine thermal energy power system using nuclear power plant thermal water discharge

InactiveCN106246271AIncrease the differential pressureReduce wasteSteam/vapor condensersStationary conduit assembliesThermal energyHydraulic pump

The invention discloses an eccentric type turbine thermal energy power system using nuclear power plant thermal water discharge. The eccentric type turbine thermal energy power system comprises a thermal collection device, a gasifying device, a turbine motor, a condensation device and a one-way hydraulic pump which are sequentially and circularly connected through circulating pipelines. A circulating working medium is contained in the circulating pipelines. The thermal collection device and the gasifying device are mounted in a nuclear power plant thermal water discharge channel. The condensation device is mounted in a deepwater low temperature zone. The eccentric type turbine motor comprises a turbine motor shell, a rotary turbine structure, a gas inlet and a gas exhaust port. A rotary shaft of the rotary turbine structure is eccentrically mounted in the turbine motor shell. The gas inlet and the gas exhaust port are distributed in the radial two sides of the turbine motor shell. The eccentric type turbine thermal energy power system using the nuclear power plant thermal water discharge has the advantages that the thermal energy conversion efficiency is high, the turbine moment is large, and the power is adjustable.

Owner:郭远军

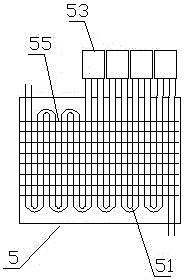

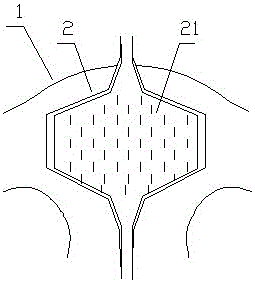

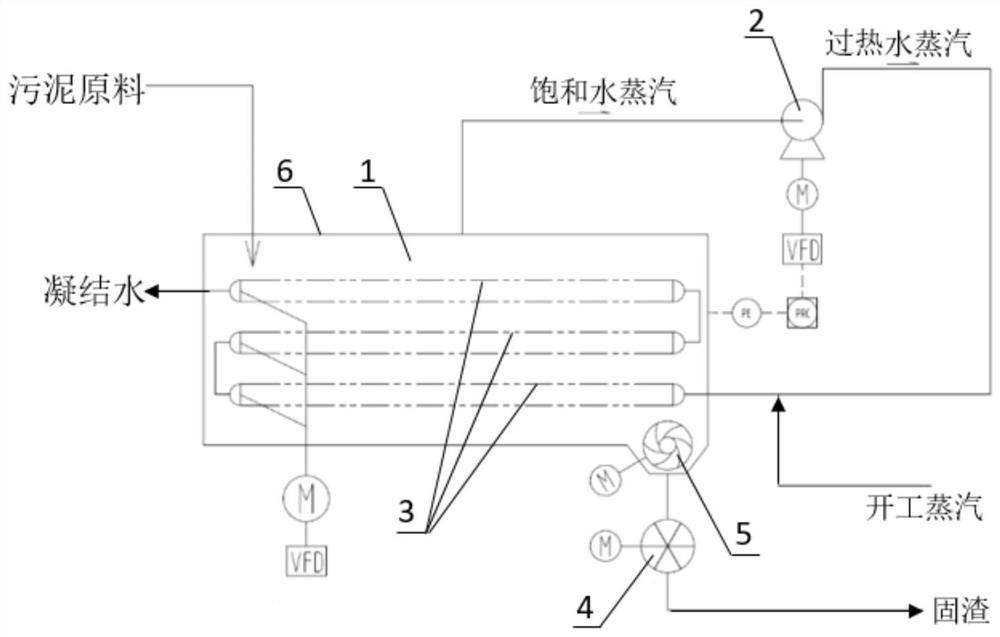

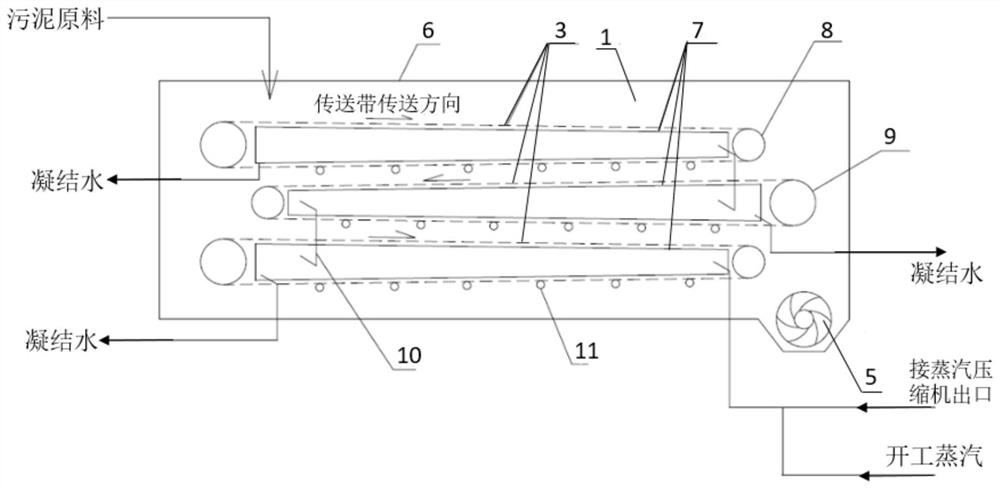

Sludge heat drying method

PendingCN112624561AReduce condensation energy consumptionEasy to handleSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSteam condensationSludge

The invention relates to a sludge heat drying method. A steam heating jacket is arranged below a conveying device, so that a sludge raw material on a conveying surface can be subjected to heat exchange with superheated steam in the steam heating jacket in the conveying process to realize continuous drying treatment, and the treatment capacity of the device and the sludge drying efficiency are improved. In addition, by means of the mode that saturated steam generated in the drying process enters a steam compressor to be compressed, obtained superheated steam is circulated back to the steam heating jacket, the heating steam consumption and saturated steam condensation energy consumption in the drying process are greatly reduced, and the method has the advantages of being high in integration degree, small in occupied area and easy to operate.

Owner:湖南长科诚享石化科技有限公司

Warm drainage cooling equipment and method

ActiveCN111777116ACondensation costs are highReduce energy consumptionGeneral water supply conservationSeawater treatmentSeawaterPower station

The invention discloses warm drainage cooling equipment and a method, and belongs to the technical field of warm drainage cooling. The equipment comprises a cooling box which comprises a heat exchangetube bundle arranged in a penetrating manner, a spraying device arranged in the cooling box, and a seawater pipeline; a compressing and condensing device which comprises a condenser arranged at the top, a piston arranged at a bottom opening, a fresh water pipeline and a second valve arranged on the fresh water pipeline; a steam pipeline which is used for communicating the cooling box with the interior of the compressing and condensing device; and a first valve which is arranged on the steam pipeline. The equipment has the beneficial effects that the heat of warm discharged water of a power station can be absorbed through seawater evaporation, so that the warm discharged water of the power station is cooled, the thermal pollution influence of the warm discharged water on a sea area is relieved, seawater desalination is realized while the warm discharged water is cooled, and the economic cost of the power station warm discharged water cooling process is integrally reduced.

Owner:武汉润德工程技术有限公司

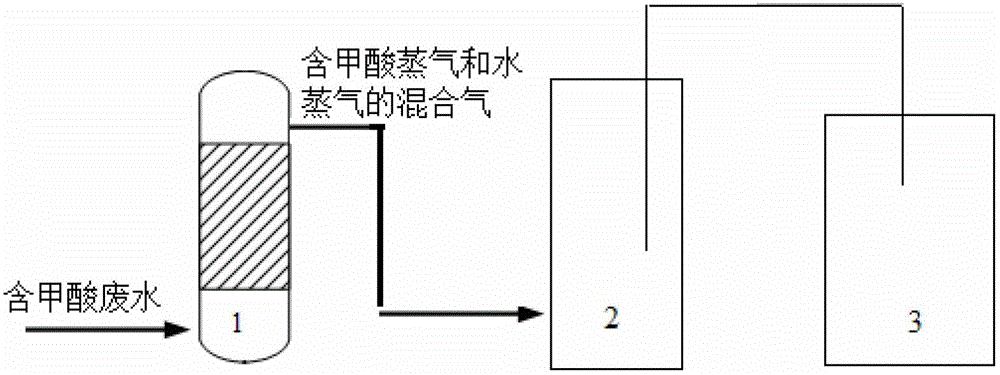

A method of utilizing waste water containing formic acid

ActiveCN103772184BEfficient recyclingImprove processing efficiencyOrganic compound preparationNature of treatment waterOil and greaseDistillation

The invention provides a method for utilizing waste water containing formic acid. The method comprises the following steps: carrying out reduced pressure distillation on the waste water containing formic acid so as to obtain gas mixture containing formic acid steam and water steam, wherein the waste water containing formic acid contains formic acid, water and grease substance; enabling the gas mixture containing formic acid steam and water steam to be directly contacted with slurry containing calcium carbonate. According to the method provided by the invention, the reduced pressure distillation is carried out on the waste water containing formic acid so as to obtain the gas mixture containing formic acid steam and water steam, and then the gas mixture containing formic acid steam and water steam is directly contacted with the slurry containing calcium carbonate, so that the method provided by the invention can efficiently recycle formic acid from the waste water containing the formic acid and is high in yield of calcium formate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Oil field waste heat energy power system based on gasification of cellular cavity

InactiveCN106246266AImprove efficiencyPrevent backflowSteam/vapor condensersStationary conduit assembliesThermal energyCombustion chamber

The invention discloses an oil field waste heat energy power system based on gasification of a cellular cavity. The system comprises a gasification device, a turbine, a condensing device and a one-way hydraulic pump which are circularly communicated successively through a circulating pipeline; the circulating pipeline comprises a circulating working medium, a heat collecting device is mounted on the outer side of the gasification device, the heat collecting device communicates with an oil field waste gas combustion device, and the oil field waste gas combustion device comprises a waste gas inlet, an oil field waste gas induced draft fan, a waste gas combustion chamber, a lasting fire guider and a hot gas discharge pipe; the gasification device comprises a gasification chamber is a cavity where the working medium in the gasification device is gasified; the gasification device is located in the heat collecting chamber, and the gasification chamber is cellular. The oil field waste heat energy power system disclosed by the invention has the advantages of high gasification efficiency, high heat energy conversion efficiency, adjustable power and the like.

Owner:郭远军

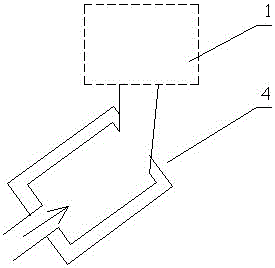

Internal combustion engine exhaust gas utilization heat energy power system based on working medium cyclic condensation

InactiveCN106246258AReduce the temperatureReduce pressureSteam engine plantsHydraulic pumpEngineering

The invention discloses an internal combustion engine exhaust gas utilization heat energy power system based on working medium cyclic condensation. The internal combustion engine exhaust gas utilization heat energy power system comprises a gasification device, a turbine, a condensation device and a unidirectional hydraulic pump which cyclically communicate with one another in sequence through a circulating pipeline, wherein a circulating working medium is accommodated in the circulating pipeline; the heat collection device is mounted outside the gasification device, and communicates with an internal combustion engine exhaust gas pipe; the gasification device comprises a gasification cavity and a preheating cavity pipe; a pre-condensation cavity is arranged at an exhaust opening of the turbine; and the preheating cavity pipe and the pre-condensation cavity are in contact in parallel. The internal combustion engine exhaust gas utilization heat energy power system based on working medium cyclic condensation can accelerate condensation, improve the efficiency of the turbine and reduce the discharging amount of heat energy, so that the heat energy conversion efficiency can be improved.

Owner:郭远军

Working medium circulation condensation heat energy power system utilizing heat water drainage of nuclear power station

InactiveCN106224030AReduce the temperatureReduce pressureSteam engine plantsThermal energyNuclear power

The invention discloses a working medium circulation condensation heat energy power system utilizing heat water drainage of a nuclear power station. The working medium circulation condensation heat energy power system comprises a heat collection device, a gasification device, a turbine, a condensation device and a one-way hydraulic pump which are sequentially in circulation communication through a circulation pipeline. A circulation working medium is included in the circulation pipeline. The heat collection device and the gasification device are mounted in a heat water drainage channel of the nuclear power station. The condensation device is mounted in a deep water low-temperature area. The gasification device comprises a gasification heat absorption cavity and a preheating cavity pipe. A pre-condensation cavity is formed in an exhaust opening of the turbine, and the preheating cavity pipe and the pre-condensation cavity are in parallel contact. According to the working medium circulation condensation heat energy power system utilizing heat water drainage of the nuclear power station, condensation can be accelerated, the efficiency of the turbine can be improved, the discharge amount of heat energy can be reduced, and therefore the conversion efficiency of the heat energy is improved.

Owner:郭远军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com