Internal combustion engine exhaust gas utilization heat energy power system based on working medium cyclic condensation

A technology of working medium circulation and power system, which is applied in the direction of machines/engines, mechanical equipment, steam engine devices, etc., can solve the problems of high exhaust port pressure, small external waste heat absorption rate, and small output power of thermal energy generators, etc., to achieve reduction Effects of heat energy waste and cooling energy consumption, improvement of gasification efficiency and condensation efficiency, stabilization of gasification temperature and working medium flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

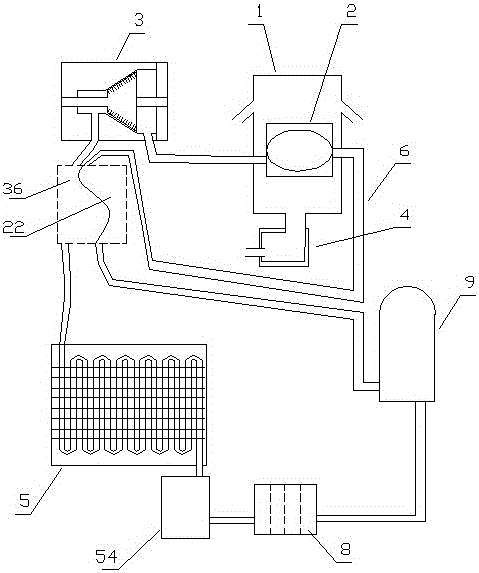

[0082] Embodiment one (such as figure 1 Shown): A power system for utilizing heat energy of internal combustion engine exhaust gas based on working medium circulation condensation, including heat collector 1, gasification device 2, turbine 3, internal combustion engine exhaust pipe 4, condensing device 5, circulation pipeline 6, and circulating working medium 7 And the one-way hydraulic pump 9, the gasification device 2, the turbine 3, the condensing device 5 and the one-way hydraulic pump 9 realize the circulation communication through the circulation pipeline 6 in sequence. Outside the gasification device 2, it is used for gasification heating of the working fluid in the gasification device 2;

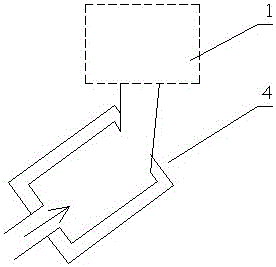

[0083] (Such as figure 2 As shown) the exhaust pipe 4 of the internal combustion engine is connected to the heat collector 1;

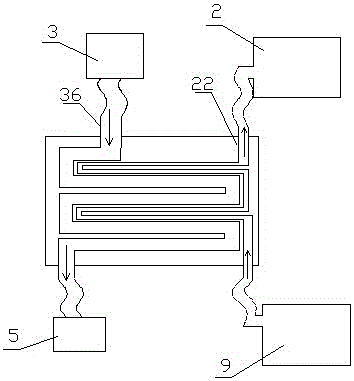

[0084] (Such as image 3 As shown) the gasification device 2 includes a gasification chamber 21 and a preheating chamber tube 22, the preheating chamber...

Embodiment 2

[0096] Embodiment two (such as Image 6 Shown): The difference from Embodiment 1 is that the heat collecting device 1 includes an upper cover 11 and a lower cover 12, a heating port 13 is provided in the middle of the lower cover 12, and the upper cover 11 and the lower cover 12 are respectively located on the upper and lower sides. Between 11 and the lower cover 12 is a heat collecting chamber 14, two layers of upper cover protruding rings 111 are distributed on the lower part of the upper cover 11 of the heat collecting device 1, and two layers of lower cover protruding rings 121 are distributed on the upper part of the lower cover 12 of the heat collecting device 1, The protruding ring 111 of the upper cover and the protruding ring 121 of the lower cover are staggered.

[0097] By carrying out experiments on the internal combustion engine tail gas utilization heat energy power system based on working medium circulation condensation in the above-mentioned embodiment two, th...

Embodiment 3

[0098] Embodiment three (such as Figure 7 Shown): The difference from Embodiment 1 is that the lower part of the upper cover 11 of the heat collecting device 1 is provided with a three-layer upper cover protruding ring 111, and the upper part of the lower cover 12 of the heat collecting device 1 is distributed with a three-layer lower cover protruding ring 121 , the upper cover protruding ring 111 and the lower cover protruding ring 121 are staggered.

[0099] By carrying out experiments on the internal combustion engine tail gas utilization heat energy power system based on working medium circulation condensation in the above-mentioned embodiment three, the exhaust gas of different temperatures is discharged into the heat collector 1, the exhaust gas displacement is 1.5L / s, and the working medium flow rate in the circulation pipe is according to The exhaust gas of the internal combustion engine based on the circulation and condensation of the working fluid is adjusted by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com