Sludge heat drying method

A sludge and heating surface technology, applied in chemical instruments and methods, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problem of high energy consumption and small processing capacity of a paddle dryer , complex equipment structure and other issues, to achieve the effect of saving heating steam consumption and saturated water vapor condensation energy consumption, increasing device processing capacity, and high device integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

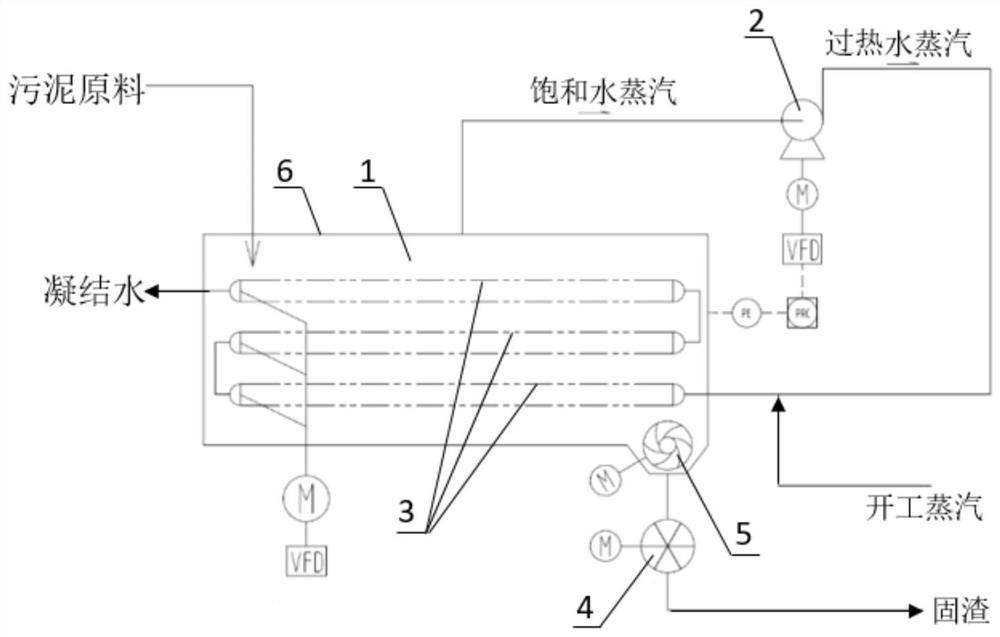

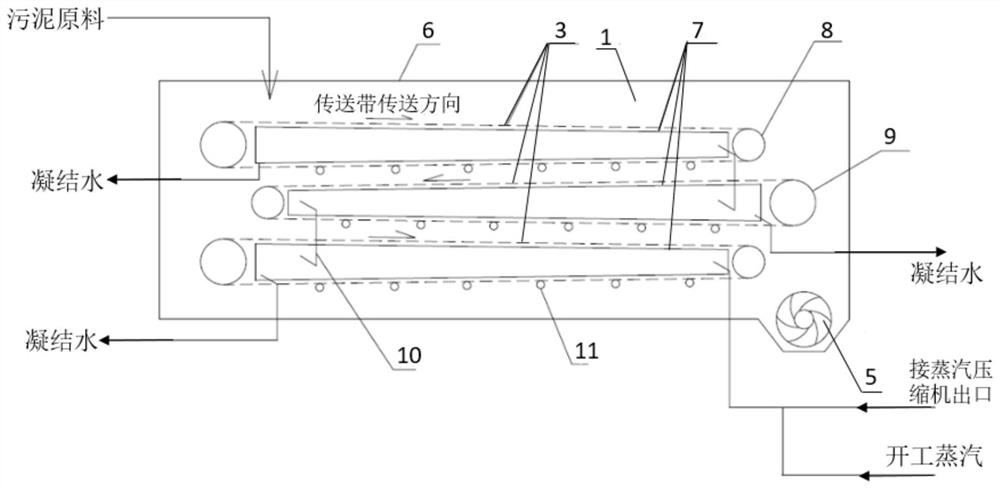

[0050] use as figure 1 The sludge thermal drying system shown is for sludge thermal drying. The system includes a sludge vacuum dryer 1 and a steam compressor 2. The sludge vacuum dryer 1 is provided with a sealed casing 6; The mud raw material inlet and the saturated steam outlet are provided with a solid slag outlet at the bottom, and a screw conveyor 5 located inside the sealed casing 6 is arranged at the solid slag outlet, as well as a feeding conveyor on the pipeline extending outward from the solid slag outlet. Valve 4; the first conveyor belt, the second conveyor belt and the third conveyor belt are arranged vertically from top to bottom in the sealed housing 6, and the first conveyor belt, the second conveyor belt and the third conveyor belt are slidingly arranged below the first conveyor belt, respectively. The steam heating jacket, the second steam heating jacket and the third steam heating jacket, the top of the sealed housing 6 is provided with a saturated water va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com