A method of utilizing waste water containing formic acid

A technology for formic acid wastewater and formic acid, which is applied in chemical instruments and methods, carboxylate preparation, carboxylate preparation and other directions, can solve the problems of heavy burden, difficulty, and lack of sewage treatment technology for enterprises, so as to improve treatment efficiency and save money. The effect of simple cost and process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

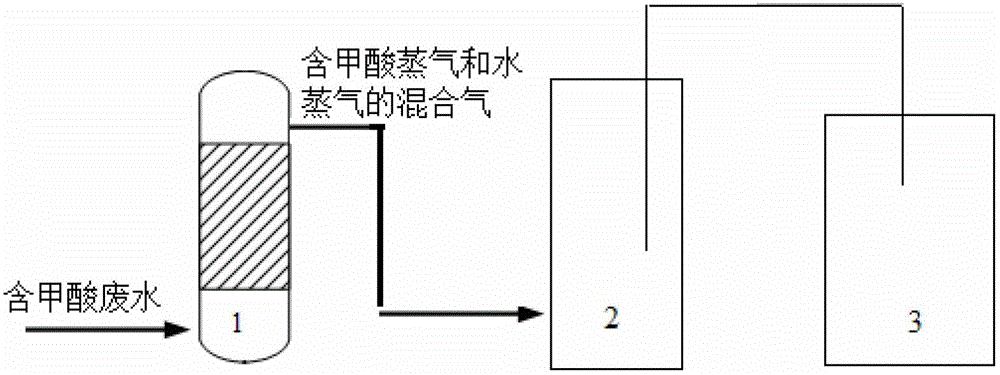

[0040] as attached figure 1 As shown, the waste water containing formic acid is sent to the still 1 (the still 1 is decompressed through the decompression system 3) for vacuum distillation, and the conditions of the vacuum distillation are such that components with a boiling point not higher than formic acid are distilled out , the obtained mixed gas containing formic acid vapor and water vapor directly enters the reactor 2 through the conduit connecting the distillate outlet of the still 1 to the feed port of the reactor 2 (the reactor 2 is decompressed through the decompression system 3) in contact with slurries containing calcium carbonate;

[0041] Concentrate the product obtained by contacting under reduced pressure to obtain a concentrated solution, then filter the concentrated solution obtained by concentrating under reduced pressure, and dry the filtered solid to obtain calcium formate.

[0042] According to the method of the present invention, the calcium carbonate s...

Embodiment 1

[0047] according to figure 1 The shown flow process carries out the method of the present invention utilizing waste water containing formic acid.

[0048] Wherein, 200g of soybean oil methyl ester epoxidation waste liquid (wherein, pH value is 2.8, COD concentration is 12000mg / L, formic acid content is 6 weight %, The content of hydrogen peroxide is 0.9% by weight, the concentration of oily substances is 0.055% by weight, and the rest is water), and 10g of calcium carbonate and 20g of deionized water are charged in the reactor 2 (the reactor 2 is provided with a mechanical stirring paddle and a pH meter). And stirring beating obtains calcium carbonate slurry; And distillation still 1 and reactor 2 carry out the control of pressure by same decompression system 3, and concrete process is as follows:

[0049] (1) Raise the temperature of the liquid in distillation kettle 1 to 65°C, and the temperature of liquid in reaction kettle 2 to 55°C, and start the decompression system 3 t...

Embodiment 2

[0052] according to figure 1 The shown flow process carries out the method of the present invention utilizing waste water containing formic acid.

[0053] Wherein, 200g of soybean oil epoxidation waste liquid (pH value is 2.2, COD concentration is 20000mg / L, formic acid content is 7% by weight, hydrogen peroxide content is 200g as the soybean oil epoxidation waste water of formic acid waste water described in the present invention is loaded into distillation still 1. 0.8% by weight, the concentration of lipids is 0.055% by mass, and the rest is water), and 12g of calcium carbonate and 20g of deionized water are charged into the reactor 2 (the reactor 2 is provided with a mechanical stirring paddle and a pH meter) and stirred for beating Obtain calcium carbonate slurry; And distillation still 1 and reactor 2 carry out the control of pressure by same decompression system 3, and concrete process is as follows:

[0054] (1) Raise the temperature of the liquid in distillation kett...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com