A kind of process device and method for preparing acetal by monoalcohol-air catalytic conversion

A technology of catalytic conversion and process equipment, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as inability to quickly and accurately control production conditions, inability to continue industrial production, and high risk of safety and environmental protection. Achieve fast and precise control of production conditions, facilitate raw material intake, and facilitate production conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

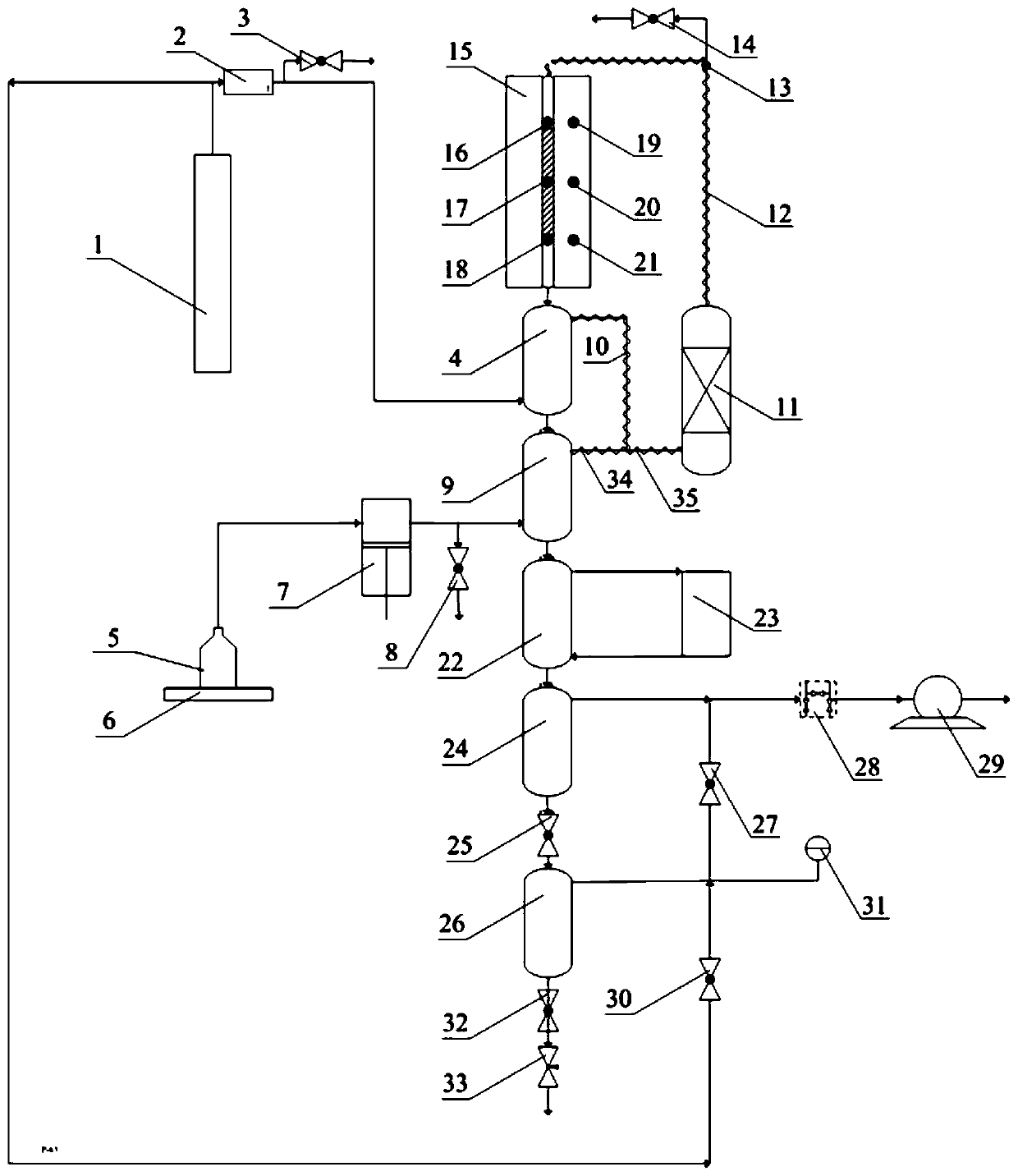

[0041] as attached figure 1 As shown, this embodiment provides a monohydric alcohol-air catalytic conversion process device for preparing acetal, which has a simple structure, scientific design, easy operation, can effectively reduce device investment, production cost and energy consumption, is safe and environmentally friendly, and has high conversion efficiency , and at the same time facilitate rapid and precise control of production conditions, enabling continuous industrial production. The monoalcohol-air catalytic conversion process device for preparing acetal includes a feed system, a heating and mixing system, a catalytic conversion system, a condensation system and a gas-liquid separation system.

[0042] Described feeding system comprises the raw material tank 5 that dresses monohydric alcohol liquid, the reciprocating metering pump 7 that is connected with the outlet pipeline of described raw material tank 5, is used to produce the air generating device 1 of air and ...

Embodiment 2

[0053] This embodiment provides the method for producing acetal by monoalcohol-air catalytic conversion of the present invention, which is carried out by using the process device in Example 1, and specifically includes the following steps:

[0054] With analytically pure methanol as the monoalcohol raw material, with air as the mixture of oxidizing gas and diluent gas, the methanol feed rate of the reciprocating metering pump 7 is set to 5.0mL / h, the outlet pressure of the air generating device 1 is 0.53MPa, and the mass The air flow rate of flow meter 2 is 1.96L / h;

[0055] Methanol from the reciprocating metering pump 7 enters the liquid preheater 9, and after the tail gas reacts with the reactor 15 for heat exchange and preheating, it is further heated through the liquid preheating pipeline 34 and enters the gas-liquid mixing preheating pipeline 35, After the air from the mass flow meter 2 is heated by the gas preheater 4, it is further heated through the gas preheating pip...

Embodiment 3

[0070] This embodiment provides the method for producing acetal by monoalcohol-air catalytic conversion of the present invention, which is carried out by using the process device in Example 1, and specifically includes the following steps:

[0071] With analytical pure ethanol as the monoalcohol raw material, with air as the mixture of oxidizing gas and diluent gas, the ethanol feed rate of the reciprocating metering pump 7 is set to 7.5mL / h, the outlet pressure of the air generating device 1 is 3.0MPa, the mass The air flow rate of flowmeter 2 is 8.30L / h;

[0072] The ethanol from the reciprocating metering pump 7 enters the liquid preheater 9, and after the tail gas reacts with the reactor 15 for heat exchange and preheating, it is further heated through the liquid preheating pipeline 34 and enters the gas-liquid mixing preheating pipeline 35, After the air from the mass flow meter 2 is heated by the gas preheater 4, it is further heated through the gas preheating pipeline 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com