A method and device for purifying exhaust gas from an oil storage tank

An oil storage tank and exhaust gas technology is applied in the field of oil and gas recovery devices for recovering hydrocarbons from volatile oil and gas in tank areas. Emissions, reduce condensation energy consumption, ensure the effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

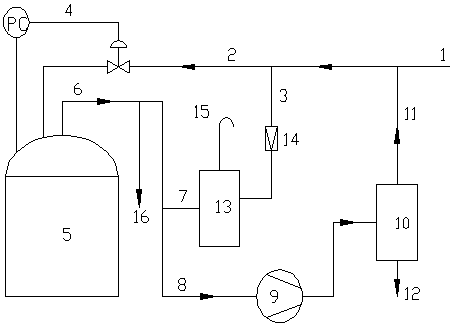

[0031] Such as figure 1 shown, four 5000m 3 The exhaled gas volume of the finished gasoline storage tank 5 is about 300m 3 / h, the gas phase space on the top of the oil storage tank is connected, and low-pressure gas is used as the protective gas on the top of the oil storage tank. The waste gas is collected into the gas compressor 9, and the gas compressor 9 adopts a liquid ring compressor, and the exhaust pressure of the gas compressor 9 shown is 0.4 MPa. The exhaust gas enters the condensation system 10 after being compressed, and is cooled to -30°C with low-temperature brine. When the pressure in the oil storage tank 5 reaches 1200Pa, start the gas compressor 9 to bleed air; when the pressure in the oil storage tank 5 reaches 600Pa, stop the gas compressor 9 to bleed air. When the pressure in the oil storage tank 5 is 200Pa, the pressure control and adjustment system 4 automatically replenishes the gas into the oil storage tank 5; when the pressure in the oil storage ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com