Production technology and equipment system for improving quality and yield of cyclohexanone oxime

A technology of cyclohexanone oxime and production process, which is applied in the field of preparation of cyclohexanone oxime, can solve problems such as non-compliance, low conversion rate of cyclohexanone oxime, and increase of hydrogen peroxide, so as to reduce unit consumption and increase effective conversion rate , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

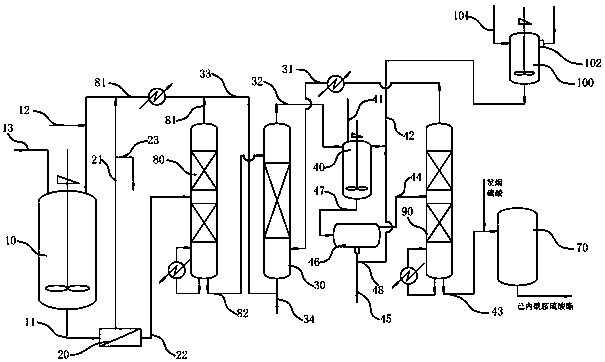

[0057] refer to figure 1 , the equipment system of the present embodiment includes: a direct ammonia oximation reactor 10, a membrane separator 20, a tert-butanol recovery tower 80, an organic solvent extraction tower 30, a secondary oximation reactor 40 and a toluene recovery through pipelines in sequence. Tower 90;

[0058] The direct ammoximation reactor 10 is connected with a reaction liquid line 11 and a tail gas discharge line 13, which is connected to the membrane separator 20 through the reaction liquid line 11;

[0059] The membrane separator 20 is connected with a catalyst circulation line 21 and a reaction clear liquid line 22, which is connected to the direct ammoximation reactor 10 through the catalyst circulation line 21, and is recovered with tert-butanol through the reaction clear liquid line 22. The tower 80 is connected, the catalyst circulation pipeline 21 is connected with the reaction material pipeline 12, and the catalyst circulation pipeline 21 is conne...

Embodiment 2

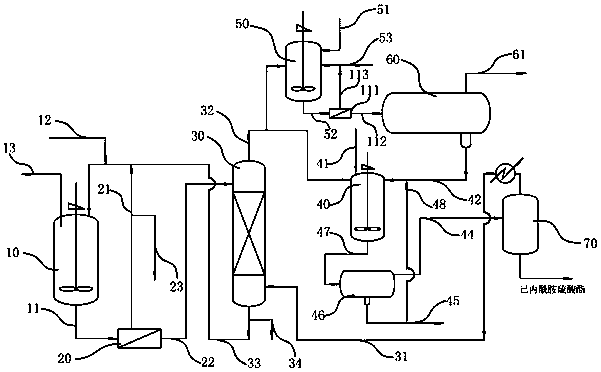

[0071] refer to figure 2 , The equipment system of this embodiment includes: a direct ammoximation reactor 10, a membrane separator 20, an organic solvent extraction tower 30 and a secondary ammoximation reactor 40 connected through pipelines in sequence;

[0072] The direct ammoximation reactor 10 is connected to a reaction liquid line 11 and a tail gas discharge line 13, and is connected to a membrane separator 20 through the reaction liquid line 11;

[0073] The membrane separator 20 is connected with a catalyst circulation line 21 and a reaction clear liquid line 22, which is connected to the direct ammoximation reactor 10 through the catalyst circulation line 21, and connected to the organic solvent extraction tower through the reaction clear liquid line 22. 30 connection, the catalyst circulation pipeline 21 is connected with a reaction material pipeline 12, and the catalyst circulation pipeline 21 is connected with a catalyst recovery pipeline 23;

[0074] The organic...

Embodiment 3

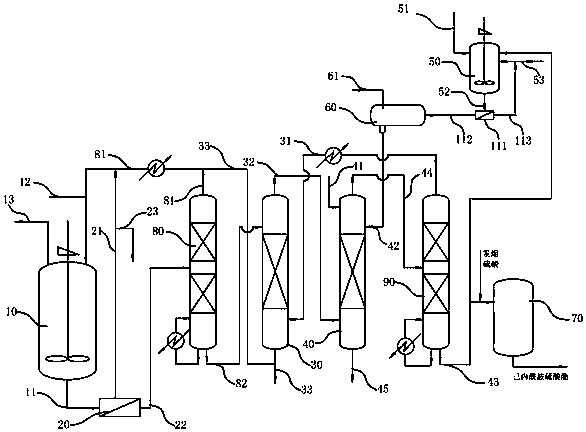

[0082] refer to image 3 , the equipment system of the present embodiment includes: a direct ammonia oximation reactor 10, a membrane separator 20, a tert-butanol recovery tower 80, an organic solvent extraction tower 30, a secondary oximation reactor 40 and toluene recovery through pipelines in sequence. Tower 90;

[0083] The direct ammoximation reactor 10 is connected with a reaction liquid line 11 and a tail gas discharge line 13, which is connected to the membrane separator 20 through the reaction liquid line 11;

[0084] The membrane separator 20 is connected with a catalyst circulation line 21 and a reaction clear liquid line 22, which is connected to the direct ammoximation reactor 10 through the catalyst circulation line 21, and is recovered with tert-butanol through the reaction clear liquid line 22. The tower 80 is connected, the catalyst circulation pipeline 21 is connected with the reaction material pipeline 12, and the catalyst circulation pipeline 21 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com