Composite additive used for roasting vanadium extracting and use method of additive

A composite additive and roasting technology, applied in the field of metallurgy, can solve the problems of complex process, low vanadium conversion rate, complex process, etc., and achieve the effects of accelerating the conversion rate, improving the surface activity, and accelerating the reaction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

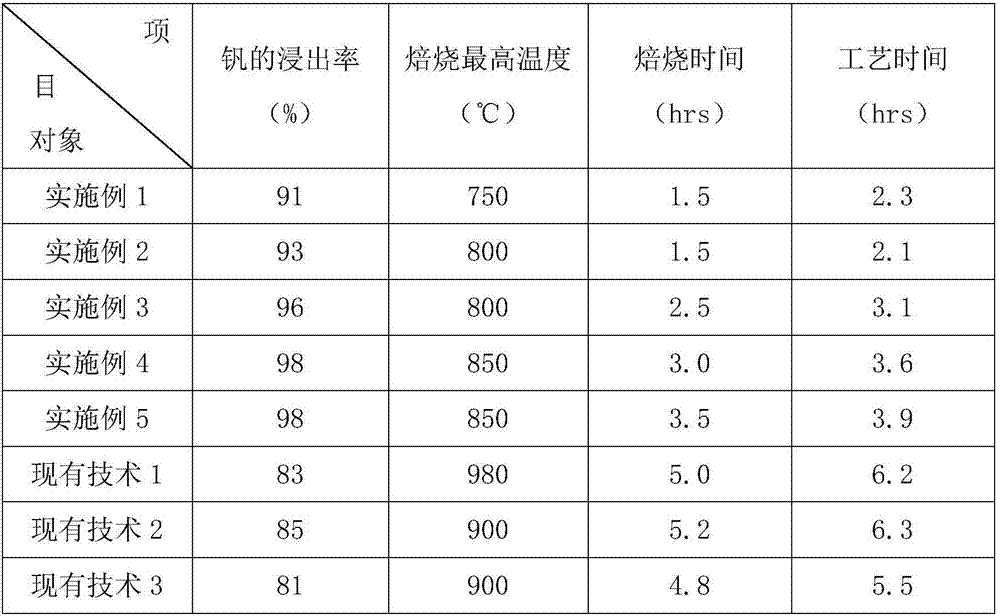

Examples

Embodiment 1

[0054] A composite additive for roasting and extracting vanadium provided in this example is prepared by mixing and grinding the following four materials to 80 mesh: sodium-containing material, calcium-containing material, vanadium-containing material and titanium-containing material, wherein the sodium-containing material by Na 2 SO 4 and Na 2 CO 3 According to the mass ratio of 9:2, the calcium-containing material is composed of CaO and CaF 2 It is mixed according to the mass ratio of 95:1, and the vanadium-containing material is composed of V 2 o 5 and Ca(VO 3 ) 2 According to the mass ratio of 1:1, the titanium-containing material is composed of titanium concentrate. The mixing ratio method of sodium-containing material, calcium-containing material, vanadium-containing material and titanium-containing material is: mix Na 2 SO 4 and Na 2 CO 3 The mass is converted into the equivalent equivalent of Na 2 O, combining CaO and CaF 2 Convert the quality of CaO to th...

Embodiment 2

[0059] A composite additive for roasting and extracting vanadium provided in this example is prepared by mixing and grinding the following four materials to 85 mesh: sodium-containing material, calcium-containing material, vanadium-containing material and titanium-containing material, wherein the sodium-containing material by Na 2 SO 4 and Na 2 CO 3 According to the mass ratio of 7:2, the calcium-containing material is composed of CaO and CaF 2 It is mixed according to the mass ratio of 80:1, and the vanadium-containing material is composed of V 2 o 5 and NaVO 3 According to the mass ratio of 2:1, the titanium-containing material is composed of rutile. The mixing ratio method of sodium-containing material, calcium-containing material, vanadium-containing material and titanium-containing material is: mix Na 2 SO 4 and Na 2 CO 3 The mass is converted into the equivalent equivalent of Na 2 O, combining CaO and CaF 2 Convert the quality of CaO to the equivalent equival...

Embodiment 3

[0064] A composite additive for extracting vanadium by roasting provided in this example is prepared by mixing and grinding the following four materials to 90 mesh: sodium-containing material, calcium-containing material, vanadium-containing material and titanium-containing material, wherein the sodium-containing material by Na 2 SO 4 It is mixed with Na2CO3 according to the mass ratio of 7:1, and the calcium-containing material is composed of CaO and CaF 2 It is mixed according to the mass ratio of 95:5, and the vanadium-containing material is composed of V 2 o 5 and FeVO 3 According to the mass ratio of 3:1, the titanium-containing material is composed of high-titanium slag. The mixing ratio method of sodium-containing material, calcium-containing material, vanadium-containing material and titanium-containing material is: mix Na 2 SO 4 and Na 2 CO 3 The mass is converted into the equivalent equivalent of Na 2 O, combining CaO and CaF 2 Convert the quality of CaO to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com