Method capable of improving methane yield in sludge anaerobic digestion process and enhancing heavy metal stabilization process

An anaerobic digestion and heavy metal technology, applied in the direction of physical/chemical process catalysts, other chemical processes, chemical instruments and methods, etc., can solve the problems of affecting the efficiency of sludge anaerobic digestion, reducing the activity of methane bacteria, and limited organic matter content, etc. Achieve superior adsorption performance, uniform distribution, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

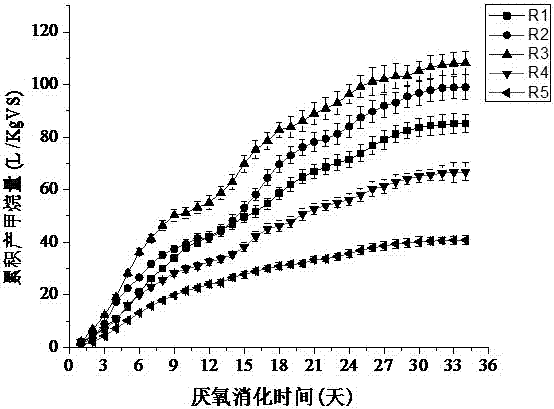

Examples

Embodiment 1

[0028] Embodiment 1: The specific steps of this embodiment are as follows:

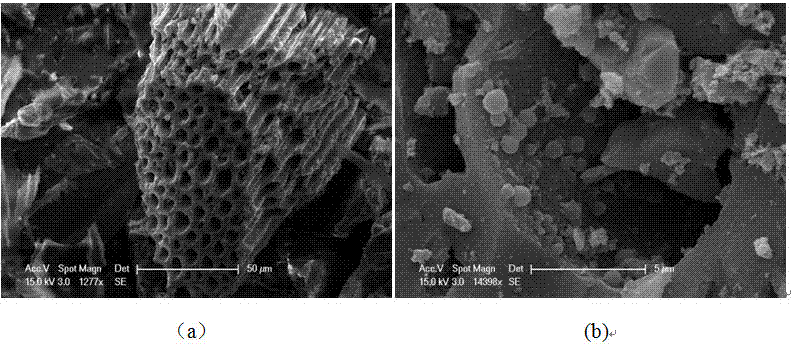

[0029] Activated carbon pretreatment: straw soaked in ZnCl 2 activation in solution (straw and ZnCl 2 The mass ratio is 1:2), centrifuged after magnetic stirring for 7 hours (4000r min -1 ), oven-dried. After drying, the samples were carbonized for 180 min in an OTF-1200x vacuum tube furnace. Set the carbonization temperature to 550°C, N 2 As protective gas, the heating rate is 20°C min -1 . The prepared crude samples were washed repeatedly with deionized water and dried at low temperature to constant weight.

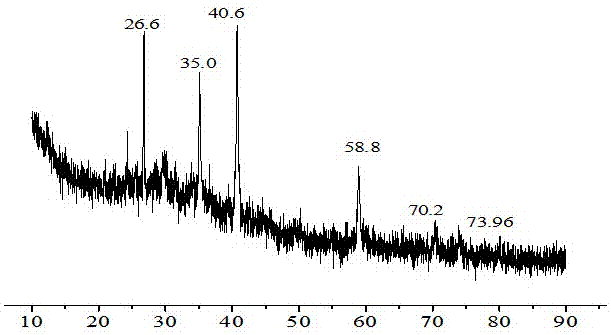

[0030] Preparation of activated carbon (BC-MnO) loaded with MnO nanomaterials: the pretreated activated carbon was ground through a 100-mesh sieve, and 6 g of activated carbon was soaked in KMnO 4 solution, making BC and KMnO 4 The mass ratio is 1:15. The suspension was sonicated at room temperature for 3 hours and then dried in an oven. After drying, it was transferred to a tube furna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com