Method for continuous pyrolysis and gasification of material

A technology of pyrolysis gasification and materials, applied in the manufacture of combustible gas, petroleum industry, etc., can solve the problems of increased cost and limited space, and achieve the effect of improving the efficiency of energy recovery and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The preparation of the catalyst used in the embodiment

[0060] Using the method of dry ball milling, nickel oxide, potassium hydroxide and biocoke generated during the pyrolysis process were mixed according to the mass ratio of 1:1:10, and ball milled at a speed of 150 rpm for 2 hours to obtain uniform charcoal Powdered catalyst, then cold pressed into strip particles, the size is φ4mm×6mm, the obtained catalyst is defined as NiO 1.0 KOH 1.0 / C 10 , where the NiO content is 8.33%, and the KOH content is 8.33%.

Embodiment 1

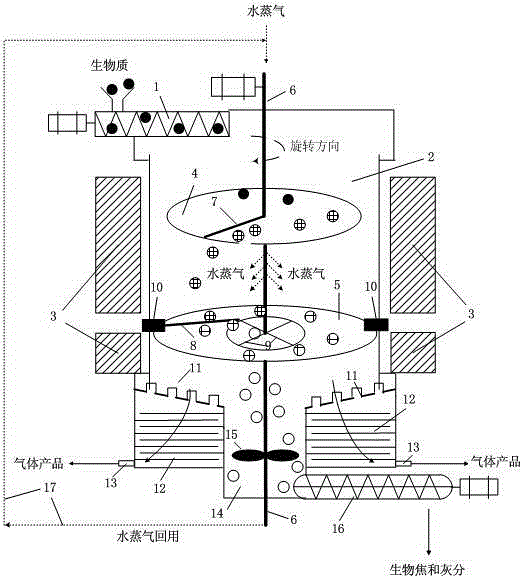

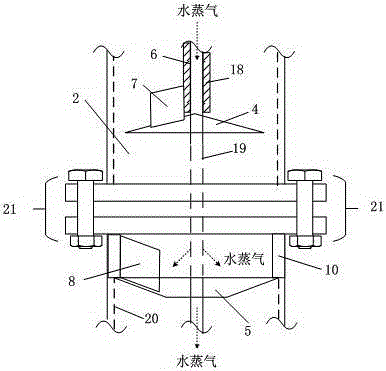

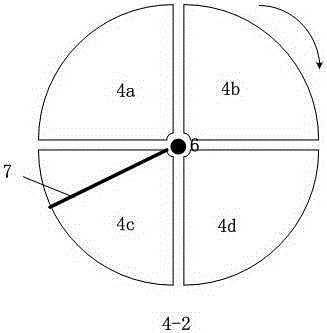

[0062] Biomass raw material and microwave catalyst NiO 1.0 KOH 1.0 / C 10 According to the ratio of 15:1, it is sent into the microwave reaction chamber 2 through the screw feeder 1, and falls into the first-stage rotating disk 4 under the action of gravity (the diameter of the bottom surface of the cone is 3 / 5 of the inner diameter of the microwave reaction chamber, and the conical busbar and the horizontal direction The included angle is 15°), when the first-stage rotating disk 4 is basically covered with materials, simultaneously rotate the first-stage rotating disk 4 and the second-stage rotating disk 5 (the diameter of the bottom surface of the round platform is 19 / of the inner diameter of the microwave reaction chamber 20. The diameter of the upper bottom surface of the round table is 1 / 4 of the inner diameter of the microwave reaction chamber, and the angle between the busbar of the round table and the horizontal direction is 20°), under the action of the first-stage p...

Embodiment 2

[0064] Biomass raw material and microwave catalyst NiO 1.0 KOH 1.0 / C 10 According to the ratio of 2:1, it is sent into the microwave reaction chamber 2 through the screw feeder 1, and falls into the first-stage rotating disk 4 under the action of gravity (the diameter of the bottom surface of the cone is 1 / 2 of the inner diameter of the microwave reaction chamber, and the conical busbar and the horizontal direction The included angle is 10°), when the first-stage rotating disk 4 is basically covered with materials, simultaneously rotate the first-stage rotating disk 4 and the second-stage rotating disk 5 (the diameter of the bottom surface of the round platform is 9 / of the inner diameter of the microwave reaction chamber 10. The diameter of the upper bottom surface of the round table is 1 / 5 of the inner diameter of the microwave reaction chamber, and the angle between the busbar of the round table and the horizontal direction is 45°), under the action of the first-stage pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com