Patents

Literature

35results about How to "Increase processing scale" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

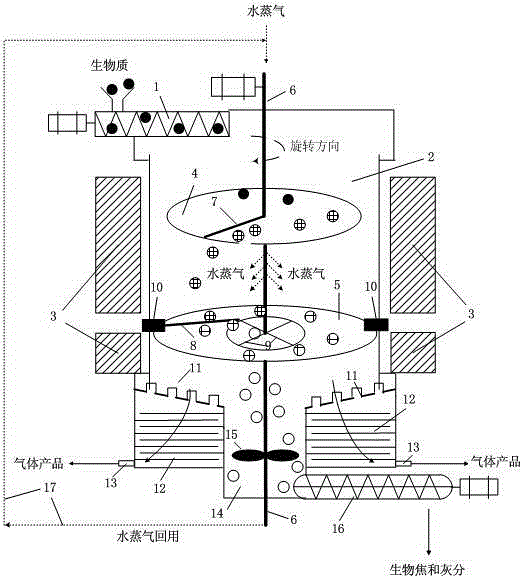

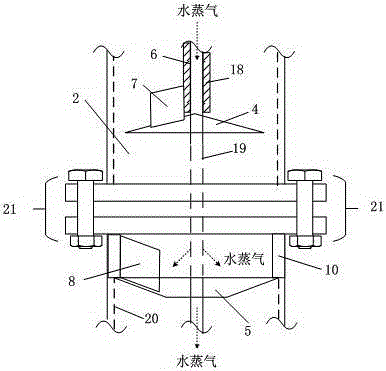

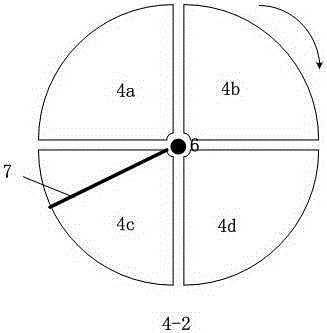

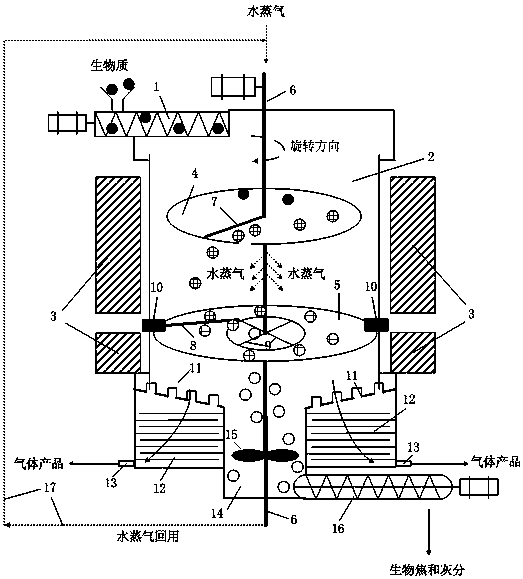

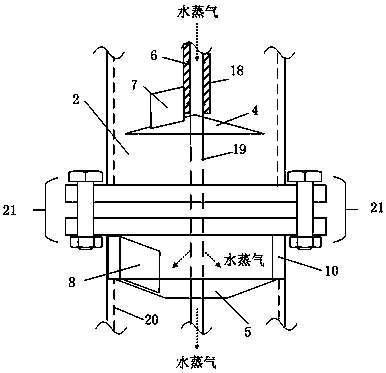

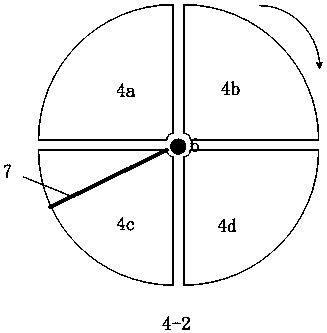

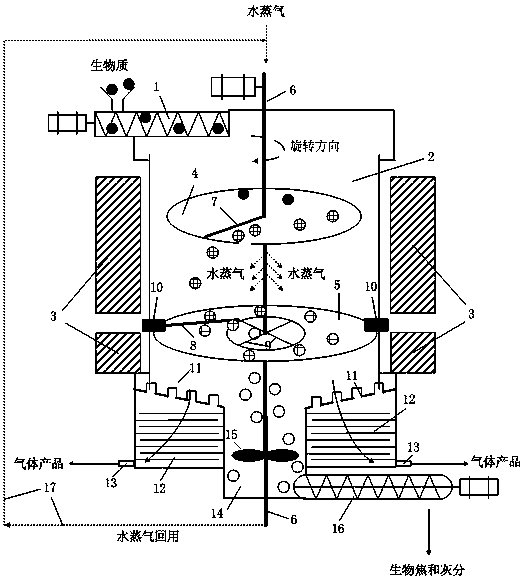

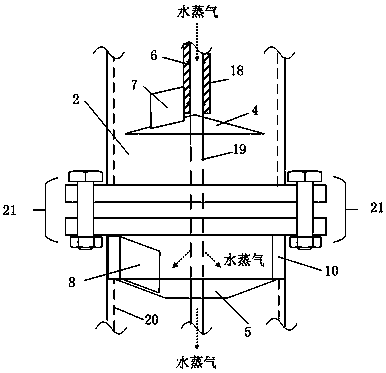

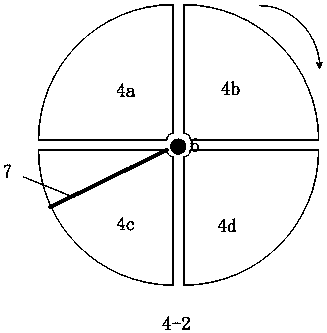

Method for continuous pyrolysis and gasification of material

ActiveCN106675661ASmall footprintExtended stayCombustible gas productionMicrowave pyrolysisWater vapor

The invention discloses a method for continuous pyrolysis and gasification of a material. The method comprises the following steps: 1, a raw material and a catalyst enter a microwave pyrolysis and gasification system, fall to a first-stage rotating disc of a microwave reaction chamber, and sequentially undergo drying, activating and pyrolysis treatment with rotating; 2, a pyrolysis treated material falls to a second-stage rotating disc of the microwave reaction chamber, and the pyrolysis treated material and a pyrolysis volatile compound undergo a gasification and reforming reaction under the action of water vapor; and 3, a solid product obtained in step 2 falls to a residue storage tank below the microwave reaction chamber from middle holes of the second-stage rotating disc through a second-stage pushing baffle plate, and is discharged from a reaction system under stirring and screw dual action, and a gas product enters a settlement chamber from an annular sieve plate at the bottom of the microwave reaction chamber, and undergoes settlement treatment to obtain the gasification product. The method has the advantages of fast cracking speed, high gasification efficiency, high quality of the gas product, meeting of liquid fuel synthesis requirements, and good application prospect.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEMICALS CO LTD +1

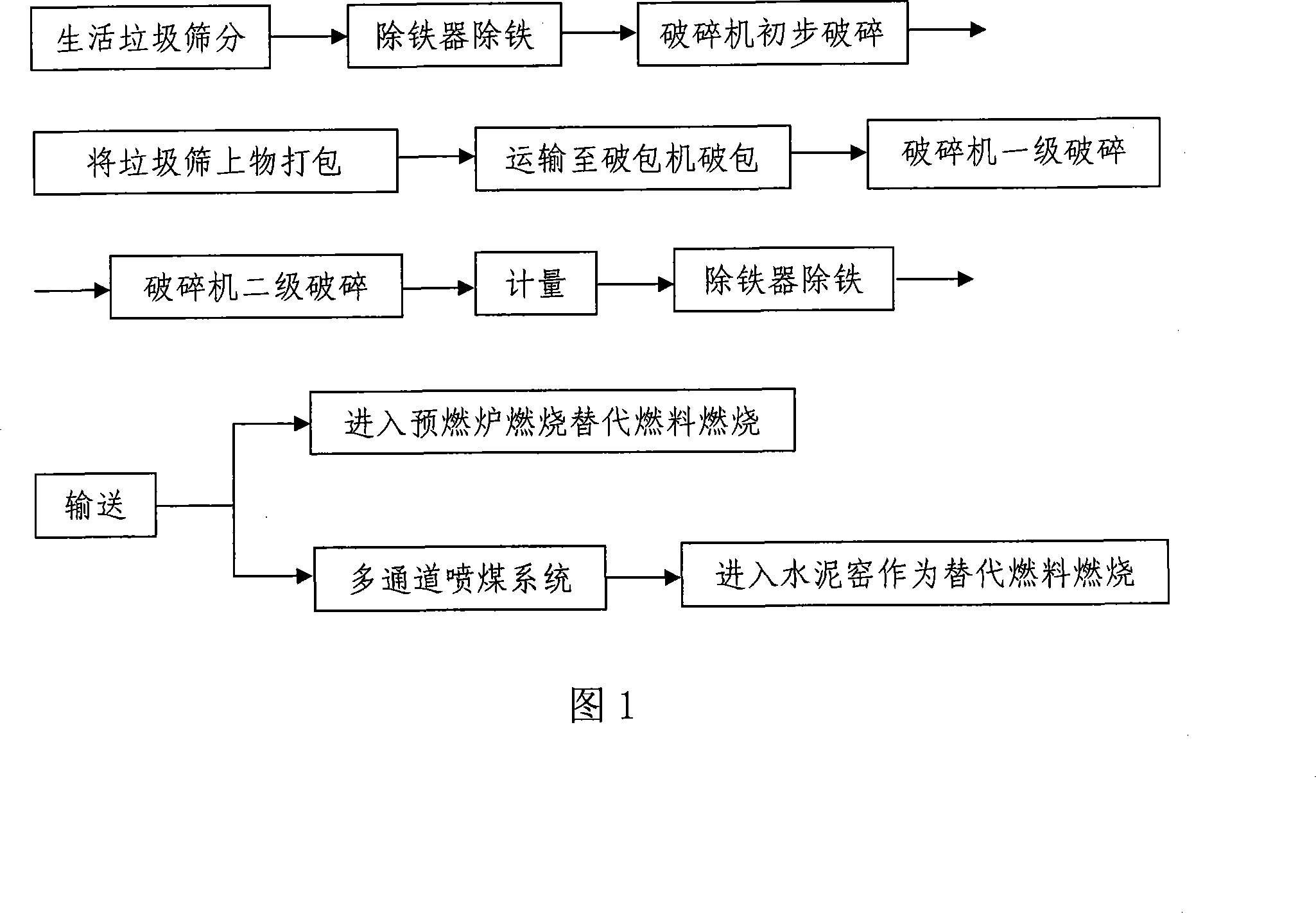

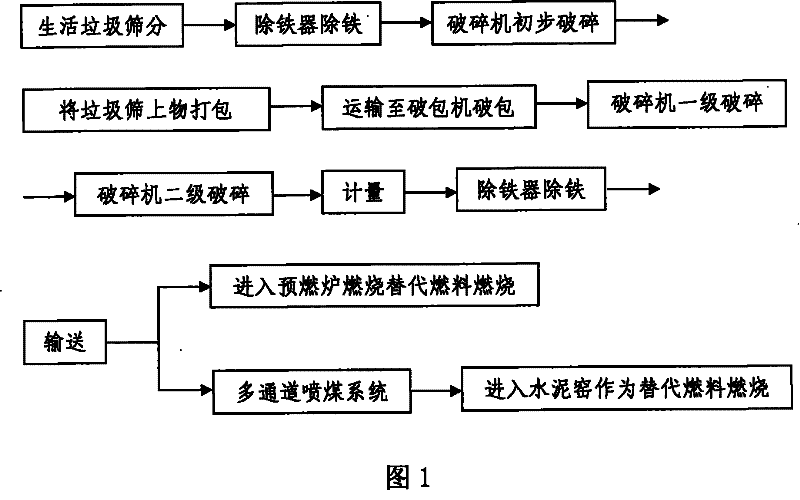

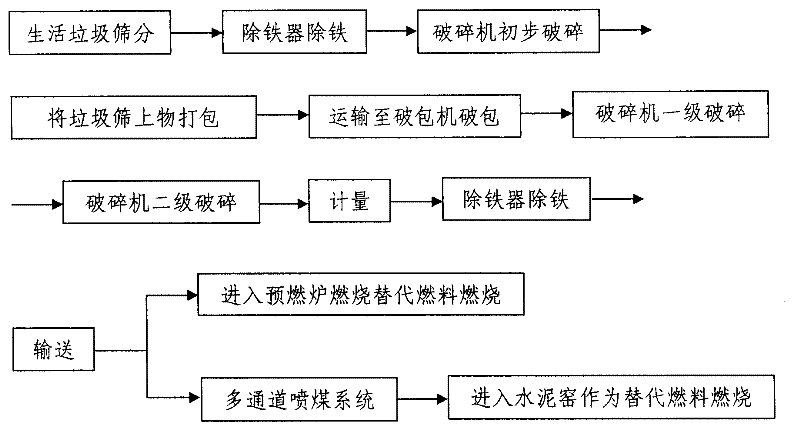

Method for substituting cement kiln fuel with garbage derived overtails

ActiveCN101173196AHigh calorific valueAvoid enteringBiofuelsSolid fuelsAlternative fuelsProcess engineering

The invention relates to a method for adopting waste derivative oversize material as substitute for cement kiln fuel, which is characterized in that the domestic waste in refuse reclamation station is separated and sorted, broken in packages, crushed and completely stirred and mixed, one part of the waste enters a precombustion furnace in the kiln tail of a cement kiln for combustion, while the other part of the waste enters the cement kiln from the kiln hood for combustion, thus the substitute fuel for cement production is produced. The invention has the advantages that the waste derivative oversize material having calorific value is adopted to substitute for industrial fuel in the cement kiln, thus resources of waste derivative oversize material are fully utilized, and coal energy resources are saved; simultaneously the cement kiln has the characteristics of high temperature, large carrying capacity, no residue after waste treatment and no secondary pollution, therefore the invention has the great advantages of energy saving and environmental protection.

Owner:LINGCHUAN JINYU CEMENT

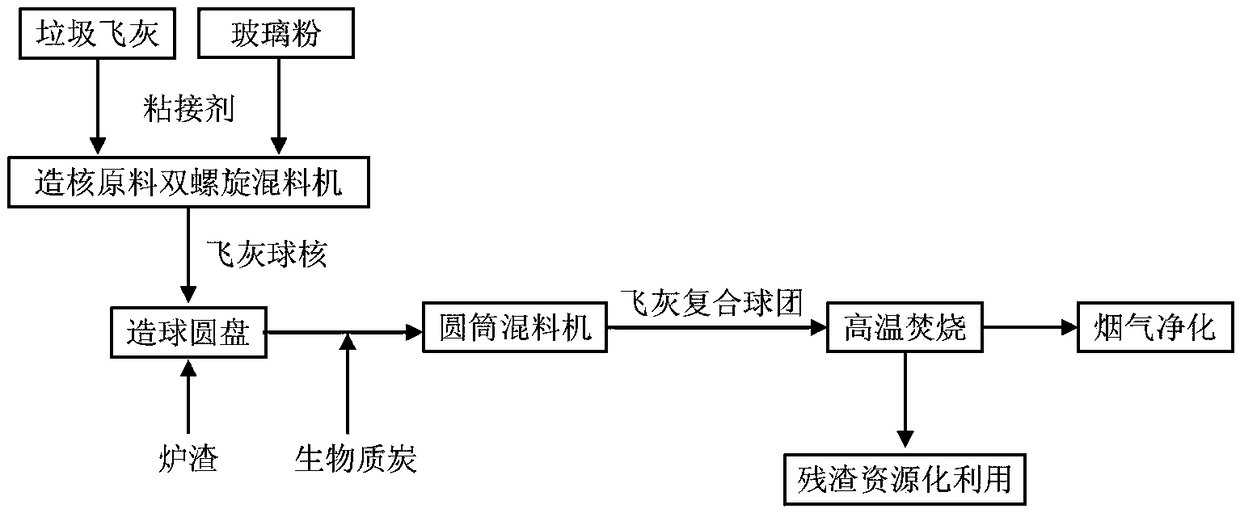

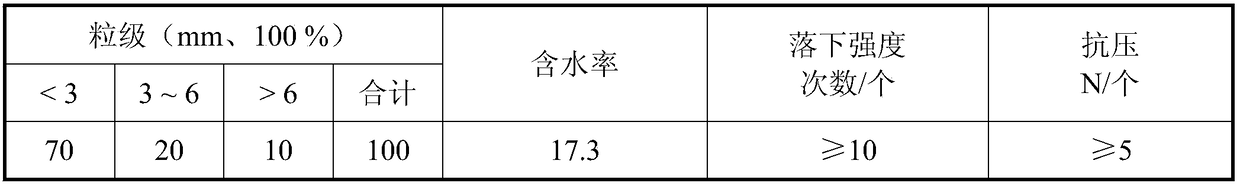

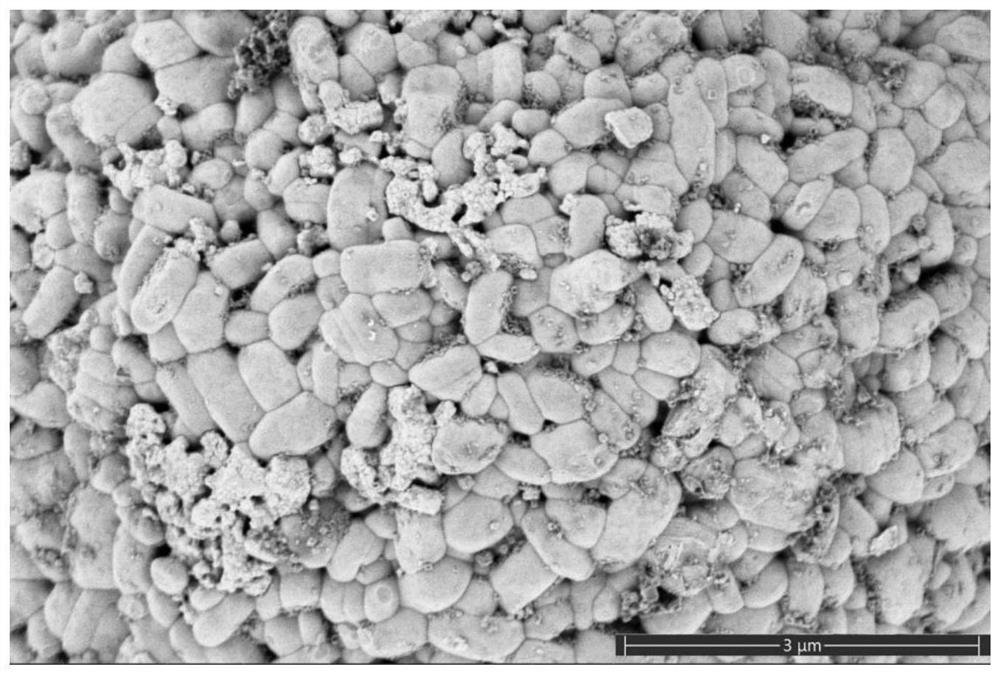

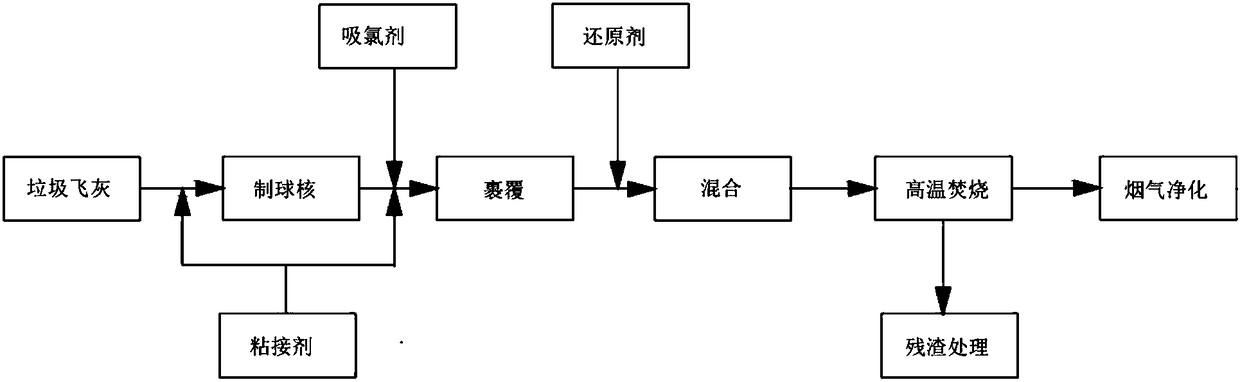

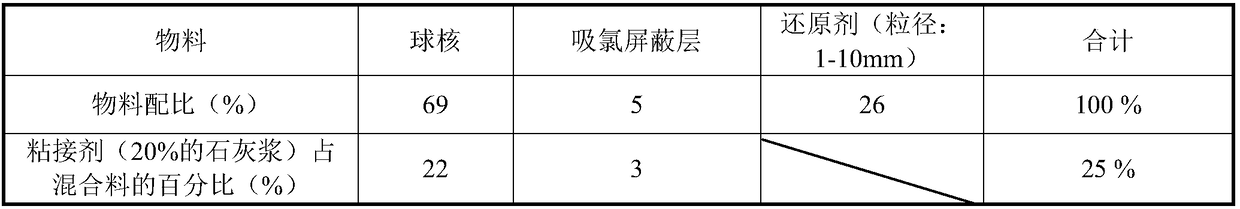

Garbage incineration fly ash high-temperature melting innocuous treatment process

ActiveCN109404916AShorten and simplify the balling processRealize nearby processingIncinerator apparatusBiomass carbonSlag

The invention relates to a garbage incineration fly ash high-temperature melting innocuous treatment process. The garbage incineration fly ash high-temperature melting innocuous treatment process comprises the steps that (1) garbage fly ash and glass powder are mixed to prepare fly ash ball cores; (2) fly ash composite pellets are obtained by adding slag to coat the surfaces of the ball cores; (3)the fly ash composite pellets are mixed with biomass carbon to obtain mixtures; and (4) the mixtures are directly accessed into an incineration device of an existing garbage incineration plant for high-temperature incineration, flue gas generated by incineration is purified by flue gas purification equipment of the garbage incineration plant, and incineration residue is subjected to residue treatment. According to the garbage incineration fly ash high-temperature melting innocuous treatment process, only the garbage fly ash and the glass powder are adopted to prepare the ball cores, the ballcores are coated with slag substances, and the obtained composite pellets are mixed with biomass carbon particles to form the mixtures, so that the ball forming process of the garbage fly ash is shortened and simplified, solid melting of heavy metals in the fly ash is facilitated, glass melts are formed, and leaching toxicity requirements are met; and meanwhile, the required equipment is less, andthe process is matched with the existing garbage incineration plant for implementation, so that nearby treatment of the garbage fly ash can be realized.

Owner:CHONGQING ANGRUIYUE SCI & TECH +1

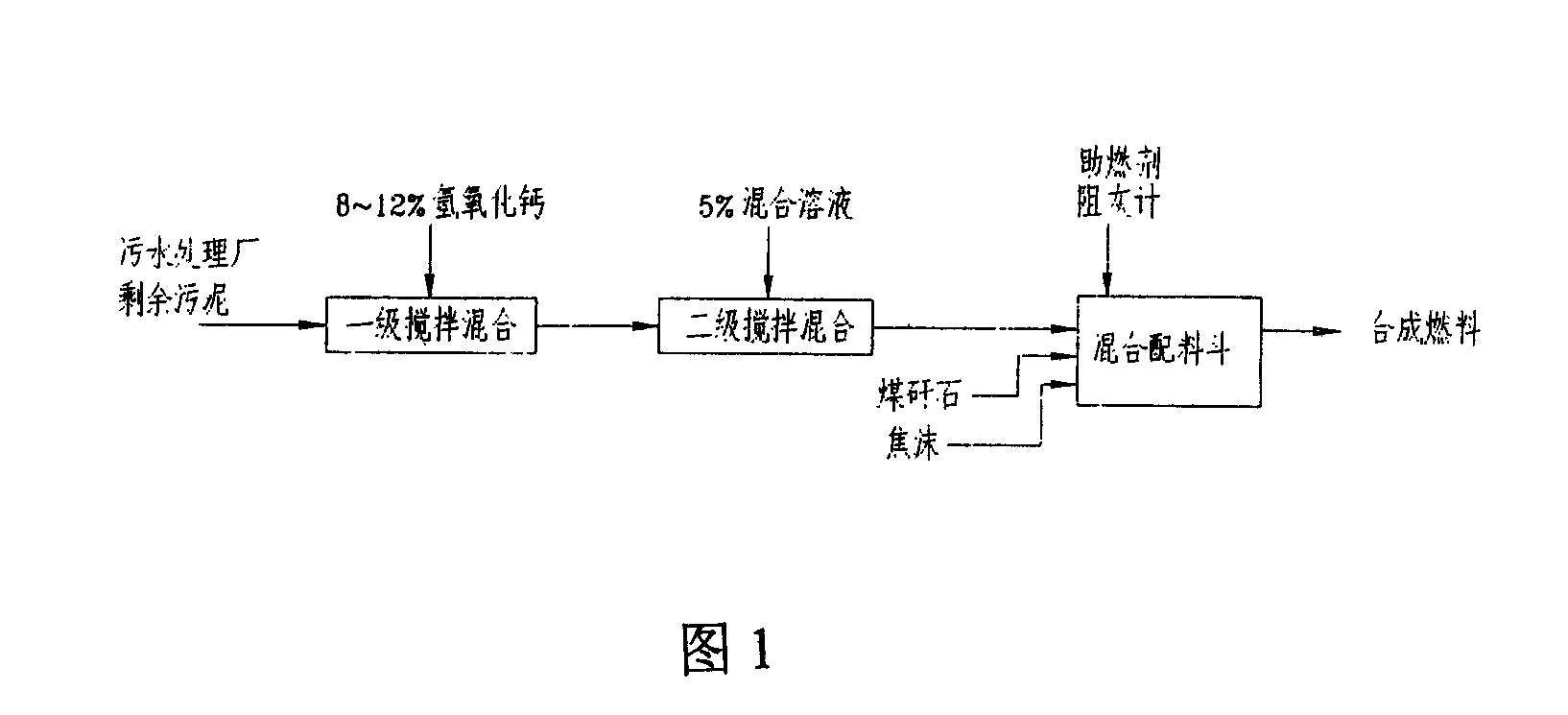

Technique for producing synthetic fuel by sludge of municipal sewage plant

InactiveCN101250456ARealize harmless disposalRealize resourcesBiofuelsSolid fuelsDeodorantWastewater

The invention relates to a technological method which utilizes sludge from wastewater treatment plant to prepare synthetic fuel, which comprises the following steps: firstly, feeding sludge whose water content is 80% after being dewatered by a municipal wastewater treatment plant into a stable stirring tank, adding CaO which is 8-12% of the amount of sludge, stirring for 10 minutes, lowering water content to 65%, feeding sludge whose water content is lowered to 65% into a deodorant stirring tank, adding Fe2(SO4), FeSO4(NH4)SO4.6H2O, CuSO4, CO(NH2)2 and water to prepare mixed solution which is 5%, stirring and mixing for 5 minutes, leading sludge to be totally loosed and stable to be end product sludge, feeding 30-40% end product sludge, 40-50% coke foam and 20% coal gangue into an automatic batch hopper, simultaneously adding 0.05-0.1g Fe2O3, stirring, mixing for 5 minutes, and preparing synthetic fuel. The invention achieves innocent treatment and resource treatment of sludge, and achieves comprehensive utilization of coal making industry.

Owner:刘志刚 +1

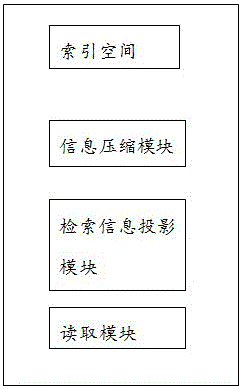

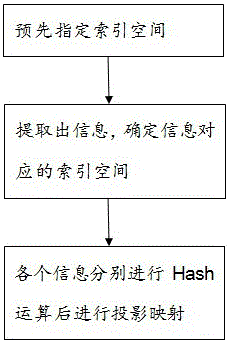

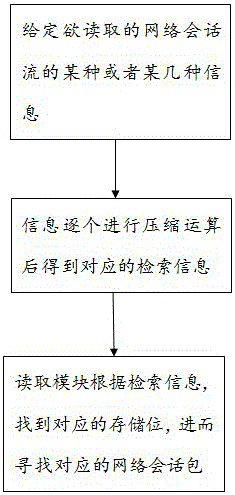

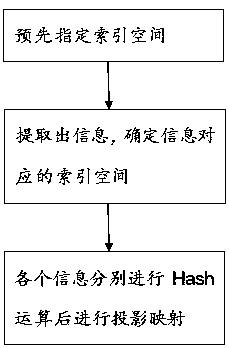

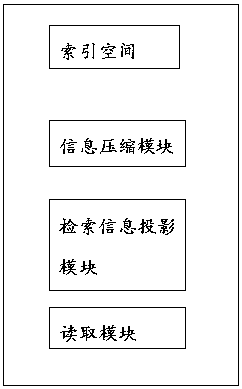

Novel index system of network conversation package

ActiveCN106446028AIncrease processing scaleReduce volumeTransmissionSpecial data processing applicationsRelevant informationComputer module

The invention provides a novel index system of a network conversation package. The system comprises at least one index space used for storing retrieval information of a type of information of the network conversation package, an information compression module, a retrieval information projection module, and a reading module. A plurality of storage positions are arranged in the index space, one storage position corresponds to a type of retrieval information, and the storage positions have the same initial values; the information compression module is used for performing compression operation on one or more types of information of the specified network conversation package to obtain the retrieval information corresponding to the information; the retrieval information projection module is used for projecting and mapping related information of the network conversation package to the corresponding storage positions of the index space which stores the retrieval information of the information, and the projected storage position is marked to be already projected when being projected for the first time; and the reading module is used for finding the corresponding network conversation package. According to the system, the system performance can be greatly improved.

Owner:科来网络技术股份有限公司

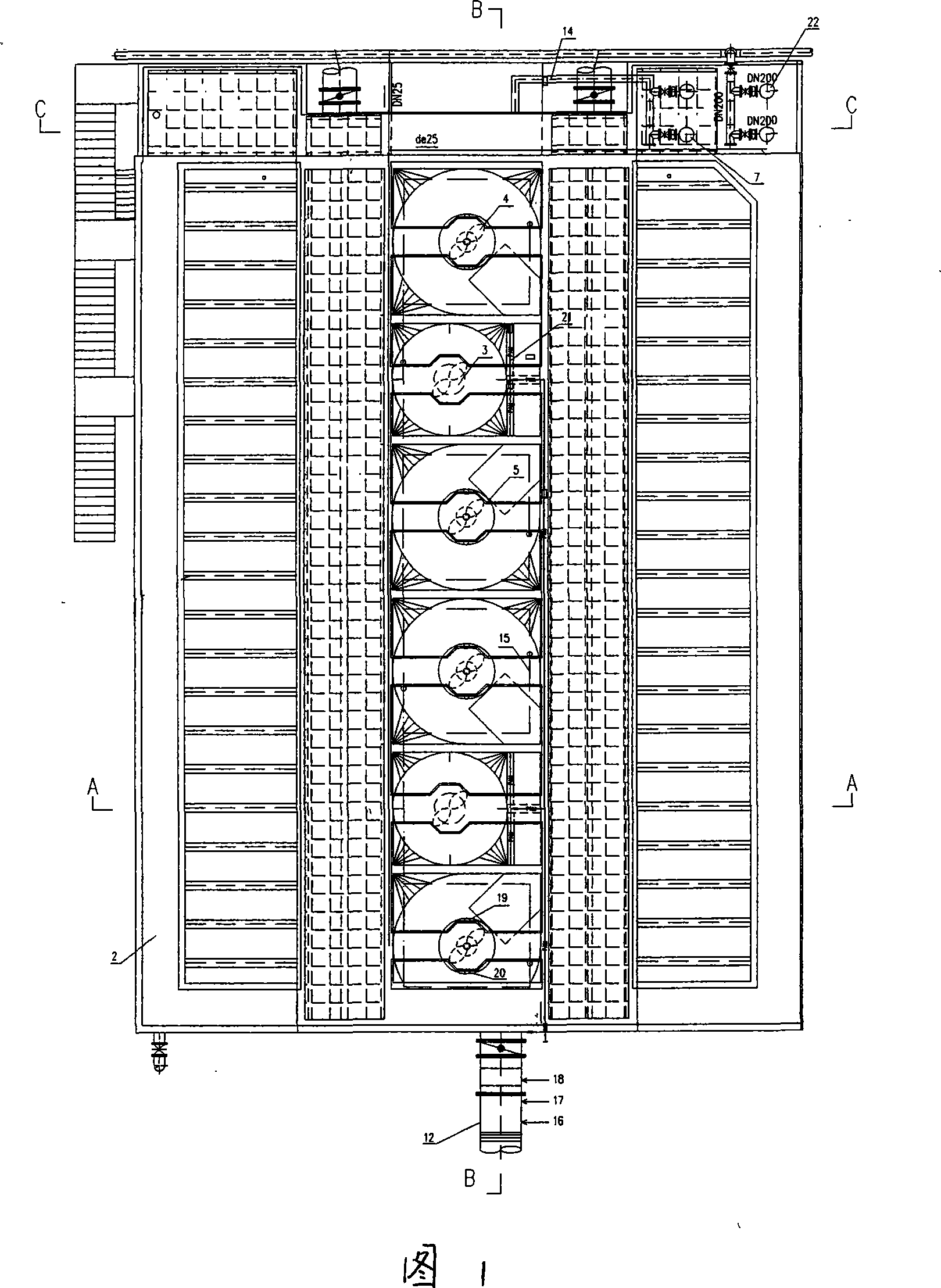

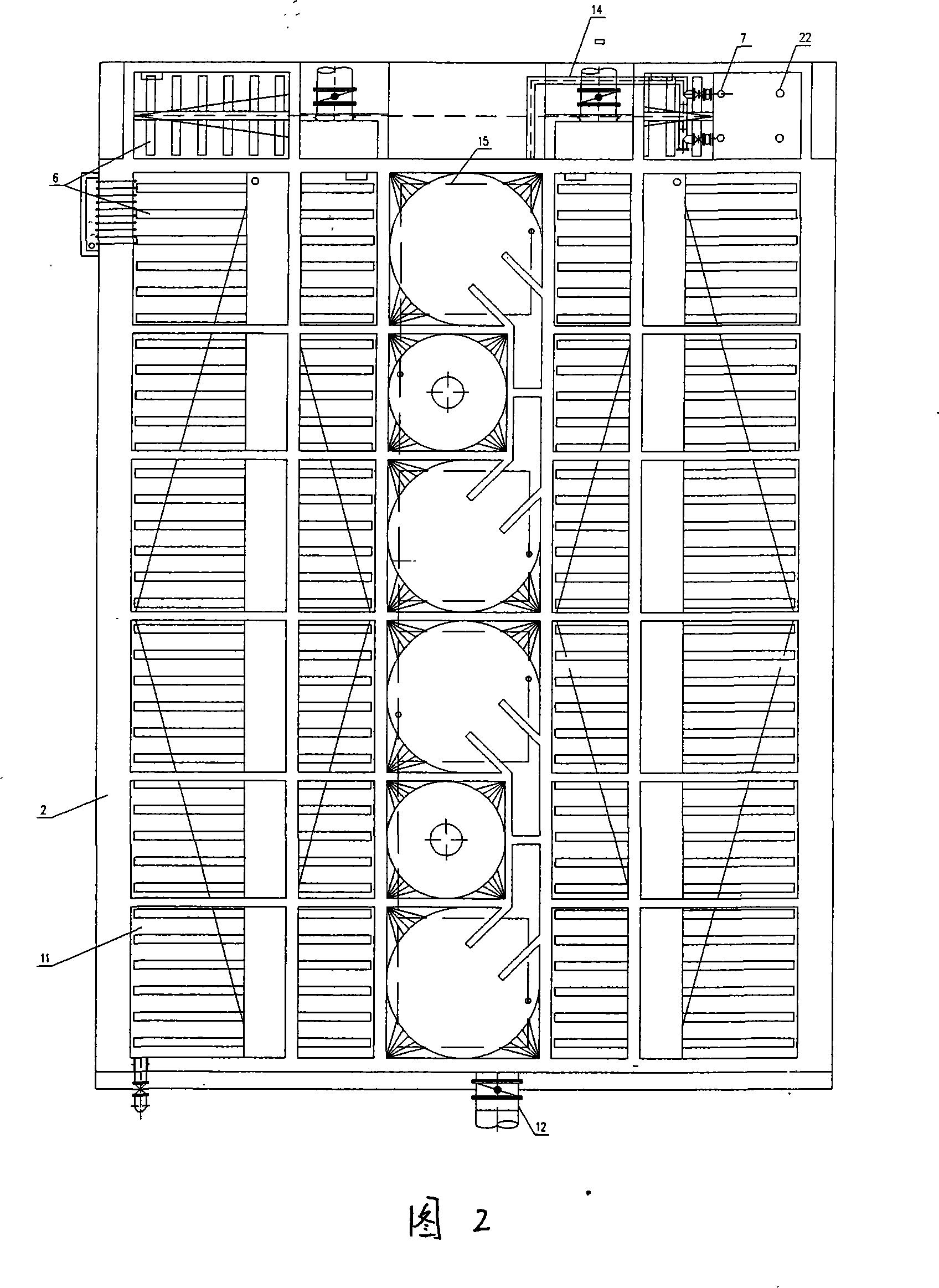

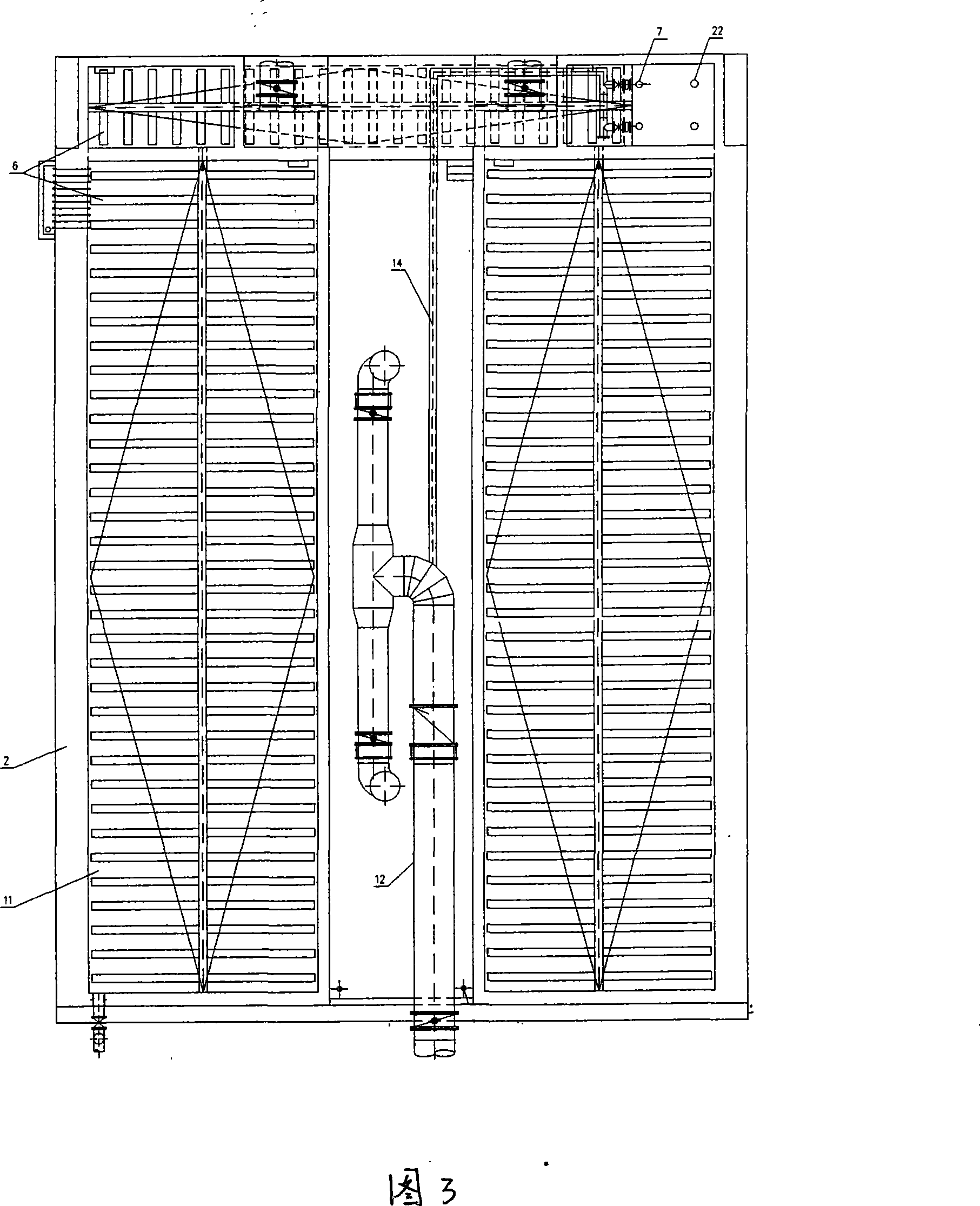

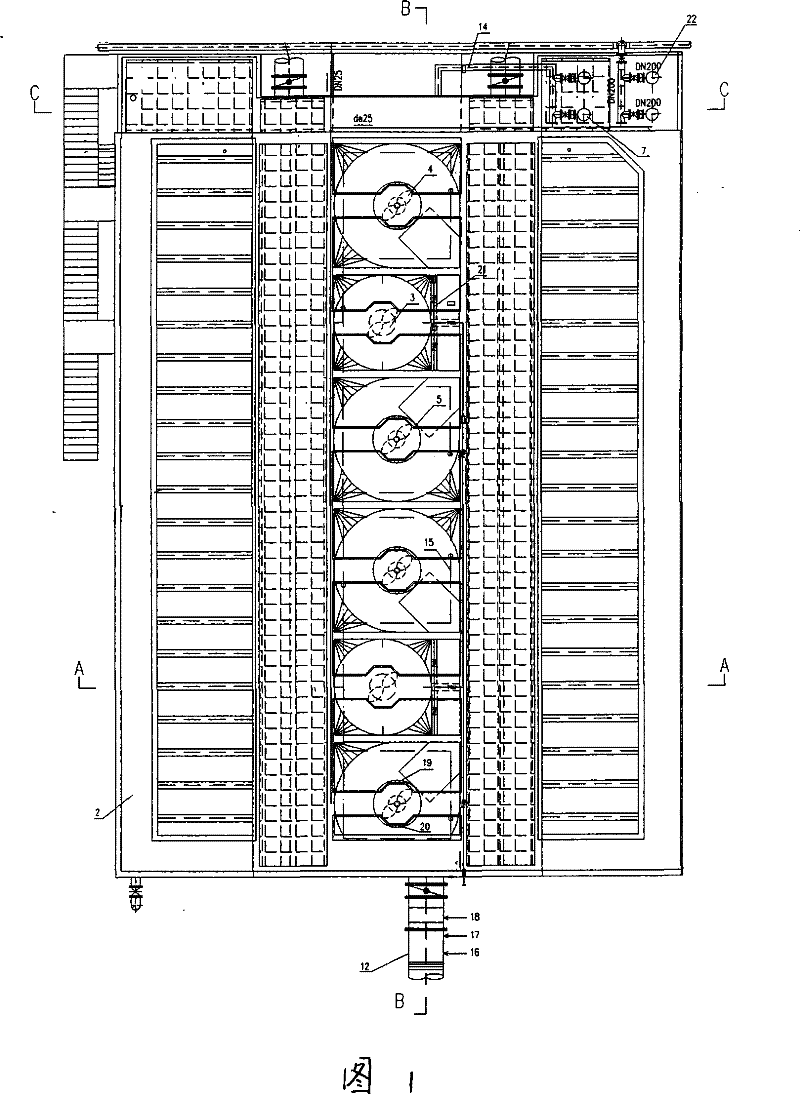

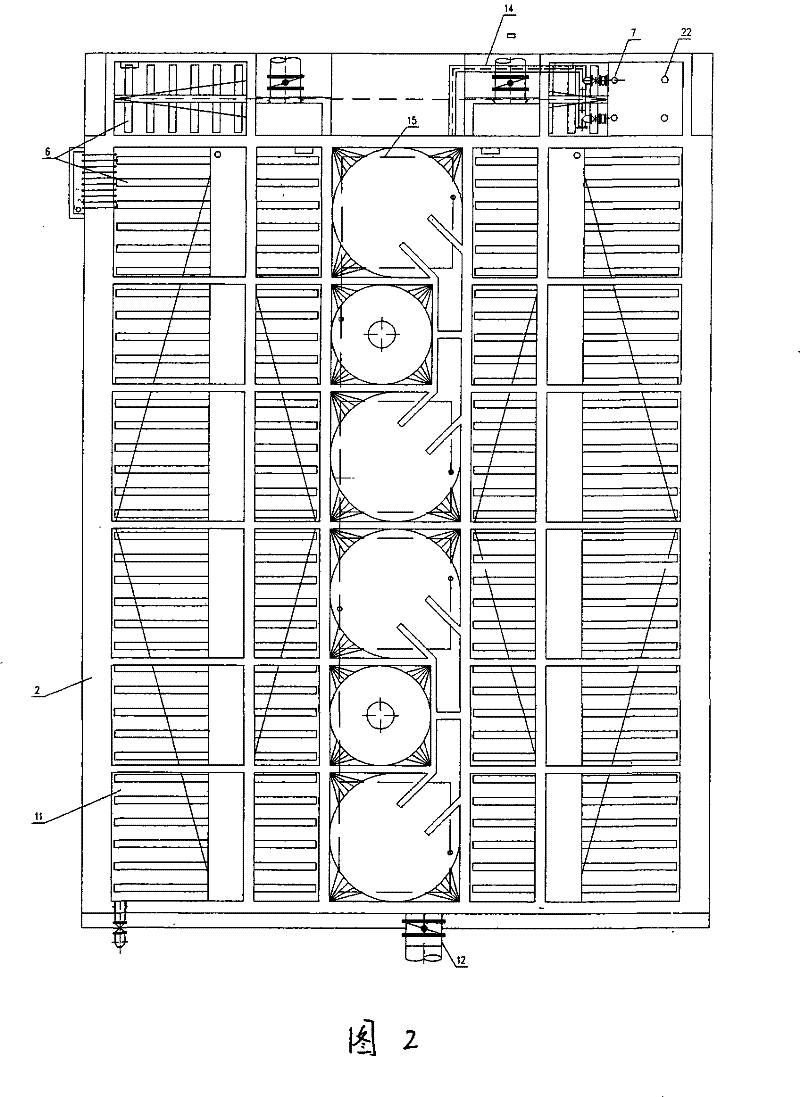

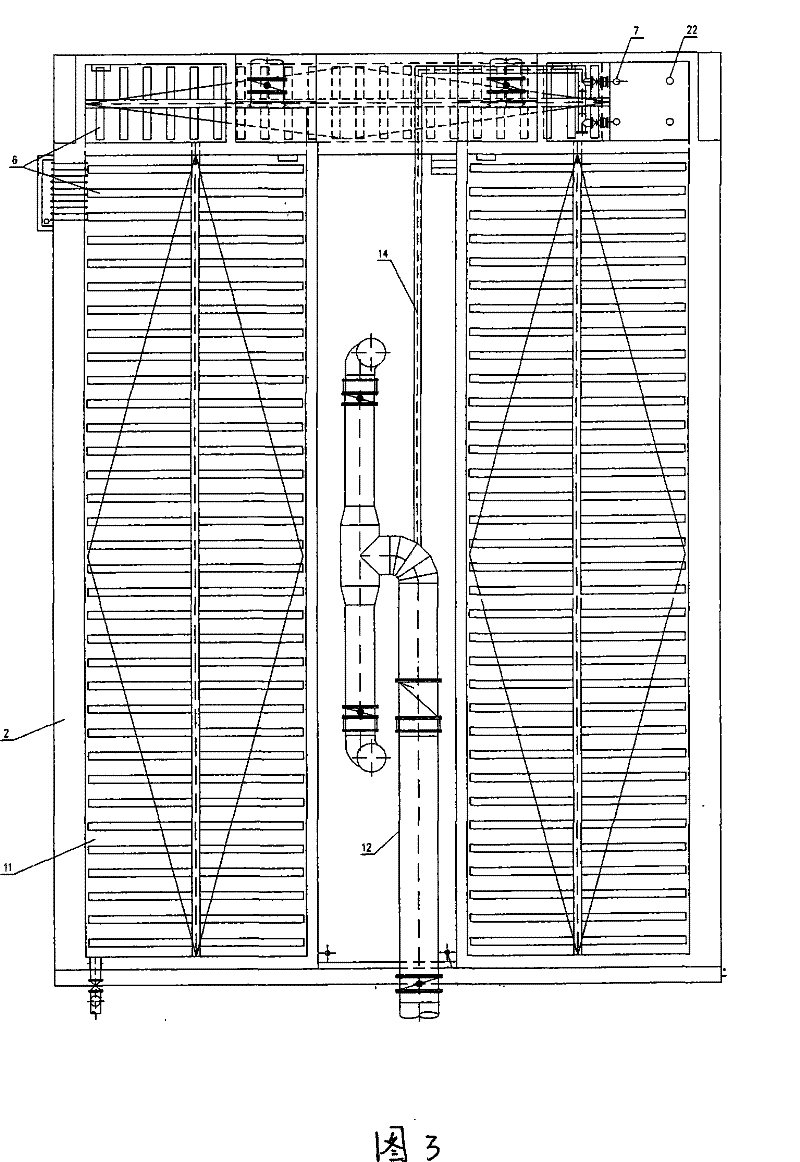

Centralized aerobic mud pulling sedimentation tank

ActiveCN101172695ASmall footprintIncrease processing scaleTreatment using aerobic processesSustainable biological treatmentFlocculationFrequency conversion

The invention discloses a centralized aerobic mud pushing sedimentation basin, which is characterized in that a main basin body is internally provided with an aerated pipeline; a mud reflow pump and a mud discharging pump are arranged at the side in the main basin body; a water inlet pipe positioned outside the main basin body is provided with a medicament feeding point; the main basin body is also internally provided with a medicament feeding point. The different parts of the invention are tightly matched through pipelines; the structure is more rational and the water distribution is more even so as to realize complete mud water internal circulation. The aerated pipeline provides enough dissolved oxygen to the mud microorganism in the basin so as to strengthen the organism function. The multi-point feeding of a plurality of kinds of medicament in and out of the basin body further strengthens the physical flocculation function. A lifting dasher and a mud reflow pump are controlled by a frequency conversion motor, and can be flexibly adjusted according to the factual conditions so as to guarantee the water quality. A concentrated mud pushing machine can realize the centralization of the mud and the concentration of the mud, thereby being suitable to be used in strengthening the normal treating of the water plant, in the sewage plant treating and the special water treating.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

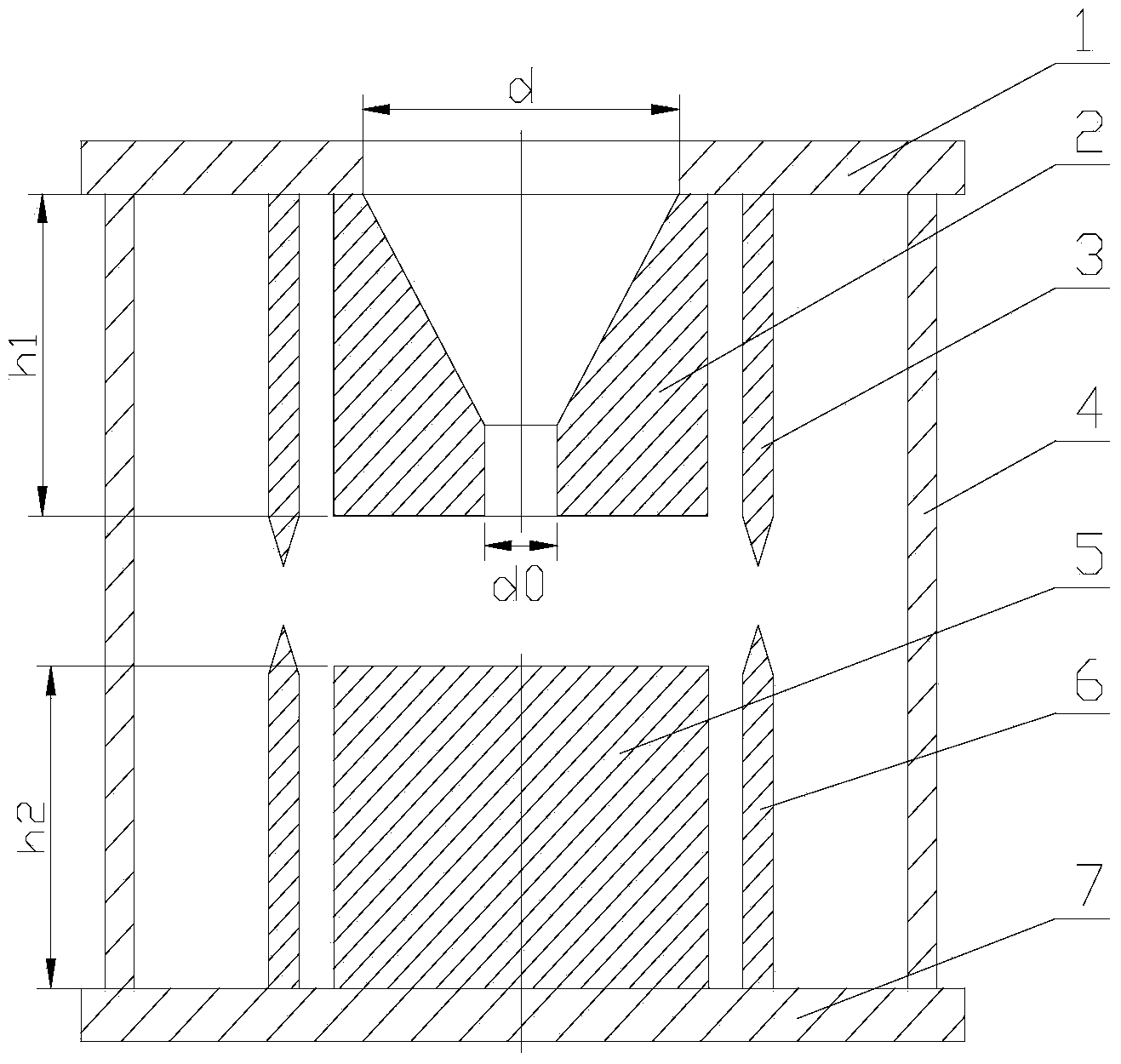

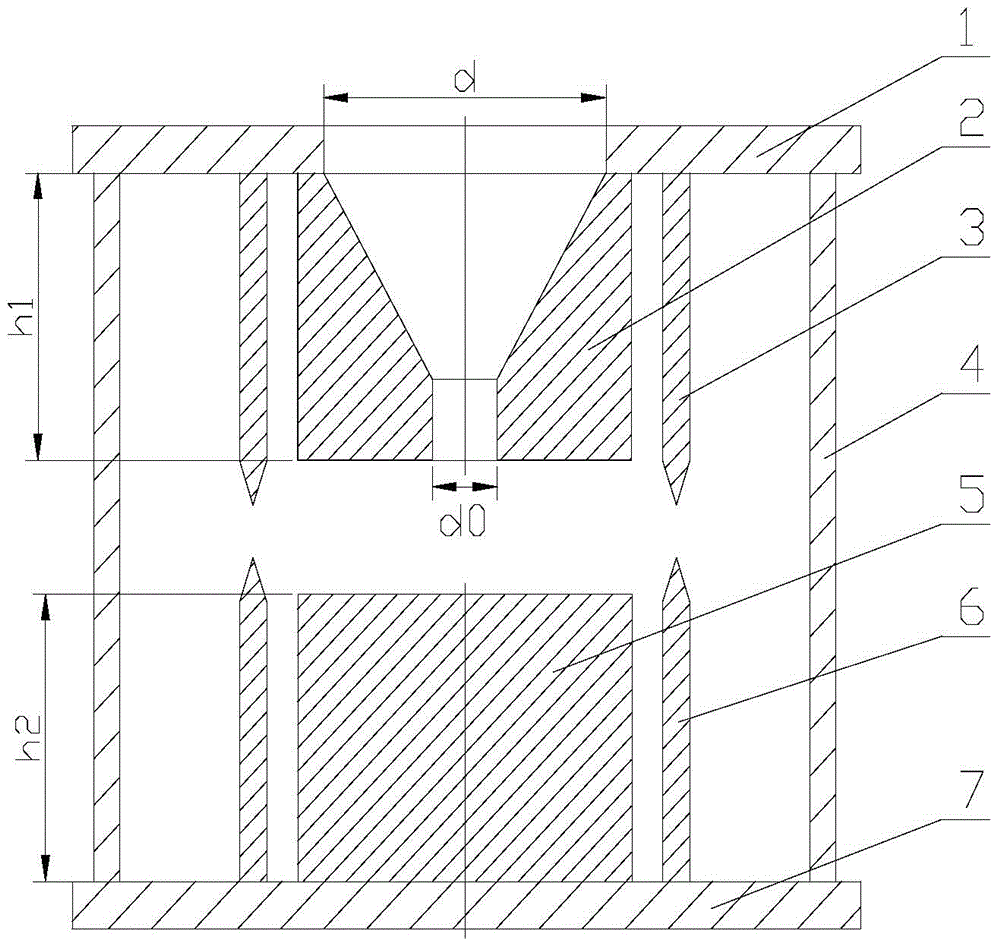

Hydraulic multi-frequency ultrasonic generator

InactiveCN103936099AImprove and intensify the treatment effectIncrease processing scaleWater/sewage treatment with mechanical oscillationsJet flowLiquid medium

The invention relates to a hydraulic multi-frequency ultrasonic generator. At least two connecting rods are arranged between an inlet plate and a base plate; a convergent nozzle extending inwards is processed at the center of the inlet plate; at least two inlet spring plates are arranged on the outer side of the nozzle; a barrier body is arranged at the center of the base plate; the length of the barrier body is not equal to that of the nozzle; a bottom spring plate is arranged at the outer side of the barrier body. A liquid medium disturbs and generates retroaction on jet flow near the nozzle by using the jet flow from the nozzle and a barrier with a certain geometrical shape; alternating pressure field and speed field are generated between the nozzle and the barrier body; vibration is generated to generate a sound wave, so as to improve and intensify the ultrasonic wastewater treatment effect. The nozzle and the barrier are different in length, and the corresponding inlet spring plate and the bottom spring plate are also different in length, so that the multi-frequency ultrasonic wave is generated, the ultrasonic frequency can also be changed by changing the lengths of the nozzle, the barrier body, the inlet spring plate and the bottom spring plate, and the adjustable frequency is achieved.

Owner:SHAANXI NORMAL UNIV

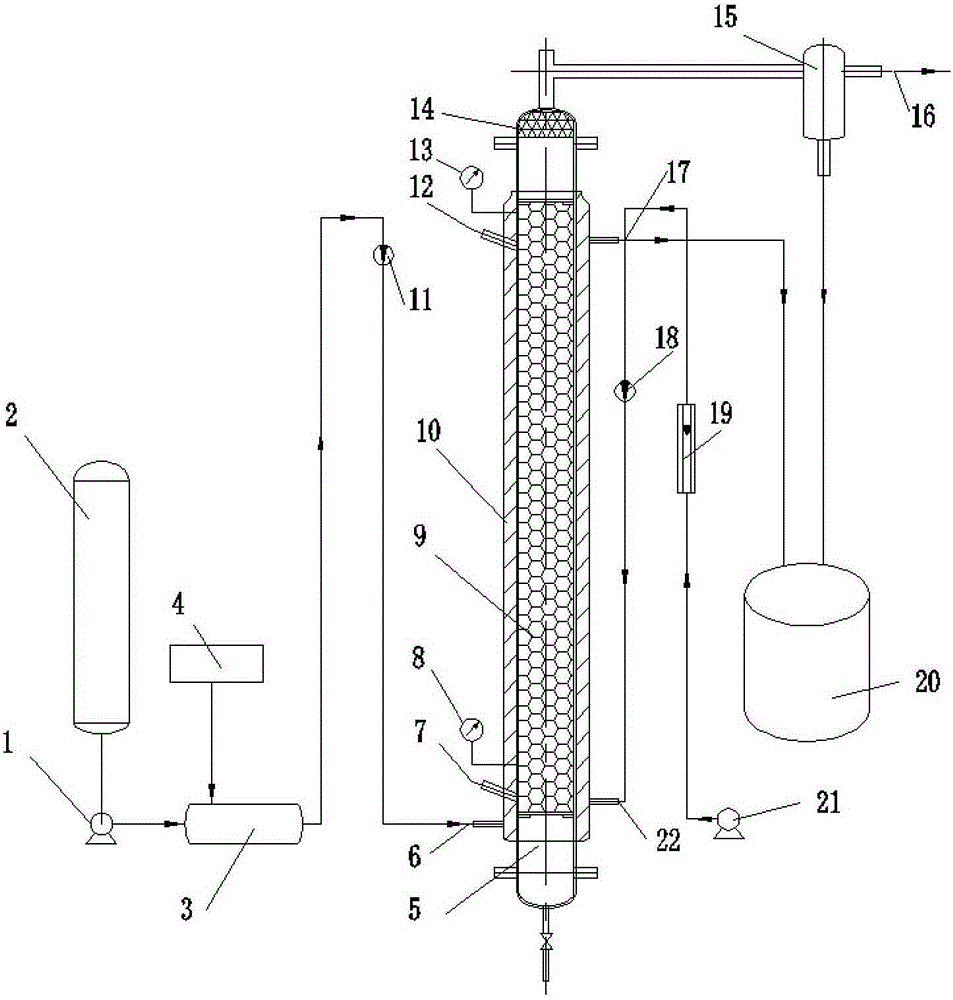

Apparatus for removing nitrous acid in reprocessing feed solution

InactiveCN104332210AIncrease processing scaleGood removal effectRadioactive decontaminationSteam distillationPUREXContinuous operation

The invention, which belongs to the technical field of nuclear fuel reprocessing, discloses an apparatus for removing nitrous acid in reprocessing feed solution in the nuclear fuel reprocessing Purex process. The apparatus comprises a removal tower, an air generator and a feed solution receiving tank, wherein a feed solution inlet is arranged on the top end of the removal tower, an air inlet is arranged on the lower end of the removal tower, a feed solution outlet is arranged on the bottom of the removal tower, and a heater is arranged on the external wall of the removal tower; the feed solution receiving tank is connected with the feed solution outlet of the bottom of the removal tower through a feed solution output pipe; packing is arranged in the removal tower, and feed solution to be treated enters the removal tower via the feed solution inlet of the removal tower to be in countercurrent contact with the air entering the air inlet. The apparatus has the advantages of good nitrous acid removal effect, high speed, continuous operation and high treatment capability.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

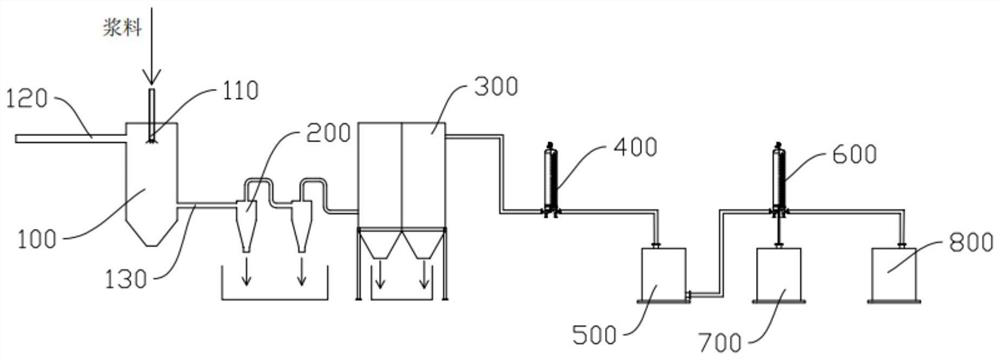

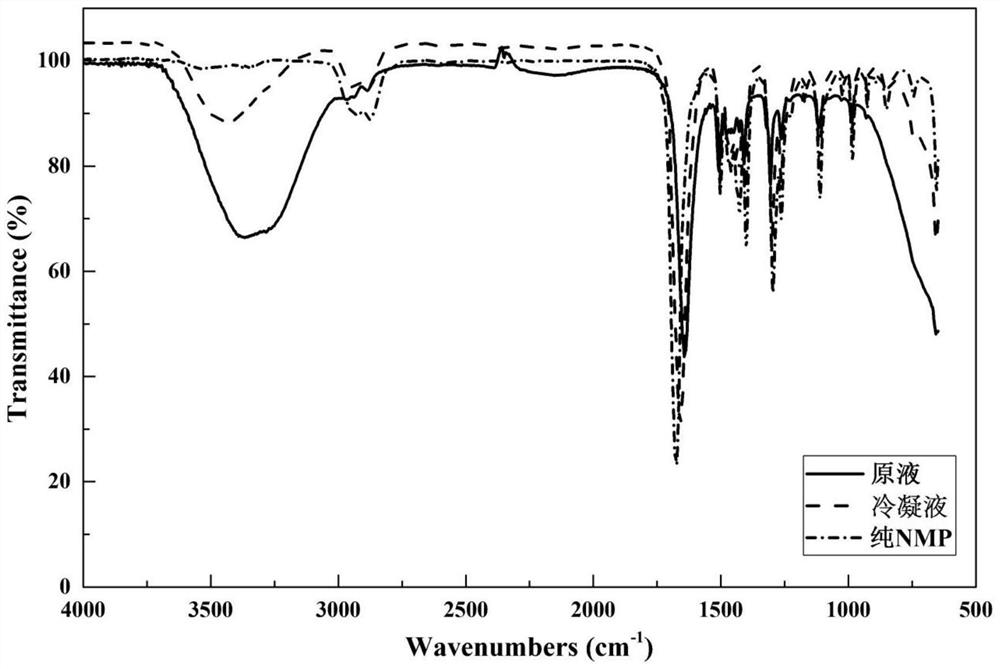

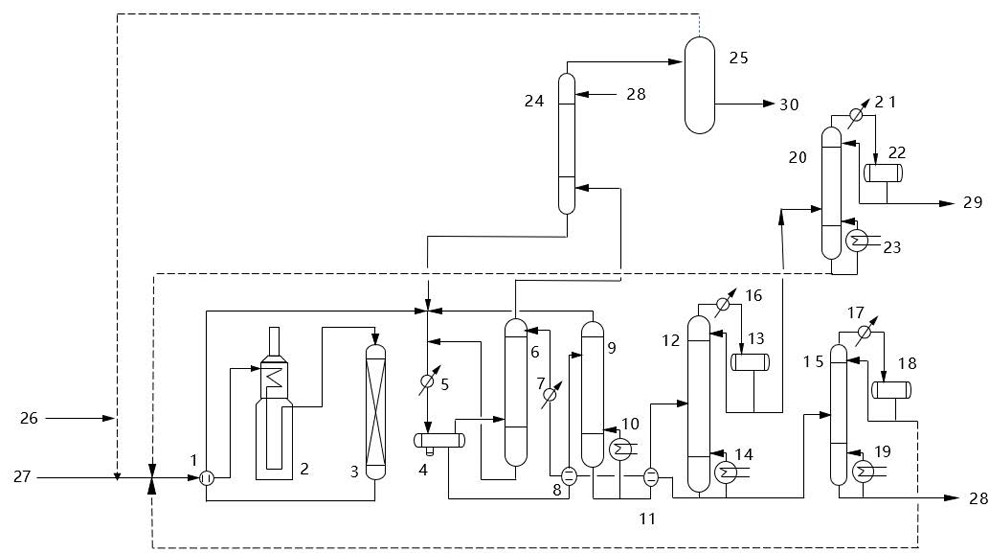

Method and equipment for recovering lithium battery slurry

ActiveCN113648670AEfficient separationHigh purityHuman health protectionCombination devicesPhysical chemistrySpray dried

The invention discloses a method for recycling lithium battery slurry, which comprises the following steps of: pretreating the lithium battery slurry, performing centrifugal spray drying on the pretreated lithium battery slurry, and separating a solid phase from a solvent. According to the method, a positive electrode material and NMP can be completely and efficiently separated by adopting centrifugal spraying, impurity elements are not introduced in the process, the purity of the NMP is improved, the treatment cost is low, meanwhile, the pollution to the environment is reduced, and the method has a very good industrial application prospect. The invention also discloses equipment for recycling the lithium battery slurry, which is a centrifugal spray drying system and comprises a spray chamber, a cyclone separator, a condenser, a condensate storage tank and a rectifying tower. The system improves original centrifugal spray drying equipment, and is designed by combining centrifugal spray drying with NMP condensation recovery processes, so that NMP can be directly recovered after the positive electrode material and NMP are separated, the treatment efficiency is high, and continuous production can be realized.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

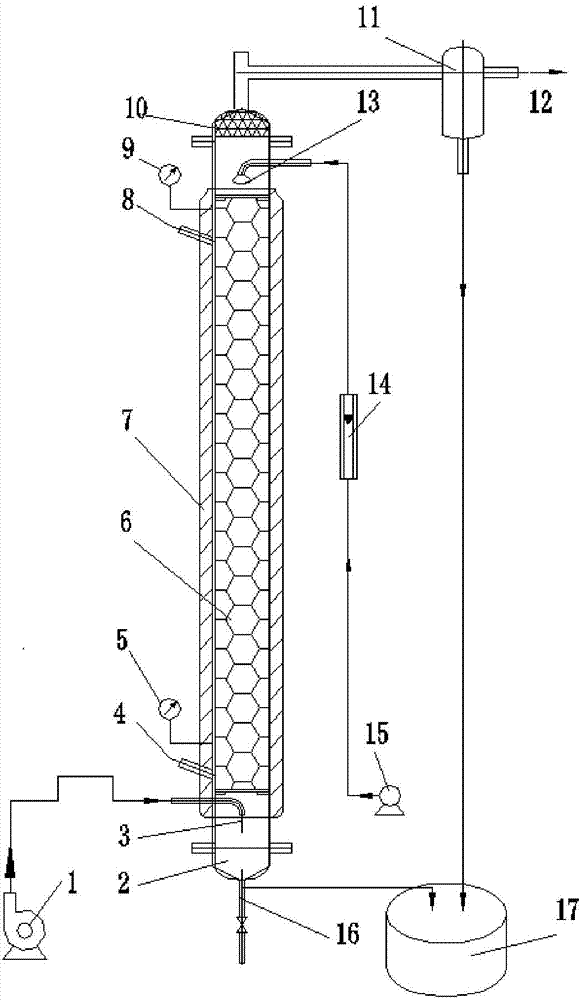

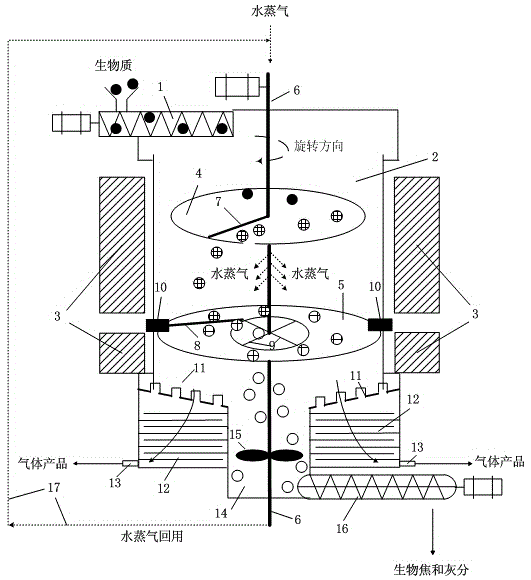

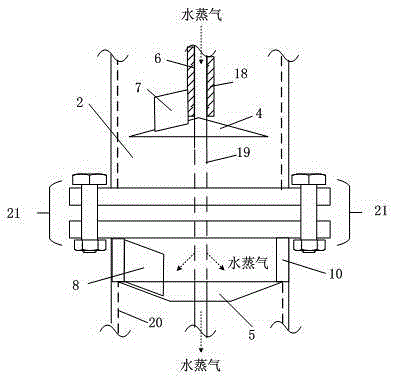

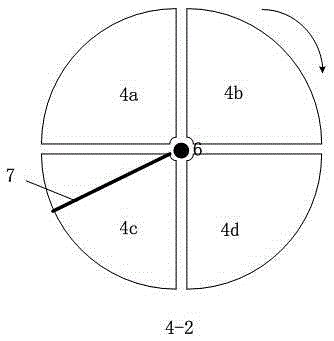

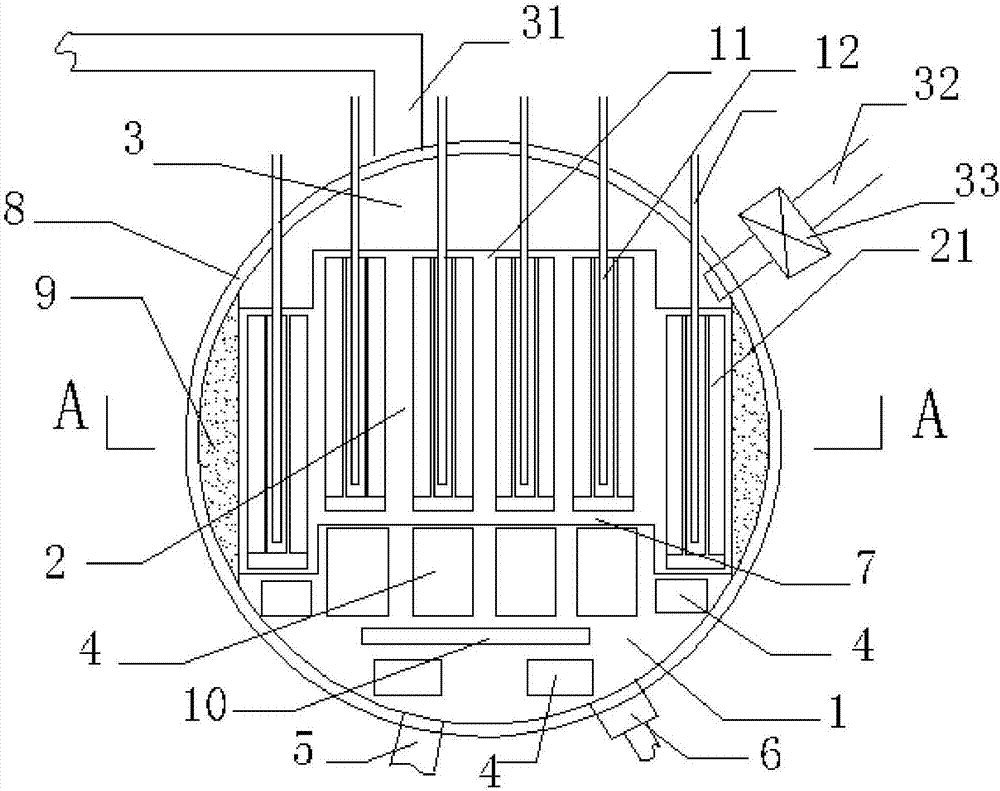

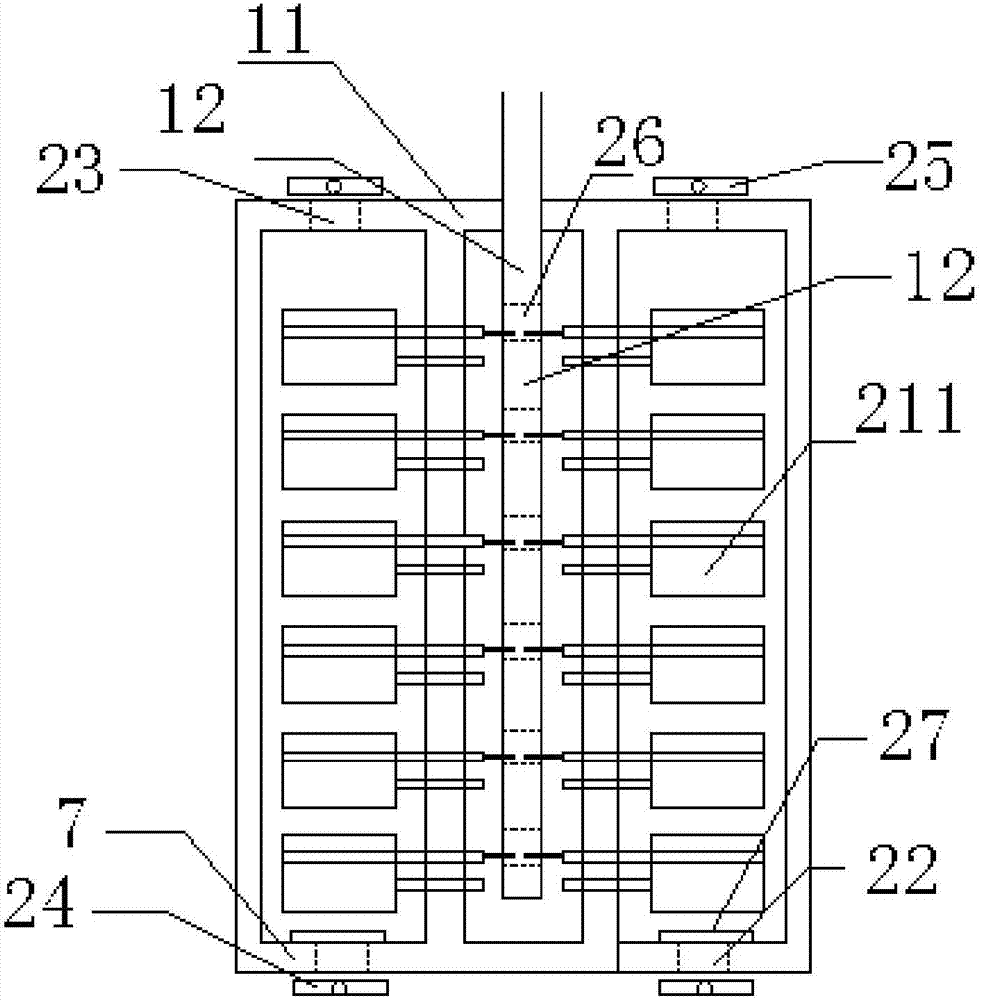

Continuous material pyrolysis gasification device

ActiveCN106675662AIncrease throughputSmall footprintGranular/pulverulent flues gasificationProduct gasEngineering

The invention discloses a continuous material pyrolysis gasification device which comprises a spiral feeder, a microwave reaction cavity, a microwave generator, a first-stage rotating disc, a second-stage rotating disc, a hollow rotating shaft, a screening plate, a settling chamber, a residue storage tank and a spiral residue discharge device, wherein the spiral feeder is positioned at the upper part of the microwave reaction cavity; the microwave generator is arranged outside the microwave reaction cavity; the first-stage rotating disc and the second-stage rotating disc are arranged inside the microwave reaction cavity; the two stages of rotating discs are fixed through the hollow rotating shaft; the bottom of the microwave reaction cavity takes the shape of a ring and consists of a screening plate which tilts downwards; the settling chamber is connected below the screening plate; a gas product outlet is formed in the settling chamber; a non-screening plate part at the bottom of the microwave reaction cavity communicates with the residue storage tank below; and the residue storage tank is internally provided with a stirrer and communicates with the spiral residue discharge device. The continuous material pyrolysis gasification device is high in pyrolysis speed, high in gasification efficiency, high in gas product quality, capable of meeting requirements of synthesizing liquid fuel, and good in application prospect.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEM +1

Reconstruction method for upgrading and capacity expansion of sewage treatment system

InactiveCN106927644AReasonable structural designMake full use of spaceSpecific water treatment objectivesTreatment involving filtrationMunicipal sewageReconstruction method

The invention provides a reconstruction method for upgrading and capacity expansion of a sewage treatment system. The method is based on a sewage treatment plant original process of: water inflow, coarse grid, fine grid, grit basin, membrane grid, biological tank, sedimentation tank, disinfection tank and water outflow, performs reconstruction on a structure of the original process, transforms the structure of the biological tank, and reforms the sedimentation tank into a membrane tank, enables reasonable structure layout, improves the sewage treatment scale from the original 10 thousand tons / day to 20 thousand tons / day, at the same time improves the outflow water quality from the grade II standard of original "municipal sewage treatment plant pollution discharge standards" to IV standard of surface water (except TN), and simultaneously in the reconstruction process, the method ensures normal operation of the overall sewage treatment plant, and avoids loss brought about in the reconstruction period.

Owner:中信环境技术(天津)有限公司

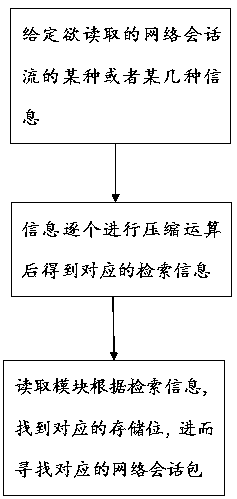

Network conversation packet indexing method based on projection of retrieval information

ActiveCN106326464AIncrease processing scaleReduce volumeSpecial data processing applicationsRelevant informationComputer science

The invention provides a network conversation packet indexing method based on projection of retrieval information. With the method, certain or several pieces of information of the designated network conversation packet is subjected to compression calculation to obtain the retrieval information corresponding to each piece of information. Projection module of the retrieval information can project relevant information of the network conversation packet to the corresponding bit of the index space that stores the retrieval information of such information, and the projected storage bit is marked as being projected during the first projection; the corresponding network conversation packet can be found according to the projection relationship in reading. The method can greatly improve the system performance.

Owner:科来网络技术股份有限公司

A kind of oxidation adjustment equipment for oxidizing pu(iii) to pu(iv)

ActiveCN104328291BIncrease profitReduced disposal burdenRadioactive decontaminationEngineeringNitric oxide

The invention belongs to the technical field of nuclear fuel reprocessing and discloses an oxidizing valence-adjusting equipment for oxidizing Pu (III) to Pu (IV). The equipment mainly comprises an oxidizing tower, a feed liquid receiving tank and a NOX storage tank, wherein a feed liquid outlet is formed at the upper end of the oxidizing tower, a Pu (III) feed liquid inlet and a NOX feed inlet are formed at the lower end, and the feed liquid outlets at the upper parts of the feed liquid receiving tank and the oxidizing tower are connected by virtue of a pipeline; the main body of the oxidizing tower and packing in the tower are both radiation-resistant and nitric acid corrosion-resistant materials; a heating device is arranged on the outer tower wall of the oxidizing tower; the Pu (III) feed liquid enters the oxidizing tower from the Pu (III) feed liquid inlet at the lower part of the oxidizing tower; NOX gas provided by the NOX storage tank enters into the oxidizing tower from the NOX feed inlet at the lower part of the oxidizing tower separately or together with carrier gas; the valence-adjusted feed liquid enters the feed liquid receiving tank from the feed liquid outlet at the upper part of the oxidizing tower. The equipment is large in processing scale, high in NOx utilization ratio, safe and stable in valence-adjusting process and low in processing burden of nitric oxide tail gas.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

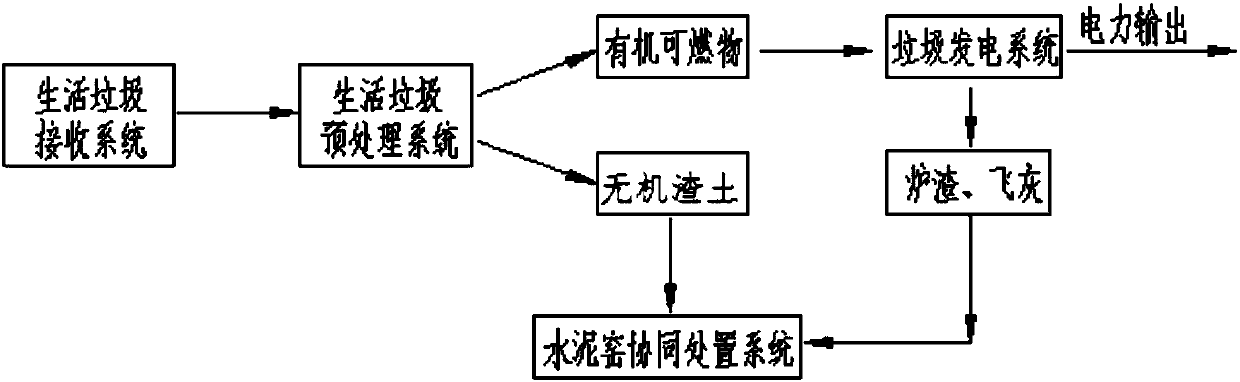

Household garbage comprehensive disposal and multicomponent utilization method

InactiveCN107617630ALess investmentImprove power generation efficiencySolid waste disposalProduction lineEnvironmental effect

The invention discloses a household garbage comprehensive disposal and multicomponent utilization method, which belongs to the technical field of resources and environmental protection. Municipal household garbage is presorted into two parts including organic combustibles and inorganic muck; after presorting, the organic combustibles are conveyed to a garbage power plant so as to be burnt to generate power, generated slag enters a dry cement production line and is used as cement raw materials so as to be mixed, generated fly ash enters the dry cement production line, and the inorganic muck isconveyed to the dry cement production line so as to be burnt in a cement kiln and then is used as cement raw materials so as to be mixed. According to the household garbage comprehensive disposal andmulticomponent utilization method, the problem of small scale of cooperative garbage disposal of an existing cement kiln is solved, and the problem of slag and fly ash disposal in garbage power is solved; a good environmental effect is guaranteed, the high household garbage disposal capability is provided, recycling is realized during household garbage disposal, and a good economic effect is achieved.

Owner:成都建筑材料工业设计研究院有限公司 +2

Method for substituting cement kiln fuel with garbage derived overtails

Owner:LINGCHUAN JINYU CEMENT

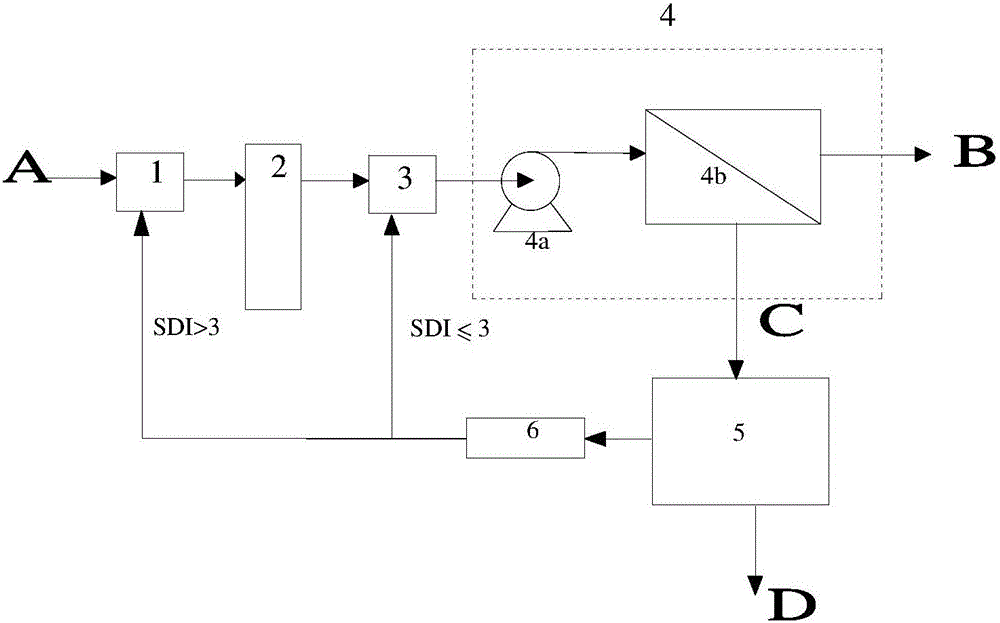

High-yield and one-time desalted water preparing process device and method

ActiveCN106336050AImprove reverse osmosis yieldSave waterGeneral water supply conservationSpecific water treatment objectivesElectricitySaline water

The invention provides a high-yield and one-time desalted water preparing process device and method. The process device comprises a front ultrafiltration water tank, a pretreatment system, a middle water tank, a reverse osmosis system, an electrically driven ionic membrane device and an online SDI value control system. The process method includes the steps that 1, the reverse osmosis treatment scale of the device and the treatment scale of the electrically driven ionic membrane device are set; 2, raw water is fed into the pretreatment system; 3, reverse osmosis is conducted on the pretreated water; 4, reverse-osmosis concentrated water enters the electrically driven ionic membrane device for desalting treatment; 5, the produced water of an electrically driven ionic membrane is detected by the online SDI value control system, when SDI is smaller than or equal to 3, the produced water of the electrically driven ionic membrane returns to the middle water tank at the front end of the reverse osmosis system, and when the SDI is greater than 3, the produced water of the electrically driven ionic membrane returns to the front ultrafiltration water tank at the front end of the pretreatment system. The process can improve the one-time desalted water reverse-osmosis yield and has the advantages of being high in system yield, capable of saving energy, low in operation cost and making the system safely and stably operating for a long period of time.

Owner:沈阳艾柏瑞环境科技有限公司

Centralized aerobic mud pulling sedimentation tank

ActiveCN101172695BSmall footprintIncrease processing scaleTreatment using aerobic processesSustainable biological treatmentFlocculationSludge

The invention discloses a centralized aerobic mud pushing sedimentation basin, which is characterized in that a main basin body is internally provided with an aerated pipeline; a mud reflow pump and a mud discharging pump are arranged at the side in the main basin body; a water inlet pipe positioned outside the main basin body is provided with a medicament feeding point; the main basin body is also internally provided with a medicament feeding point. The different parts of the invention are tightly matched through pipelines; the structure is more rational and the water distribution is more even so as to realize complete mud water internal circulation. The aerated pipeline provides enough dissolved oxygen to the mud microorganism in the basin so as to strengthen the organism function. The multi-point feeding of a plurality of kinds of medicament in and out of the basin body further strengthens the physical flocculation function. A lifting dasher and a mud reflow pump are controlled by a frequency conversion motor, and can be flexibly adjusted according to the factual conditions so as to guarantee the water quality. A concentrated mud pushing machine can realize the centralization of the mud and the concentration of the mud, thereby being suitable to be used in strengthening the normal treating of the water plant, in the sewage plant treating and the special water treating.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

A kind of method for producing propane by conversion of hydrogenated light hydrocarbons

ActiveCN113307717BLow reaction temperatureHigh feed space velocityMolecular sieve catalystDistillation purification/separationAlkanePtru catalyst

The invention discloses a method for producing propane by hydrogen conversion of light hydrocarbons. The light hydrocarbon raw material, hydrogen-rich gas and circulating light hydrocarbons are heated to the reaction temperature, and catalytic cracking reaction occurs under the condition of an acidic catalyst. The reaction products are cooled and fractionated to obtain dry gas, propane, and aromatic gasoline components respectively. Unreacted light components are obtained. The hydrocarbon feedstock, hydrogen-rich gas and recycle light hydrocarbons are returned to the reactor to continue the reaction. On the one hand, the present invention uses light alkanes as raw materials, which can effectively utilize a large amount of excess light alkanes in refineries; Increase feedstock conversion and propane yield.

Owner:洛阳市科创石化科技开发有限公司

Hydraulic multiple frequency ultrasonic sounder

InactiveCN103936099BImprove and intensify the treatment effectIncrease processing scaleSound producing devicesLiquid mediumJet flow

The invention relates to a hydraulic multi-frequency ultrasonic generator. At least two connecting rods are arranged between an inlet plate and a base plate; a convergent nozzle extending inwards is processed at the center of the inlet plate; at least two inlet spring plates are arranged on the outer side of the nozzle; a barrier body is arranged at the center of the base plate; the length of the barrier body is not equal to that of the nozzle; a bottom spring plate is arranged at the outer side of the barrier body. A liquid medium disturbs and generates retroaction on jet flow near the nozzle by using the jet flow from the nozzle and a barrier with a certain geometrical shape; alternating pressure field and speed field are generated between the nozzle and the barrier body; vibration is generated to generate a sound wave, so as to improve and intensify the ultrasonic wastewater treatment effect. The nozzle and the barrier are different in length, and the corresponding inlet spring plate and the bottom spring plate are also different in length, so that the multi-frequency ultrasonic wave is generated, the ultrasonic frequency can also be changed by changing the lengths of the nozzle, the barrier body, the inlet spring plate and the bottom spring plate, and the adjustable frequency is achieved.

Owner:SHAANXI NORMAL UNIV

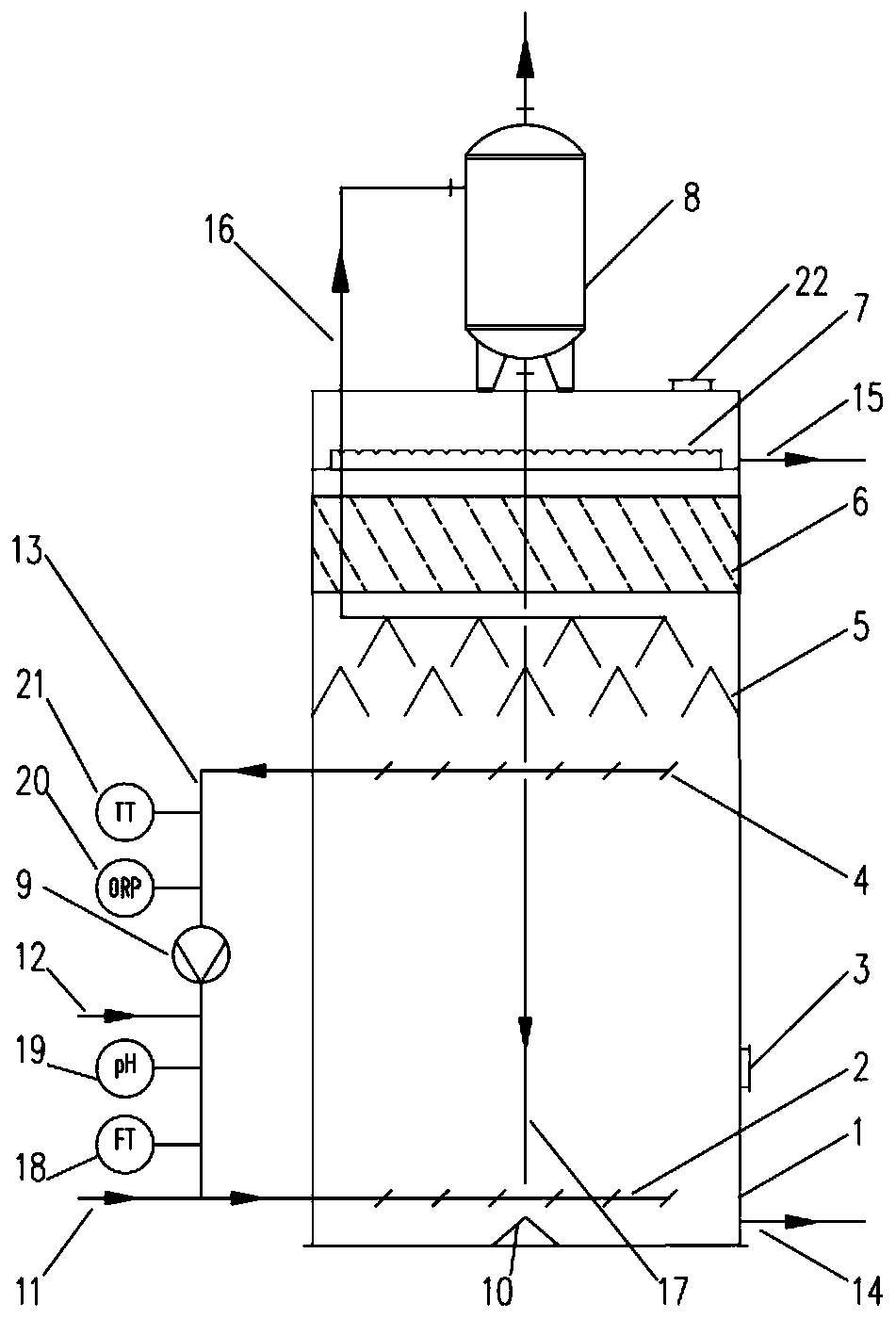

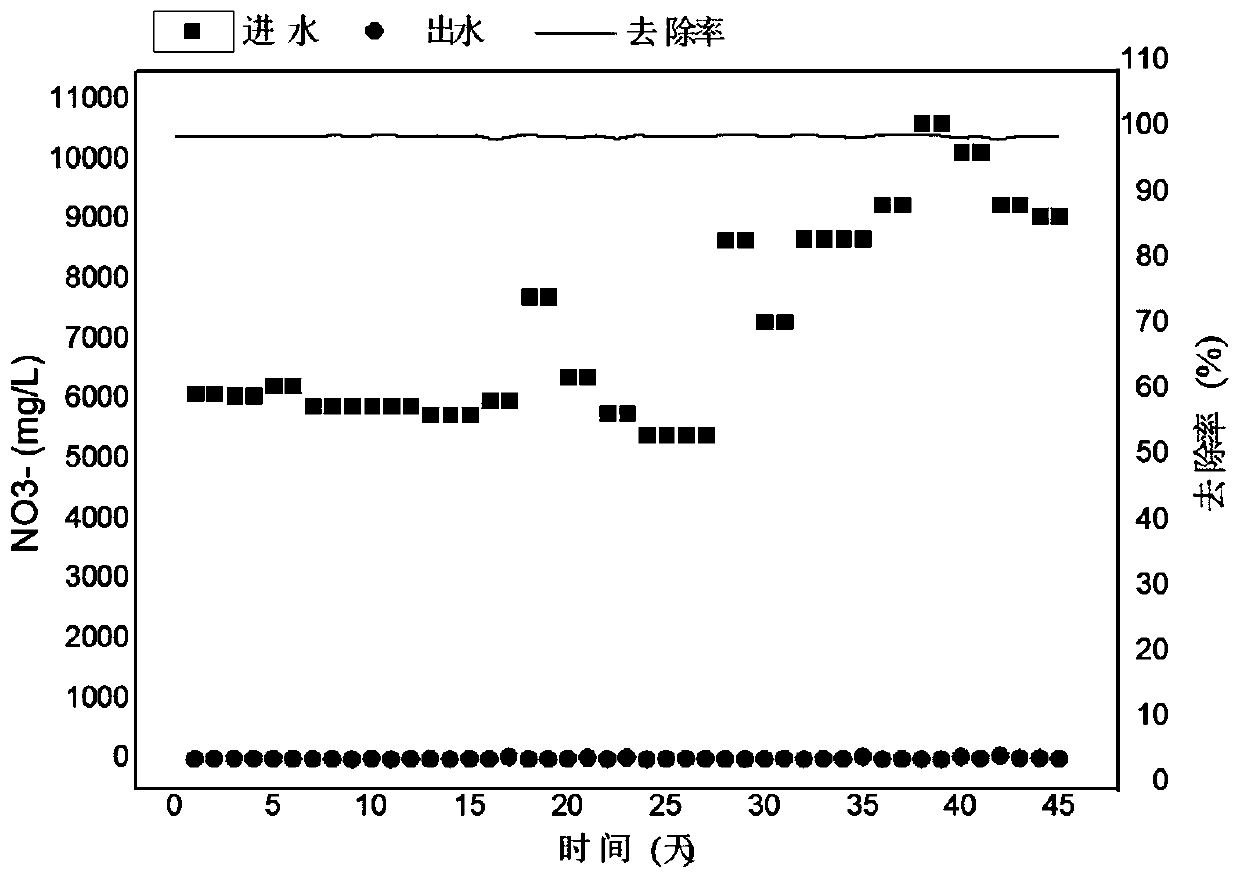

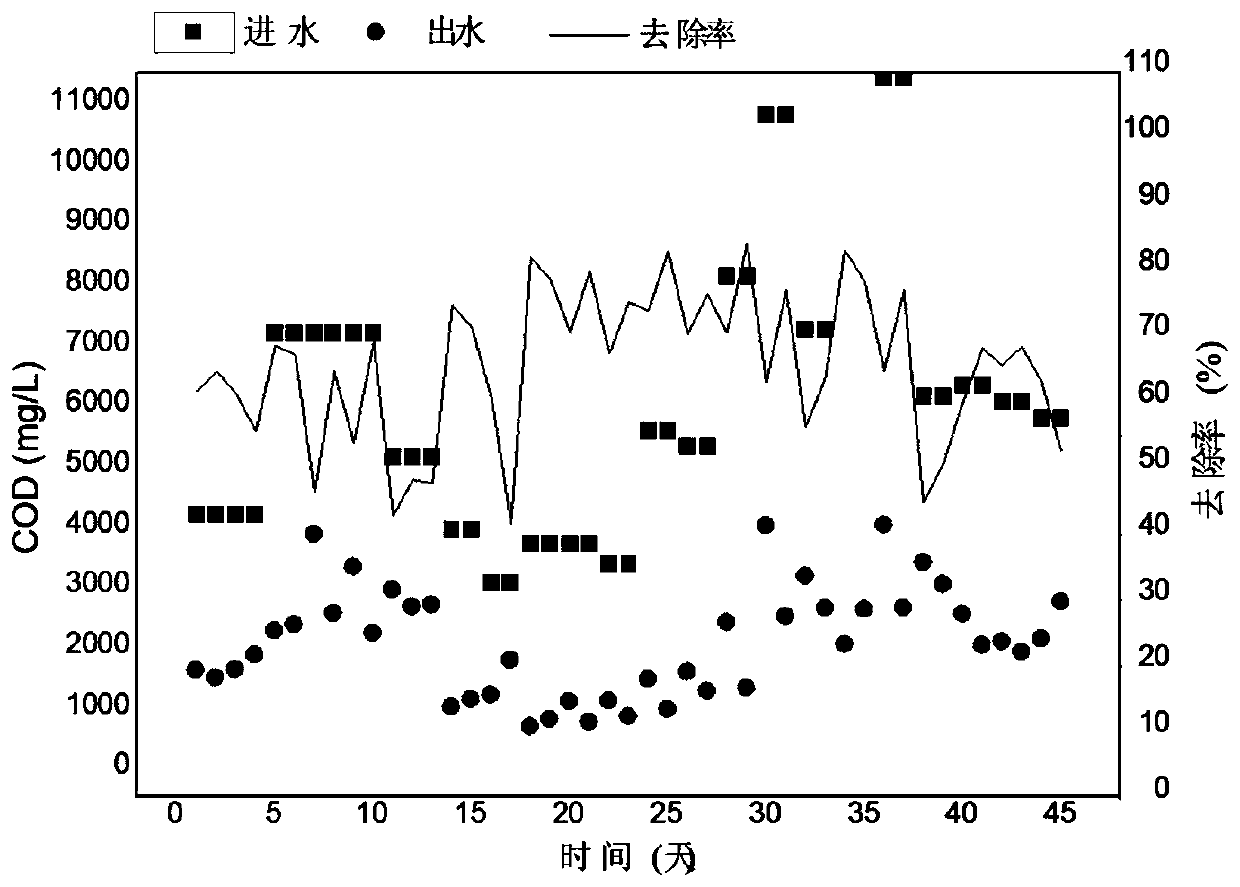

Anoxic reactor for effectively improving denitrification and denitrification effects

PendingCN110902822ASmall footprintLess investmentWater treatment parameter controlWater contaminantsGas collecting tubeVapor–liquid separator

The invention discloses an anoxic reactor for effectively improving the denitrification and denitrification effects. The anoxic reactor comprises a reactor tank body and a gas-liquid separator at thetop end of the reactor tank body; a reaction zone, a three-phase separation zone and a precipitation water outlet zone are sequentially arranged in the reactor tank body from bottom to top; a three-phase separator is arranged in the three-phase separation area, and an inclined plate / pipe and an effluent weir are arranged in the precipitation water outlet area from bottom to top; the three-phase separator is connected to the gas-liquid separator through a gas collecting tube, and the bottom end of the gas-liquid separator leads to the bottom of the reactor tank body through a return tube; and awater inlet tube is arranged at the bottom end of the reactor tank body, wastewater enters the reactor tank body through the water inlet tube and is purified, and the purified water flows out from the effluent weir. The anoxic reactor has the advantages of effective avoiding of loss of sludge and special strains, improved volume load, increase of the denitrification efficiency, high nitrate removal rate, saving of the volume and the occupied area of the reactor, and avoiding of the problems of high operation cost and difficult maintenance caused by a submersible stirrer.

Owner:DAJIANG ENVIRONMENT CORP

Material continuous pyrolysis gasification device

ActiveCN106675662BSmall footprintExtended stayGranular/pulverulent flues gasificationMicrowaveEngineering

The invention discloses a continuous material pyrolysis gasification device which comprises a spiral feeder, a microwave reaction cavity, a microwave generator, a first-stage rotating disc, a second-stage rotating disc, a hollow rotating shaft, a screening plate, a settling chamber, a residue storage tank and a spiral residue discharge device, wherein the spiral feeder is positioned at the upper part of the microwave reaction cavity; the microwave generator is arranged outside the microwave reaction cavity; the first-stage rotating disc and the second-stage rotating disc are arranged inside the microwave reaction cavity; the two stages of rotating discs are fixed through the hollow rotating shaft; the bottom of the microwave reaction cavity takes the shape of a ring and consists of a screening plate which tilts downwards; the settling chamber is connected below the screening plate; a gas product outlet is formed in the settling chamber; a non-screening plate part at the bottom of the microwave reaction cavity communicates with the residue storage tank below; and the residue storage tank is internally provided with a stirrer and communicates with the spiral residue discharge device. The continuous material pyrolysis gasification device is high in pyrolysis speed, high in gasification efficiency, high in gas product quality, capable of meeting requirements of synthesizing liquid fuel, and good in application prospect.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEMICALS CO LTD +1

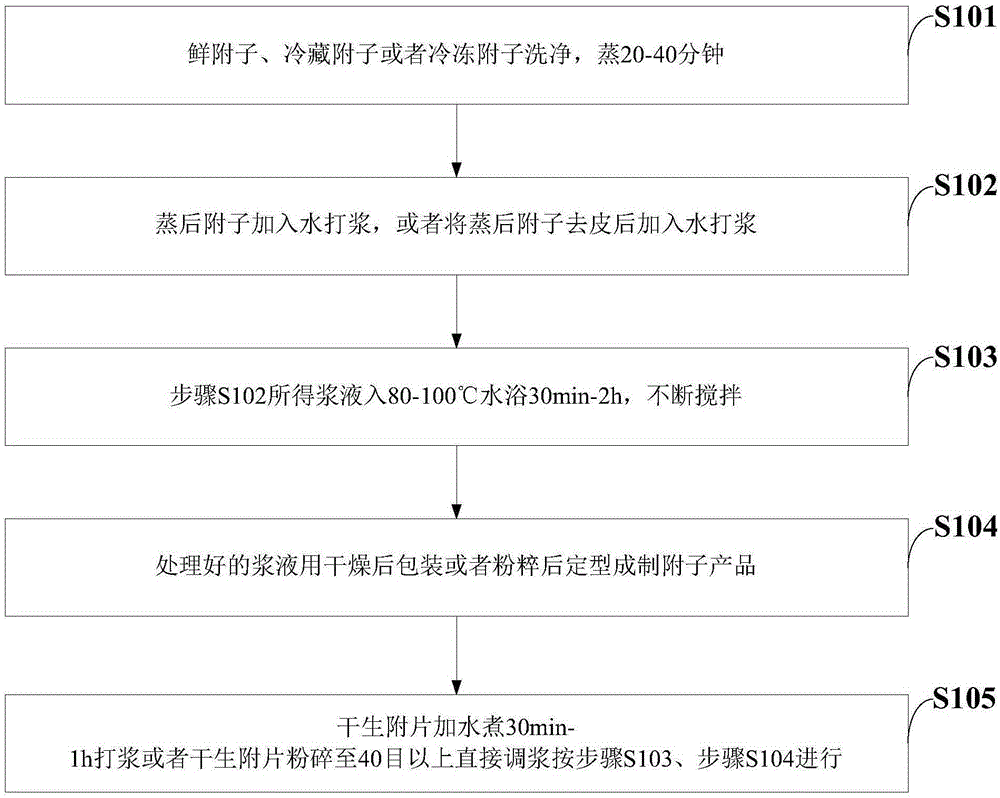

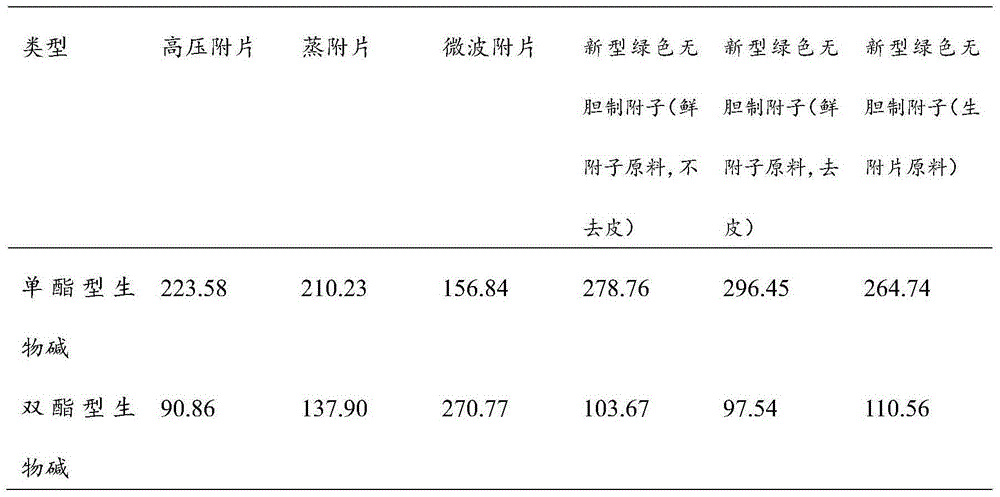

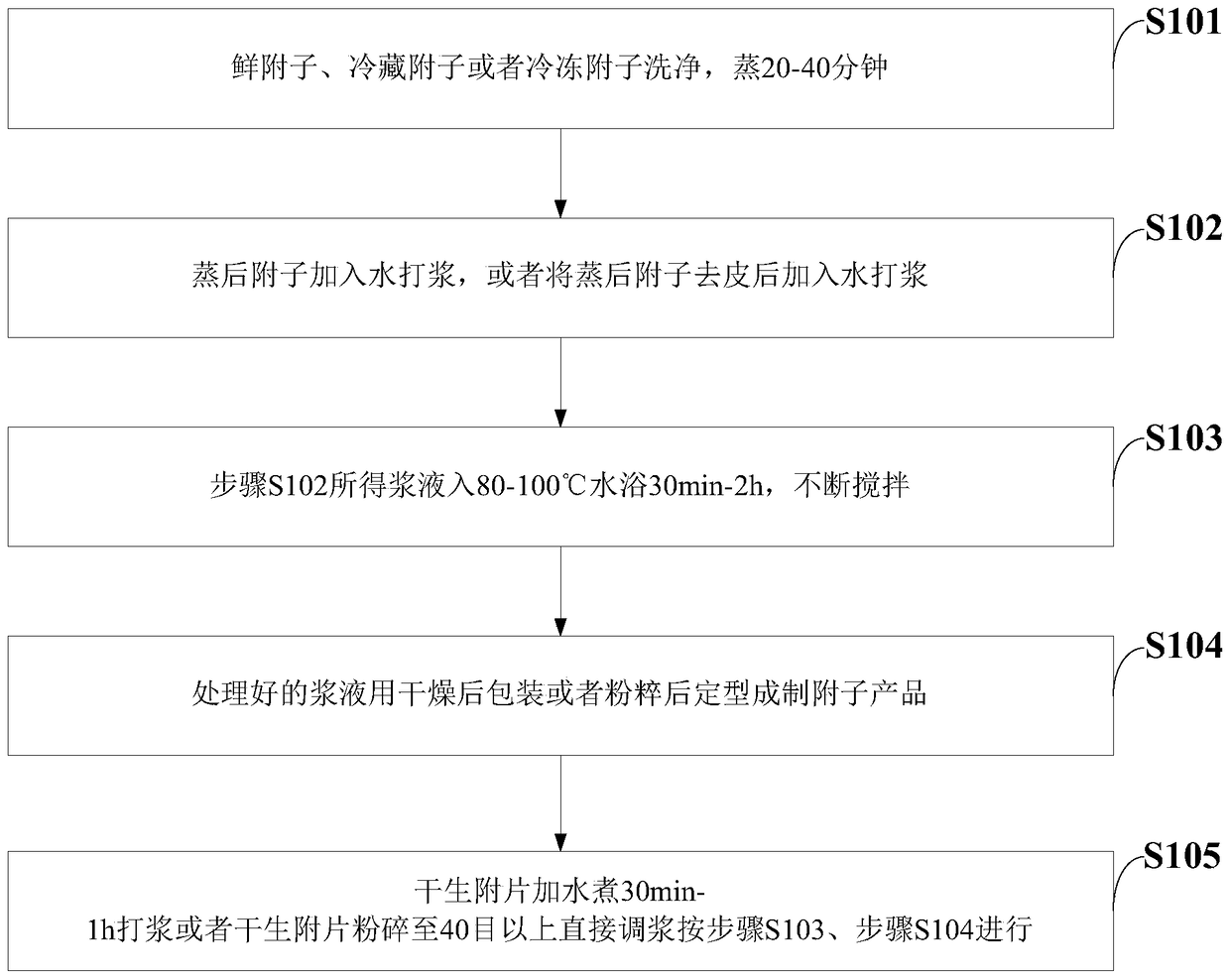

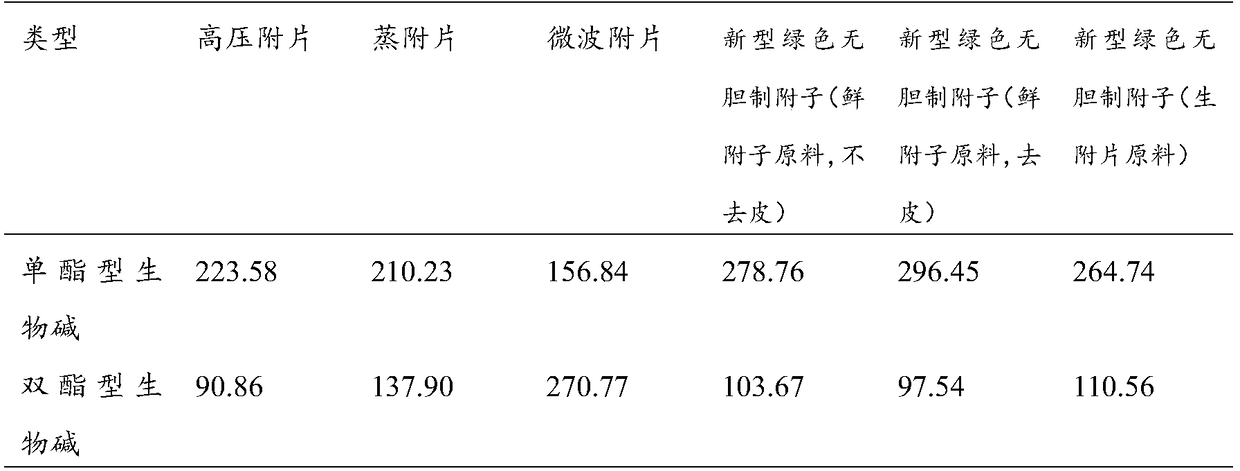

Method for processing novel green acholic radix aconiti lateralis preparata

ActiveCN105213516AQuality is not affectedSolve the side effectsPlant ingredientsWater bathsRadix Aconiti

The invention discloses a method for processing novel green acholic radix aconiti lateralis preparata, which comprises the following steps: cleaning fresh radix aconiti lateralis, refrigerated radix aconiti lateralis or frozen radix aconiti lateralis, steaming the radix aconiti lateralis in a short period, adding water into the steamed radix aconiti lateralis to pulp, adding water into dry and raw sliced radix aconiti lateralis to boil and pulp, and adding water into raw radix aconiti lateralis powder to carry out pulp-mixing; merging the obtained pulp into a water bath; after the treated pulp is dried, packaging or crushing the obtained object, and then shaping the obtained product into a radix aconiti lateralis preparata product. The tablet type and thickness of sliced radix aconiti lateralis preparata prepared according to the invention can be adjusted as required without affecting the quality; no exogenous chemical substance is introduced, so that side effects caused by exogenous chemical substances do not exist; the time of processing is greatly shortened; parameters in the working procedures of the manufacturing technique are easily controlled, so that produced sliced radix aconiti lateralis preparata is high in quality, stable in quality, and conforms to the requirements of pharmacopoeia, and parameters also can be adjusted as required so as to obtain radix aconiti lateralis preparata products with different toxicities, and the active ingredients of sliced radix aconiti lateralis preparata are not lost; and in cooperation with appropriate storage measures, sliced radix aconiti lateralis preparata can be produced all the year round, thereby avoiding the seasonality problem of radix aconiti lateralis processing.

Owner:SOUTHWEAT UNIV OF SCI & TECH

A Network Session Packet Indexing Method Based on Retrieval Information Projection

ActiveCN106326464BIncrease processing scaleReduce volumeOther databases indexingInformation projection

The invention provides a network conversation packet indexing method based on projection of retrieval information. With the method, certain or several pieces of information of the designated network conversation packet is subjected to compression calculation to obtain the retrieval information corresponding to each piece of information. Projection module of the retrieval information can project relevant information of the network conversation packet to the corresponding bit of the index space that stores the retrieval information of such information, and the projected storage bit is marked as being projected during the first projection; the corresponding network conversation packet can be found according to the projection relationship in reading. The method can greatly improve the system performance.

Owner:科来网络技术股份有限公司

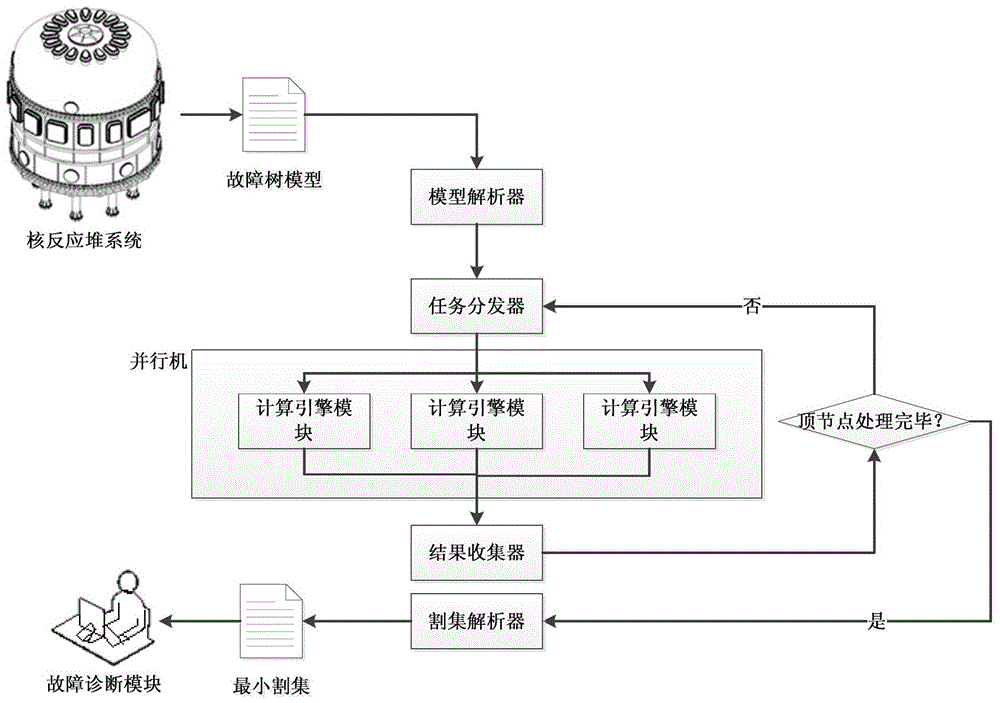

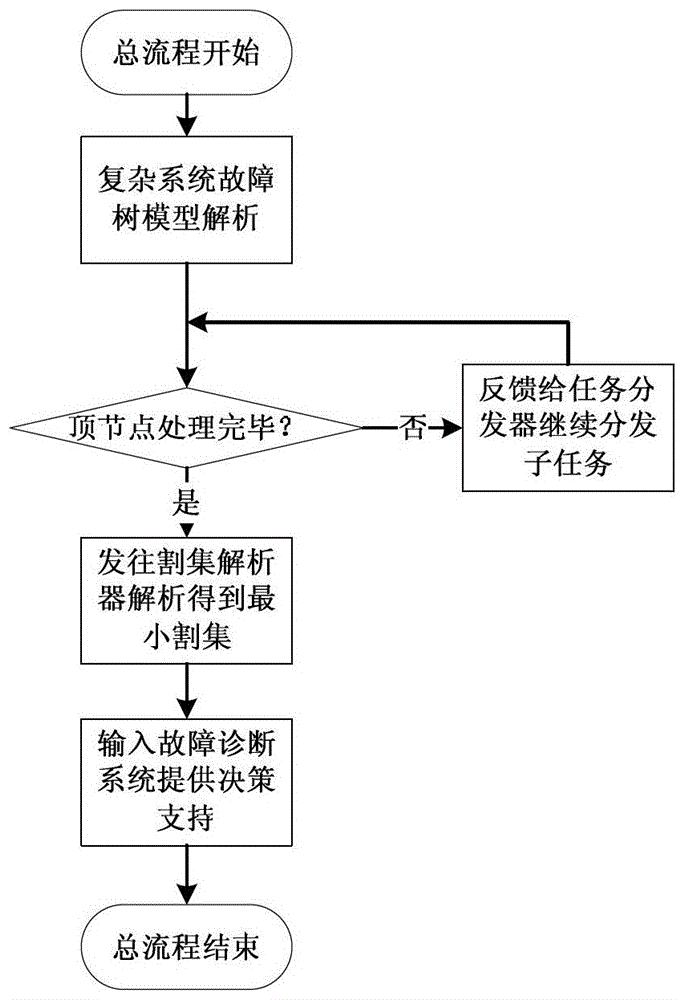

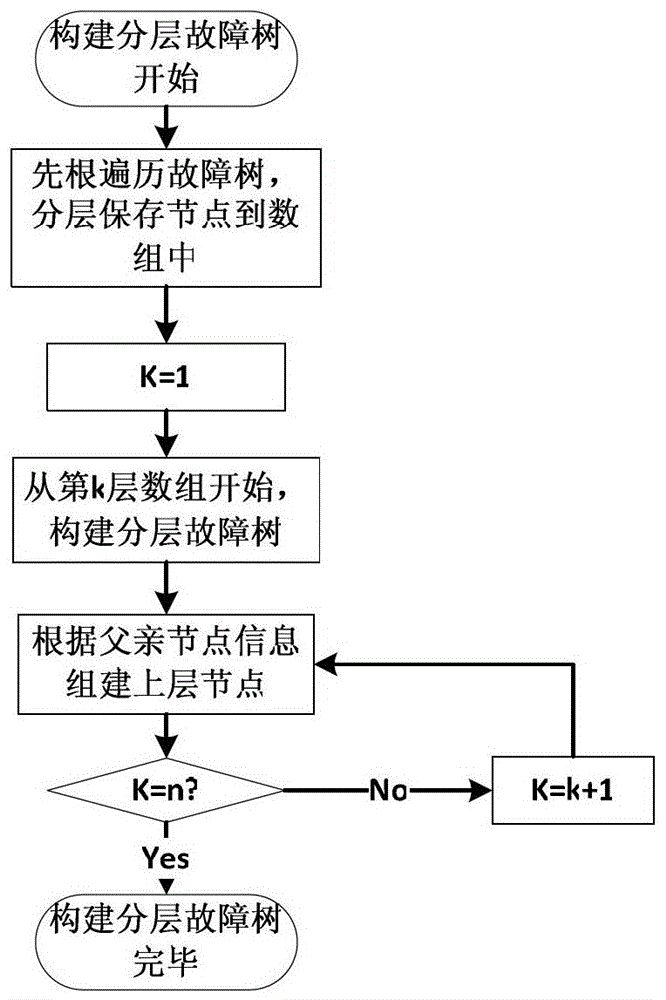

A Nuclear Reactor Fault Monitoring System Based on Minimal Cut Set

InactiveCN103235881BOptimize calculation speedIncrease processing scaleNuclear energy generationNuclear monitoringNuclear reactorConcurrent computation

A minimal cut set based system for monitoring faults of nuclear reactors provides decision support for fault diagnosis of nuclear reactor systems and can also be applied to related fields of aviation, navigation, chemical engineering and the like. The system is mainly composed of a model analyzer, a task dispatcher, a parallel machine, a result collector, a cut set analyzer and a fault diagnostor. The system has the advantages of being high in storage efficiency, fast in calculation, easy to deploy and maintain and the like. Compared with the prior art, the system performs parallel calculation on each layer of nodes of fault trees through the parallel machine, so that the calculating speed and accuracy are improved to a large extent, and faults of nuclear reactors can be diagnosed and monitored effectively.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

A kind of gallbladder-free aconite processing method

ActiveCN105213516BQuality is not affectedSolve the side effectsPlant ingredientsWater bathsSide effect

The invention discloses a method for processing novel green acholic radix aconiti lateralis preparata, which comprises the following steps: cleaning fresh radix aconiti lateralis, refrigerated radix aconiti lateralis or frozen radix aconiti lateralis, steaming the radix aconiti lateralis in a short period, adding water into the steamed radix aconiti lateralis to pulp, adding water into dry and raw sliced radix aconiti lateralis to boil and pulp, and adding water into raw radix aconiti lateralis powder to carry out pulp-mixing; merging the obtained pulp into a water bath; after the treated pulp is dried, packaging or crushing the obtained object, and then shaping the obtained product into a radix aconiti lateralis preparata product. The tablet type and thickness of sliced radix aconiti lateralis preparata prepared according to the invention can be adjusted as required without affecting the quality; no exogenous chemical substance is introduced, so that side effects caused by exogenous chemical substances do not exist; the time of processing is greatly shortened; parameters in the working procedures of the manufacturing technique are easily controlled, so that produced sliced radix aconiti lateralis preparata is high in quality, stable in quality, and conforms to the requirements of pharmacopoeia, and parameters also can be adjusted as required so as to obtain radix aconiti lateralis preparata products with different toxicities, and the active ingredients of sliced radix aconiti lateralis preparata are not lost; and in cooperation with appropriate storage measures, sliced radix aconiti lateralis preparata can be produced all the year round, thereby avoiding the seasonality problem of radix aconiti lateralis processing.

Owner:SOUTHWEAT UNIV OF SCI & TECH

A method for continuous pyrolysis and gasification of materials

ActiveCN106675661BSmall footprintExtended stayCombustible gas productionMicrowave pyrolysisWater vapor

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEMICALS CO LTD +1

A Harmless Treatment Process for Garbage Fly Ash

ActiveCN107906526BRealize nearby processingShorten and simplify the balling processEmission preventionIncinerator apparatusLitterFlue gas

The invention belongs to the technical field of solid waste treatment, and particularly relates to an innocent treatment process for waste flying ash. The innocent treatment process includes the following steps that (1) the waste flying ash is prepared into flying ash sphere kernels with the particle sizes being 1-8mm under the action of a binding agent; (2) a chlorine absorbing agent containing calcium oxide wraps the surfaces of the flying ash sphere kernels to form a chlorine absorbing shielding layer of 0.5-2mm under the action of the binding agent, and chlorine shielding pellets are obtained; (3) the chlorine shielding pellets are evenly mixed with a C-containing reducing agent with the particle sizes being 1-8mm, so that a mixture is obtained; and (4) the mixture is put into an incineration device for high-temperature incineration, flue gas generated through incineration is subjected to purification treatment, and incineration residues are subjected to residue treatment. The innocent treatment process is simple, time and labor are saved, equipment required in the process is also simple, and the floor area is small. The innocent treatment process is suitable for being matchedwith an existing waste incineration plant for implementation, and thus innocent treatment industrialization of the waste flying ash can be better realized.

Owner:CHONGQING ANGRUIYUE SCI & TECH +1

An indexing system for network session packets

ActiveCN106446028BIncrease processing scaleReduce volumeOther databases indexingTransmissionRelevant informationInformation compression

The invention provides an indexing system of a network session package, which includes at least one index space for storing certain information retrieval information of the network session package, an information compression module, a retrieval information projection module, and a reading module. There are several storage bits in the index space, one storage bit corresponds to a kind of retrieval information, and each storage bit has the same initial value; the information compression module is used to compress certain or several types of information of the specified network session packet The retrieval information corresponding to each information is obtained through calculation; the retrieval information projection module is used to project and map the relevant information of the network session packet to the corresponding storage bit of the index space storing the retrieval information of this type of information, and the projected storage location is in the first When being projected, it is marked as having been projected; the reading module is used to find the corresponding network session packet. The present invention can greatly improve system performance.

Owner:科来网络技术股份有限公司

Garbage biomass pyrolysis gasification system

PendingCN113528166AImprove power densityIncrease the number of placementsBiofuelsSpecial form destructive distillationPtru catalystCyclonic separation

The invention discloses a garbage biomass pyrolysis gasification system which is characterized in that: blending a dried biomass raw material and a microwave catalyst on a feeding screw, and after the material reaches 100-300 DEG C, pumping the material into a microwave reactor for pyrolysis gasification; carrying out gas-solid separation on the pyrolysis product to obtain gaseous pyrolysis volatile components and solids; returning the solid to the reactor, enabling the solid and the residual solid in the reactor to enter a lifting pipe for combustion, and performing cyclone separation on a combustion product to obtain a regenerated catalyst and high-temperature flue gas; and subjecting the regenerated catalyst and the gaseous pyrolysis volatile component in the step to a high-temperature cracking reaction through a return pipe to prepare a high-quality biomass gas product. The biomass pyrolysis gasification system comprises a raw material dryer, a microwave generator, a pyrolysis reaction cavity, a lifting pipe combustor and a return pipe. The method and the system are high in pyrolysis speed and low in energy consumption, the obtained biomass gas is high in quality, the requirement of synthesizing liquid fuel can be met, and the method and the system have good application prospects.

Owner:四川运辉环保工程有限公司

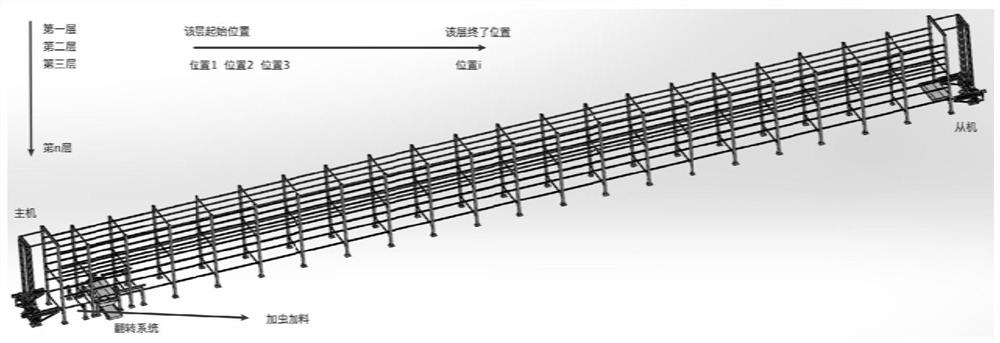

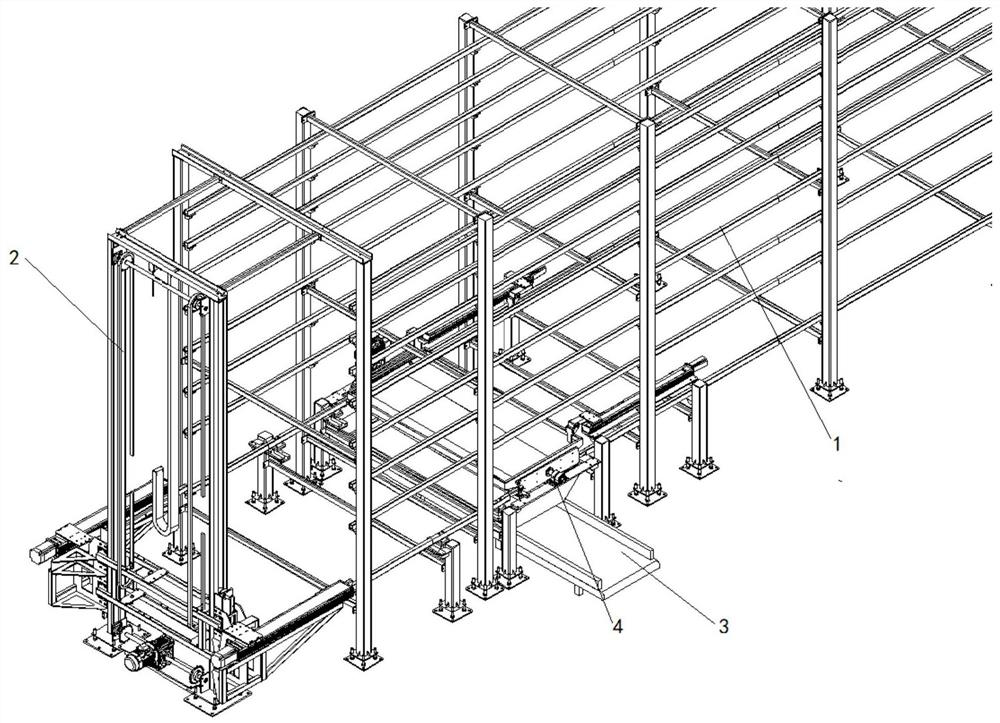

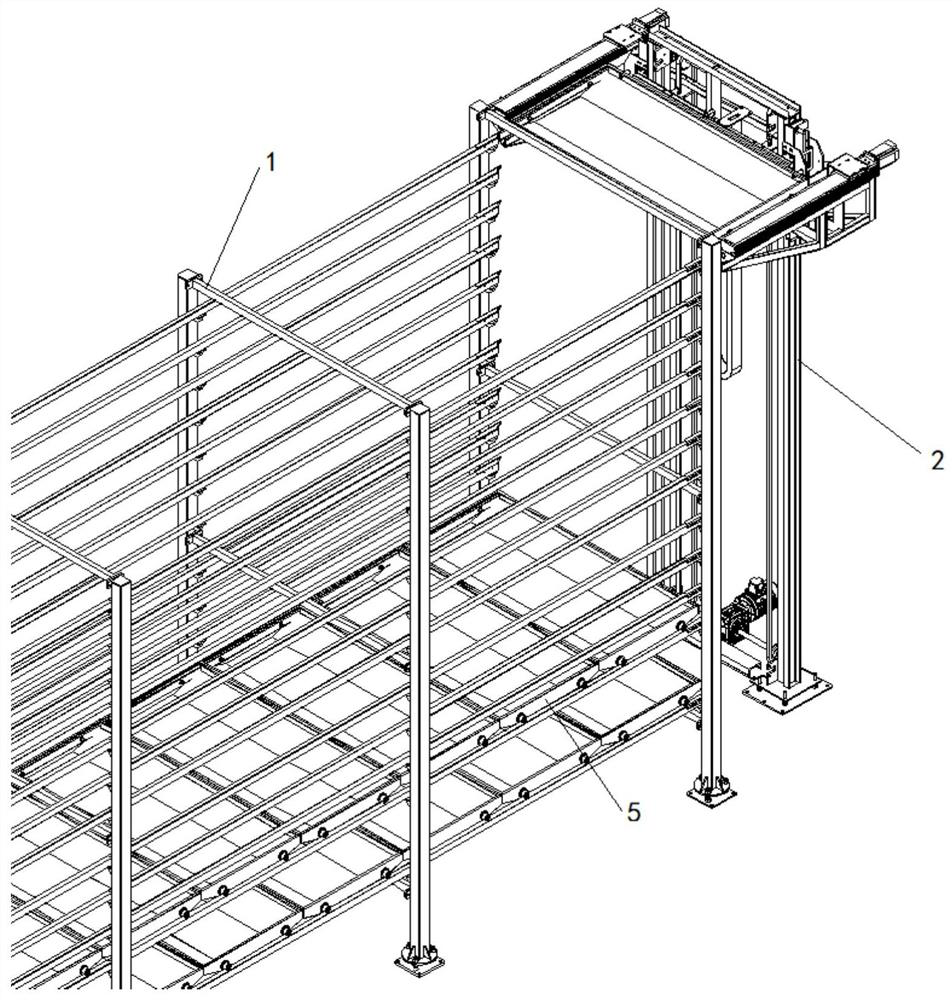

An automatic processing system for perishable garbage and its application method

ActiveCN112705554BImprove efficiencyIncrease processing scaleSolid waste disposalAnimal husbandryProcess engineeringHandling system

An embodiment of the present disclosure provides an automatic treatment system for perishable garbage. The system uses insects to process perishable garbage. The system includes: insect feeding, feeding components, breeding components, supporting components, lifting components, and conveying components , an overturning assembly, an induction assembly, and a central control assembly; wherein, the overturning assembly is disposed on the lowermost layer of the support assembly, and the induction assembly includes a plurality of induction elements arranged on the support assembly, the lifting assembly, the transmission assembly and the overturning assembly. The automatic processing system for perishable garbage provided by the embodiments of the present disclosure, the processing system improves the efficiency of space use through multi-layer three-dimensional equipment, the same floor area, the breeding efficiency is n (n is the reaction layer) of ground farming The number of layers, n≥1) times. In addition, the equipment realizes the addition of perishable garbage and insects used to deal with perishable garbage at the bottom layer, which is convenient for manual operation, observation and recording, and convenient for daily maintenance and repair when abnormal situations occur.

Owner:湖南自然创造生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com