A kind of gallbladder-free aconite processing method

A technology for making aconite and aconite, which is applied in the field of new-type green gallbladder-free aconite processing, which can solve problems such as difficult quality control, over-processing of aconite, and large side effects, and achieves the effects of obvious advantages, large side effects, and high crushing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

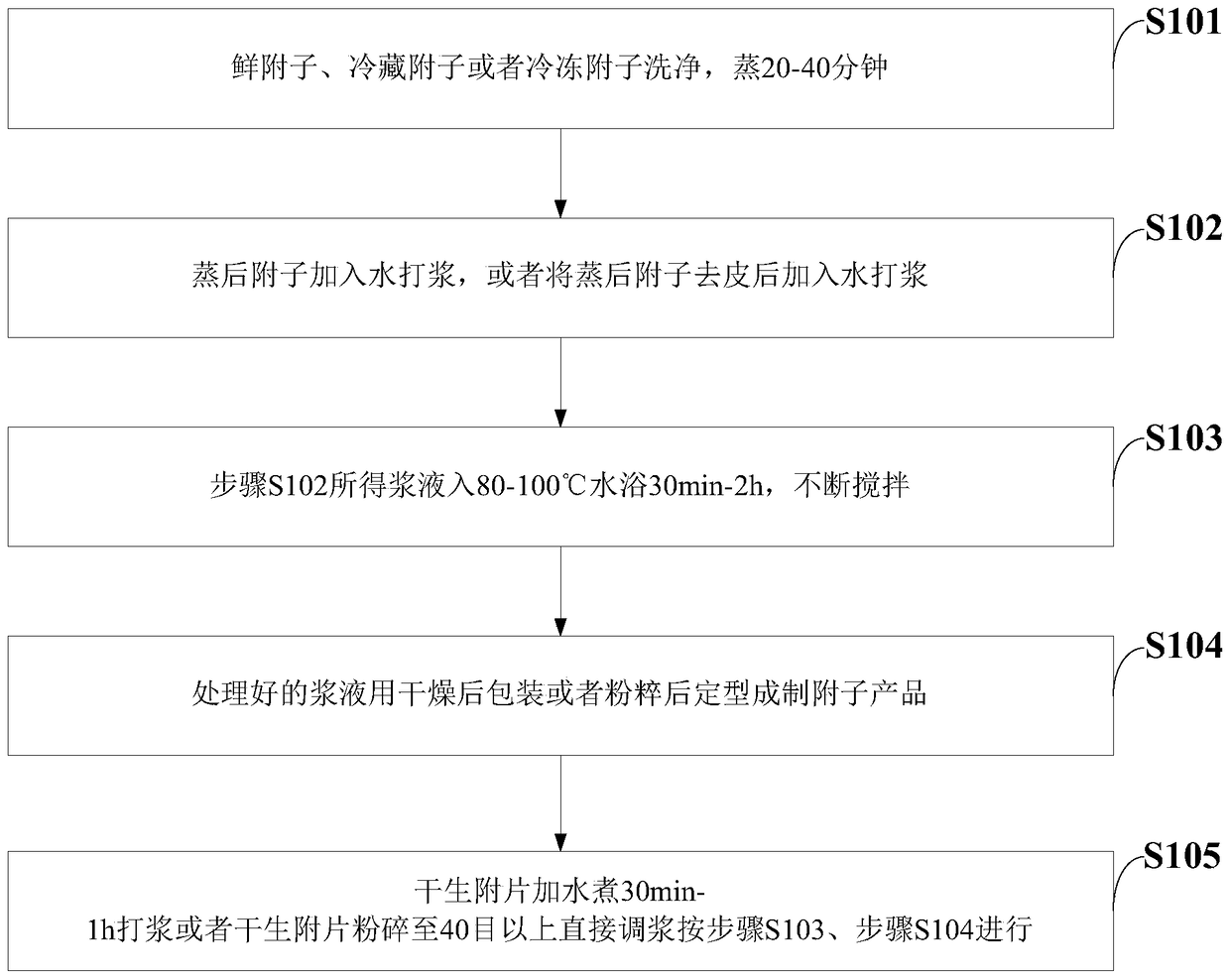

Method used

Image

Examples

example 1

[0044] 1. Take 5 kg of fresh aconite, wash it, steam for 20-30 minutes, put the aconite in a stainless steel bucket after steaming, add 4 times the amount of water, and homogenate;

[0045] 2. Fresh aconite or directly add 4 times of water to cook for 20-30 minutes, then transfer the water into a stainless steel bucket to homogenize and homogenize;

[0046] 3. Put the stainless steel barrel into a water bath at 95-100°C and stir for 1 hour;

[0047] 4. After the water bath is over, the oar liquid is dried with a drum dryer to obtain a snowflake-shaped attachment sheet;

[0048] 5. Either pulverize the snowflake-shaped Fuzi powder to obtain Fuzi powder, or shape it again to obtain Zhifu tablet.

example 2

[0050] 1. Take 5kg of fresh aconite, wash it, steam for 20-30 minutes, peel off the skin after steaming, put the aconite in a stainless steel bucket, add 4 times the amount of water, and homogenate;

[0051] 3. Put the stainless steel barrel into a water bath at 95-100°C and stir for 1 hour;

[0052] 4. After the water bath is over, the oar liquid is dried with a drum dryer to obtain a snowflake-shaped attachment sheet;

[0053] 5. Either pulverize the snowflake-shaped Fuzi powder to obtain Fuzi powder, or shape it again to obtain Zhifu tablet.

example 3

[0055] 1. Take 2 kg of raw aconite powder (passed through a 40-mesh sieve) and put it in a stainless steel bucket, add 8 times the amount of water to mix;

[0056] 2. Put the stainless steel barrel into a water bath at 95-100°C and stir for 1 hour;

[0057] 3. After the water bath is over, the oar liquid is dried with a drum dryer to obtain a snowflake-shaped attachment sheet;

[0058] 4. Either pulverize the snowflake-shaped Fuzi powder to obtain Fuzi powder, or shape it again to obtain Zhifu tablet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com