Anoxic reactor for effectively improving denitrification and denitrification effects

A reactor and denitrification technology, used in chemical instruments and methods, anaerobic digestion treatment, water treatment parameter control, etc. Improve denitrification efficiency and improve the effect of shock load resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

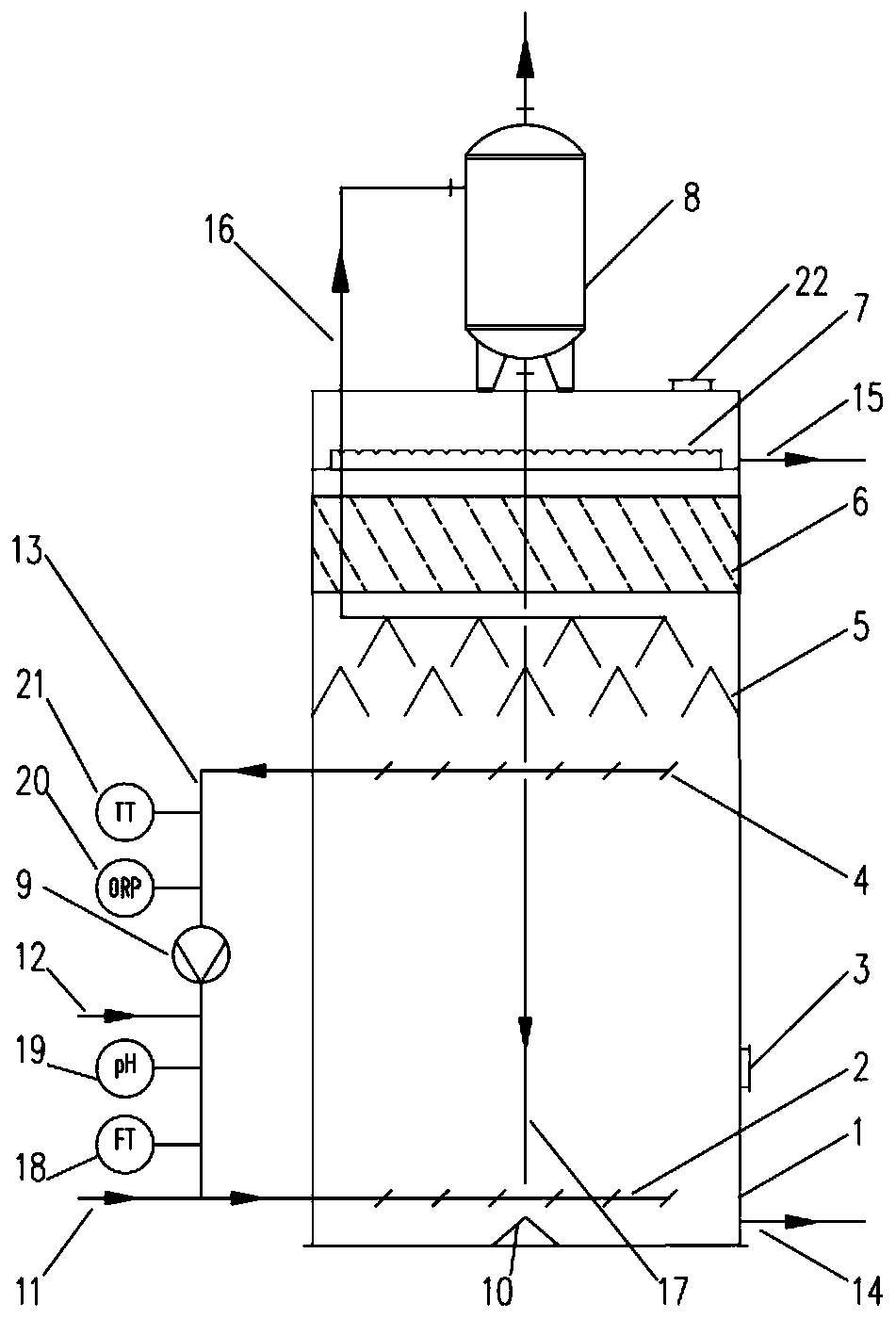

[0029] Such as figure 1 , an anoxic reactor for effectively improving the effect of denitrification and denitrification, comprising a reactor tank 1 and a gas-liquid separator 8 at the top of the reactor tank 1; the interior of the reactor tank 1 is sequentially arranged from bottom to top A reaction zone, a three-phase separation zone and a precipitation outlet area; a three-phase separator 5 is arranged in the three-phase separation zone, and an inclined plate / pipe 6 and an outlet weir 7 are arranged from bottom to top in the precipitation outlet zone; the three-phase separation zone The device 5 is connected to the gas-liquid separator 8 through the gas collecting pipe 16, and the bottom end of the gas-liquid separator 8 leads to the bottom of the reactor tank 1 through the return pipe 17; the bottom end of the reactor tank 1 is provided with a water inlet pipe 11, and the waste water passes through The water inlet pipe 11 enters the reactor tank body 1 for purification, an...

Embodiment 2

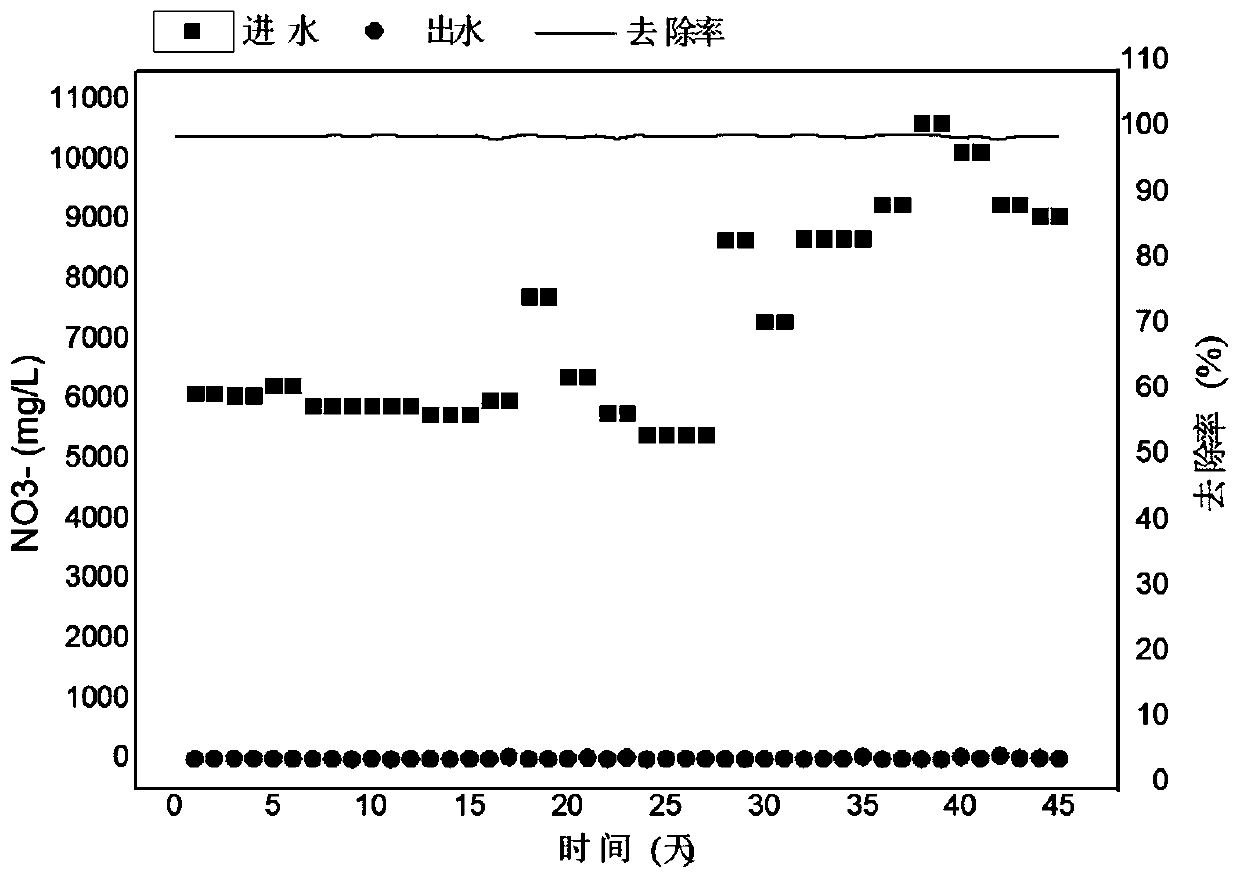

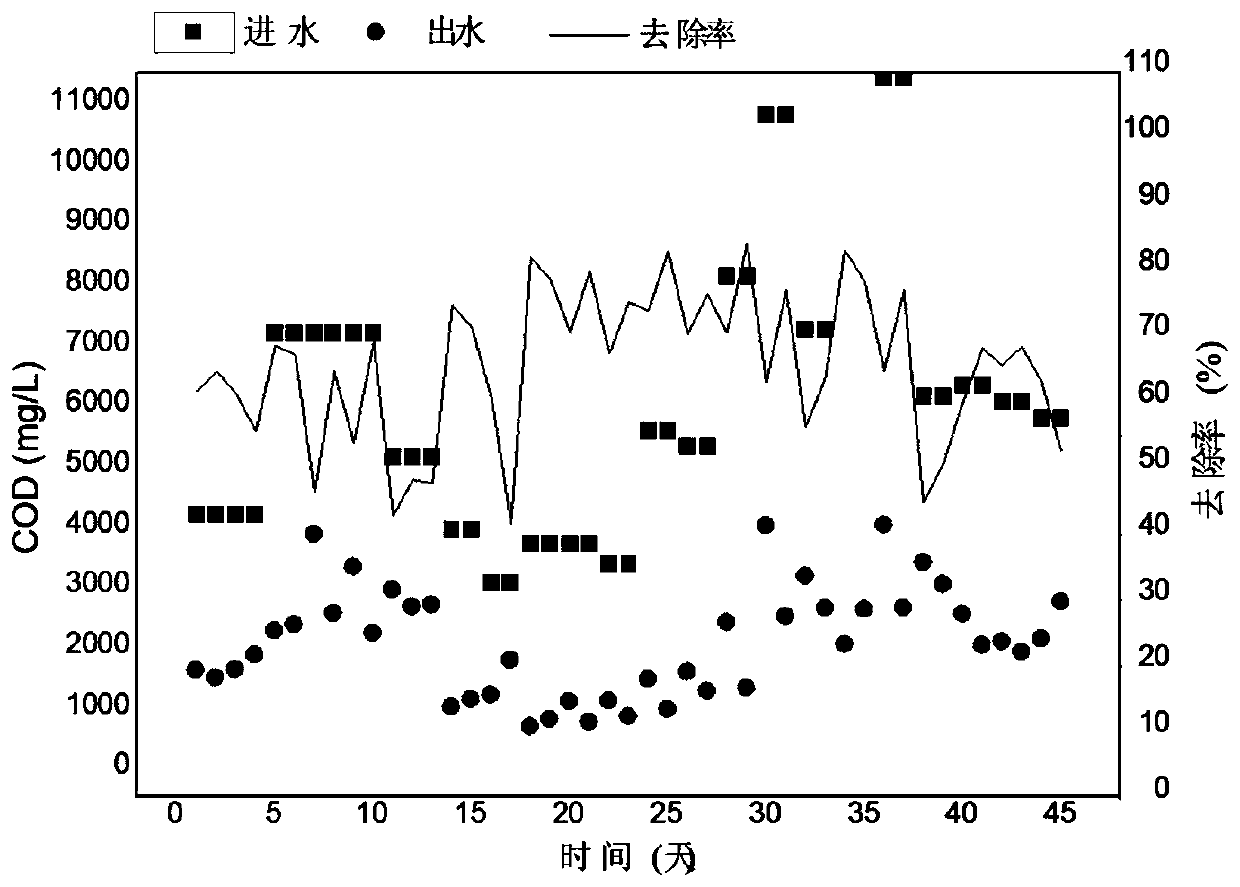

[0034]The anoxic reactor effectively improving the effect of denitrification and denitrification described in Example 1 is used to treat industrial wastewater. The working process is: the wastewater enters through the water inlet pipe 11, and the sewage is evenly introduced into the reactor tank 1 by the water distribution device 2. In the zone, the high-concentration nitrate in the wastewater is denitrified in the reaction zone. The denitrifying bacteria use nitrate as an electron acceptor, use organic matter as a carbon source and electron donor to provide energy and obtain oxidation stability, and reduce nitrate It is nitrogen, when pH8.0) and carbon-nitrogen ratio2 ) enters the gas-liquid separator 8 through the gas collecting pipe 16, and the waste water enters the sedimentation outlet area from the three-phase separation area further. The loss of sludge and functional bacteria keeps the denitrifying bacteria in a stable working environment for a long time, which is conduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com