Method for substituting cement kiln fuel with garbage derived overtails

A waste-derived and derived sieve technology, which is applied in the energy field, can solve environmental pollution and other problems, and achieve the effect of long passing time and increased calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

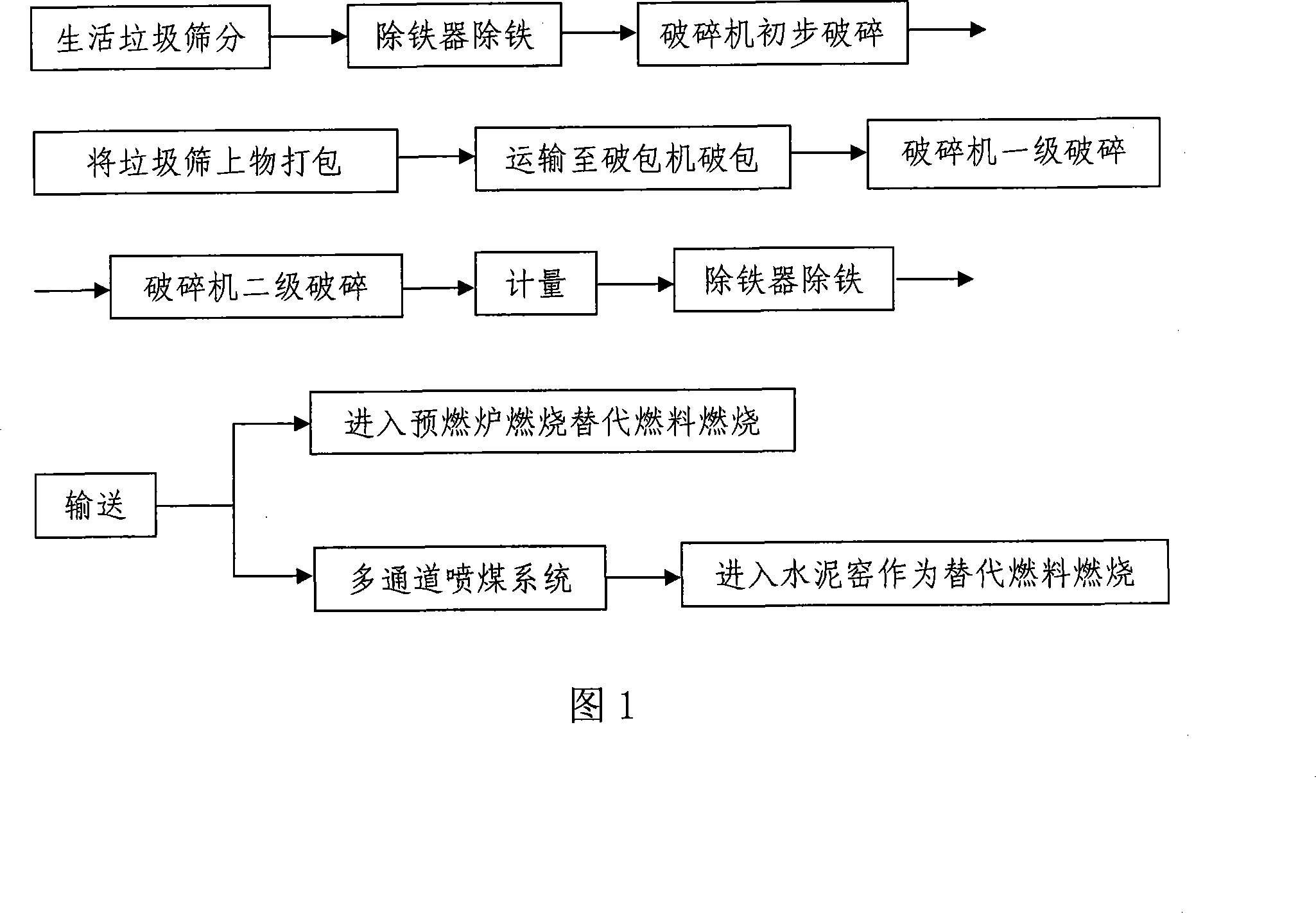

[0023] Shown in Fig. 1 is the technological process of an embodiment of the present invention, at first house refuse is sub-sieved, and the main composition of the obtained garbage derived oversize is: waste cotton fabrics, straw and plastics, and the garbage derived oversize After preliminary crushing, it is packed into cylindrical garbage bags weighing about 1.5 tons. After being transported to the factory area by a transport vehicle, it is lifted to the platform bag breaker in the pretreatment workshop, and then crushed by a crusher. In this example, German-made automatic garbage bags are used. The crusher generally adopts two-stage or three-stage crushing, and the crushing particle size is less than 60mm×60mm, preferably 50mm×40mm. It is stirred and mixed to make it uniform. One part is transported to the pre-combustion furnace for combustion, and the other part is sprayed into the cement kiln from the kiln head through the multi-channel coal injection pipe, so that the was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com