Patents

Literature

55results about How to "Stable combustion conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

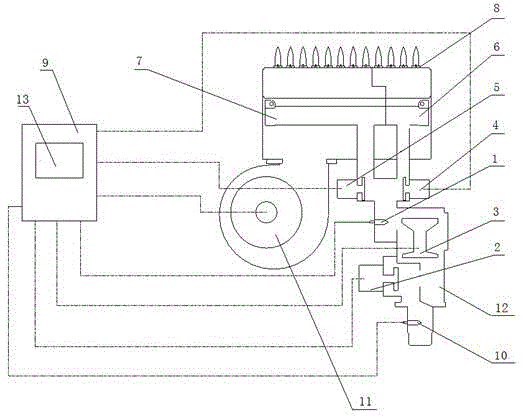

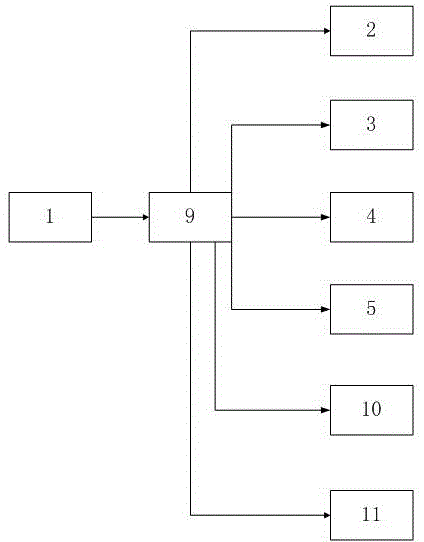

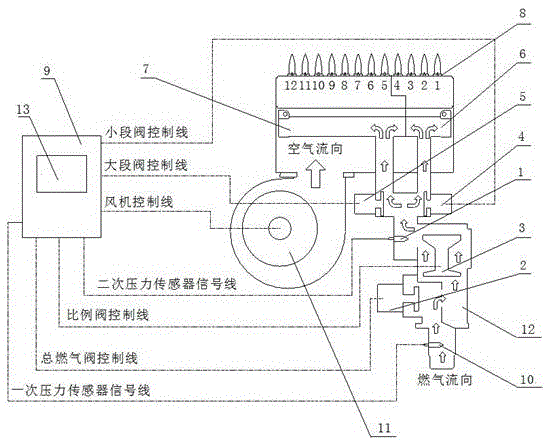

Combustible-gas-self-adapting combustible gas water heater and control method thereof

ActiveCN105605796AImprove adaptabilityStable combustion conditionsFluid heatersThermodynamicsDisplay device

The invention discloses a combustible-gas-self-adapting combustible gas water heater and a control method thereof. The combustible gas water heater comprises a combustion flame grate, a flame grate switch valve, a combustible gas proportioning valve, a total combustible gas switch valve, a fan, a primary pressure sensor, a secondary pressure sensor, a controller and a combustible gas pipeline, wherein the flame grate switch valve, combustible gas proportioning valve and total combustible gas switch valve are sequentially arranged on the combustible gas pipeline from top to bottom; the primary pressure sensor is arranged on the combustible gas pipeline between the total combustible gas switch valve and a combustible gas inlet; the secondary pressure sensor is arranged on the combustible gas pipeline between the combustible gas proportioning valve and the flame grate switch valve; and the controller is provided with a display unit. The water heater can automatically sense the combustible gas pressure variation condition, can automatically correct the deviation of the proportioning valve so that the combustion working condition is stabler, and can automatically regulate the ignition and the high / low load pressure, thereby ensuring that the user can use the water heater under the condition of both high and low gas pressures, and enhancing the adaptability of the combustible gas water heater.

Owner:成都前锋电子有限责任公司

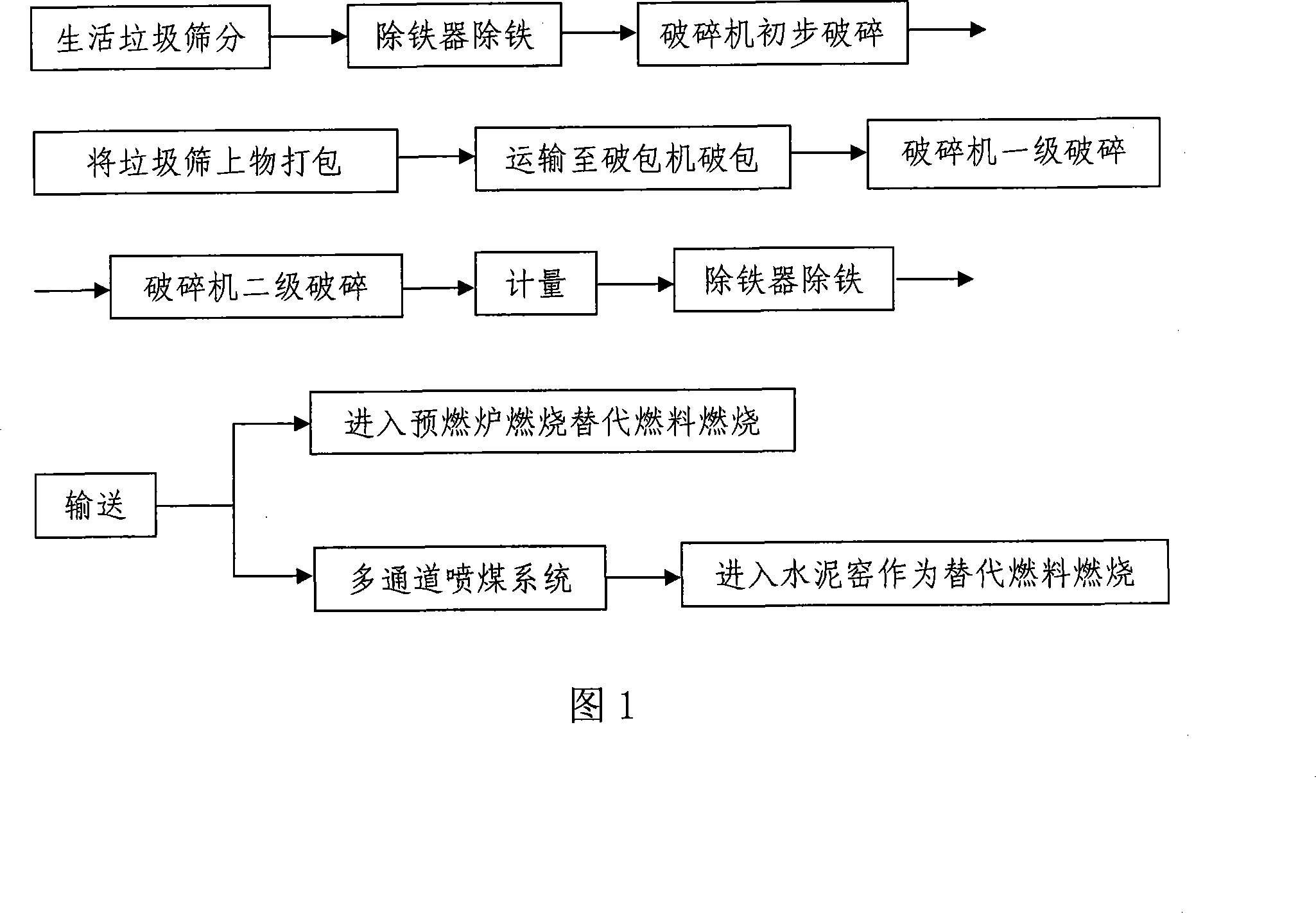

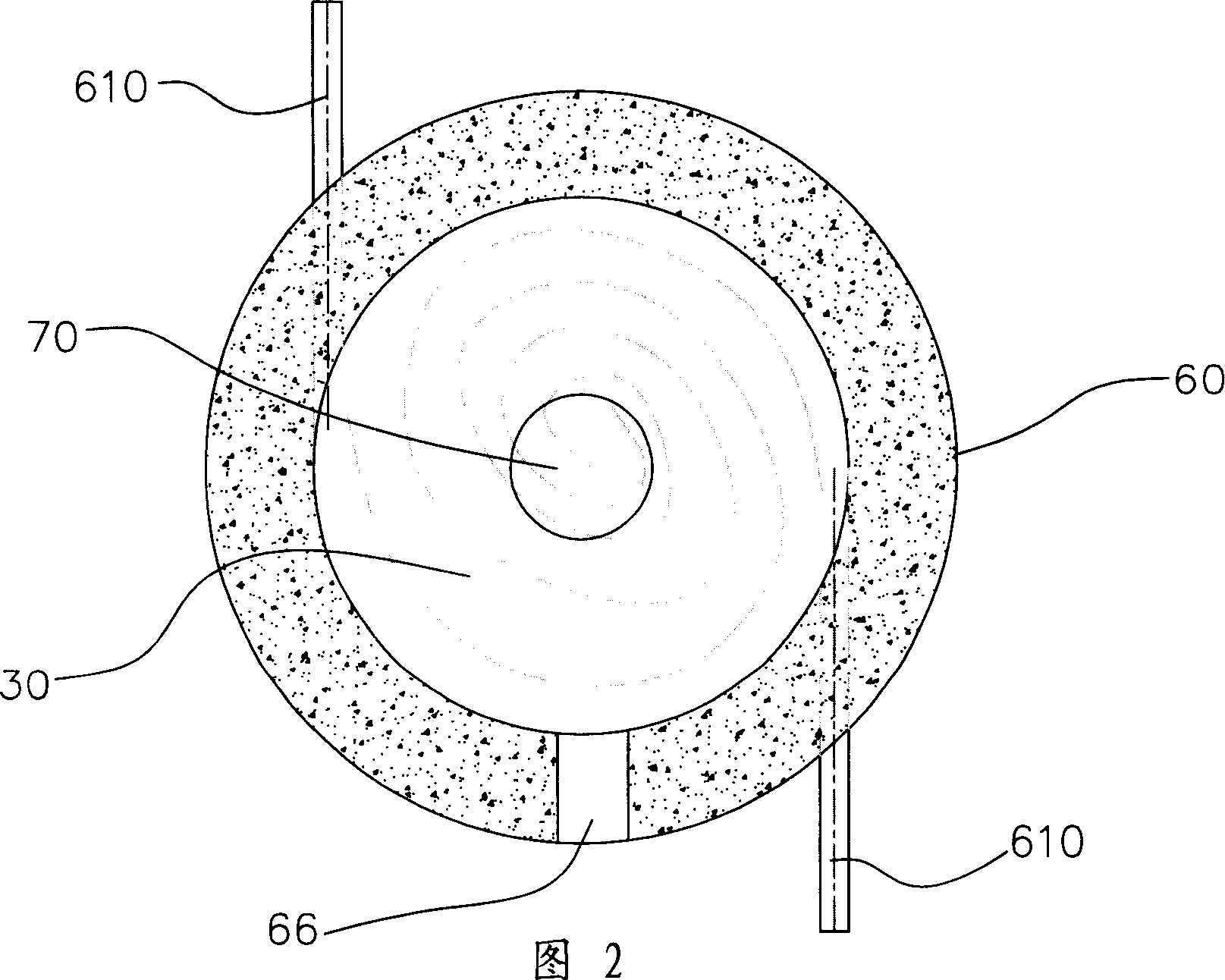

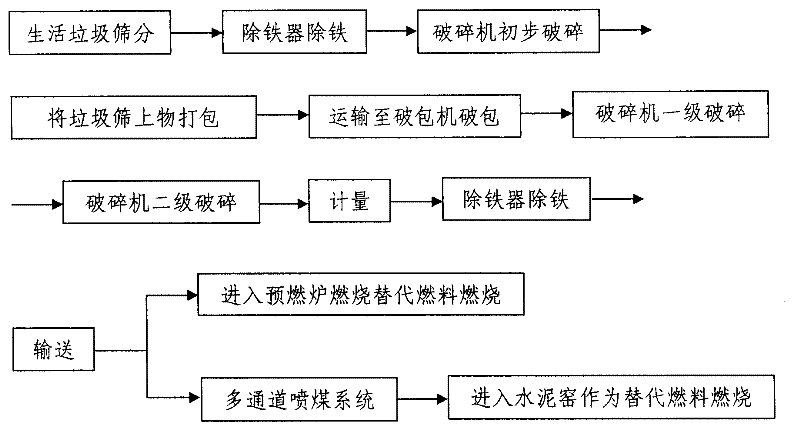

Method for substituting cement kiln fuel with garbage derived overtails

ActiveCN101173196AHigh calorific valueAvoid enteringBiofuelsSolid fuelsAlternative fuelsProcess engineering

The invention relates to a method for adopting waste derivative oversize material as substitute for cement kiln fuel, which is characterized in that the domestic waste in refuse reclamation station is separated and sorted, broken in packages, crushed and completely stirred and mixed, one part of the waste enters a precombustion furnace in the kiln tail of a cement kiln for combustion, while the other part of the waste enters the cement kiln from the kiln hood for combustion, thus the substitute fuel for cement production is produced. The invention has the advantages that the waste derivative oversize material having calorific value is adopted to substitute for industrial fuel in the cement kiln, thus resources of waste derivative oversize material are fully utilized, and coal energy resources are saved; simultaneously the cement kiln has the characteristics of high temperature, large carrying capacity, no residue after waste treatment and no secondary pollution, therefore the invention has the great advantages of energy saving and environmental protection.

Owner:LINGCHUAN JINYU CEMENT

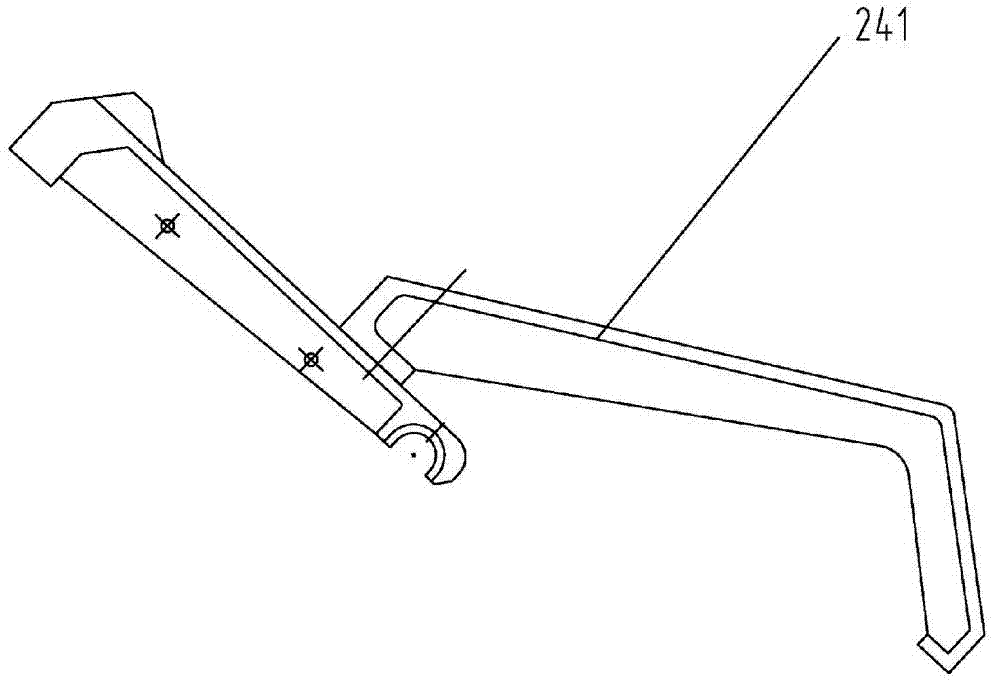

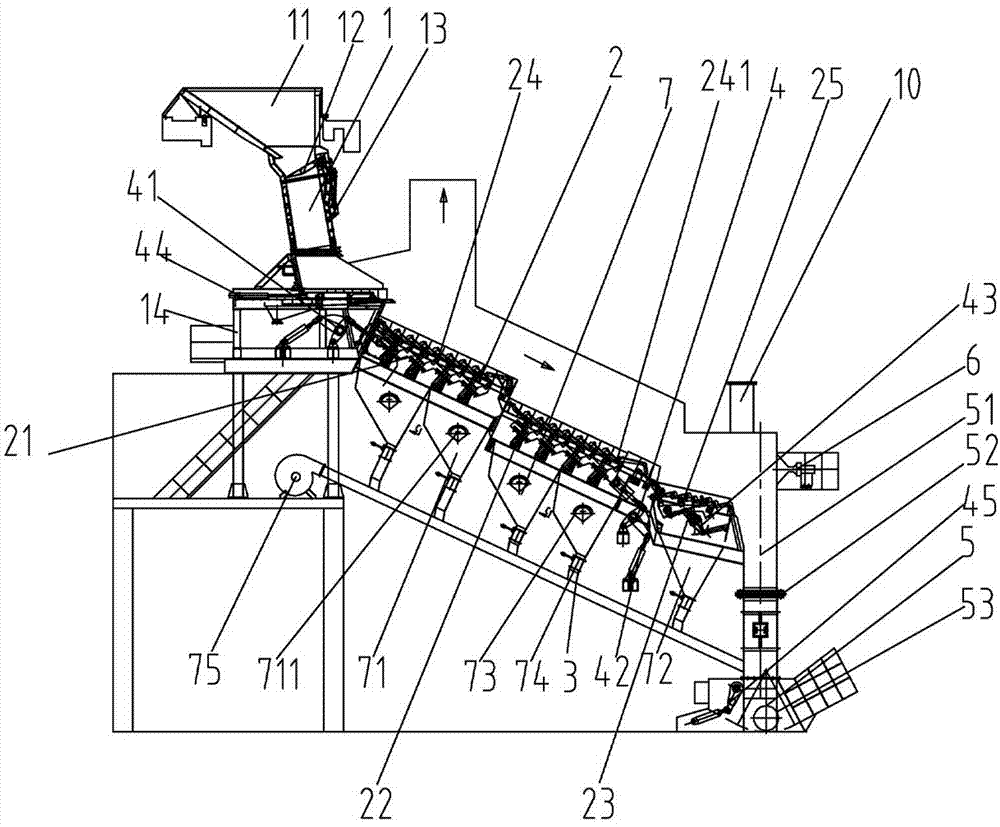

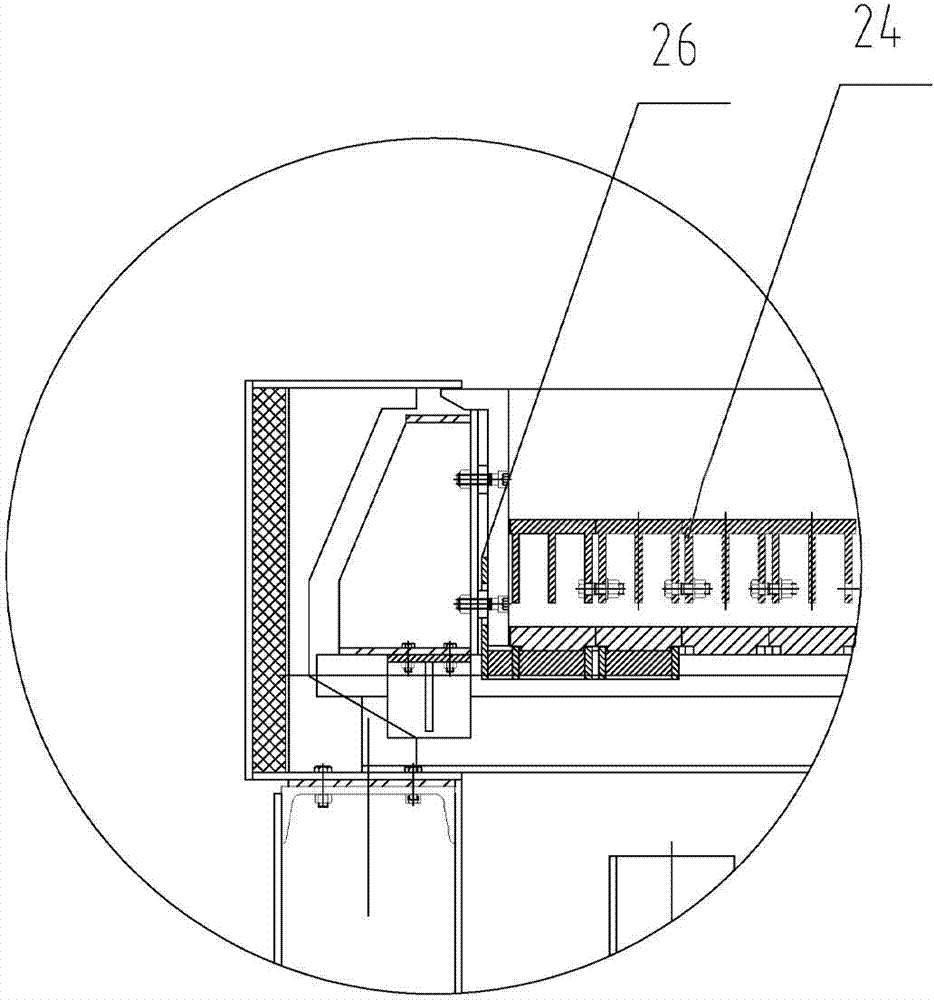

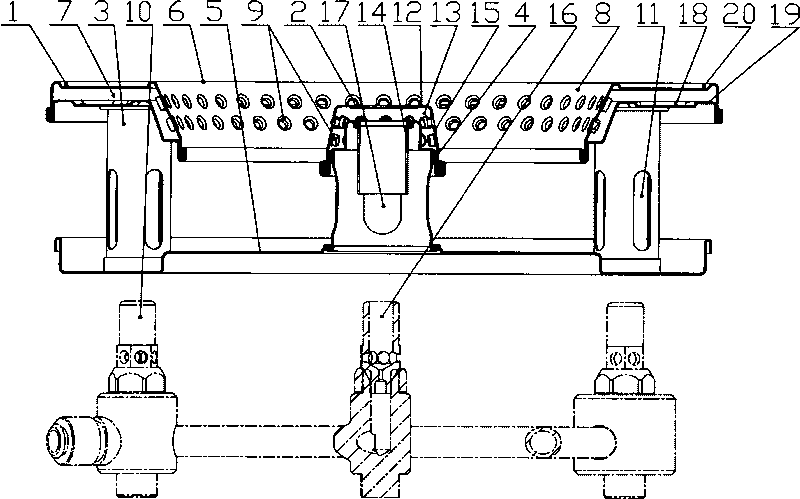

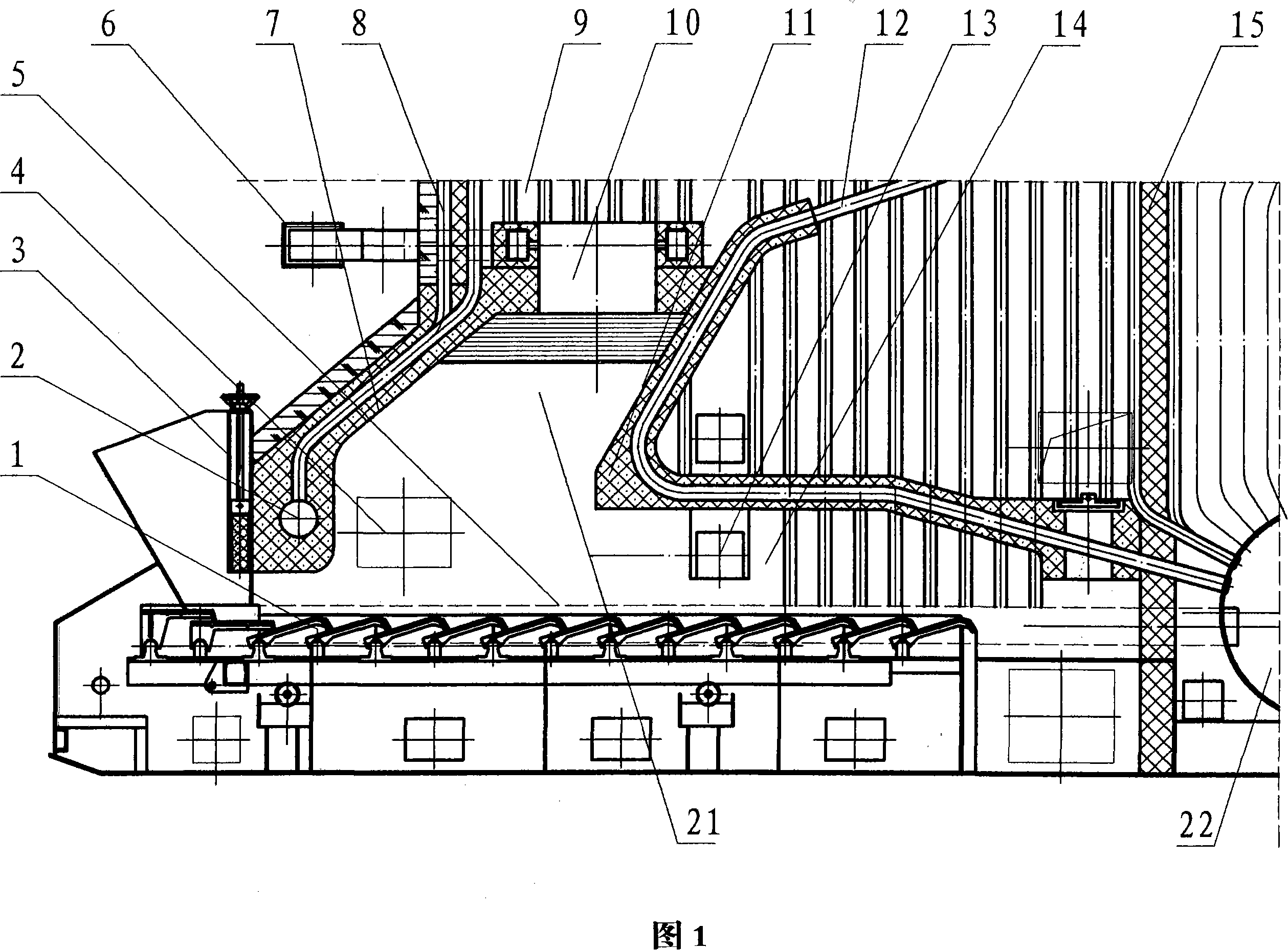

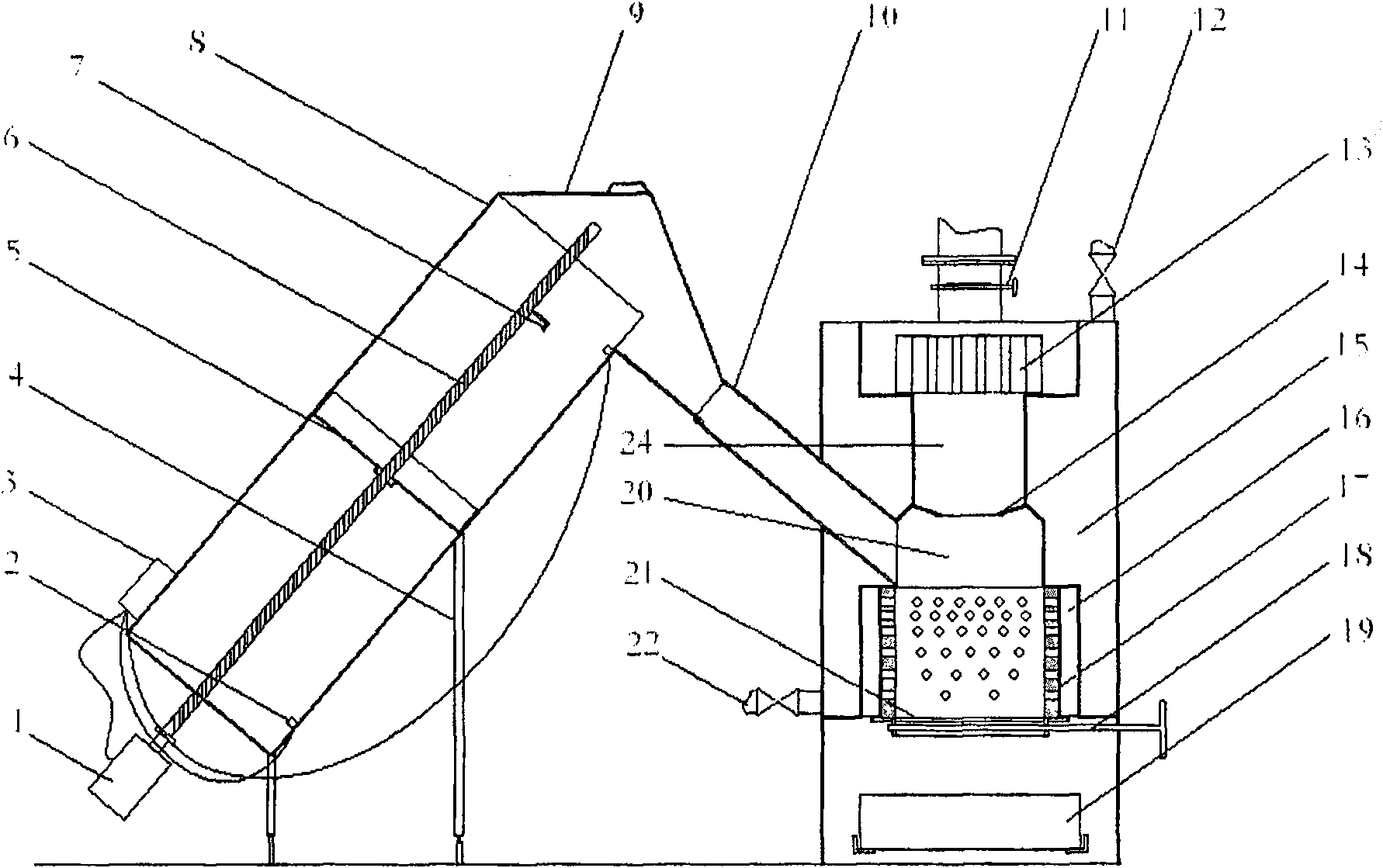

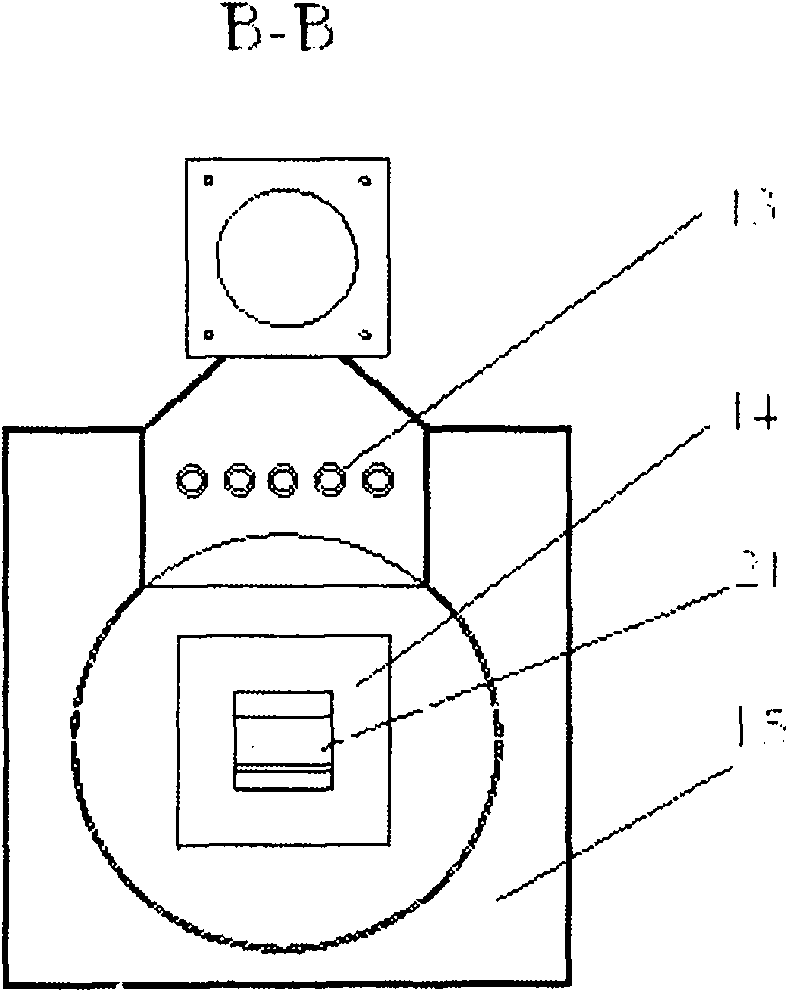

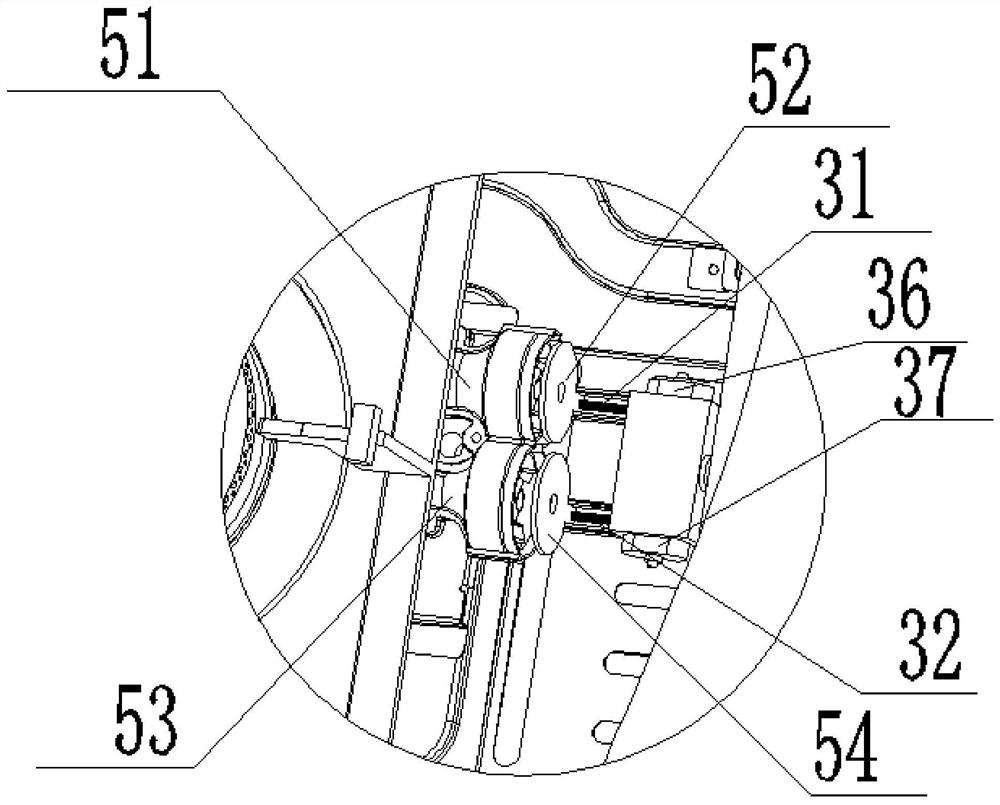

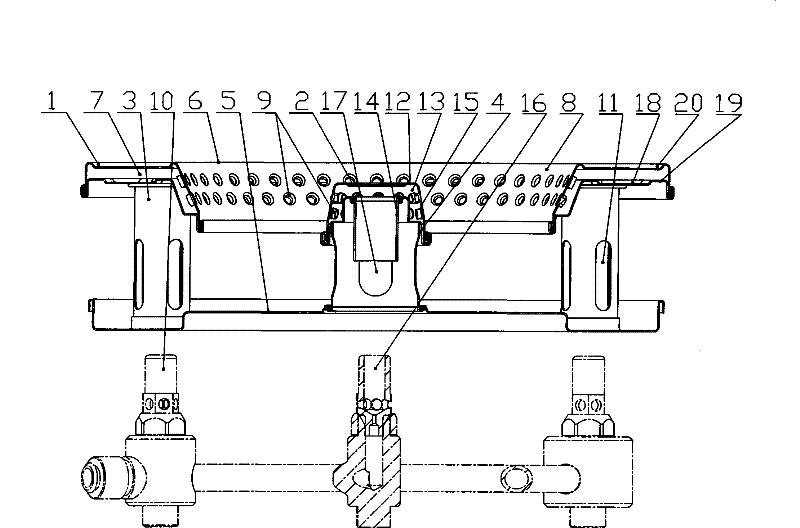

Reciprocating grate furnace with two-section-reverse-acting and one-section-forward-acting grate

InactiveCN102901108AStable combustion conditionsImprove incineration efficiencyIncinerator apparatusCombustionSlag

The invention provides a reciprocating grate furnace with a two-section-reverse-acting and one-section-forward-acting grate. The reciprocating grate furnace with the two-section-reverse-acting and one-section-forward-acting grate provided by the invention comprises a feeding system, a hydraulic device, a grate, an automatic grate control system, a slag discharge device, an air chamber and an ash-placing channel, wherein the grate is divided into a drying section, a combustion section and a burnout section in sequence from top to bottom; a height difference is reserved between every two sections; both the grate bodies of the drying section and the combustion section are in a reverse-acting type; and the grate body of the burnout section is in a forward-acting type. By the reciprocating grate furnace adopting a two-section-reverse-acting and one-section-forward-acting grate structure implemented by the invention, the problems that the conventional mechanical grate furnace is inadequate in drying and incomplete in stirring and scattering, and agglomerates are easily formed during drying and combusting can be solved; the waste incineration efficiency can be improved effectively; the incineration cost can be reduced; and the reciprocating grate furnace is applicable to incinerate the waste with high moisture content and a low calorific value.

Owner:福建省丰泉环保控股有限公司

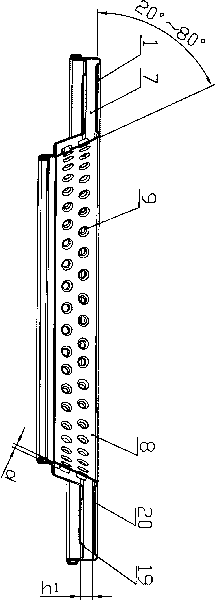

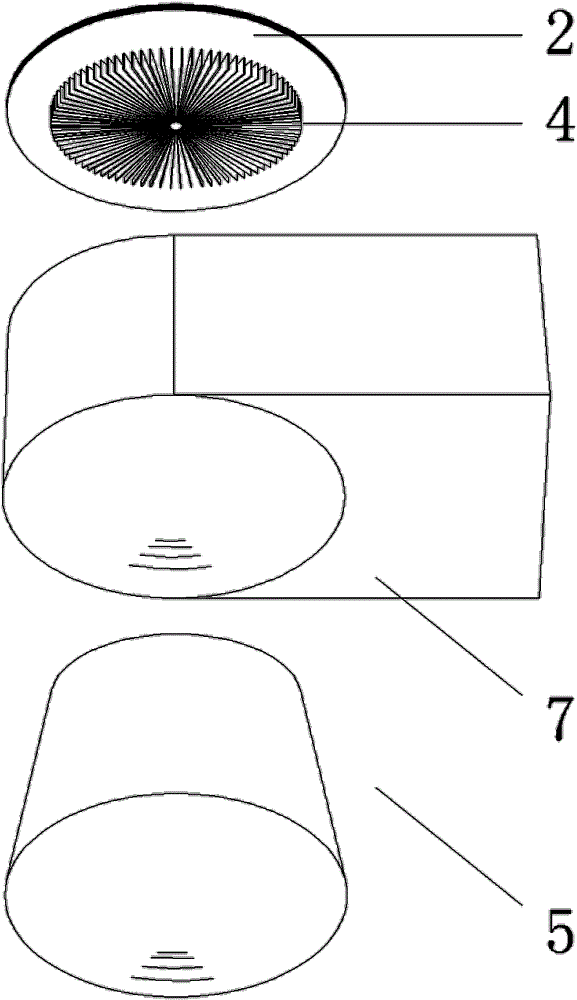

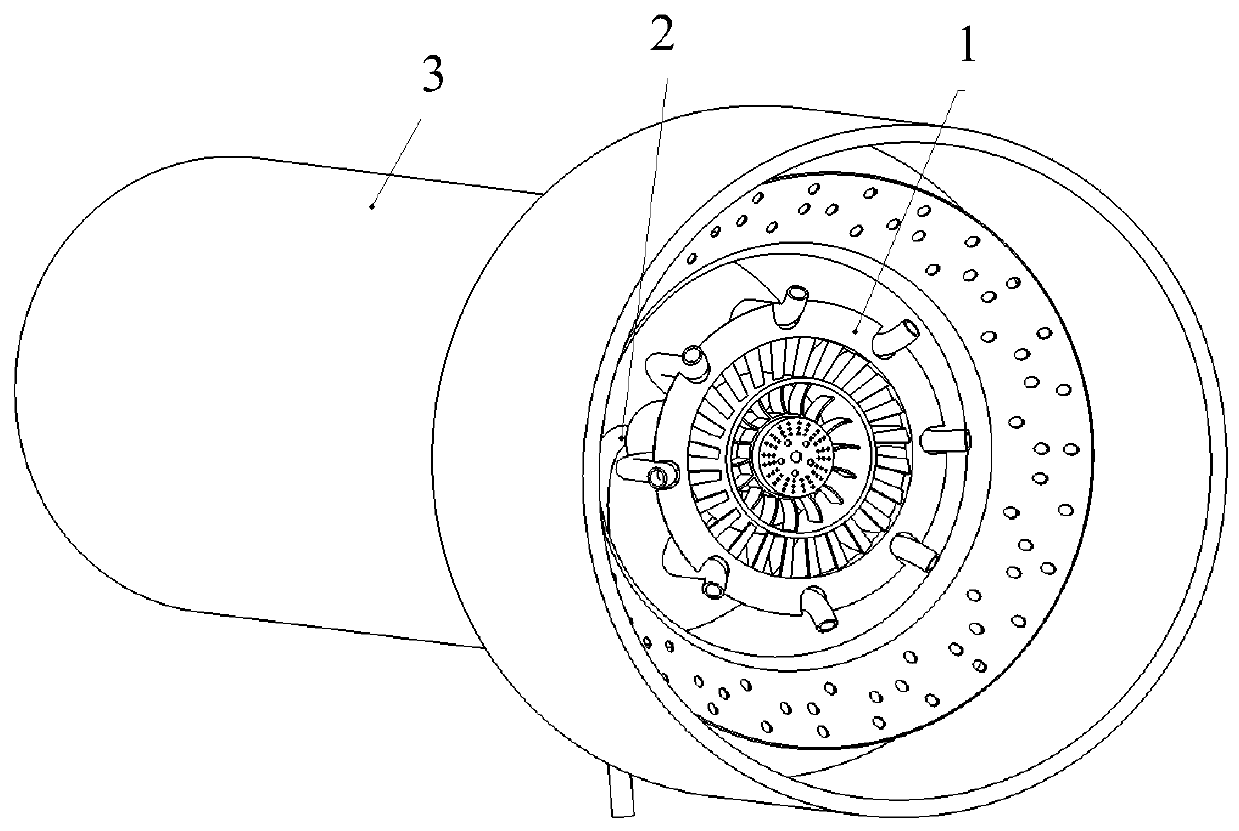

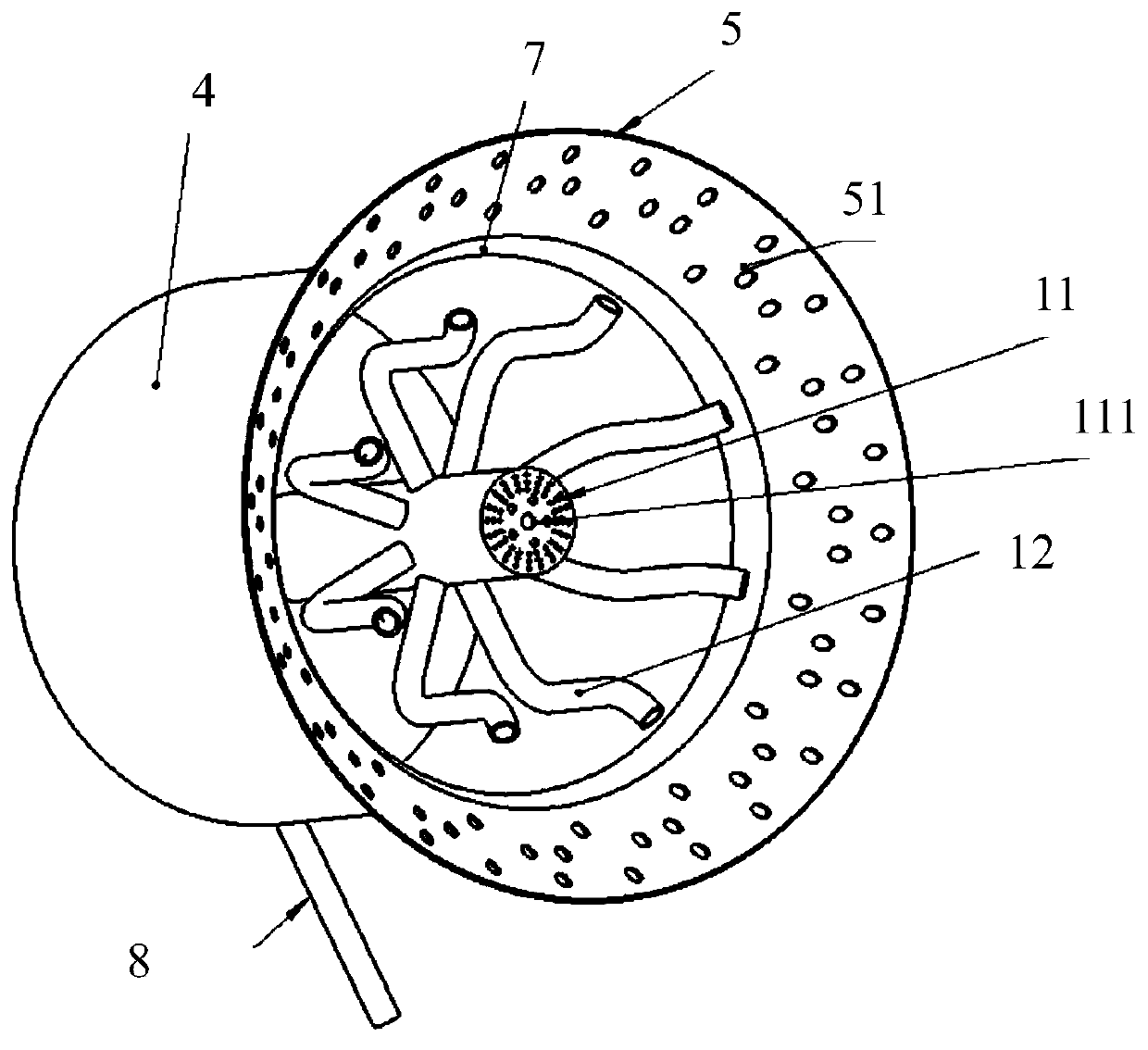

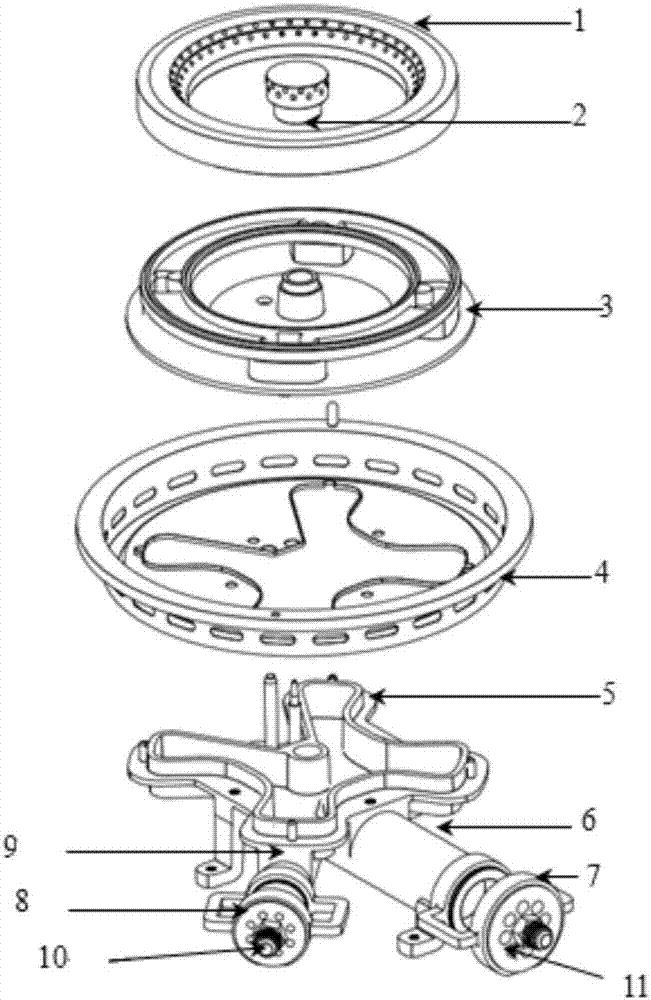

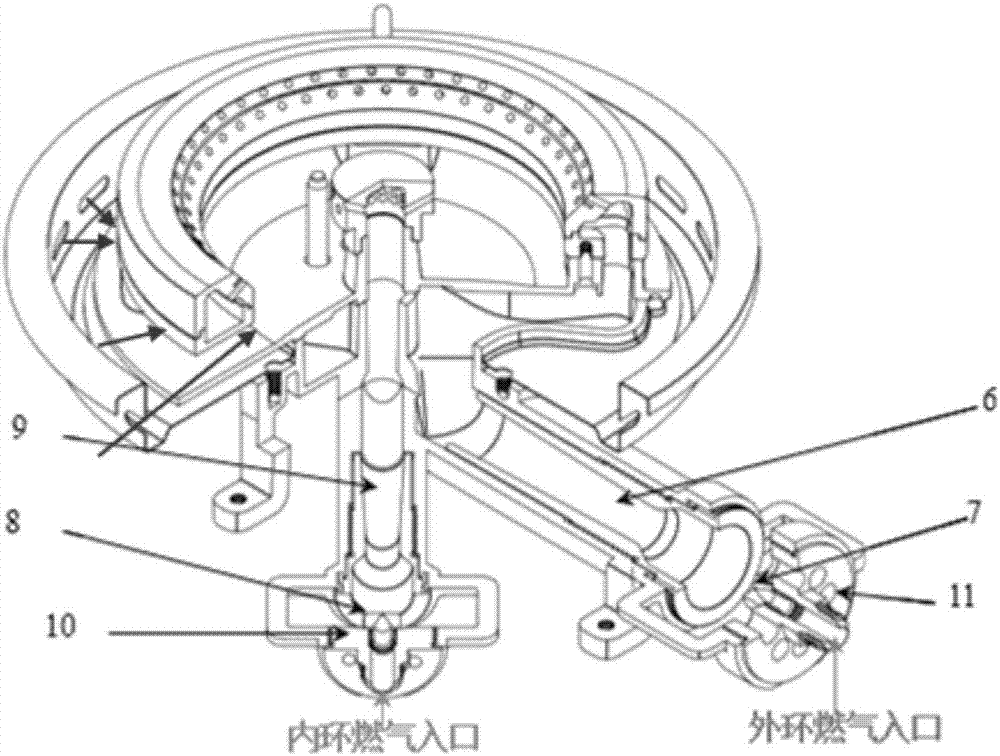

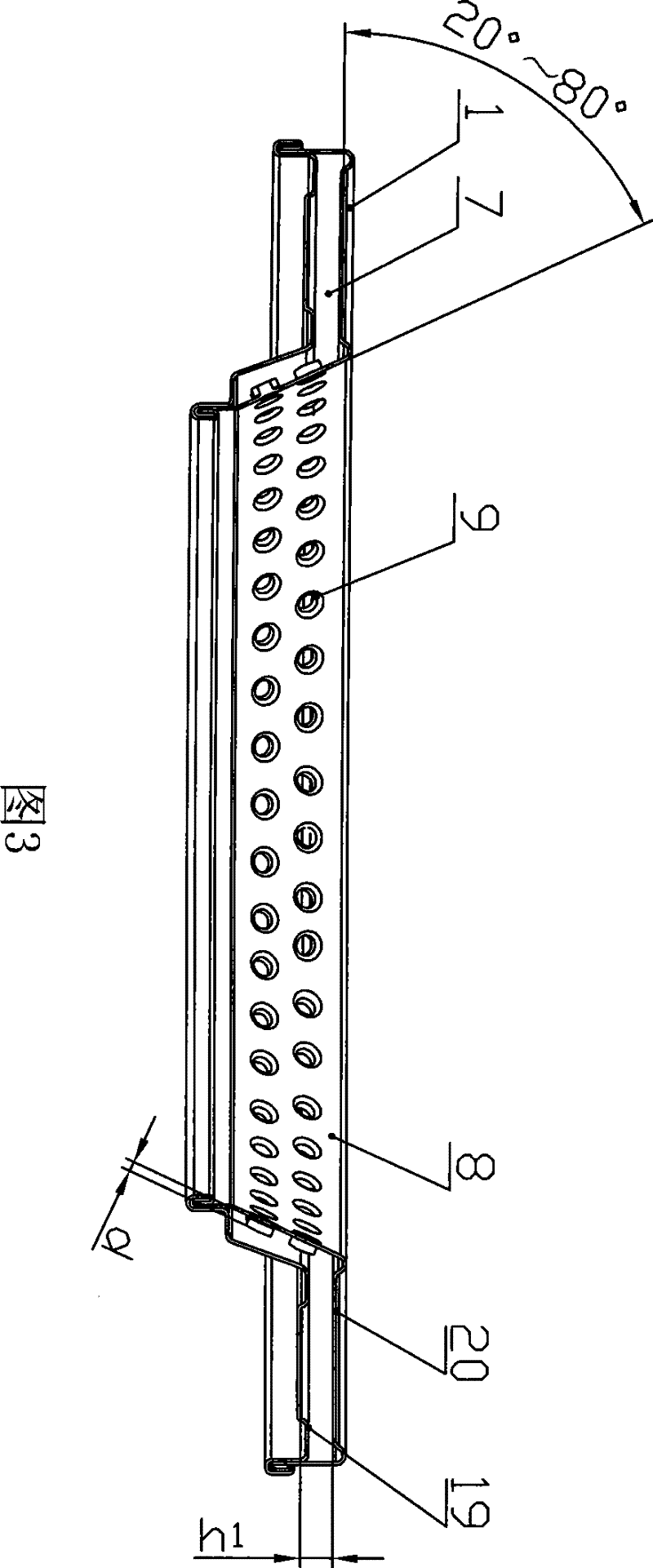

Inner flame energy-concentrating riser pipe type gas burner

ActiveCN101725987AGood energy gathering effectIncrease heat loadGaseous fuel burnerMultiple burner assemblyGas burnerThermal efficiency

The invention discloses an inner flame energy-concentrating riser pipe type gas burner, which comprises a big fire burner, a small fire burner, a mixing tube of the big fire burner, a positioning tube of the small fire burner, and a water collector. An inner ring of an annular shell of the big fire burner is an inverted frustum which forms an angle between 20 and 80 DEG with a horizontal plane, and 1 to 5 fire exhaust holes are formed on the inner ring. One end of the mixing tube of the big fire burner is connected with the annular shell and communicated with an inner cavity of the annular shell, while the other end is communicated with a big fire nozzle which is arranged on the lower part of the water collector. The small fire burner comprises a frustum cap shell and an inner cavity of the frustum cap shell, wherein 1 to 5 fire exhaust holes are formed on external side face of the frustum cap shell, and the inner cavity of the frustum cap shell is communicated with a small fire nozzle which is positioned on the lower part of the water collector by a mixing tube of the small fire burner. The inner flame energy-concentrating riser pipe type gas burner has the advantages of reasonable structure, high thermal efficiency, material conservation, convenient processing, excellent energy-saving effect, less exhaust emission and the like.

Owner:三峰实业有限公司

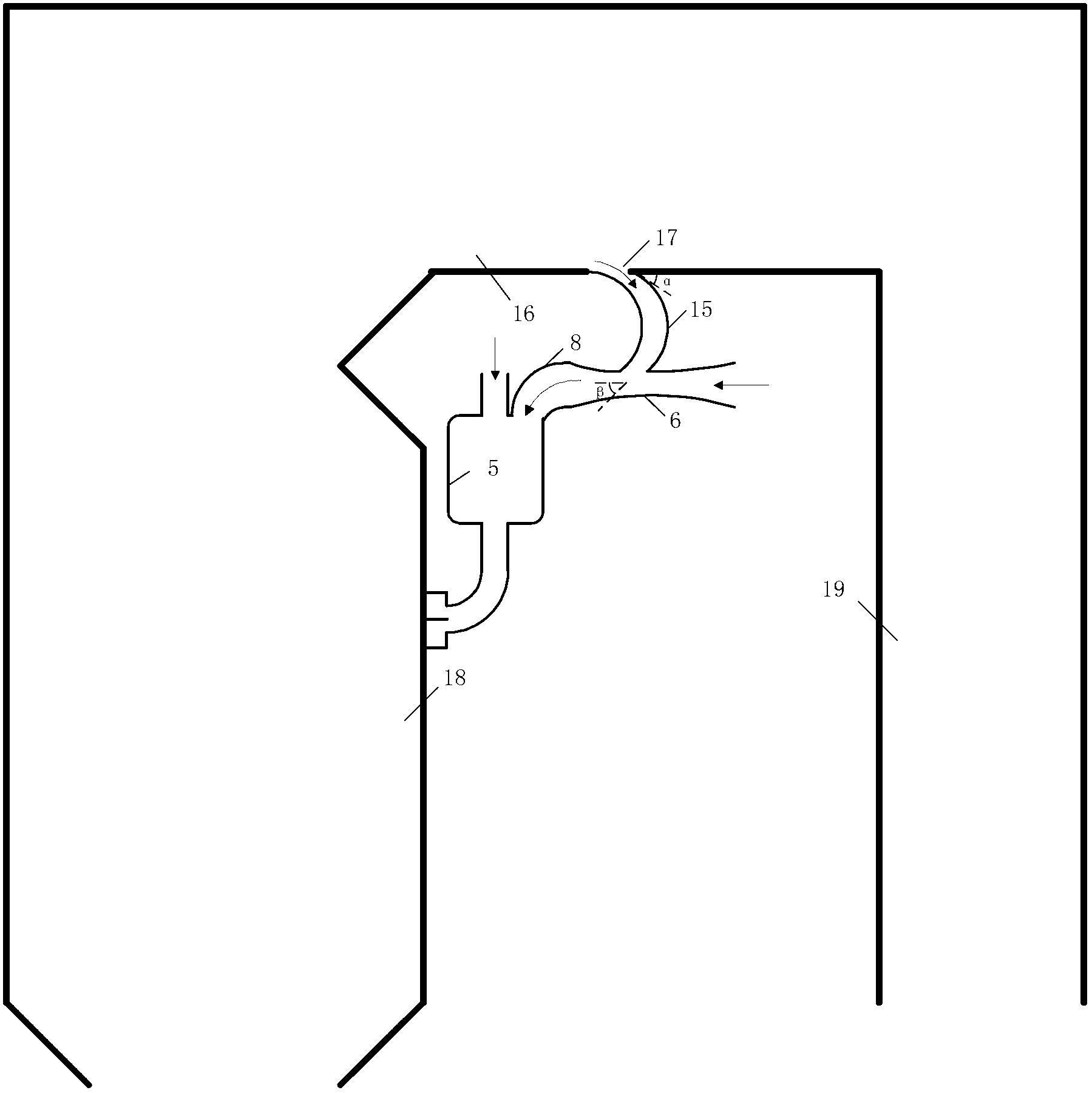

Low-load burner capable of achieving boiler flue heat recycling for boiler

ActiveCN103175199AStable combustion conditionsFully ignitePulverulent fuel combustion burnersGranular/pulverulent flues gasificationCombustorLow load

The invention discloses a low-load burner capable of achieving boiler flue heat recycling for a boiler. The low-load burner capable of achieving boiler flue heat recycling for the boiler comprises a front-end wind-powder pipeline, a coal pyrolysis chamber, a coal pyrolysis gas nozzle, a smoke guiding pipeline, a Laval nozzle, and an air supply duct, wherein the front end of the air supply duct is communicated with an inlet end of the coal pyrolysis chamber, and is connected with the wind-powder pipeline in parallel and jointes at the inlet end of the coal pyrolysis chamber, the rear end of the air supply pipeline is communicated with the front end of the Laval nozzle, the rear end of the Laval nozzle is used for connecting an air feeder, the Laval nozzle is arranged in a transverse mode, the smoke guiding pipeline is a bent pipe arranged in a vertical mode, the upper end of the smoke guiding pipeline is used for communicating with a horizontal boiler flue and the lower end of the smoke guiding pipeline is communicated with the throat portion of the Laval nozzle, and high temperature flue gas in the horizontal boiler flue is guided into the coal pyrolysis chamber through the smoke guiding pipeline to provide a heat source for coal powder pyrolysis. The low-load burner capable of achieving boiler flue heat recycling for the boiler is simple in structure and capable of achieving low-load stable operation of an adjusting peak set, and operation efficiency and safety of the set are improved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Garbage incinerator capable of measuring garbage thickness and method for measuring garbage thickness

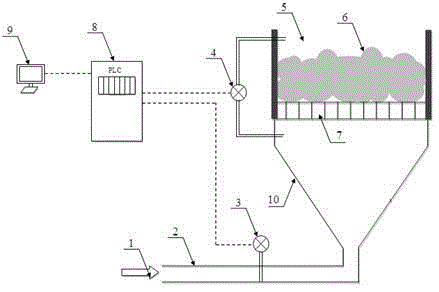

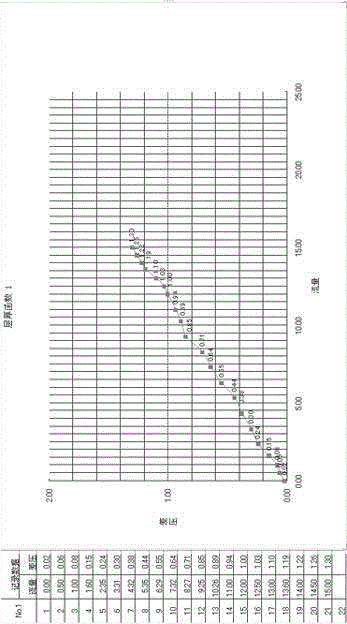

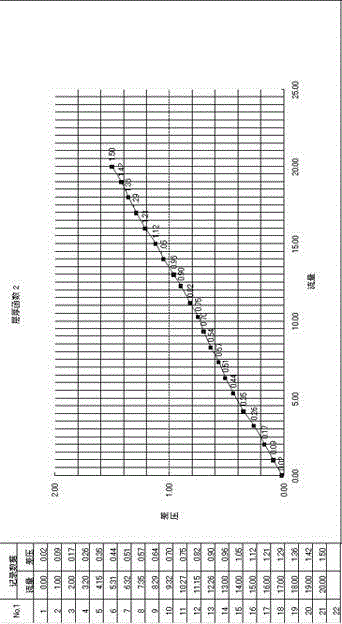

InactiveCN102865582AAutomatic measurement is validConvenient automatic measurementIncinerator apparatusCombustion chamberDifferential pressure

The invention relates to a garbage incinerator capable of measuring garbage thickness. The garbage incinerator comprises a combustion air pipeline, a combustion chamber and a multistage furnace grate, wherein the combustion air pipeline is communicated with the combustion chamber and an air supply chamber is also arranged between the combustion air pipeline and the combustion chamber. The garbage incinerator also comprises a flowmeter for measuring air flow in the combustion air pipeline, a differential pressure transmitter for measuring the pressure difference between the combustion chamber and the air supply chamber, and a data processing unit which converts readings to required pressure data and flow data. The method for measuring garbage thickness in the garbage incinerator comprises the following steps: obtaining a garbage thickness value k by virtue of the function y=nkx according to the air flow data x(kPa) of the combustion air pipeline and the pressure difference data y(km3 / h) between the combustion chamber and the air supply chamber; and comparing x1 and y1 in real-time measurement, where x1 / y1=k1, and if k1 is larger than nk, the garbage thickness is large, and otherwise the garbage thickness is small; and thereby adjusting garbage feeding and multistage furnace grate speed.

Owner:上海南一环保科技有限公司

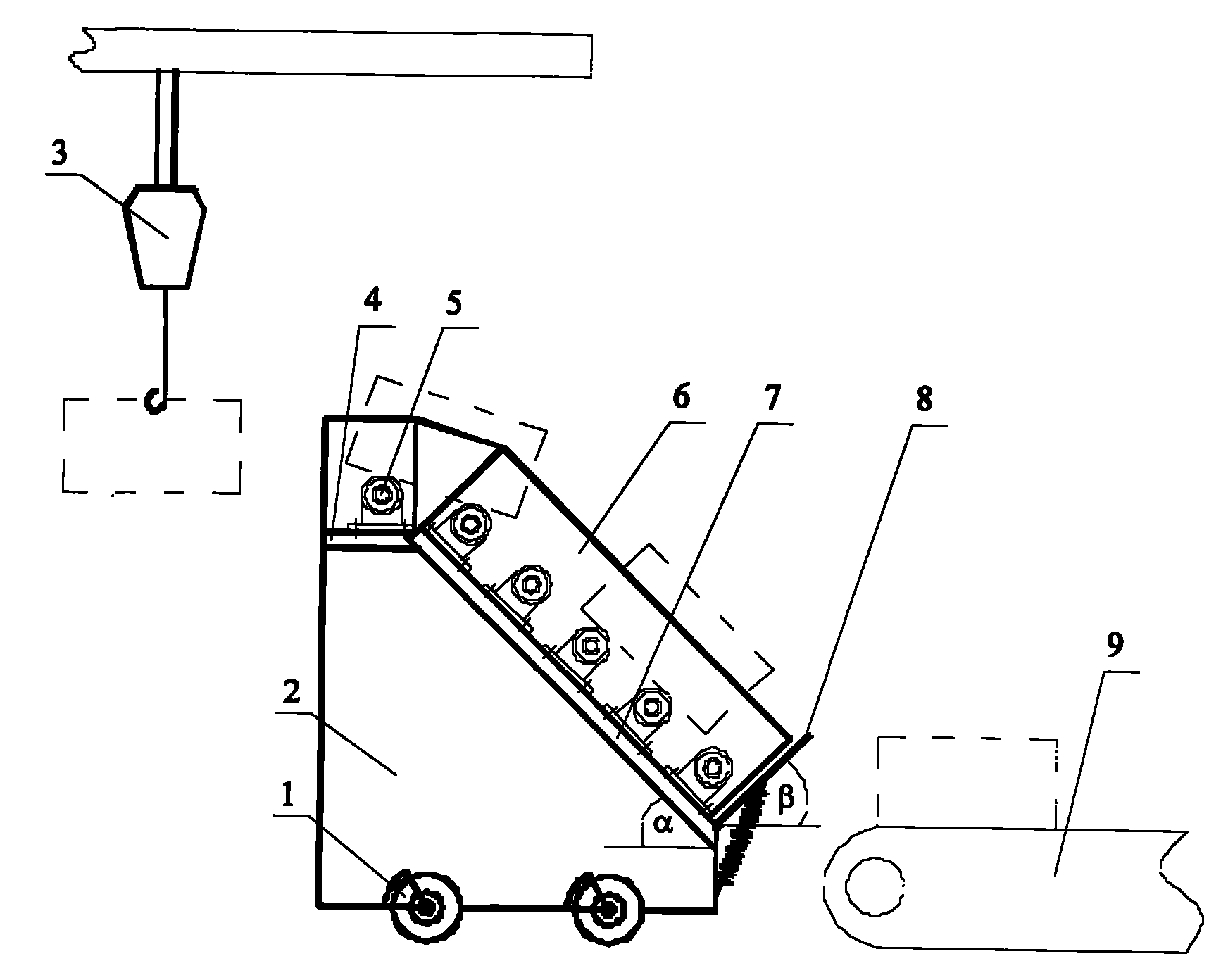

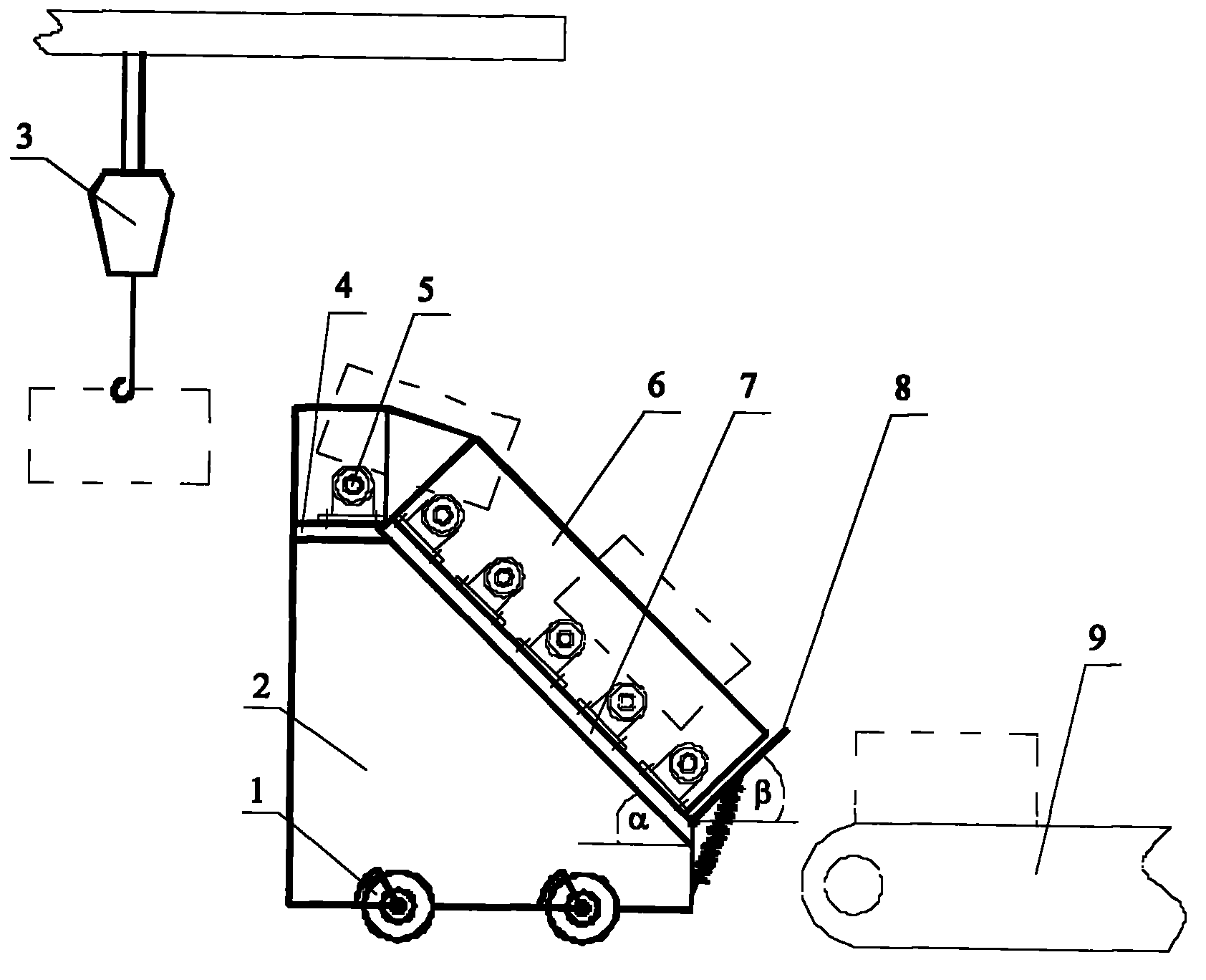

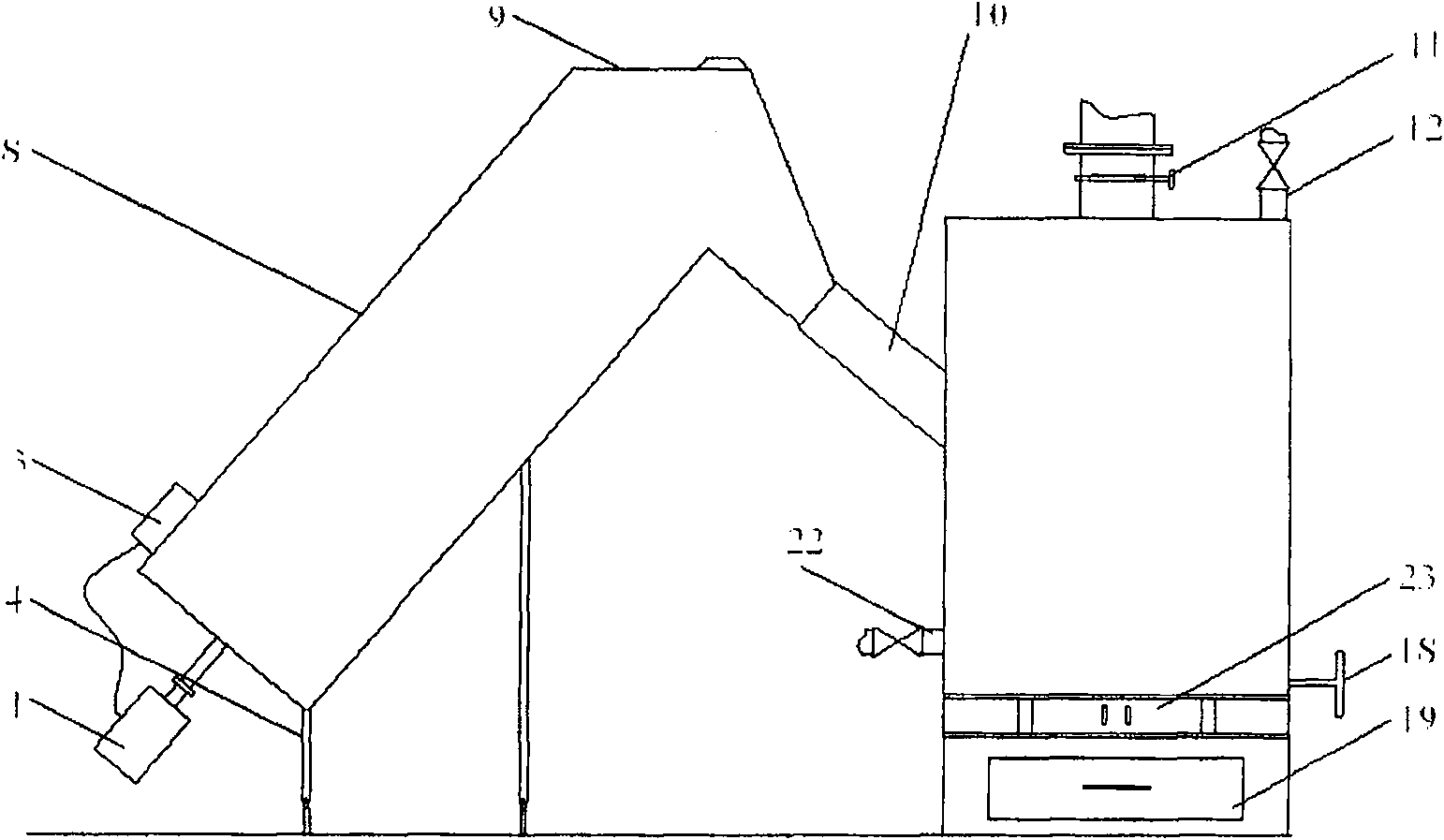

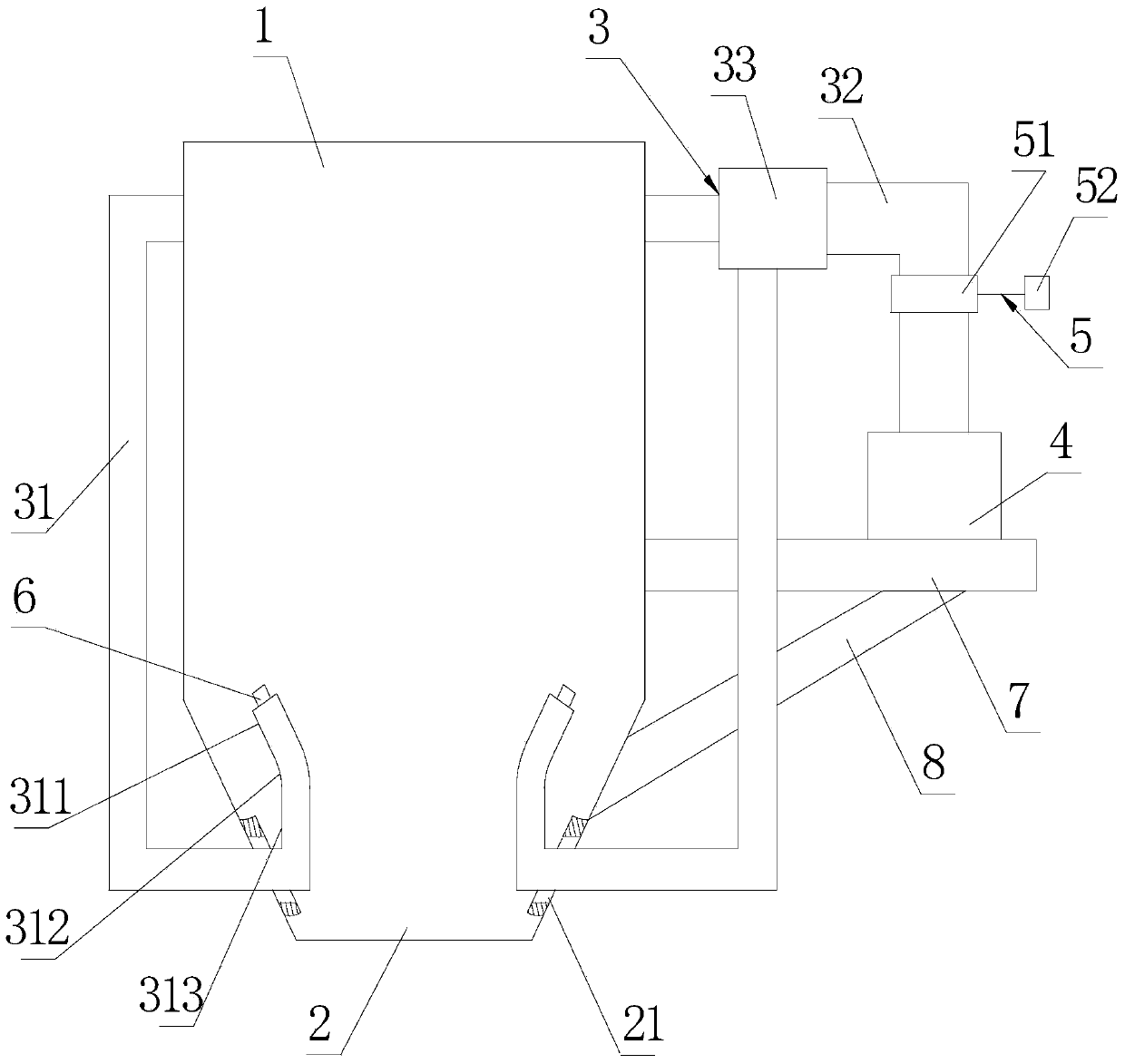

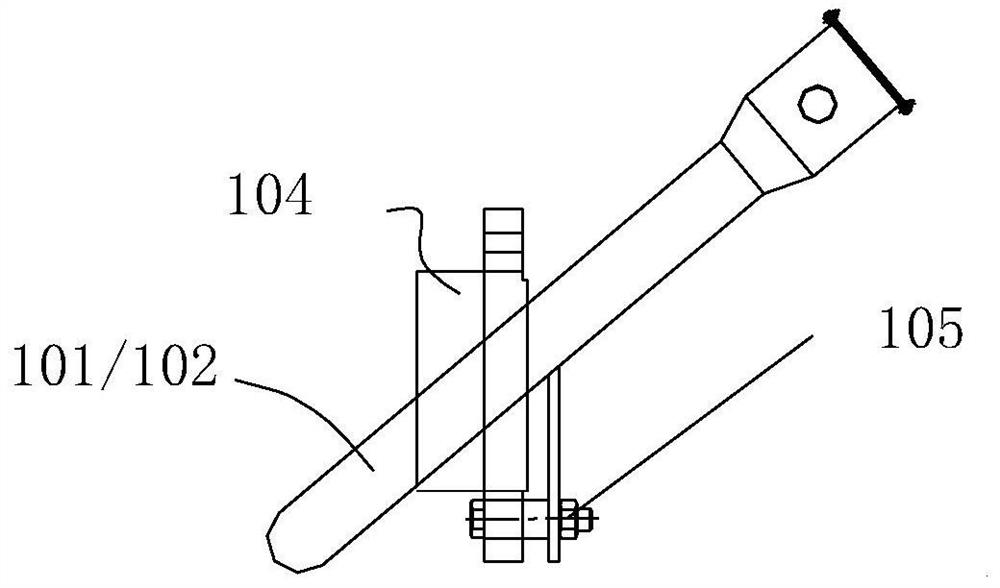

Bundled biomass feeding device

InactiveCN101949547AStable combustion conditionsSimple structureLump/pulverulent fuel feeder/distributionCombustionEngineering

The invention relates to a bundled biomass feeding device. The bundled biomass feeding device consists of a crane and a mobile platform, wherein the crane is arranged above the mobile platform; the mobile platform has a trapezoid structure; the inclined section of the trapezoid structure of the mobile platform is a self-sliding slope; the included angle of the self-sliding slope and the horizontal direction is more than 45 DEG and less than 90 DEG; the upper horizontal surfaces of the self-sliding slope and the mobile platform are provided with rollers; both sides of the upper horizontal surfaces of the self-sliding slope and the mobile platform are provided with guard boards; and the bottom of the self-sliding slope is provided with a rotary lapping baffle plate. The bundled biomass feeding device solves the problems of unstable feeding and easy abrasion of the feeding device of combustion equipment taking bundled biomass as fuel. The bundled biomass feeding device has the advantages of simple equipment structure, small investment, simple operation, stable operation and the like.

Owner:TSINGHUA UNIV +1

Closed gas stove

InactiveCN105091040AImprove efficiencyConducive to intelligenceDomestic stoves or rangesLighting and heating apparatusProcess engineeringCombustion chamber

A closed gas stove comprises a burner, a stove face, a stove shell, a heat conductor, a combustor, a flue gas channel and the like, wherein the burner and the combustor are arranged in a hearth; the combustor is of a semi-closed or fully-closed structure; and the gas stove is provided with the heat conductor composed of heat conductive blocks and fins, the heat conductive blocks are exposed and are connected with or make contact with the fins, and the fins are used for enhancing the flame or flue gas heat energy absorbing or transferring capacity of the heat conductive blocks. The closed gas stove has the beneficial effects that the heat efficiency is higher than that of a common gas stove, appearance is more elegant, and dirt is avoided.

Owner:彭萍芳

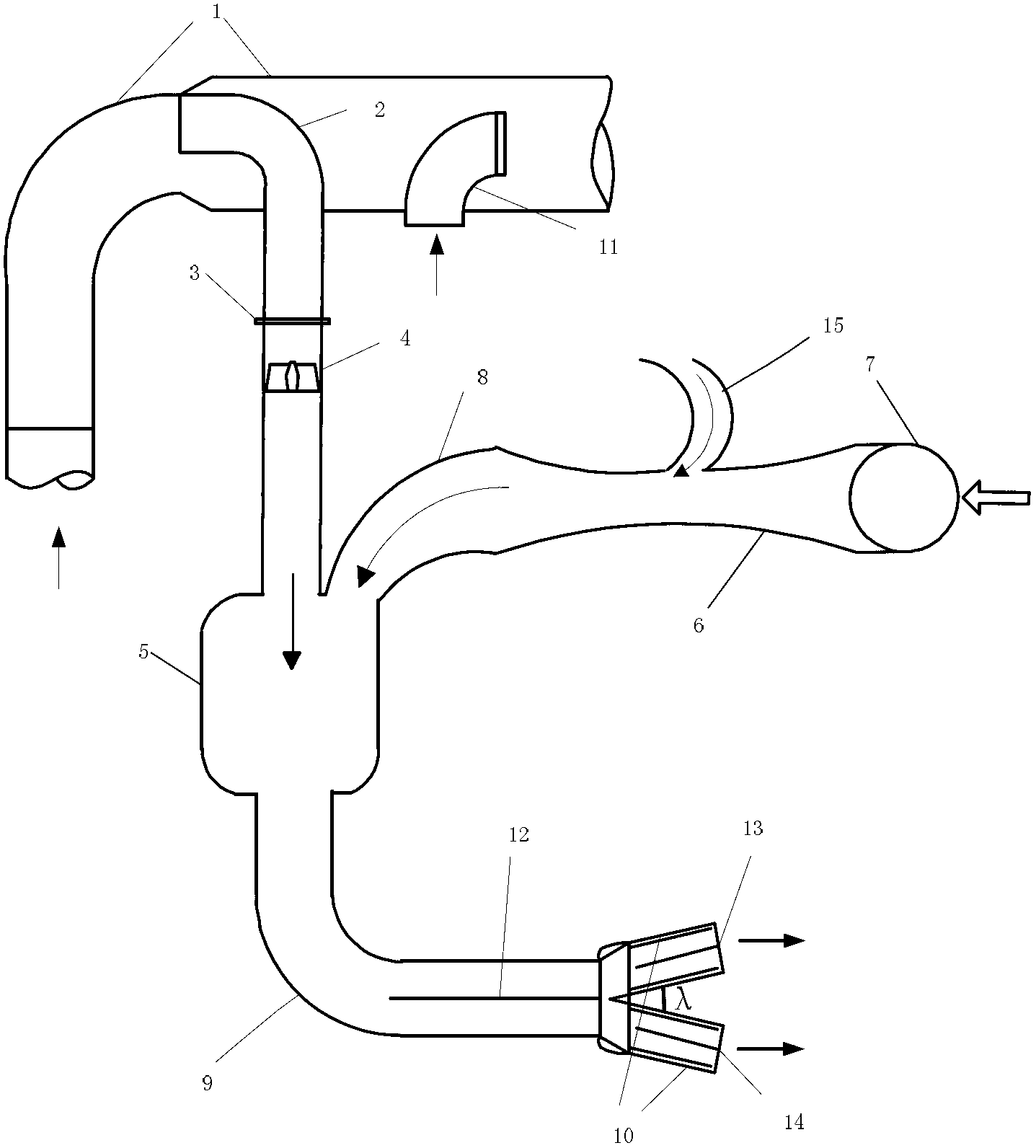

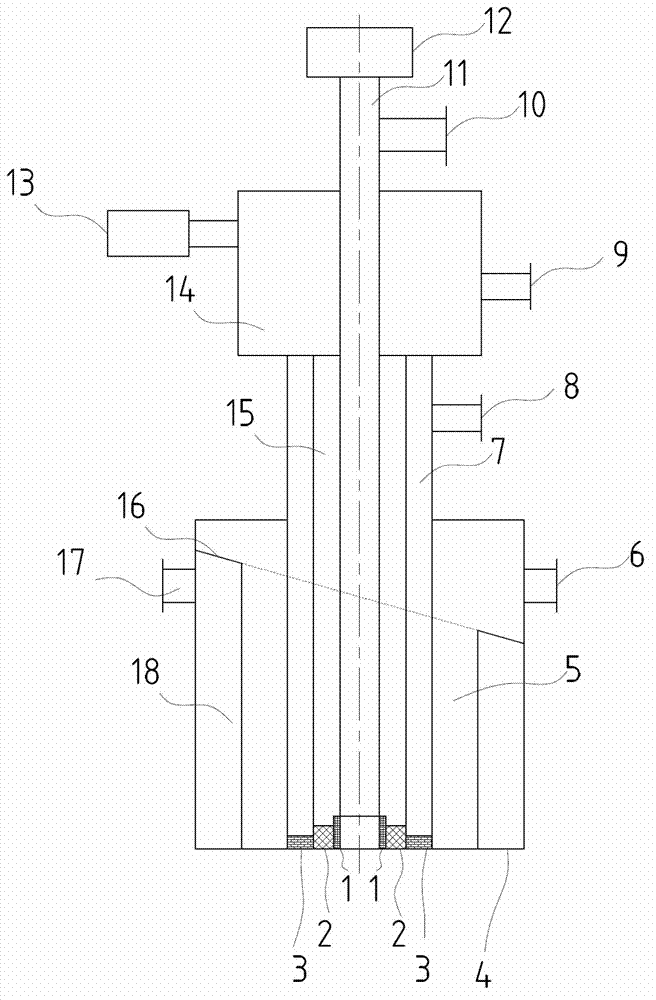

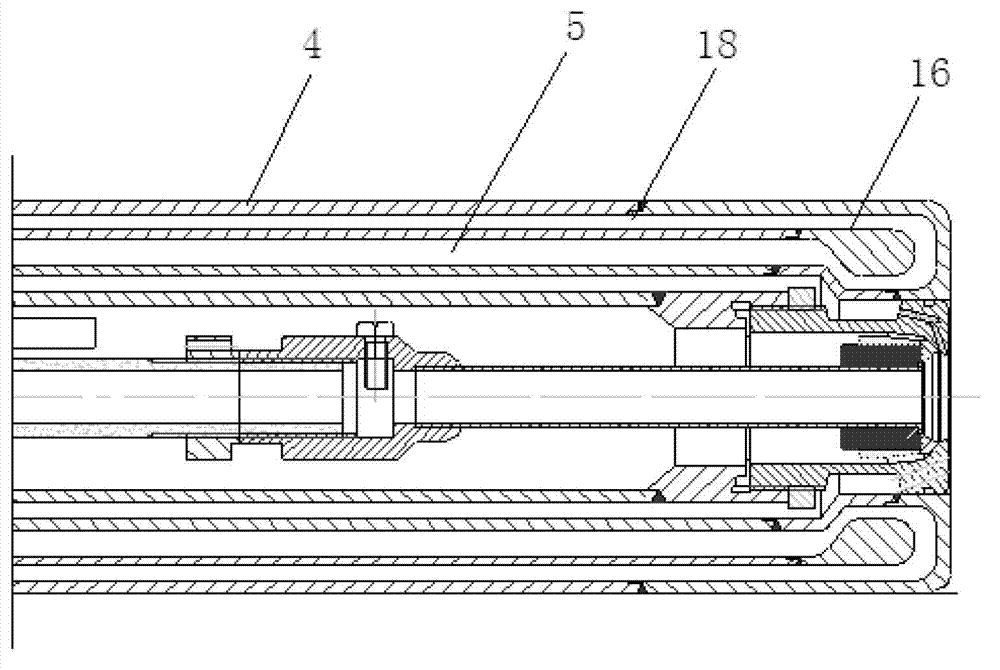

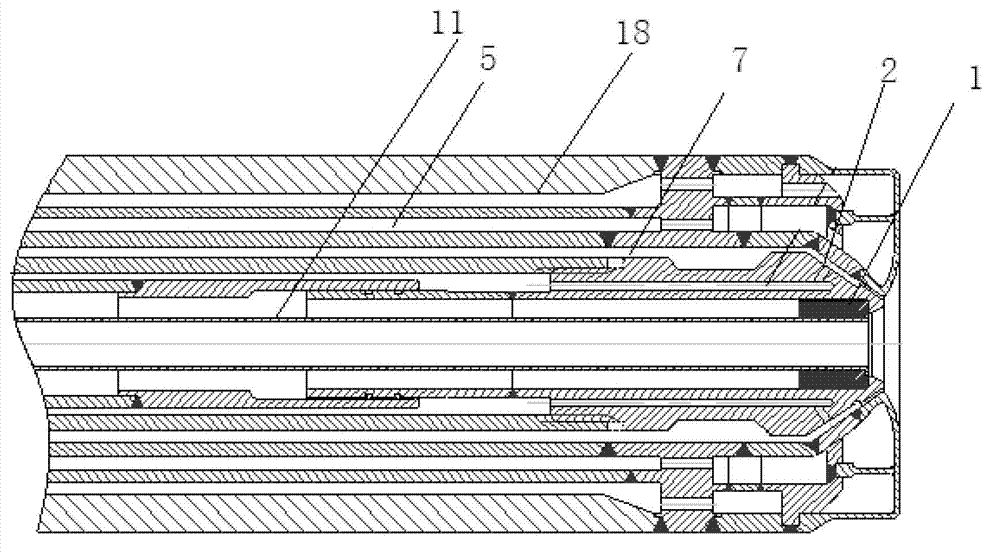

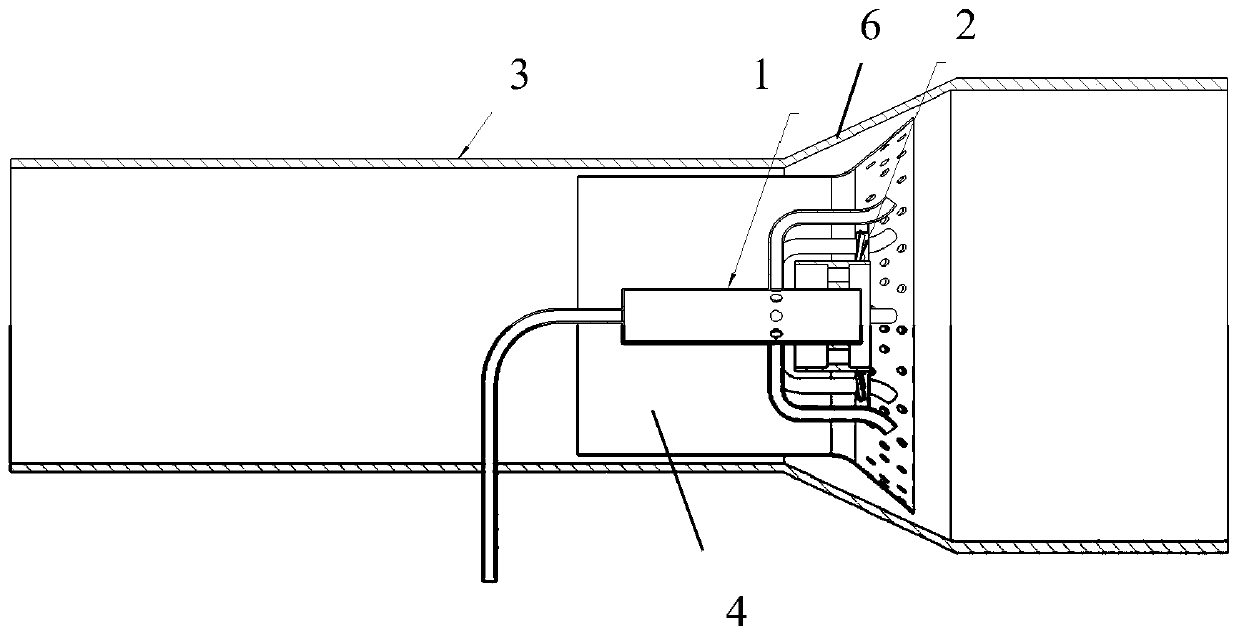

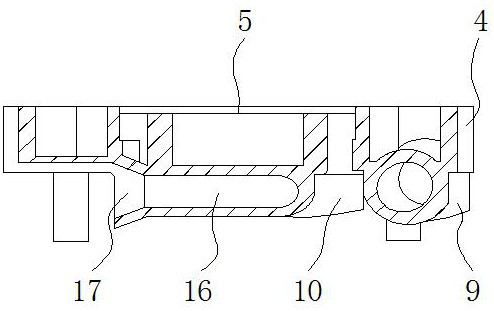

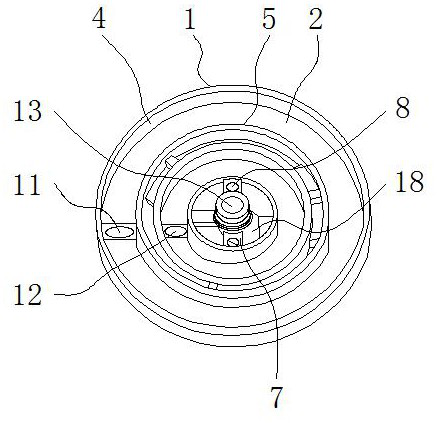

Integral gasification furnace ignition device under pressure

ActiveCN102954490AStrong anti-pollution abilityIncrease ignition energyCombustion ignitionHigh energyEngineering

The invention belongs to the technical field of a structural design of a gasification furnace, in particular to an integral gasification furnace ignition device, which comprises a high energy igniter (1), a fuel nozzle (2), an oxygen nozzle (3), a water jacket (4), an oxygen delivery pipe (7), a central pipe (11), a flame detector (12), an igniter power supply connecting piece (13), a flange end seat (14) and a fuel delivery pipe (15), wherein the high energy igniter (1), the fuel nozzle (2), the oxygen nozzle (3) and the water jacket (4) are coaxially sleeved from inside to outside; the high energy igniter (1) is in cup joint with the central pipe (11) so as to be used as a flame detecting opening; the speed and the flow of fuel are controlled through a chute on the fuel nozzle (2); the speed and the flow of oxygen required by combustion of a nozzle are controlled by holes on the oxygen nozzle (3); the high energy igniter power supply (13) is conducmmunicated with the high energy igniter (1); and the water jacket (4) is used for cooling protection. The integral gasification furnace ignition device can be used for realizing stable ignition under pressurization condition.

Owner:NO 711 RES INST CHINA SHIPPING HEAVY IND GRP

Graded low-nitrogen gas combustor based on rotational flow

The invention provides a graded low-nitrogen gas combustor based on rotational flow. The graded low-nitrogen gas combustor comprises a combustor barrel body, a connecting barrel body and a combustor hood which are sequentially arranged, the diameter of the combustor barrel body is smaller than that of the combustor hood, the diameter of the connecting barrel body is gradually increased in the direction from the combustor barrel body to the combustor hood, a rotational flow flame stabilizing disc is further arranged between a main fuel gas spray pipe and an auxiliary fuel gas spray pipe, the rotational flow flame stabilizing disc comprises a first cylinder and a second cylinder which are coaxially arranged, the first cylinder is arranged inside the second cylinder, a first rotational flow blade is arranged between the first cylinder and the second cylinder, a flame stabilizing disc end part is further arranged in the circumferential direction of the second cylinder, a second rotationalflow blade is arranged between the second cylinder and the flame stabilizing disc end part, and the distance between the first rotational flow blade and the combustor barrel body in the central axis direction is smaller than the distance between the second rotational flow blade and the combustor barrel body in the central axis direction. By means of the technical scheme, the mixing degree of gas can be enhanced, and therefore the key performance of a combustor is improved.

Owner:HUAQIAO UNIVERSITY

Afterheat recovering device and dry slag-discharging boiler with same

The invention relates to an afterheat recovering device for a boiler and in particular provides the afterheat recovering device for a dry slag-discharging boiler. The afterheat recovering device substitutes a transition slag hopper (slag well) of the boiler or is arranged in the transition slag hopper (slag well) for absorbing the radiant heat from the bottom of the boiler in a running process of the boiler and the heat of high-temperature ash slag, is connected to a condensate pump of a steam turbine or an outlet of a first-stage low-pressure regenerative heater and transfers the absorber heat to an inlet of a second-stage regenerative heater. The afterheat recovering device can further absorb the heat of the high-temperature ash slag and the radiant heat from the bottom of the boiler on the basis of a dry slag-discharging system of the boiler so as to improve the thermal efficiency of the boiler and improve the adaptability of the traditional air-cooled dry slag-discharging system to the changes of the coal quality and slag-discharging amount of the boiler.

Owner:任振伟

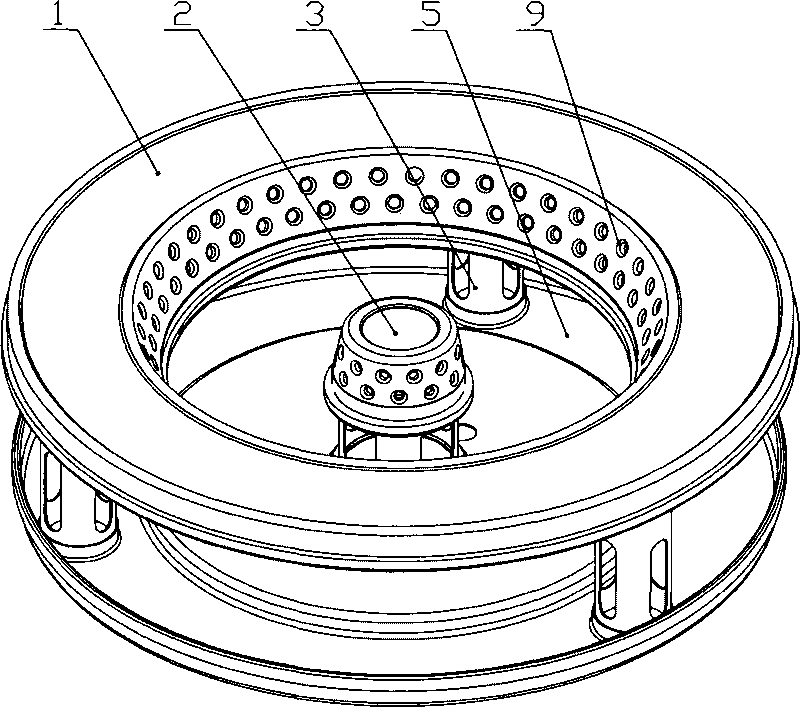

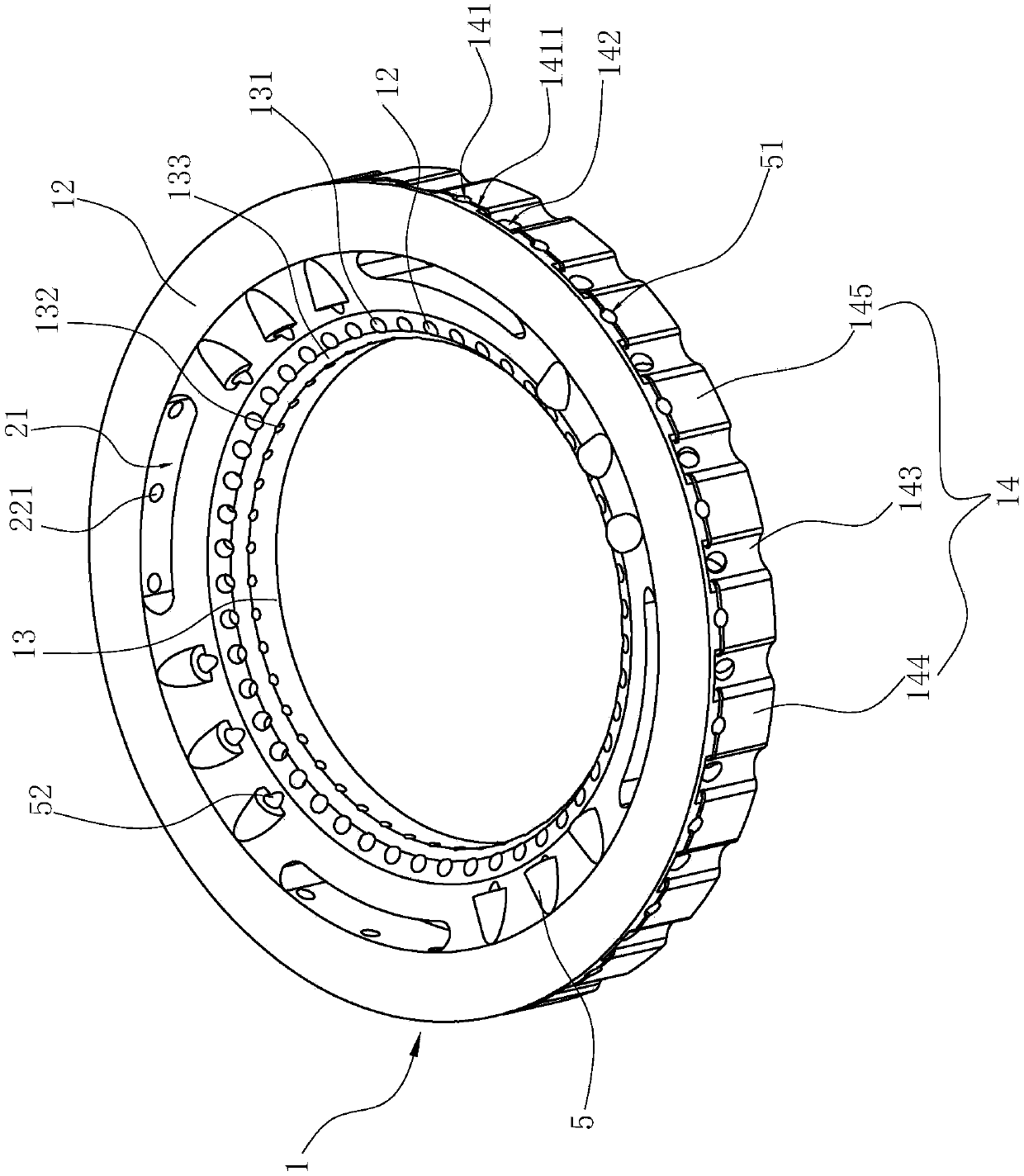

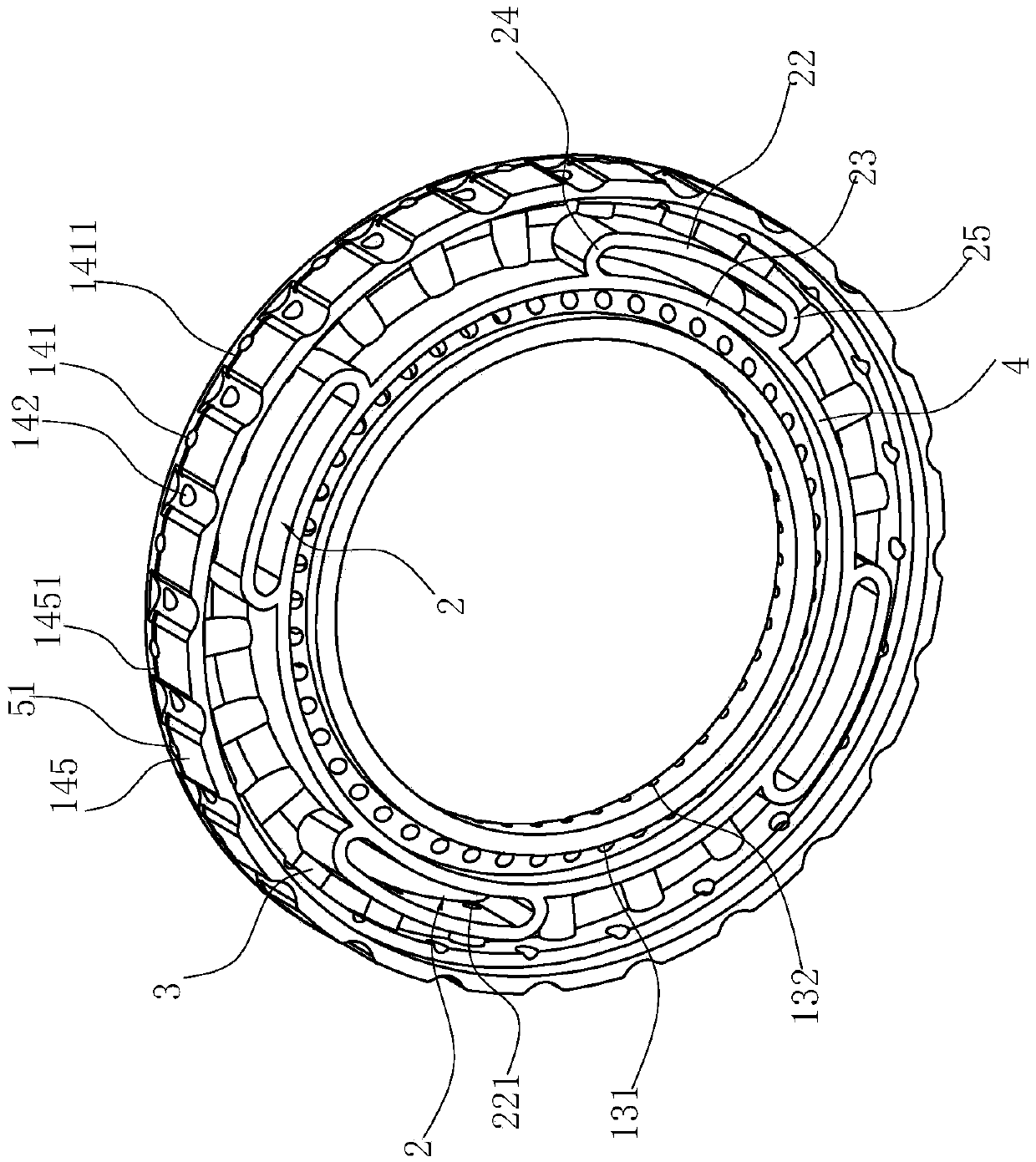

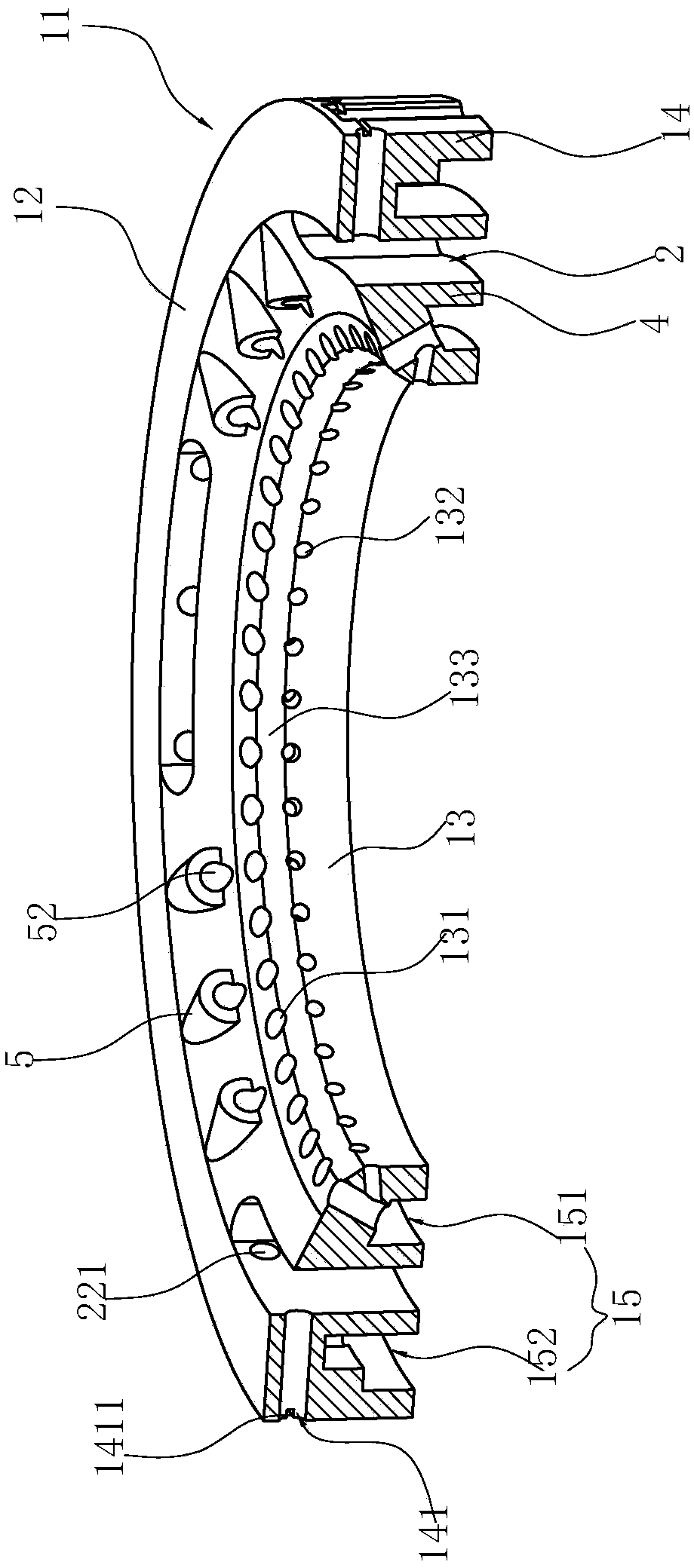

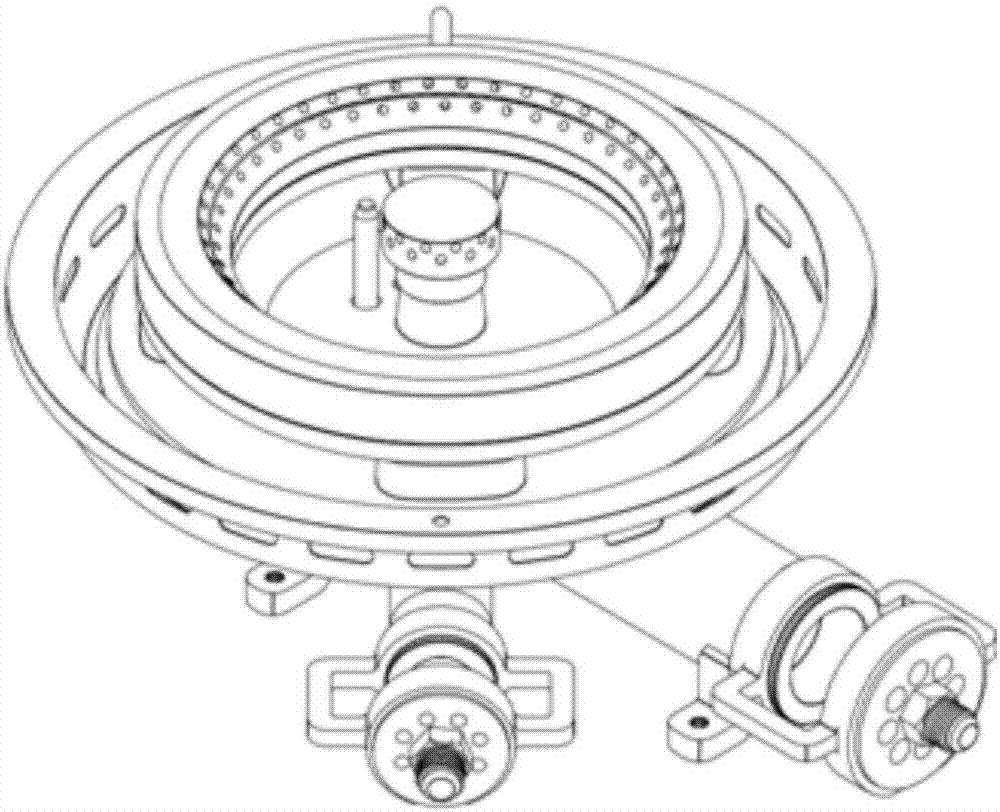

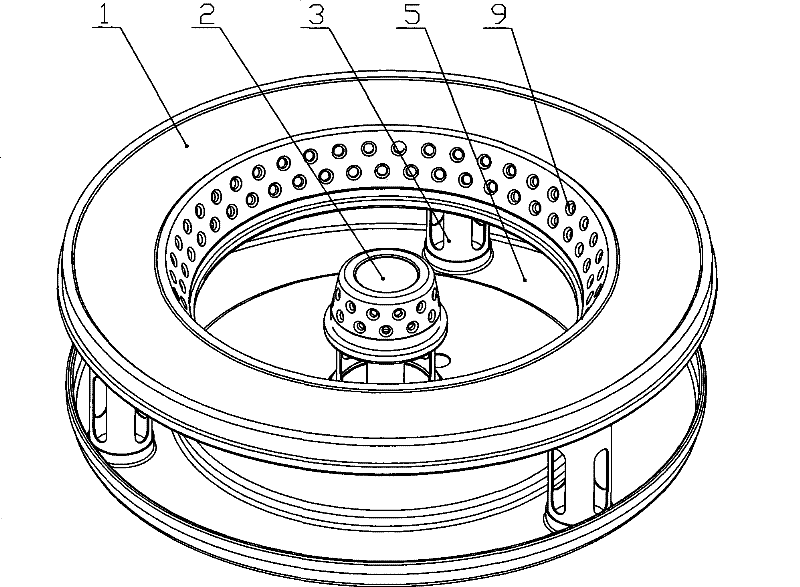

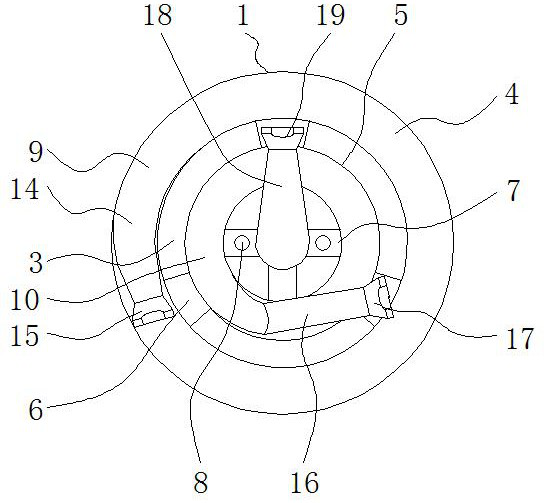

Fire cover for gas stove

ActiveCN110966605AGuaranteed air replenishmentStable combustion conditionsGaseous fuel burnerThermodynamicsEngineering

The invention relates to a fire cover for a gas stove. The fire cover includes a fire cover body and an air mixing chamber. The fire cover is characterized in that air supplementing chambers which arerelatively isolated are arranged in the air mixing chamber, at least one wall of each air supplementing chamber is provided with an air inlet hole in fluid communication with outside air, the outer ring wall is provided with a first air outlet hole in fluid communication with the air supplement chamber at the position corresponding to the air supplementing chamber, the outer ring wall is providedwith at least one main fire hole communicating with the air mixing chamber in the circumferential direction at the position below the first air outlet hole, and each first air outlet hole communicates with the main fire hole corresponding to the first air outlet hole. Compared with the prior art, the fire cover has the advantages that the air supplementing chambers which are relatively isolated are arranged in the air mixing chamber, air is supplemented to the main fire holes independently through the air supplementing chambers, the air supplementing amount in the main fire holes in the outerring walls can be ensured, the burning working condition of the first fire outlet holes is stable, and the material and manufacturing cost are reduced accordingly.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

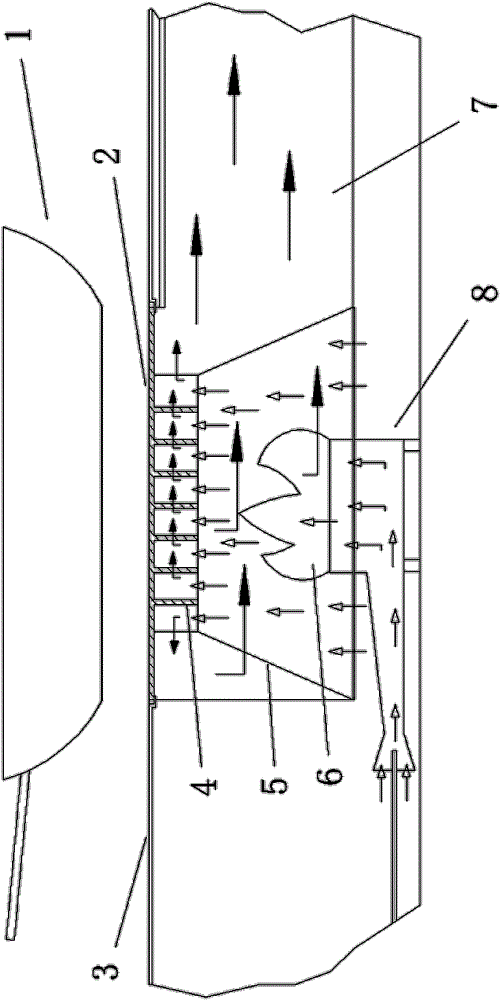

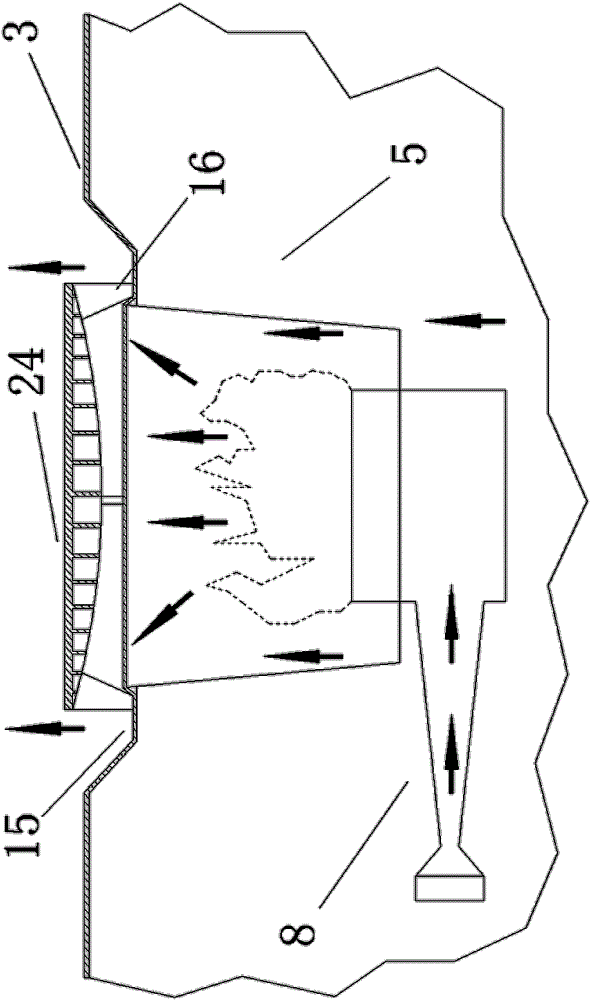

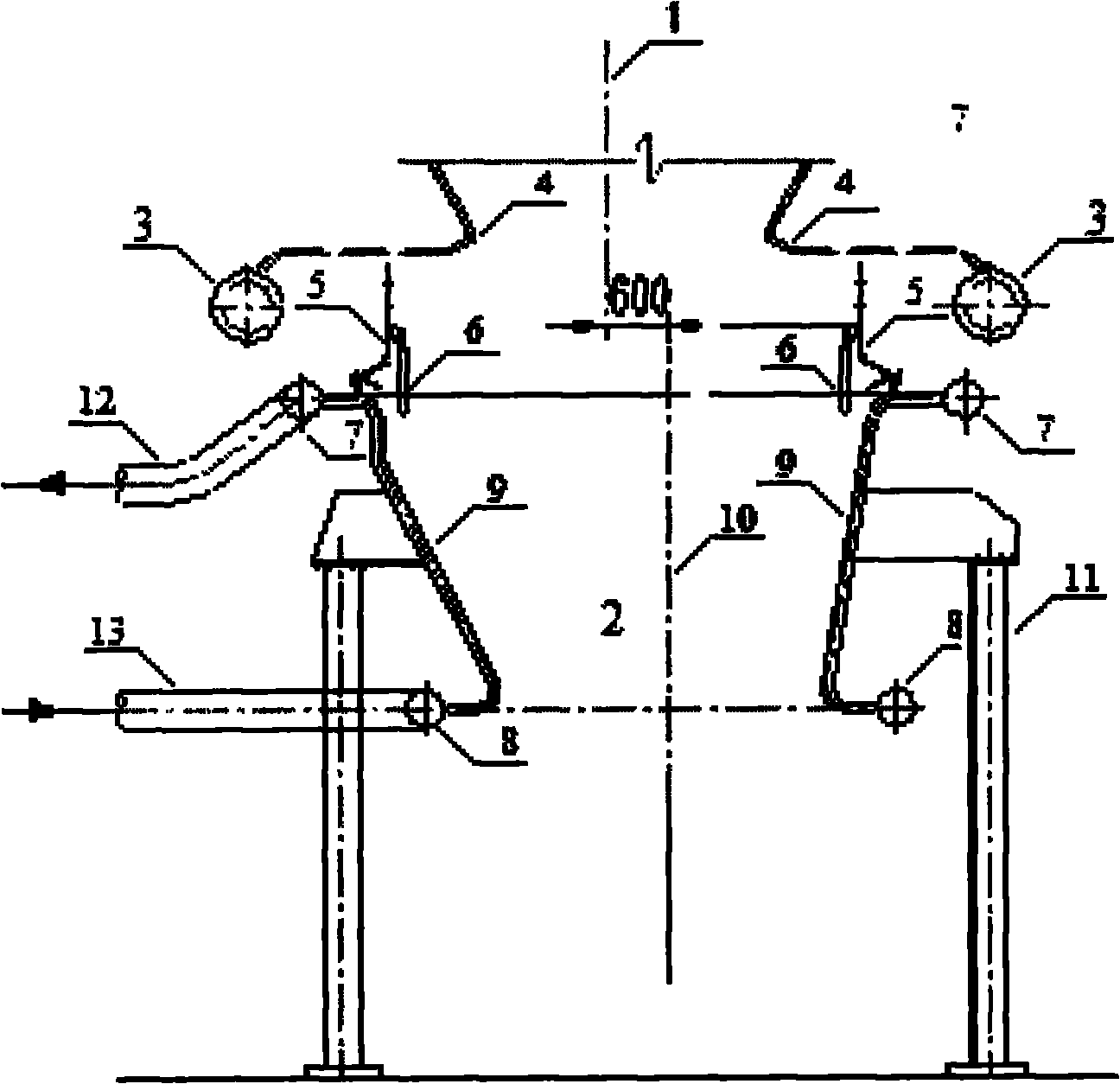

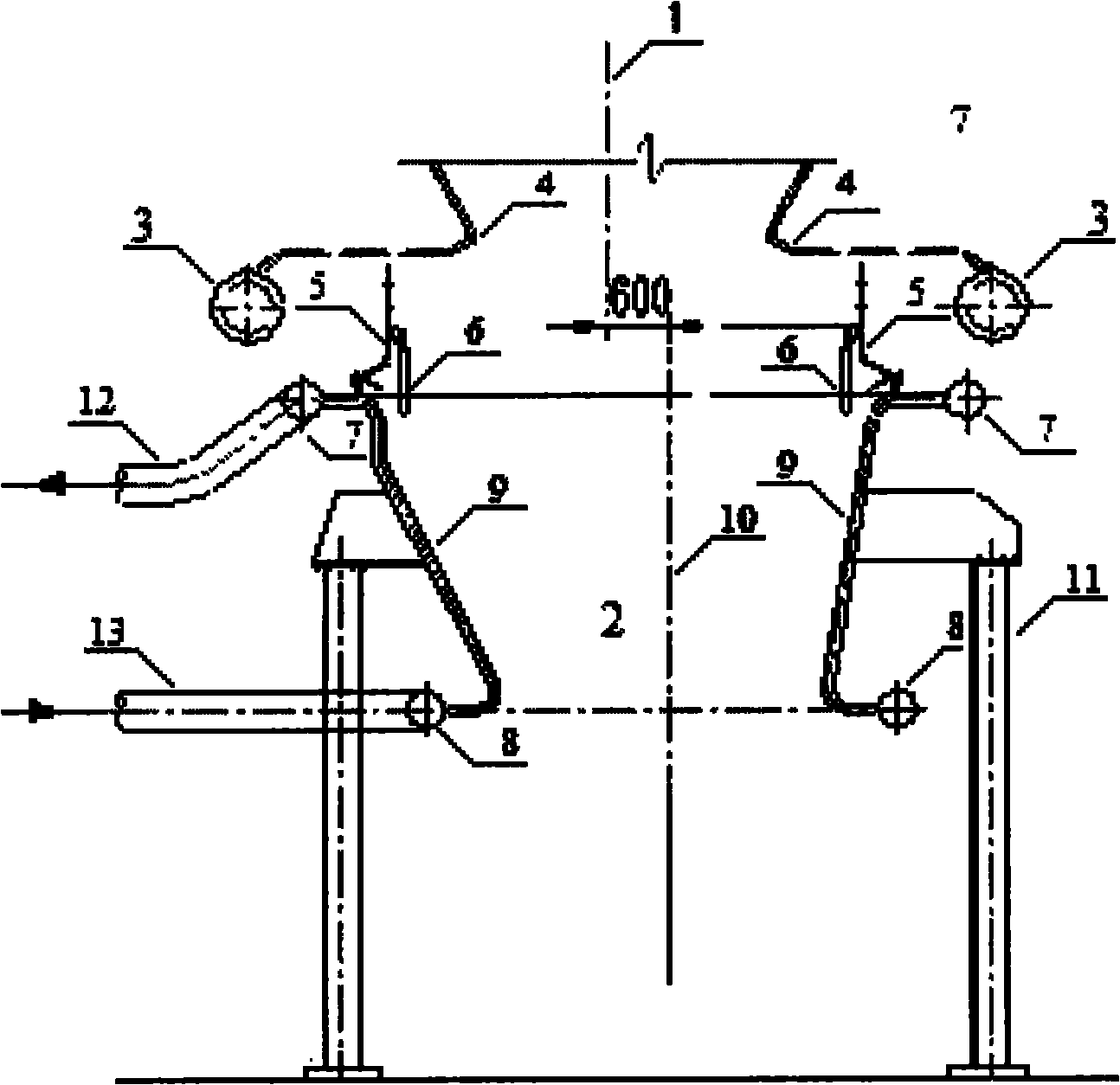

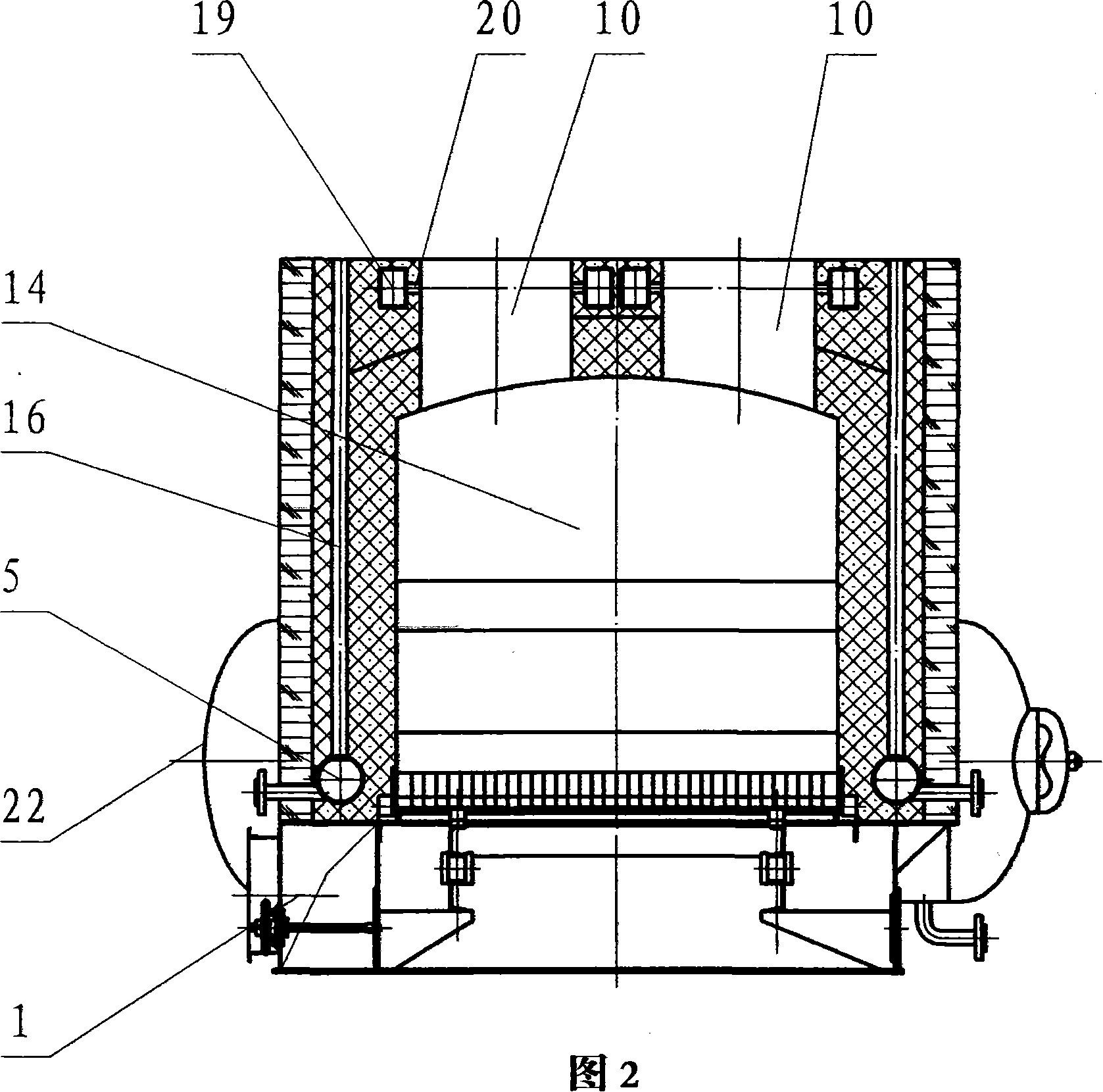

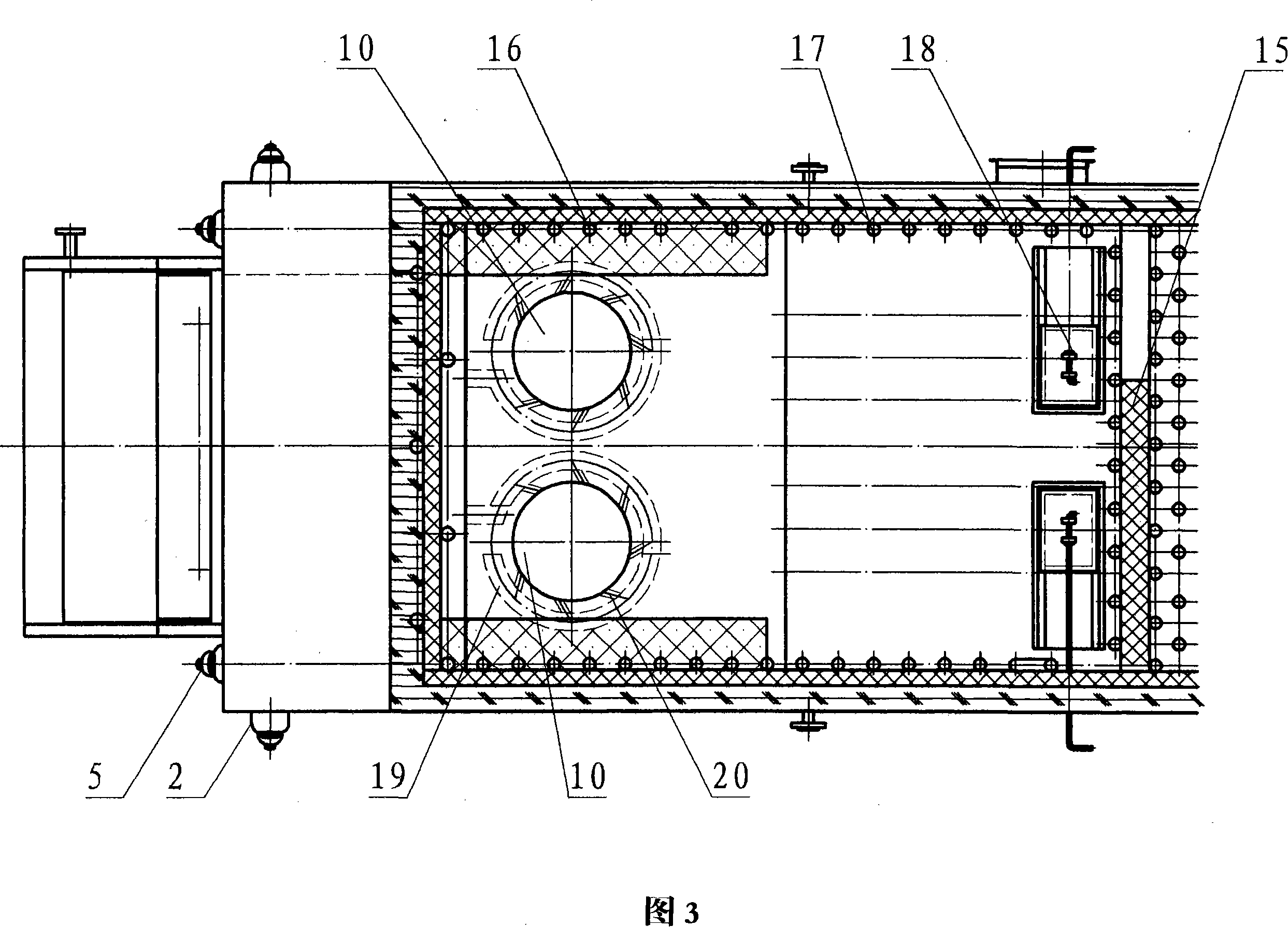

High-temperature thermal storage type combined oven arch embedded second rotational flow overfire air burning inferior fuel

InactiveCN101118061AExtended stayGuaranteed timeCasings/liningsNon-combustible gases/liquids supplySpray nozzleEngineering

The present invention relates to a high-temperature heat accumulating type combined boiler arch with built-in rotational flow secondary wind for burning low-grade fuel, which belongs to the boiler technical field, in particular to a high-temperature heat accumulating type combined boiler arch with built-in rotational flow secondary wind for burning high volatile combustible, high moisture, and low heat value low-grade fuel in a highly effective and environment protective burning high volatile combustible, high moisture, and low heat value low-grade fuel boiler. Two high-temperature heat accumulating type cylinder shape rotational flow middle arches are arranged between a face arch and a rear arch, and above the middle and front part of a fire grate, the fore part is connected with the face arch, and the rear part is connected with the rear arch; a round secondary-air air inlet tube is connected with a main secondary air tube, a rotational flow secondary air spray nozzle is connected with the round secondary-air air inlet tube, the round secondary-air air inlet tube is positioned in the high-temperature heat accumulating type cylinder shape rotational flow middle arch, and the outlet of the rotational flow secondary air spray nozzle is connected with the inner wall of the high-temperature heat accumulating type cylinder shape rotational flow middle arch. Because the structure is adopted by the present invention, when the low-grade fuel is burnt, the fuel adaptability is evidently enhanced, the burning working condition in the boiler hearth is stable, the boiler thermal efficiency is improved by about 15 percentage points, and the present invention has the advantages that the fuel adaptability is wide, the thermal efficiency is high, black smoke is not existed, and the effect of the environment protection is good.

Owner:袁福林 +1

Novel inner flame sunken burner and gas stove with oxygen supplementing function

ActiveCN108006637AStable combustion conditionsSimple structureDomestic stoves or rangesGaseous fuel burnerEngineeringOxygen

The invention provides a novel inner flame sunken burner and a gas stove with an oxygen supplementing function. The novel inner flame sunken burner comprises a outer ring burner cap, an inner ring burner cap, a gas separating seat and a stove head seat, and the end faces of the gas separating seat and the stove head seat are matched; the inner ring burner cap is matched with a center gas outlet ofthe gas separating seat, and the outer ring burner cap is matched with the peripheral area of the gas separating seat; the inner ring burner cap is provided with a main flame gas outlet used for ejecting a part of gas mixtures, and a steady flame slot used for ejecting the other part of the gas mixtures; and the inner ring burner cap located above the main flame gas outlet is provided with a supplementing slot for supplementing inside secondary air for inner ring main flame. The novel inner flame sunken burner provided by the invention has the advantages of inner ring flame with the oxygen supplementing function, high heat efficiency and roaring fire.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

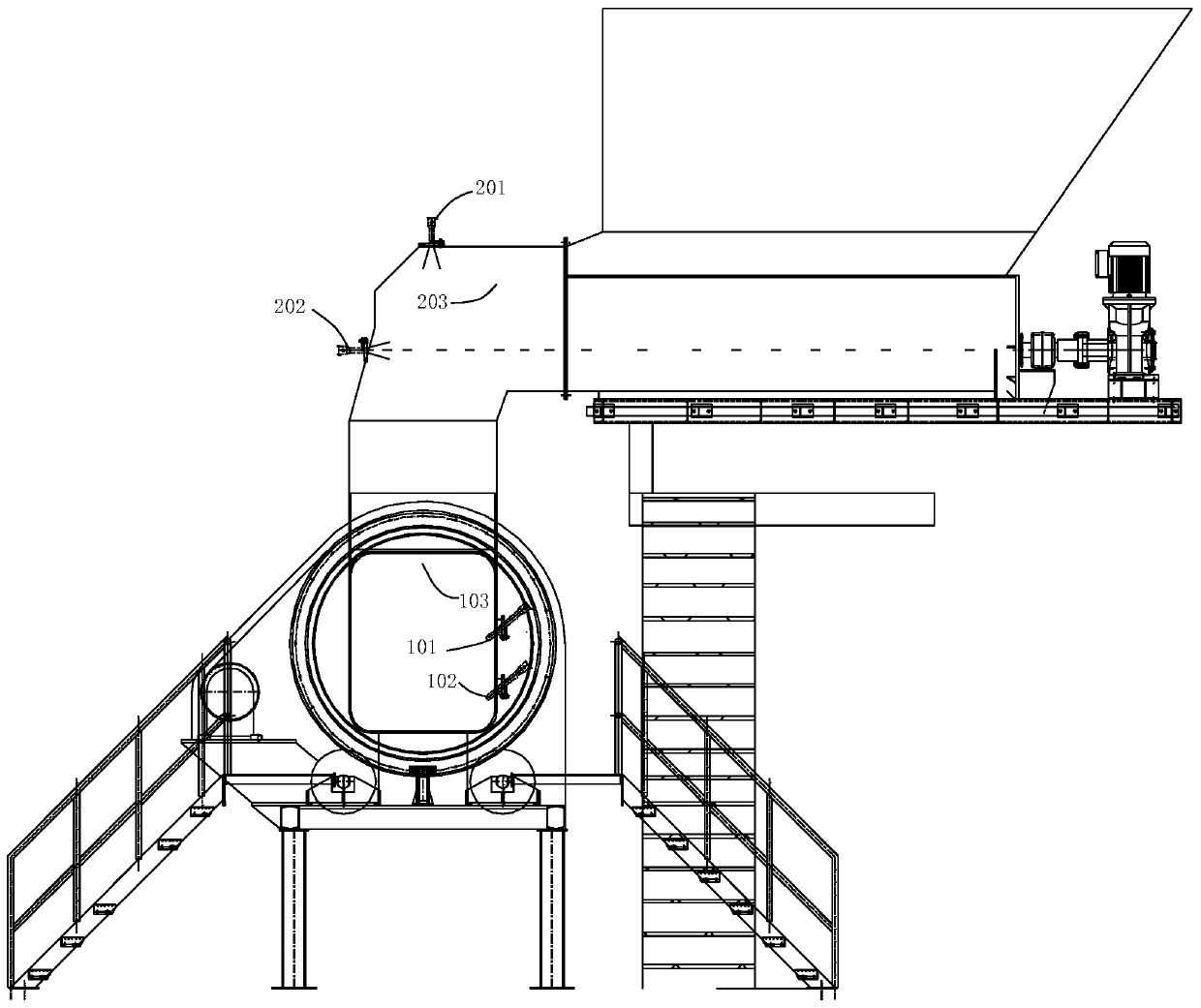

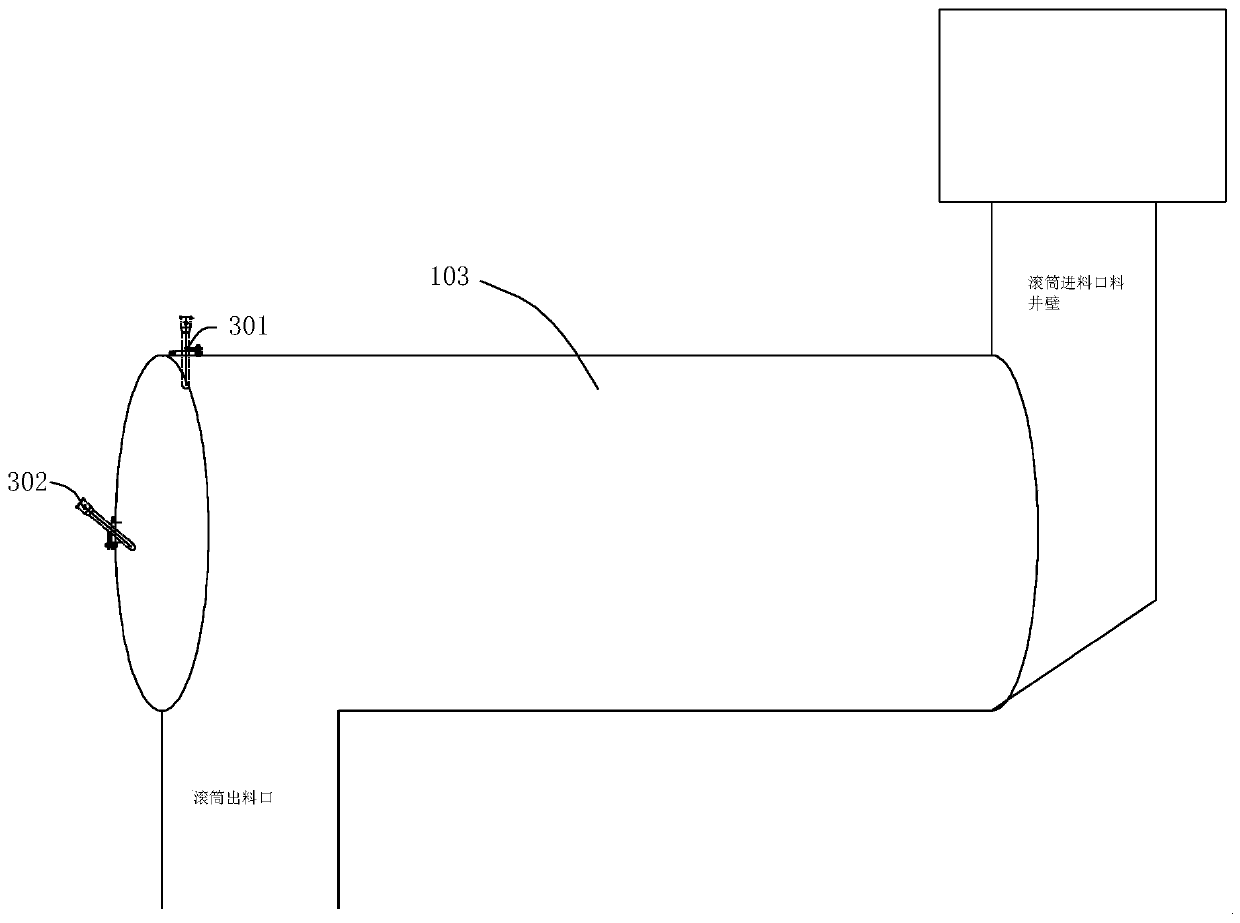

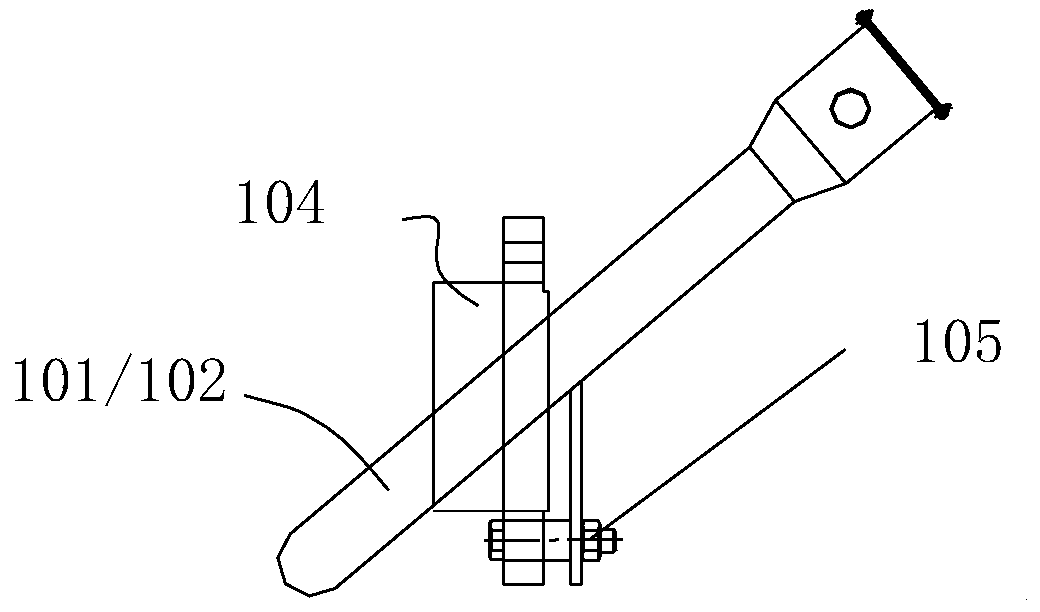

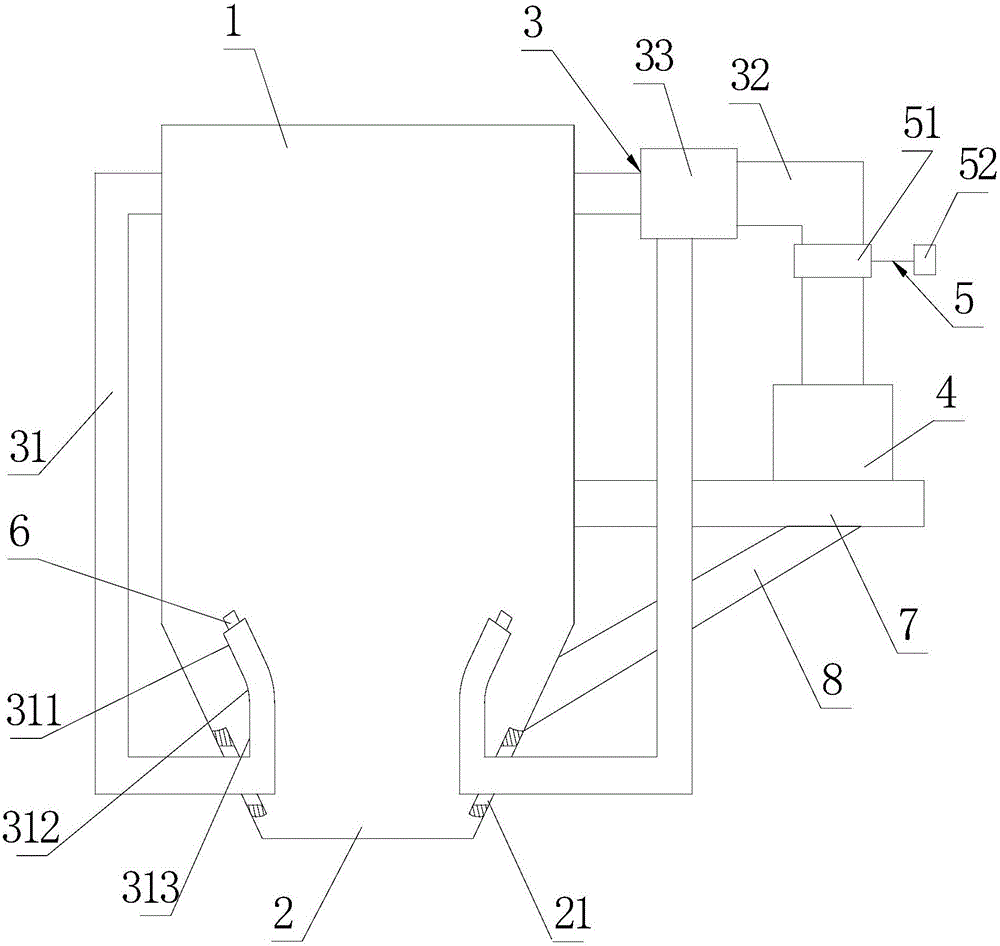

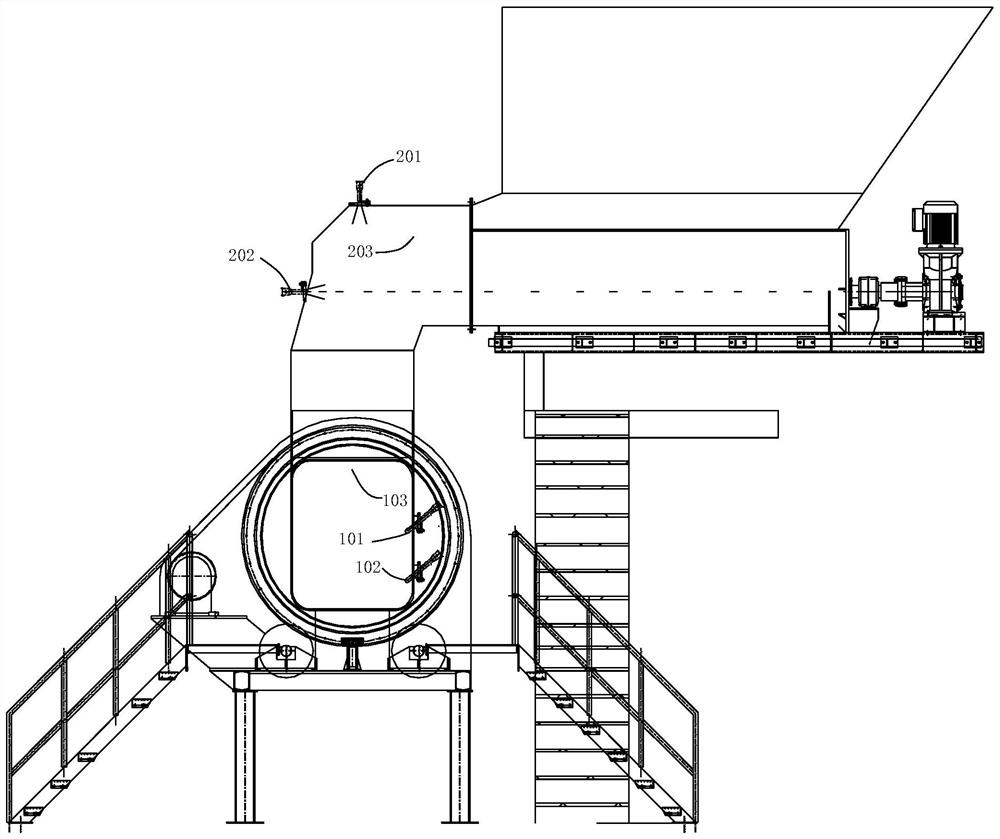

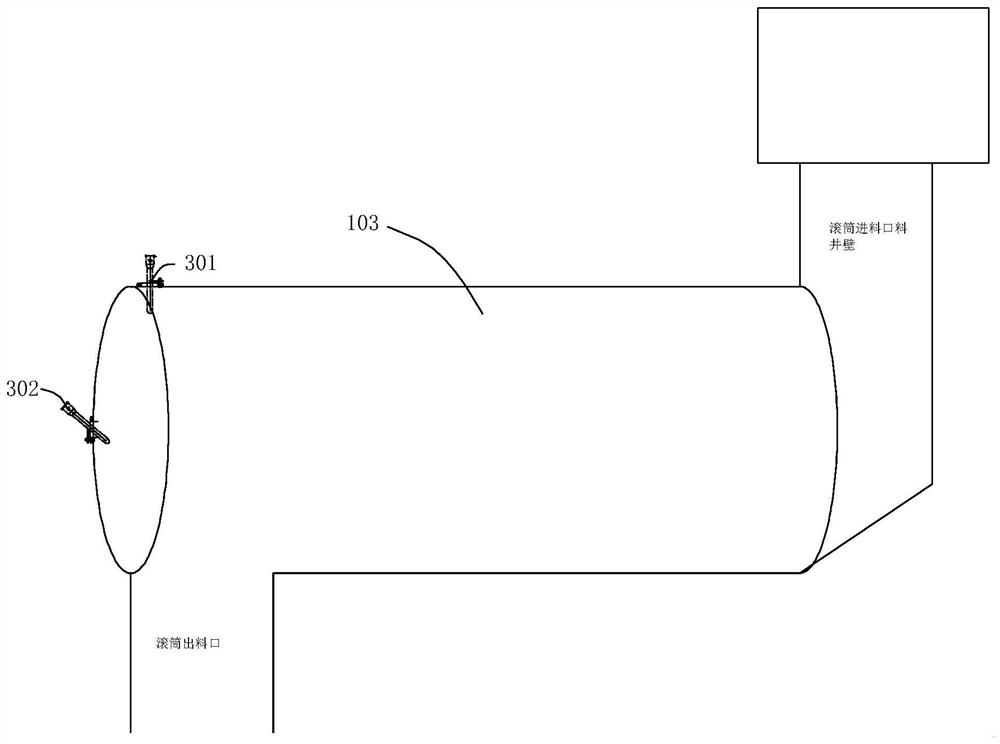

System for automatically controlling garbage feeding

ActiveCN110482166ARealize automatic stable feeding functionAutomatically stabilize combustion conditionsControl devices for conveyorsUltrasonic sensorCombustion

The invention discloses a system for automatically controlling garbage feeding. The system comprises a first radio frequency admittance material level switch, at least one second radio-frequency admittance material level switch and an ultrasonic sensor, wherein the first radio frequency admittance material level switch is provided with a low material level switch and a high material level switch;the low material level switch and the high material level switch are arranged on a drum feeding port material well wall from bottom to top; a flange sleeve is arranged at the mounting position of thefirst radio frequency admittance material level switch; a first radio frequency admittance material level meter is fixed on the flange sleeve and can be movably adjusted; the second radio-frequency admittance material level switch is arranged on the drum discharging port material well wall, and stops upper and lower feeding and sending an alarm of a high material level at the lower position underthe condition of high material level; and the ultrasonic sensor comprises a first ultrasonic sensor and a second ultrasonic sensor. According to the system, the automatic stable feeding function of aboiler feeding system can be realized, and material level detection, material breaking alarming, feeding port material level height limit alarming, automatic material supplementing, automatic feedingadjustment, automatic material breaking in an abnormal state and the like can be realized, so that the workload and pressure of operators are relieved, and the boiler combustion working condition is more stable.

Owner:武汉市绿色环保能源有限公司

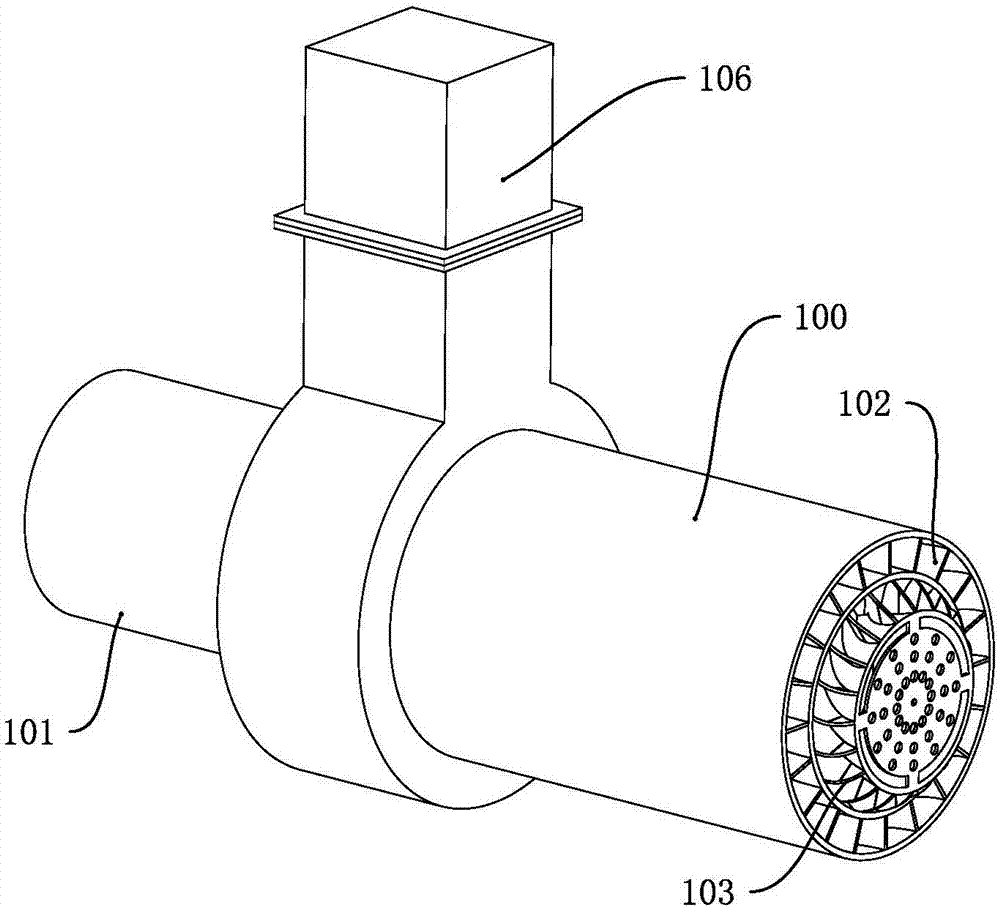

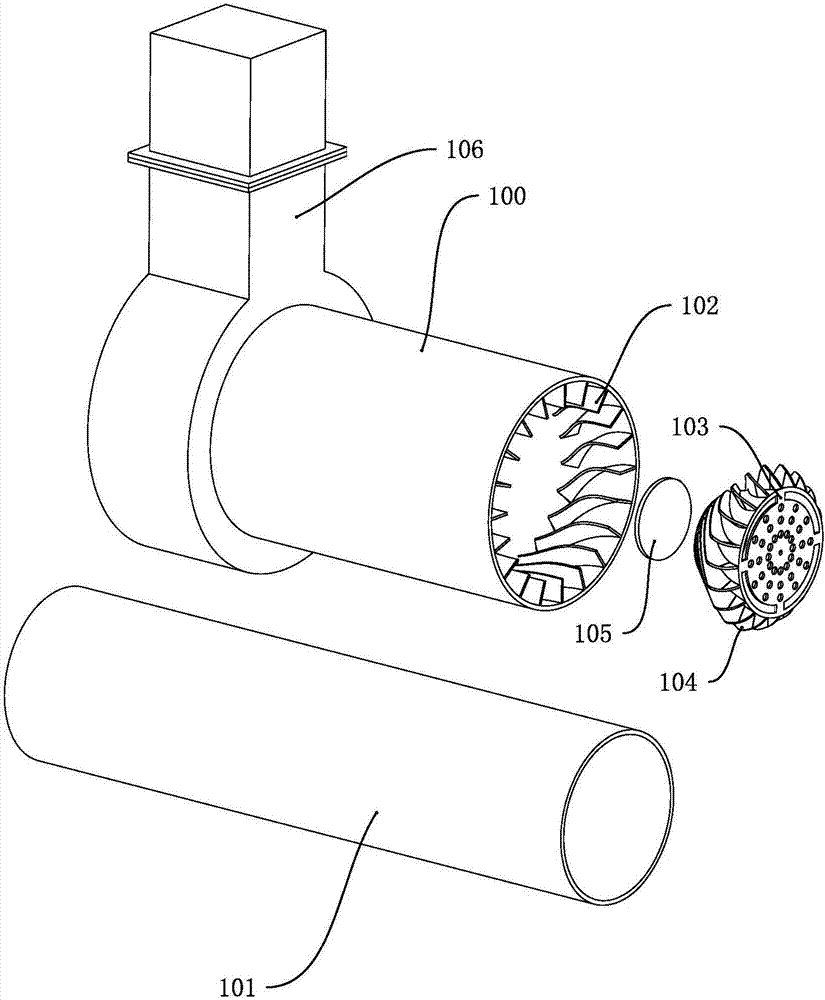

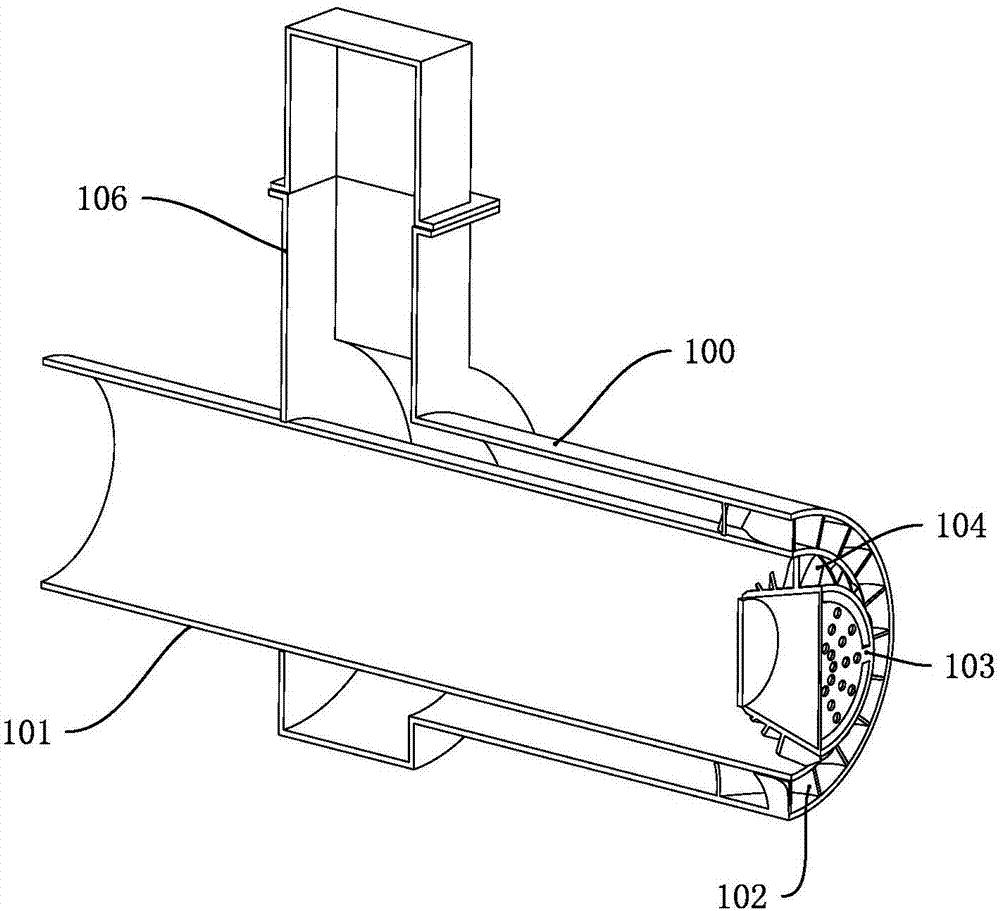

Biomass gas burner

The invention discloses a biomass gas burner. The biomass gas burner comprises an air guide pipe, a combustion pipe and a gas log which is arranged in the front end of the combustion pipe. First guide vanes are arranged on the inner wall of the front end of the air guide pipe. The front end of the combustion pipe stretches into the air guide pipe at the rear end of the combustion pipe, and a gap is reserved between the front end of the combustion pipe and the inner wall of the air guide pipe. The combustion pipe is connected with the rear end of the air guide pipe in a sealing mode, and the front end of the combustion pipe is flush with the front end of the air guide pipe. The gas log is in a frustum shape, and second guide vanes are arranged on the outer wall of the gas log. The first guide vanes and the second guide vanes form a flow guide air duct used for mixing air and biomass gas. The biomass gas burner has the advantages that the biomass gas and the air are mixed at the front end of the combustion pipe, the first guide vanes and the second guide vanes form the flow guide air duct, the flow guide air duct can make the air and the biomass gas be fully and evenly mixed, and therefore the combustion condition is more stable, and combustion is made more sufficient.

Owner:王夏飞

Civil heating stove for automatically feeding with stalk briquette as fuel

ActiveCN100570219CRealize manual feedingRealize automatic feedingStove/ranges for heating waterHome appliance efficiency improvementCombustion chamberWater jacket

The invention relates to a civil heating stove feeding automatically and taking haulm briquettes as fuel, which comprises two parts, namely, a stove body and an automatic feeding device. The stove body essentially comprises a combustion chamber, a wind box, a rocking grate, a flue channel and a water jacket. The automatic feeding device essentially comprises a motor, a screw rod, a stock driving groove, a limit switch and a hopper and can realize 8 hours to 12 hours of timed and rationed automatic feeding. The civil heating stove is applicable to the clean combustion process of biomass fuels, has the advantages of high combustion efficiency, high thermal efficiency, low emission of contaminants, low generation of tar and labor conservation and the like, does not cause problems like indoor contamination resulted from condensation of the tar, and has simple structure, low cost and broad application prospect.

Owner:HEBEI UNIV OF TECH

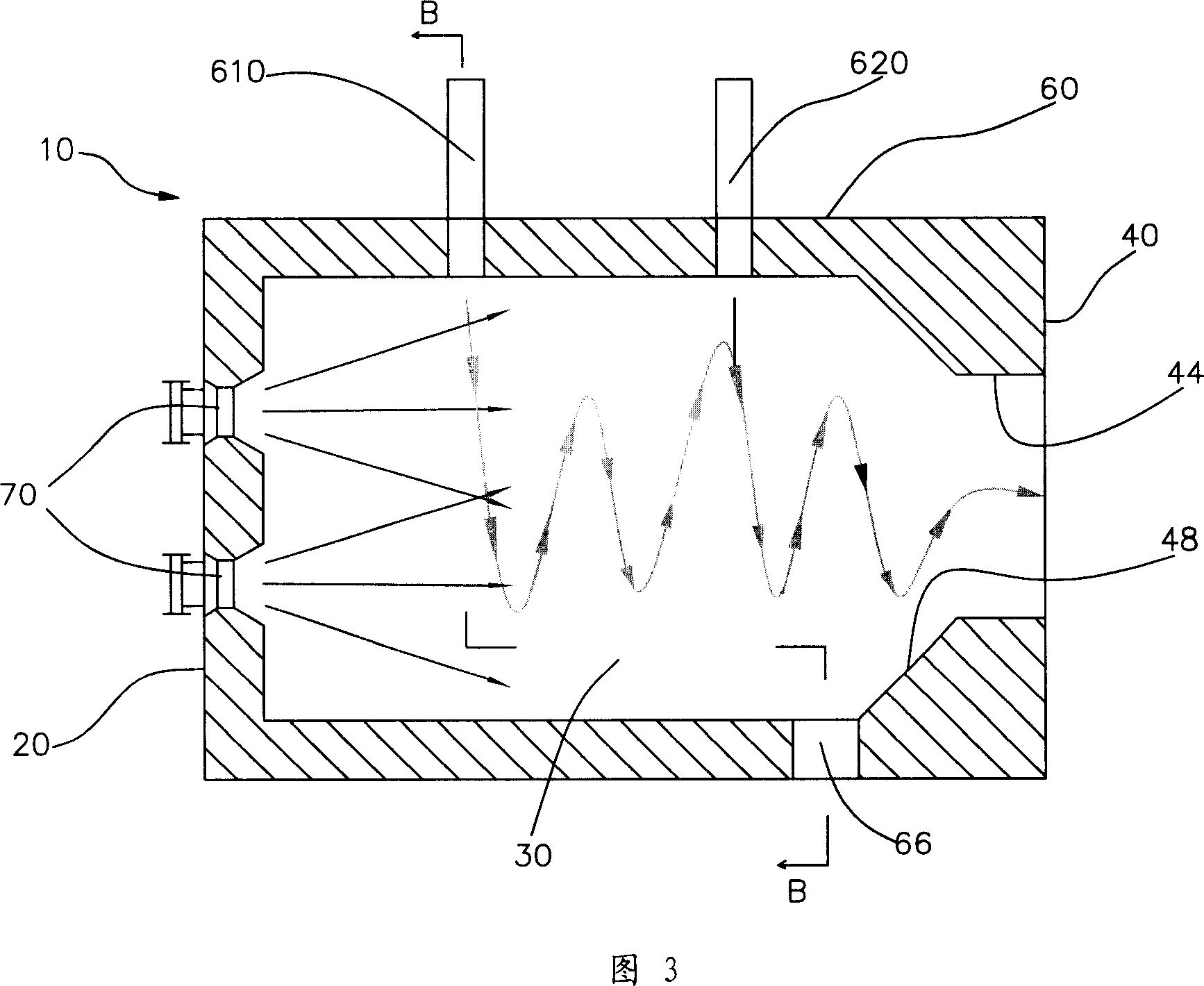

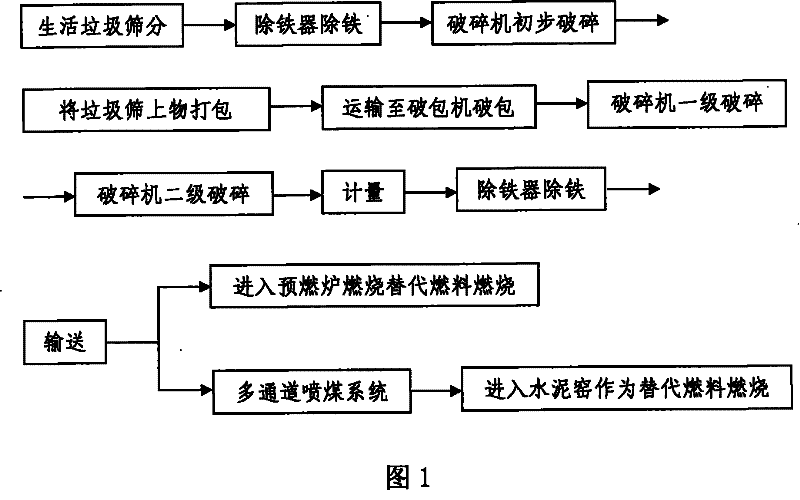

Method for preparing alternative fuel for cement kiln by using composite material waste

InactiveCN102607047AStable combustion conditionsDoes not increase emissionsLump/pulverulent fuel feeder/distributionLump/pulverulent fuel preparationAlternative fuelsCombustor

The invention provides a method for preparing alternative fuel for a cement kiln by using composite material waste. A glass reinforced plastic composite material waste is crushed into grains with a grain diameter less than 20mm or slices to be used as the alternative fuel; the alternative fuel is sent into a preburning furnace of the cement kiln and is burnt under a pressure of -500Pa to -800Pa; or the alternative fuel is sprayed into the cement kiln from a multichannel burner at the head of the cement kiln. Through the method provided by the invention, the difficulty in treatment of the glass reinforced plastic composite material waste can be overcome and the fuel problem caused by high energy consumption of the cement industry can be solved.

Owner:BEIJING JINYU MANGROVE ENVIRONMENTAL PROTECTION TECH

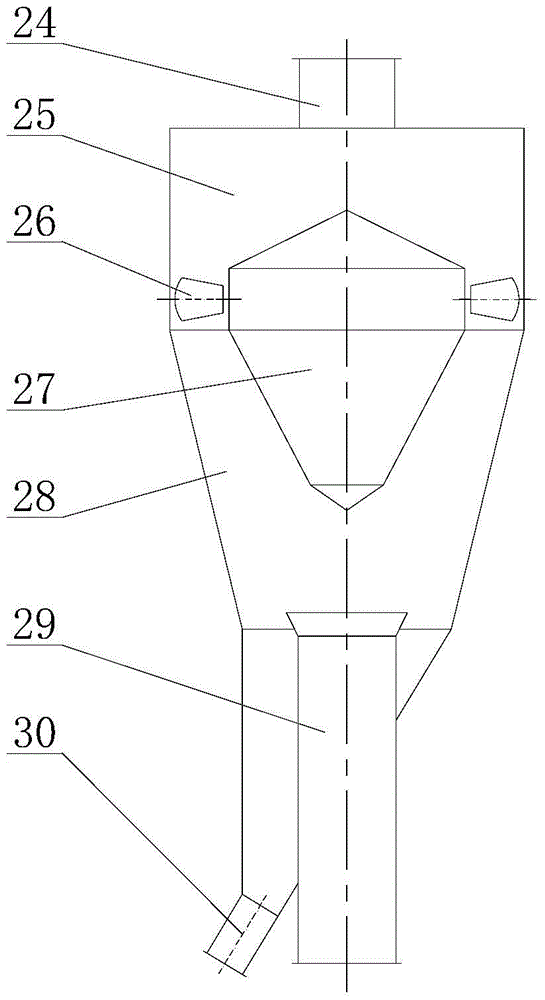

Coal bunker

ActiveCN103629688AGuaranteed continuityStable combustion conditionsLarge containersLump/pulverulent fuel feeder/distributionCombustionKinetic energy

The invention relates to a coal bunker. The coal bunker comprises an upper coal bunker body and a lower coal bunker body which is connected with at least one air pipe, the air pipe injects air in the lower coal bunker body from bottom to top, the air pipe is connected with an air supply device used for supplying air into the lower coal bunker body, the air pipe is provided with a control device, and the air in the air pipe enters the lower coal bunker body under the control of the control device. The coal bunker has the advantages that the air in the air supply device enters the lower coal bunker through the air pipe under the control of the control device, coal blocked in the lower coal bunker body can be loosened by means of kinetic energy produced by the air flowing from bottom to bottom, continuity of coal feeding of a boiler is guaranteed, combustion conditions of the boiler are stabilized greatly, work intensity is reduced, safety is good, and manpower is saved.

Owner:CHANGXING XINCHENG ENVIRONMENTAL PROTECTION

Emusified coking-slurry cyclone burner

InactiveCN101029729AAvoid fouling and cokingReduce generationCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCycloneFlue gas

This invention discloses an emulsification burning device that consists of a front end wall, back end wall and the side crust inside which forms a cylindraceous burning space. There are at least one emulsification burning device and at least a fuel burning device or at least air burning device. The side of the crust sets two or more tangential wind inlet openings each of which includes two or more tangential wind inlet openings which can make the tangential wind inside the burning space form circumfluence along the side of the crust. There are at least one dreg outlet opening near the back end wall at the side of the bottom of the burning space. The cross section of the dreg outlet opening lies between the cross section of the tangential wind inlet opening near the back end wall and the inside of the back end wall. The emulsification burning device of this invention can realize the liquid slag avoiding the deposition and coking of the flue gases on the heating surface.

Owner:GUANGZHOU DEVOTION THERMAL TECH

Method for substituting cement kiln fuel with garbage derived overtails

Owner:LINGCHUAN JINYU CEMENT

Gas injection boiler using the emulsifying coke mortar combustion device

InactiveCN101021313AEfficient and stable combustionReasonable useCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelSlurryEngineering

The present invention discloses a steam-injecting boiler adopting emulsified coke slurry combustion equipment. It includes boiler self-body and emulsified coke slurry combustion equipment. Said boiler self-body includes furnace cavity, at least one steam pipe set in the furnace cavity interior and smoke outlet cut on one end wall far-separated from the emulsified coke slurry combustion equipment. Said emulsified coke slurry combustion equipment includes a shell body formed from front end wall, rear end wall and side wall, a cylindrical combustion space is formed in the shell body, on the front end wall at least one emulsified coke slurry combustor, at least one oil combustor and / or at least one gas combustor are set, its rear end wall is equipped with an outlet, said outlet is communicated with furnace cavity.

Owner:广州迪森热能设备有限公司

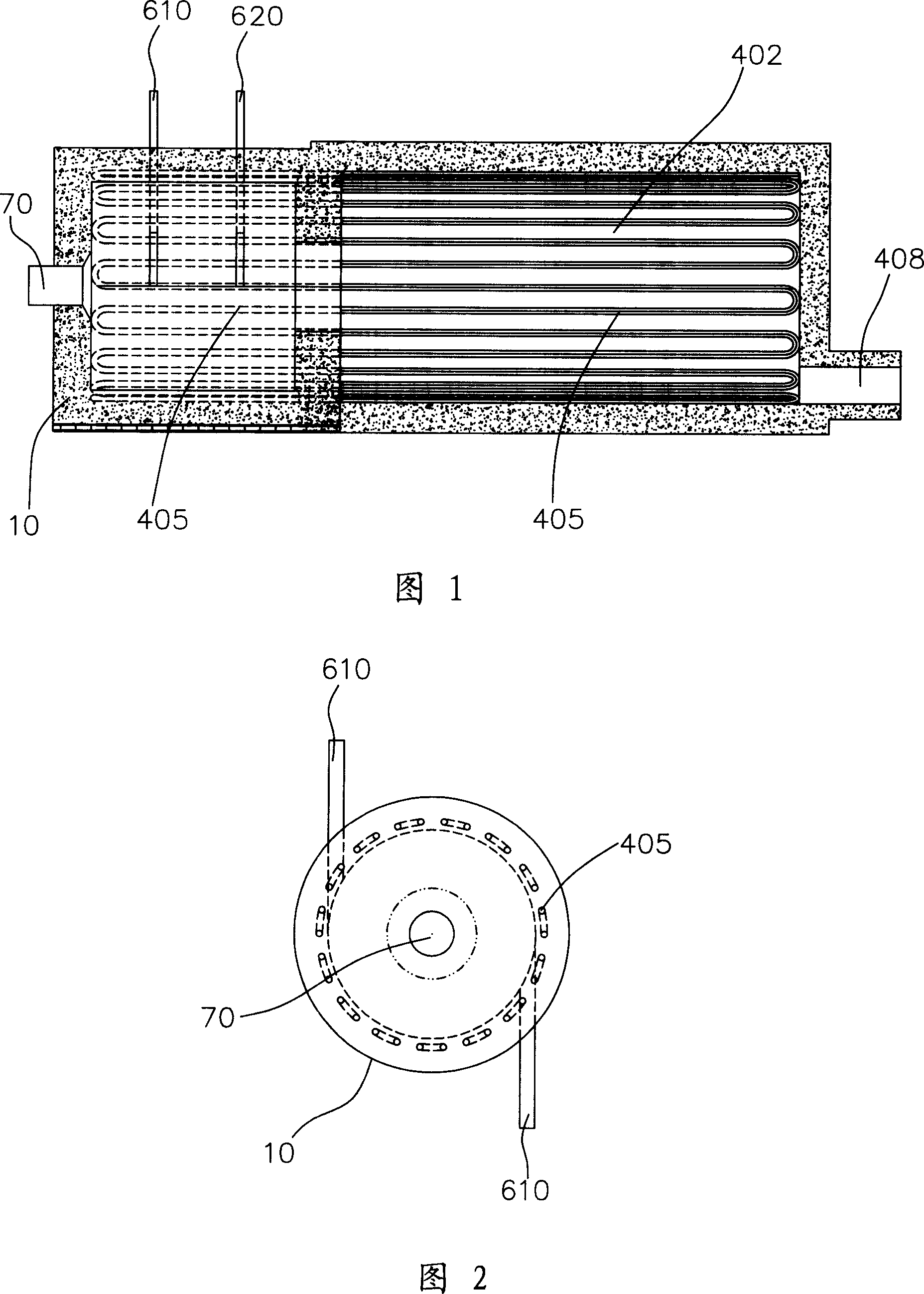

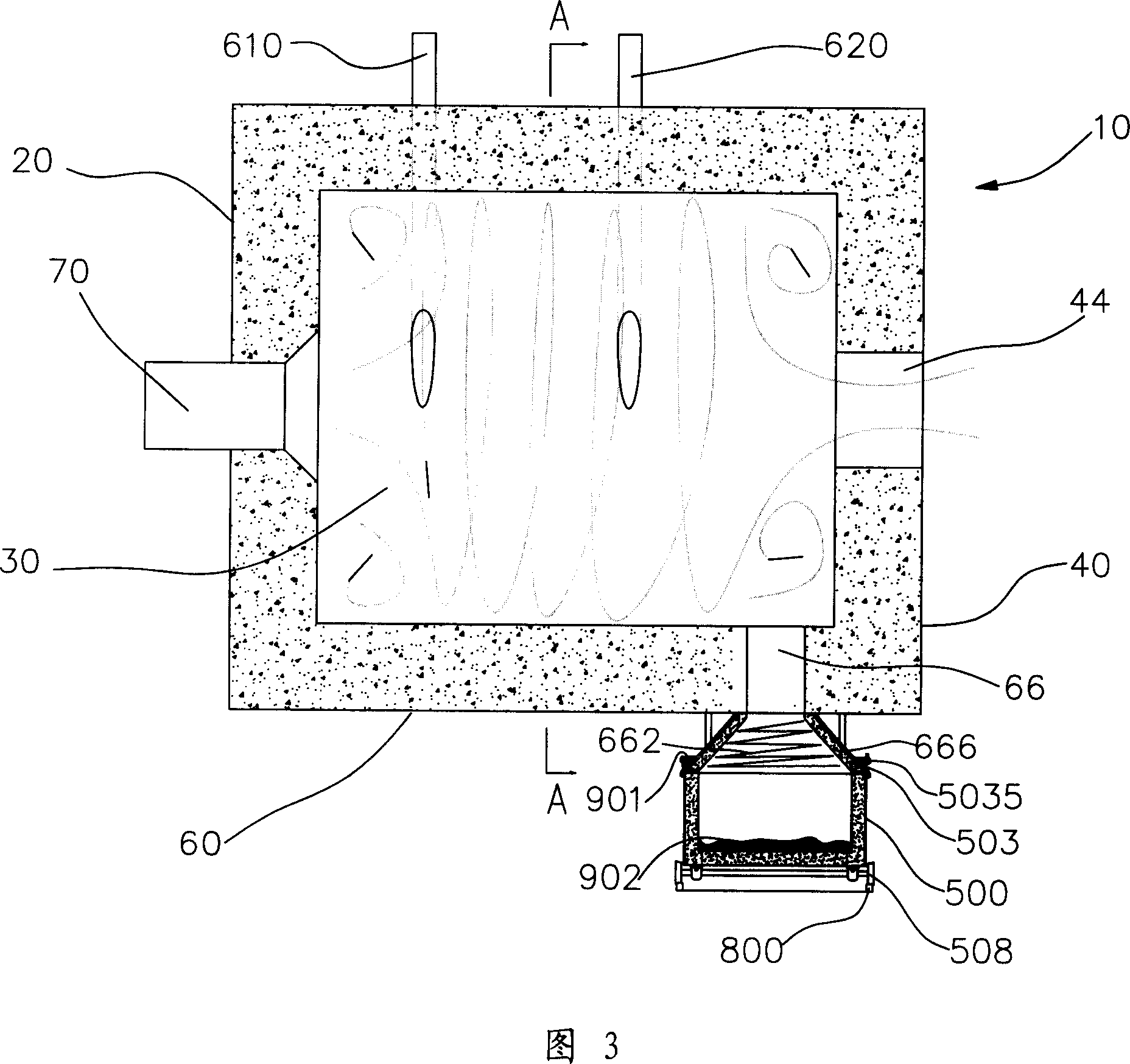

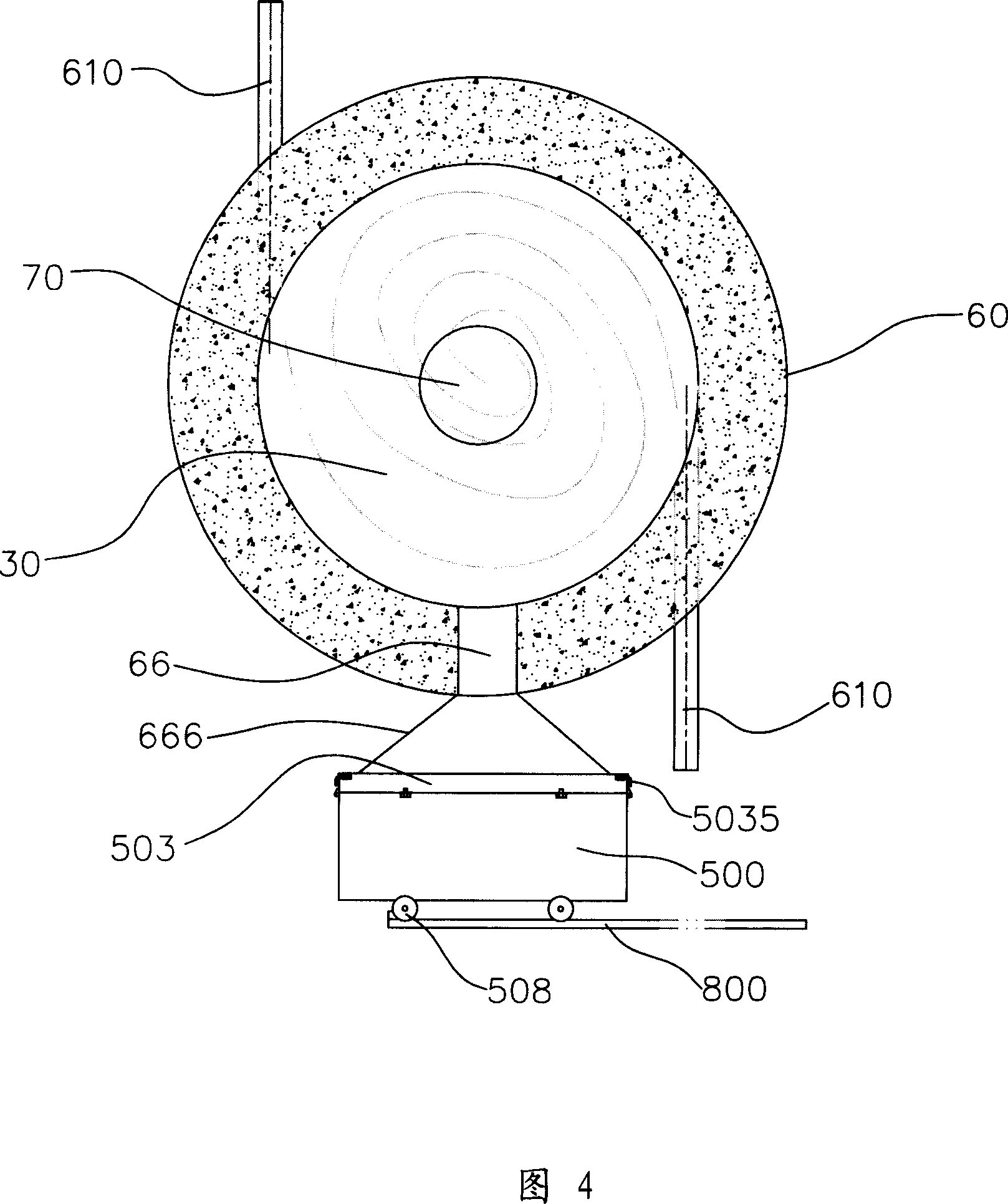

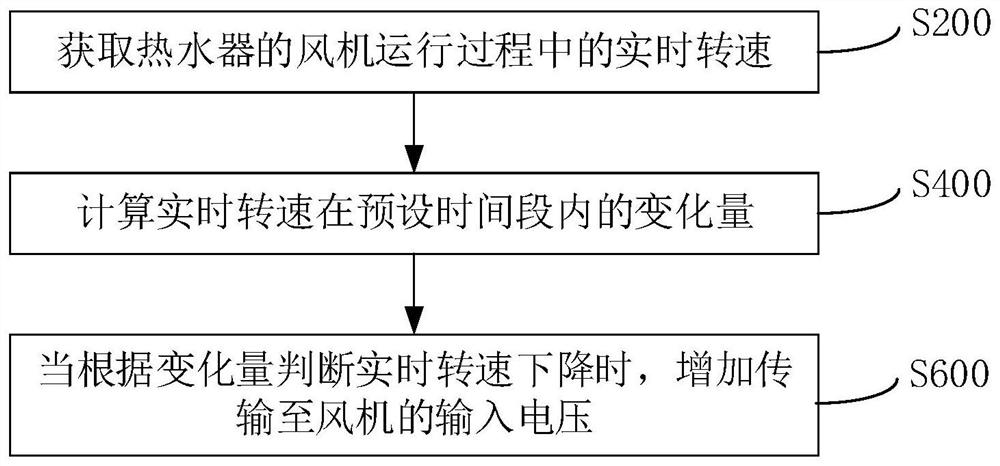

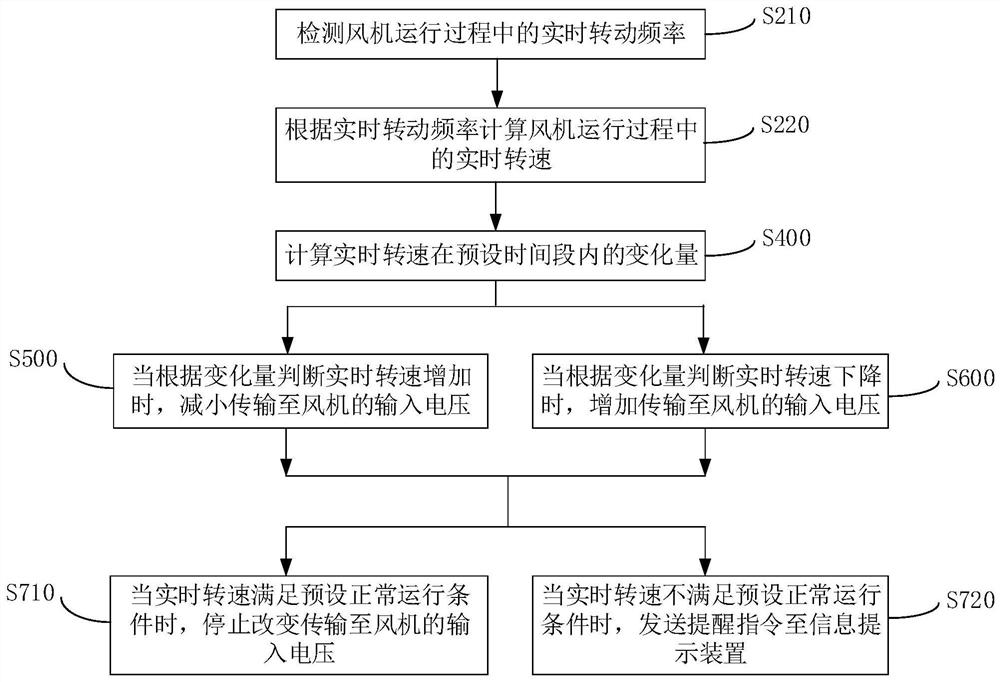

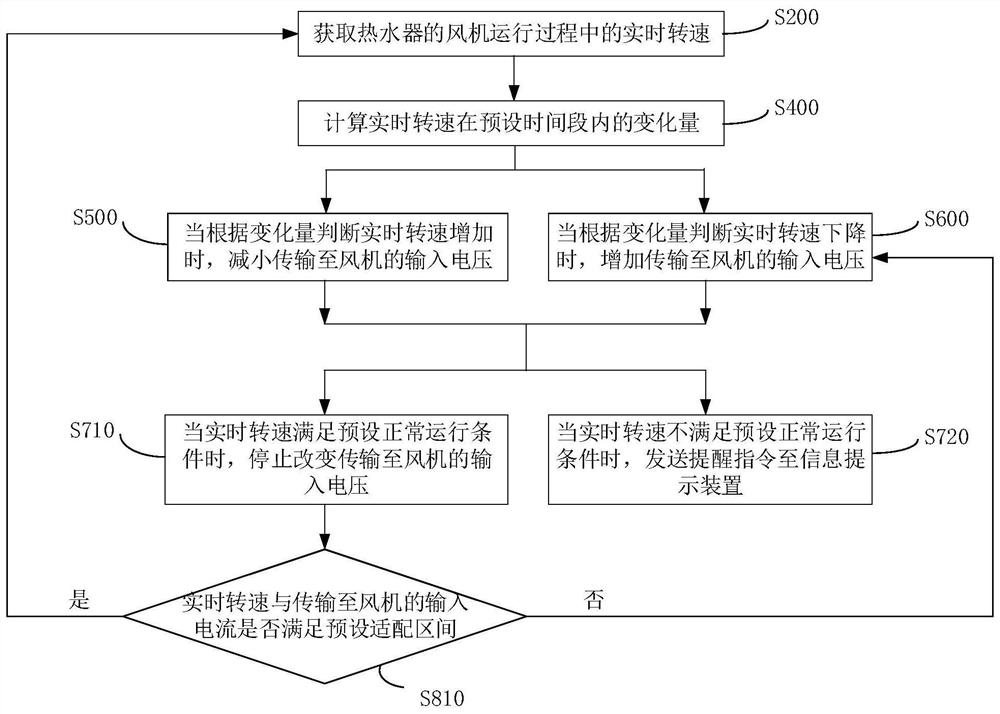

Water heater fan control method, device and equipment and water heater

The invention relates to a water heater fan control method, device and equipment and a water heater. The method comprises the steps that after the real-time rotating speed of a fan of the water heaterin the running process is obtained, the variable quantity of the real-time rotating speed within a preset time period is calculated, and when it is judged that the real-time rotating speed is decreased according to the variable quantity, and the input voltage transmitted to the fan is increased till the real-time rotating speed meets the preset normal running condition. In the normal combustion process of the water heater, when a smoke outlet is blocked due to external factors or strong wind directly blows the smoke outlet, the wind pressure value in a smoke pipe can be changed, the wind resistance is increased, the rotating speed of the fan is decreased under the condition that the input voltage is not changed, the input voltage transmitted to the fan is increased at the moment, and therotating speed of the fan can be increased by increasing the input voltage. The increment of wind resistance is balanced by the increased rotating speed of the fan, so that a hearth maintains a stablecombustion working condition, a series of problems caused by combustion imbalance are avoided, and the thus the using reliability of the water heater is improved.

Owner:GREE ELECTRIC APPLIANCES INC

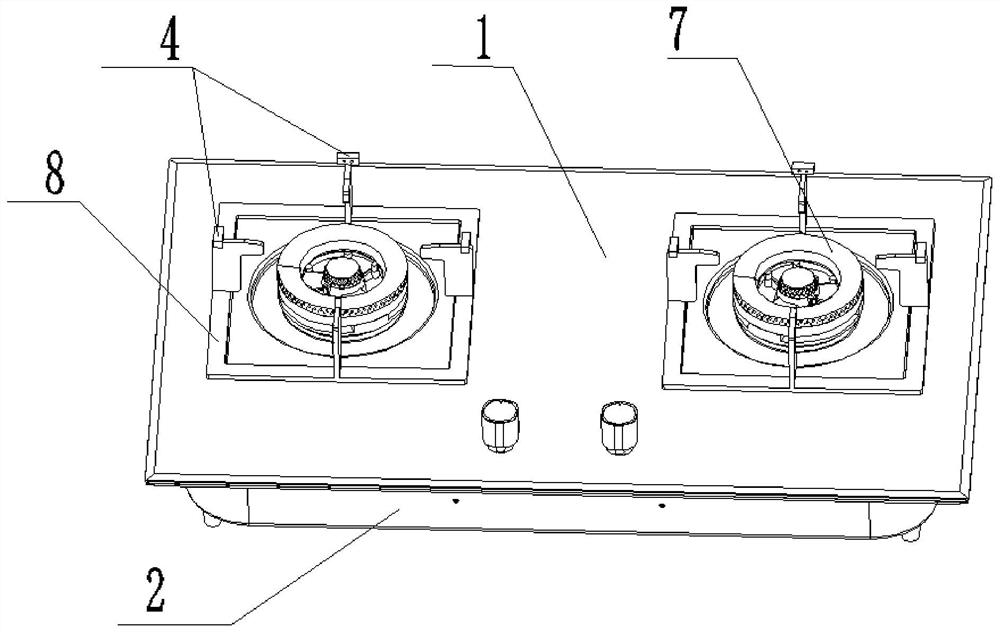

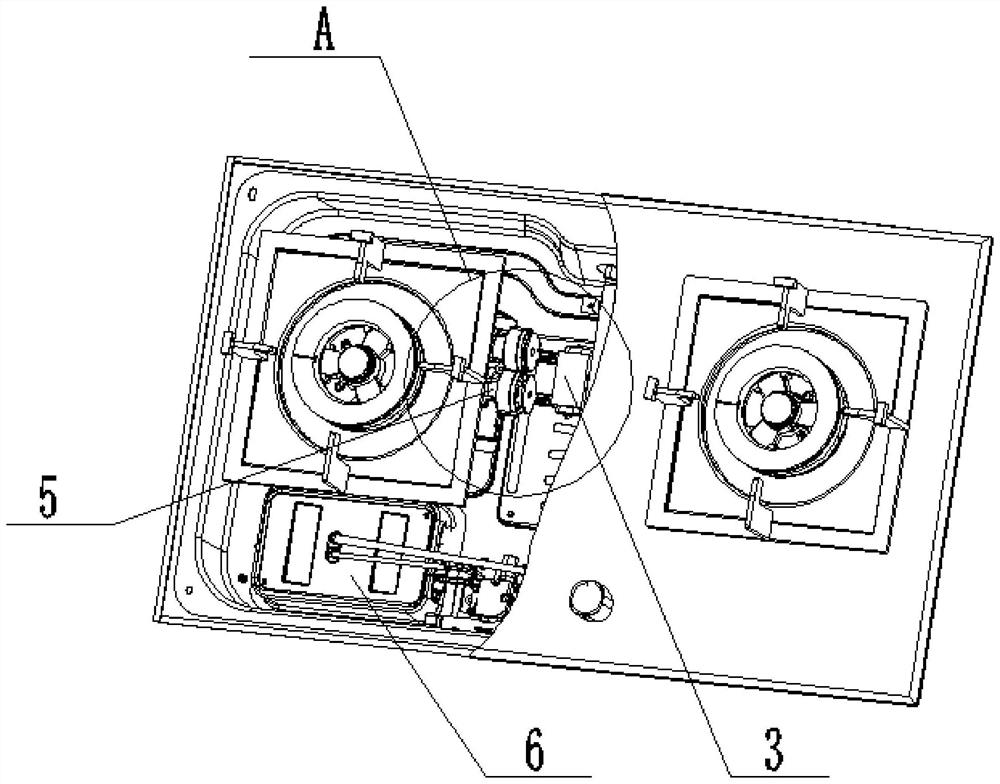

Gas stove and gas stove control method

PendingCN112161300AGuaranteed to workRealize automatic adjustmentDomestic stoves or rangesLighting and heating apparatusThermodynamicsProcess engineering

The invention provides a gas stove and a gas stove control method. The gas stove comprises a panel and a bottom shell, wherein the panel is provided with a combustor and a support structure arranged in the circumferential direction of the combustor. The gas stove further comprises an air door adjusting device, a gas detection device and a controller, wherein the air door adjusting device is arranged inside the bottom shell and is suitable for adjusting the ventilation amount of an air door structure connected with the combustor; the gas detection device is arranged on the panel and is suitablefor detecting gas components in smoke emitted by the combustor in a working state; and the controller is arranged inside the bottom shell and is in communication connection with the air door adjusting device and the gas detection device. The gas components in the smoke are detected through the gas detection device, after signals are transmitted to the controller, whether the air supply amount ofthe combustor in the working environment is sufficient or not is judged through comparison and recognition, the ventilation amount of the air door adjusting device is controlled according to the condition, normal work of the combustor is guaranteed, the air door structure can be automatically adjusted, the combustion working condition is more stable and efficient, and a user can use the gas stoveconveniently.

Owner:GREE ELECTRIC APPLIANCES INC

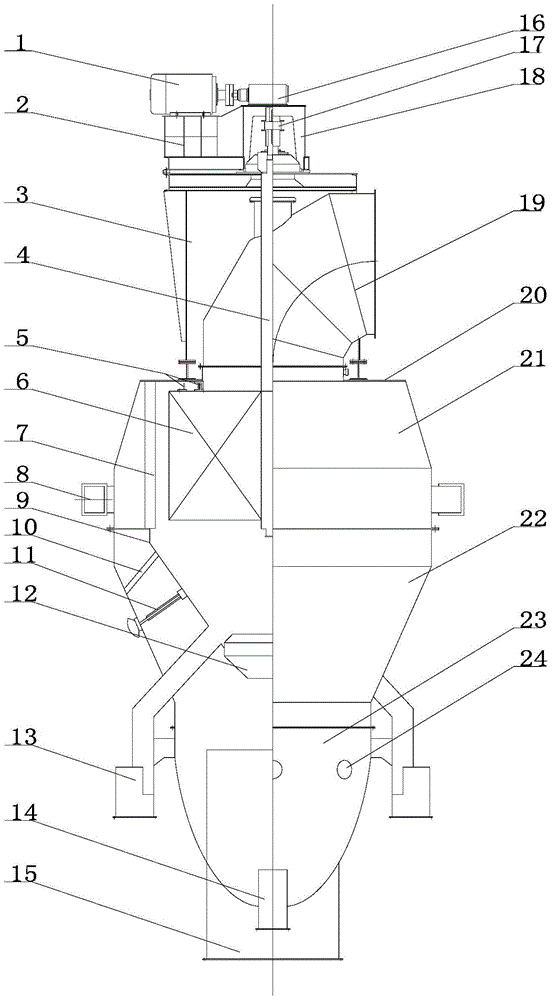

A wind-swept dynamic and static combined high-efficiency dust separator

ActiveCN104190621BQuality improvementLow resistivityGas current separationFrequency changerAgricultural engineering

The invention discloses a wind sweeping type moving and motionless combination efficient separator. The wind sweeping type moving and motionless combination efficient separator mainly comprises an air outlet, an upper cover plate, an upper cylinder body, a cage type rotor, a middle cylinder body, a lower cylinder body, an inner cone, a medium dust discharging opening, a coarse dust discharging opening and an air inlet. The separator is characterized in that a motor and a transmission device are arranged on the upper cover plate, the cage type rotor is composed of a support, a main shaft, grading blades and the like, and is in key connection with the main shaft, transmission is achieved by the motor through a speed reducer, a fine dust grading chamber is formed between the outer ring of the cage type rotor and the guide blades, the inner cone is arranged on the lower portion of the fine dust grading chamber, a coarse dust grading area is formed by the inner cone and the middle cylinder body, the inner cone is connected to a lower cone through a fixed plate, and flexible adjusting and control over product fineness and grain fineness distribution can be achieved by utilizing a frequency changer.

Owner:SINOMA INT ENG

Inner flame energy-concentrating riser pipe type gas burner

ActiveCN101725987BHigh thermal efficiencyStable combustion conditionsGaseous fuel burnerMultiple burner assemblyThermal efficiencyExhaust emission

The invention discloses an inner flame energy-concentrating riser pipe type gas burner, which comprises a big fire burner, a small fire burner, a mixing tube of the big fire burner, a positioning tube of the small fire burner, and a water collector. An inner ring of an annular shell of the big fire burner is an inverted frustum which forms an angle between 20 and 80 DEG with a horizontal plane, and 1 to 5 fire exhaust holes are formed on the inner ring. One end of the mixing tube of the big fire burner is connected with the annular shell and communicated with an inner cavity of the annular shell, while the other end is communicated with a big fire nozzle which is arranged on the lower part of the water collector. The small fire burner comprises a frustum cap shell and an inner cavity of the frustum cap shell, wherein 1 to 5 fire exhaust holes are formed on external side face of the frustum cap shell, and the inner cavity of the frustum cap shell is communicated with a small fire nozzle which is positioned on the lower part of the water collector by a mixing tube of the small fire burner. The inner flame energy-concentrating riser pipe type gas burner has the advantages of reasonable structure, high thermal efficiency, material conservation, convenient processing, excellent energy-saving effect, less exhaust emission and the like.

Owner:三峰实业有限公司

Bunker

ActiveCN103629688BGuaranteed continuityStable combustion conditionsLarge containersLump/pulverulent fuel feeder/distributionCombustionUltimate tensile strength

The invention relates to a coal bunker. The coal bunker comprises an upper coal bunker body and a lower coal bunker body which is connected with at least one air pipe, the air pipe injects air in the lower coal bunker body from bottom to top, the air pipe is connected with an air supply device used for supplying air into the lower coal bunker body, the air pipe is provided with a control device, and the air in the air pipe enters the lower coal bunker body under the control of the control device. The coal bunker has the advantages that the air in the air supply device enters the lower coal bunker through the air pipe under the control of the control device, coal blocked in the lower coal bunker body can be loosened by means of kinetic energy produced by the air flowing from bottom to bottom, continuity of coal feeding of a boiler is guaranteed, combustion conditions of the boiler are stabilized greatly, work intensity is reduced, safety is good, and manpower is saved.

Owner:CHANGXING XINCHENG ENVIRONMENTAL PROTECTION

A suspended three-chamber aluminum furnace head

ActiveCN109737403BSolve ejection problemsStable combustion conditionsDomestic stoves or rangesGaseous fuel burnerCombustorEngineering

The invention discloses a suspension three-cavity aluminum burner, and relates to the technical field of combustors. The suspension three-cavity aluminum burner is composed of a burner main body, a mixing cavity and a burner cap; the interior of the burner main body is provided with the mixing cavity, and the burner cap is installed on the surface of the mixing cavity; the burner main body is composed of an outer ring body and a center ring body; the mixing cavity is composed of an outer ring mixing cavity, a middle ring mixing cavity and a center mixing cavity, the outer ring mixing cavity isarranged on the inner side of the outer ring body, the middle ring mixing cavity is arranged on the inner side of the center ring body, and the center mixing cavity is arranged in the center of an inner ring of the center ring body; and the outer surface of the outer ring body is fixedly connected with an outer ring arc pipe. According to the suspension three-cavity aluminum burner, a nozzle andan injection pipe are arranged above a combustor panel or a water pond, primary air, secondary air and third air required from combustion are guided in from the upper portion of the panel or the waterpond, the problem that injection of the combustor is conducted from the interior of a bottom shell is solved, and complete upper air feeding combustion is achieved.

Owner:佛山市宇煜五金有限公司

Automatic Waste Feed Control System

ActiveCN110482166BRealize automatic stable feeding functionAutomatically stabilize combustion conditionsControl devices for conveyorsControl systemStructural engineering

The invention discloses a system for automatically controlling garbage feeding. The system comprises a first radio frequency admittance material level switch, at least one second radio-frequency admittance material level switch and an ultrasonic sensor, wherein the first radio frequency admittance material level switch is provided with a low material level switch and a high material level switch;the low material level switch and the high material level switch are arranged on a drum feeding port material well wall from bottom to top; a flange sleeve is arranged at the mounting position of thefirst radio frequency admittance material level switch; a first radio frequency admittance material level meter is fixed on the flange sleeve and can be movably adjusted; the second radio-frequency admittance material level switch is arranged on the drum discharging port material well wall, and stops upper and lower feeding and sending an alarm of a high material level at the lower position underthe condition of high material level; and the ultrasonic sensor comprises a first ultrasonic sensor and a second ultrasonic sensor. According to the system, the automatic stable feeding function of aboiler feeding system can be realized, and material level detection, material breaking alarming, feeding port material level height limit alarming, automatic material supplementing, automatic feedingadjustment, automatic material breaking in an abnormal state and the like can be realized, so that the workload and pressure of operators are relieved, and the boiler combustion working condition is more stable.

Owner:武汉市绿色环保能源有限公司

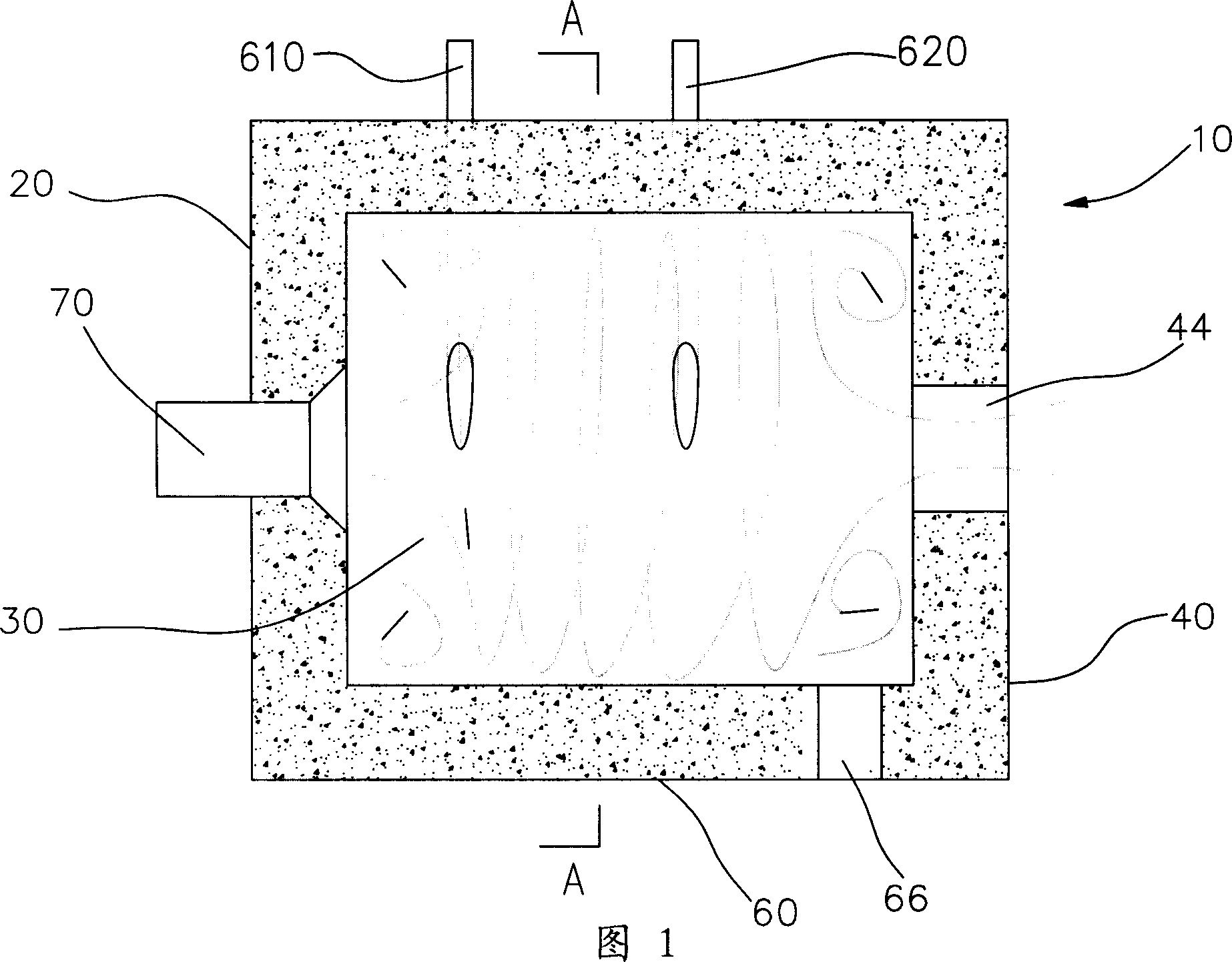

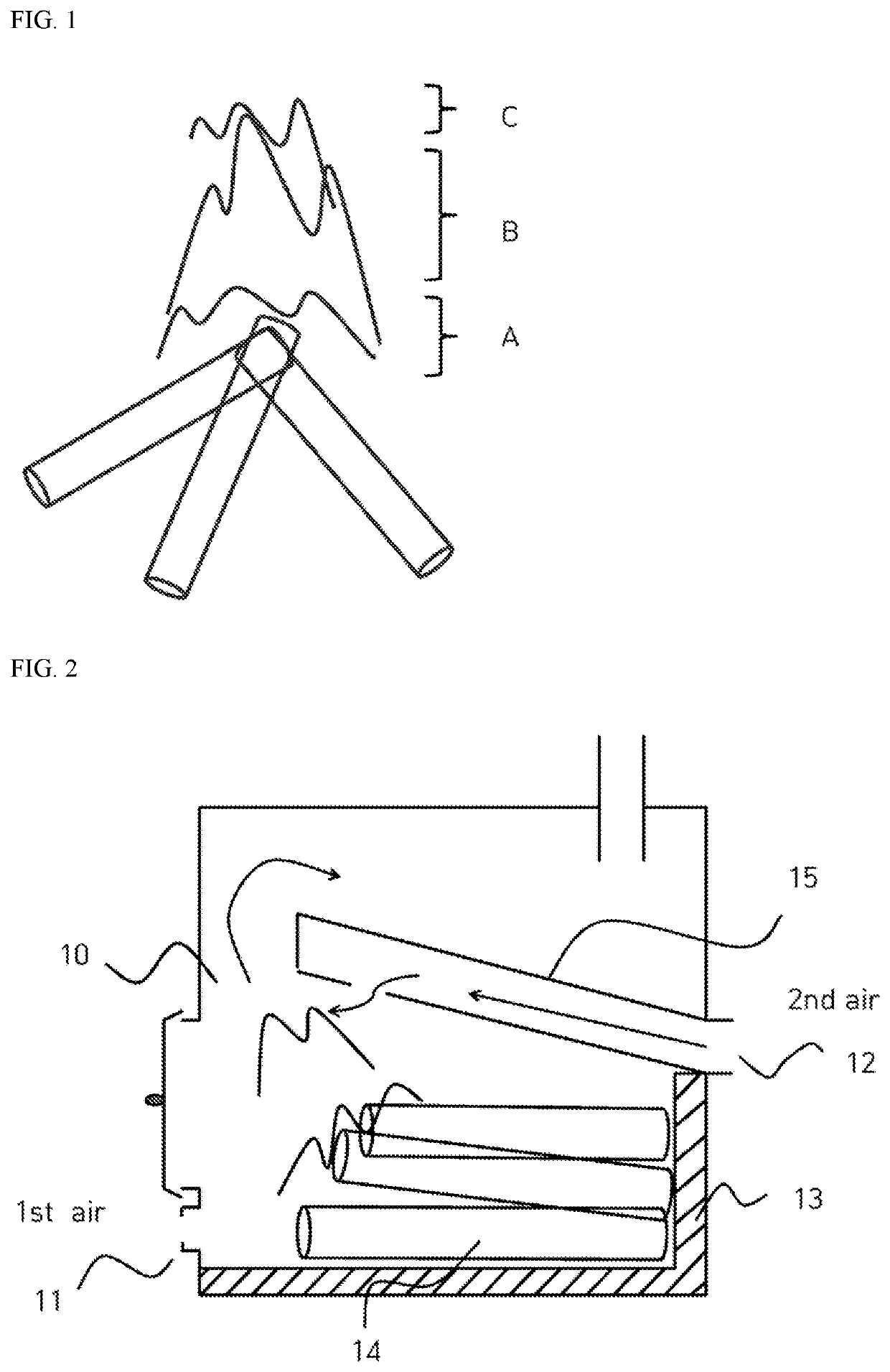

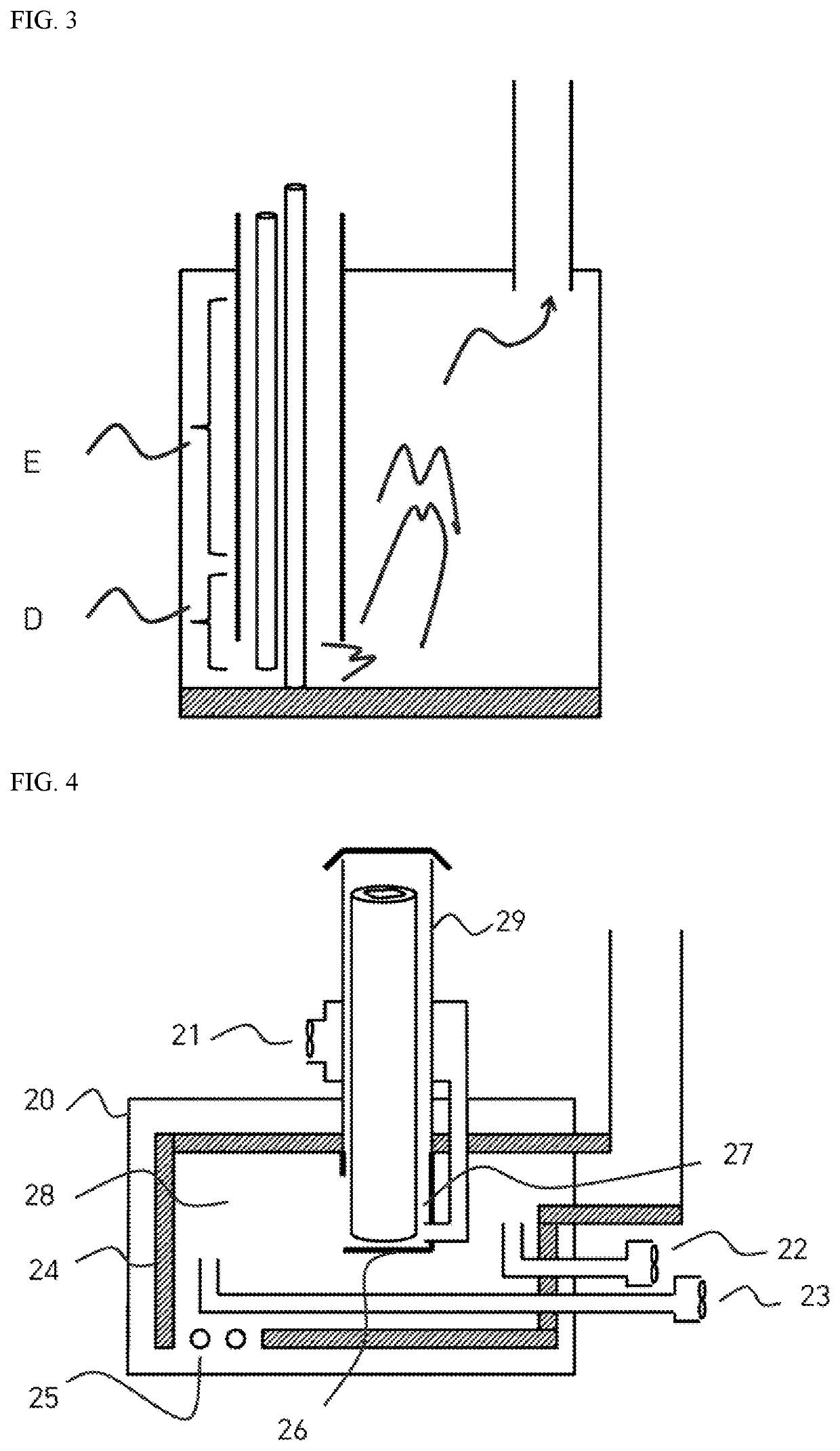

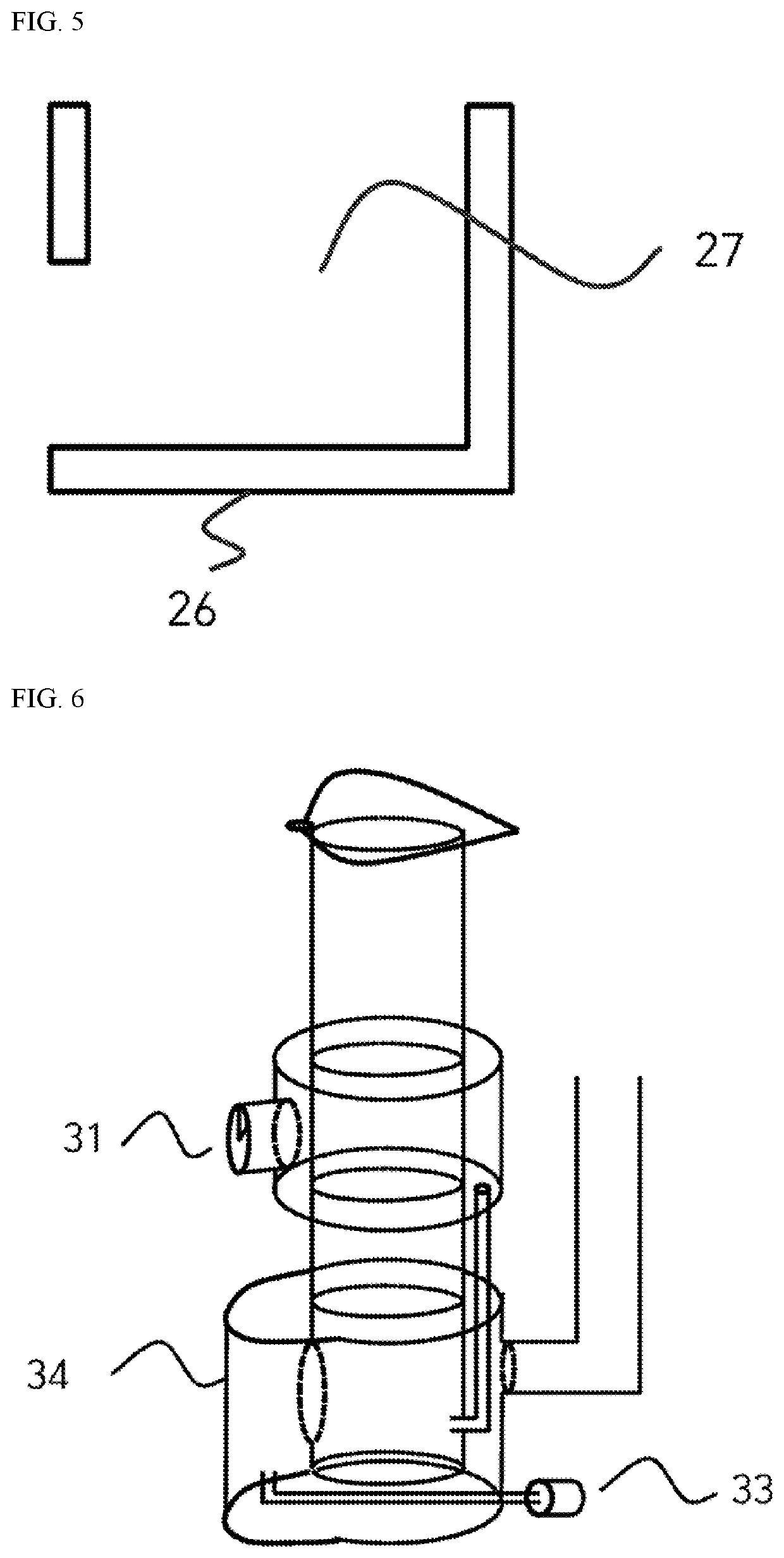

Combustor for various types of solid fuels

ActiveUS10890321B2Stable combustion conditionsA large amountCombustion-air/flue-gas circulation for stovesSolid fuel combustionFirewoodCombustion chamber

A solid fuel combustion device includes: a fuel supply device including a firewood feed pipe or another fuel supplier; a primary combustion chamber coupled to the fuel supply device; a secondary combustion chamber including a wall formed of a fireproof material and having a structure in which a space is formed at a side of the combustion gas outlet of the primary combustion chamber to induce primary combustion gas to be secondarily expanded and combusted; and an air supply system including at least one air supply device in an entire combustion path formed in the primary combustion chamber and the secondary combustion chamber.

Owner:KIM SEONG WOO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com