Biomass gas burner

A gas burner and biomass technology, which is applied to gas fuel burners, burners, combustion methods, etc., can solve the problems of inability to burn biomass gas well and the calorific value of biomass gas is unstable, and achieve stable combustion conditions. , the effect of full combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

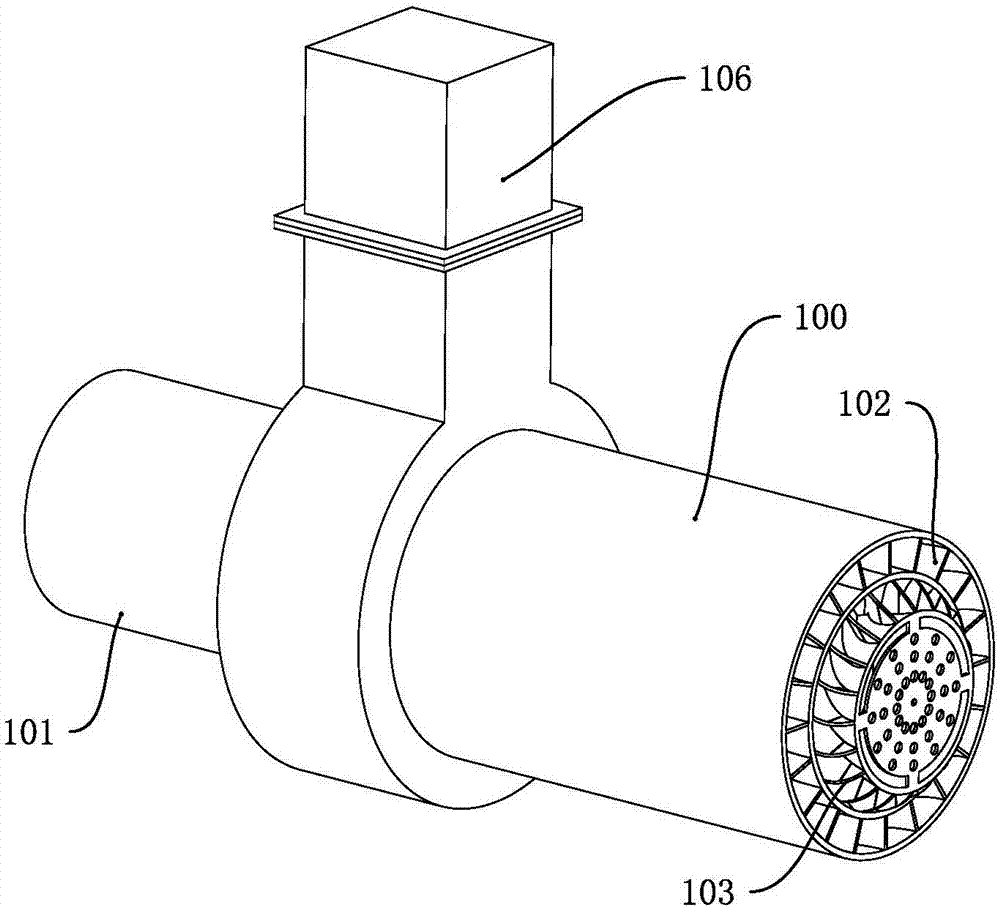

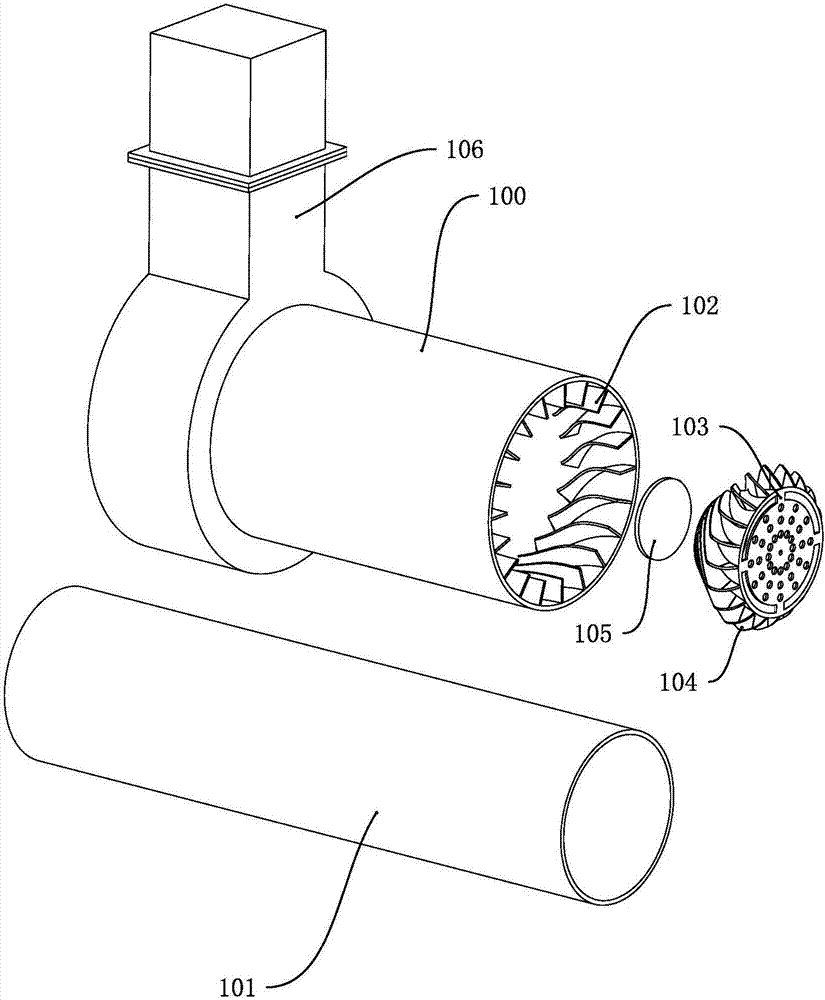

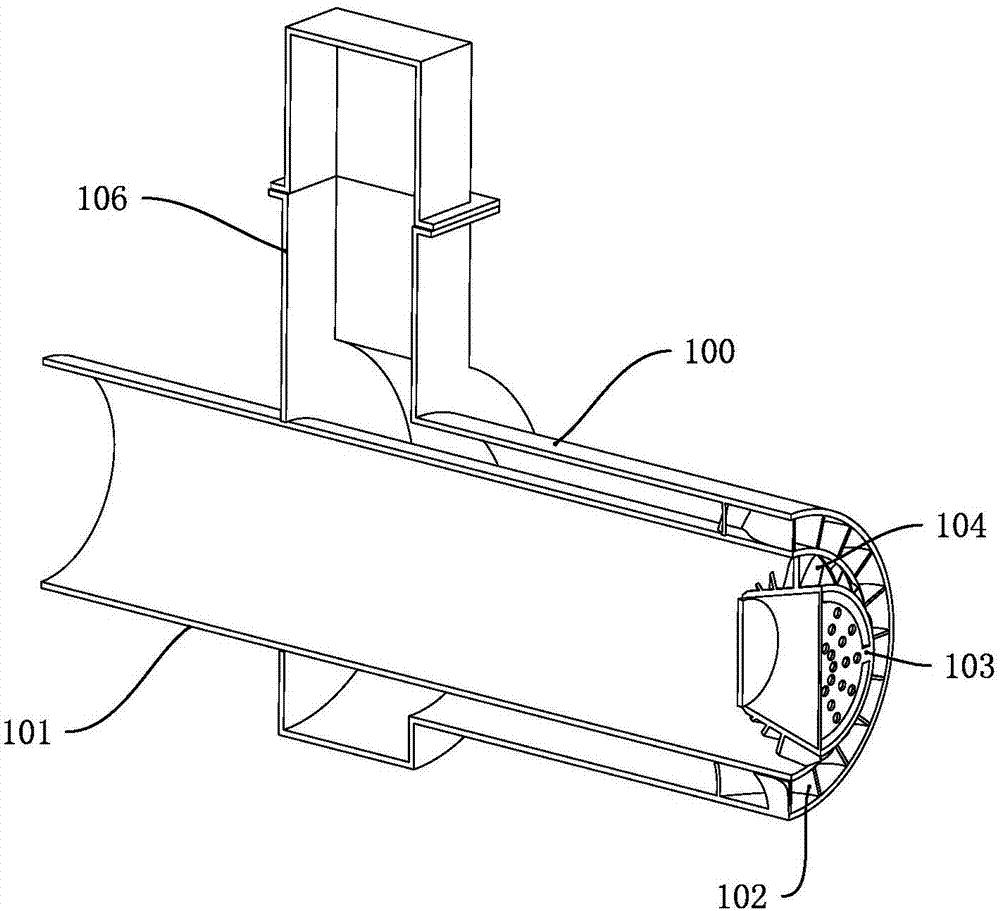

[0019] Such as Figure 1 to Figure 3 As shown, a biomass gas burner includes an air duct 100 for introducing air, a combustion tube 101 whose rear end is connected to an external biomass gas delivery pipeline, and a burner 103 located in the front end of the combustion tube 101 . The front end inner wall of the air guide pipe 100 is provided with a first guide vane 102, and the front end of the combustion pipe 101 extends into the air guide pipe 100 at the rear end of the combustion pipe 101 and there is a gap between the inner wall of the air guide pipe 100. The combustion pipe 101 It is sealed and connected with the rear end of the air guide pipe 100, and the front end of the combustion pipe 101 is flush with the front end of the air guide pipe 100; the shape of the burner 103 is a cone shape, a truncated cone, and the outer wall of the burner 103 is provided with a second flow guide The vanes 104, the first guide vanes 102 and the second guide vanes 104 form a guide air cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com