Integral gasification furnace ignition device under pressure

The technology of an ignition device and a gasifier is applied in the direction of combustion ignition, lighting and heating equipment, combustion methods, etc., which can solve the problems of ignition burner pollution, ignition failure, unstable operation, etc., and achieve strong anti-pollution ability, ignition high energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

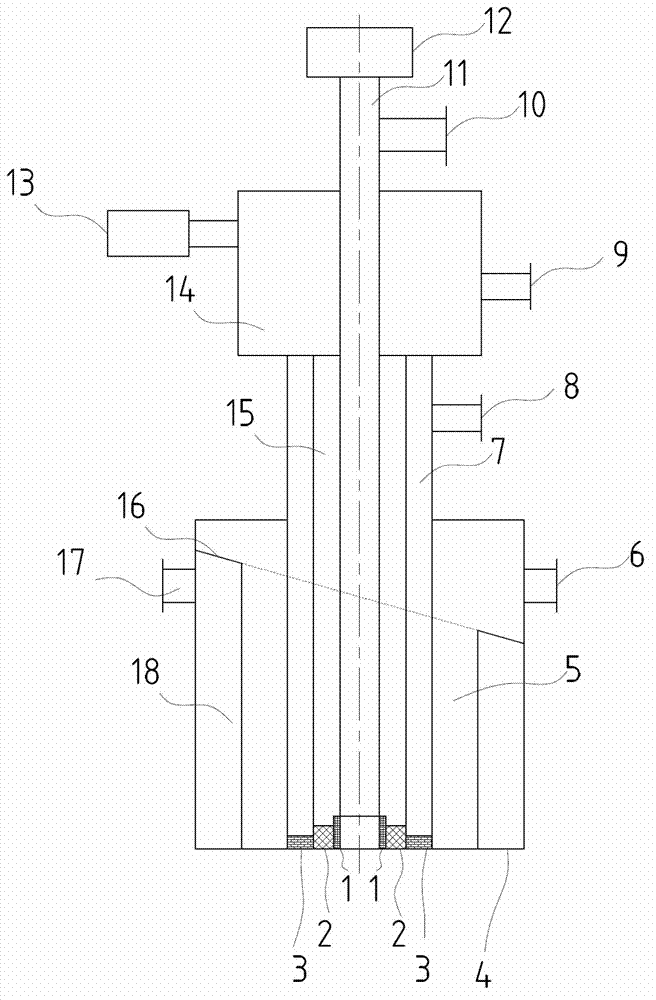

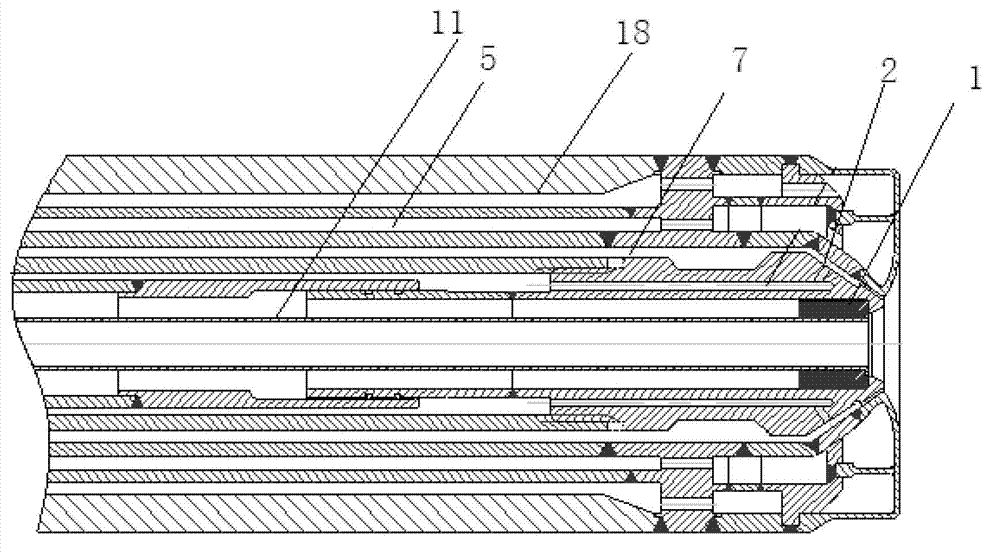

[0016] See attached figure 1 , a pressure ignition device for an integrated gasifier, which includes: a high-energy igniter 1, a fuel nozzle 2, an oxygen nozzle 3, a water jacket 4, an oxygen delivery pipe 7, a center pipe 11, a flame detector 12, and an igniter Power connector 13, flange end seat 14 and fuel delivery pipe 15;

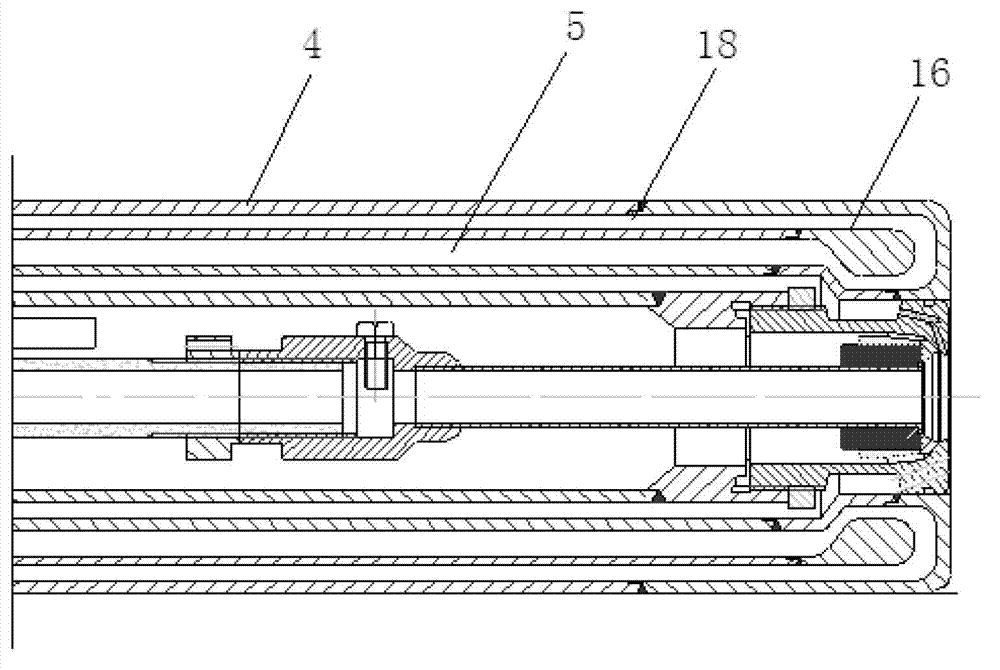

[0017] The water jacket 4 is provided with a water inlet 6 and a water return port 17. The inside of the water jacket 4 is divided into two layers inside and outside by a partition 16. The inner layer is the water inlet channel 5, and the outer layer is the return water channel 18. The water inlet channel 5 communicates with the water inlet 6, and the water return channel 18 is connected with the water return port 17;

[0018] The center of the igniter power connector 13 is a conductive metal, which is connected to the high-energy igniter 1 through a conductive wire, and a layer of ceramics is wrapped around the conductive metal. The ceramic is covere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com