Zwitterionic monomer containing bisamide structure and preparation method of zwitterionic monomer

A technology of zwitterion and bisamide, which is applied in the field of zwitterion compound synthesis, can solve the problems of increased sailing resistance of the hull, blocked and destroyed pipelines, and reduced sailing speed, and achieves the effects of less by-products, low cost and mild reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

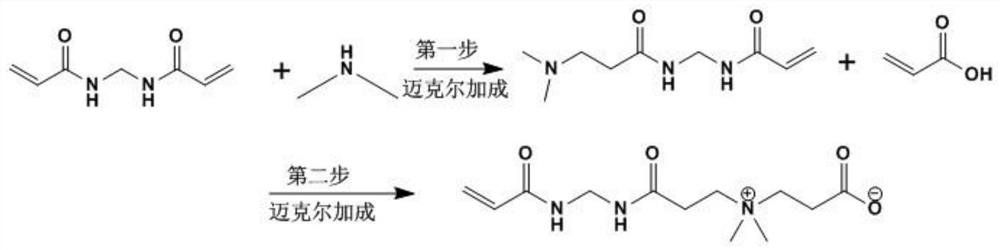

Method used

Image

Examples

Embodiment 1

[0021] Take 3.08g of N,N'-methylenebisacrylamide (MBAA), dissolve 5.00mL of dimethylamine in 80mL of methanol, stir the reaction at 20°C for 48h, and then rotate the mixture after the reaction. Add 20mL acetone and 3mL acrylic acid to the rotary steamed product, stir and react at 20°C for 48h, add 20mL triethylamine and stir for 24h, after centrifugation, wash with acetone, dimethyl sulfoxide (DMSO), diethyl ether for several times, centrifuge, vacuum After drying, a white zwitterionic monomer powder containing a bisamide structure is obtained.

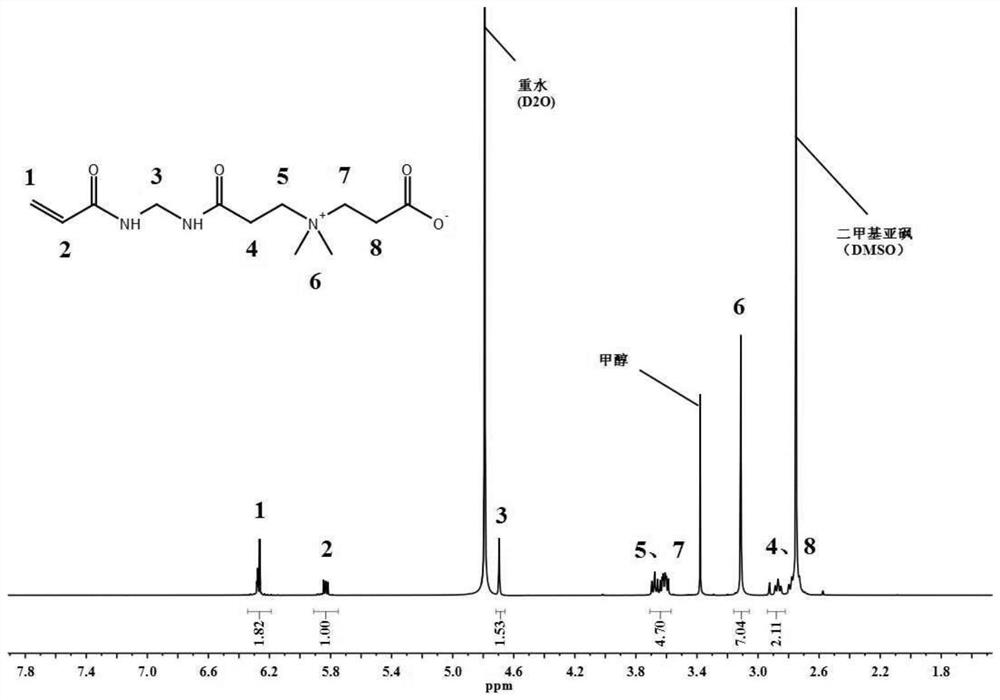

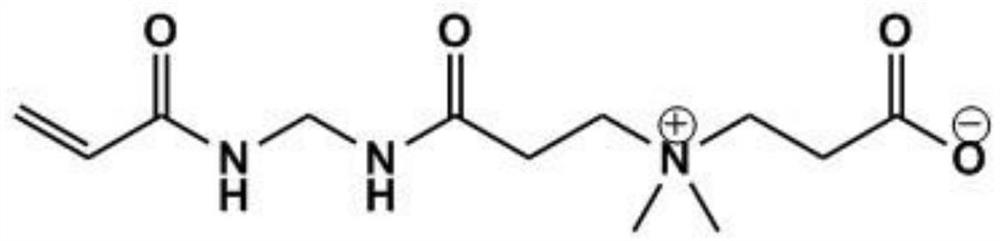

[0022] Such as figure 2 As shown, the structure of the zwitterionic monomer containing the bisamide structure obtained in Example 1 is characterized by proton nuclear magnetic resonance: 1H-NMR (400MHz, D 2 O): δ6.26(2H), 5.83(1H), 4.69(2H), 3.67(2H), 3.60(2H), 3.11(6H), 2.86(2H), 2.76(3H). Among them, 6.26 and 5.83 are the characteristic peaks of the double bond of the monomer; 4.69 is the characteristic peak of the methylene betw...

Embodiment 2

[0024] Take 13g of N,N'-methylenebisacrylamide (MBAA), dissolve 35mL of dimethylamine in 250mL of methanol and stir the reaction at 10°C for 12h, then rotate the mixture after the reaction. Add 200mL of acetone and 19mL of acrylic acid to the rotary evaporated product, stir and react at 25°C for 48h, add 60mL of triethylamine and stir for 12h, wash with acetone, dimethyl sulfoxide (DMSO) and ether several times after centrifugation, centrifuge, vacuum After drying, a white zwitterionic monomer powder containing a bisamide structure is obtained.

Embodiment 3

[0026] Take 8g of N,N'-methylenebisacrylamide (MBAA), dissolve 50mL of dimethylamine in 150mL of methanol and stir the reaction at 40°C for 12h, then rotate the mixture after the reaction. Add 200mL of acetone and 15mL of acrylic acid to the rotary evaporated product, stir and react at 30°C for 72h, add 55mL of triethylamine and stir for 24h, wash with acetone, dimethyl sulfoxide (DMSO) and ether for several times after centrifugation, centrifuge, vacuum After drying, a white zwitterionic monomer powder containing a bisamide structure is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com