Electrode for electric flocculation-fiber filtration water treatment device, electric flocculation-fiber filtration water treatment device and use method of electric flocculation-fiber filtration water treatment device

A water treatment device and fiber filtration technology, which is applied in the field of electrodes, can solve problems such as shedding, poor process economy, and high technical cost, and achieve the effects of preventing permanent blockage, strong anti-pollution ability, and good regeneration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

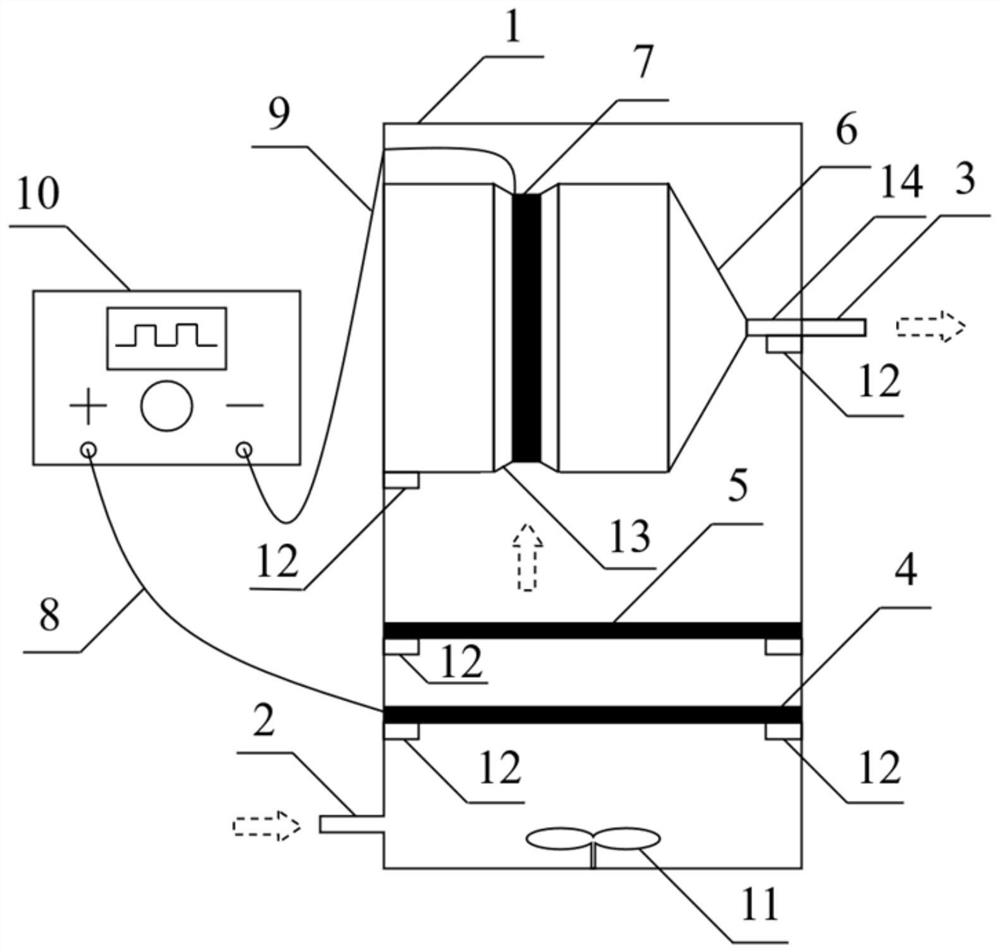

[0027] Such as figure 1 As shown, it is an electrocoagulation-fiber filtration water treatment device, including a reaction tank body 1, a water inlet 2 is provided at the bottom of one side of the reaction tank body 1, and a pool is provided at the top of the reaction tank body 1 opposite to the water inlet 2. body water outlet 3, the inside of the reaction pool body 1 is provided with an anode and a cathode, the anode includes a first anode plate 4 and a second anode plate 5, and the cathode is composed of a central filter body 6 and a carbon fiber filament 7 wound around the central filter body 6 Conductive carbon fiber filter cathode, wherein, the first anode plate 4 and the second anode plate 5 are located at the upstream of the water flow, and can be connected to the positive pole of the DC power supply 10 through the anode wire 8, and the carbon fiber filter cathode is located at the downstream of the water flow, and can pass through the cathode wire 9 is connected to t...

Embodiment 2

[0043] The electrocoagulation-fiber filtration water treatment device of Example 1 is used to process the acid orange 7 simulated dye wastewater, and the concentration of the pollutant acid orange 7 to be treated is 20 mg / L:

[0044] Control the reaction parameters: adjust the initial pH of the wastewater to 6-8, and the current density to 90A / m 2 , control the flocculation reaction time to 30min;

[0045] Treatment process: After adjusting the pH of the waste water, pass it into the reaction tank body 1, turn on the stirring device 11, then start the DC power supply 10, set the system voltage or current according to the requirements, and after a period of flocculation reaction, use the peristaltic pump to extract the waste water at a constant speed The fiber filter cathode is used for filtration and the effluent is collected.

[0046] Treatment results: Several experiments were carried out. After testing, the average removal rate of acid orange 7 was above 95%, and the maxim...

Embodiment 3

[0048] The electrocoagulation-fiber filtration water treatment device of Embodiment 1 is used to process the methylene blue simulated dye wastewater, and the methylene blue concentration of the pollutant to be treated is 20mg / L;

[0049] Control the reaction parameters: adjust the initial pH of the wastewater to 9, and the current density to 110A / m 2 , control the flocculation reaction time to 30min;

[0050] Process: same as in Example 2;

[0051] Treatment results: With the progress of the electrocoagulation process, the wastewater in the reaction tank body 1 changes from blue to dark green, reddish brown, and dark brown in turn. The lower anode 4 produces flocs, and the cathode has bubbles escaping. After filtration The color of the effluent is close to transparent; after testing, the removal rate of methylene blue in the effluent reaches 96.70%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com