Patents

Literature

143 results about "Sacrificial metal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A sacrificial metal is a metal used as a sacrificial anode in cathodic protection that corrodes to prevent a primary metal from corrosion, galvanization or rusting.

Programmable resistive memory cell with sacrificial metal

ActiveUS8097874B2Improve data retentionLow resistance stateBulk negative resistance effect devicesElectrical conductorStandard electrode potential

Programmable metallization memory cells include an electrochemically active electrode and an inert electrode and an ion conductor solid electrolyte material between the electrochemically active electrode and the inert electrode. A sacrificial metal is disposed between the electrochemically active electrode and the inert electrode. The sacrificial metal has a more negative standard electrode potential than the filament forming metal.

Owner:SEAGATE TECH LLC

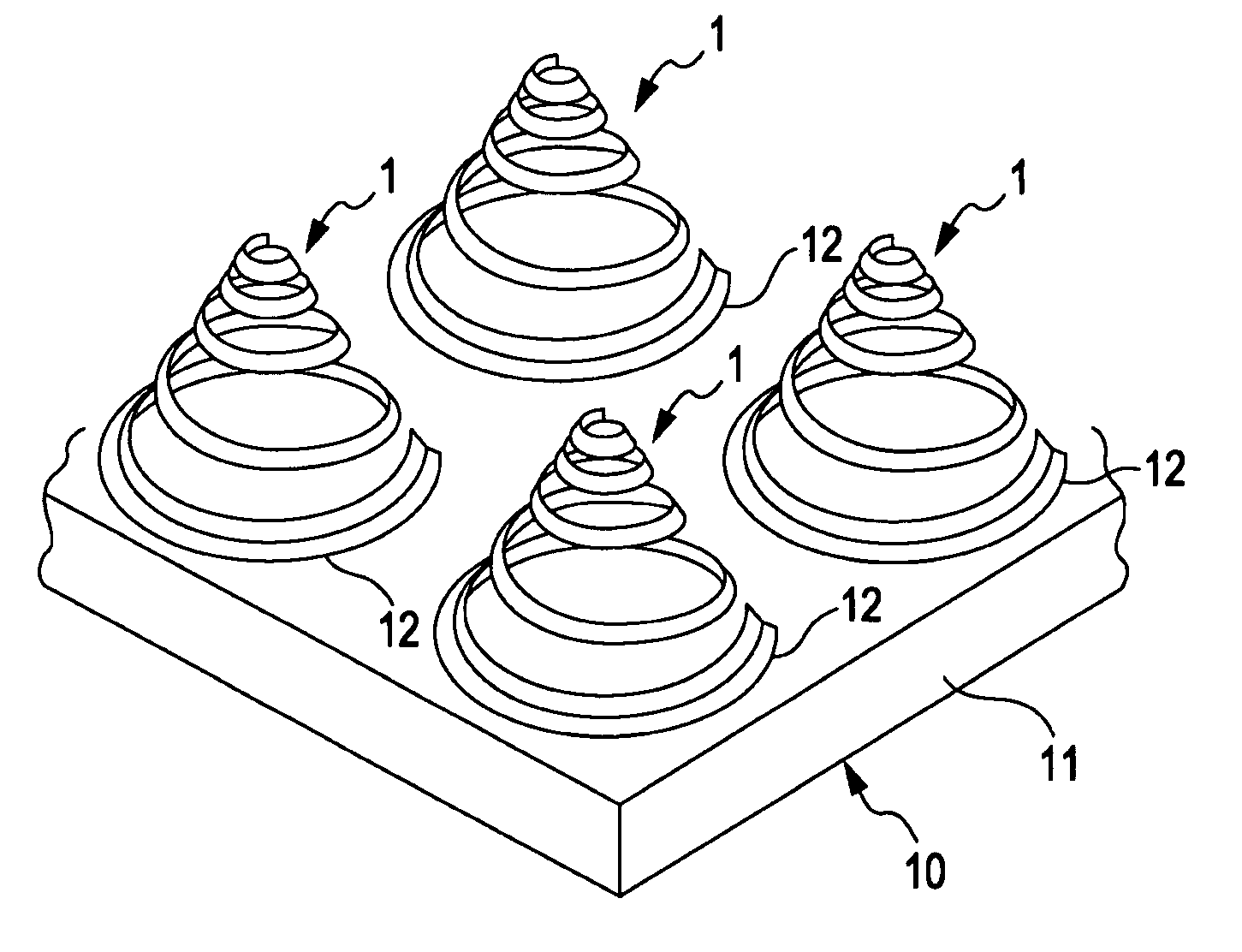

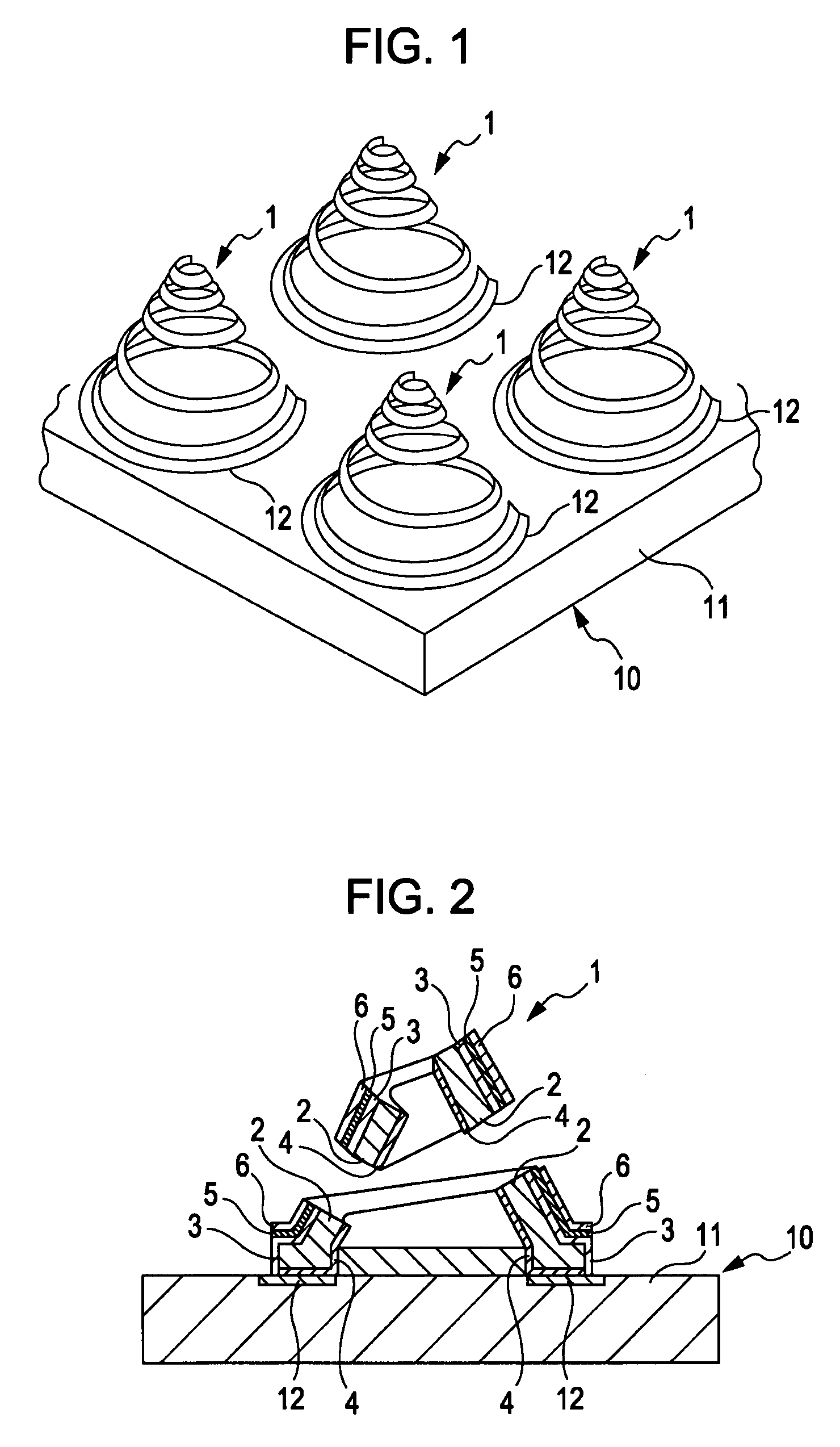

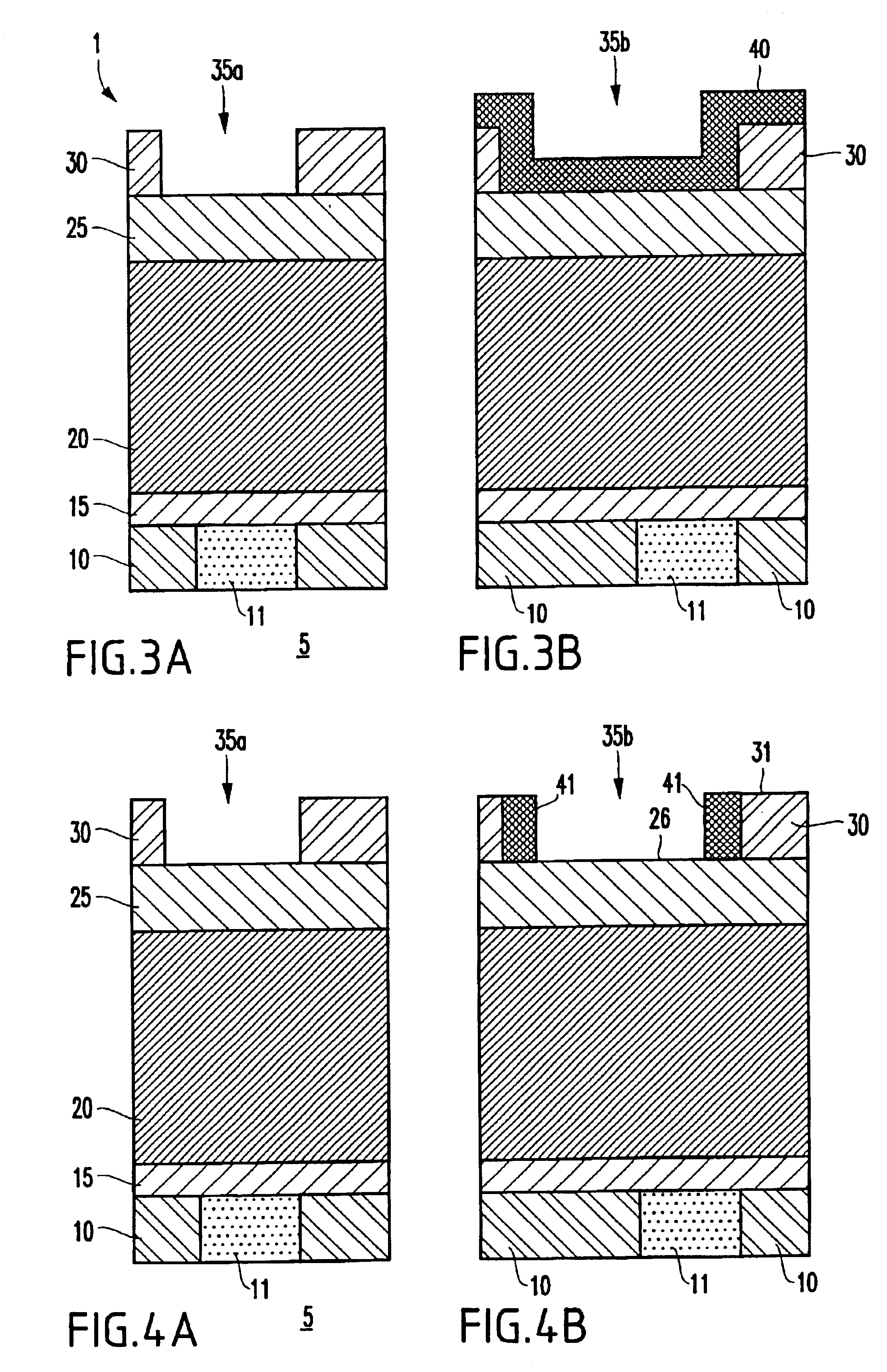

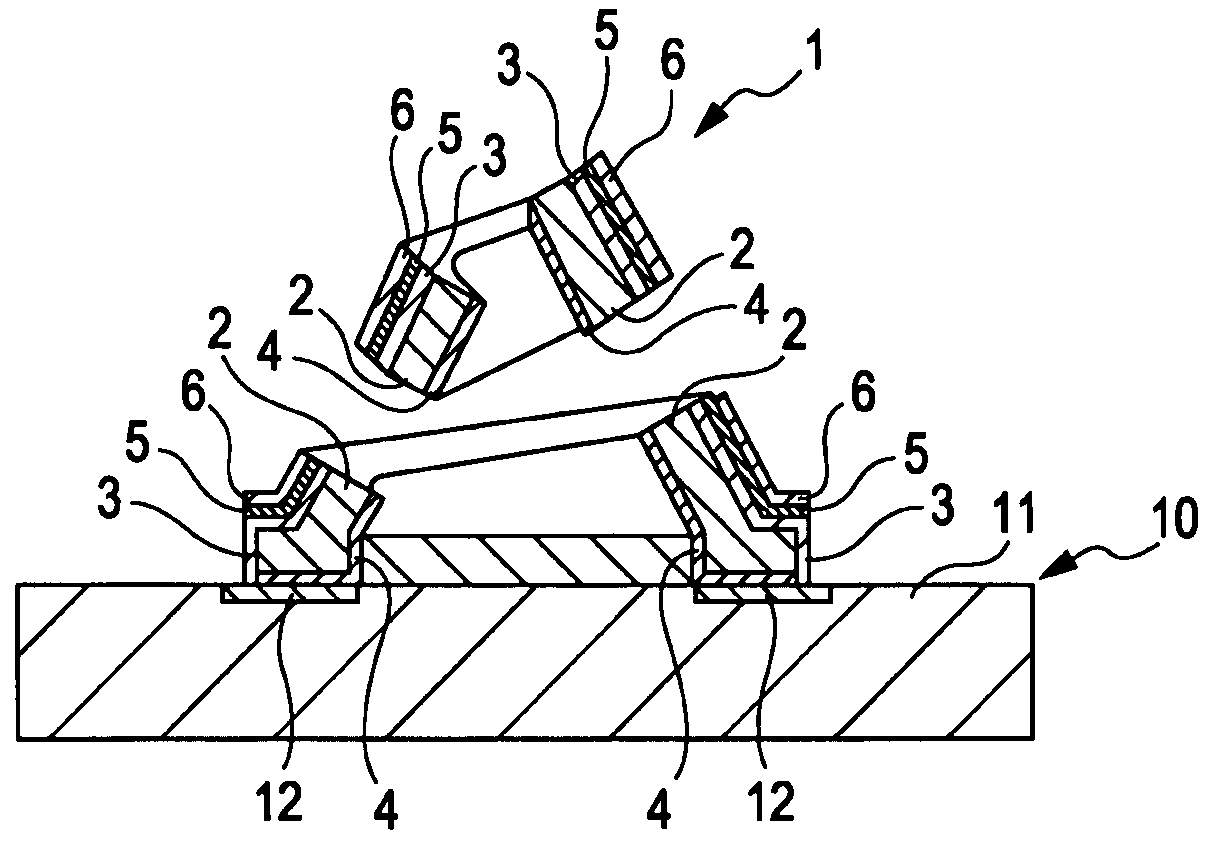

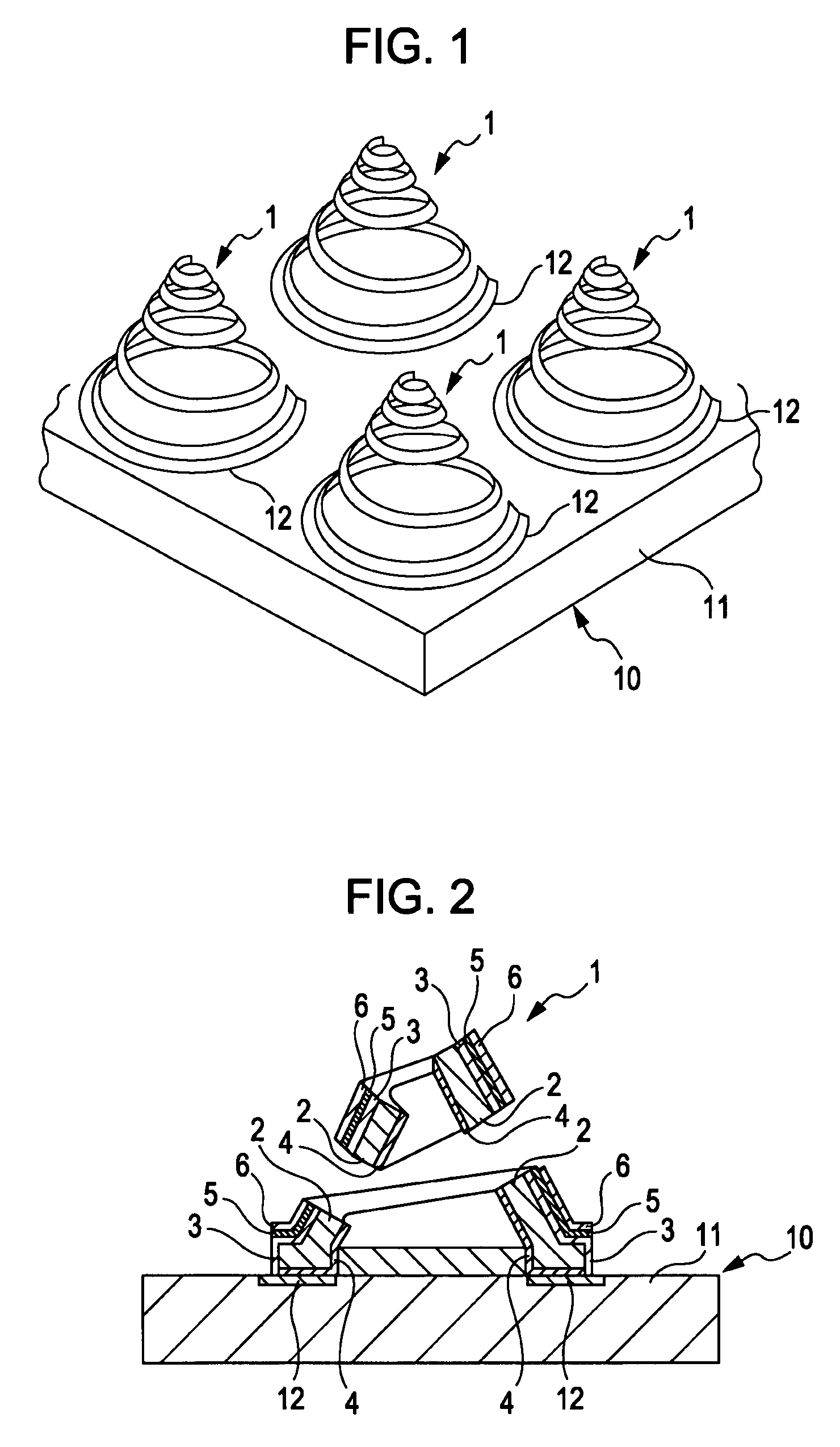

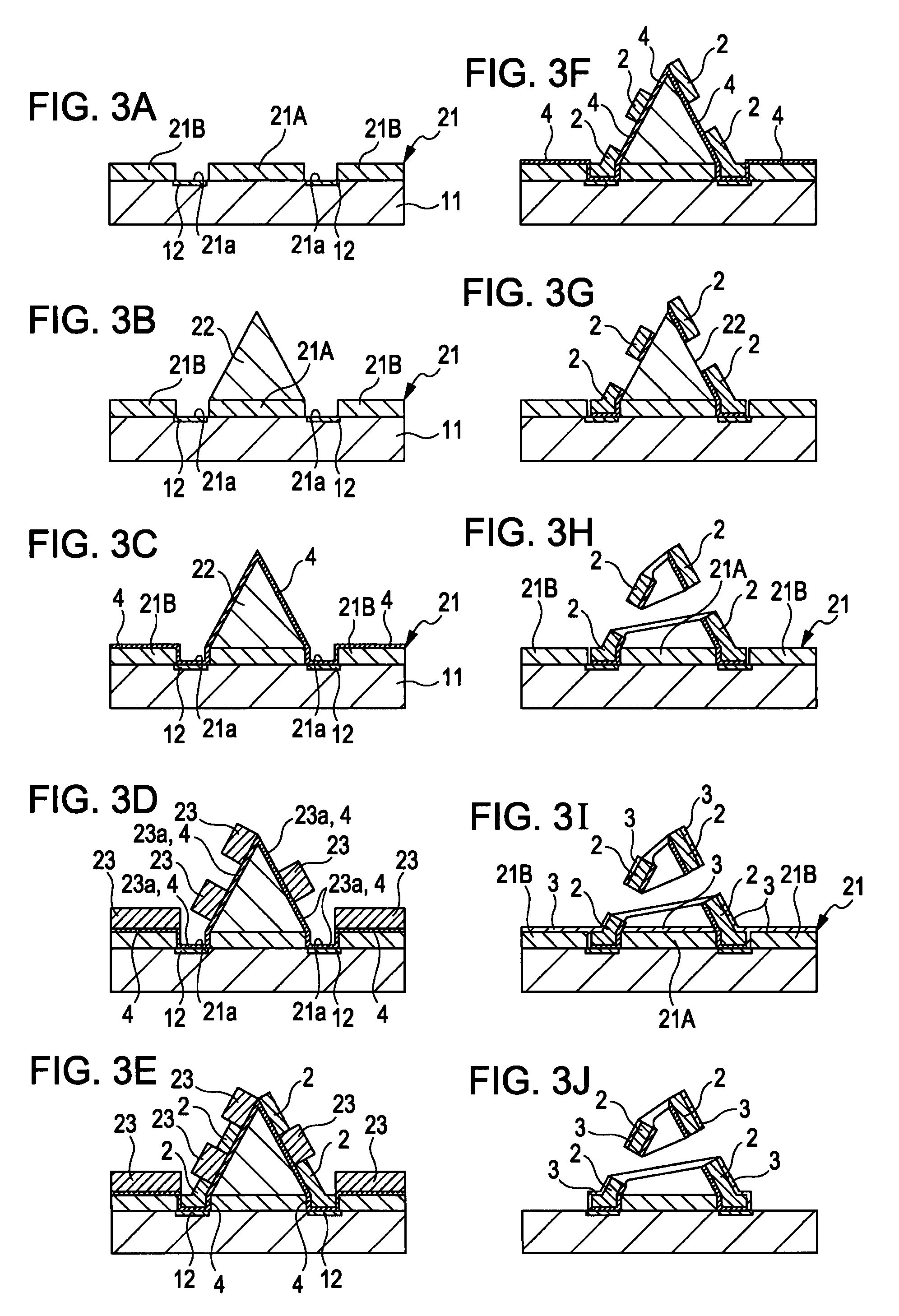

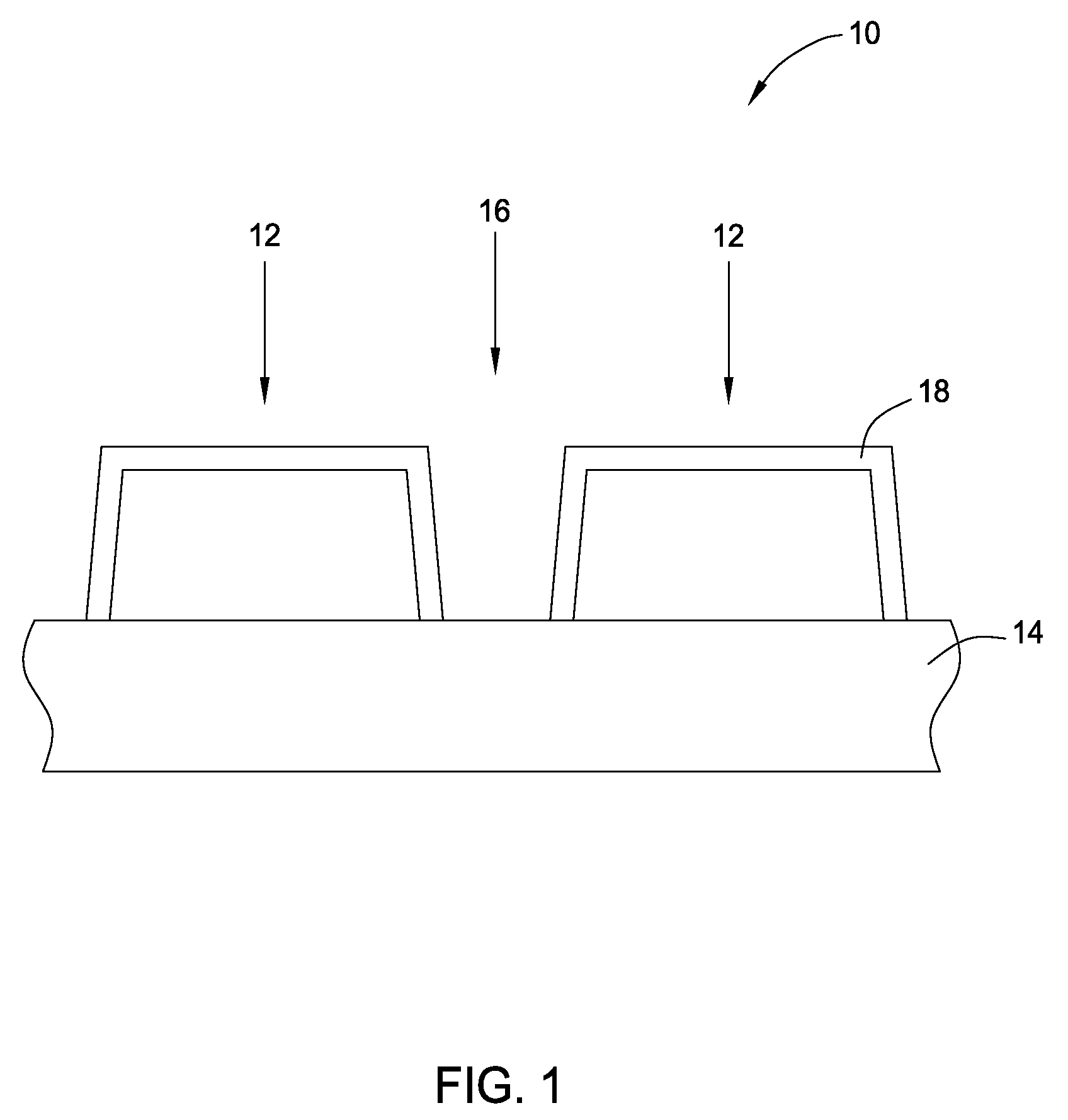

Semiconductor device contact resistant to deterioration due to heat and method for manufacturing contact

InactiveUS20080032519A1Good contact conductivityLarge elastic forceElectrical measurement instrument detailsShape memory alloy connectionsResistSputtering

A Contact according to an aspect of the present invention is formed by laminating a shape memory alloy film on a surface of a metal spring film, and the shape thereof is a conical spiral. A manufacturing method therefor is composed of 11 steps including a step of preparing a sacrificial metal film, a step of forming a resist cone, a step of patterning a resist film, a step of preparing a shape memory alloy film, and the like. Since an organic resist material has poor heat resistance, the sacrificial metal film is formed in advance, the resist is removed before sputtering of the shape memory alloy film, the sacrificial metal film is removed after sputtering of a shape memory alloy and a heat treatment, which are performed at high temperatures, so as to lift off an excess shape memory alloy film.

Owner:ALPS ALPINE CO LTD

Water treatment

InactiveUS20060000784A1Good removal effectReduce needWater/sewage treatment by irradiationWater/sewage treatment by electrochemical methodsSludgePotable water

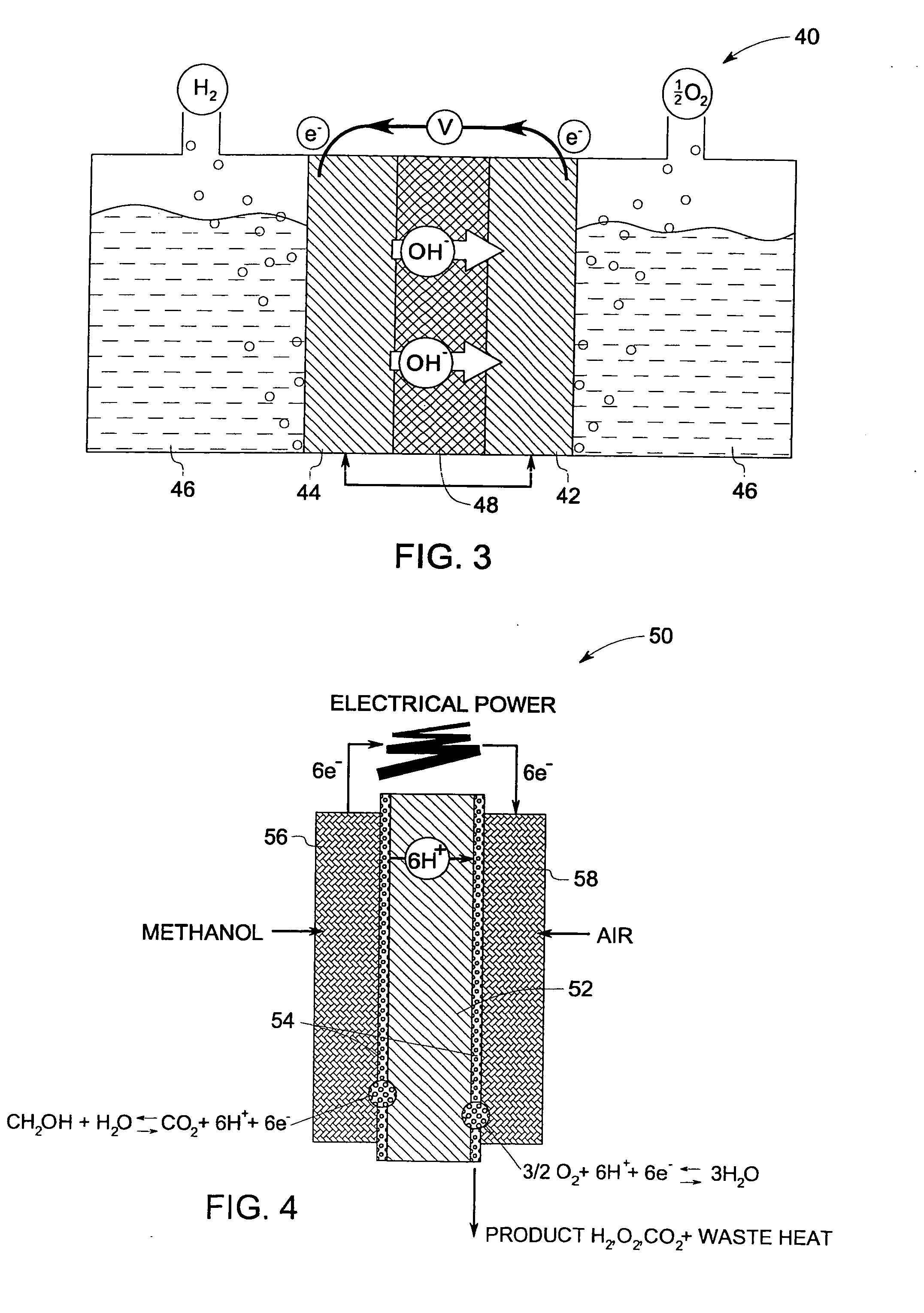

This is a method of water and wastewater treatment for removal of pollutants in at least two-step process comprising (a) treatment of water producing at least partially treated intermediate effluent, (b) treatment of the intermediate effluent with a sacrificial metal and producing ions of said sacrificial metal, and providing very thoroughly treated effluent, (c) recuperating sacrificial metal ions generated in the step (b) and recycling the recuperated ions in the step (a), the recuperated and recycled ions from the step (c) improve treatment efficiency of step (a) by additionally removing pollutants from the intermediate effluent using recuperated ions, resulting in cleaner intermediate effluent, and, therefore, the pollutant loading rate in step (b) is reduced, intermediate effluent is further treated more thoroughly, and the demand for the sacrificial metal in step (b) is reduced. Step (a) can preferably be a biological, biological-abiotic, physical chemical, or combination of these steps. Step (b) is preferably a spontaneous cementation-driven electrochemical process. The combination of said steps (a), (b) and (c) produces a synergistic effect resulting in improved removal of said pollutants and in reduced need in said sacrificial metal. For example, a drinking quality water can be very economically and reliably obtained from wastewater. In addition to the superb treatment efficiency and reduced reagent requirements, the waste sludge from the system is beneficially disposed in-sewers, in sanitary landfills or on land.

Owner:KHUDENKO BORIS

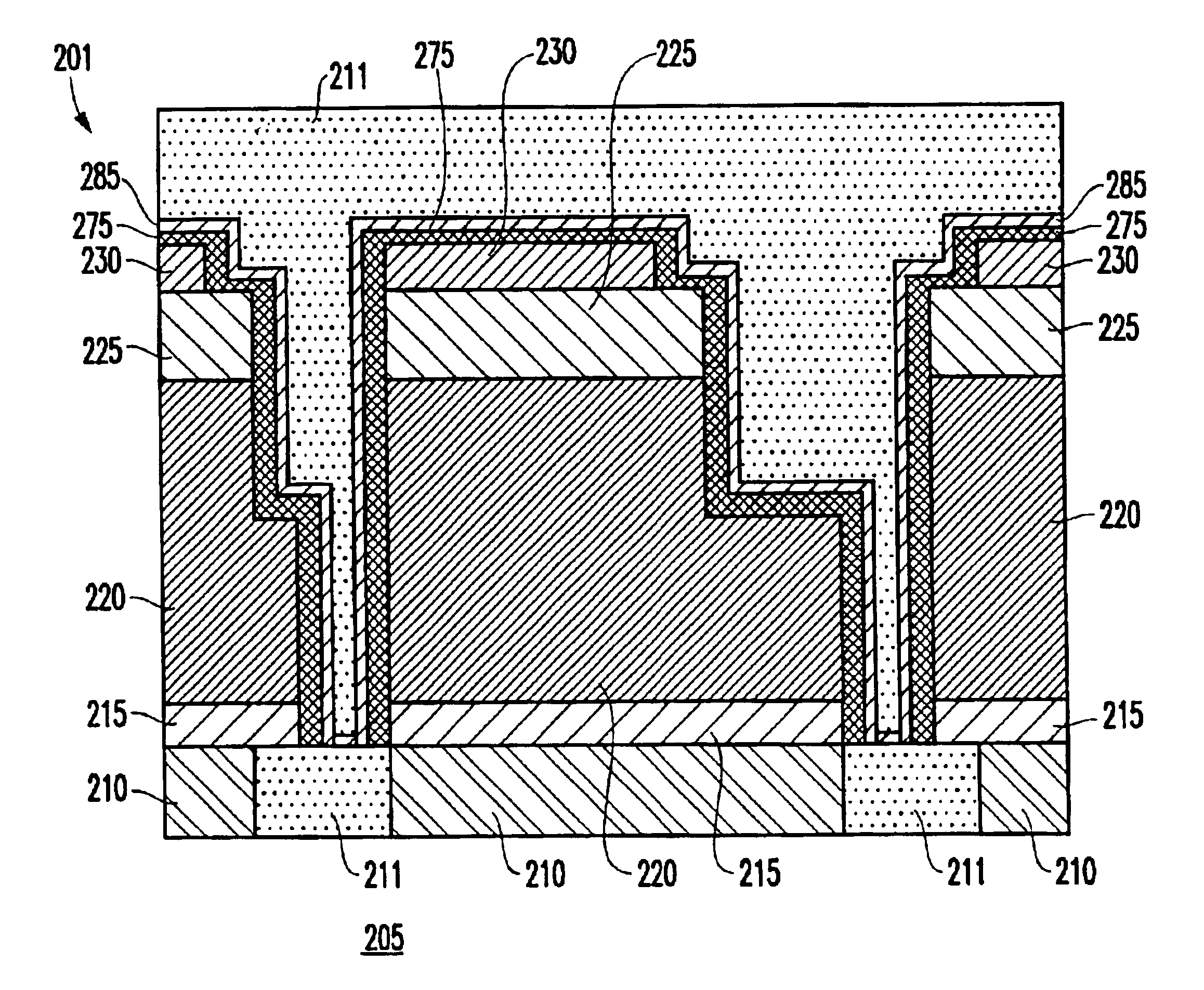

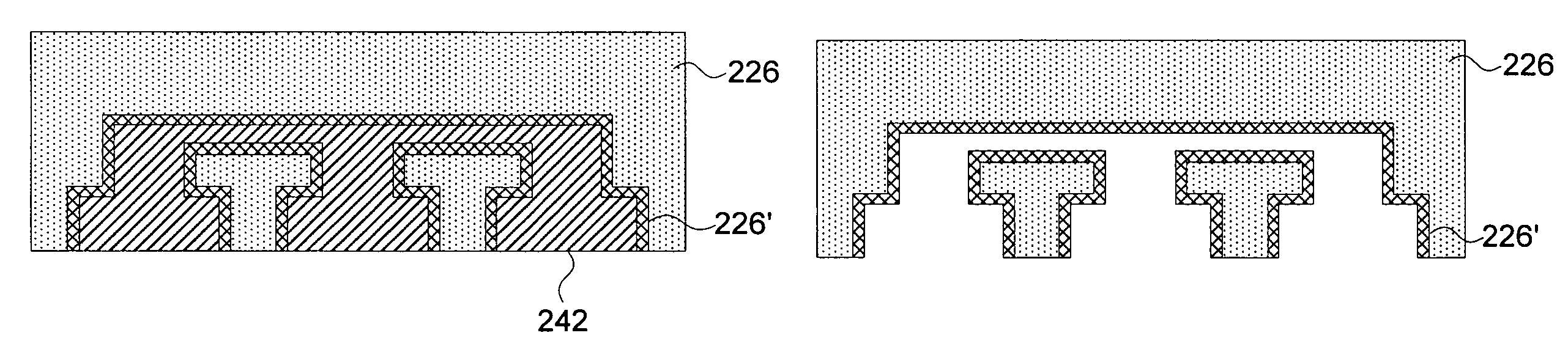

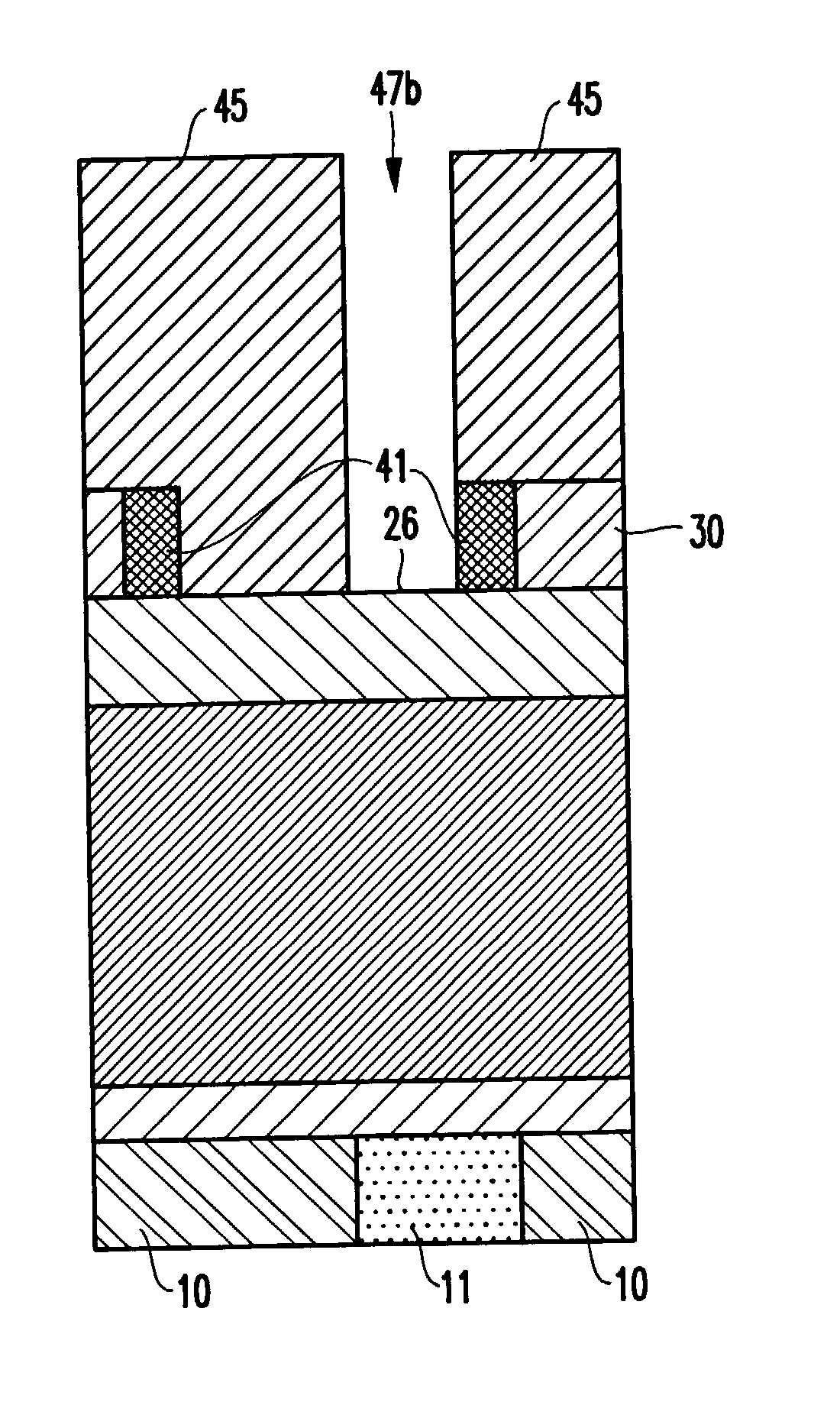

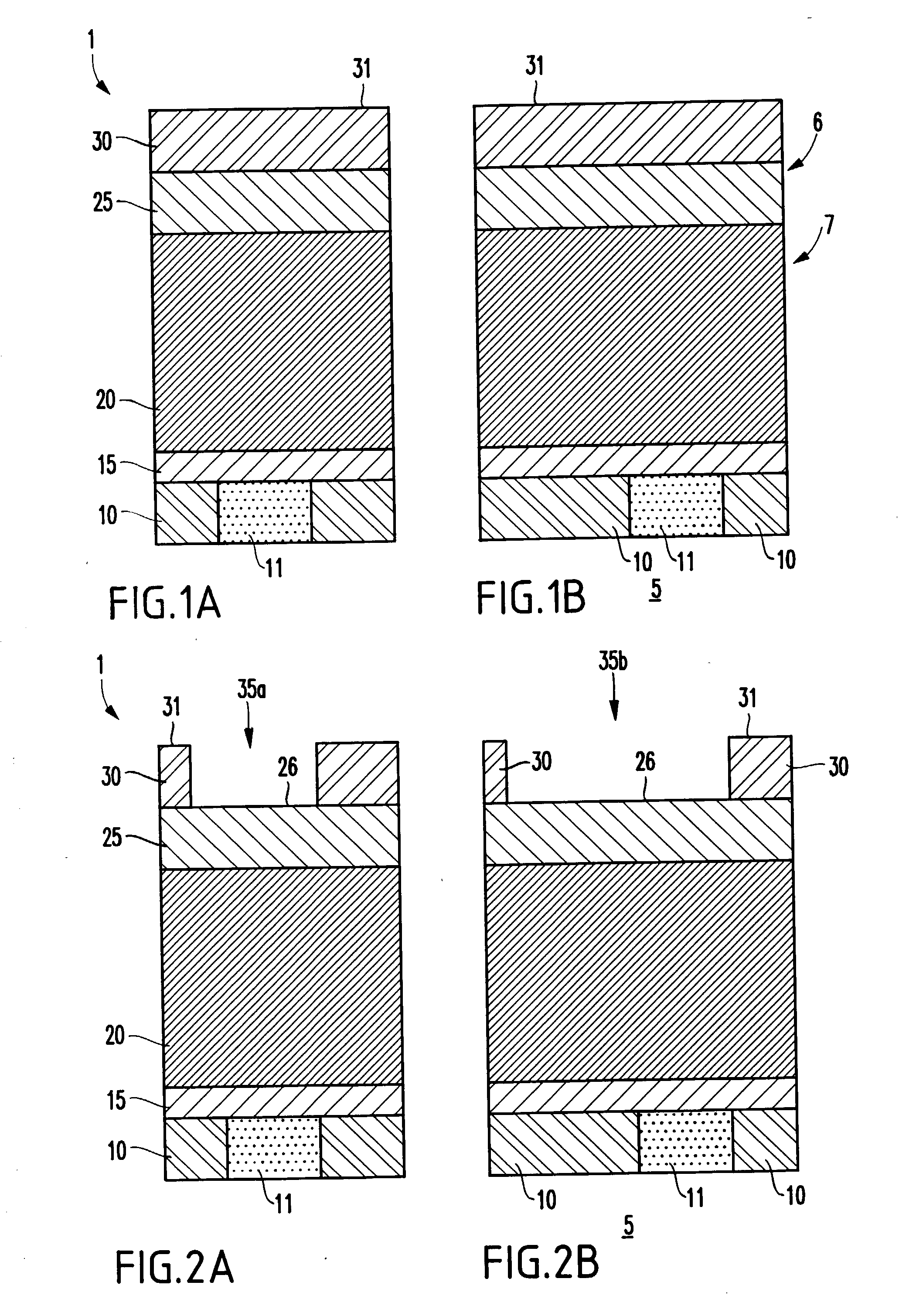

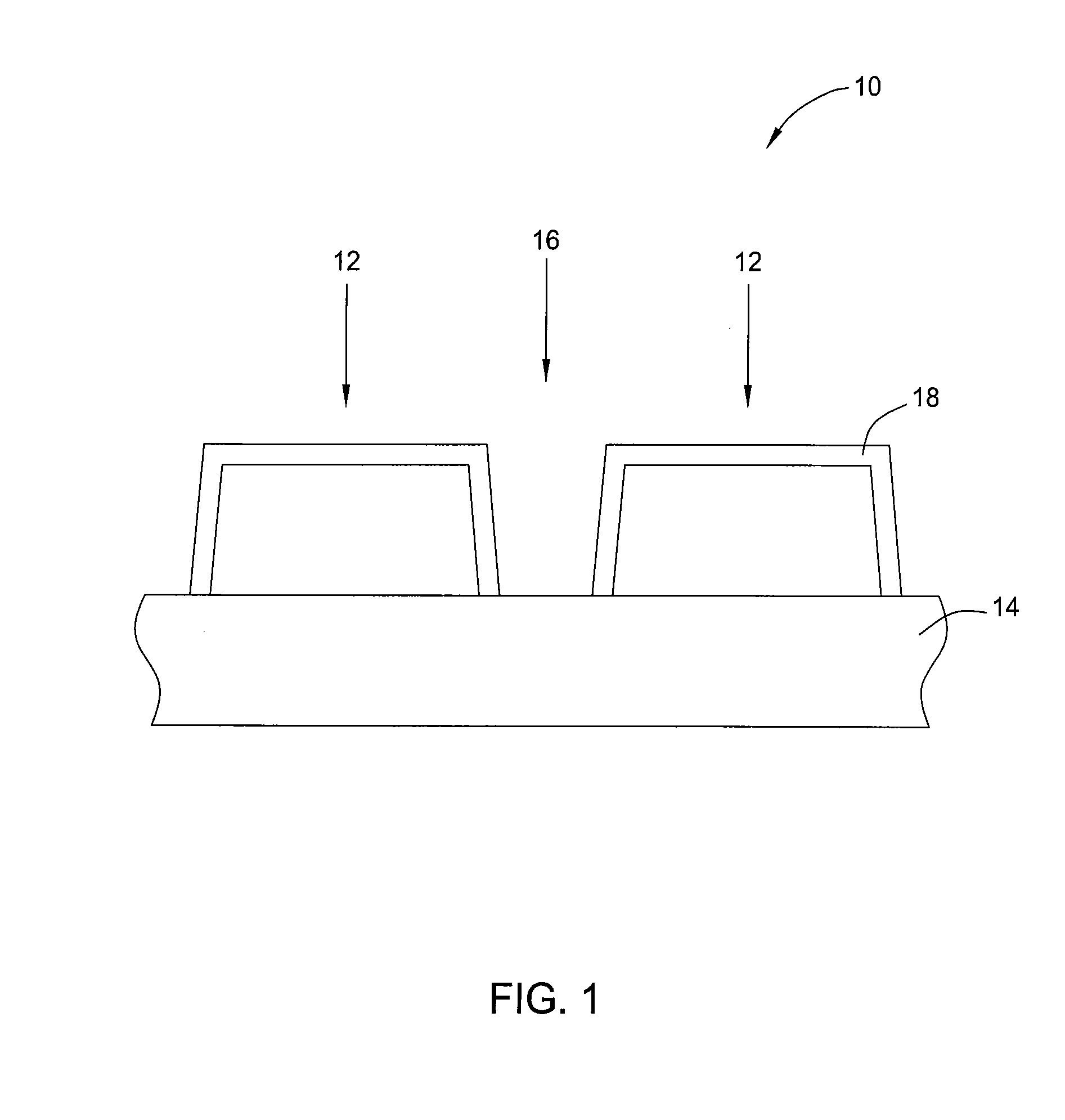

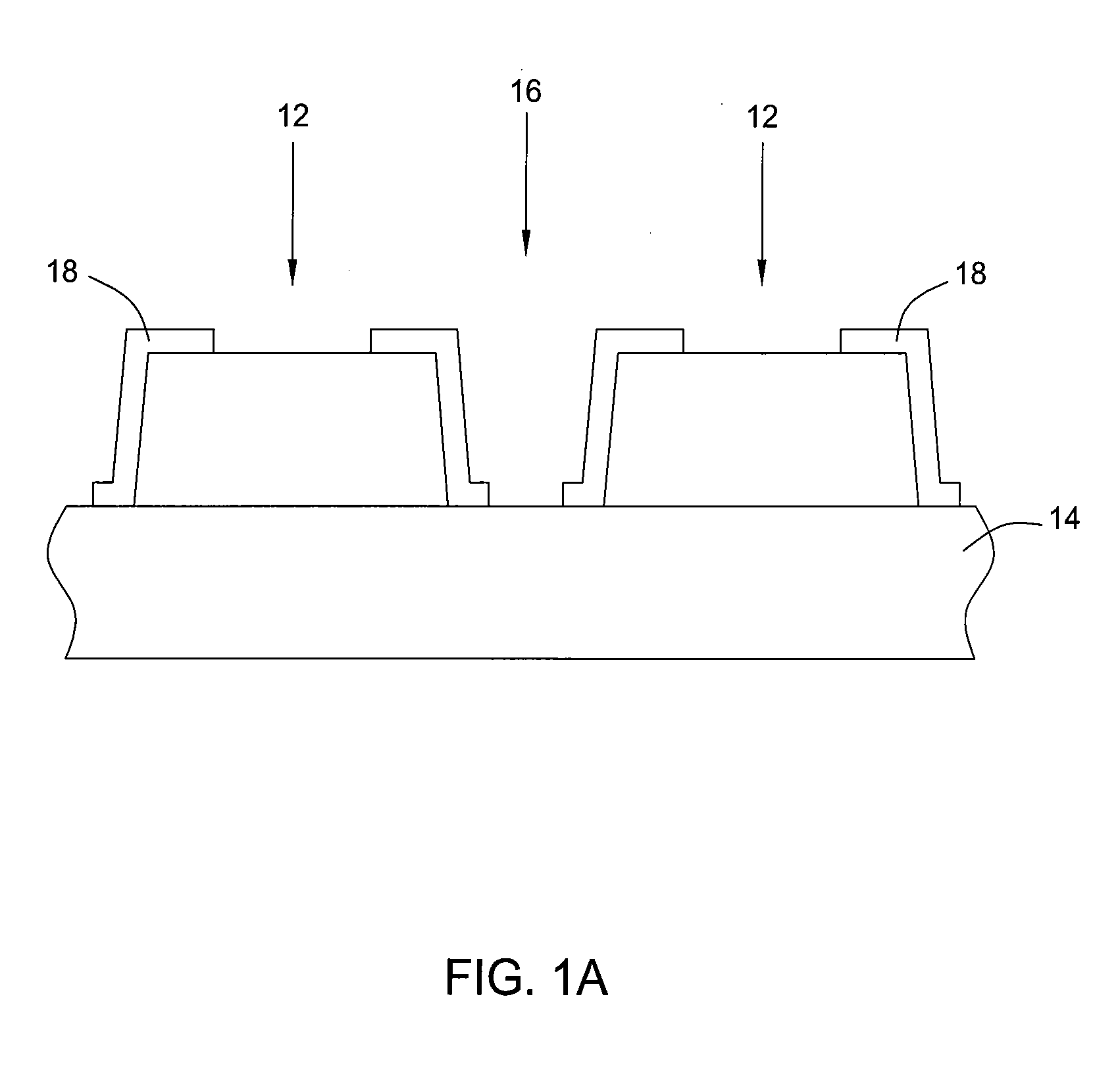

Sacrificial metal spacer damascene process

InactiveUS6846741B2Overcome limitationsEliminate the problemSemiconductor/solid-state device manufacturingSputter cleaningEngineering

A method and structure for a dual damascene interconnect structure comprises forming wiring lines in a metallization layer over a substrate, shaping a laminated insulator stack above the metallization layer, patterning a hardmask over the laminated insulator stack, forming troughs in the hardmask, creating sacrificial tungsten sidewall spacers in the troughs, patterning the laminated insulator stack, removing the sacrificial sidewall spacers, forming vias in the patterned laminated insulator stack, and depositing a metal liner and conductive material into the vias and troughs, wherein the laminated insulator stack comprises a dielectric layer further comprising oxide and polyarylene. The step of depositing prevents the laminated insulator stack from sputtering into the vias. Moreover, the step of depositing comprises cleaning the vias and troughs, optionally performing a reactive ion etching or argon sputter cleaning, depositing a plurality of metal layers over the vias and troughs, and depositing copper in the vias and troughs.

Owner:GLOBALFOUNDRIES INC

Semiconductor device contact resistant to deterioration due to heat and method for manufacturing contact

InactiveUS7527505B2Promote recoveryImprove heat resistanceElectrical measurement instrument detailsShape memory alloy connectionsResistSputtering

A Contact according to an aspect of the present invention is formed by laminating a shape memory alloy film on a surface of a metal spring film, and the shape thereof is a conical spiral. A manufacturing method therefor is composed of 11 steps including a step of preparing a sacrificial metal film, a step of forming a resist cone, a step of patterning a resist film, a step of preparing a shape memory alloy film, and the like. Since an organic resist material has poor heat resistance, the sacrificial metal film is formed in advance, the resist is removed before sputtering of the shape memory alloy film, the sacrificial metal film is removed after sputtering of a shape memory alloy and a heat treatment, which are performed at high temperatures, so as to lift off an excess shape memory alloy film.

Owner:ALPS ALPINE CO LTD

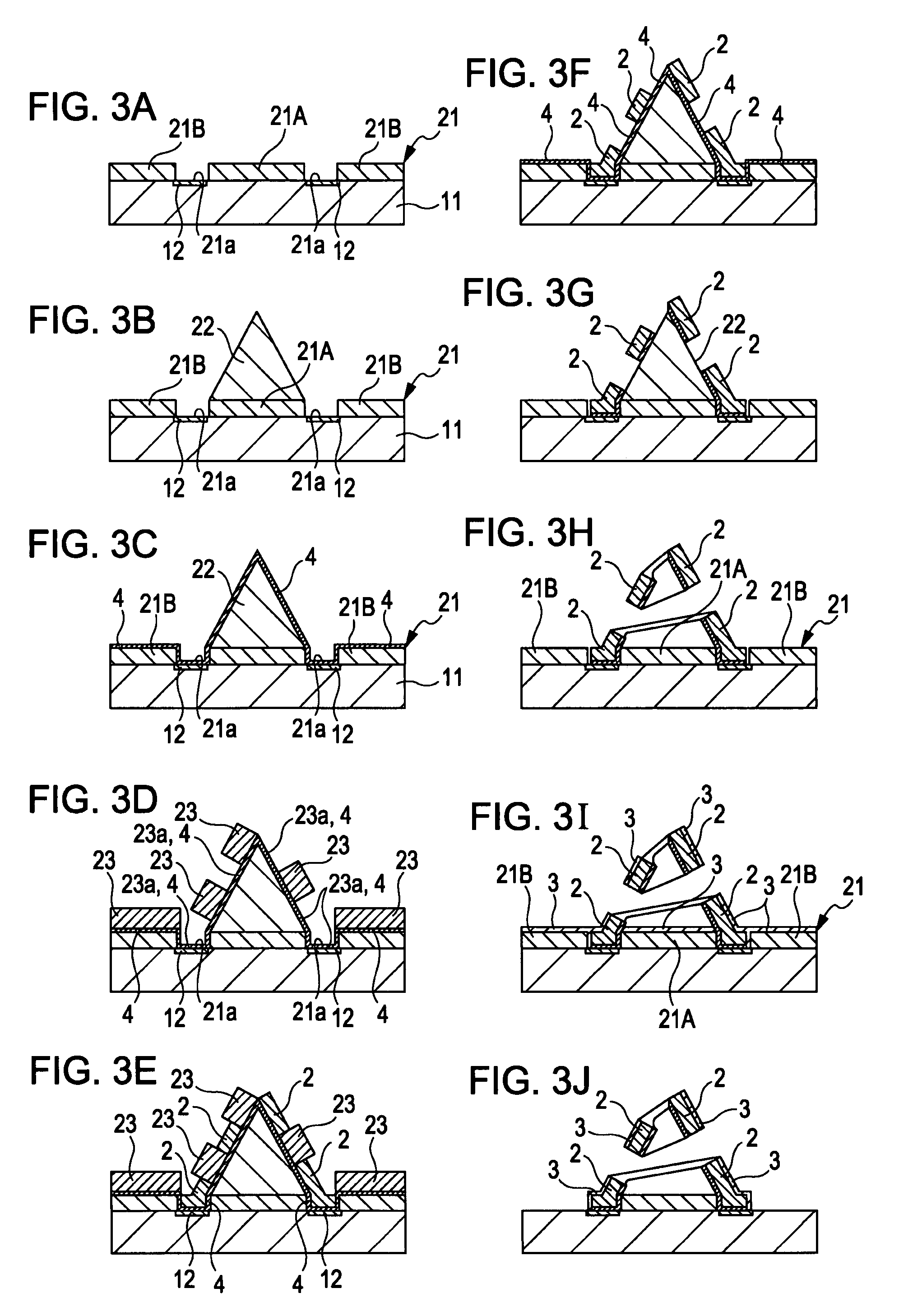

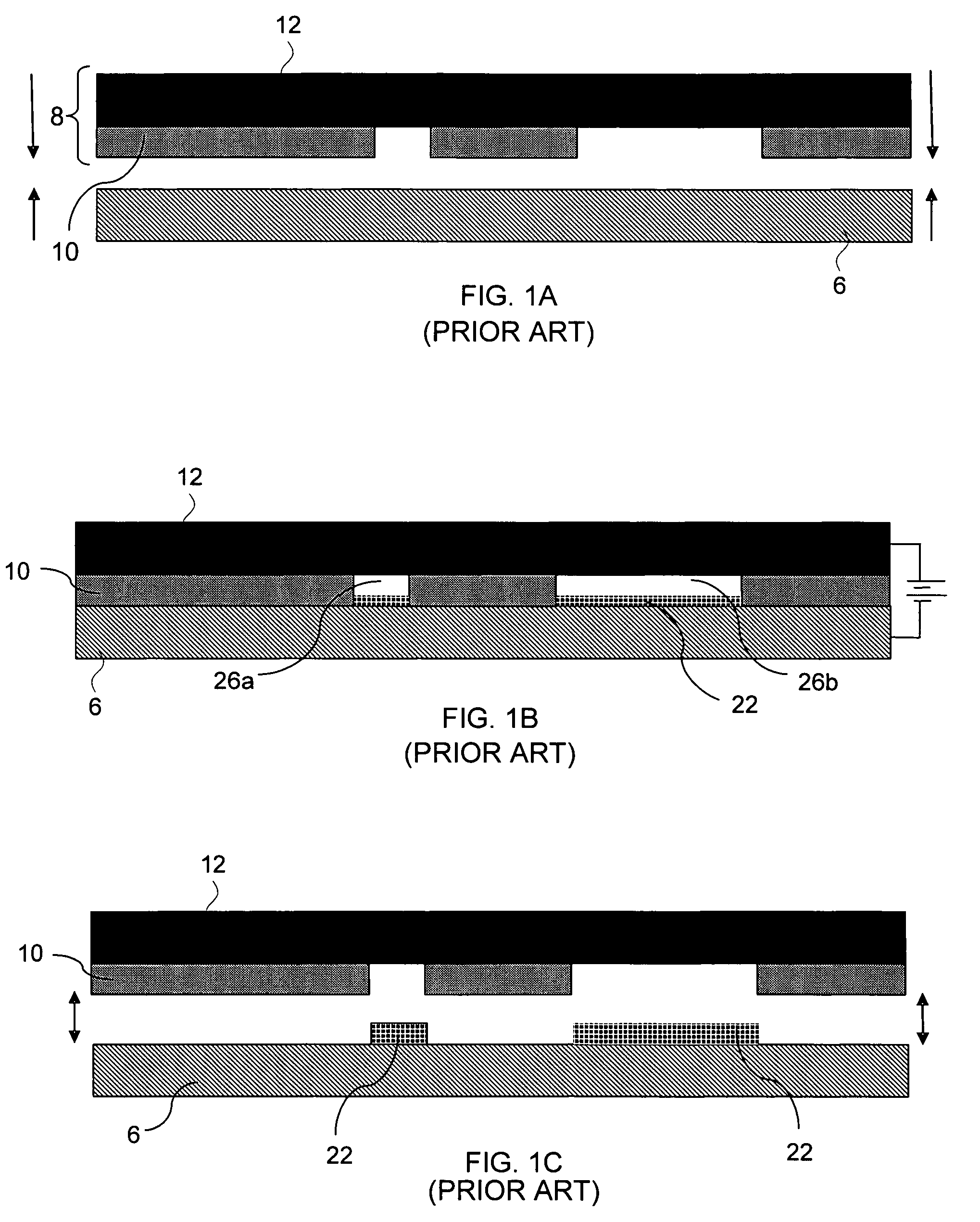

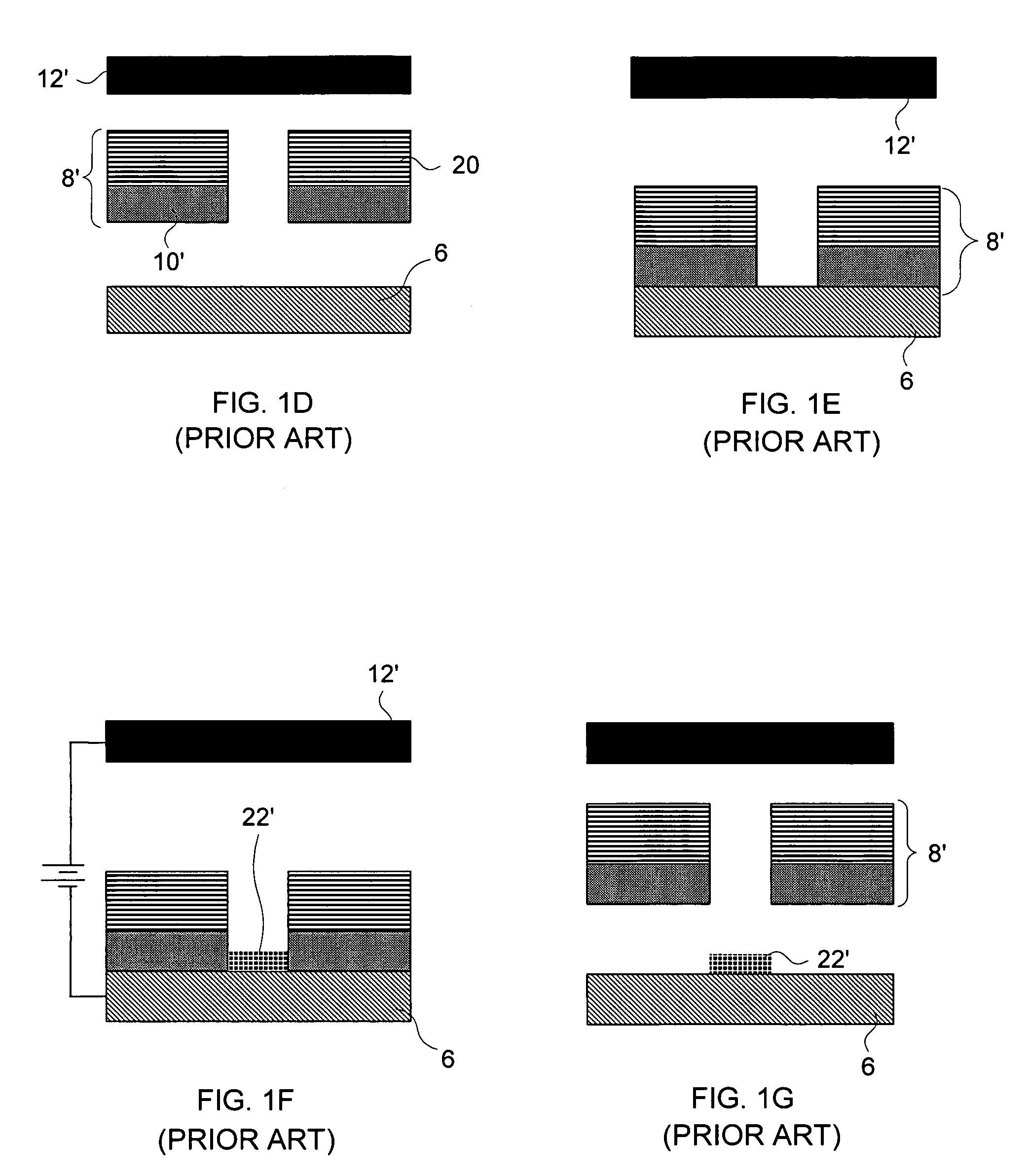

Methods of and apparatus for molding structures using sacrificial metal patterns

InactiveUS7229542B2Improve abilitiesBroaden applicationAcceleration measurement using interia forcesMouldsImage resolutionShell molding

Molded structures, methods of and apparatus for producing the molded structures are provided. At least a portion of the surface features for the molds are formed from multilayer electrochemically fabricated structures (e.g. fabricated by the EFAB™ formation process), and typically contain features having resolutions within the 1 to 100 μm range. The layered structure is combined with other mold components, as necessary, and a molding material is injected into the mold and hardened. The layered structure is removed (e.g. by etching) along with any other mold components to yield the molded article. In some embodiments portions of the layered structure remain in the molded article and in other embodiments an additional molding material is added after a partial or complete removal of the layered structure.

Owner:MEMGEN

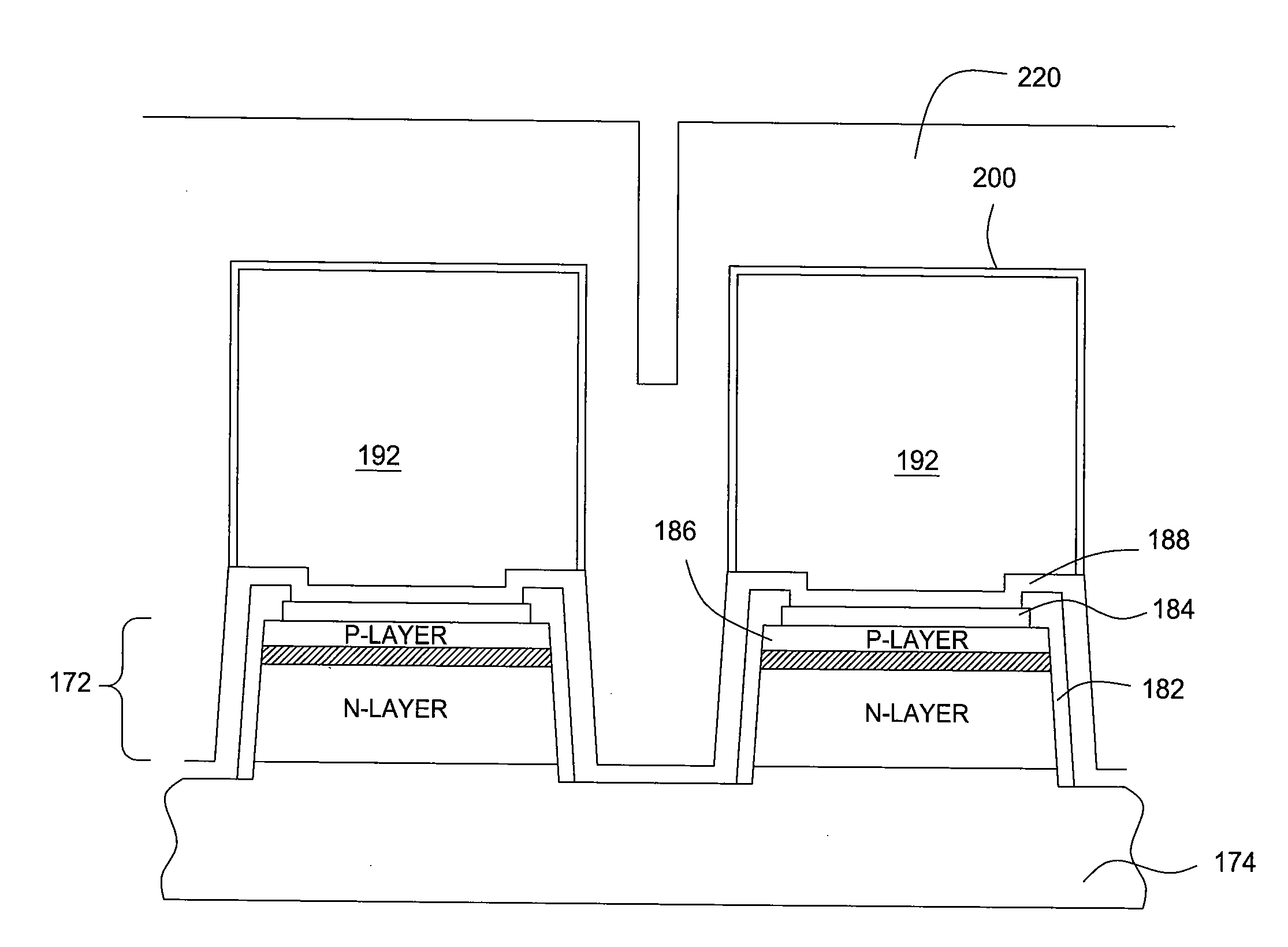

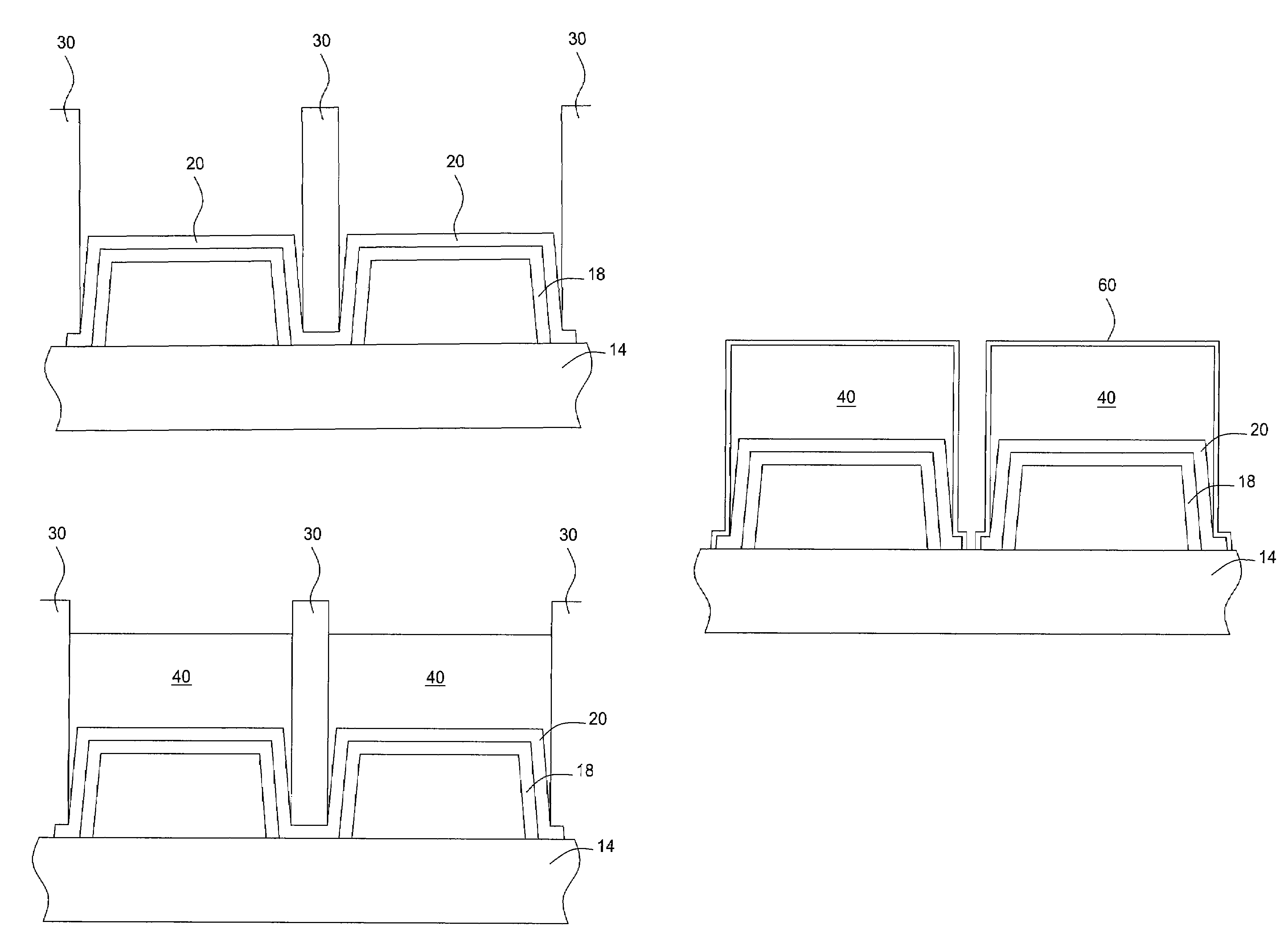

Method of separating semiconductor dies

ActiveUS20090093075A1Semiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor materialsSacrificial metal

A method for the separation of multiple dies during semiconductor fabrication is described. On an upper surface of a semiconductor wafer containing multiple dies, metal layers are deposited everywhere except where a block of stop electroplating material exists. The stop electroplating material is obliterated, and a barrier layer is formed above the entire remaining structure. A sacrificial metal element is added above the barrier layer, and then the substrate is removed. After the semiconductor material between the individual dies is eradicated, any desired bonding pads and patterned circuitry are added to the semiconductor surface opposite the sacrificial metal element, a passivation layer is added to this surface, and then the sacrificial metal element is removed. Tape is added to the now exposed barrier layer, the passivation layer is removed, the resulting structure is flipped over, and the tape is expanded to separate the individual dies.

Owner:SEMILEDS OPTOELECTRONICS CO LTD

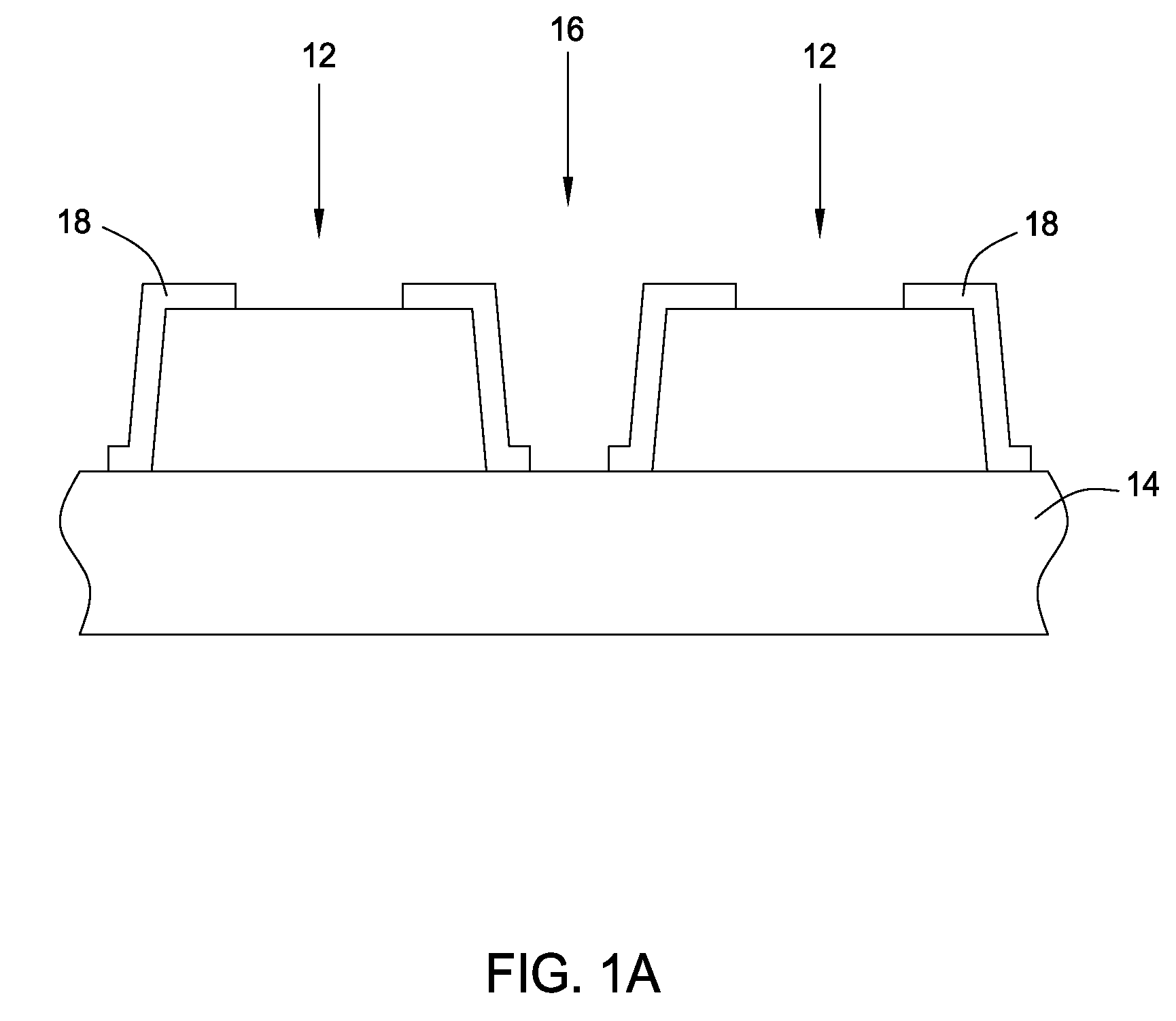

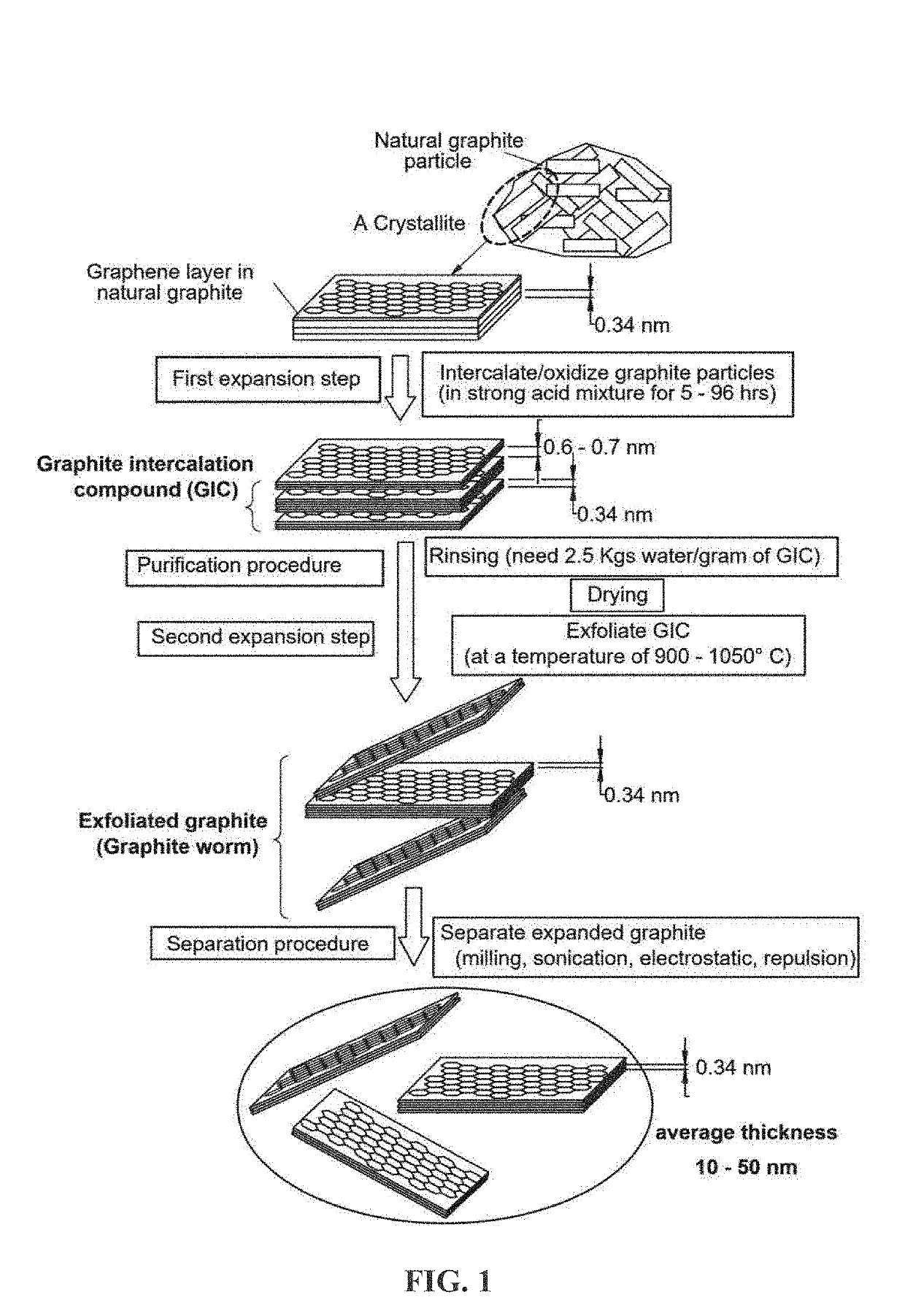

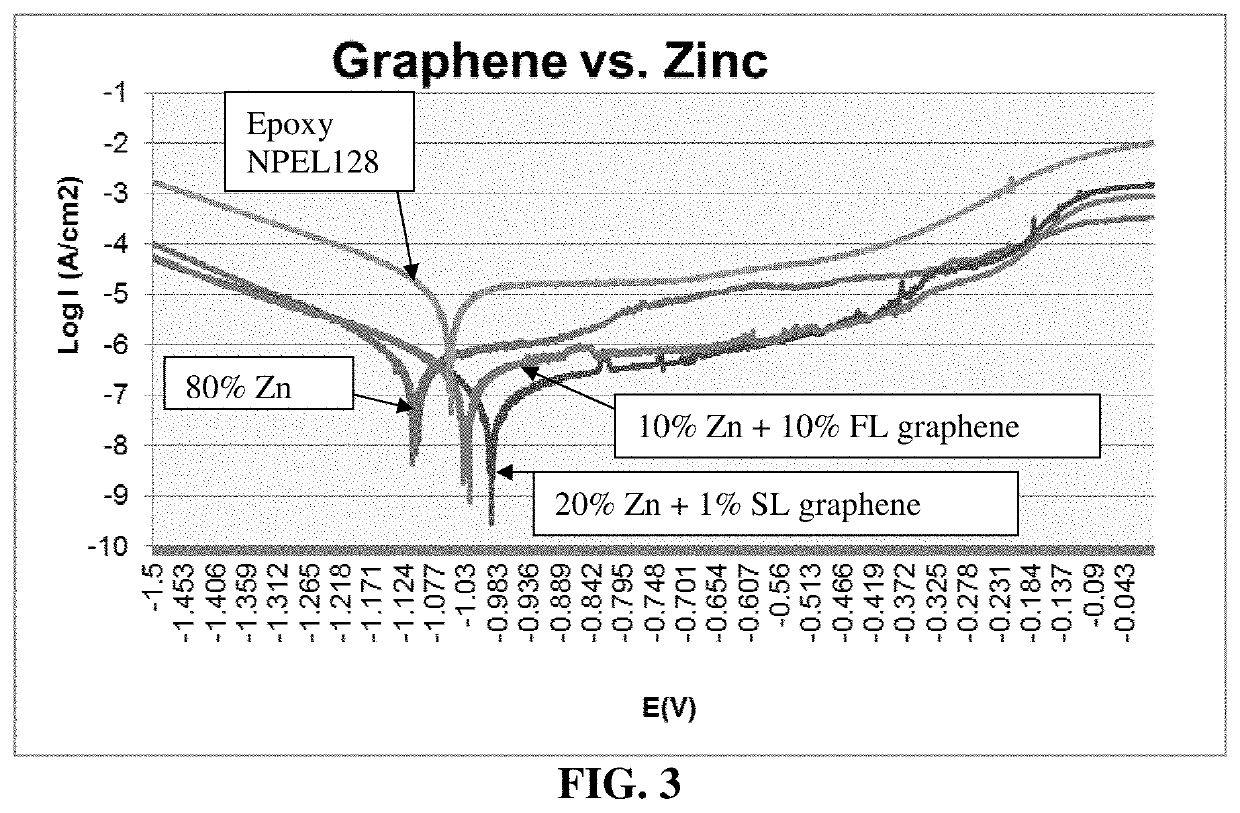

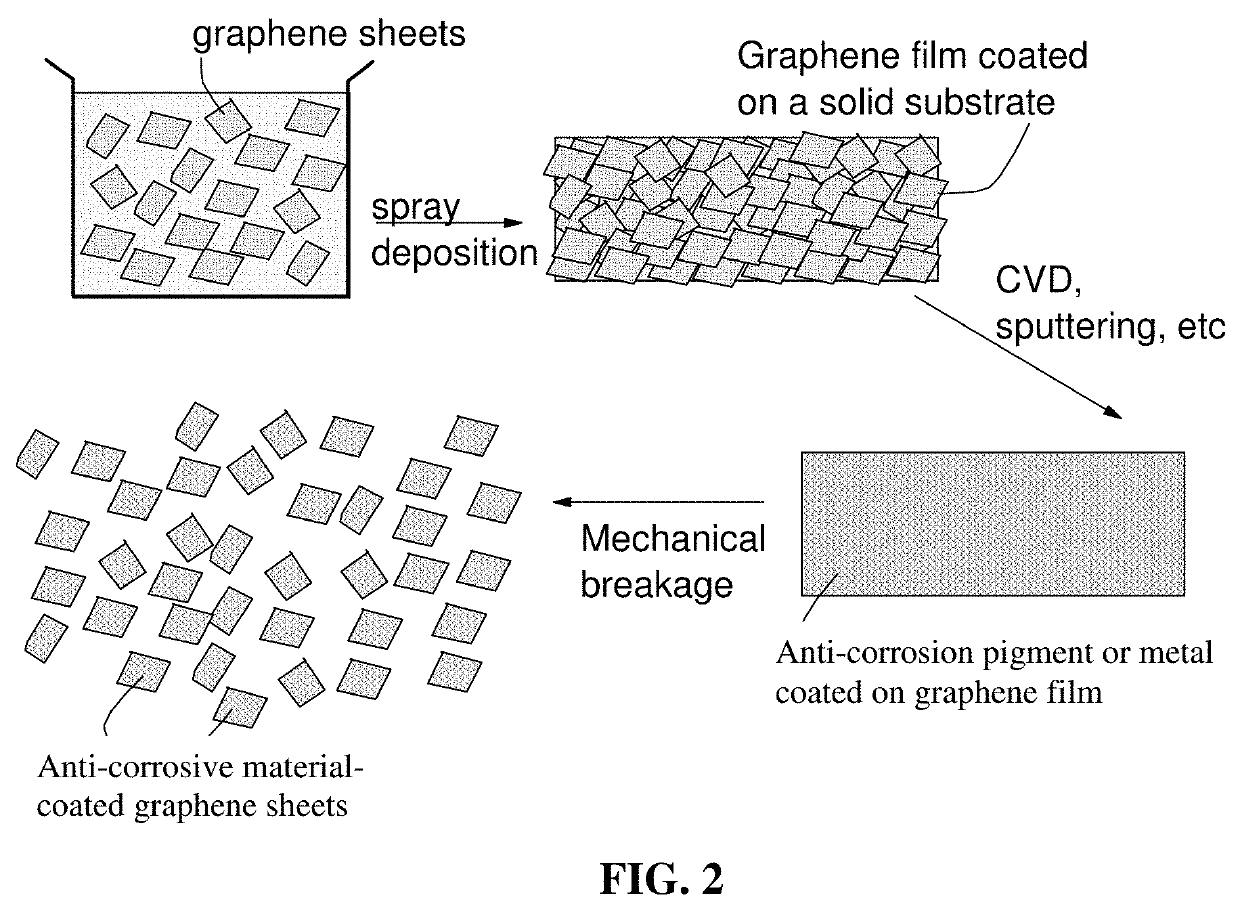

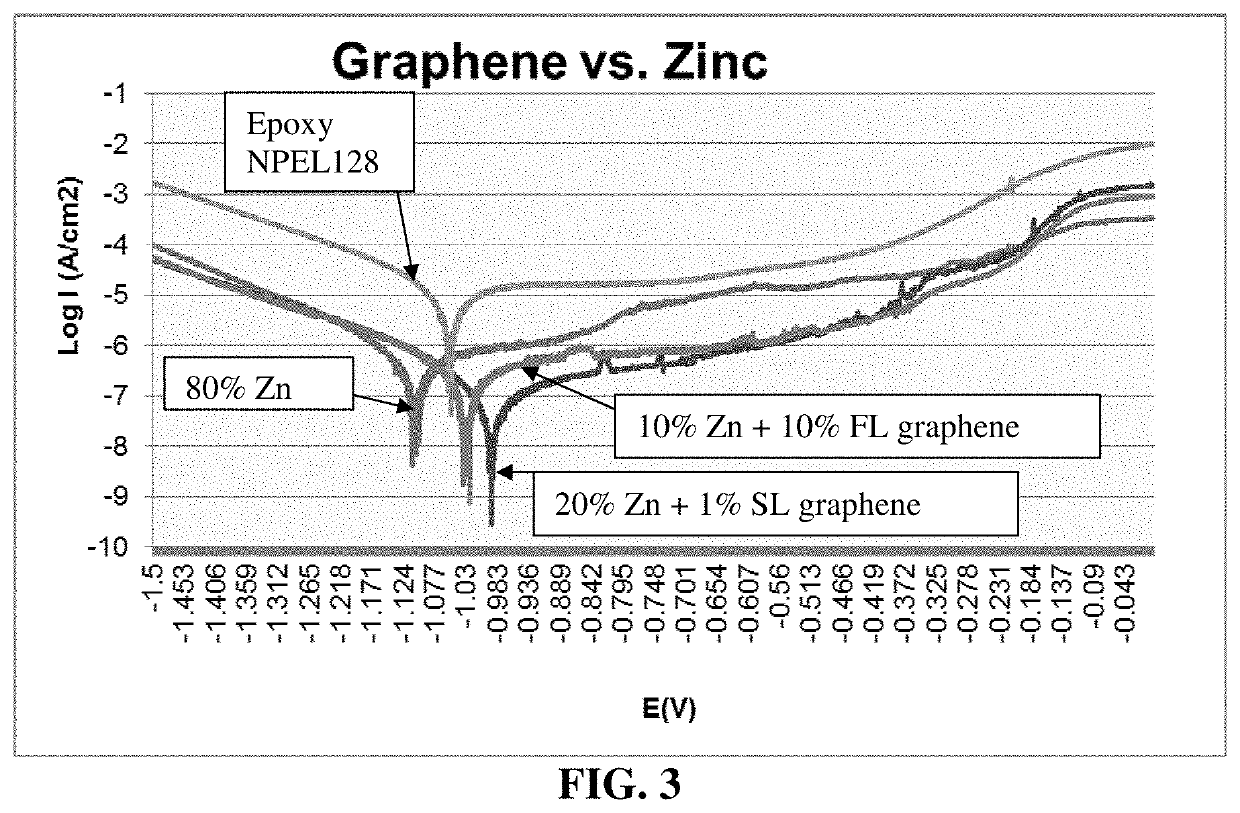

Graphene-Enabled Anti-Corrosion Coating

Provided is a graphene-based aqueous coating suspension comprising multiple graphene sheets, particles of an anti-corrosive pigment or sacrificial metal, and a waterborne binder resin dissolved or dispersed in water, wherein the multiple graphene sheets contain single-layer or few-layer graphene sheets selected from a pristine graphene material having essentially zero % of non-carbon elements, or a non-pristine graphene material having 0.001% to 47% by weight of non-carbon elements wherein the non-pristine graphene is selected from graphene oxide, reduced graphene oxide, graphene fluoride, graphene chloride, graphene bromide, graphene iodide, hydrogenated graphene, nitrogenated graphene, doped graphene, chemically functionalized graphene, or a combination thereof and wherein the coating suspension does not contain a silicate binder or microspheres dispersed therein. Also provided is an object or structure coated at least in part with such a coating.

Owner:GLOBAL GRAPHENE GRP INC

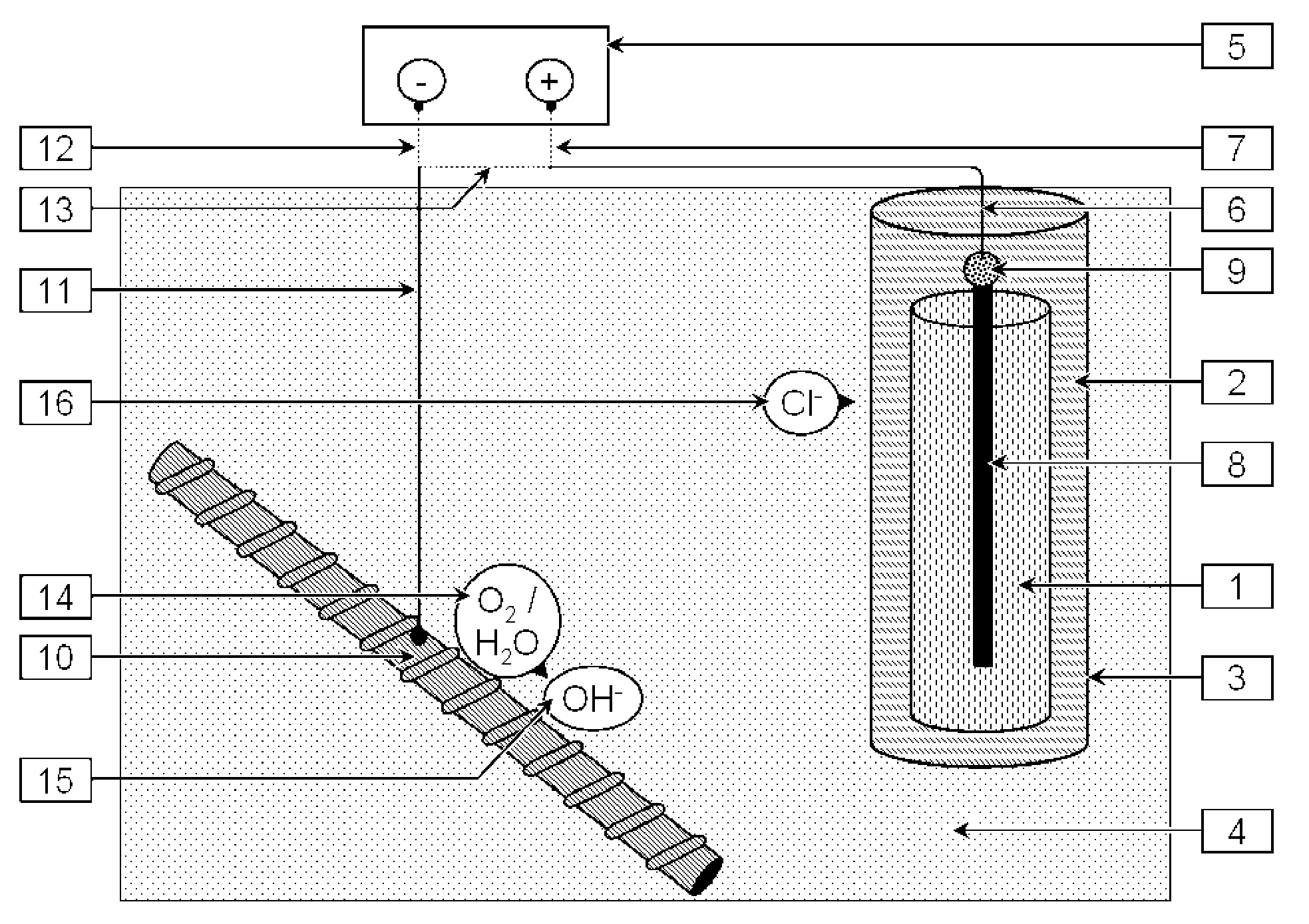

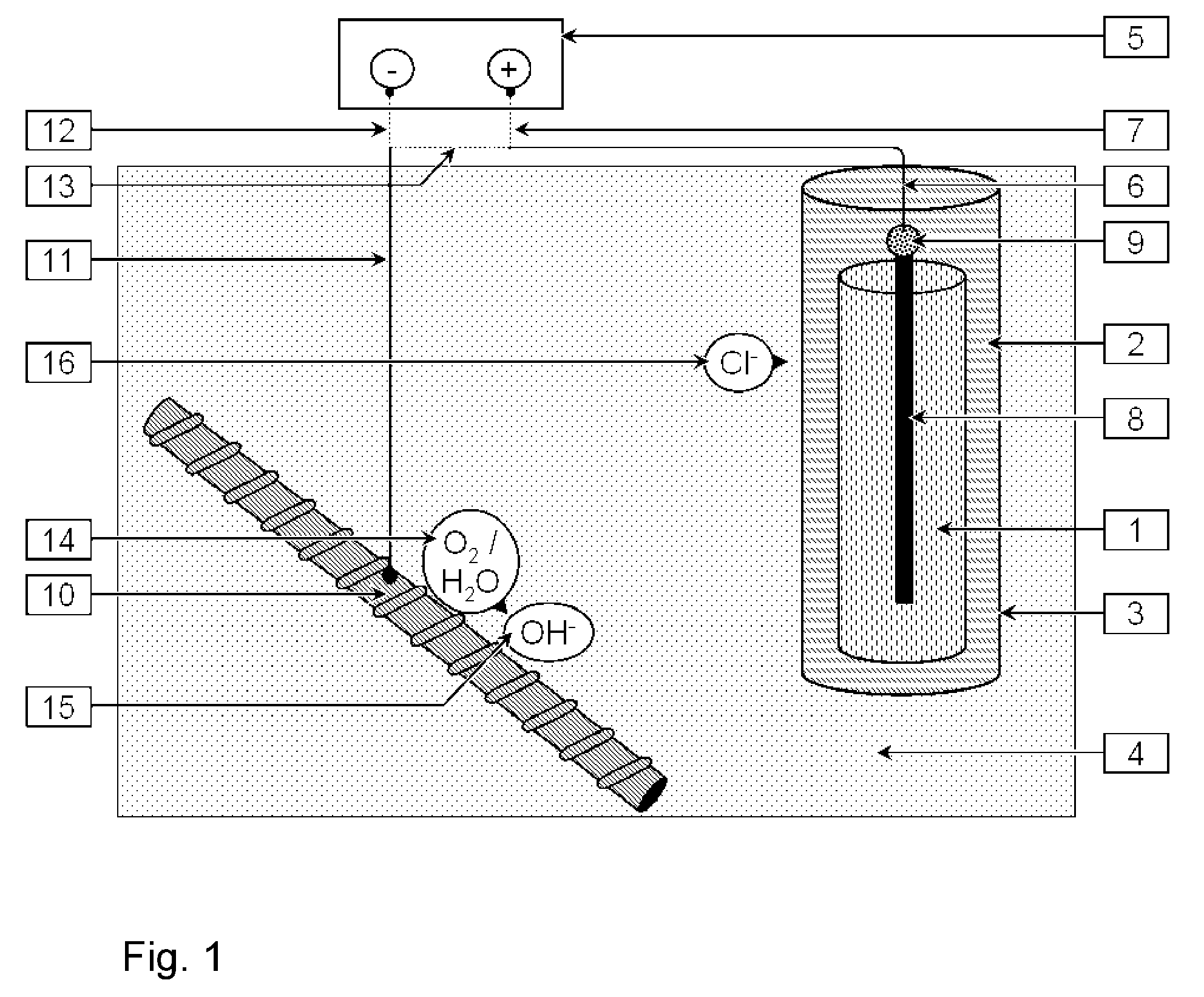

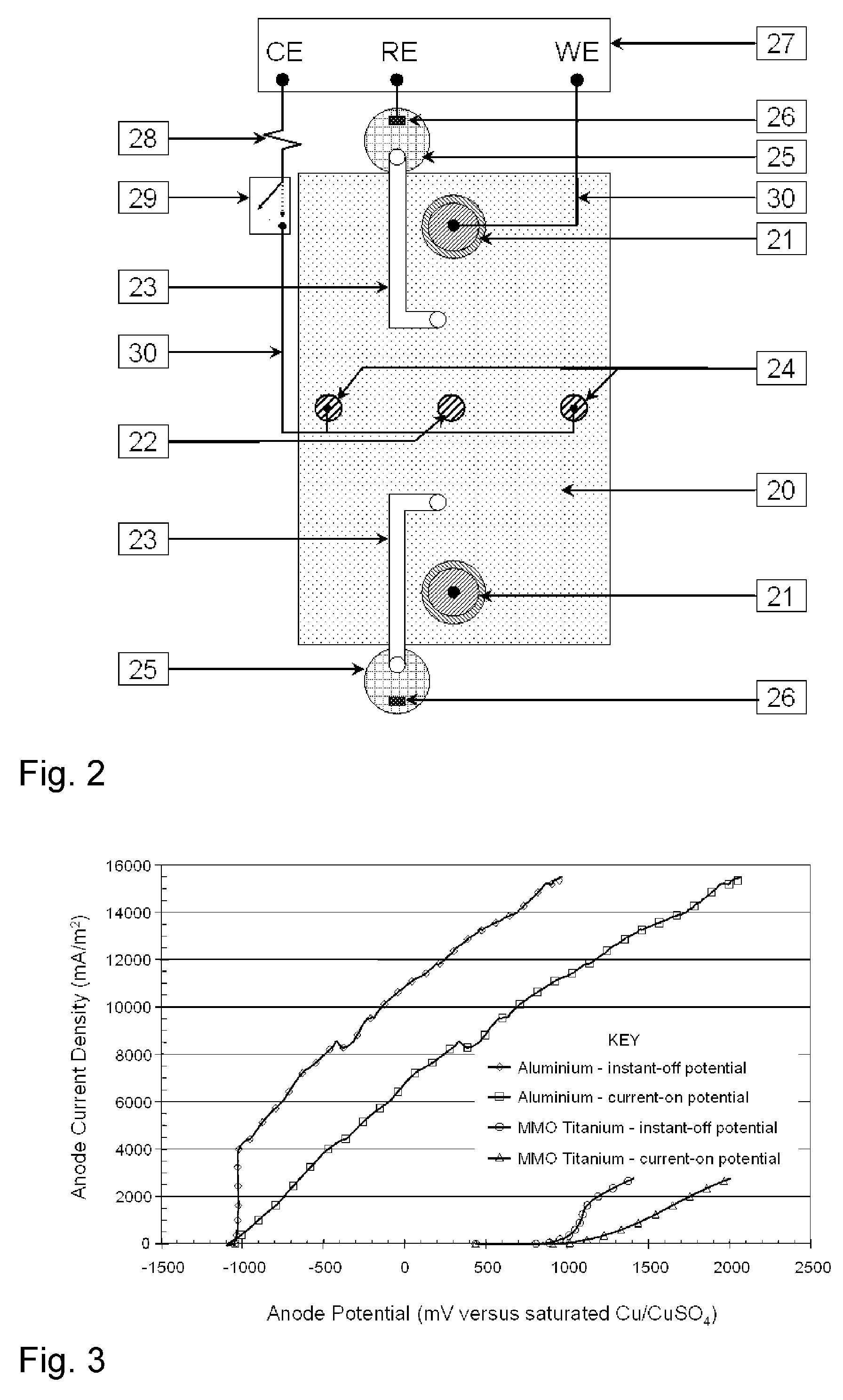

Treatment process for concrete

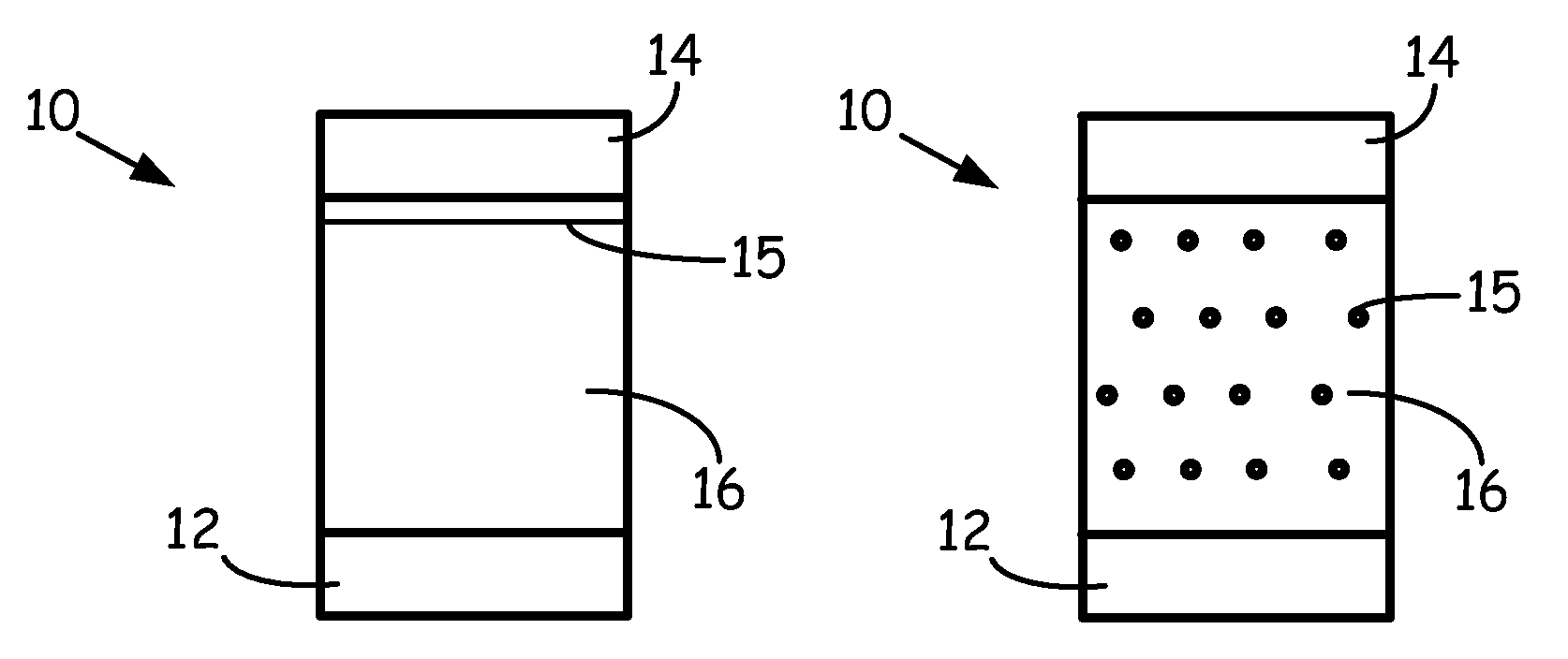

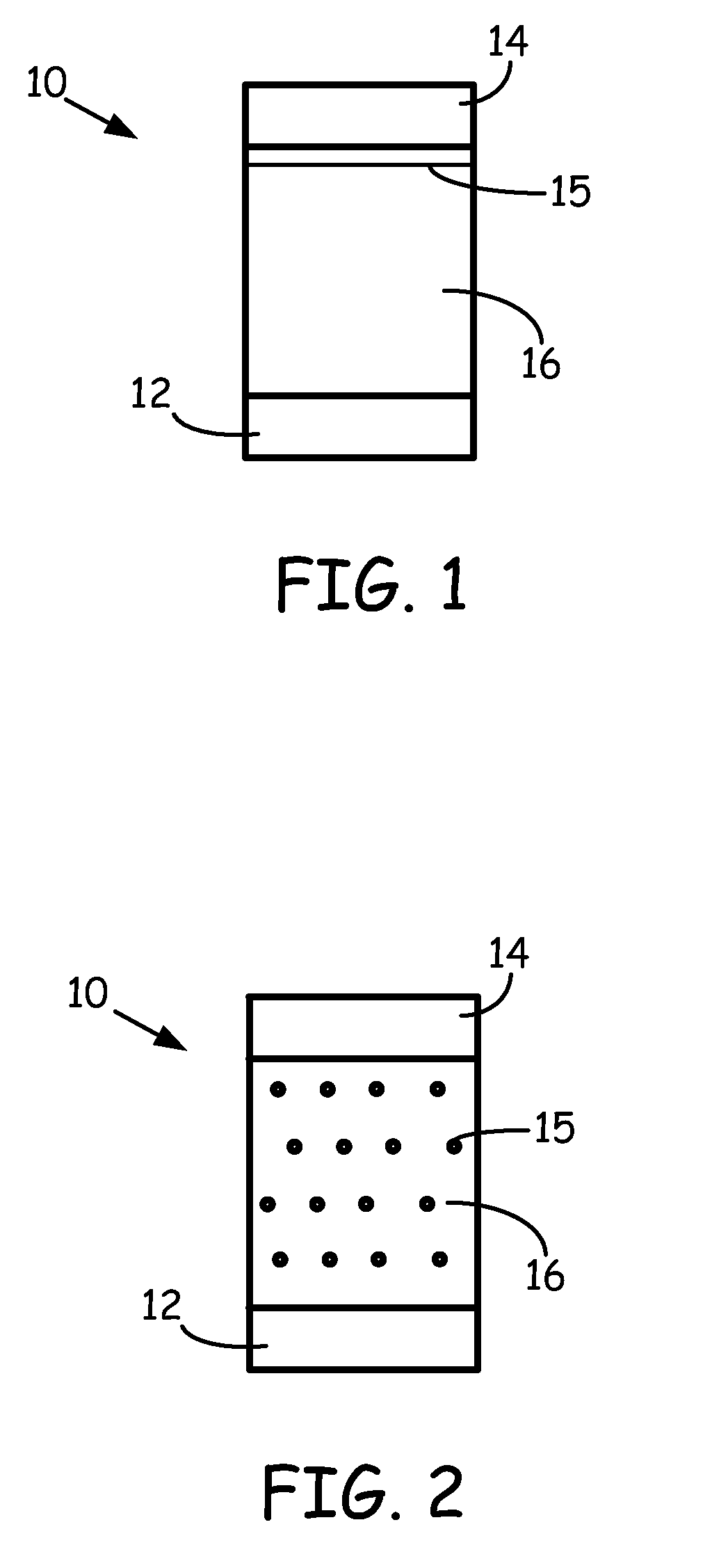

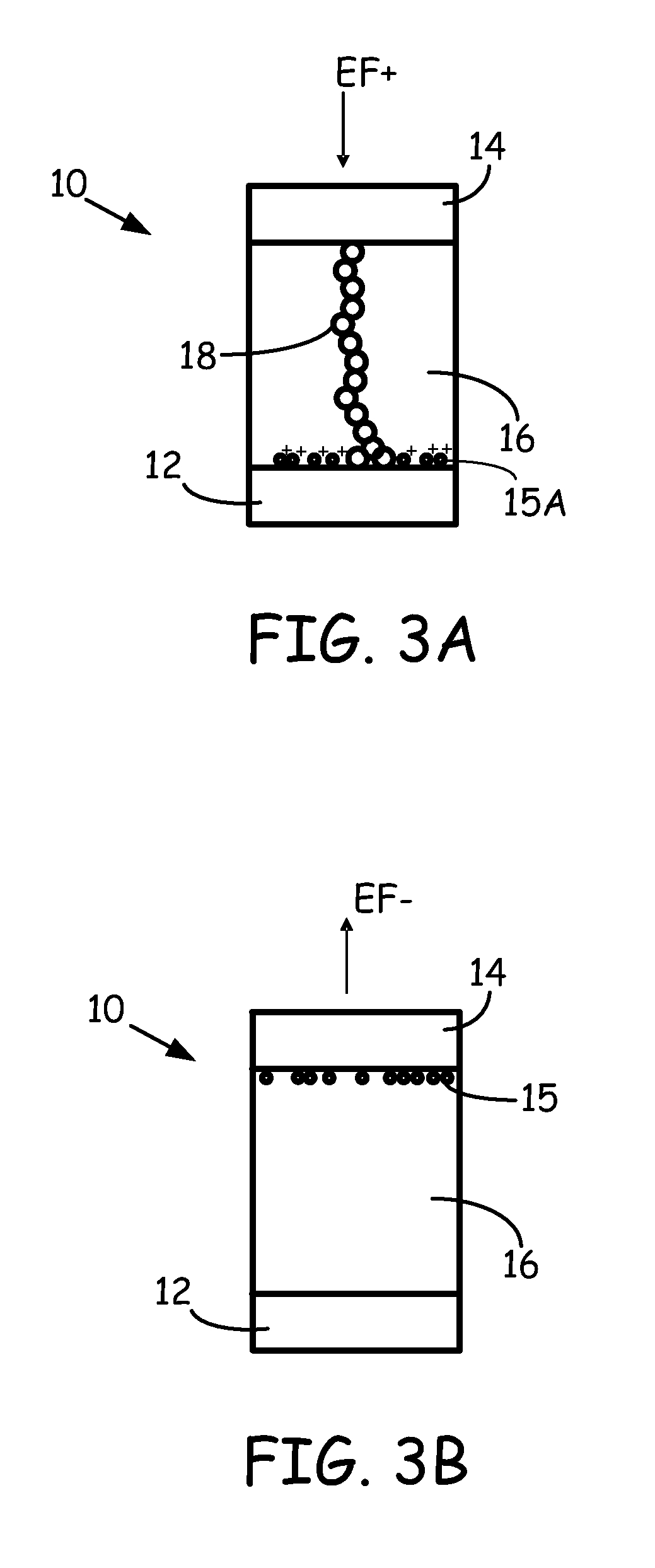

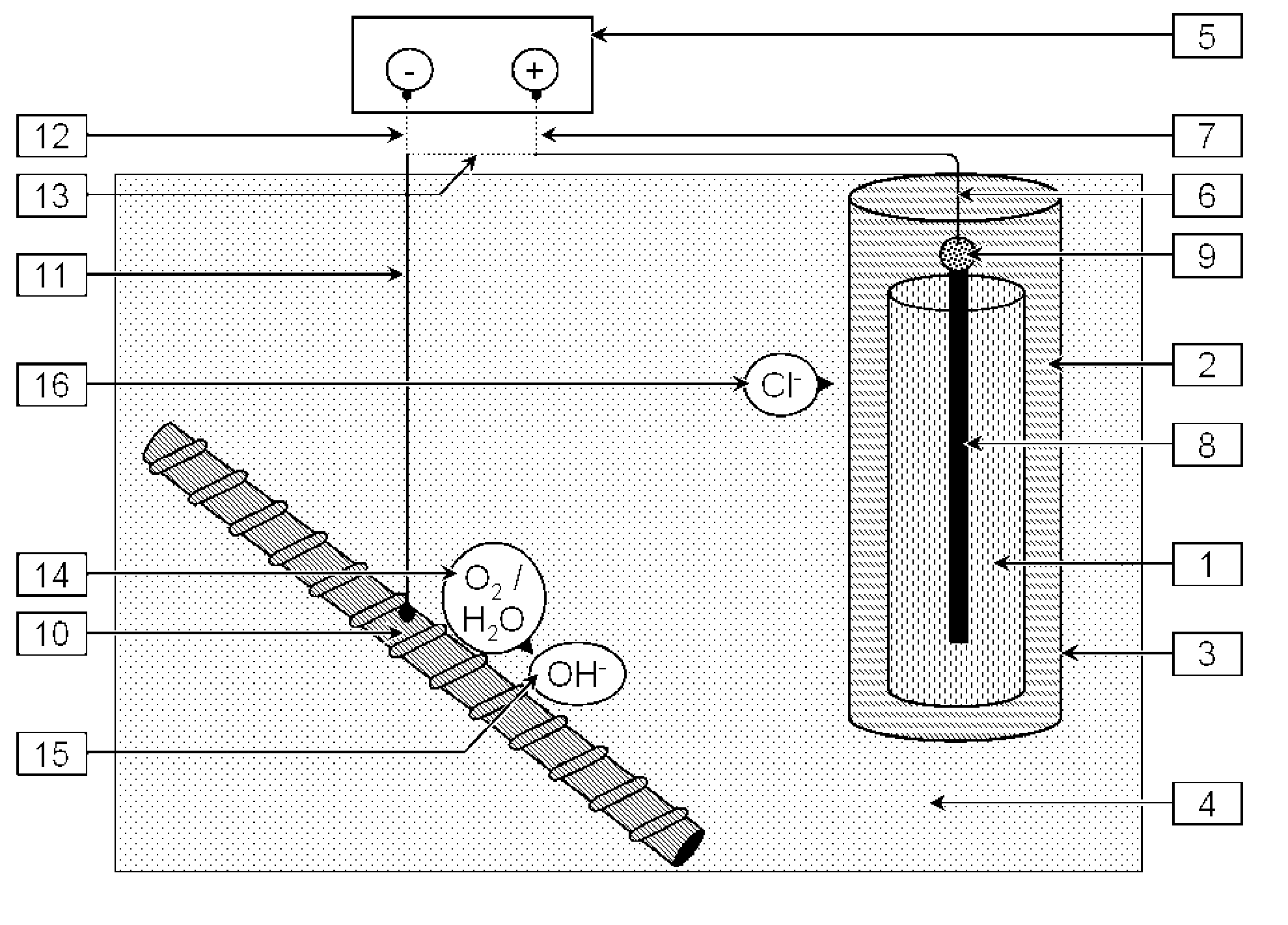

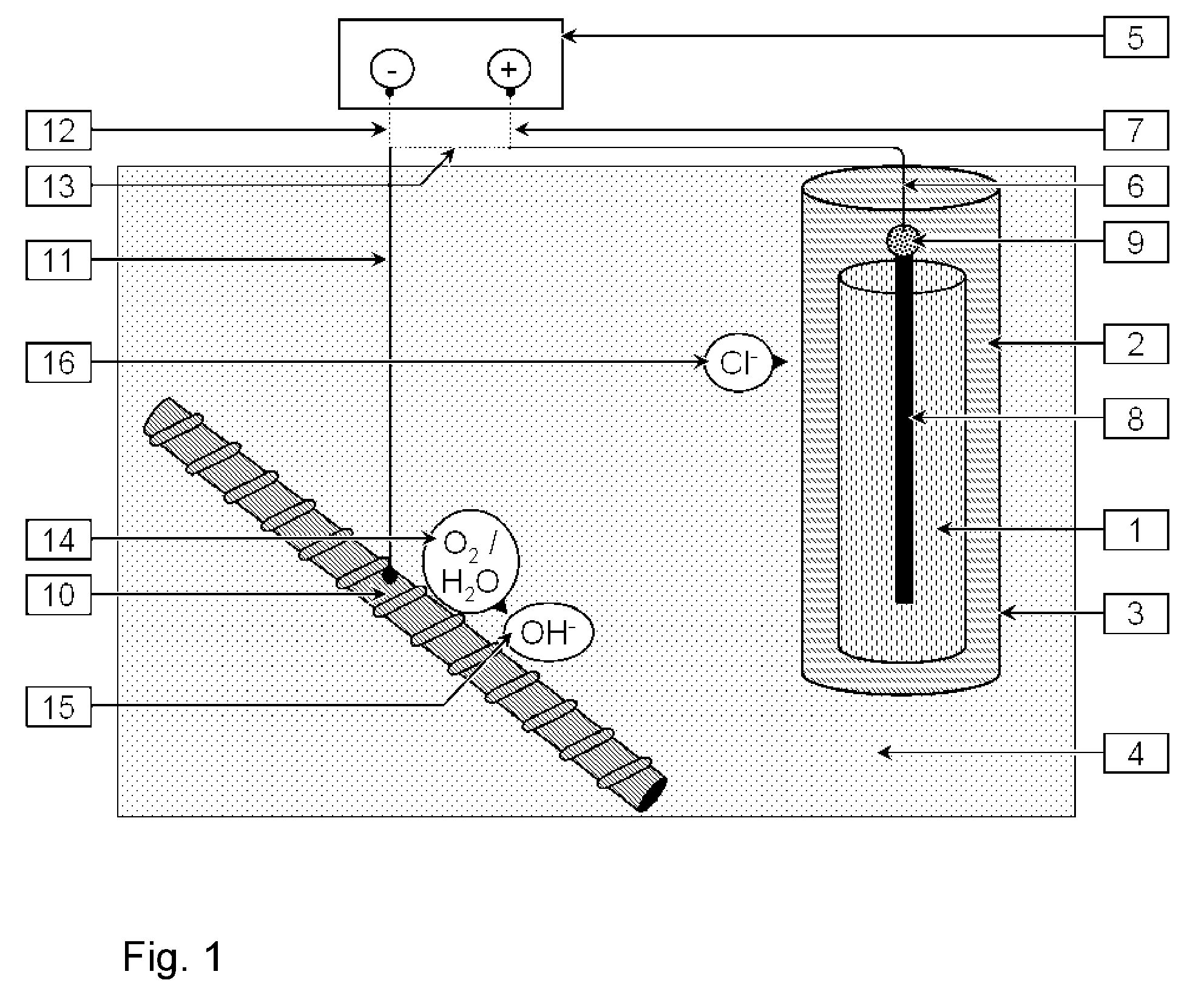

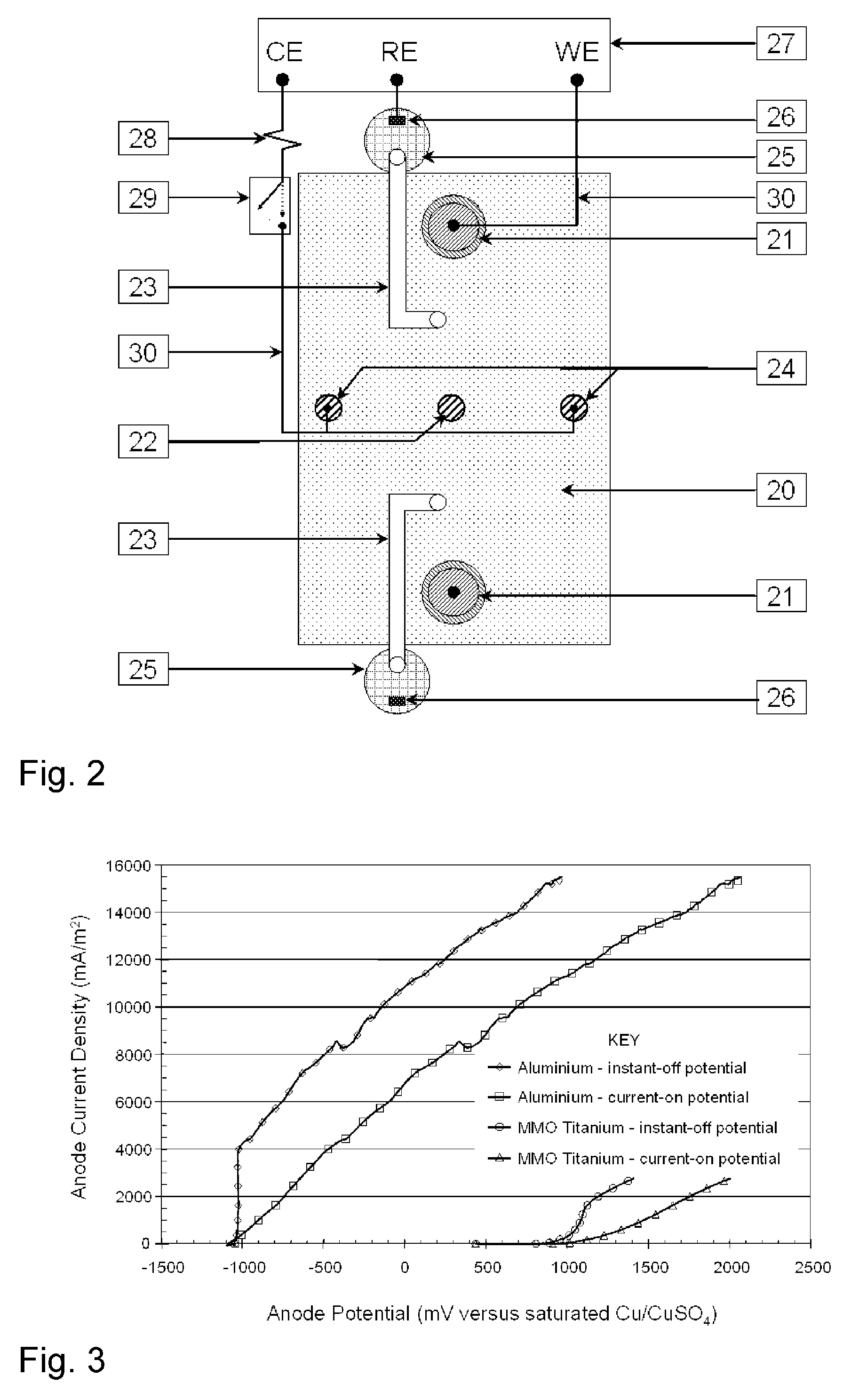

ActiveUS7909982B2Less driving voltageGenerate less acidCovering/liningsWallsChemical treatmentChloride

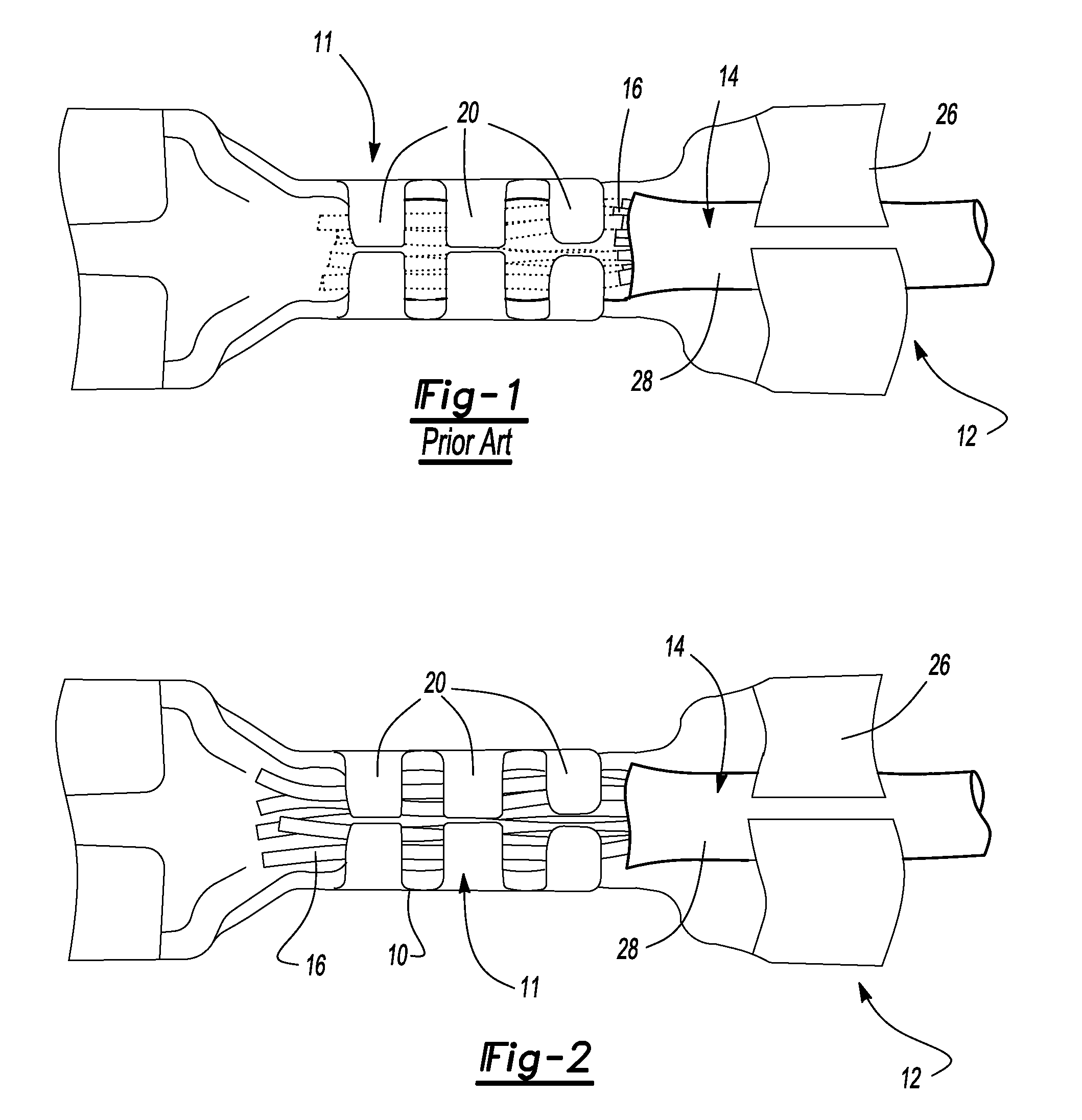

A single anode system used in multiple electrochemical treatments to control steel corrosion in concrete comprises a sacrificial metal that is capable of supporting high impressed anode current densities with an impressed current anode connection detail and a porous embedding material containing an electrolyte. Initially current is driven from the sacrificial metal [1] to the steel [10] using a power source [5] converting oxygen and water [14] into hydroxyl ions [15] on the steel and drawing chloride ions [16] into the porous material [2] around the anode such that corroding sites are moved from the steel to the anode restoring steel passivity and activating the anode. Cathodic prevention is then applied. This is preferably sacrificial cathodic prevention that is applied by disconnecting the power source and connecting the activated sacrificial anode directly to the steel.

Owner:GLASS +2

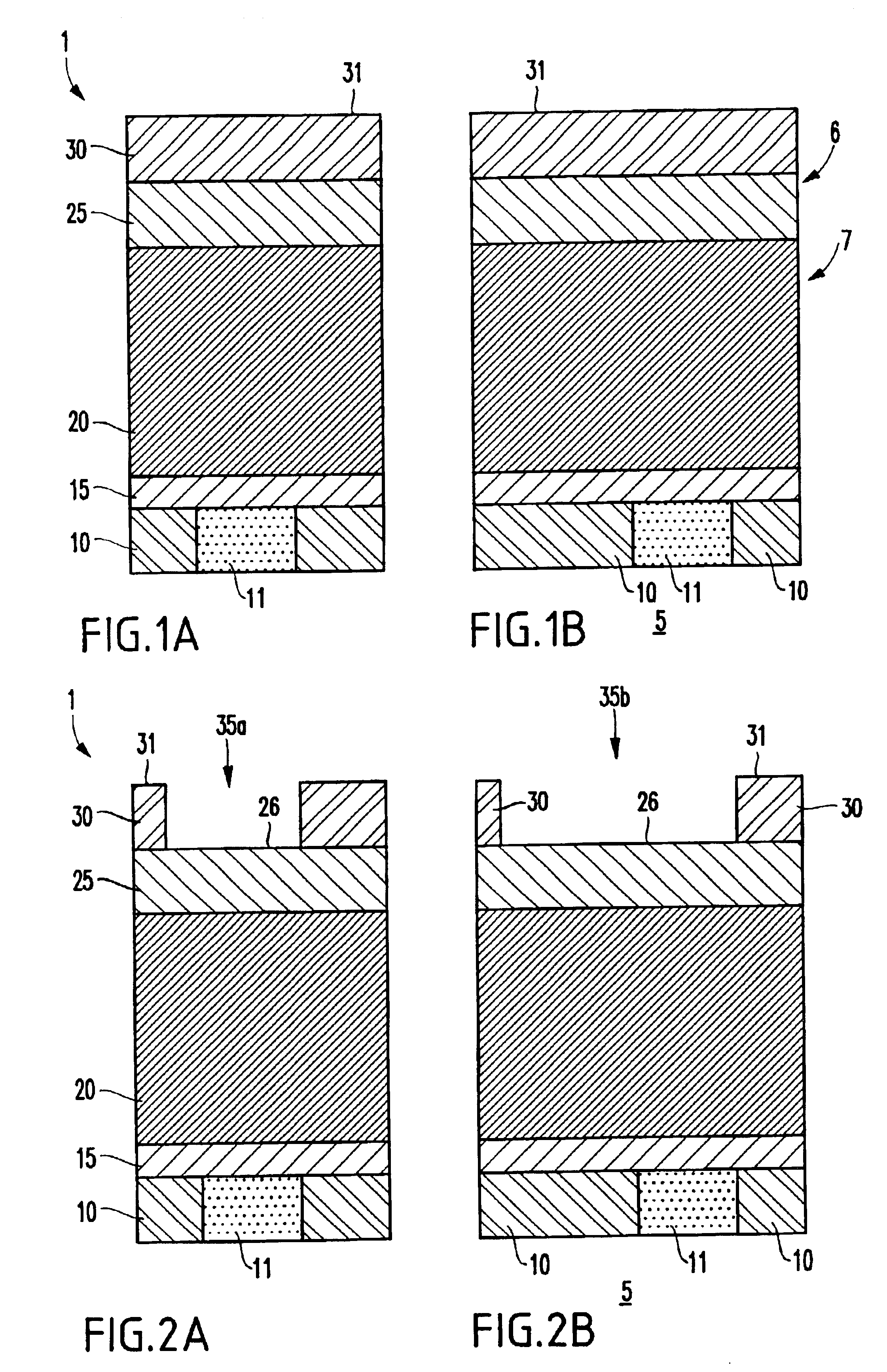

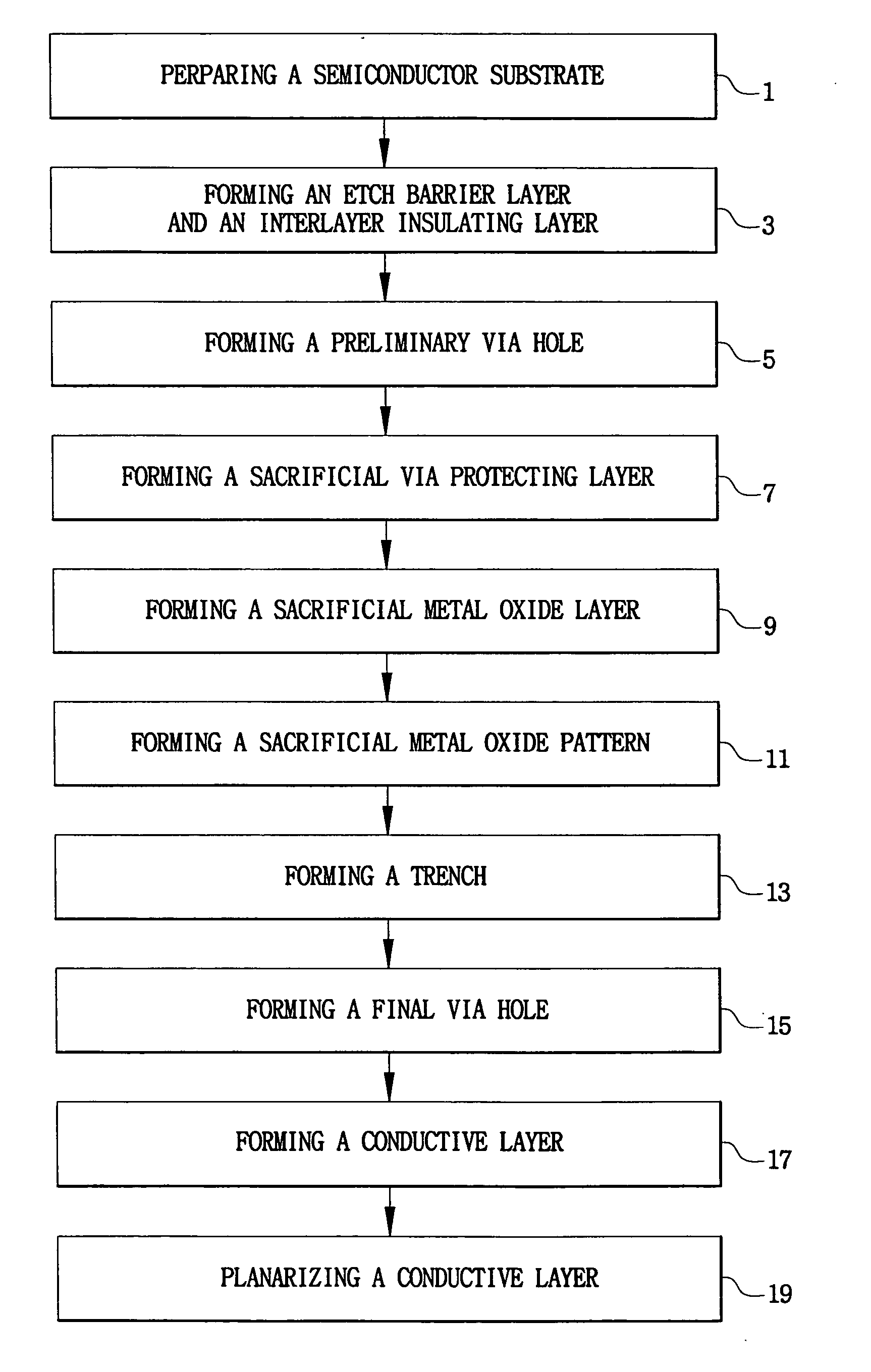

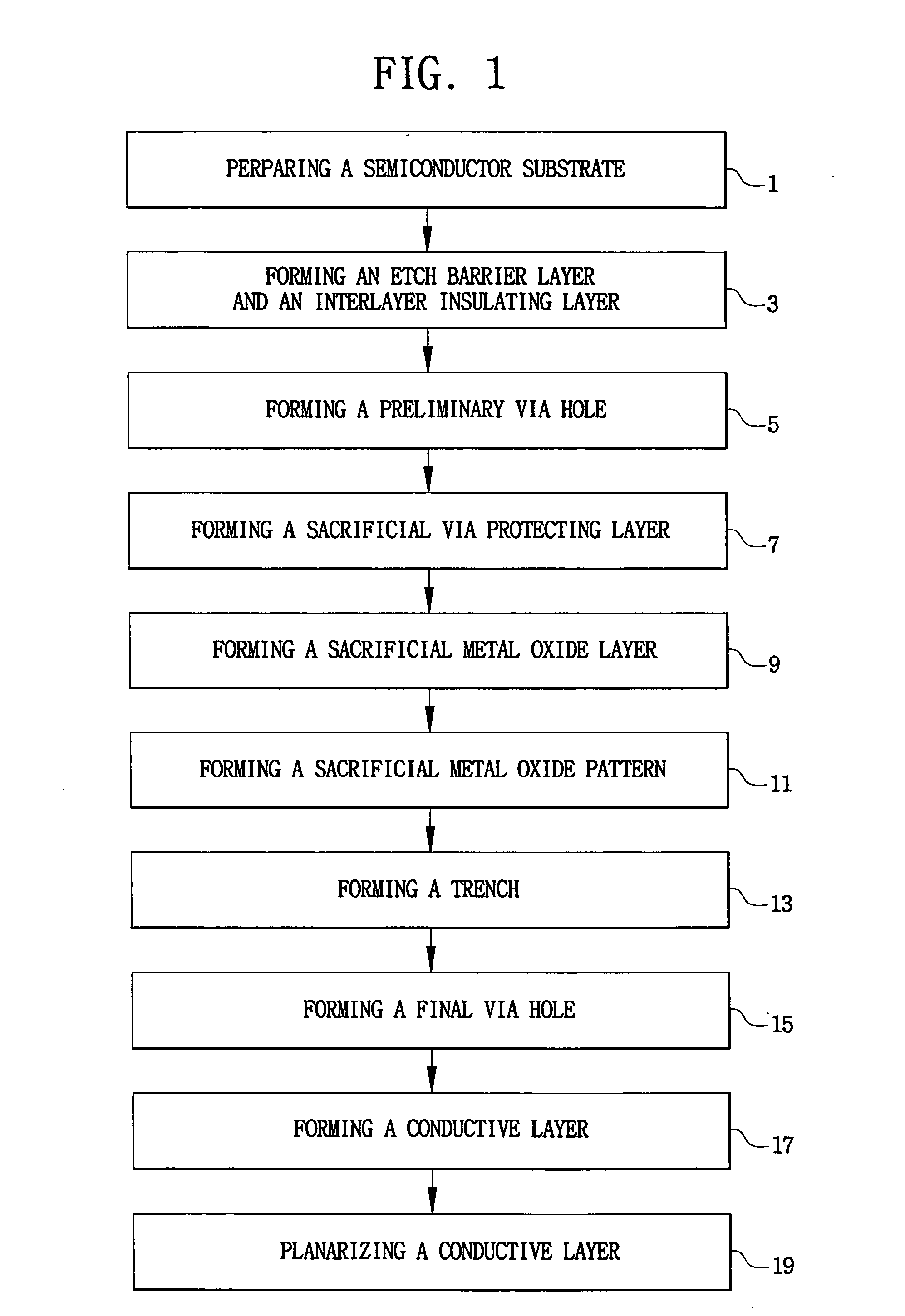

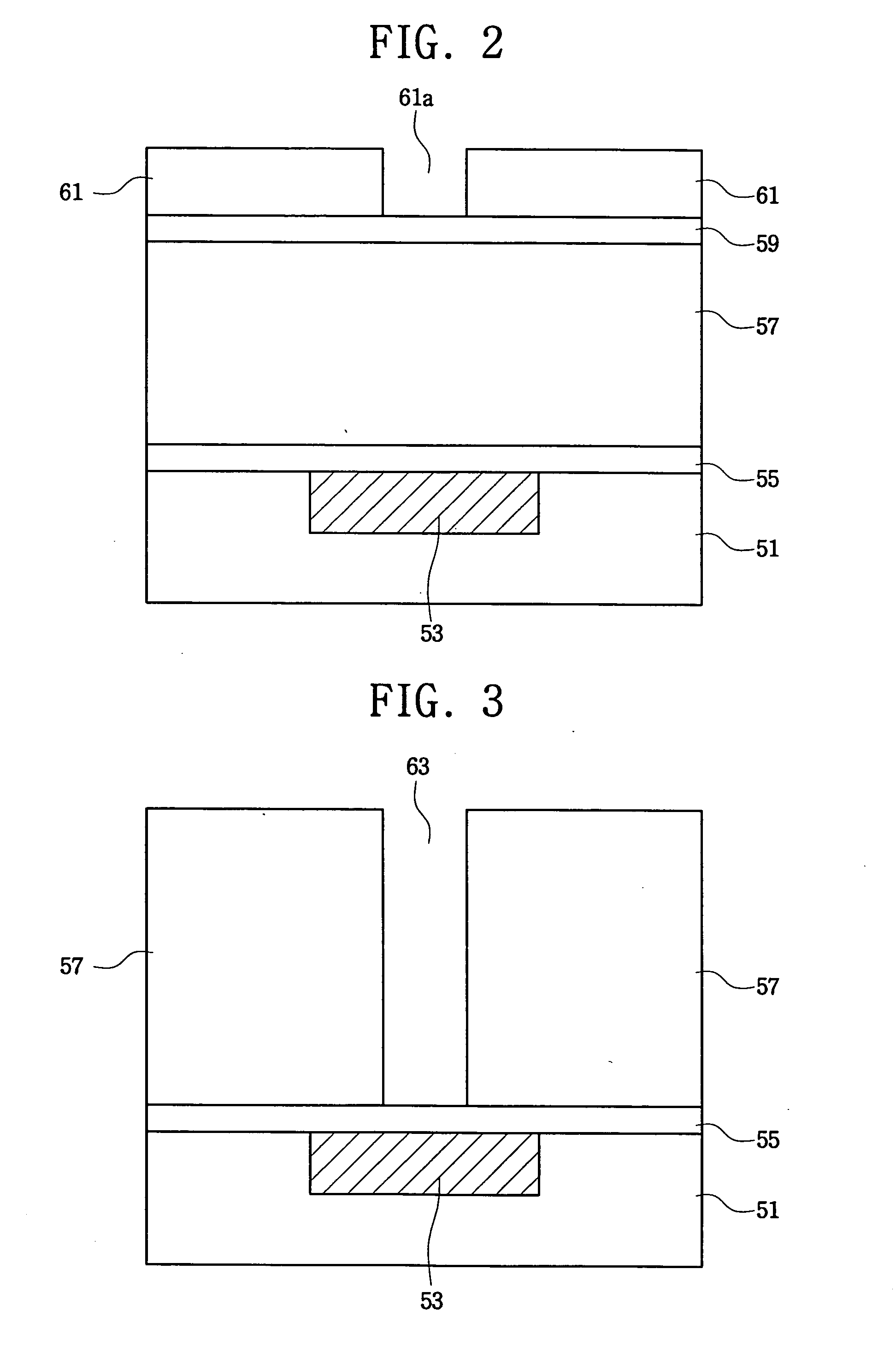

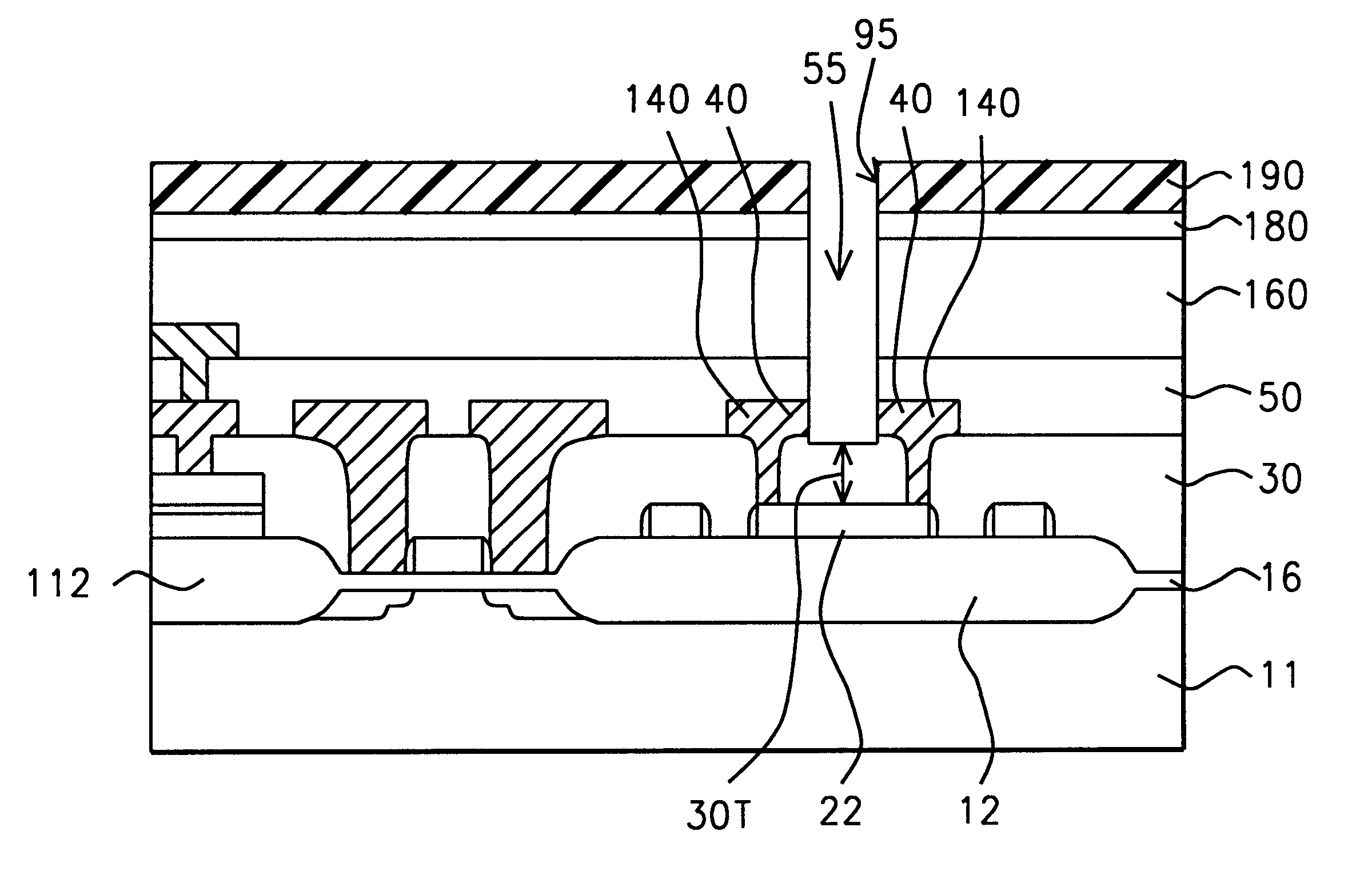

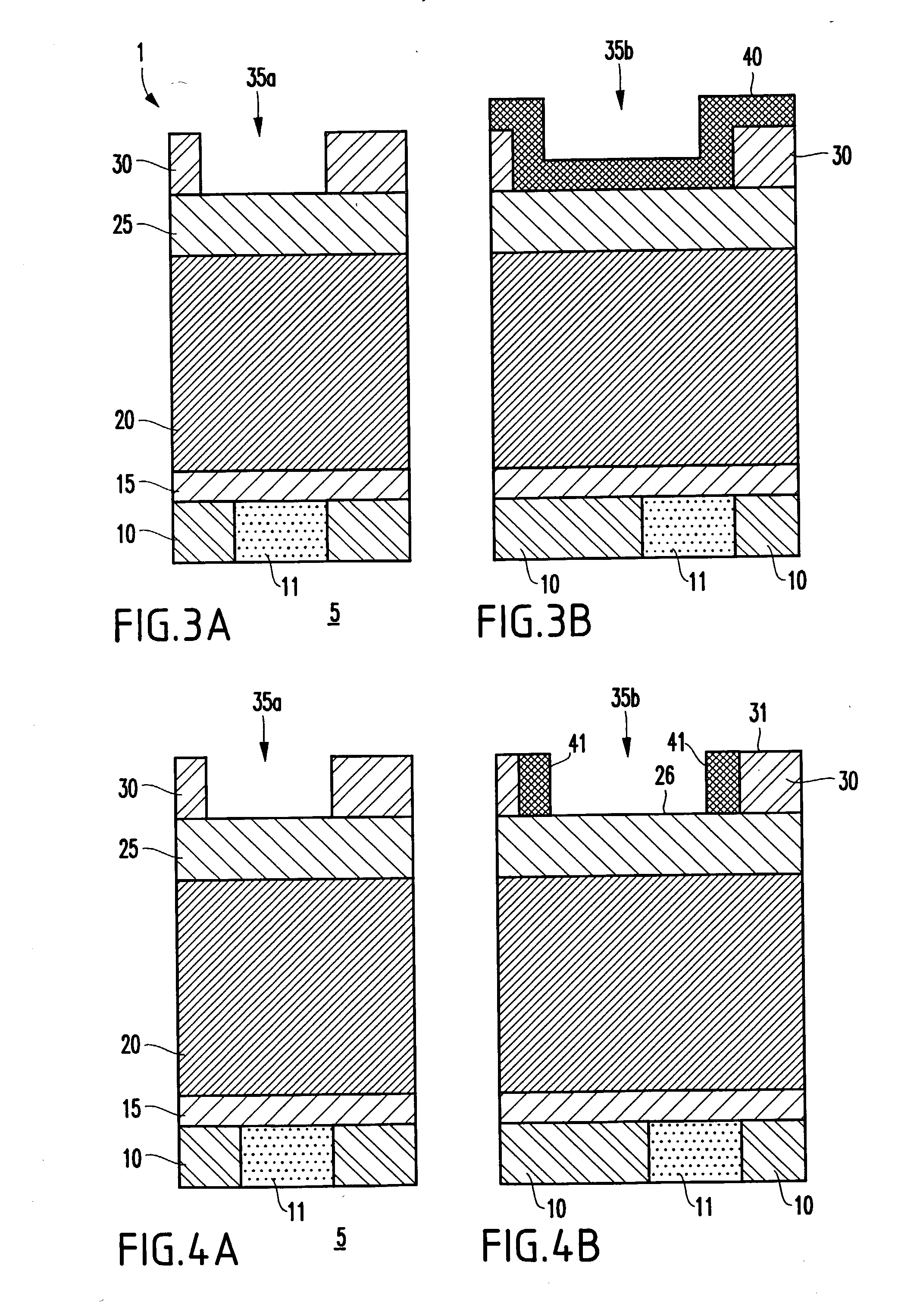

Method of forming dual damascene metal interconnection employing sacrificial metal oxide layer

ActiveUS20050124149A1Increase process marginReduce reflectivitySemiconductor/solid-state device manufacturingSemiconductor devicesInterconnectionSacrificial metal

There is provided a method of forming a dual damascene metal interconnection by employing a sacrificial metal oxide layer. The method includes preparing a semiconductor substrate. An interlayer insulating layer is formed on the semiconductor substrate, and a preliminary via hole is formed by patterning the interlayer insulating layer. A sacrificial via protecting layer is formed on the semiconductor substrate having the preliminary via hole to fill the preliminary via hole, and cover an upper surface of the interlayer insulating layer. A sacrificial metal oxide layer is formed on the sacrificial via protecting layer, the sacrificial metal oxide layer is patterned to form a sacrificial metal oxide pattern having an opening crossing over the preliminary via hole, and exposing the sacrificial via protecting layer. The sacrificial via protecting layer and the interlayer insulating layer are etched using the sacrificial metal oxide pattern as an etch mask to form a trench located inside the interlayer insulating layer.

Owner:SAMSUNG ELECTRONICS CO LTD

Method for forming a thin-film, electrically blowable fuse with a reproducible blowing wattage

InactiveUS6372652B1Reduce processing stepsUniform thicknessSemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureWindow opening

A method for forming a thin film, electrically blowable fuse with reproducible blowing wattage using a sacrificial metal patch over a fuse dielectric layer and two etch processes; wherein the first etch process is selective to the metal patch and the second etch process is selective to the fuse dielectric layer. A fuse element, having an element width, is formed over a semiconductor structure, and a fuse dielectric layer is formed over the fuse element. A sacrificial metal patch is formed on the fuse dielectric layer; wherein the patch width being greater than the fuse element width. A second dielectric layer is formed on the sacrificial metal patch, and additional metal layers and dielectric layers may be formed over the second dielectric layer, but only the dielectric layers will remain over the fuse element. The second dielectric layer and any overlying dielectric layers are patterned to form a fuse window opening, having a width greater than the sacrificial metal patch, using a first fuse window etch selective to the sacrificial metal patch. Then, the sacrificial metal patch is etched through the fuse window opening using a second fuse window etch selective to the fuse dielectric layer, leaving a reproducible thickness of the fuse dielectric layer overlying the fuse element; thereby providing a reproducible blowing wattage.

Owner:CHARTERED SEMICONDUCTOR MANUFACTURING

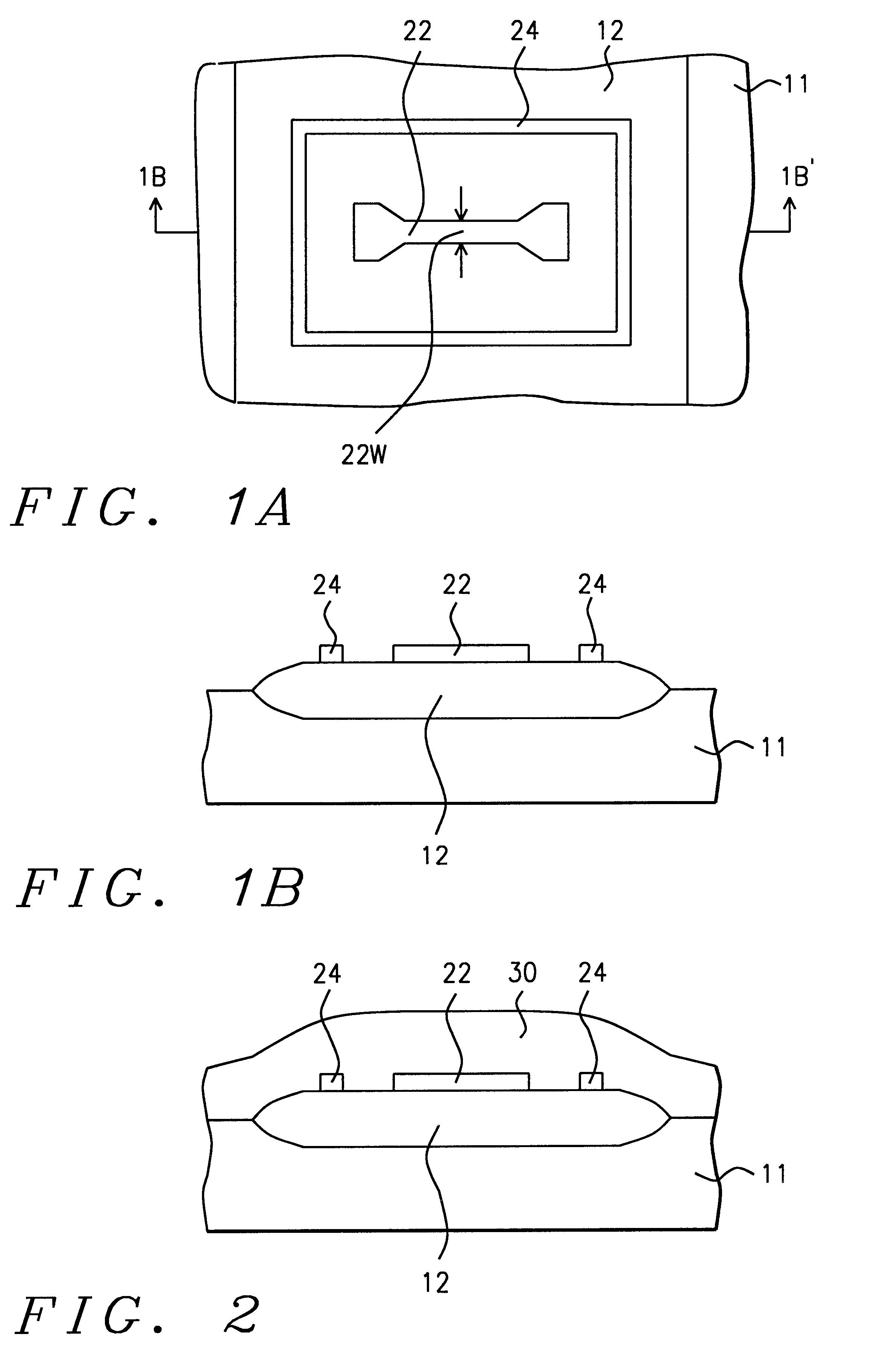

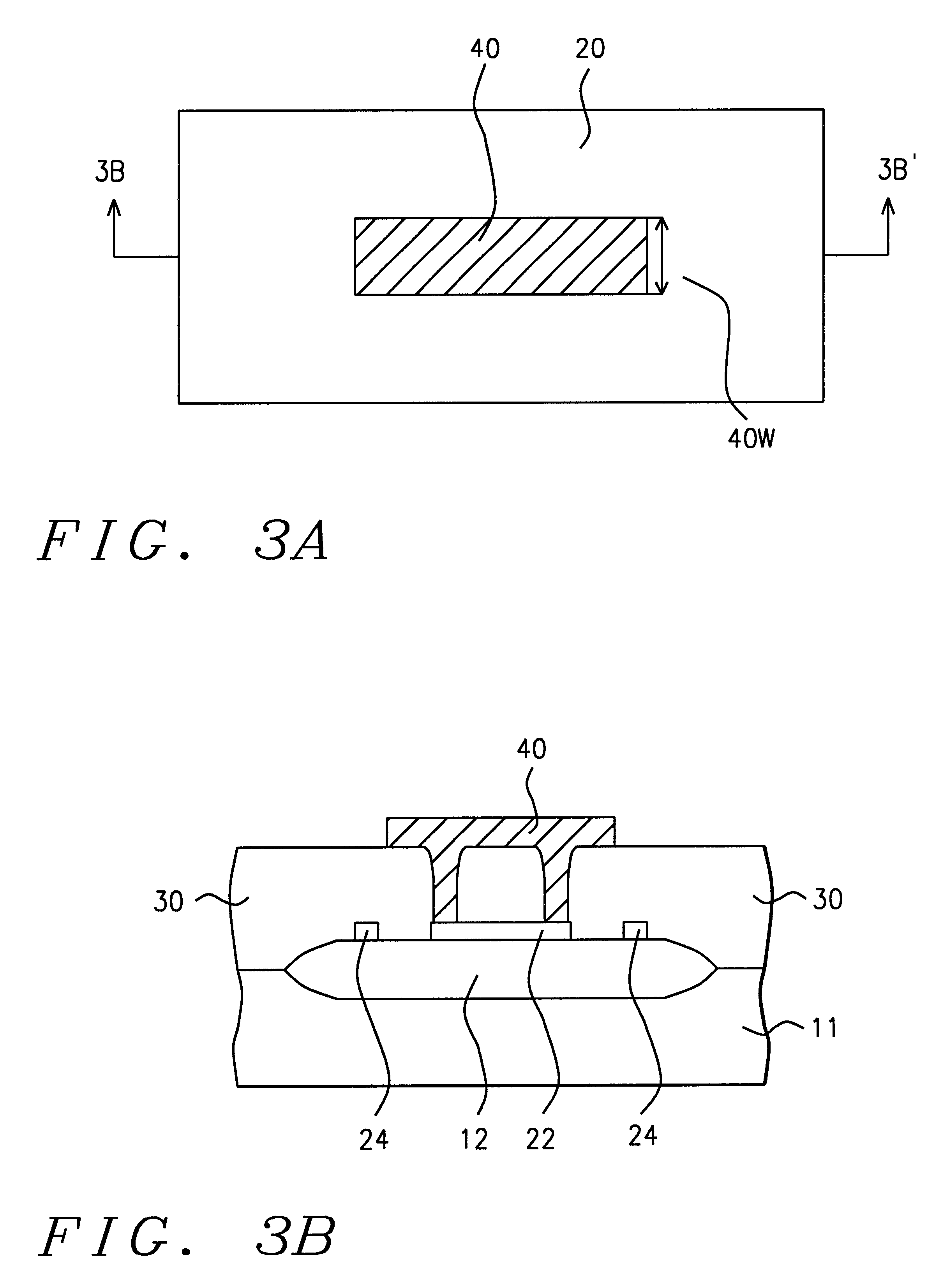

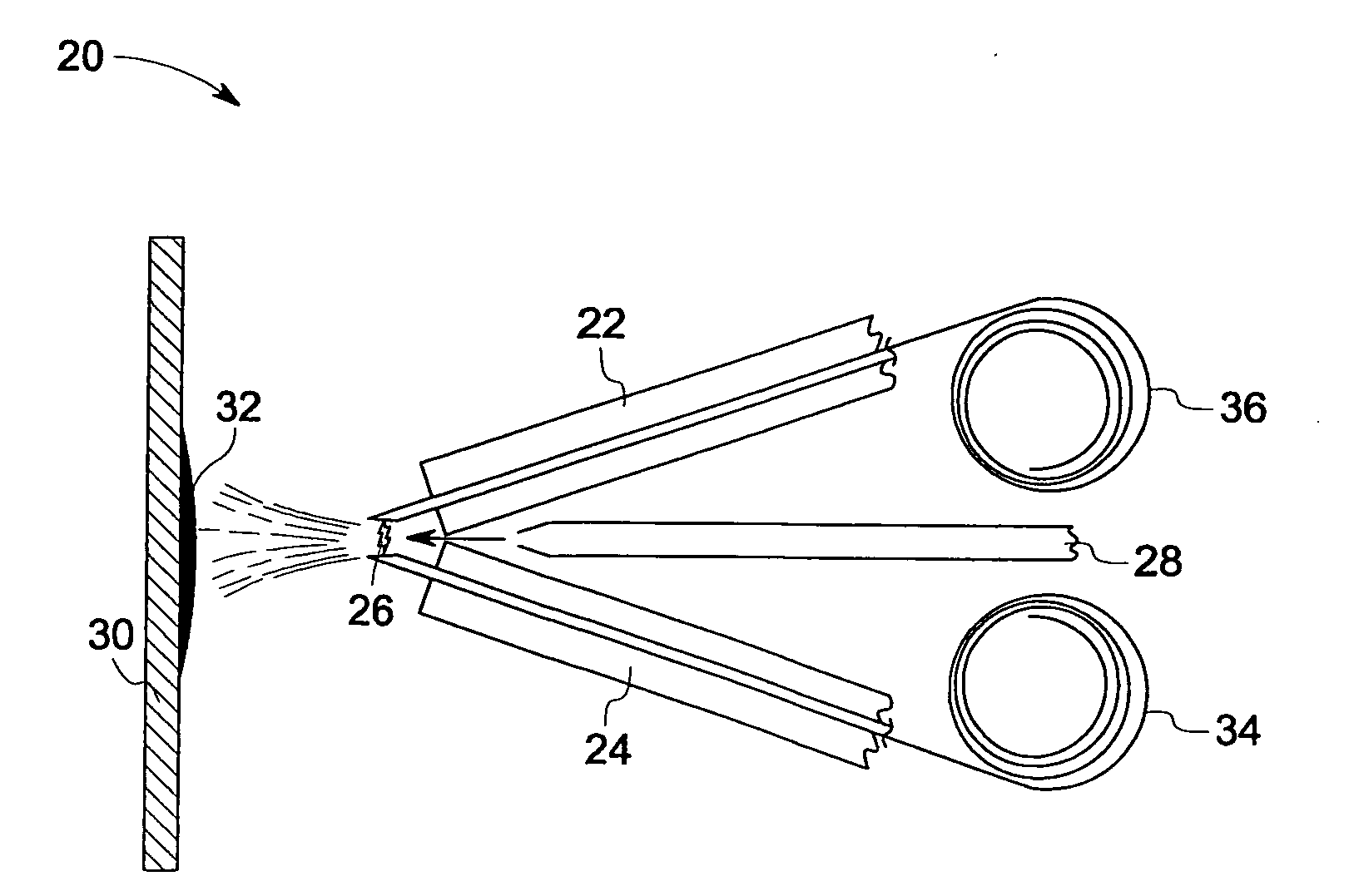

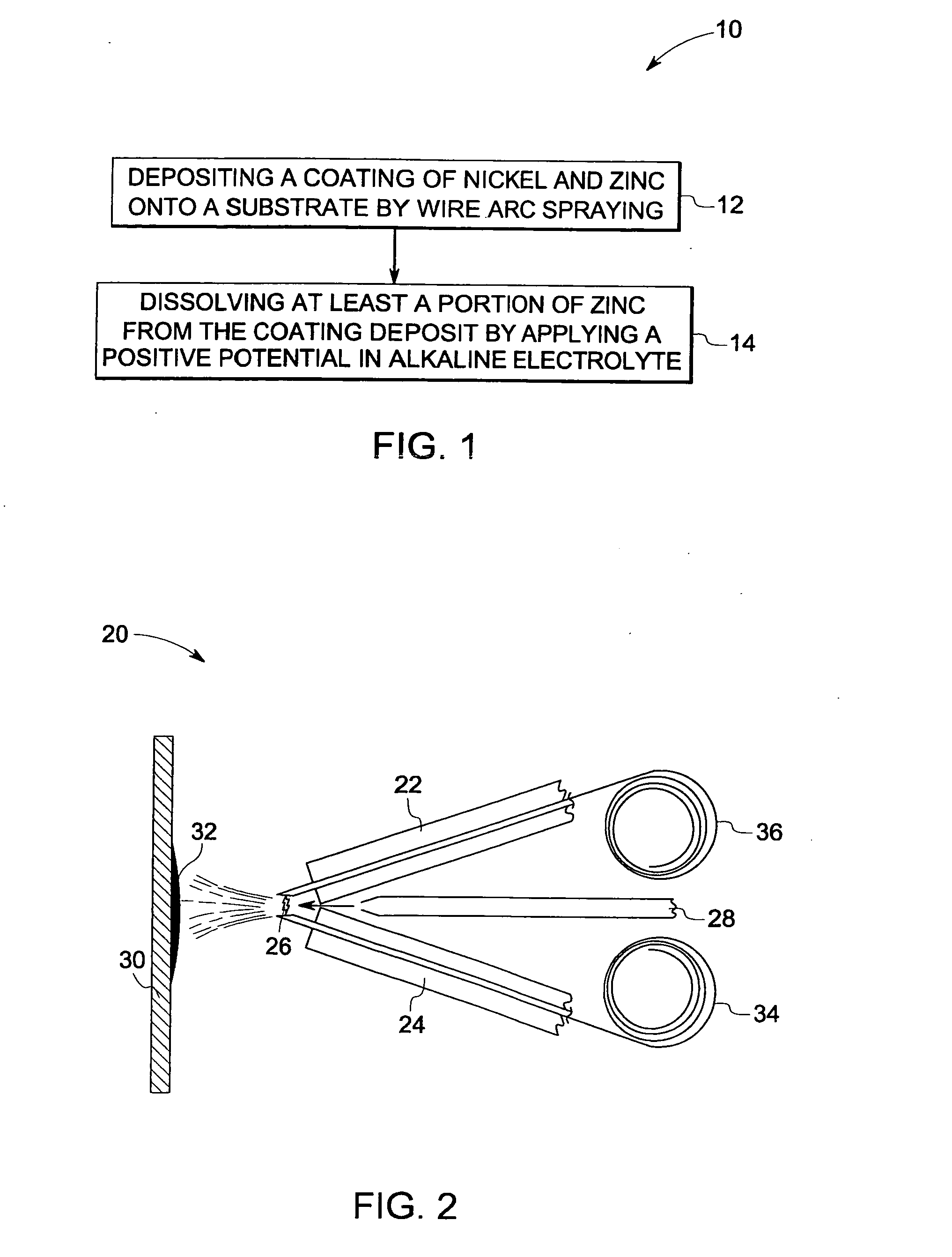

Method of forming a porous nickel coating, and related articles and compositions

InactiveUS20070278108A1Improve performanceEfficient productionPolycrystalline material growthFrom normal temperature solutionsSacrificial metalArc spray

A method of forming a porous nickel coating is provided. The method includes the steps of: depositing a coating onto a substrate by melting and atomizing two consumable electrode wires of a selected composition in a wire-arc spray device, so as to form a molten, atomized material, and directing the material to the substrate to form a coating deposit; the selected composition including nickel and a sacrificial metal; and then dissolving at least a portion of the sacrificial metal from the coating deposit by applying a positive potential in an alkaline electrolyte, so as to obtain a porous nickel coating. An electrolytic cell that includes a porous nickel coating is also described.

Owner:GENERAL ELECTRIC CO

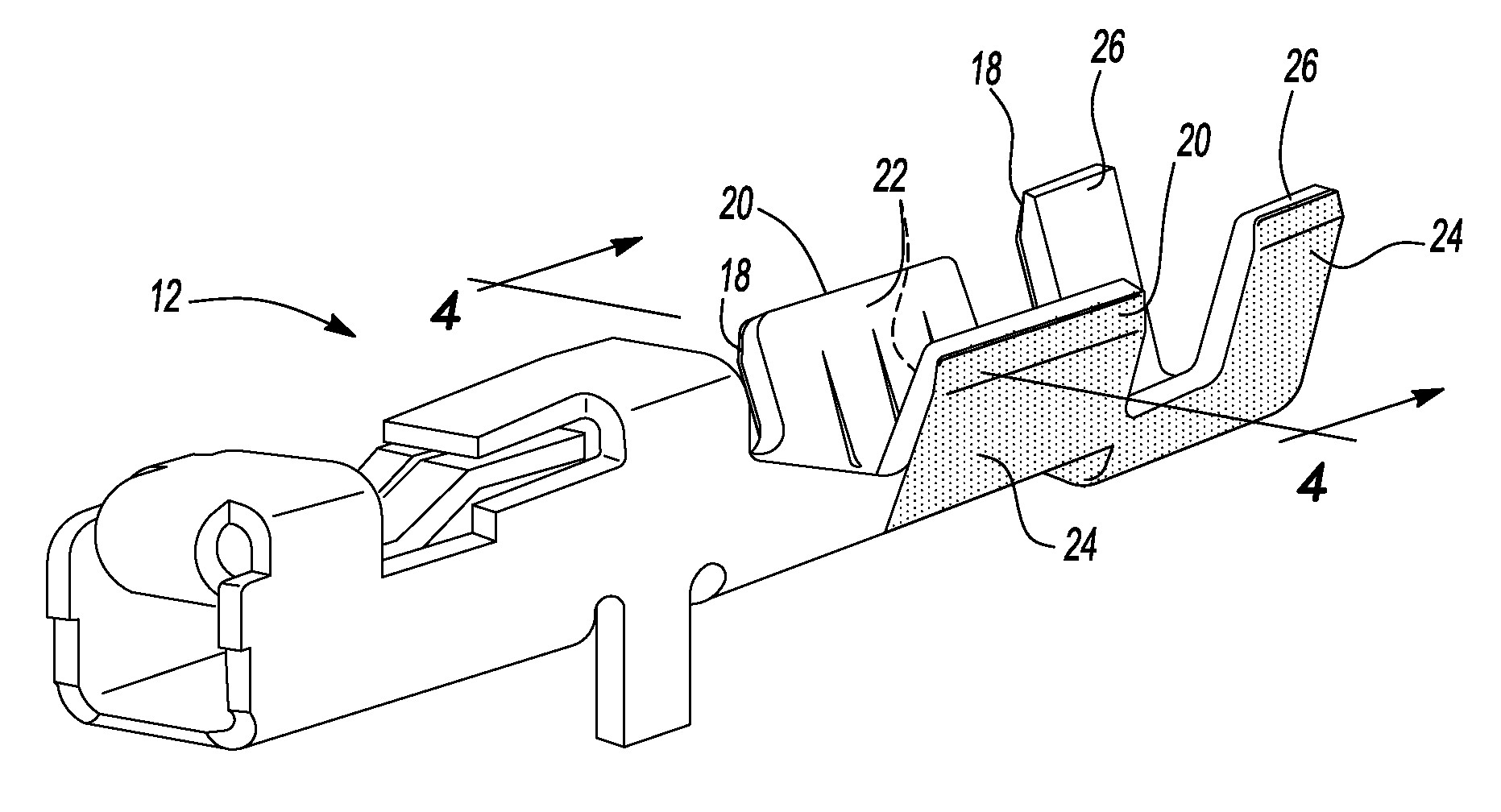

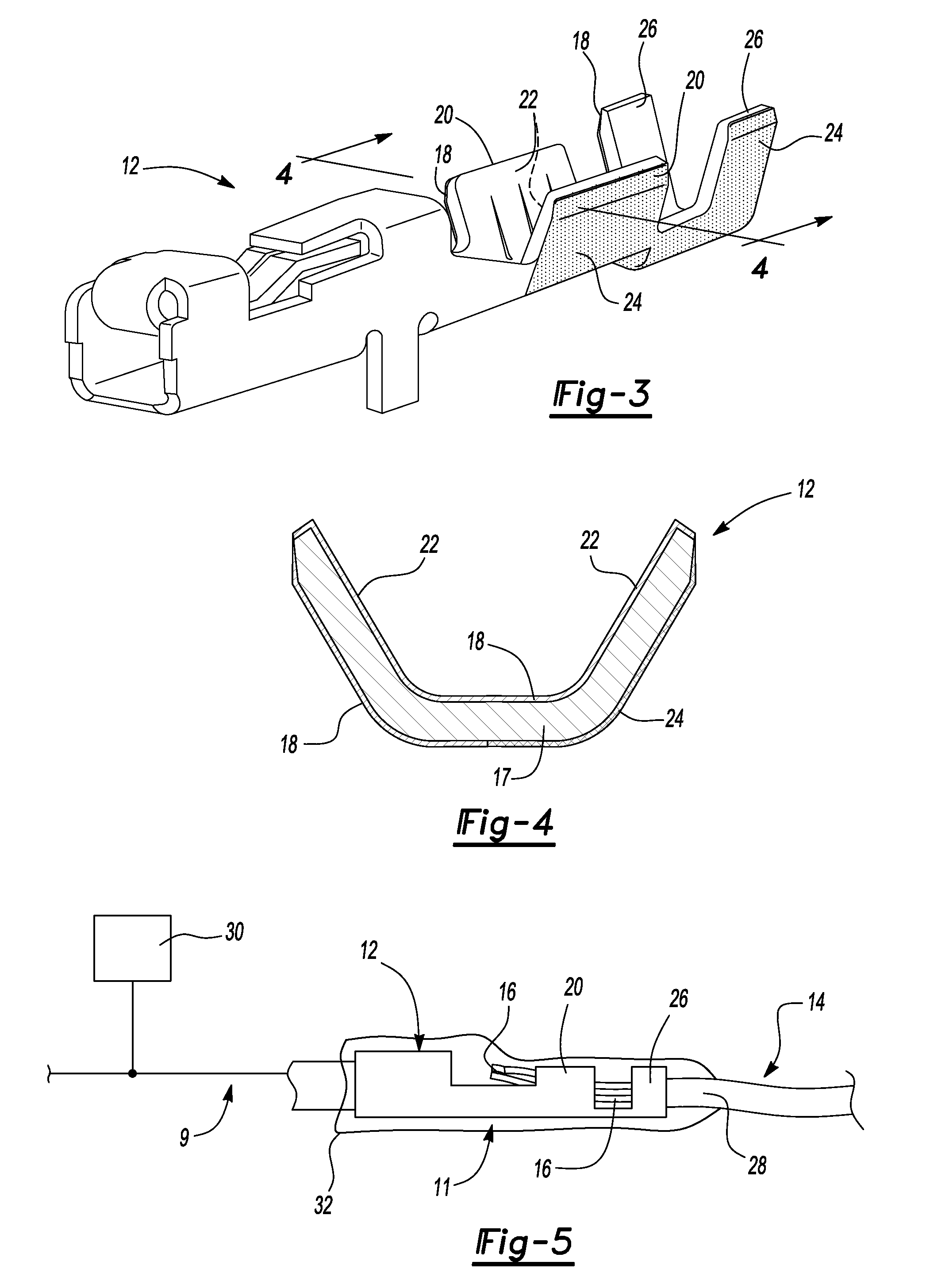

Electrical terminal connection with galvanic sacrificial metal

InactiveUS20110014825A1Avoid corrosionCoupling contact membersConnections effected by permanent deformationZinc alloysCopper

Owner:DELPHI TECH INC

Sacrificial metal spacer damascene process

InactiveUS20040018714A1Overcome limitationsEliminate the problemSemiconductor/solid-state device manufacturingSputter cleaningEngineering

A method and structure for a dual damascene interconnect structure comprises forming wiring lines in a metallization layer over a substrate, shaping a laminated insulator stack above the metallization layer, patterning a hardmask over the laminated insulator stack, forming troughs in the hardmask, creating sacrificial tungsten sidewall spacers in the troughs, patterning the laminated insulator stack, removing the sacrificial sidewall spacers, forming vias in the patterned laminated insulator stack, and depositing a metal liner and conductive material into the vias and troughs, wherein the laminated insulator stack comprises a dielectric layer further comprising oxide and polyarylene. The step of depositing prevents the laminated insulator stack from sputtering into the vias. Moreover, the step of depositing comprises cleaning the vias and troughs, optionally performing a reactive ion etching or argon sputter cleaning, depositing a plurality of metal layers over the vias and troughs, and depositing copper in the vias and troughs.

Owner:GLOBALFOUNDRIES INC

Method of separating semiconductor dies

ActiveUS20070212854A1Avoid depositionIncreasing the thicknessSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor materialsSacrificial metal

A method for the separation of multiple dies during semiconductor fabrication is described. On an upper surface of a semiconductor wafer containing multiple dies, metal layers are deposited everywhere except where a block of stop electroplating material exists. The stop electroplating material is obliterated, and a barrier layer is formed above the entire remaining structure. A sacrificial metal element is added above the barrier layer, and then the substrate is removed. After the semiconductor material between the individual dies is eradicated, any desired bonding pads and patterned circuitry are added to the semiconductor surface opposite the sacrificial metal element, a passivation layer is added to this surface, and then the sacrificial metal element is removed. Tape is added to the now exposed barrier layer, the passivation layer is removed, the resulting structure is flipped over, and the tape is expanded to separate the individual dies.

Owner:SEMI PHOTONICS CO LTD

Method of separating semiconductor dies

ActiveUS7452739B2Semiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor materialsSacrificial metal

A method for the separation of multiple dies during semiconductor fabrication is described. On an upper surface of a semiconductor wafer containing multiple dies, metal layers are deposited everywhere except where a block of stop electroplating material exists. The stop electroplating material is obliterated, and a barrier layer is formed above the entire remaining structure. A sacrificial metal element is added above the barrier layer, and then the substrate is removed. After the semiconductor material between the individual dies is eradicated, any desired bonding pads and patterned circuitry are added to the semiconductor surface opposite the sacrificial metal element, a passivation layer is added to this surface, and then the sacrificial metal element is removed. Tape is added to the now exposed barrier layer, the passivation layer is removed, the resulting structure is flipped over, and the tape is expanded to separate the individual dies.

Owner:SEMI PHOTONICS CO LTD

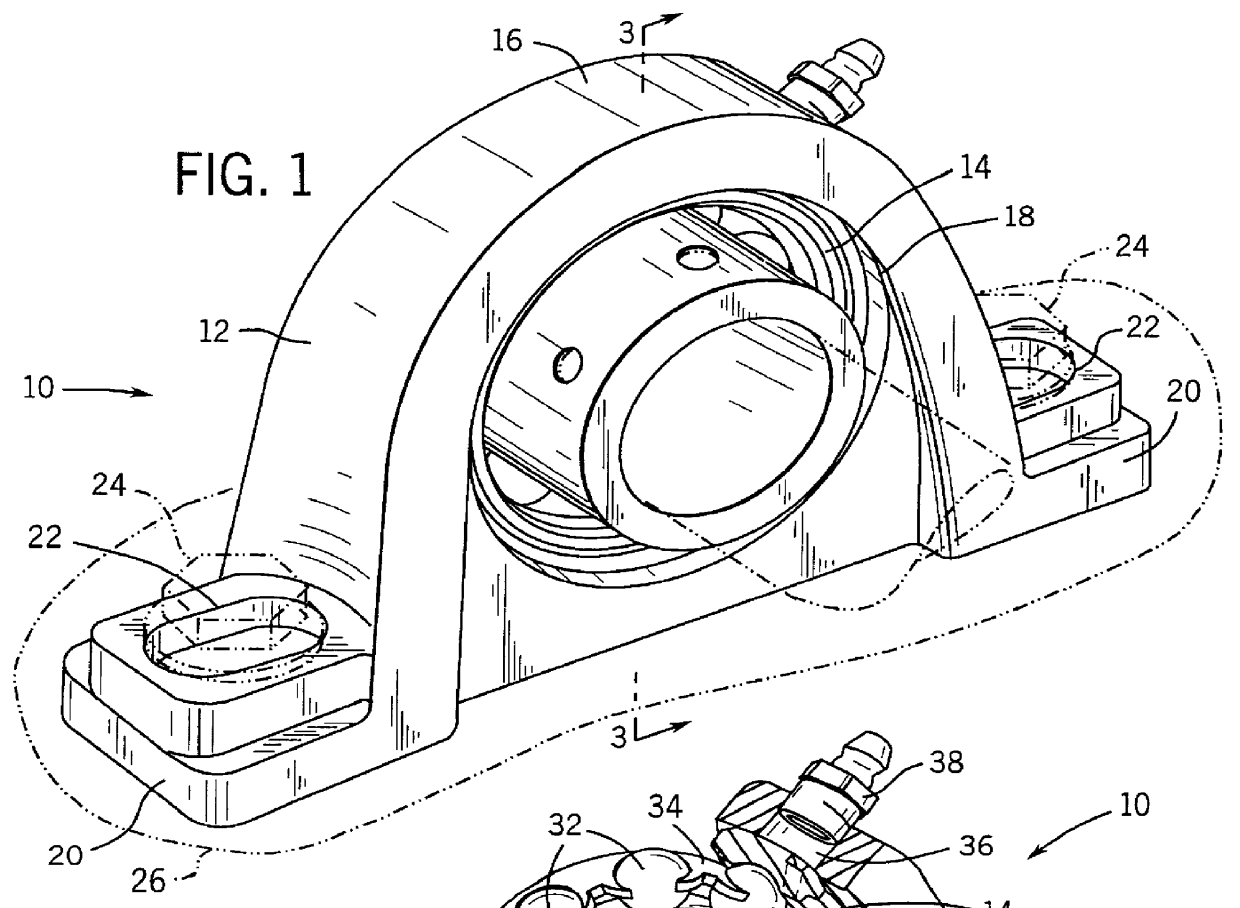

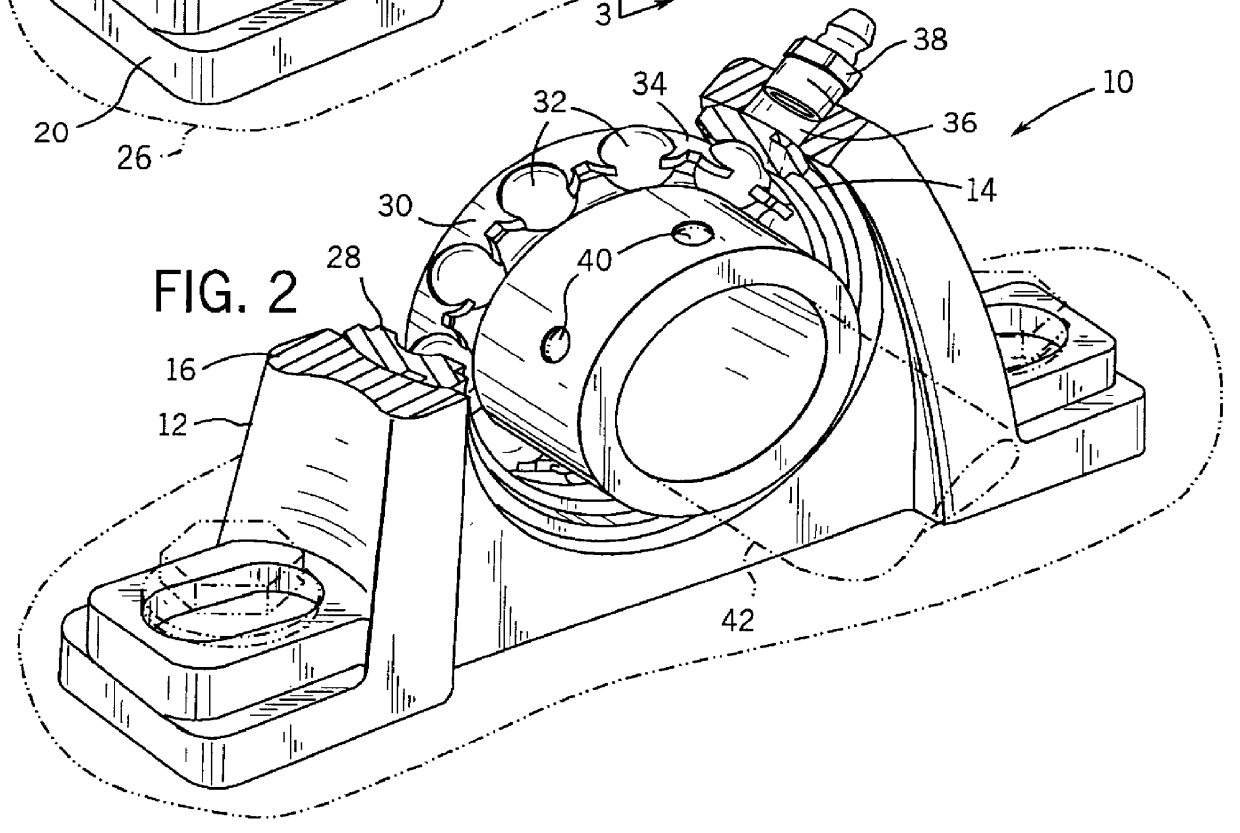

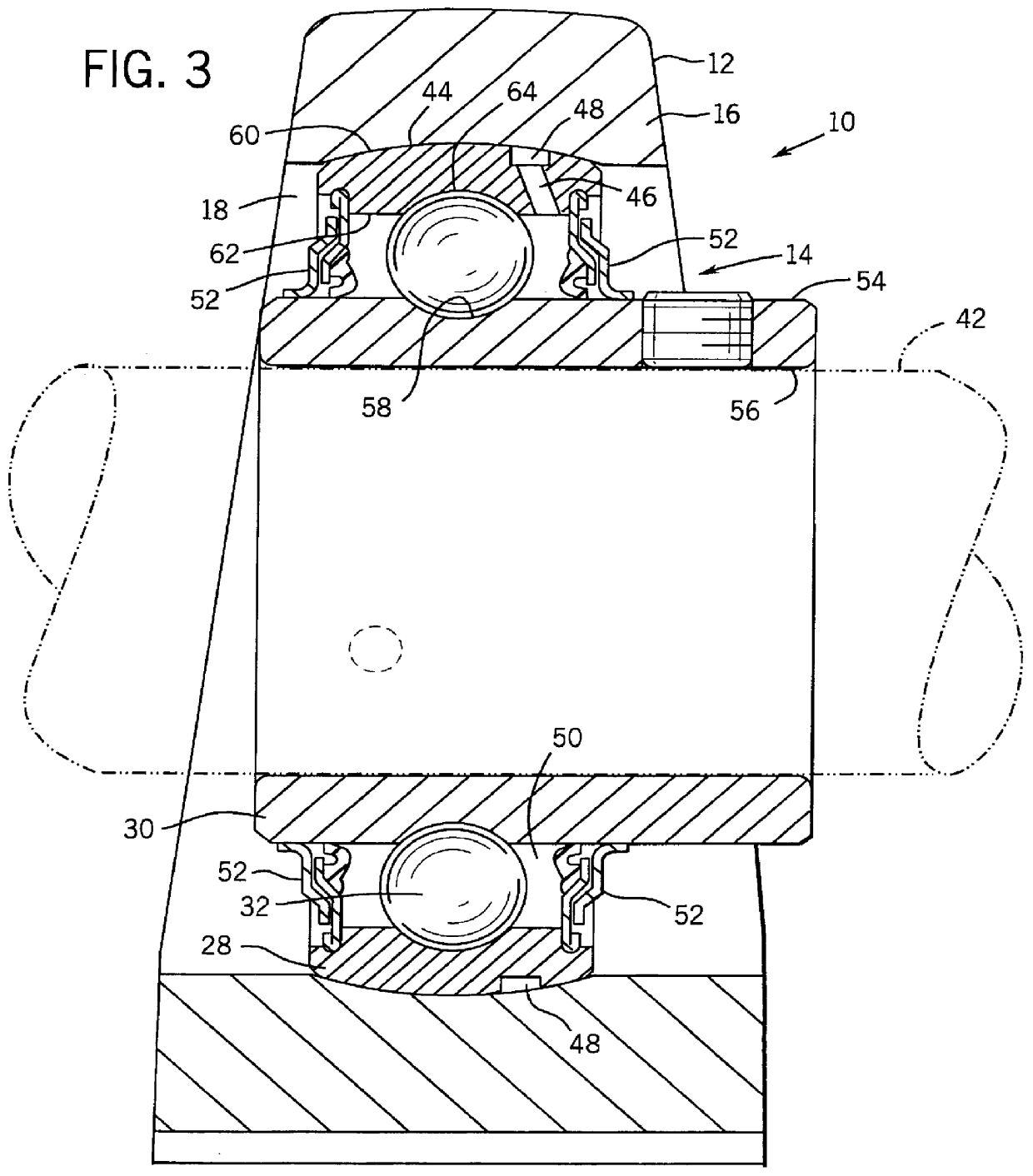

Corrosion resistant antifriction bearing and method for making same

InactiveUS6062735AAvoid corrosionExposure was also limitedShaftsBall bearingsRolling-element bearingProtection layer

A corrosion resistant bearing includes a bearing insert and a housing supporting the bearing insert. The bearing insert includes an outer ring, an inner ring and a plurality of rolling bearing elements disposed between the rings. At least one of the bearing components includes a multi-layer corrosion resistant system for inhibiting or delaying corrosion of the substrate of the component. The substrate may be made of high carbon or alloy steel. The corrosion resistant system includes a galvanic or sacrificial metallic plating layer disposed directly on the component substrate. One or more mechanical protection layers is formed or disposed over the plating layer. A first mechanical protection layer includes a clear chromate coating formed on the plating layer. Additional mechanical protection layers include non-metallic layers, such as acetate or polytetrafluoroethylene coatings. The plating layer and the mechanical protection layers may extend over the bearing ring component raceway, or one or more of the layers may stop short of the raceway. In a method for making the component, a mask may be applied to regions of the component over which one or more the protective layers is not to be applied.

Owner:BALDOR ELECTRIC COMPANY

Environmentally protected reinforcement dowel pins and method of making

InactiveUS20050265802A1Maintain integrityMaintain strengthPaving detailsFastener toolsZinc alloysSacrificial metal

Galvanically protected reinforcement dowel pins and methods of producing the same. In one embodiment, the reinforcement dowel pins comprise a bar or tube, the longitudinal exposed surfaces of which are covered by a heavy gauge of a sacrificial metal, such as zinc, zinc alloy, magnesium, magnesium alloy, aluminum, or aluminum alloy. The bar or tube comprises steel, carbon steel, or other ferrous metal. The heavy gauge of sacrificial metal is applied to the ferrous metal by various processes, such as roll bonding, lock seaming, welding, die casting, flame spraying, plasma spraying, dipping, sinking, and drawing. The resulting reinforcement dowel pins resist corrosion without sacrificing structural integrity, and are reasonable in materials and manufacturing costs. These dowel pins may be installed in adjacent concrete panels using conventional methods, and therefore do not introduce additional costs in installation.

Owner:JARDEN ZINC PRODS LLC

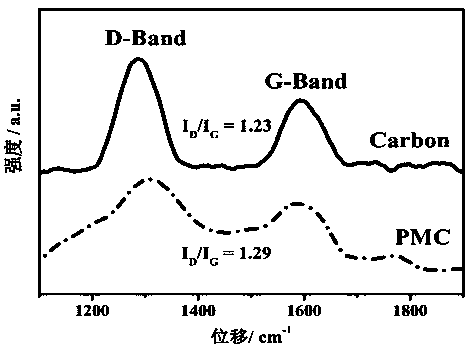

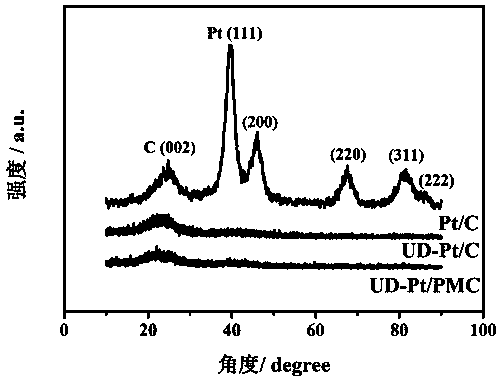

Preparation method of highly-dispersed precious metal electrocatalyst with high stability and low load capacity

InactiveCN108232210AImprove stabilityIncrease loadMaterial nanotechnologyCell electrodesIridiumAlcohol reduction

The invention provides a preparation method of a highly-dispersed precious metal electrocatalyst with high stability and a low load capacity. According to the preparation method, low content preciousmetals such as platinum, palladium, ruthenium, iridium, and the like, are taken as the catalytic active components; cheap metals such as iron, tin, cobalt, nickel, copper, and the like, are taken as sacrificial metals; alloy particles are synthesized through a hydrothermal method, an alcohol reduction method, or a hydrazine reduction method; then alloy particles are loaded on a heteroatom doped functionalized carbon carrier through the anchoring effect of the functionalized carbon carrier so as to obtain a catalyst precursor; then the catalyst precursor is soaked in an acid to dissolve the sacrificial metals, the alloy particles are cracked, the precious metals are left on the heteroatom doped functionalized carbon carrier, and the precious metal catalyst with a highly dispersed structureis obtained. The precious metal catalyst has an excellent catalytic performance, moreover, the loading amount of precious metals is greatly reduced, the utilization rate of precious metals is largelyincreased, the catalyst cost is effectively reduced, and the contradiction between the performance and cost is solved.

Owner:LANZHOU JIAOTONG UNIV

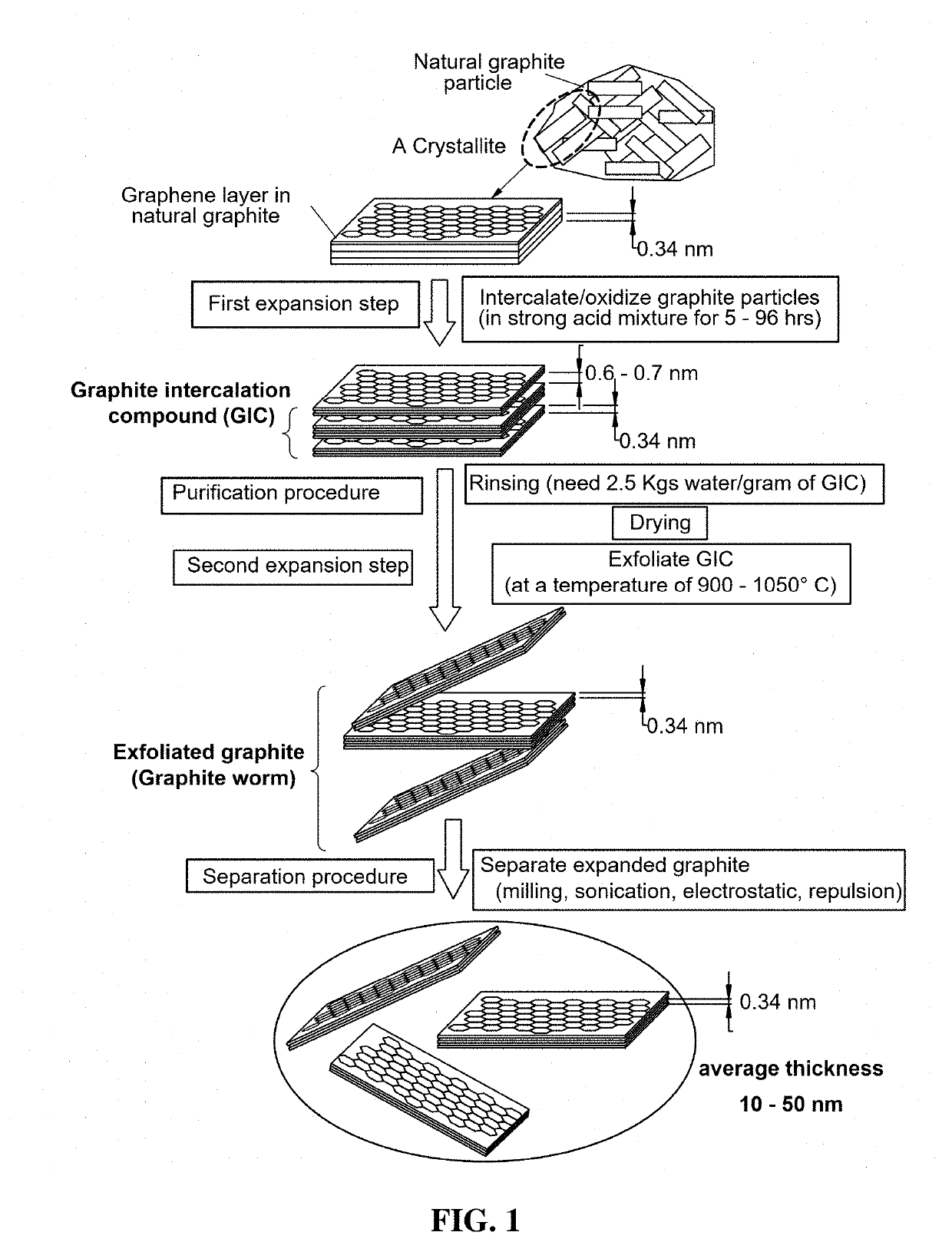

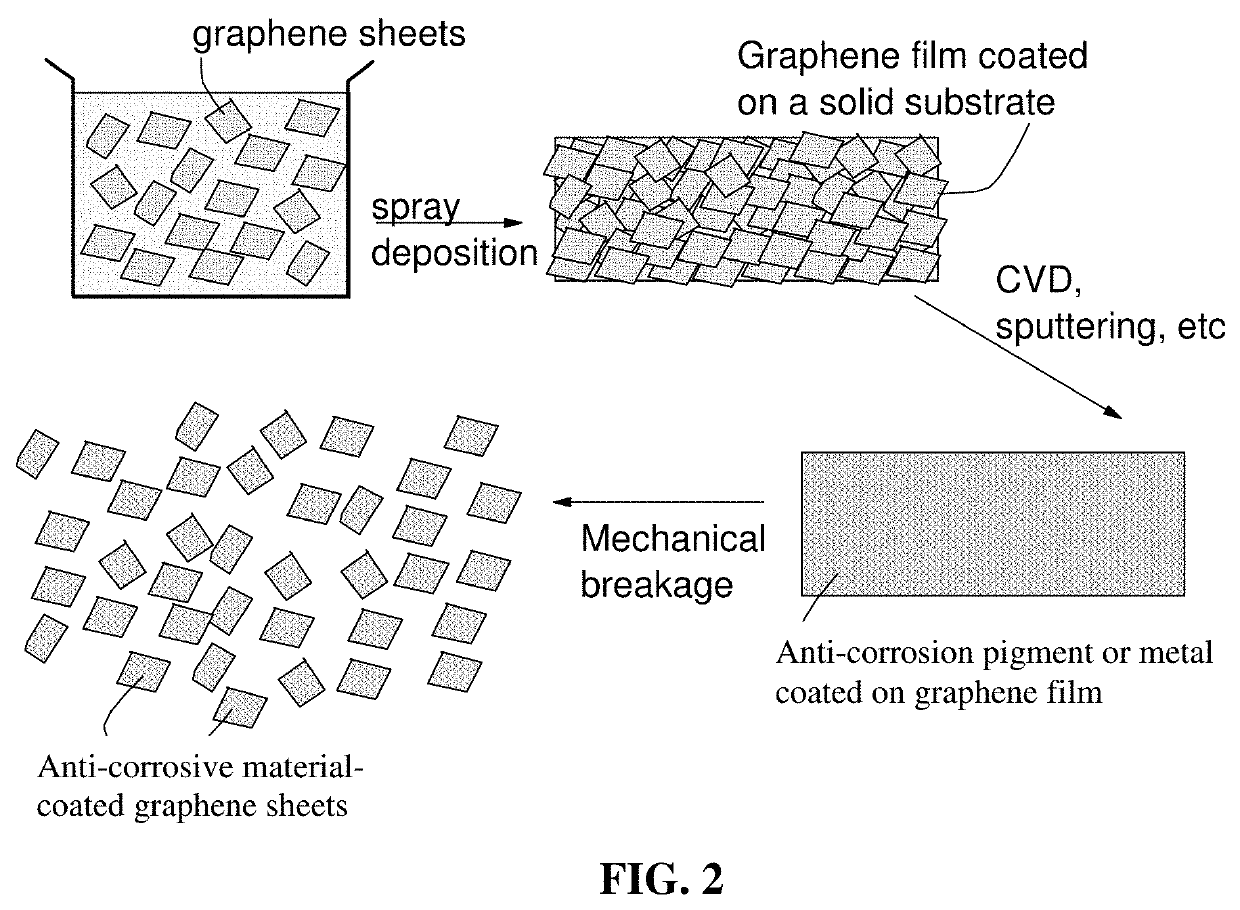

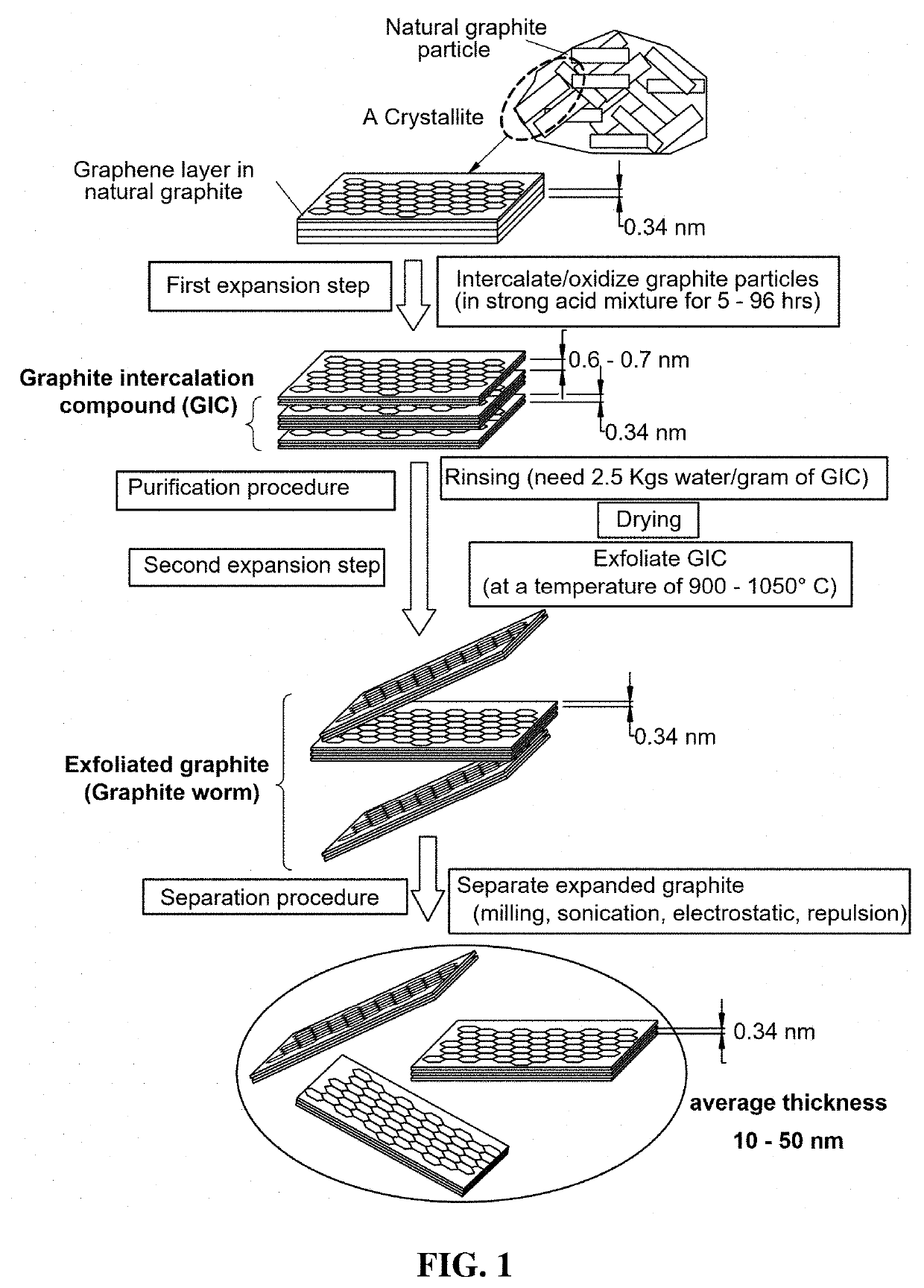

Anti-corrosion material-coated discrete graphene sheets and Anti-corrosion coating composition containing same

PendingUS20190345344A1Avoid corrosionEffective protectionAnti-corrosive paintsPolyurea/polyurethane coatingsLiquid mediumDoped graphene

Provided is a graphene-based coating suspension comprising multiple graphene sheets, thin film coating of an anti-corrosive pigment or sacrificial metal deposited on graphene sheets, and a binder resin dissolved or dispersed in a liquid medium, wherein the multiple graphene sheets contain single-layer or few-layer graphene sheets selected from a pristine graphene material having essentially zero % of non-carbon elements, or a non-pristine graphene material having 0.001% to 47% by weight of non-carbon elements wherein the non-pristine graphene is selected from graphene oxide, reduced graphene oxide, graphene fluoride, graphene chloride, graphene bromide, graphene iodide, hydrogenated graphene, nitrogenated graphene, doped graphene, chemically functionalized graphene, or a combination thereof. The invention also provides a process for producing this coating suspension. Also provided is an object or structure coated at least in part with such a coating.

Owner:GLOBAL GRAPHENE GRP INC

Graphene-enabled method of inhibiting metal corrosion

PendingUS20190345345A1Avoid corrosionEffective protectionAnti-corrosive paintsPolyurea/polyurethane coatingsLiquid mediumGraphene flake

Provided is a method of inhibiting corrosion of a structure or object having a surface, the method comprising (i) coating at least a portion of the surface with a coating suspension comprising multiple graphene sheets coated with a thin film of an anti-corrosive pigment or sacrificial metal having a thickness from 0.5 nm to 1 μm and a resin binder dispersed or dissolved in a liquid medium; and (ii) at least partially removing the liquid medium from the coating suspension upon completion of the coating step to form a protective coating layer on the surface. Preferably, the protective coating layer contains coated graphene sheets that are aligned to be substantially parallel to one another and parallel to the surface of the structure or object to be protected.

Owner:GLOBAL GRAPHENE GRP INC

Prestressable low-E layer systems for window panes

InactiveUS7211328B2Glass/slag layered productsNatural mineral layered productsDiffusion barrierSacrificial metal

A multilayer film, capable of withstanding high thermal stresses, with silver as functional layer, a sacrificial metal layer placed on top of the silver layer and antireflection dielectric layers, has a metal nitride layer between the silver layer and the sacrificial metal layer. This metal nitride layer is composed in particular of Si3N4 and / or AlN and constitutes an effective diffusion barrier. The optical and energy properties of the silver layer consequently remain, for the most part, preserved, even after undergoing high thermal stresses (for example of the bending or toughening type when curving and / or prestressing a window pane provided with the multilayer film).

Owner:SAINT-GOBAIN GLASS FRANCE

Oxide Coated Metal Pigments and Film-Forming Compositions

This invention relates to sacrificial-metal pigments coated with an effective amount of at least one metal oxide or a combination of metal oxides such as a chromium-zirconium oxide, and the process for preparing said coated pigments and combination thereof with film-forming binders for coating metal substrates to inhibit corrosion. The coated sacrificial-metal pigments are electrically active to prevent corrosion of metal substrates that are more cathodic (electropositive) than the metal oxide coated metal pigments.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY +1

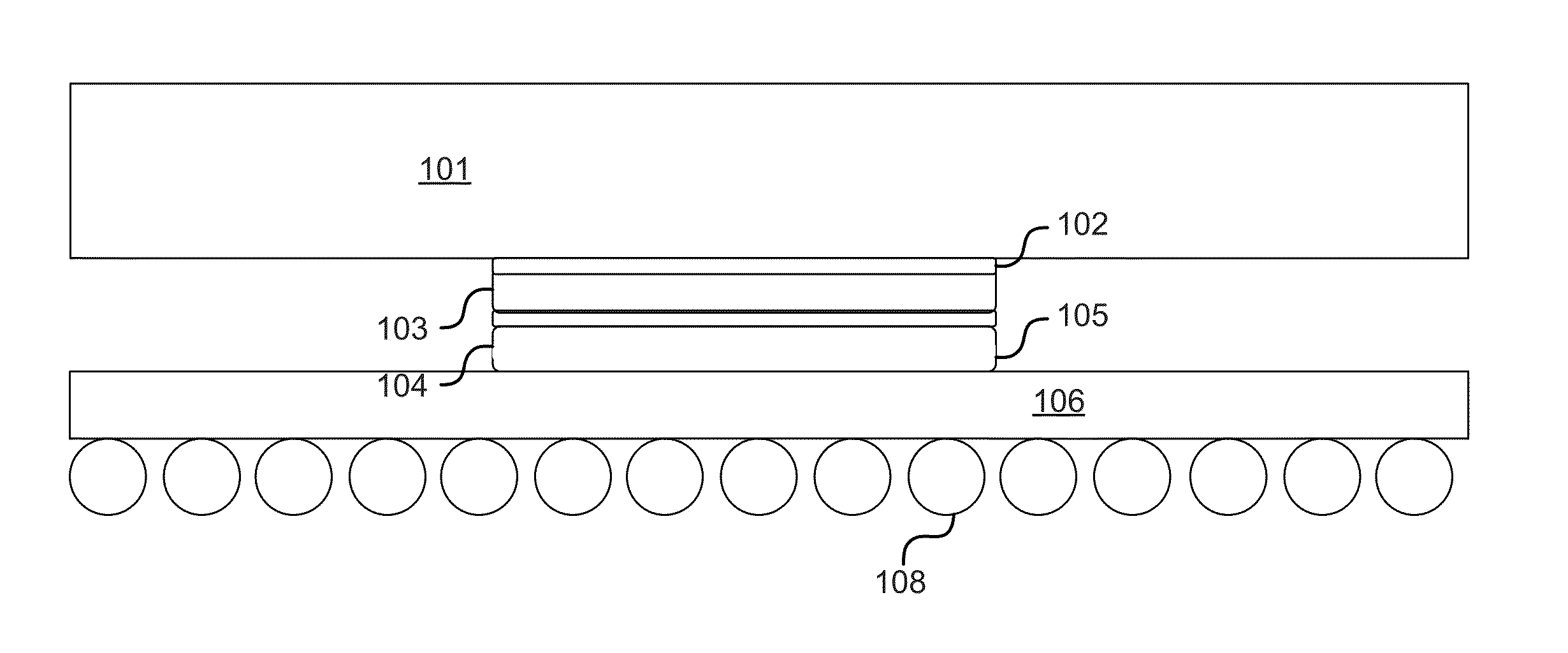

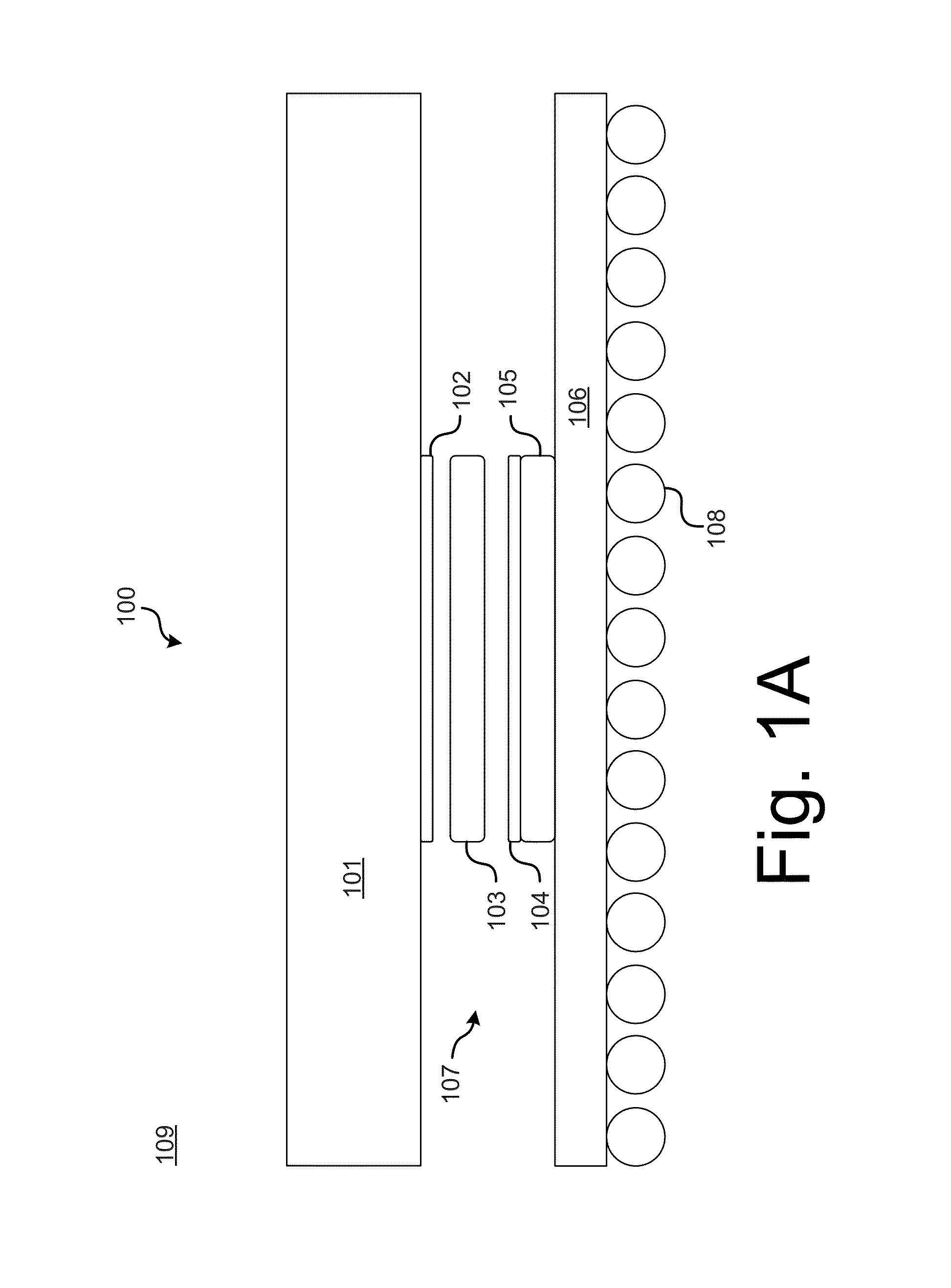

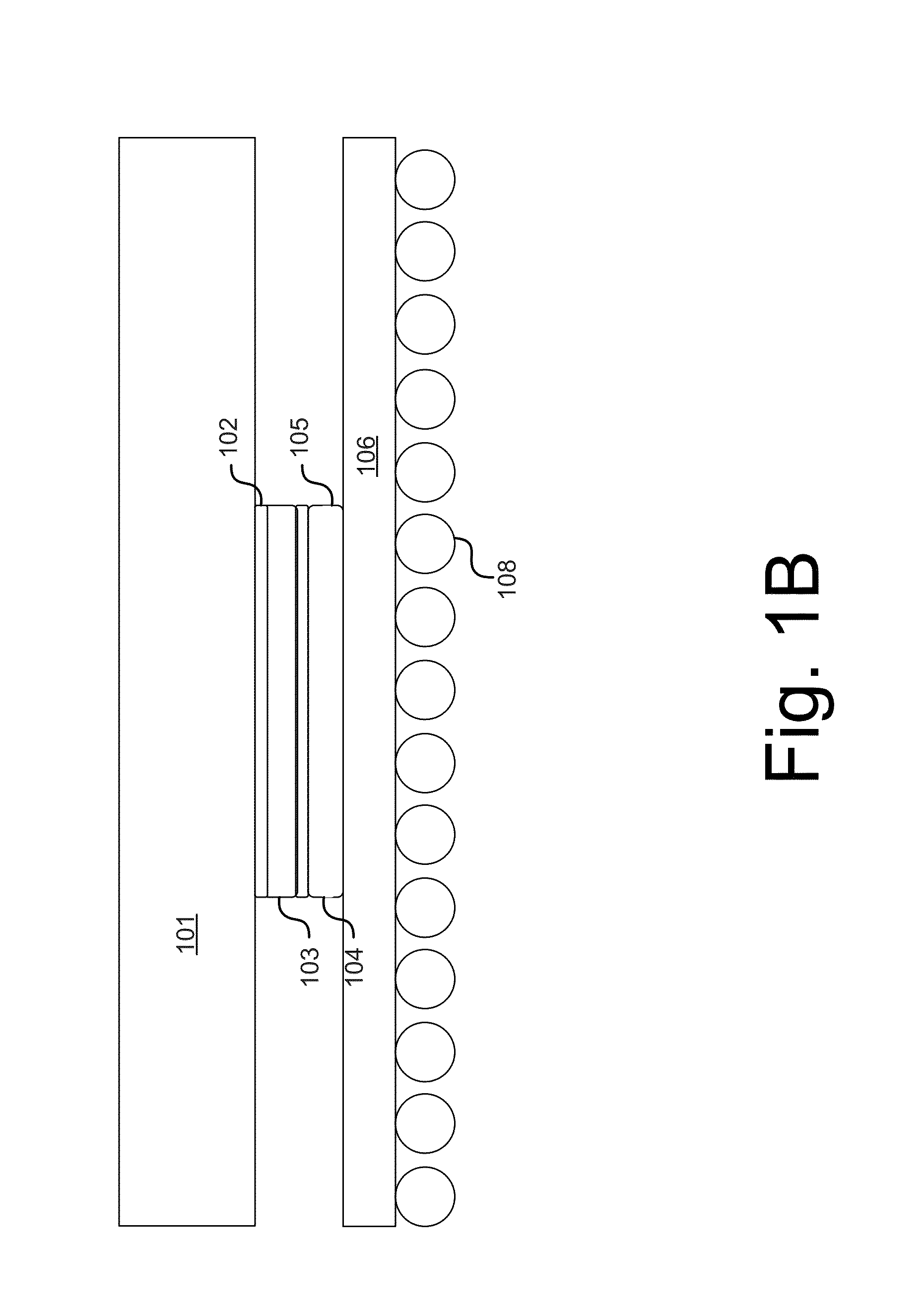

Low void solder joint for multiple reflow applications

ActiveUS20140193658A1Quickly dissolves the silverLow melting pointSemiconductor/solid-state device detailsSolid-state devicesEngineeringSacrificial metal

Methods and apparatus are provided for attaching a heat spreader to a die and includes disposing a solder thermal interface material between a first surface of a die and a first surface of a heat spreader without disposing a liquid flux between the die and the heat spreader to form an assembly, wherein at least one of the first surface of the die and a first surface of the heat spreader have disposed thereon a metallization structure comprising a transition layer and a sacrificial metallization layer, the sacrificial metallization layer disposed as an outer layer to the metallization structure adjacent the solder thermal interface material; and heating the assembly to melt the thermal interface and attach the die to the heat spreader.

Owner:INDIUM CORP

Preparation of porous copper electrode for electrochemical reduction of carbon dioxide and electrode and application thereof

InactiveCN106868536ALow costImprove efficiencyElectrolytic organic productionElectrode shape/formsPorosityCopper electrode

The invention provides a preparation method of a porous copper electrode for electrochemical reduction of carbon dioxide. The preparation method comprises the following steps: 1) a layer of a sacrificial metal is electrolytic deposited on a copper base material; 2) a heat treatment is conducted under the protection of an inert gas, so that a solid state diffusion between a metal copper and sacrificial metal atoms occurs, and an alloy layer of the sacrificial metal and the copper is obtained on the surface of the copper; 3) the electrochemical dealloying is conducted. The porosity of the porous copper electrode is 50%-95%, the pore size is 50 nm-500 nm, and the sacrificial metal content is no more than 5%. The porous copper electrode has the characteristics of adjustable pore size and quantity, good air permeability and high specific surface area. The porous copper electrode has better specificity for the selection of target products and is suitable for electrochemical reduction reaction of carbon dioxide catalyzing.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

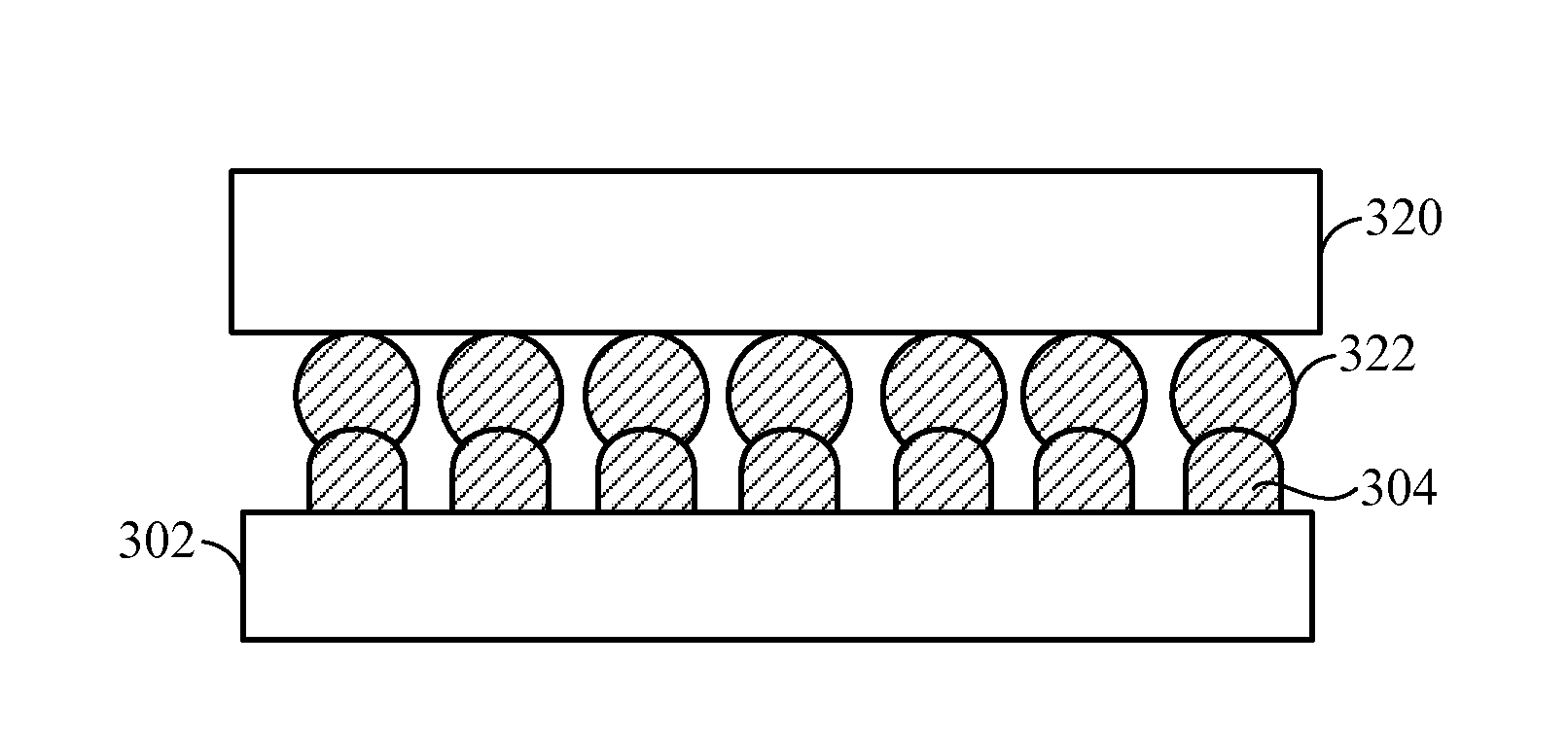

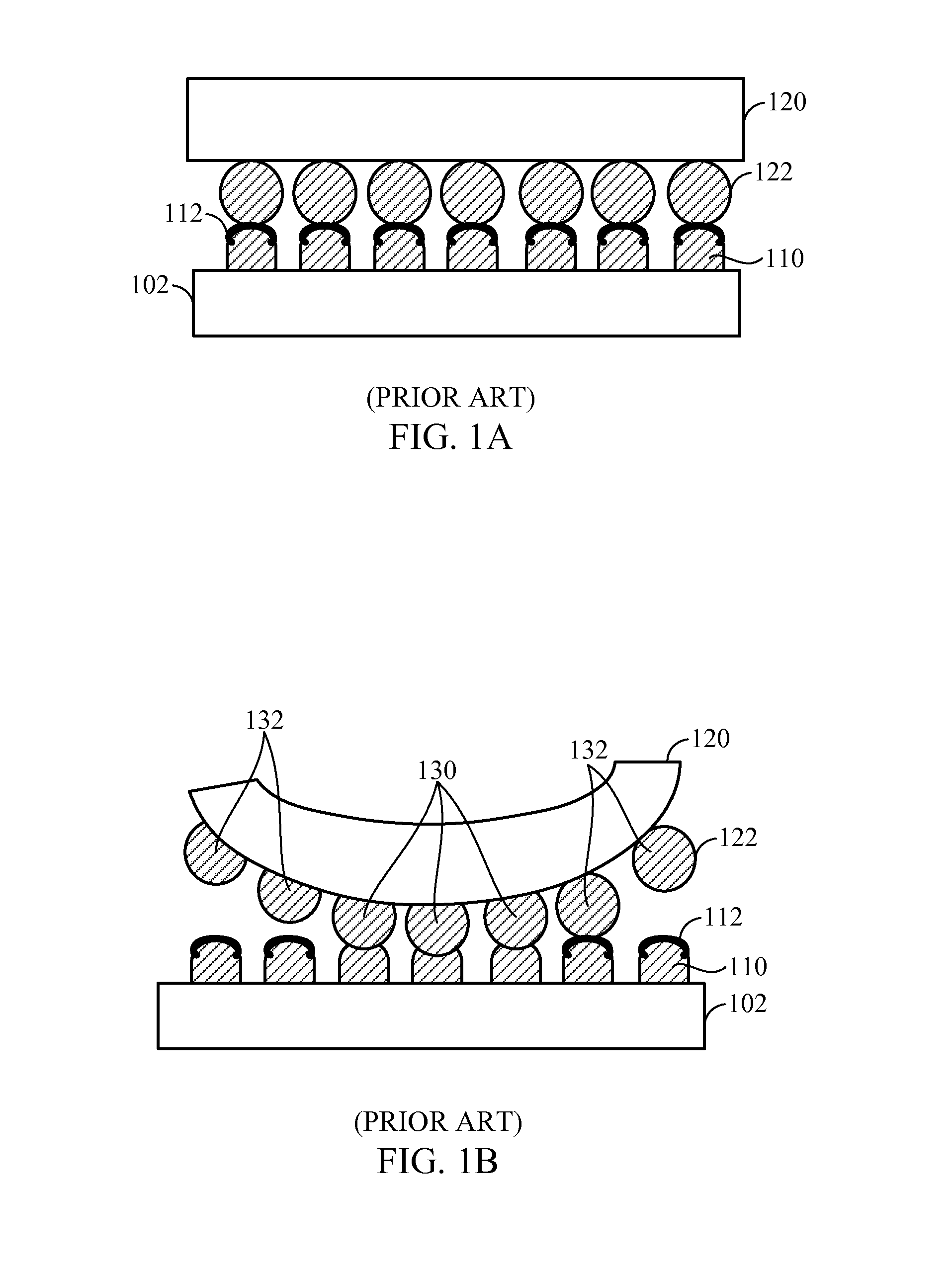

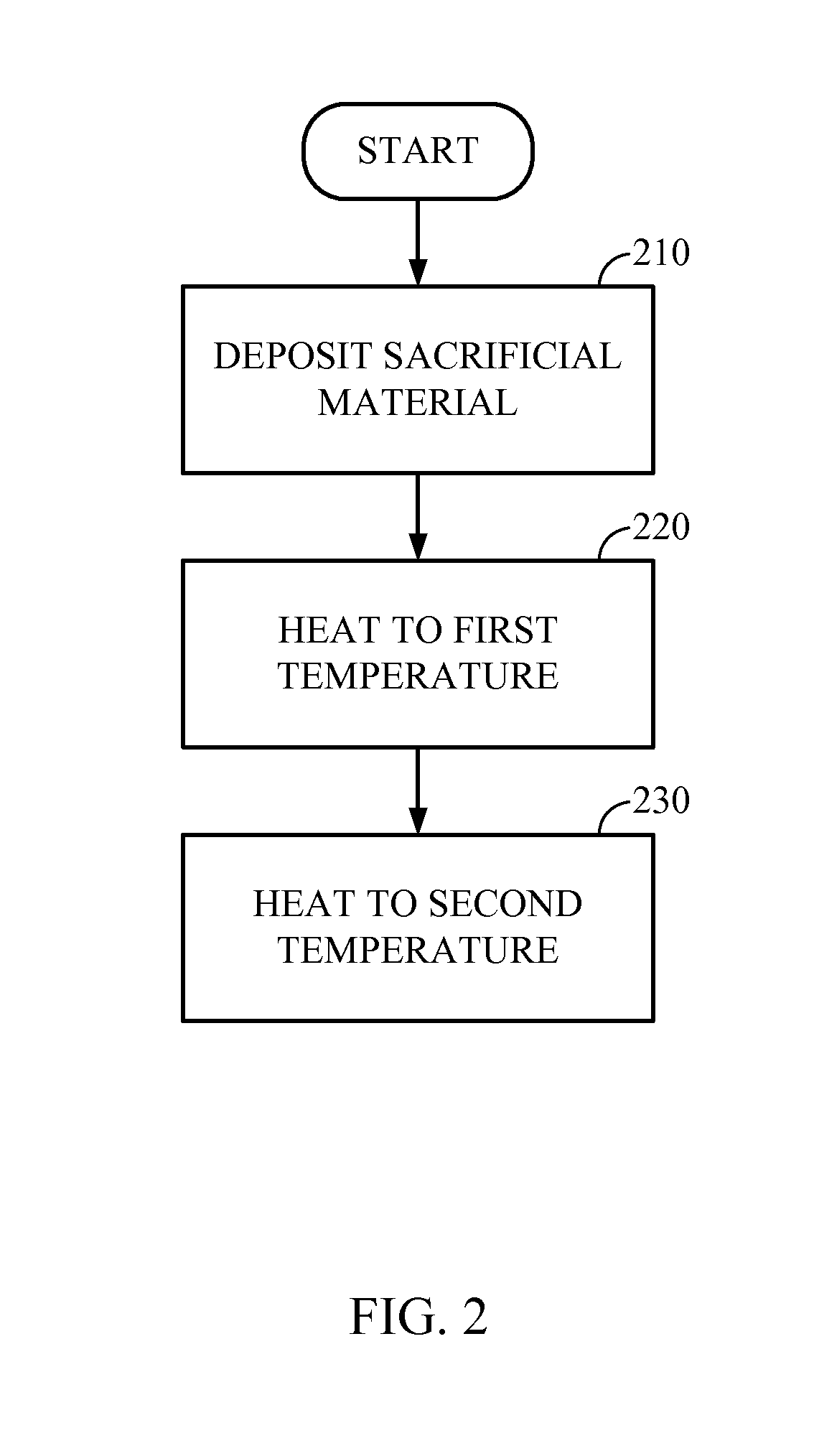

Sacrificial Material to Facilitate Thin Die Attach

ActiveUS20110233790A1Reduce warpageSemiconductor/solid-state device detailsSolid-state devicesSacrificial metalPolypropylene carbonate

A sacrificial material applied to a thin die prior to die attach provides stability to the thin die and inhibits warpage of the thin die as heat is applied to the die and substrate during die attach. The sacrificial material may be a material that sublimates at a temperature near the reflow temperature of interconnects on the thin die. A die attach process deposits the sacrificial material on the die, attaches the die to a substrate, and applies a first temperature to reflow the interconnects. At the first temperature, the sacrificial material maintains substantially the same thickness. A second temperature is applied to sublimate the sacrificial material leaving a clean surface for the later packaging processes. Examples of the sacrificial material include polypropylene carbonate and polyethylene carbonate.

Owner:QUALCOMM INC

Treatment Process For Concrete

A single anode system used in multiple electrochemical treatments to control steel corrosion in concrete comprises a sacrificial metal that is capable of supporting high impressed anode current densities with an impressed current anode connection detail and a porous embedding material containing an electrolyte. Initially current is driven from the sacrificial metal [1] to the steel [10] using a power source [5] converting oxygen and water [14] into hydroxyl ions [15] on the steel and drawing chloride ions [16] into the porous material [2] around the anode such that corroding sites are moved from the steel to the anode restoring steel passivity and activating the anode. Cathodic prevention is then applied. This is preferably sacrificial cathodic prevention that is applied by disconnecting the power source and connecting the activated sacrificial anode directly to the steel.

Owner:GLASS +2

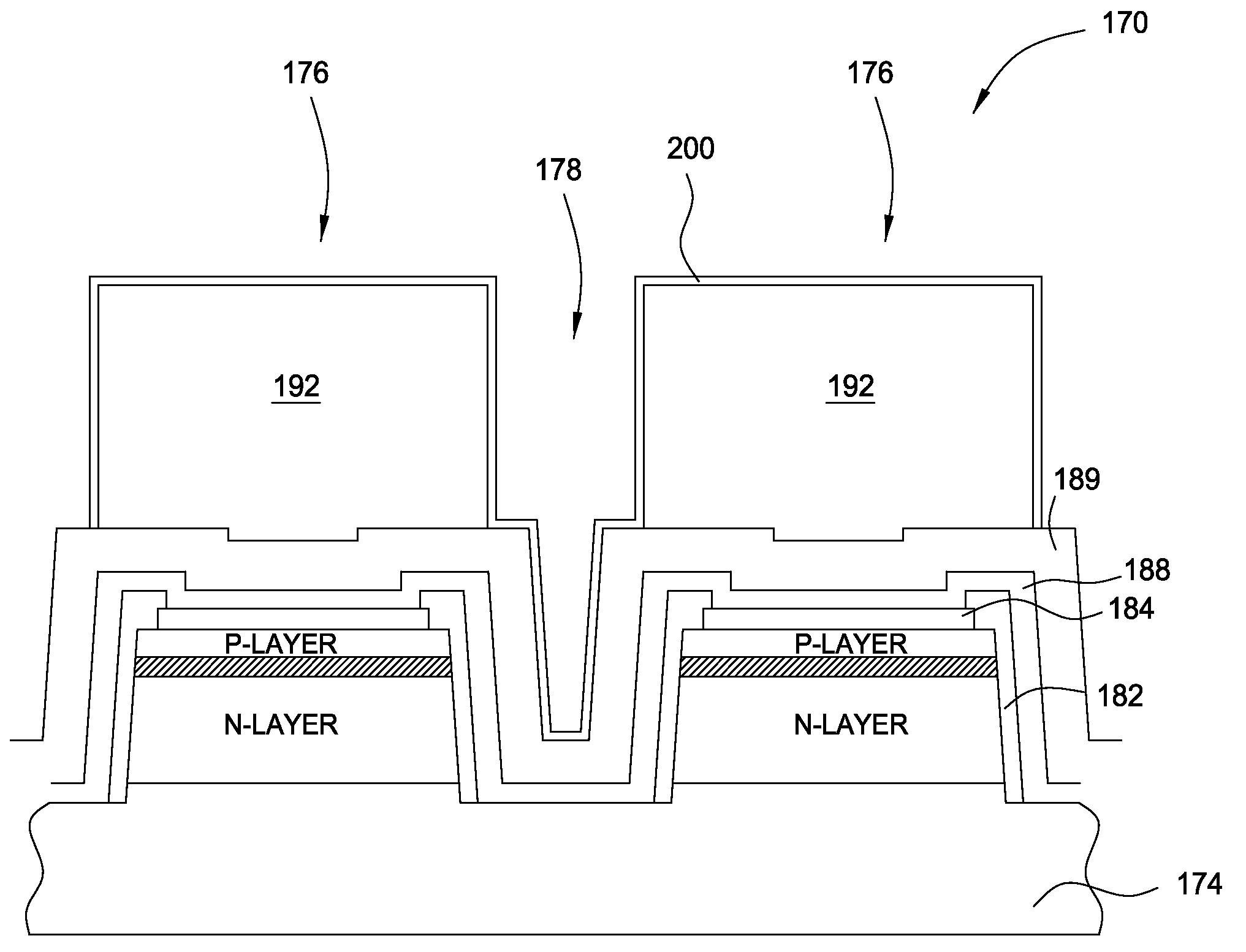

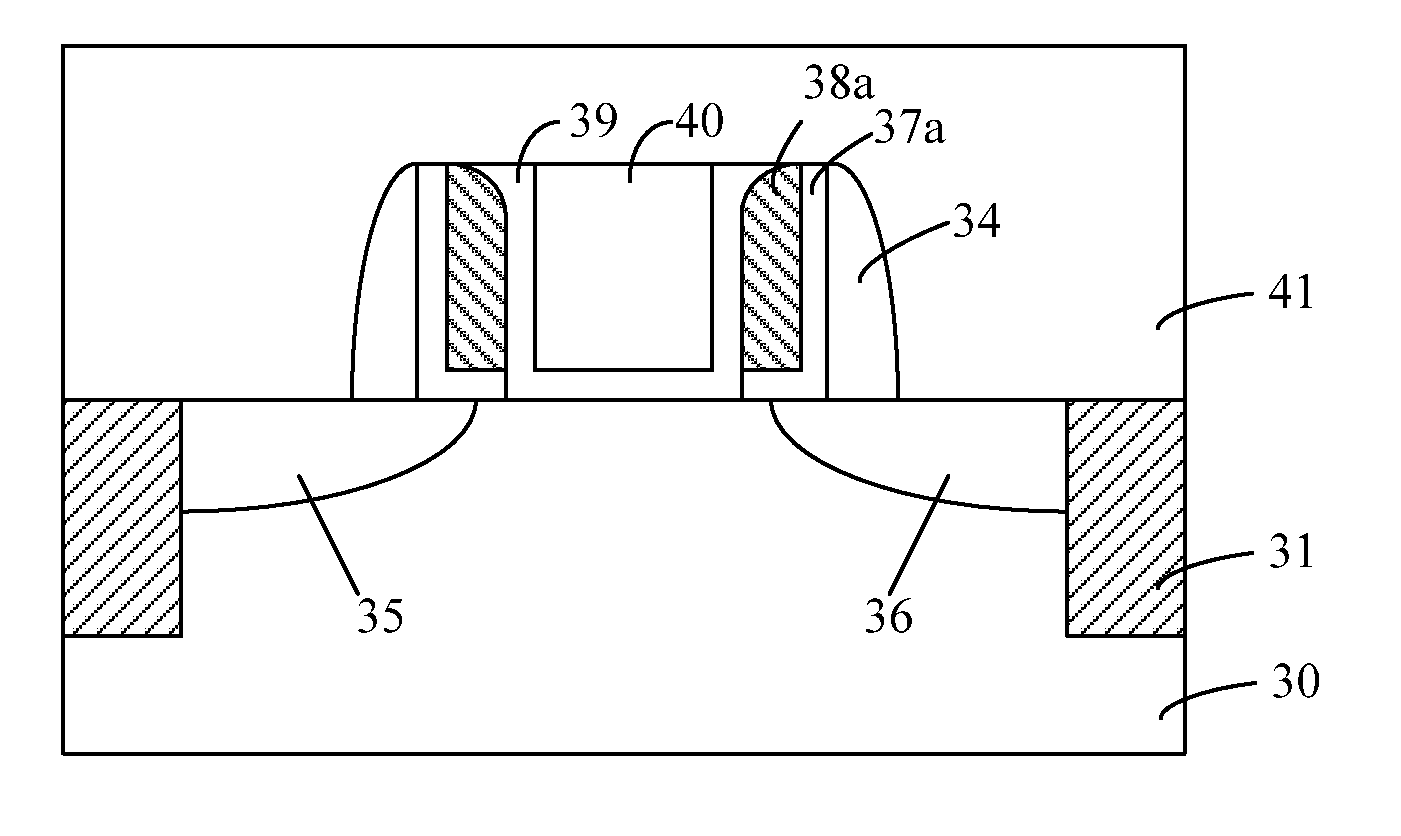

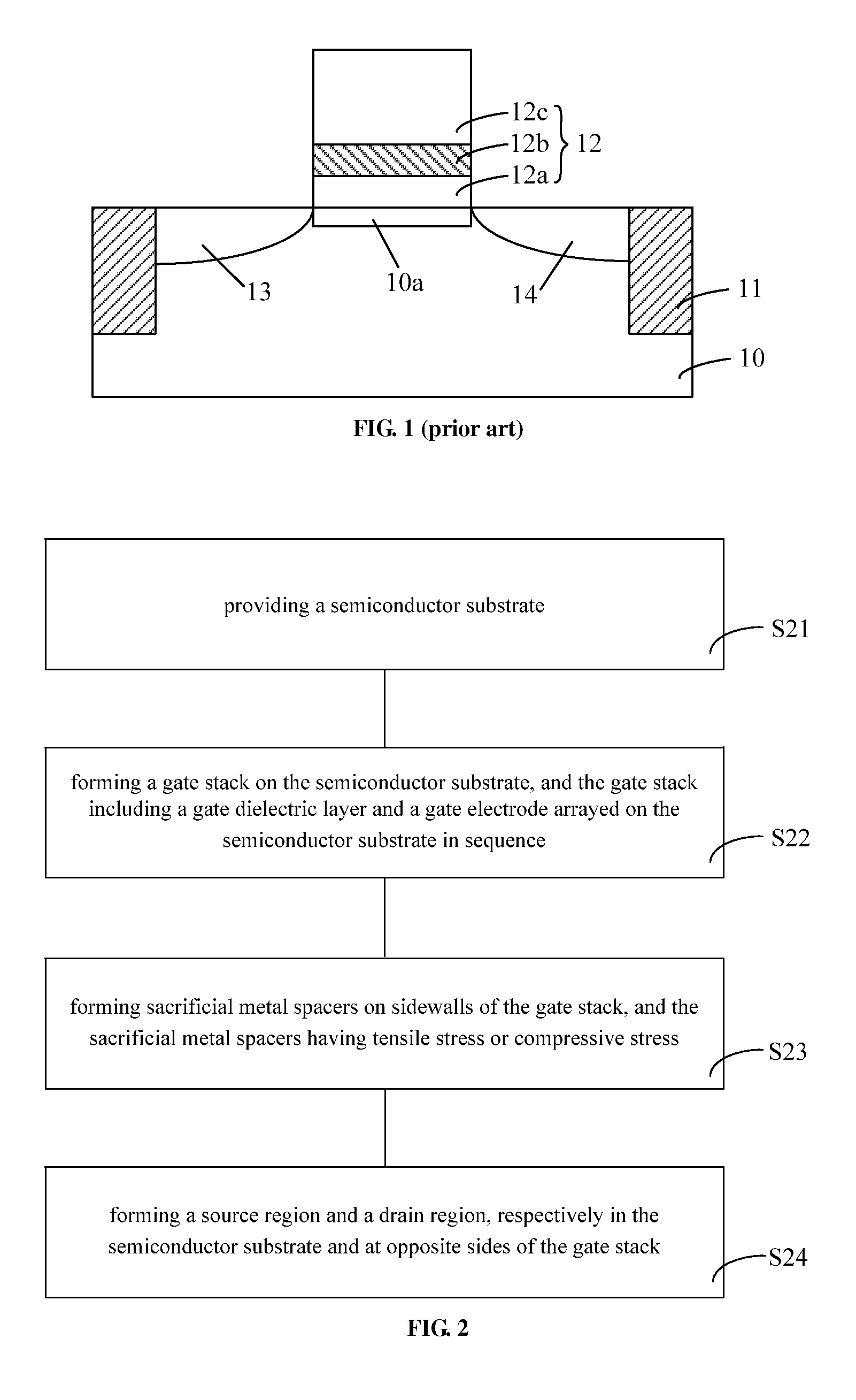

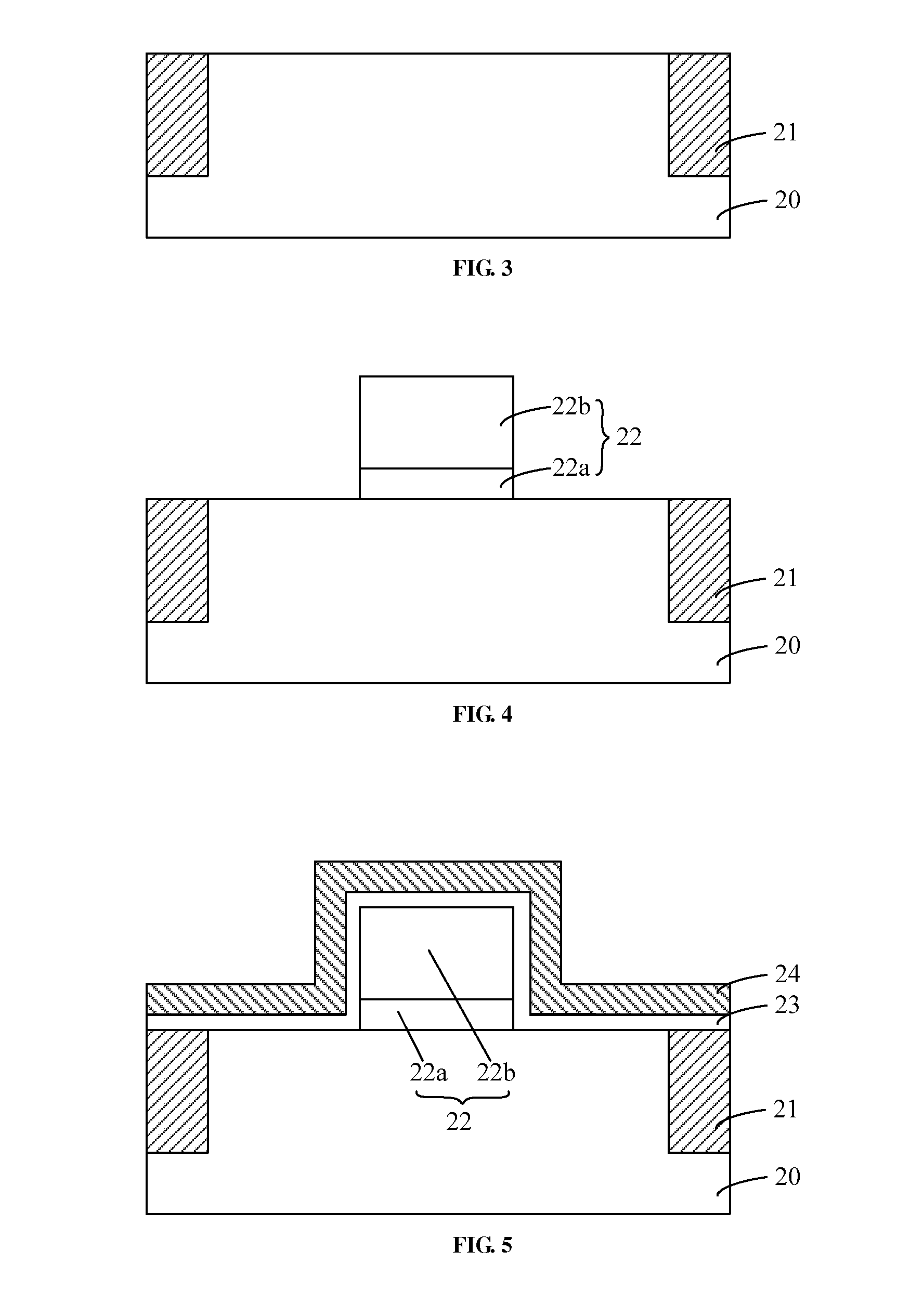

Mos transistor and method for forming the same

ActiveUS20120168829A1Reduce equivalent oxide thicknessAddress deteriorationSemiconductor/solid-state device manufacturingSemiconductor devicesEquivalent oxide thicknessGate dielectric

The invention provides a MOS transistor and a method for forming the MOS transistor. The MOS transistor includes a semiconductor substrate; a gate stack on the semiconductor substrate, and including a gate dielectric layer and a gate electrode on the semiconductor substrate in sequence; a source region and a drain region, respectively at sidewalls of the gate stack sidewalls of the gate stack and in the semiconductor; sacrificial metal spacers on sidewalls of the gate stack sidewalls of the gate stack, and having tensile stress or compressive stress. This invention scales down the equivalent oxide thickness, improves uniformity of device performance, raises carrier mobility and promotes device performance.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

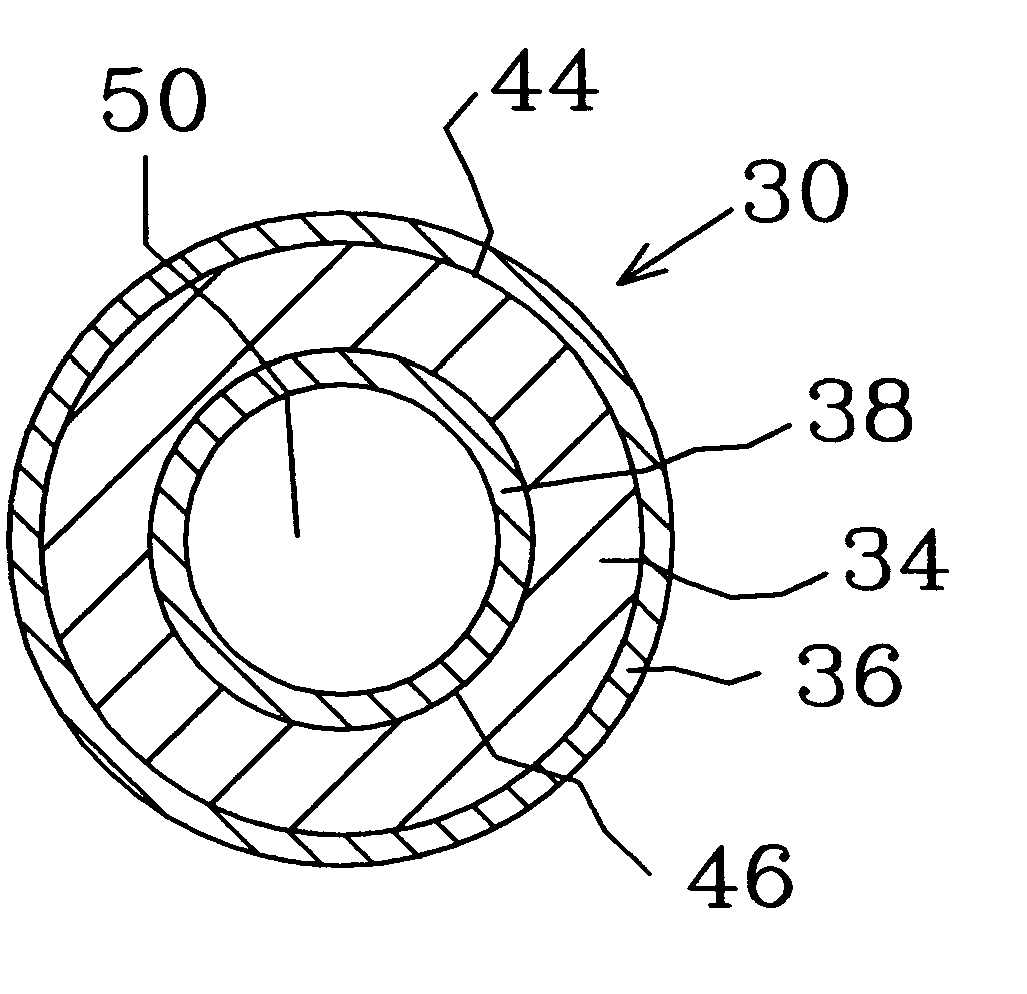

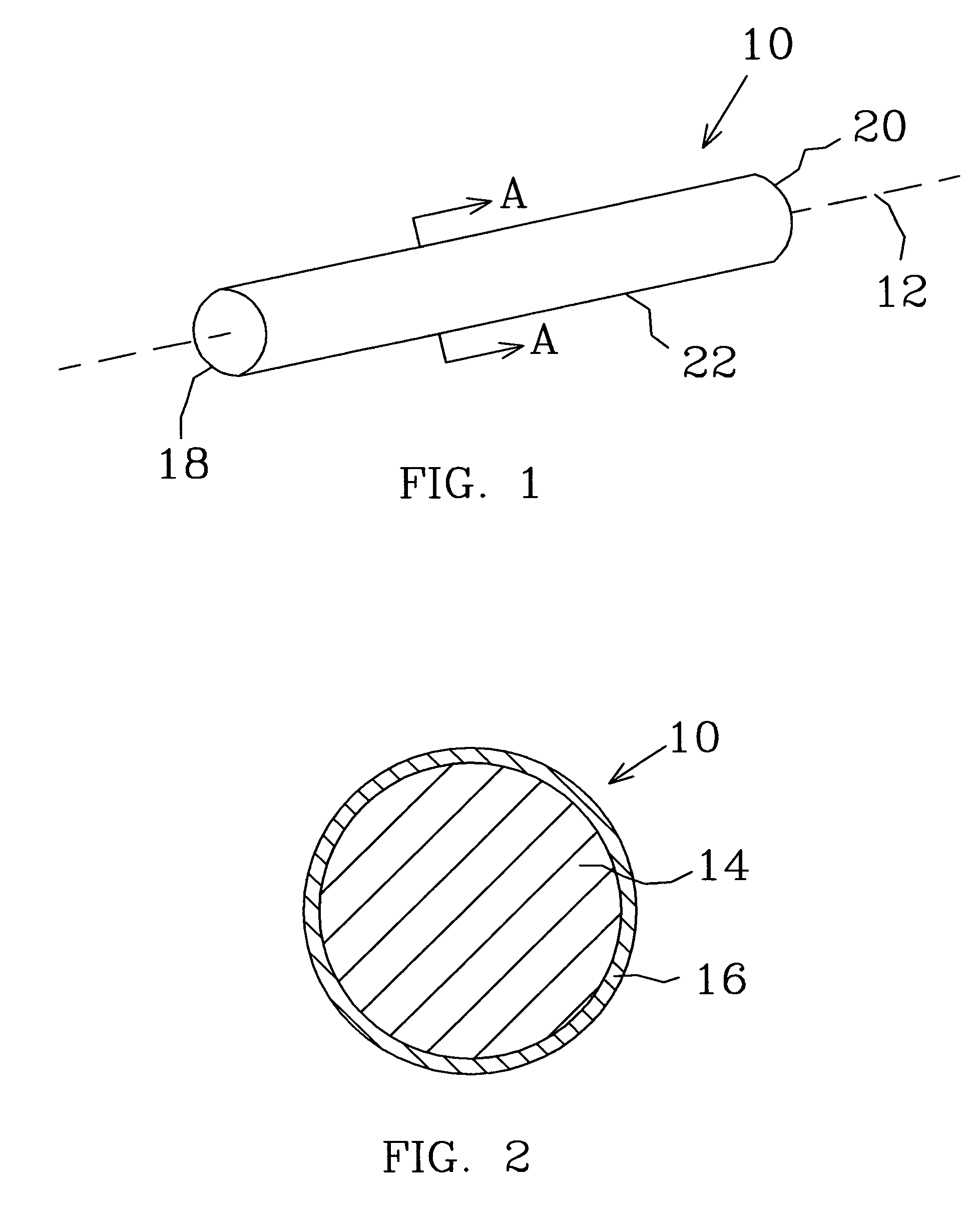

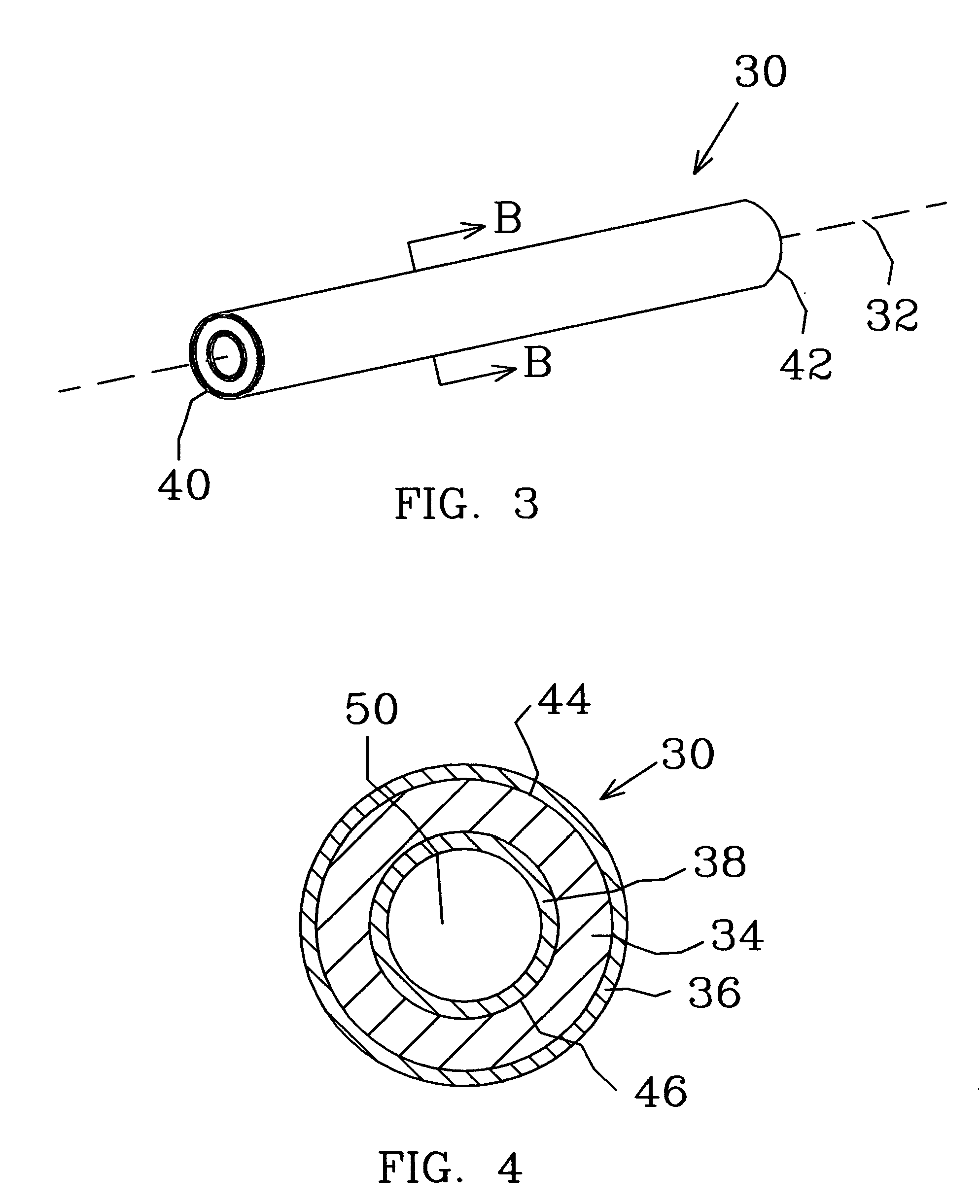

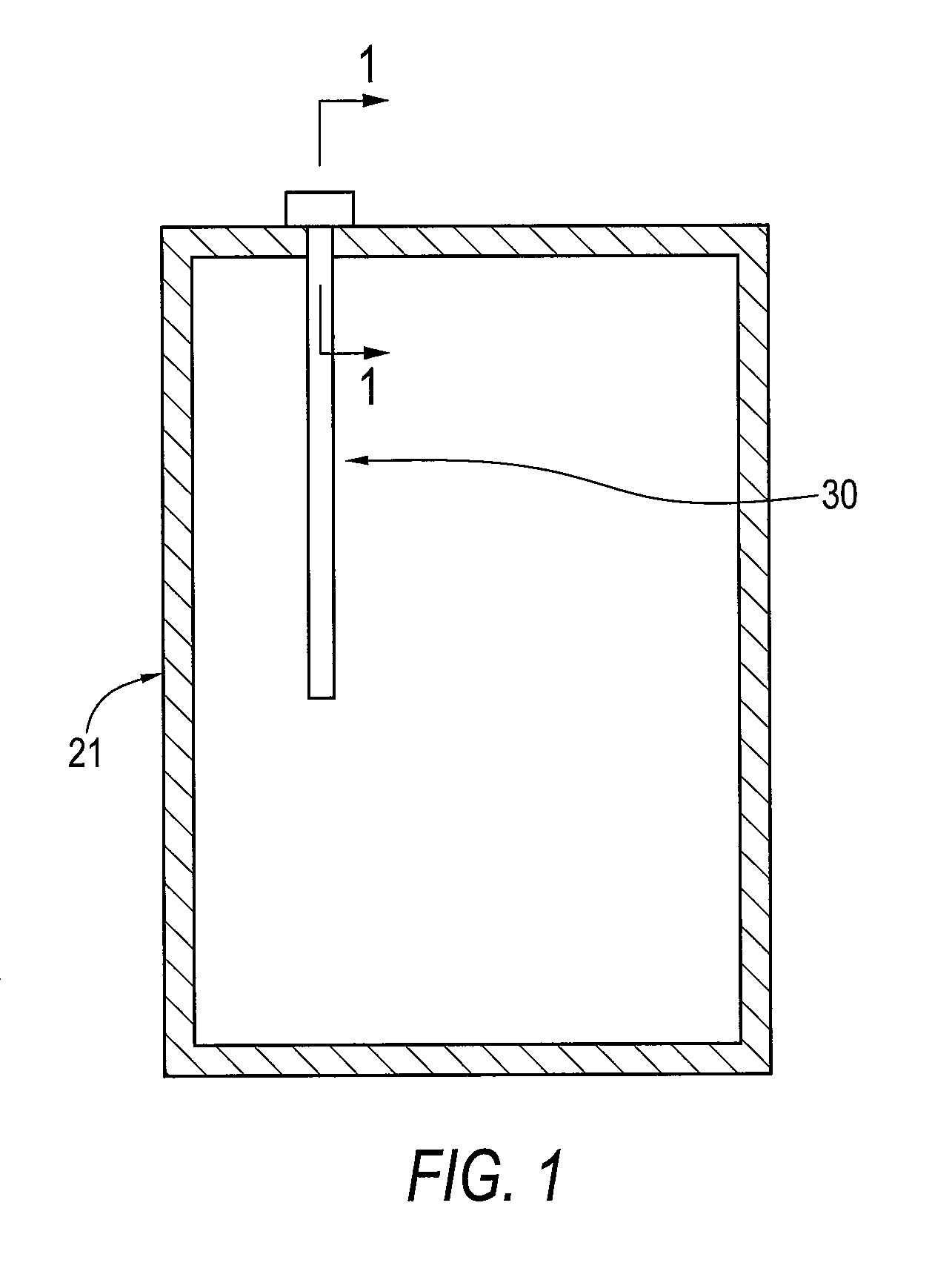

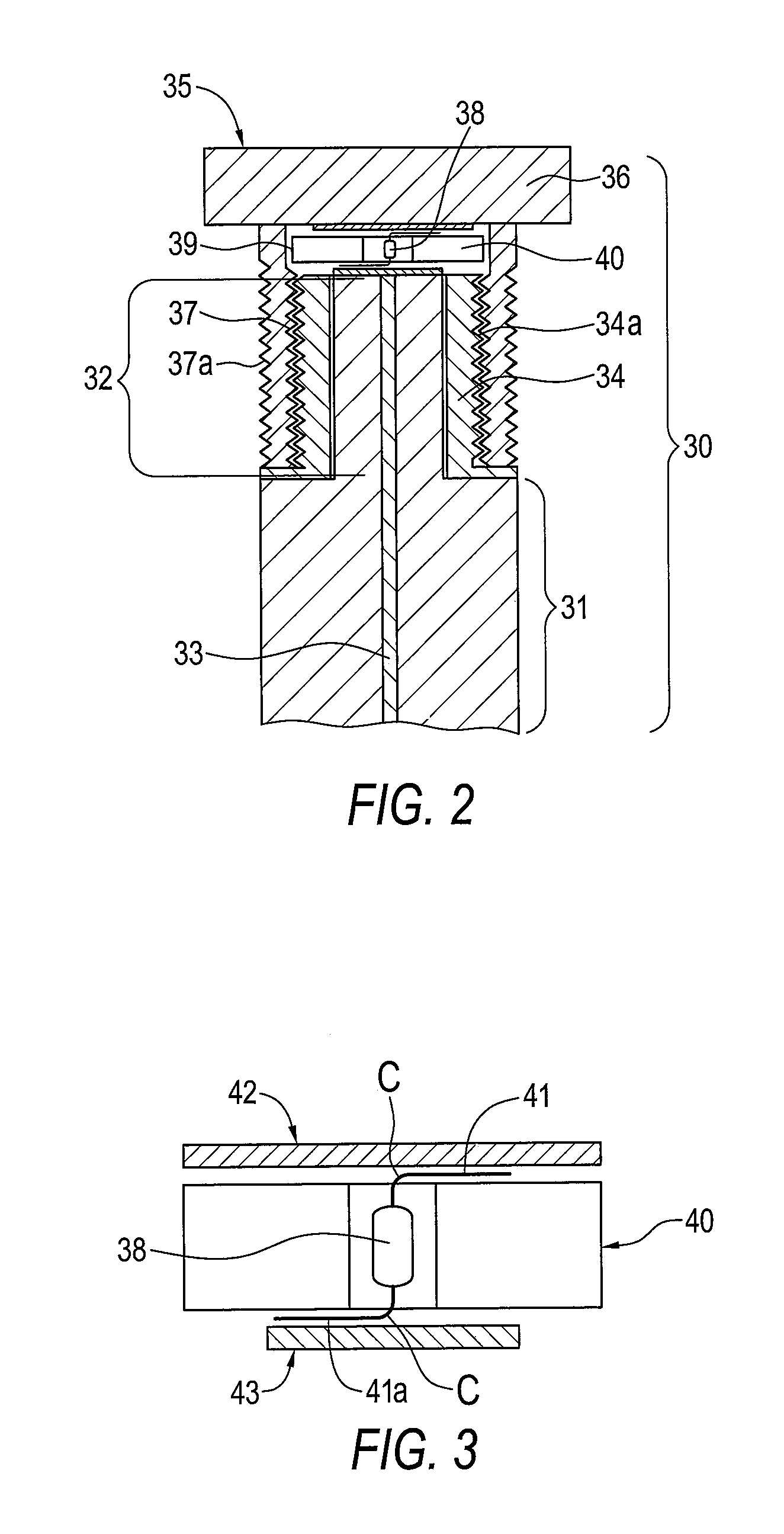

Sacrificial anode with resistor assembly for metal tank corrosion protection

A sacrificial metal anode device incorporating a resistor assembly into the construction of the sacrificial anode is insertable into a metal water storage tank. The metal water storage tank designed to contain heated water is thereby protected from corrosion by the sacrificial metal anode. The sacrificial metal anode device comprising an elongated metal anode member with a metal wire core, an insulating sleeve secured over the elongated metal anode member wherein said insulating sleeve has an external wall with threads to fixedly secure a metal cap. The metal cap having threads on an internal wall to fixedly secure the insulating sleeve further including a cylindrical receptacle for receipt of an end of the elongated metal anode member and an electrical resistor assembly.

Owner:BROTHER KOGYO KK

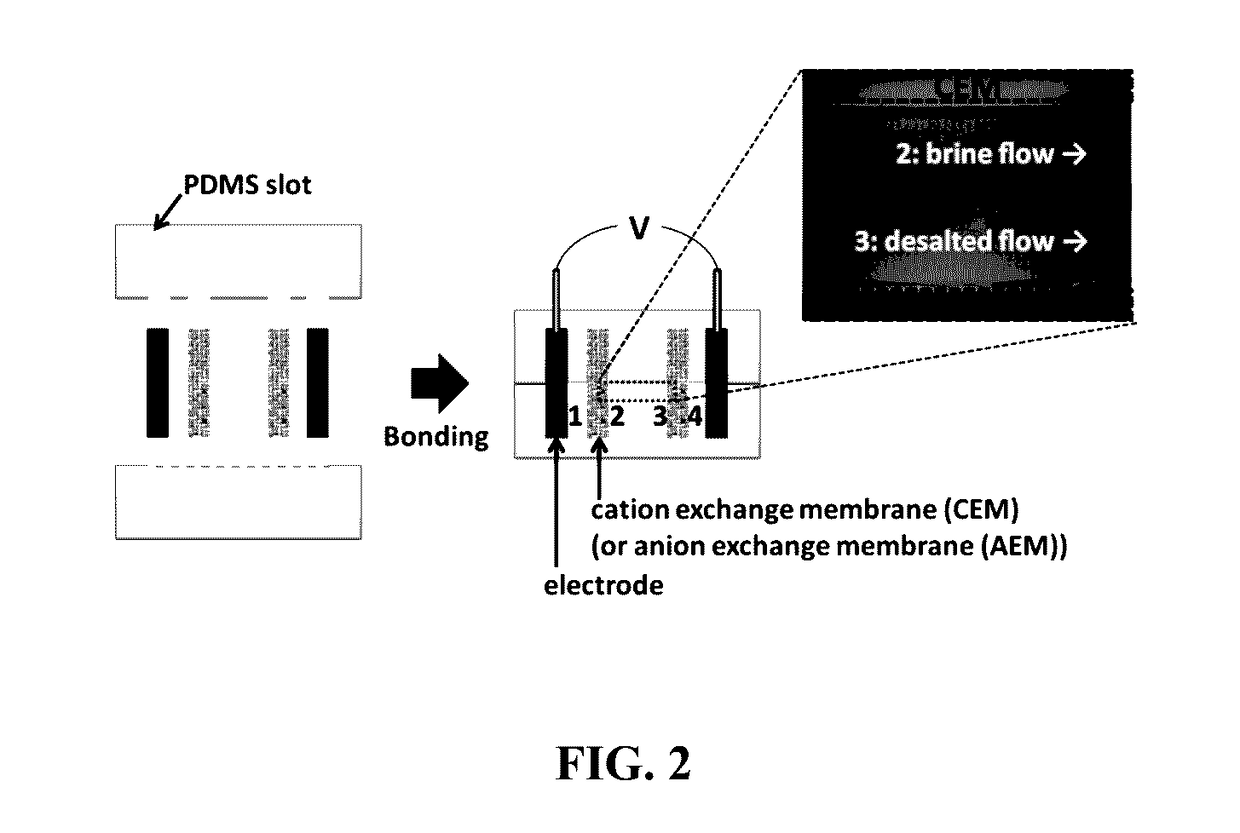

Ion Concentration Polarization-Electrocoagulation Hybrid Water Treatment System

ActiveUS20170066665A1Reduce consumptionReduce voltageMembranesSeawater treatmentWater treatment systemElectrocoagulation

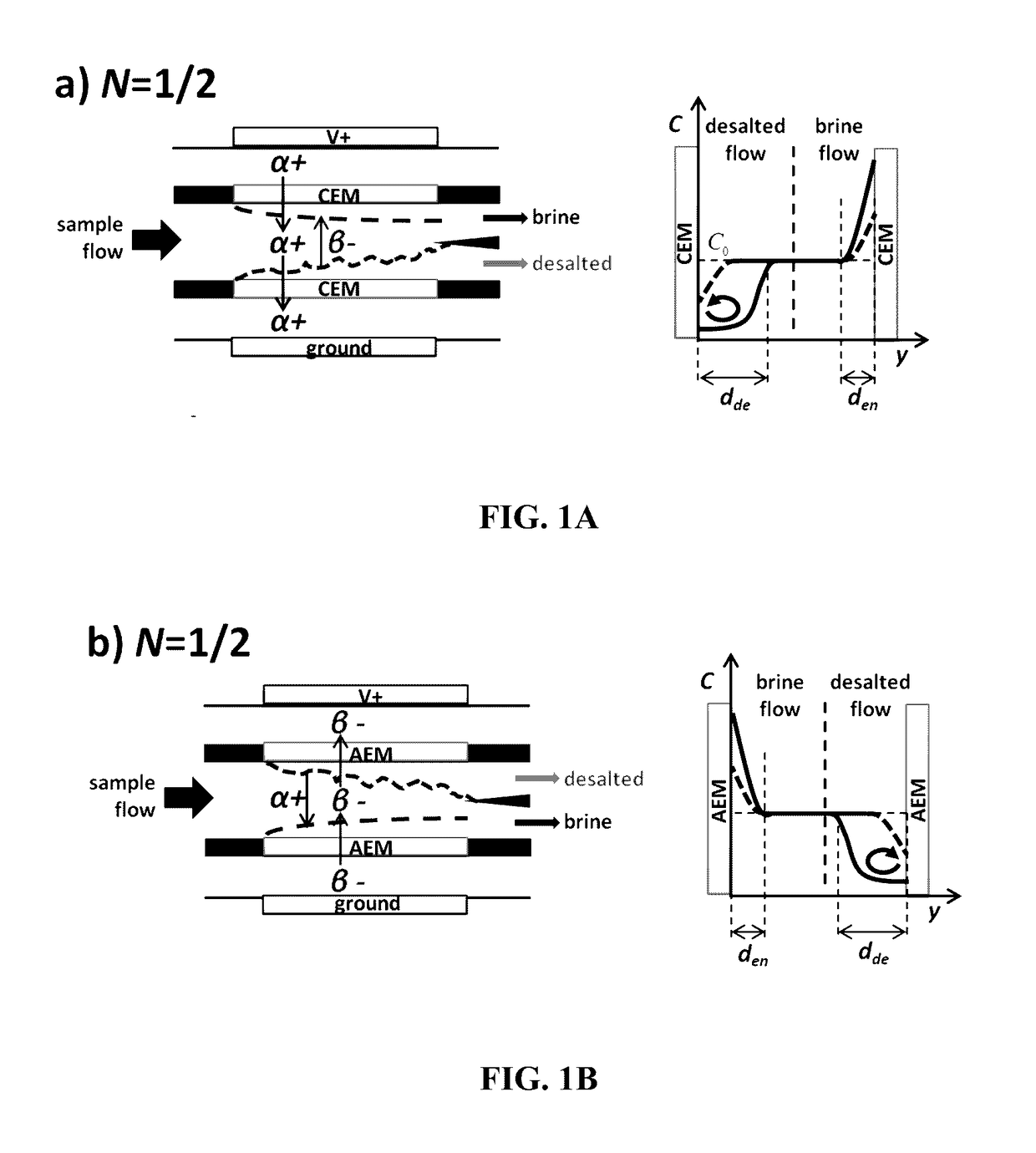

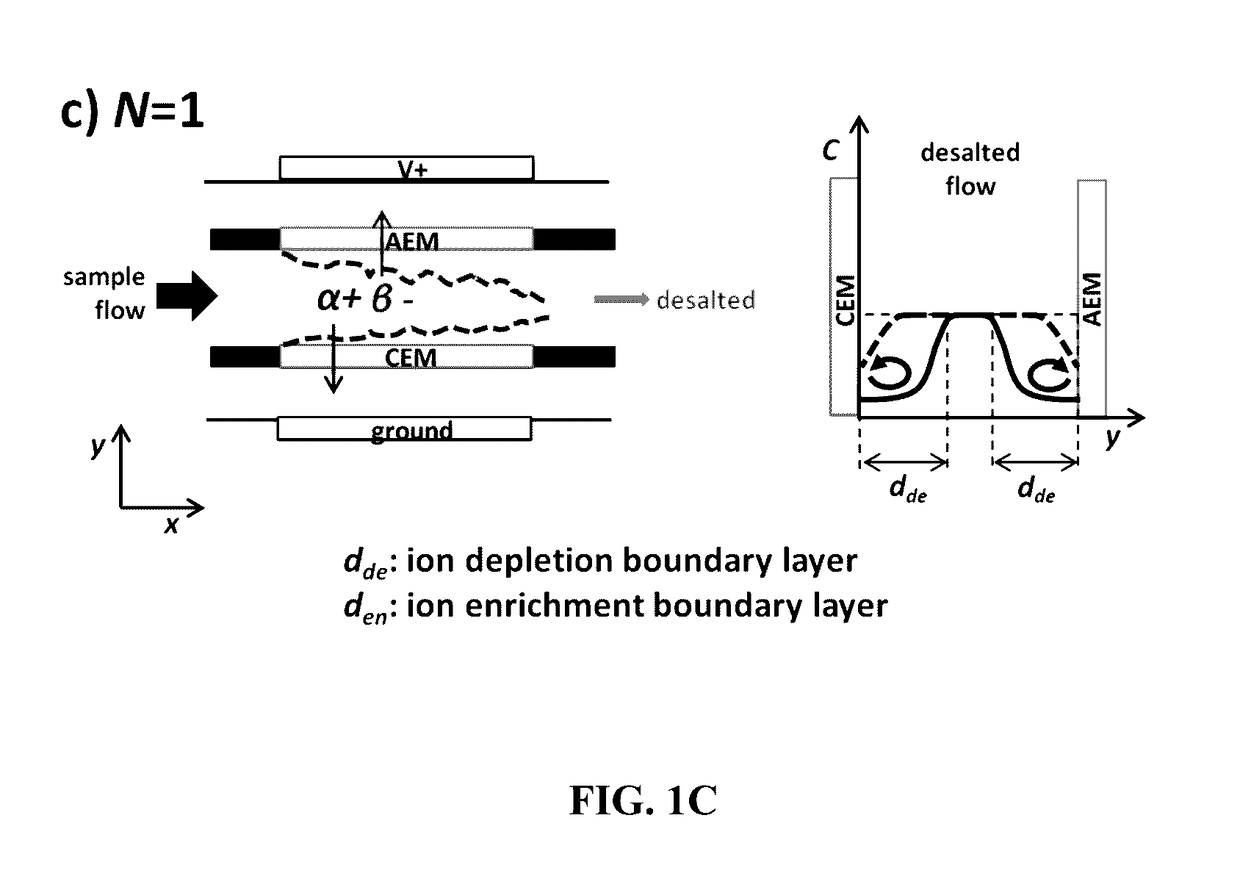

Between two juxtaposed similar ion exchange membranes (AEMs or CEMs), an ion depletion zone and ion enrichment zone are generated under an electric field. As cations are selectively transferred through the CEMs, for example, anions are relocated in order to achieve electro-neutrality, resulting in the concentration drop (increase) in ion depletion (enrichment) zone. The use of a sacrificial metal anode allows electrocoagulation (EC) concurrently with ICP thereby permitting concentration of both ionic and non-ionic impurities to occur at the same time within the same cell or device.

Owner:MASSACHUSETTS INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com