Preparation method of highly-dispersed precious metal electrocatalyst with high stability and low load capacity

A high-stability, electrocatalyst technology, applied in circuits, electrical components, battery electrodes, etc., can solve the problems of reduced catalyst stability, difficult anchoring of active component particles, and easy agglomeration of components to improve utilization. , Good anti-poisoning ability, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

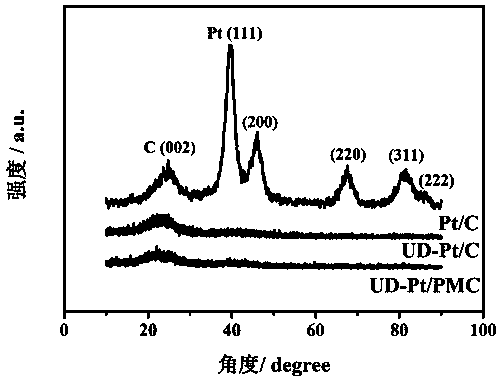

[0036] Embodiment 1: the preparation of PtPd / PMC catalyst

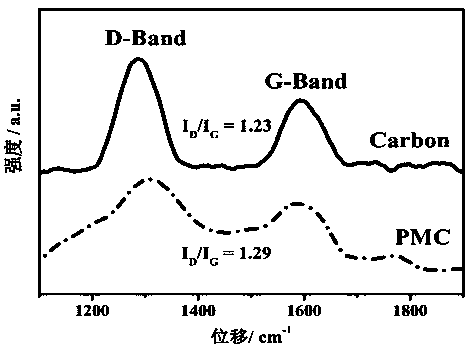

[0037] (1) Preparation of nitrogen-doped functionalized carbon support PMC: Dissolve 0.50 g of 1,10-phenanthroline and 0.24 g of nickel chloride hexahydrate in 40 mL of ethanol, add 1 g of carbon powder and disperse uniformly by ultrasonic Then stir for 12 h. The ethanol was then removed by a rotary evaporator, and the resulting black solid was dried at 80 °C for 5 h. The above black solid was calcined in a tube furnace at 800 °C for 2 h under the protection of nitrogen. After cooling to room temperature, add to 0.5M H 2 SO 4 The solution was stirred for 12 h. Then wash with ultra-pure water several times, and then fully dry at 80°C to obtain the nitrogen-doped functionalized carbon carrier PMC.

[0038] (2) Preparation of catalyst precursor: Add 6.9 mg of palladium chloride into a 100 mL round-bottomed flask, add 30 mL of ethylene glycol, stir with a magnet, and sonicate for more than 0.5 hours to completely dis...

Embodiment 2

[0041] Embodiment 2: the preparation of PtRu / PC catalyst

[0042] (1) Preparation of phosphorus-doped functionalized carbon carrier PC: Add 1 g of carbon powder into 20 mL of nitric acid (3M), stir at 90 °C for 2 h, cool to room temperature and wash repeatedly with a large amount of ultrapure water, After drying at 60 °C, the obtained solid and triphenylphosphine were mixed evenly at a mass ratio of 3:1, and the mixture was put into a tube furnace, and calcined in a tube furnace at 900 °C for 2 h under the protection of nitrogen. After cooling to room temperature, washing with ultrapure water several times, and fully drying at 60°C, the phosphorus-doped functionalized carbon support PC was obtained.

[0043] (2) Preparation of catalyst precursor: 65.6 mg of chloroplatinic acid, 33.8 mg of ruthenium trichloride, 240.4 mg of nickel chloride hexahydrate and 380.7 mg of sodium citrate were dissolved in three times of water in a round bottom flask, and stirred for half an hour. Ad...

Embodiment 3

[0046] Embodiment 3: the preparation of Ir / NMC catalyst

[0047] (1) Preparation of nitrogen-doped functionalized carbon support NMC: ultrasonically disperse 0.2 g of Al2O3 in 100 mL of ethanol, then add 2 g of phenolic resin, and stir for 2 h with a magnetic stirrer to fully dissolve it. In addition, 0.5 g of melamine was weighed and dissolved in hot water at 90°C. Then the two solutions were mixed and stirred for 2 h. After drying at 90 °C, the resulting solid was ground and calcined in a tube furnace at 800 °C for 2 h under the protection of nitrogen. After cooling to room temperature, add to 0.5M H 2 SO 4 The solution was stirred for 12 h. Then wash with ultra-pure water several times, and fully dry at 60°C to obtain nitrogen-doped functionalized carbon support NMC.

[0048] (2) Preparation of catalyst precursor: 1.7 mL of iridium chloride solution and 5.6 mg of tin chloride were ultrasonically dissolved in 30 mL of ethanol solution. Then 35 mg sodium citrate was add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com