Patents

Literature

80results about "Shape memory alloy connections" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

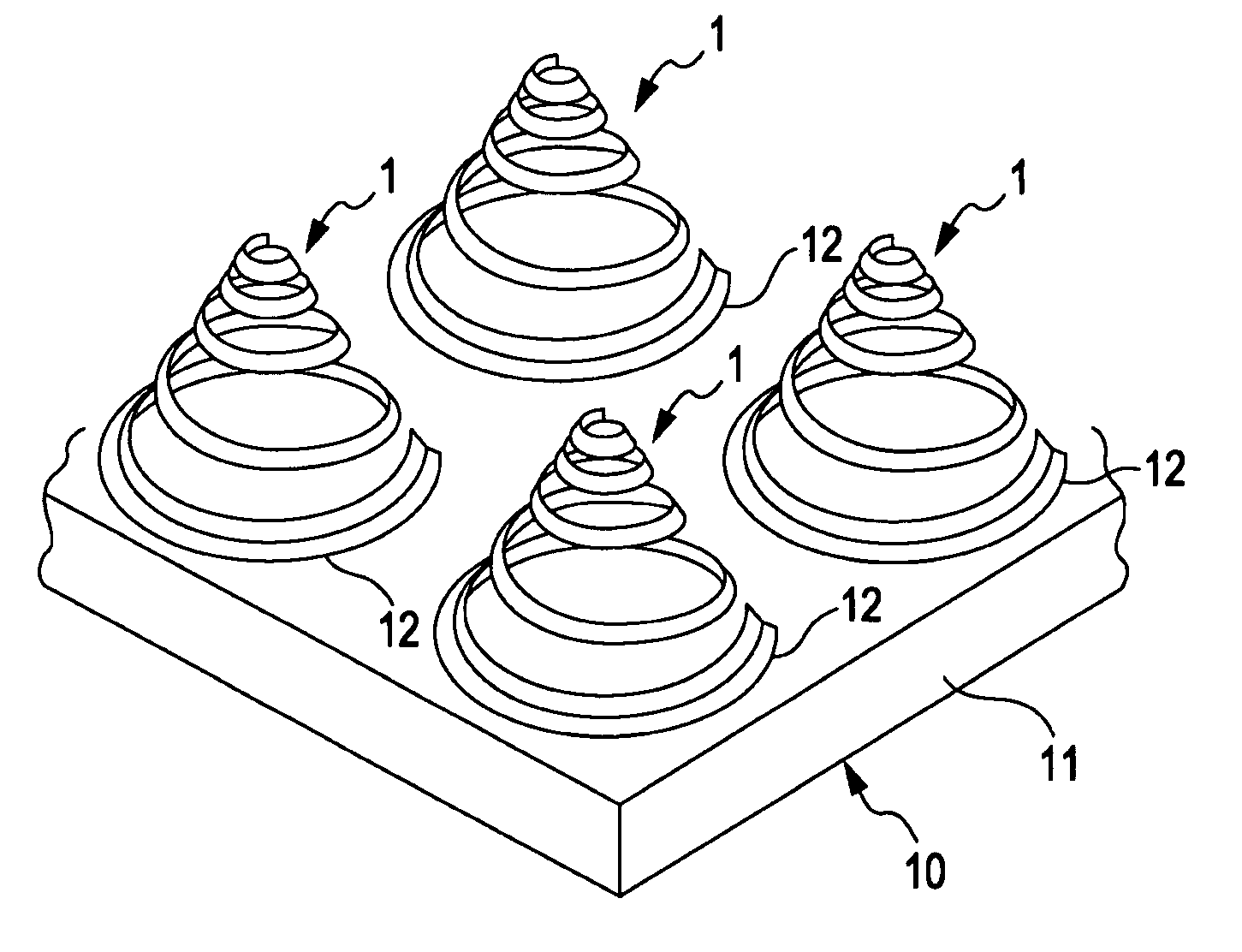

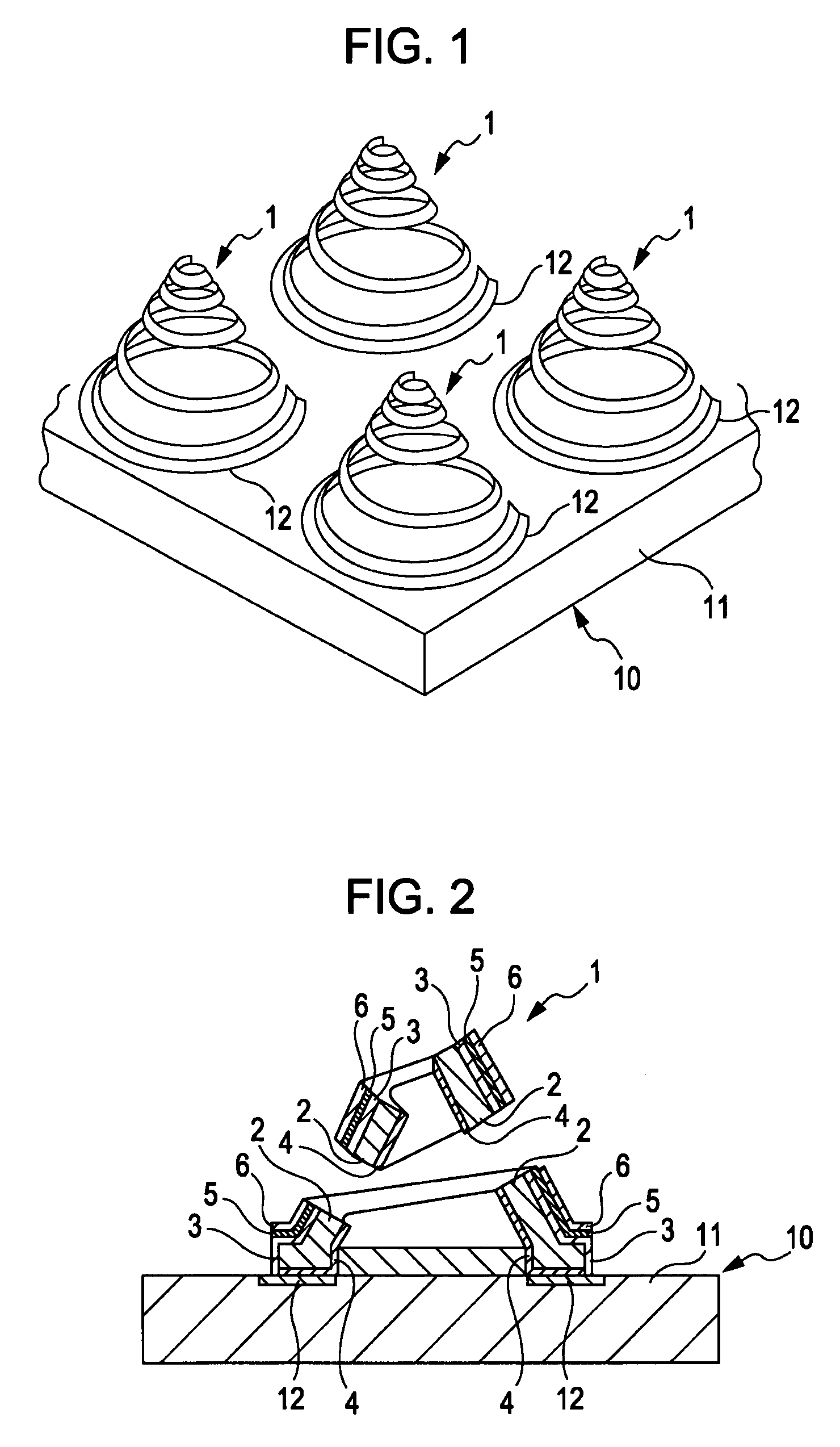

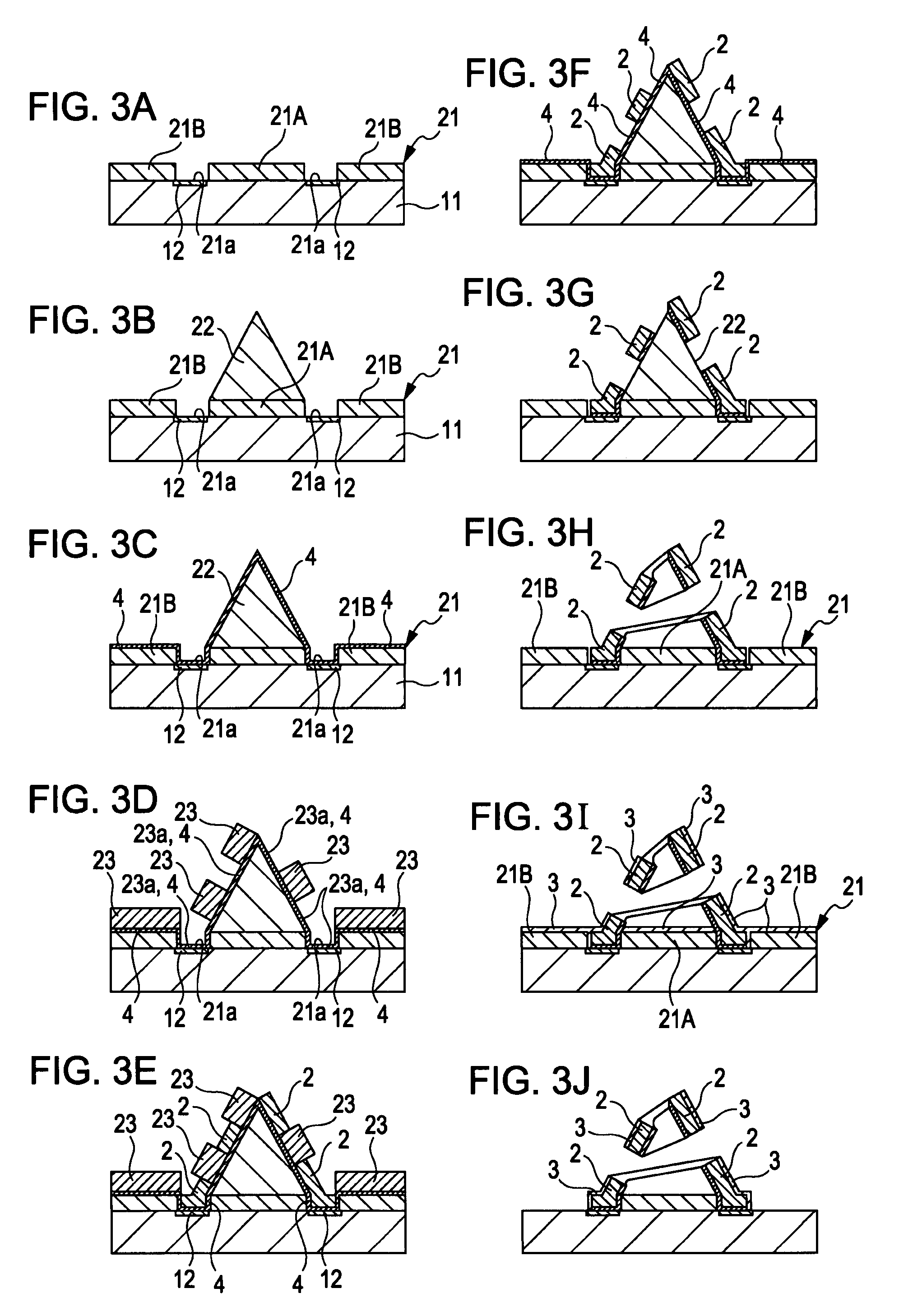

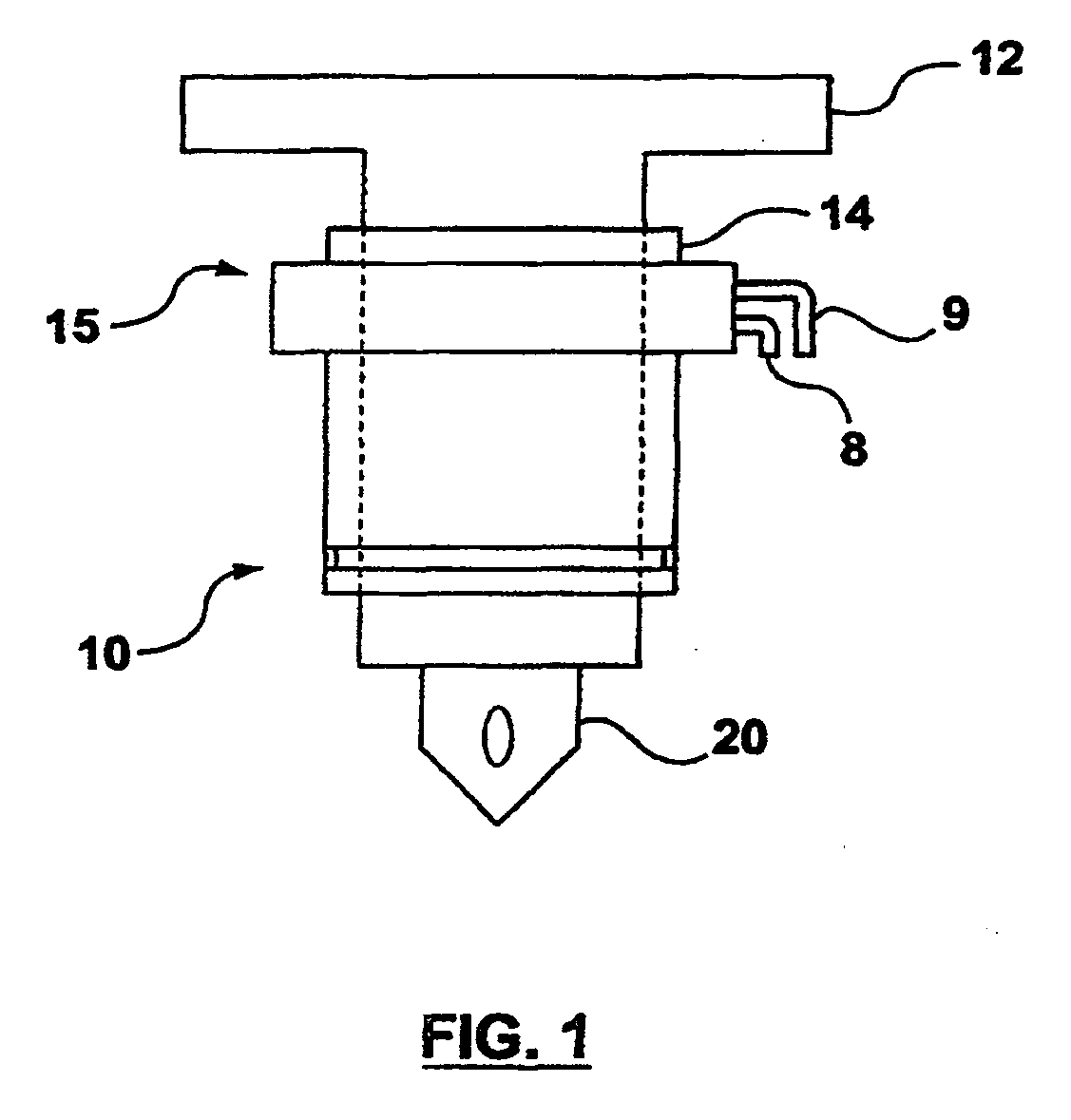

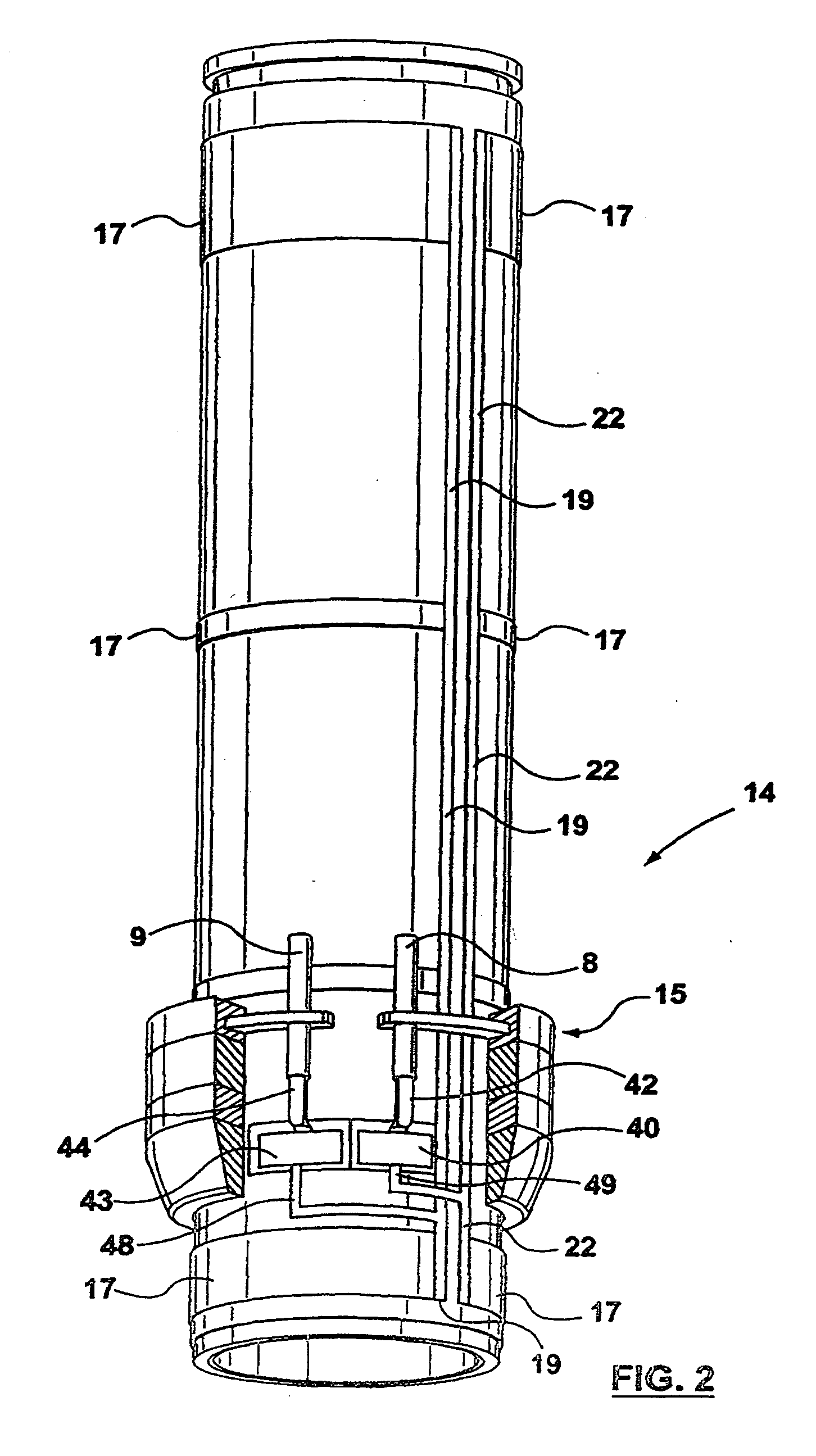

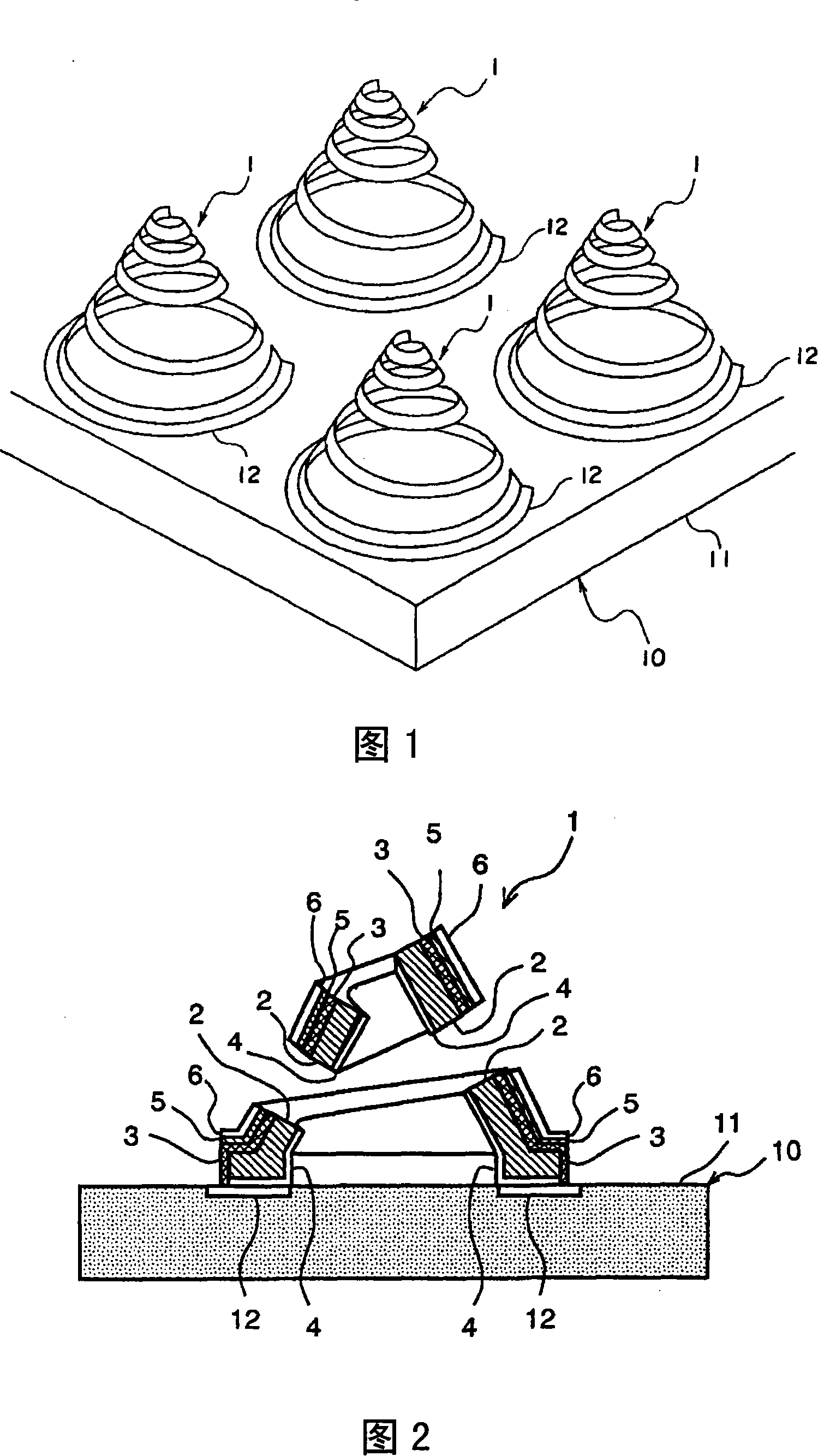

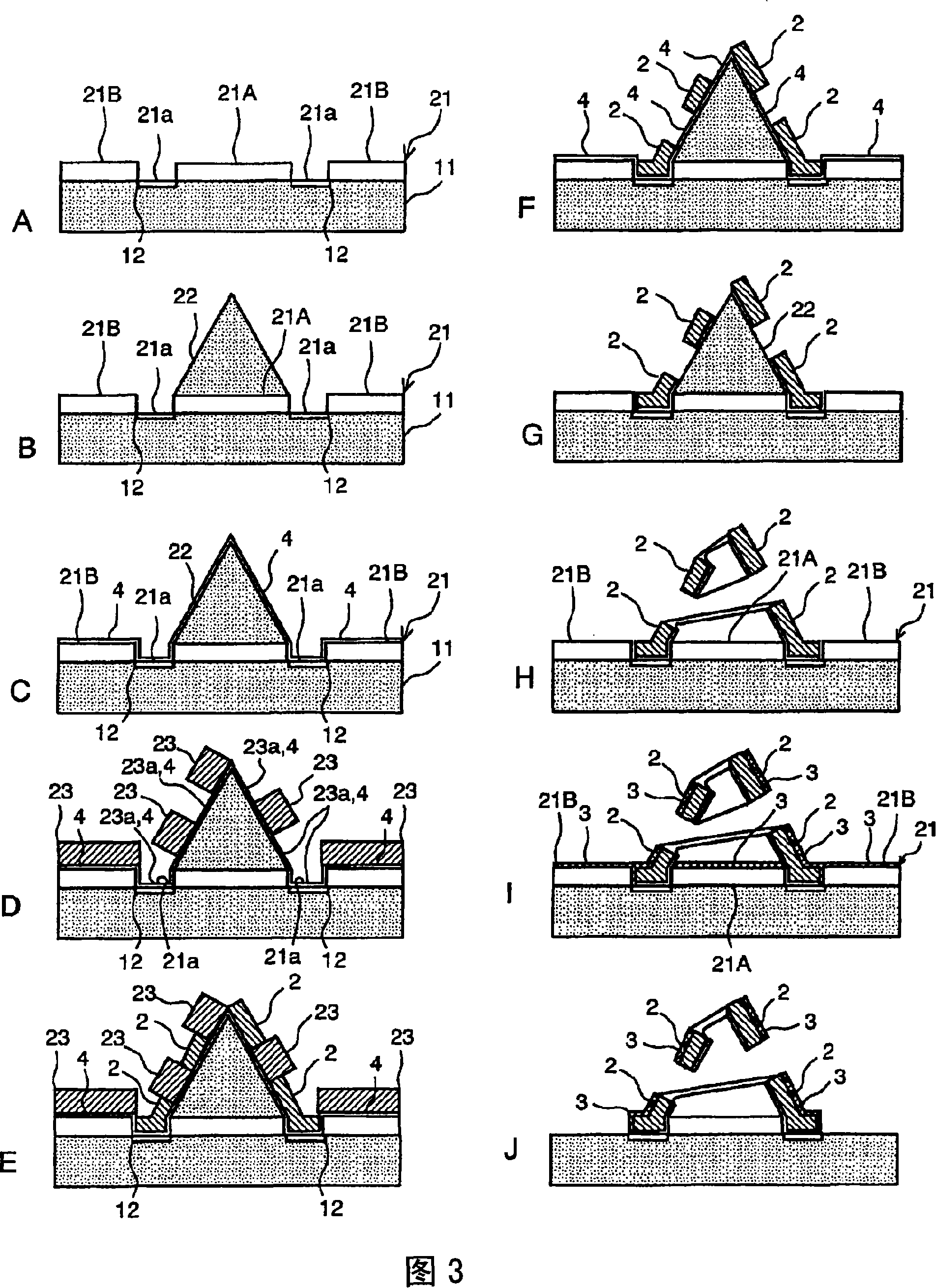

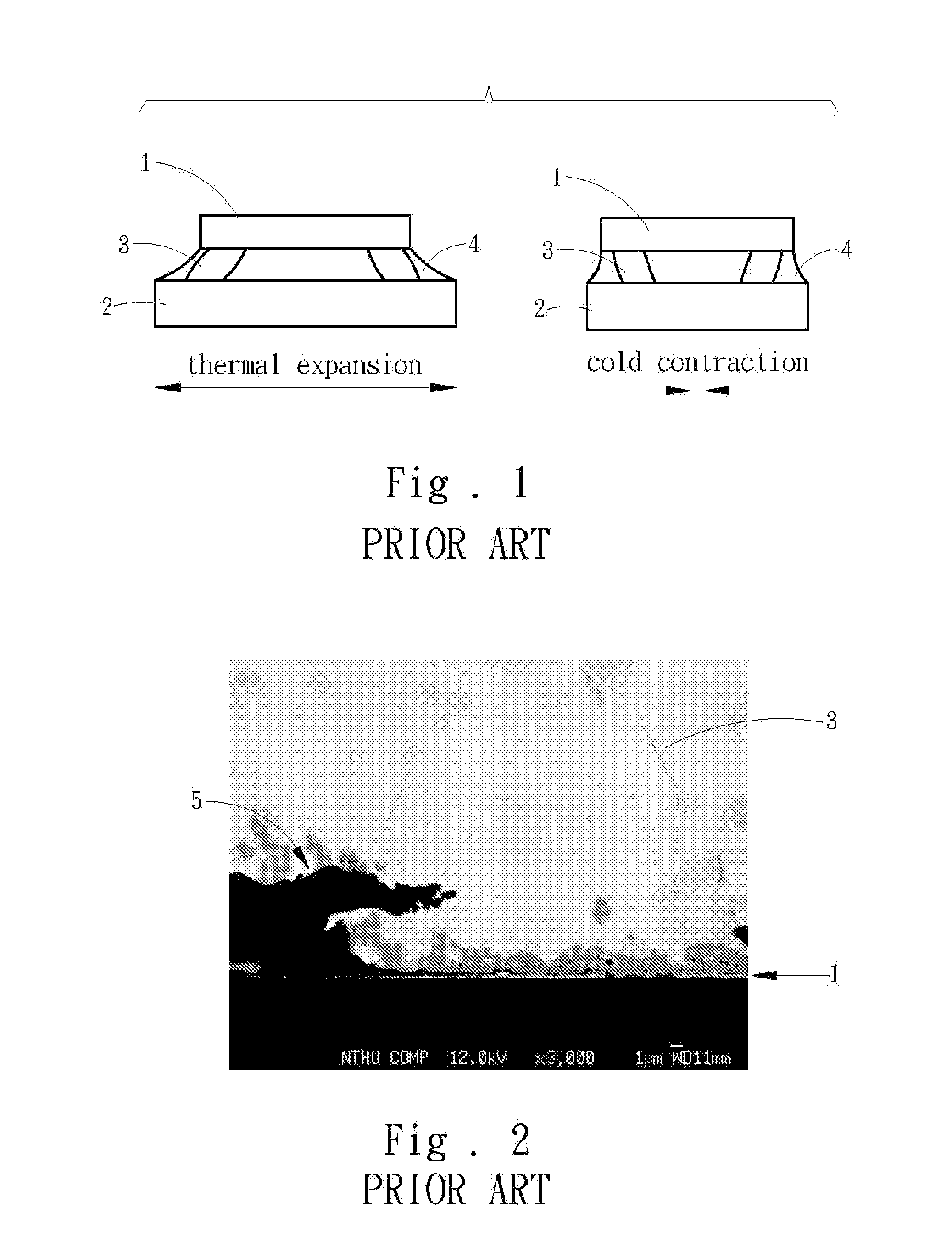

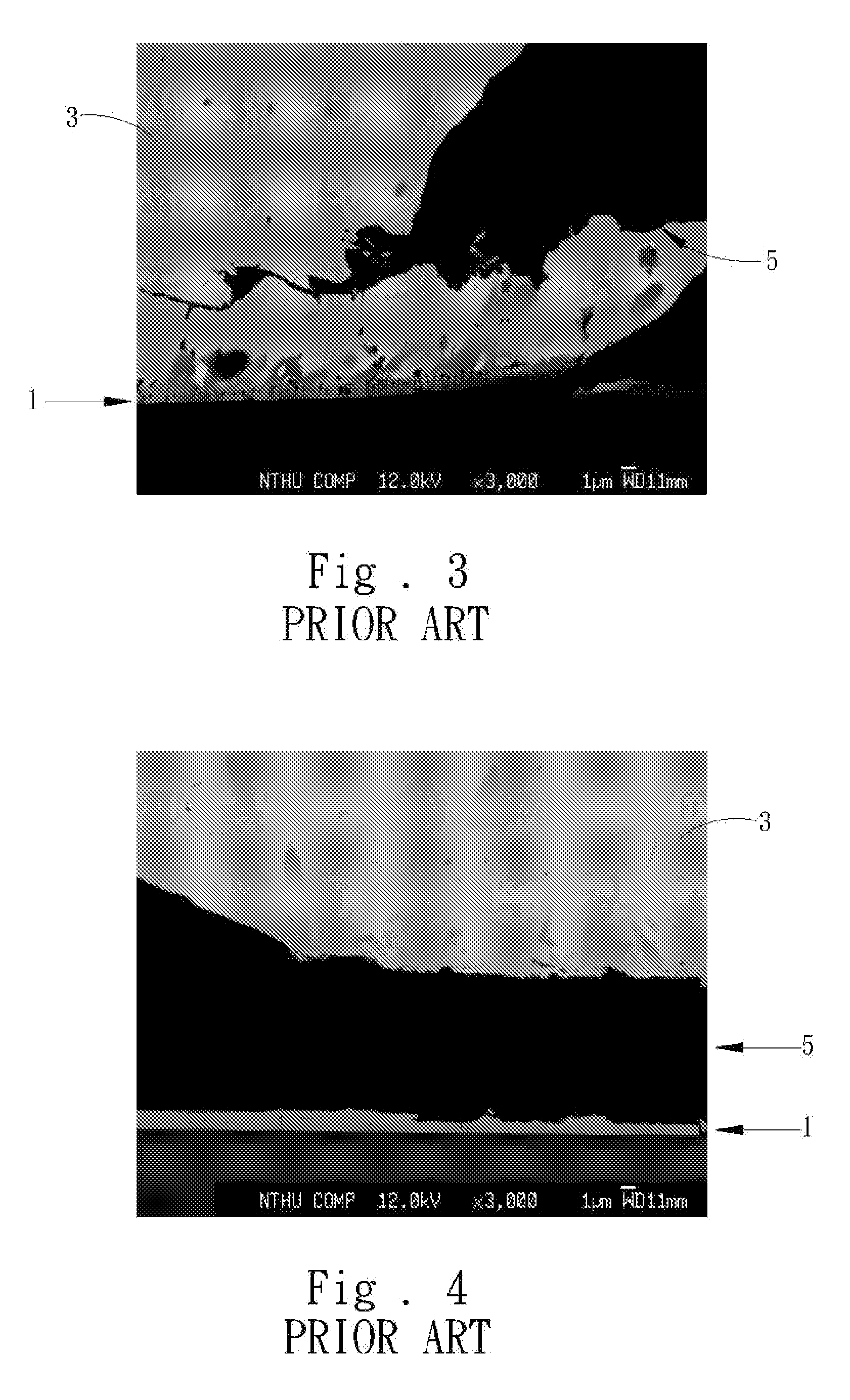

Semiconductor device contact resistant to deterioration due to heat and method for manufacturing contact

InactiveUS20080032519A1Good contact conductivityLarge elastic forceElectrical measurement instrument detailsShape memory alloy connectionsResistSputtering

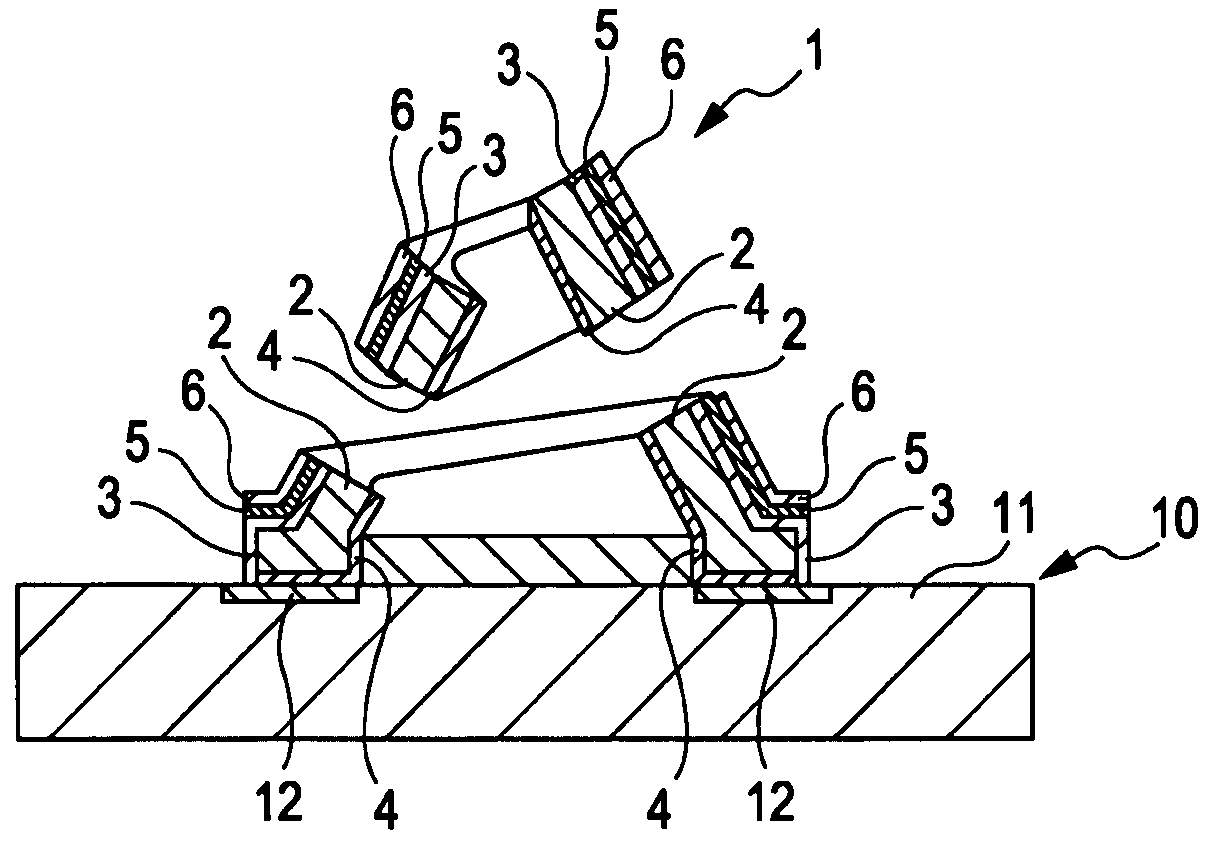

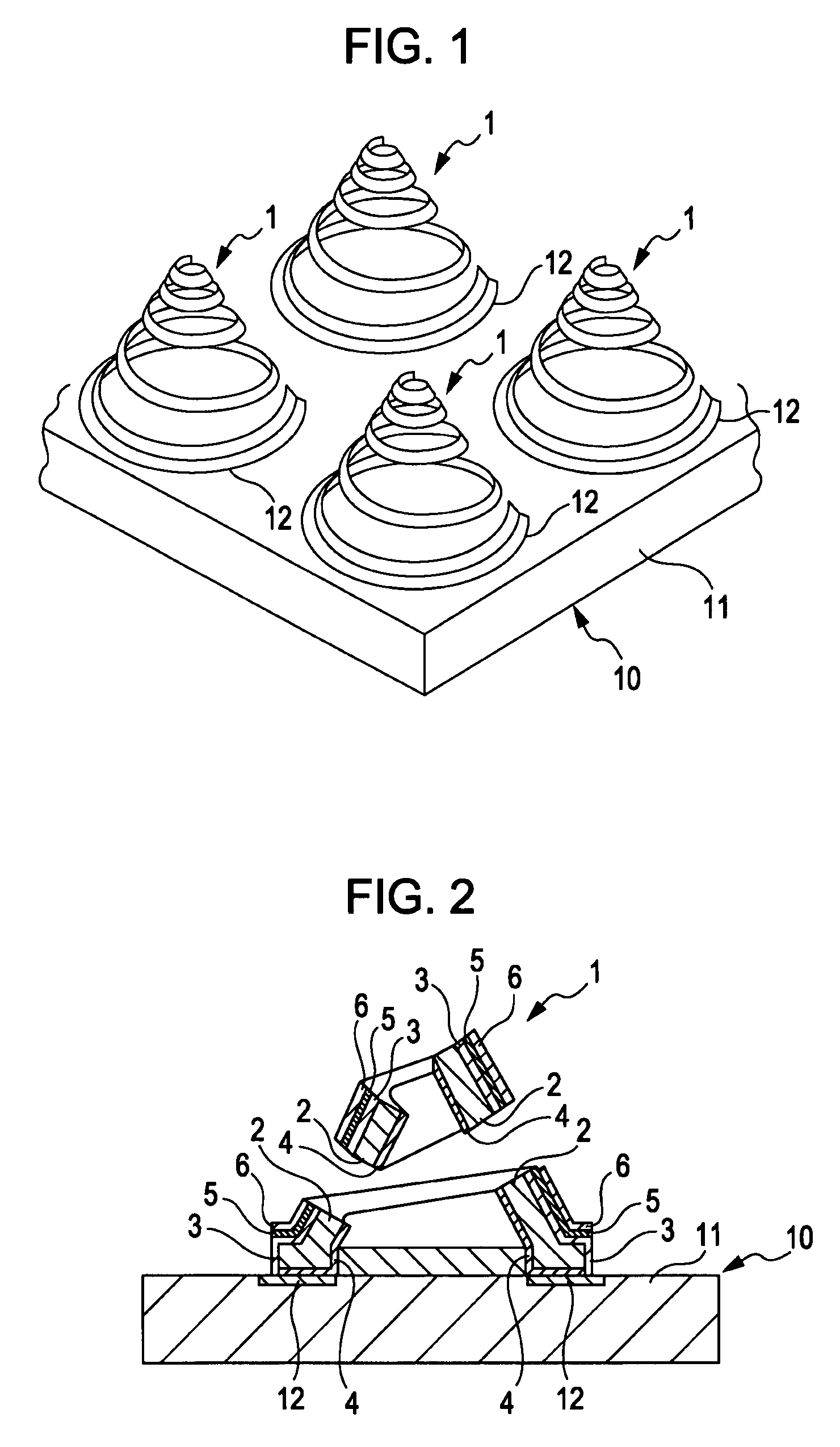

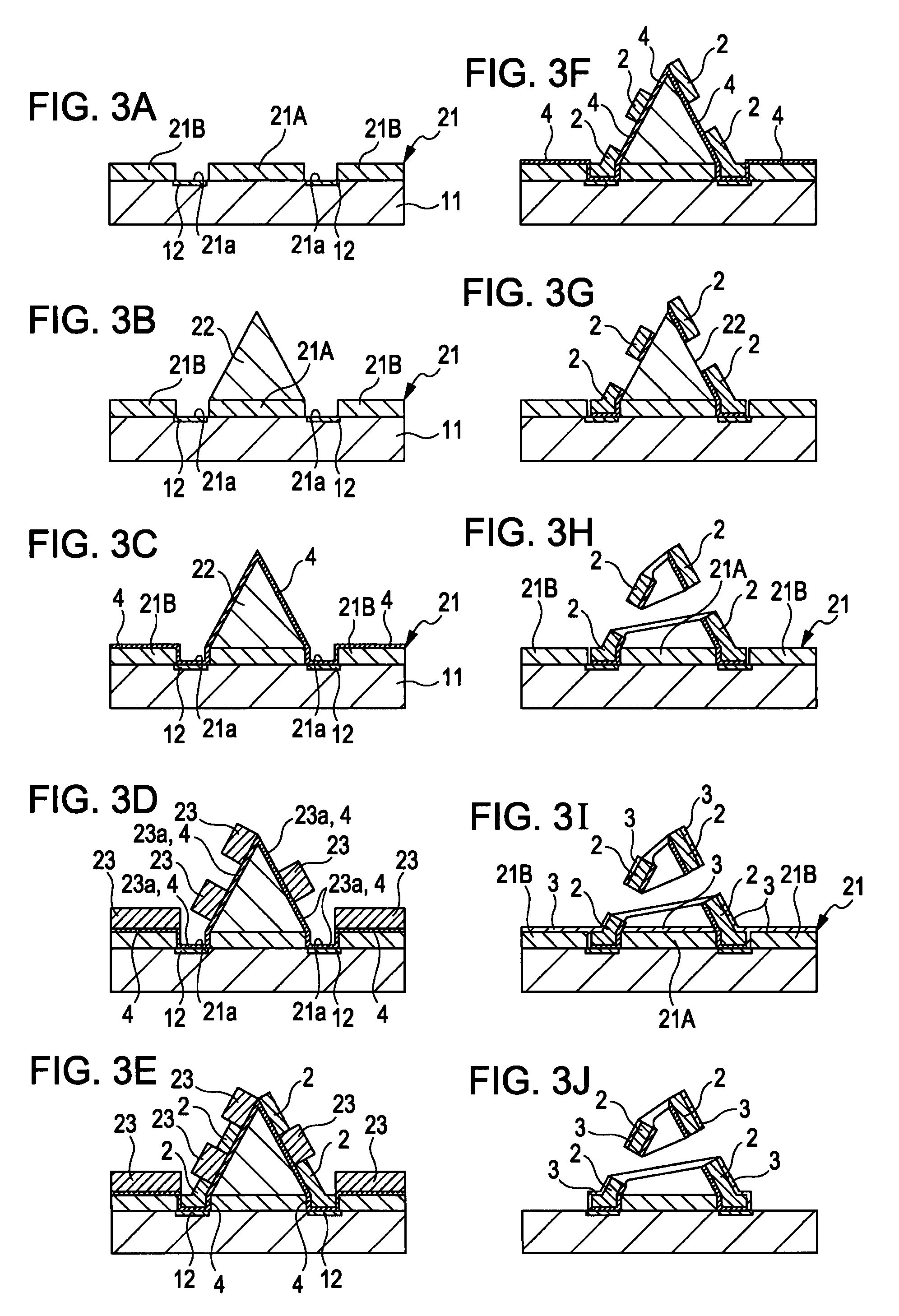

A Contact according to an aspect of the present invention is formed by laminating a shape memory alloy film on a surface of a metal spring film, and the shape thereof is a conical spiral. A manufacturing method therefor is composed of 11 steps including a step of preparing a sacrificial metal film, a step of forming a resist cone, a step of patterning a resist film, a step of preparing a shape memory alloy film, and the like. Since an organic resist material has poor heat resistance, the sacrificial metal film is formed in advance, the resist is removed before sputtering of the shape memory alloy film, the sacrificial metal film is removed after sputtering of a shape memory alloy and a heat treatment, which are performed at high temperatures, so as to lift off an excess shape memory alloy film.

Owner:ALPS ALPINE CO LTD

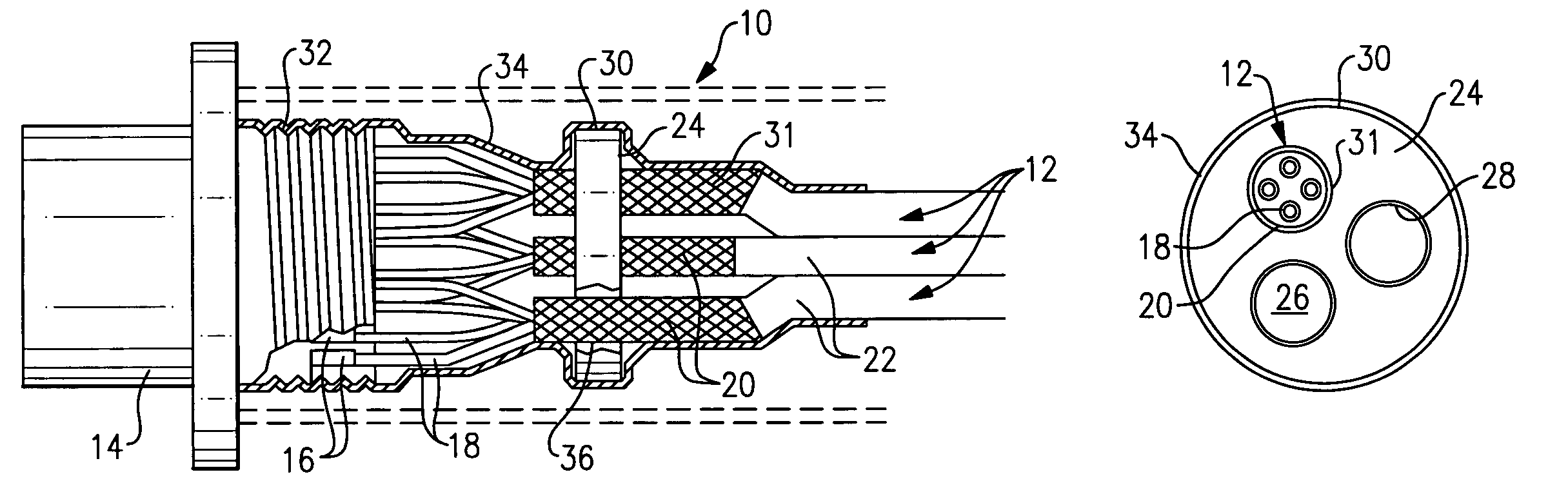

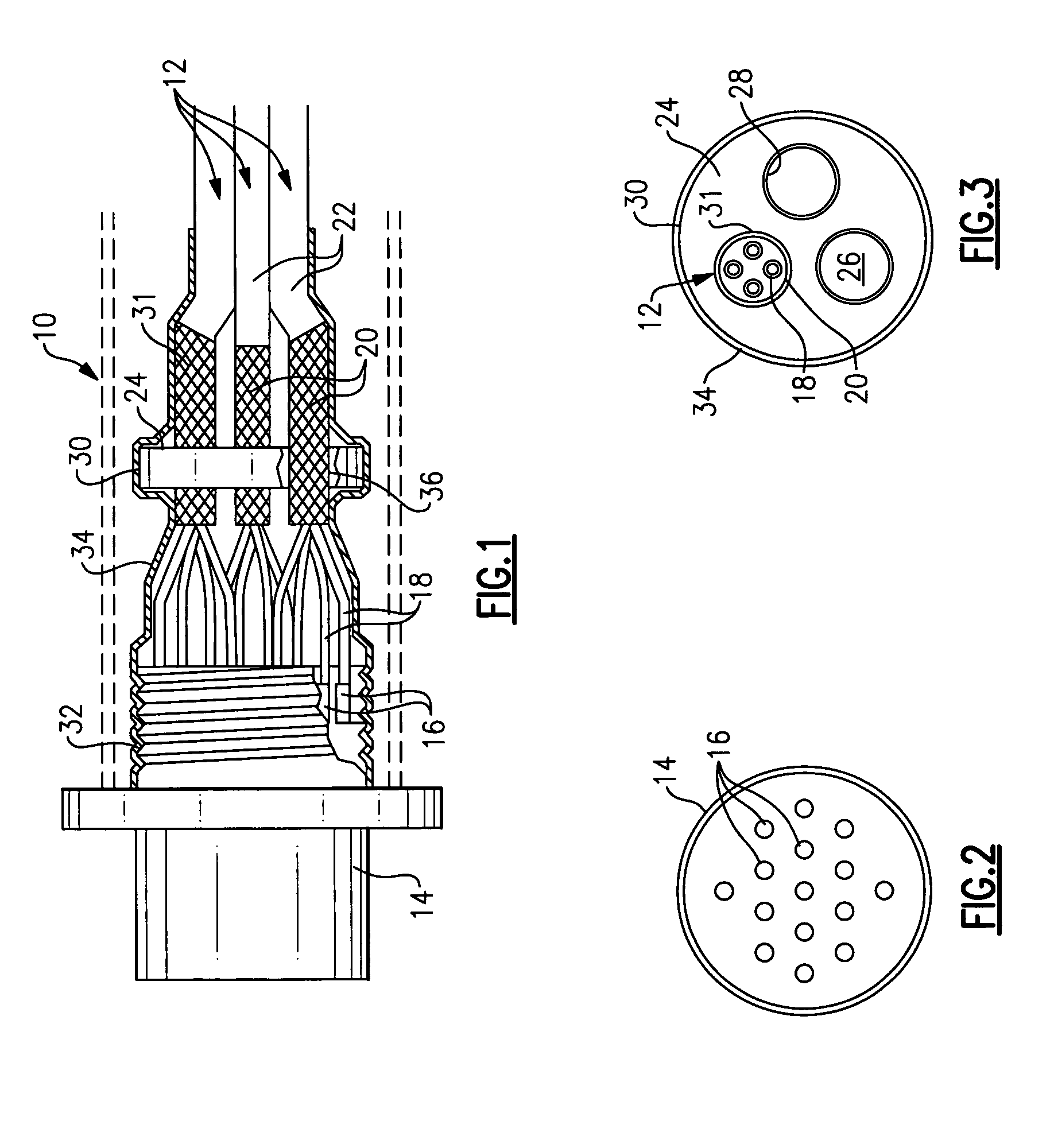

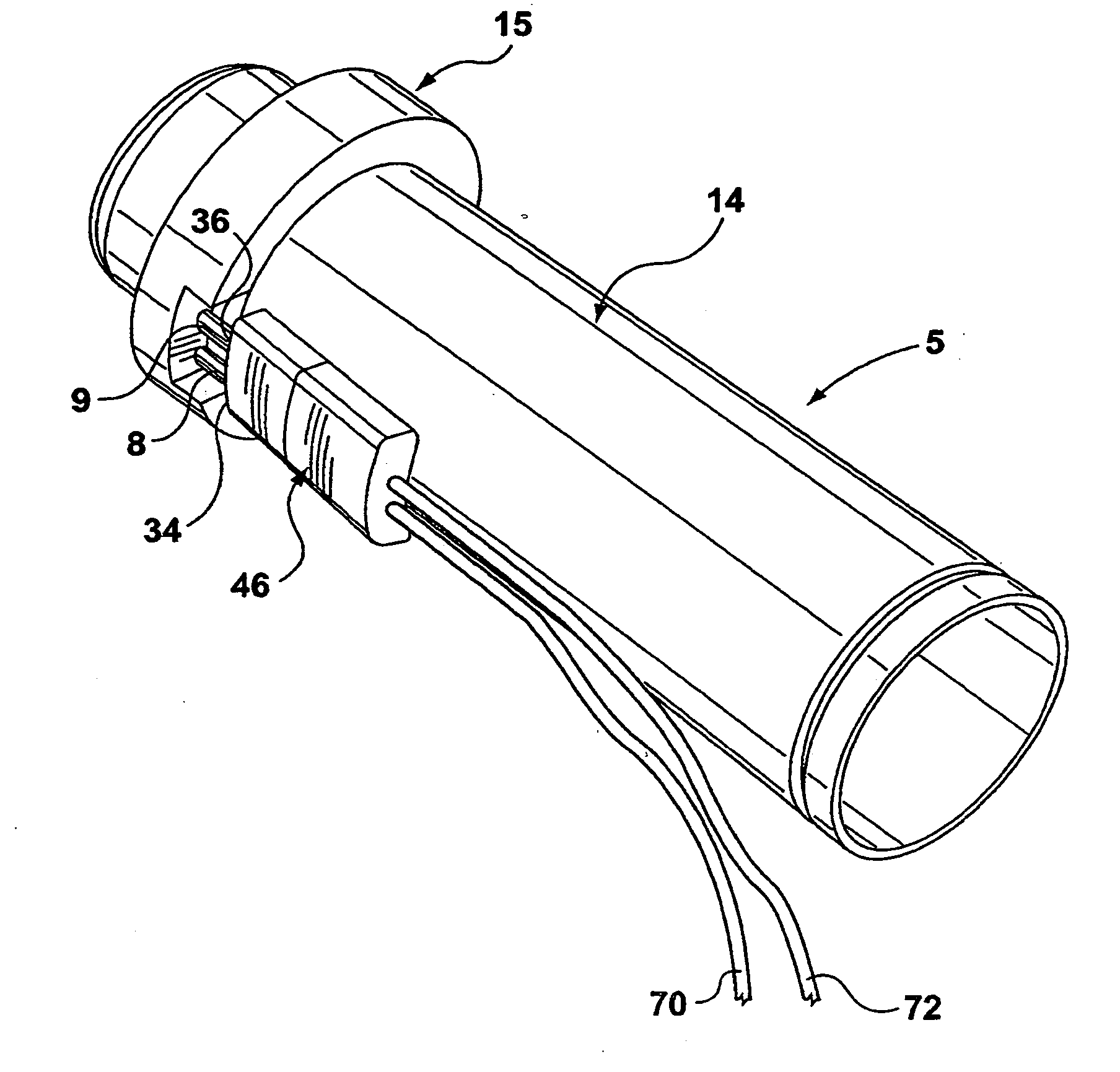

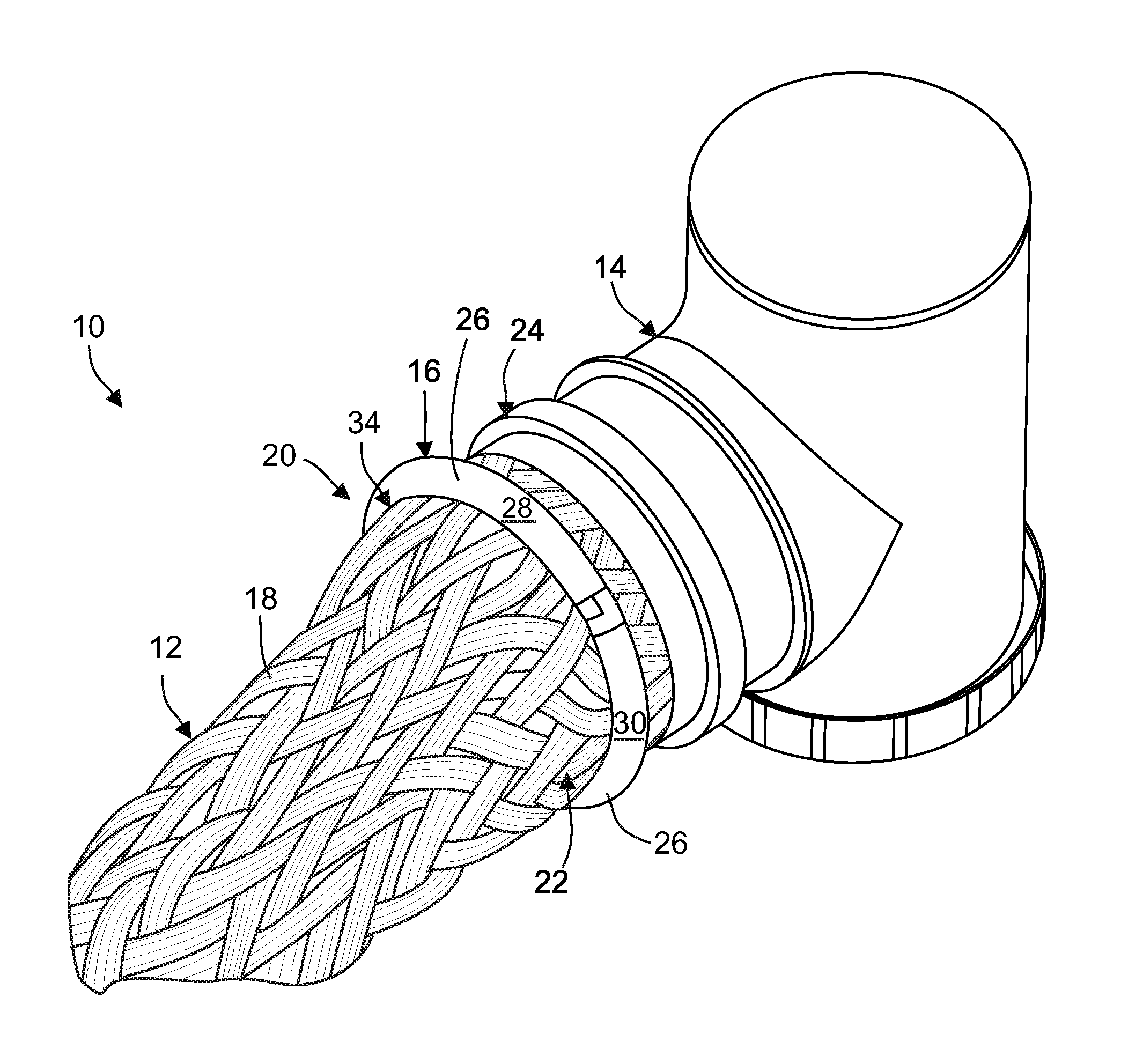

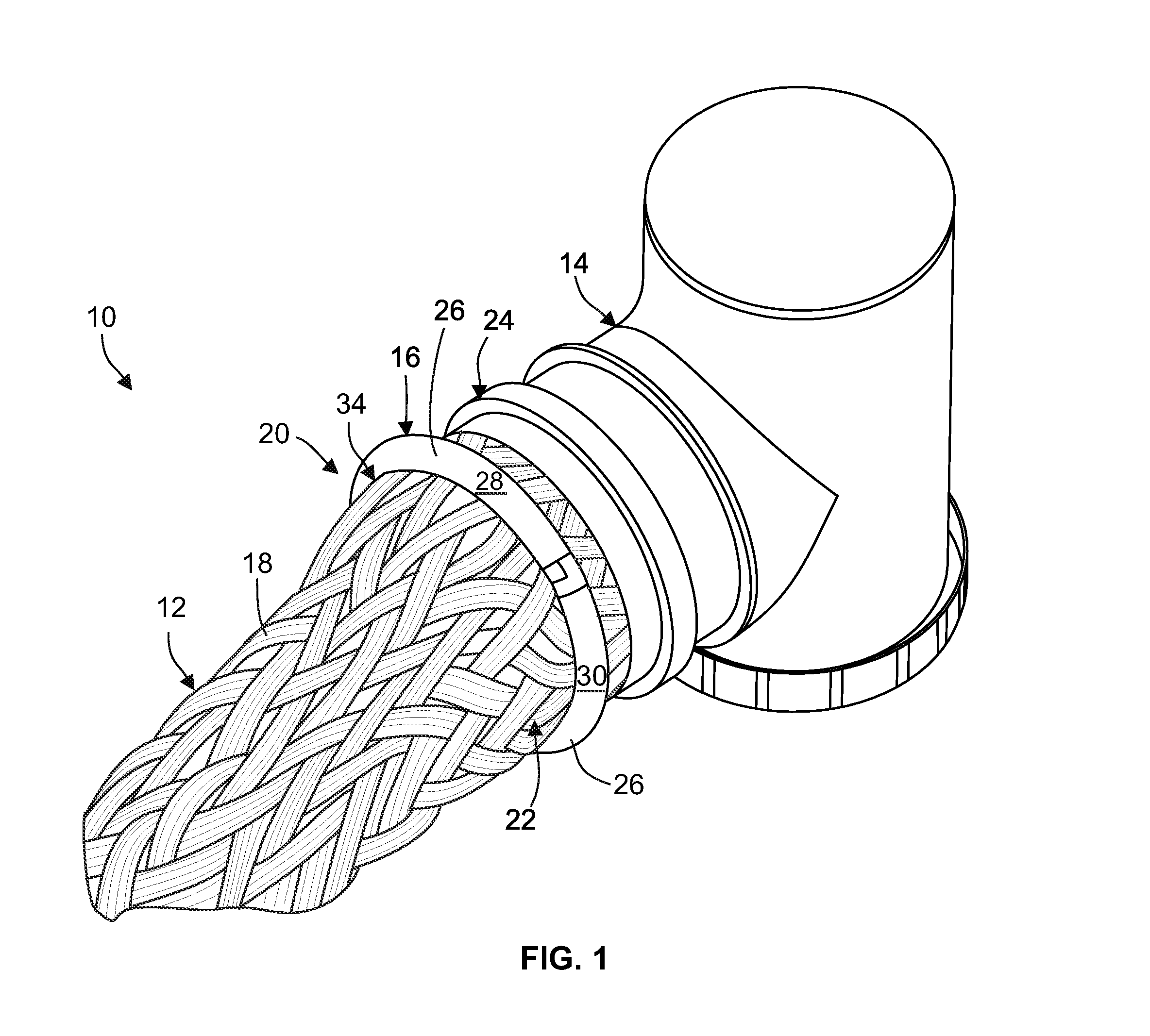

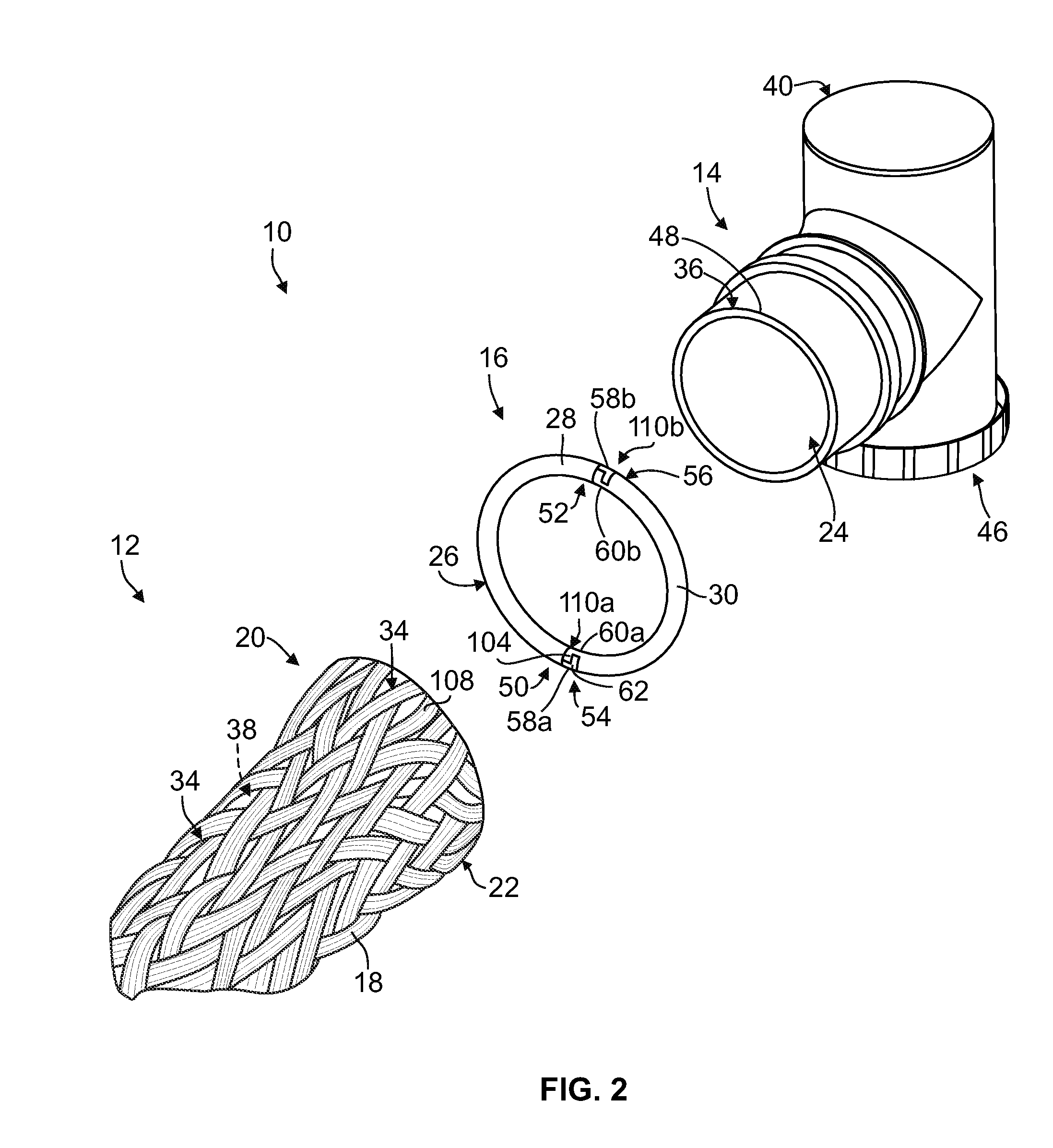

Shielding for electrical cable assemblies

An electrical cable assembly is provided including multiple cables having wires. The cables each include a shield. A connector receives ends of the wires and includes an outer surface. A conductive shield ring has an outer periphery and includes multiple holes receiving the cables. The shield of each cable engages an inner surface provided by a corresponding hole in the shield ring. In one example, the circumference of each shield is soldered to the corresponding hole. A wrap engages the outer periphery and the outer surface to electrically connect the connector to the shields. In one example, the wrap is conductive heat shrink wrap that surrounds and engages the entire outer surface of the shield ring.

Owner:HAMILTON SUNDSTRAND CORP

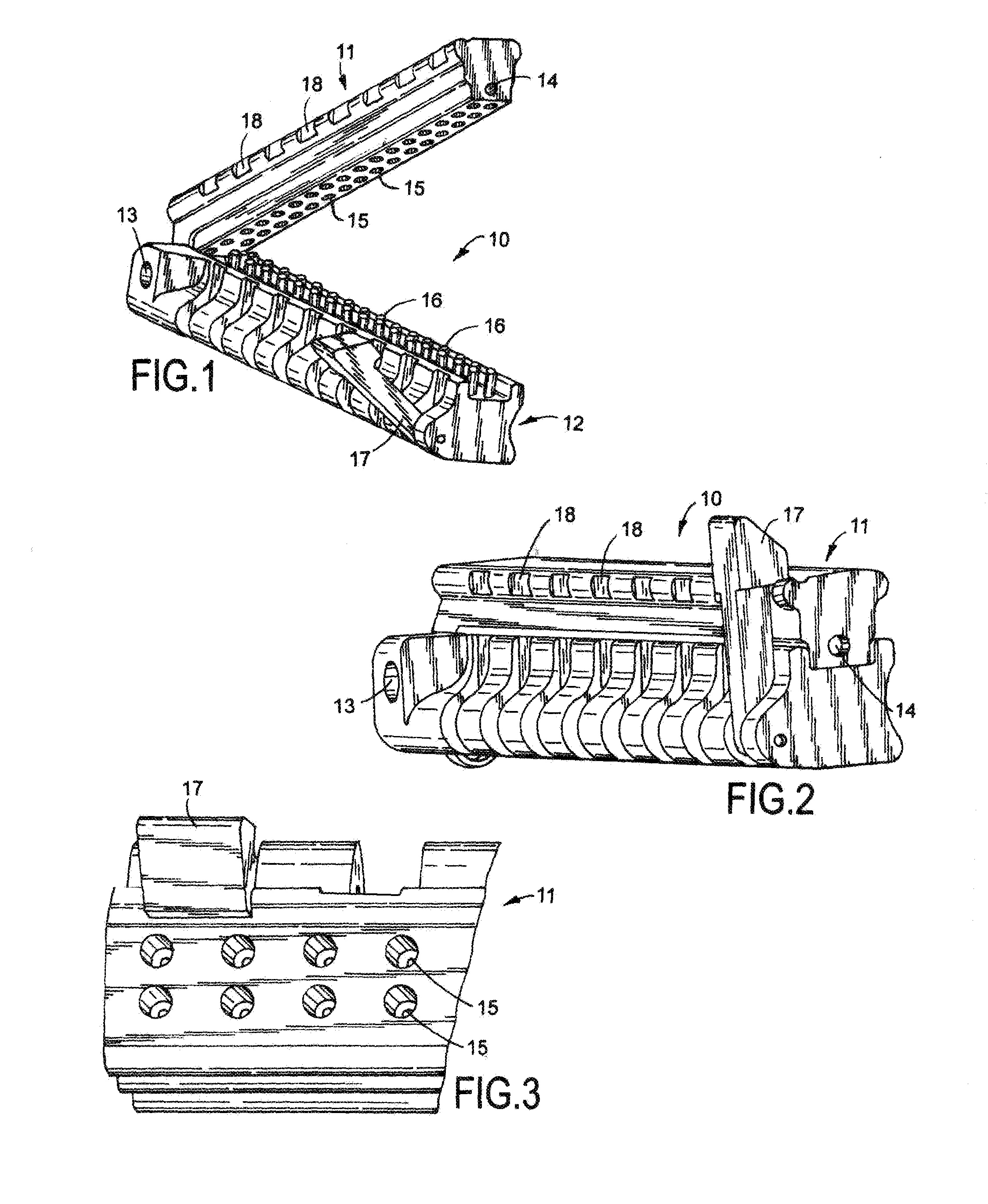

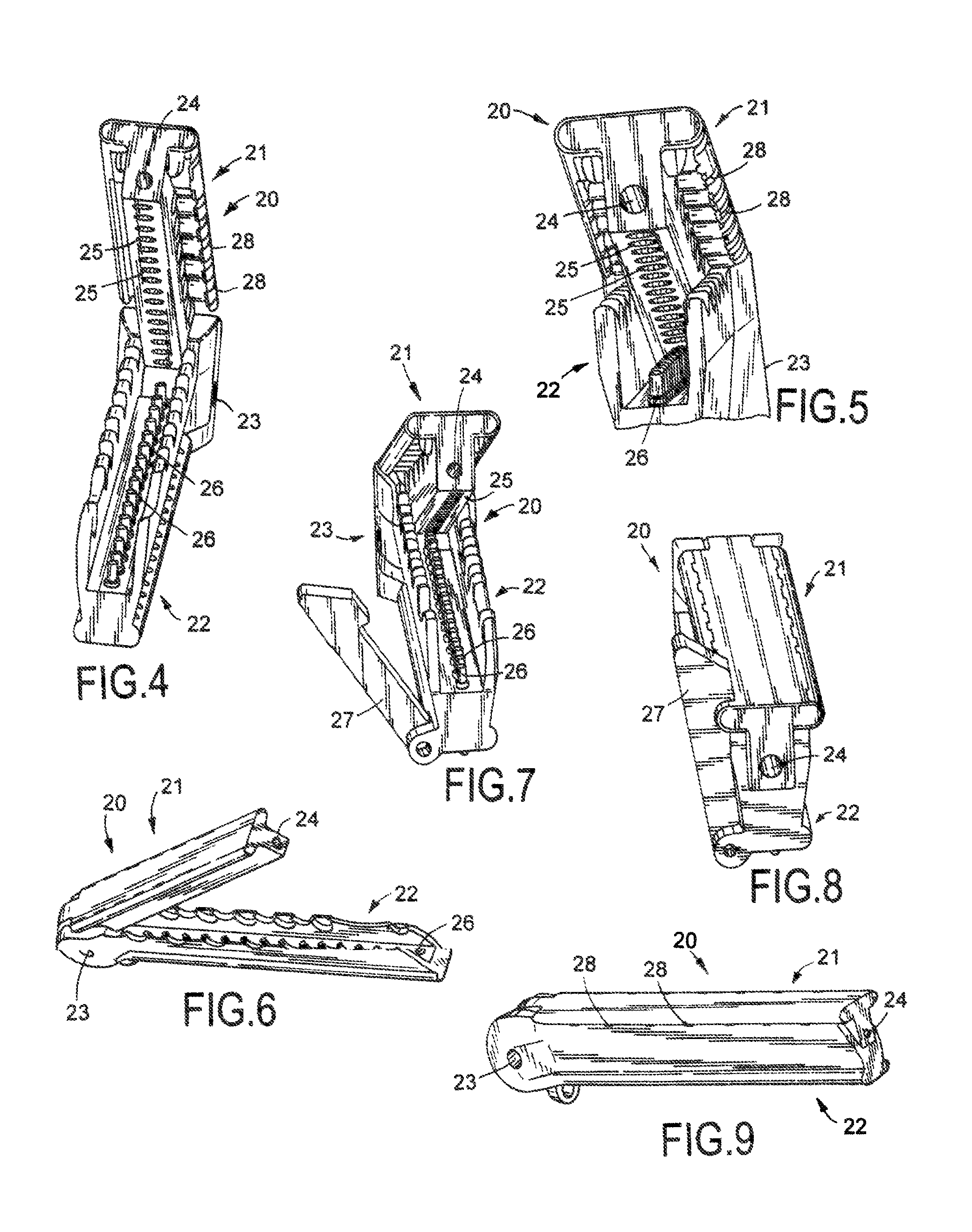

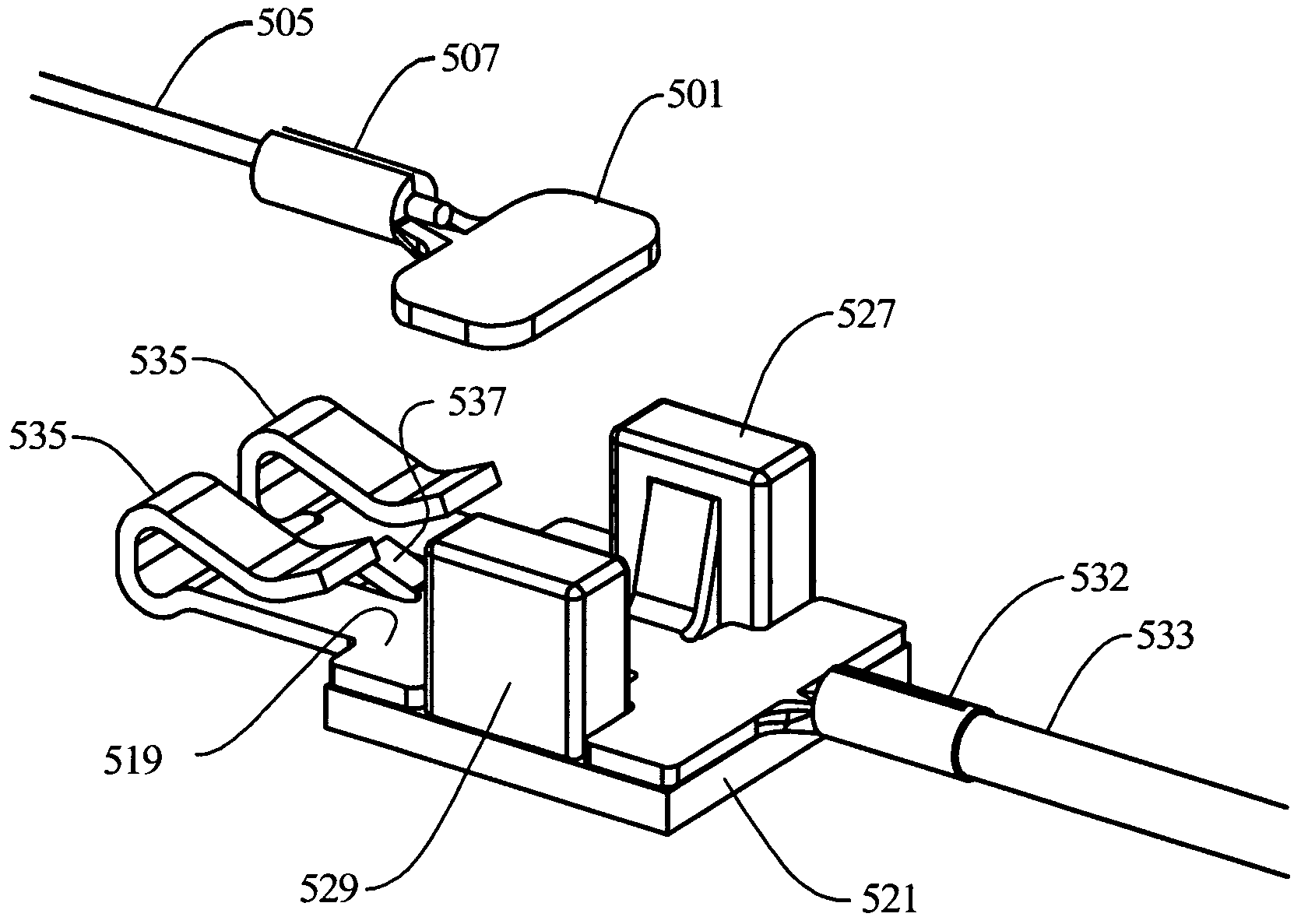

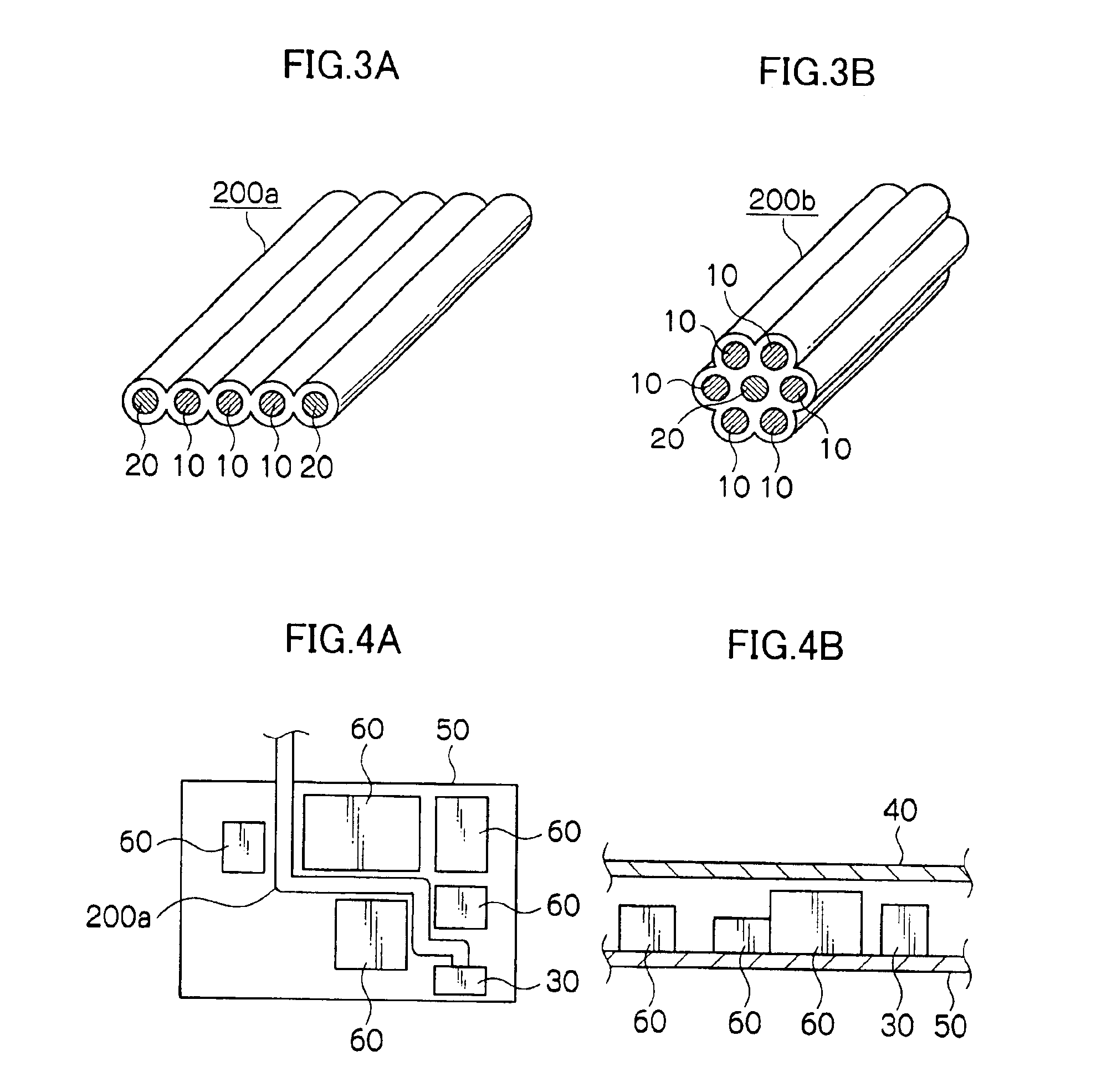

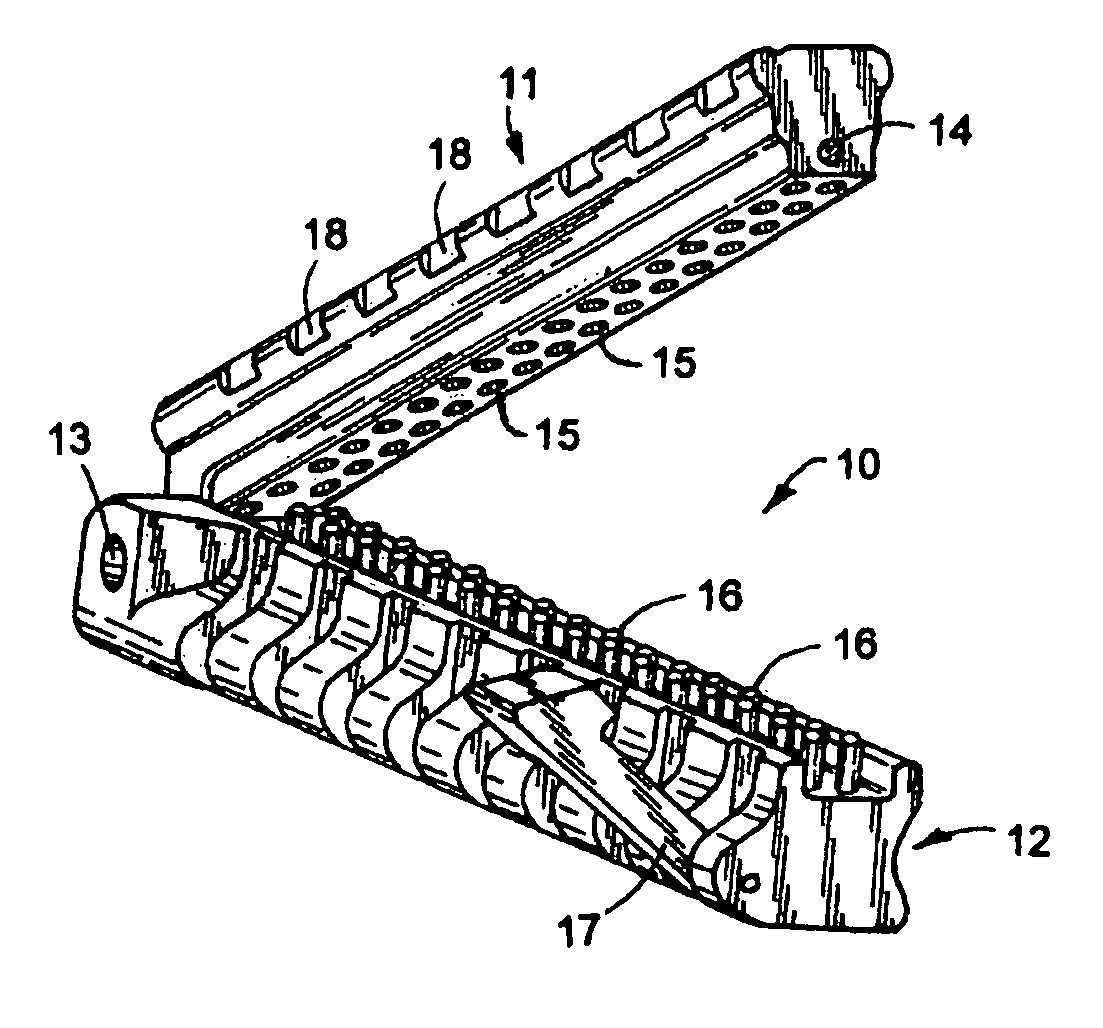

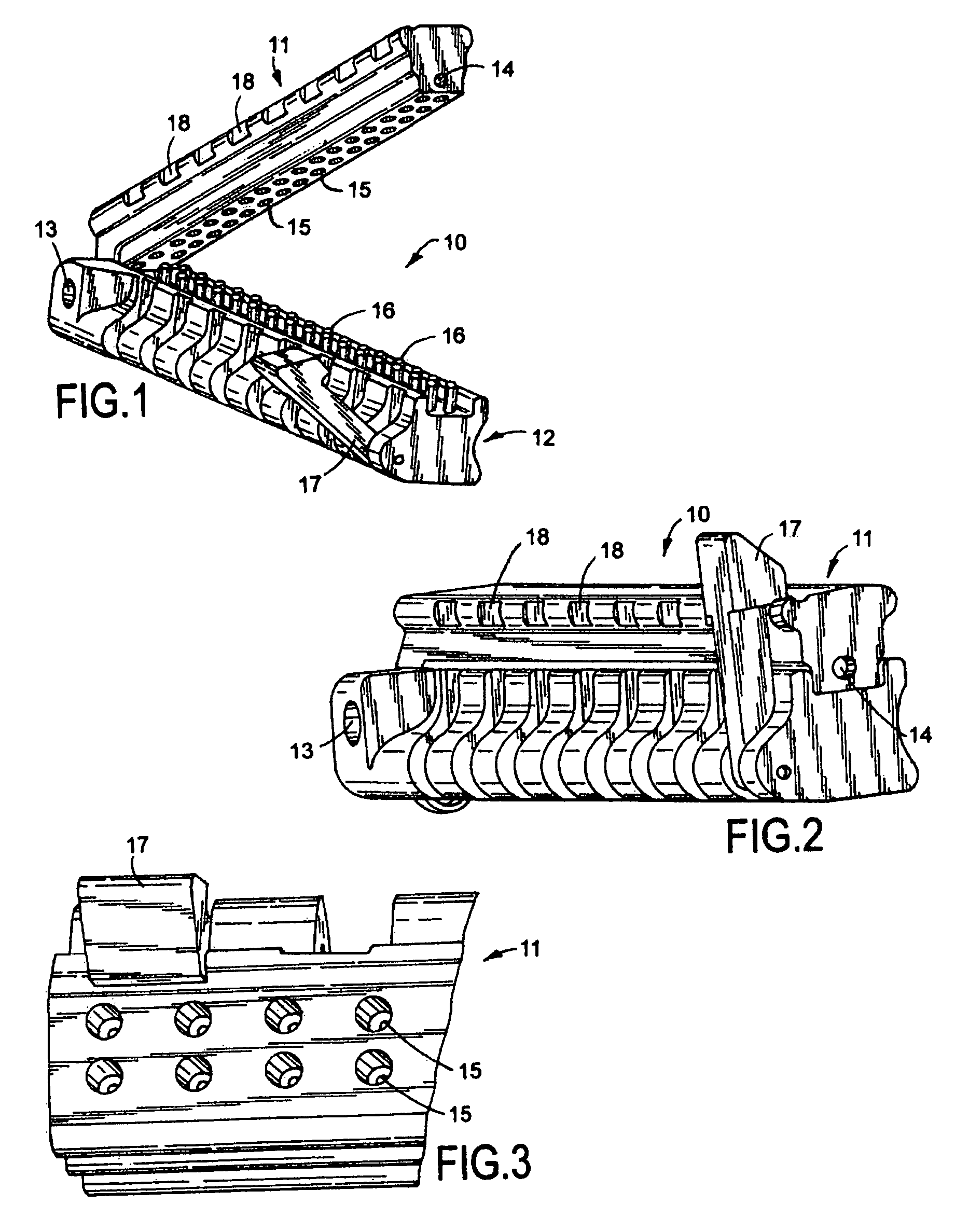

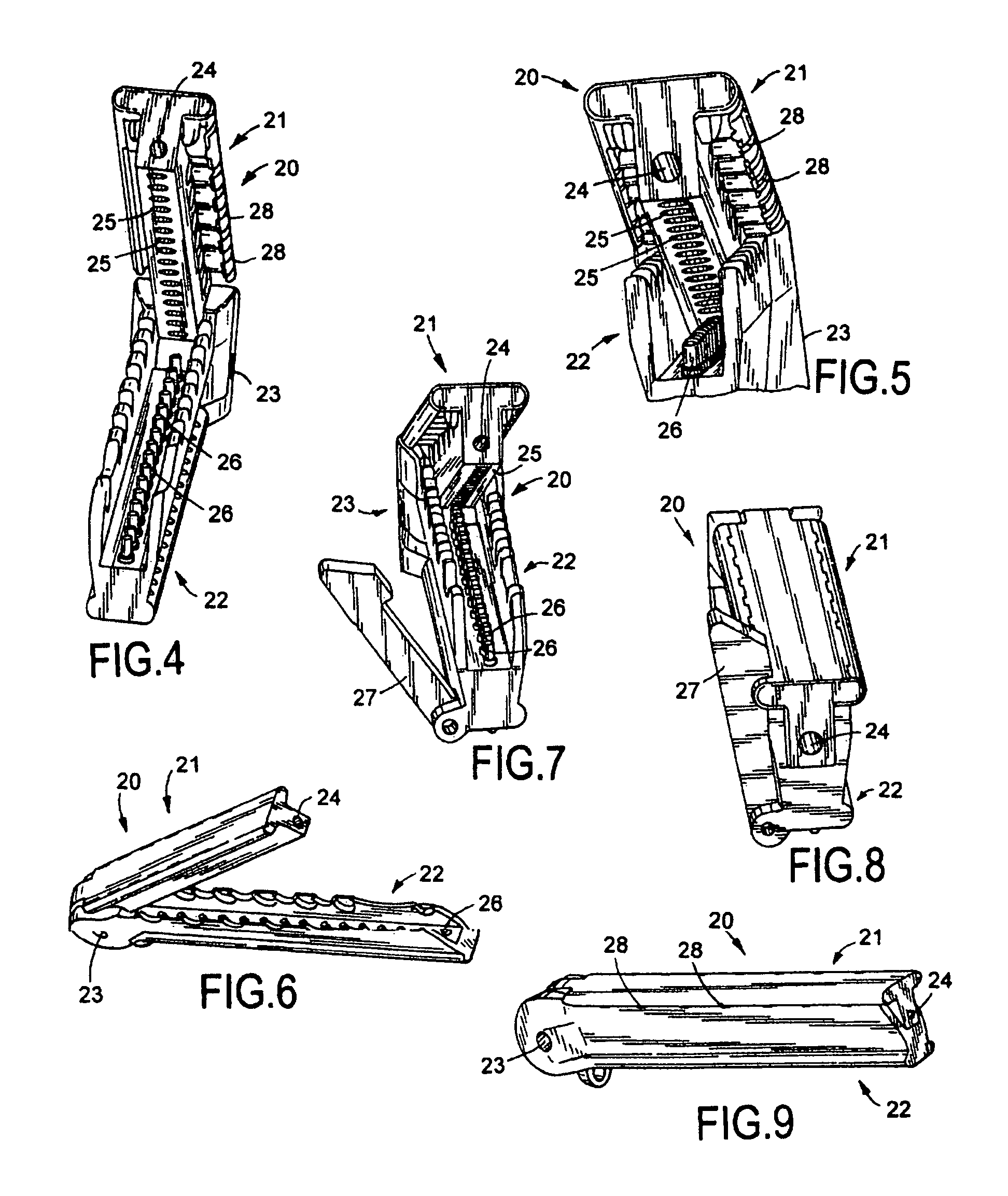

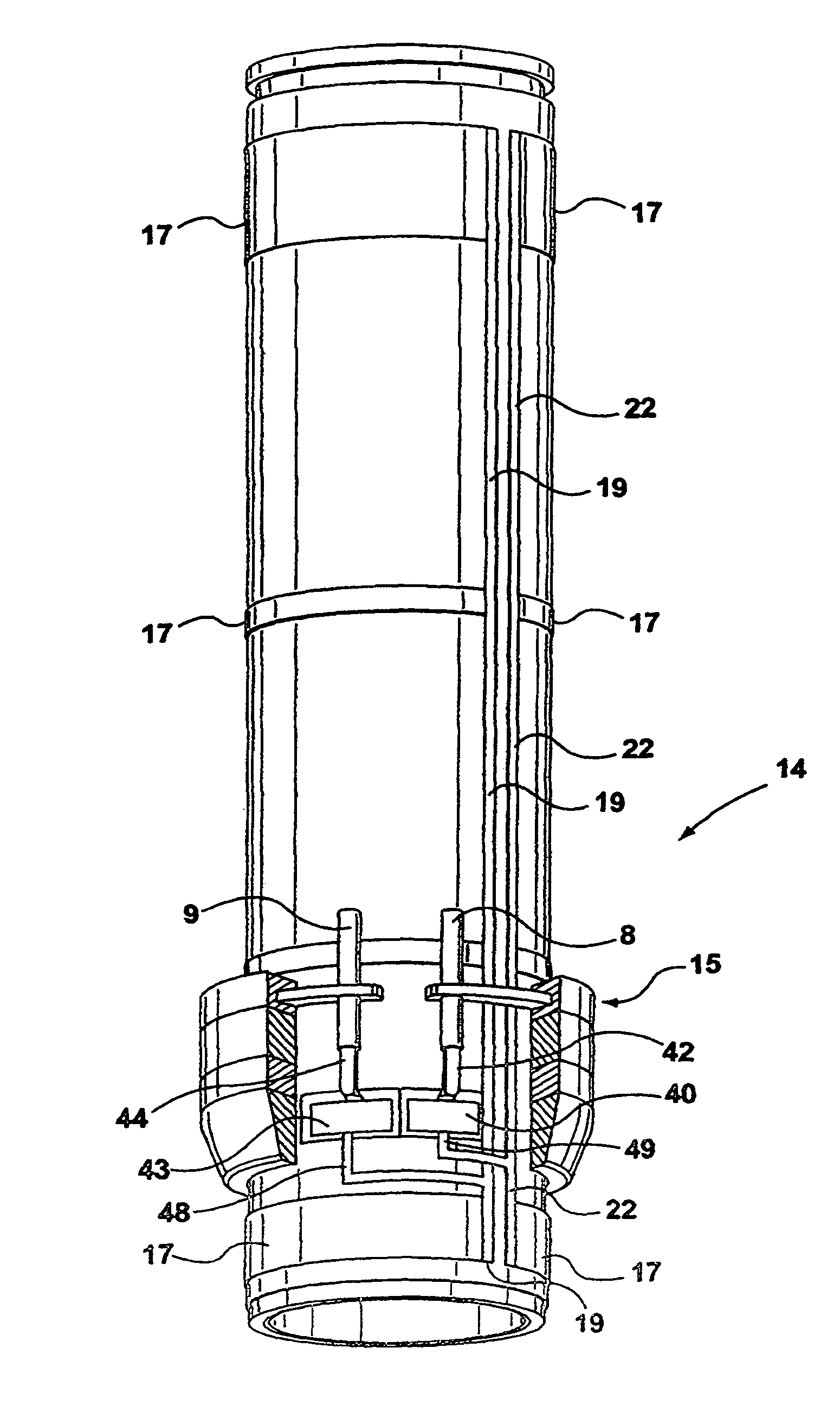

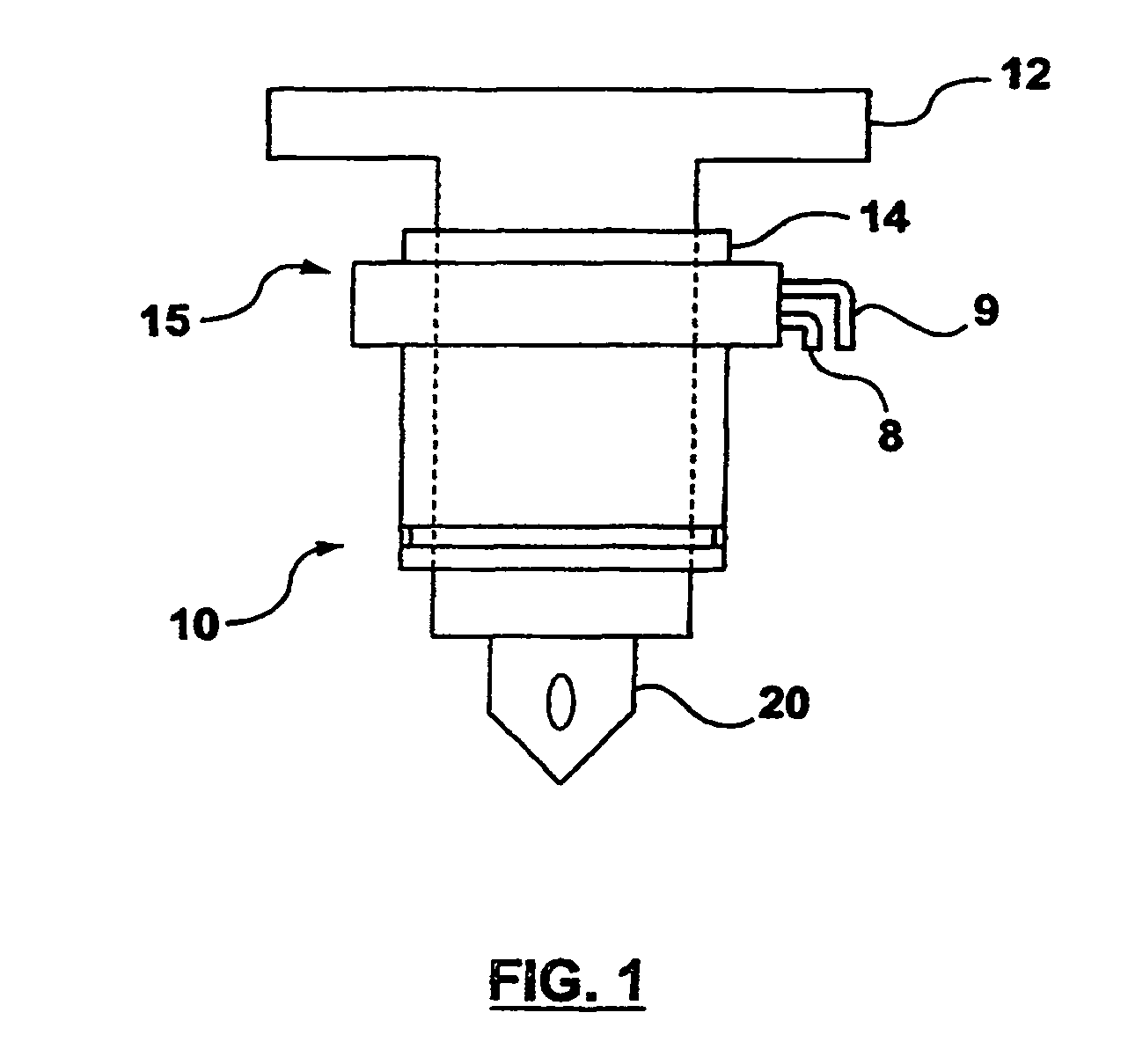

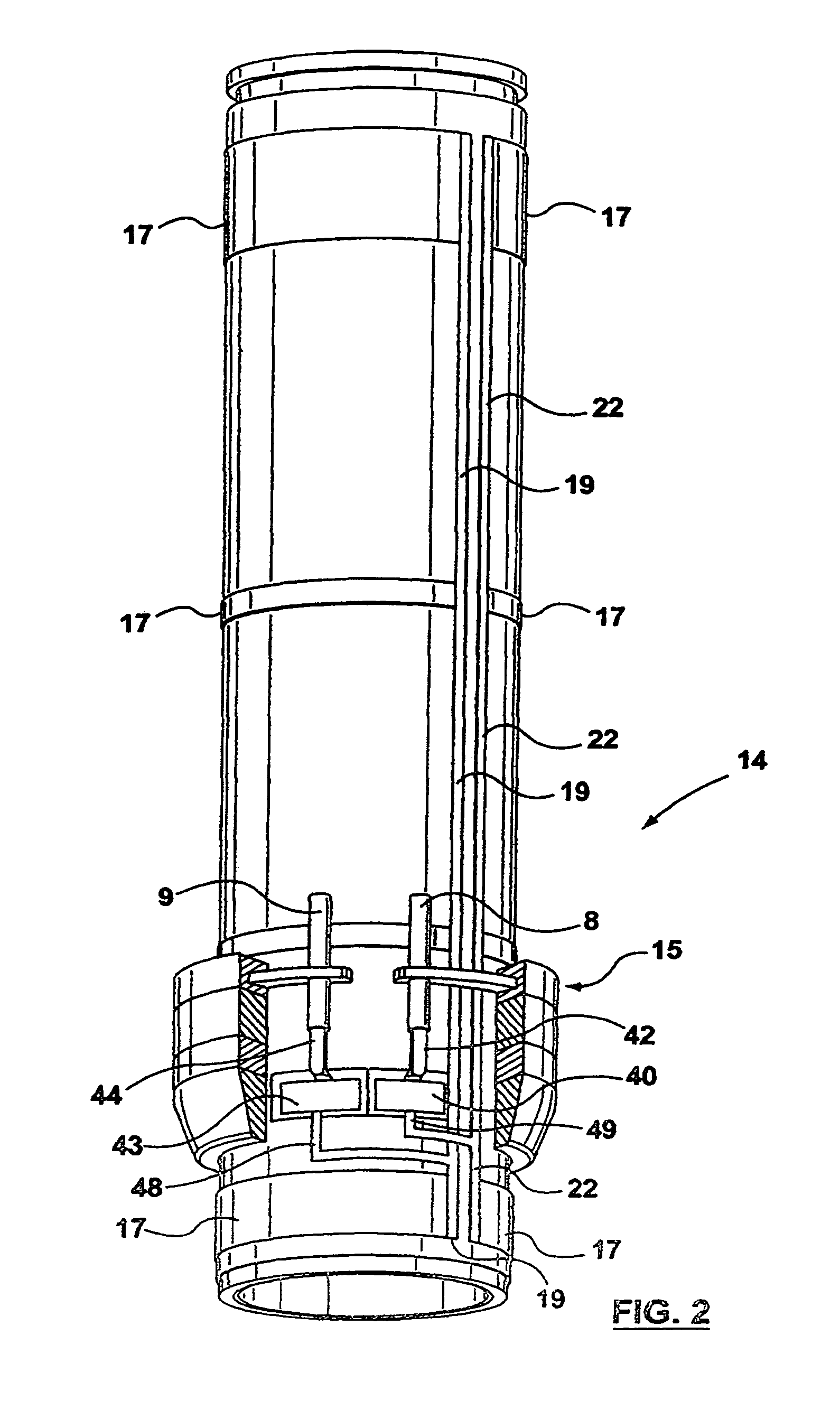

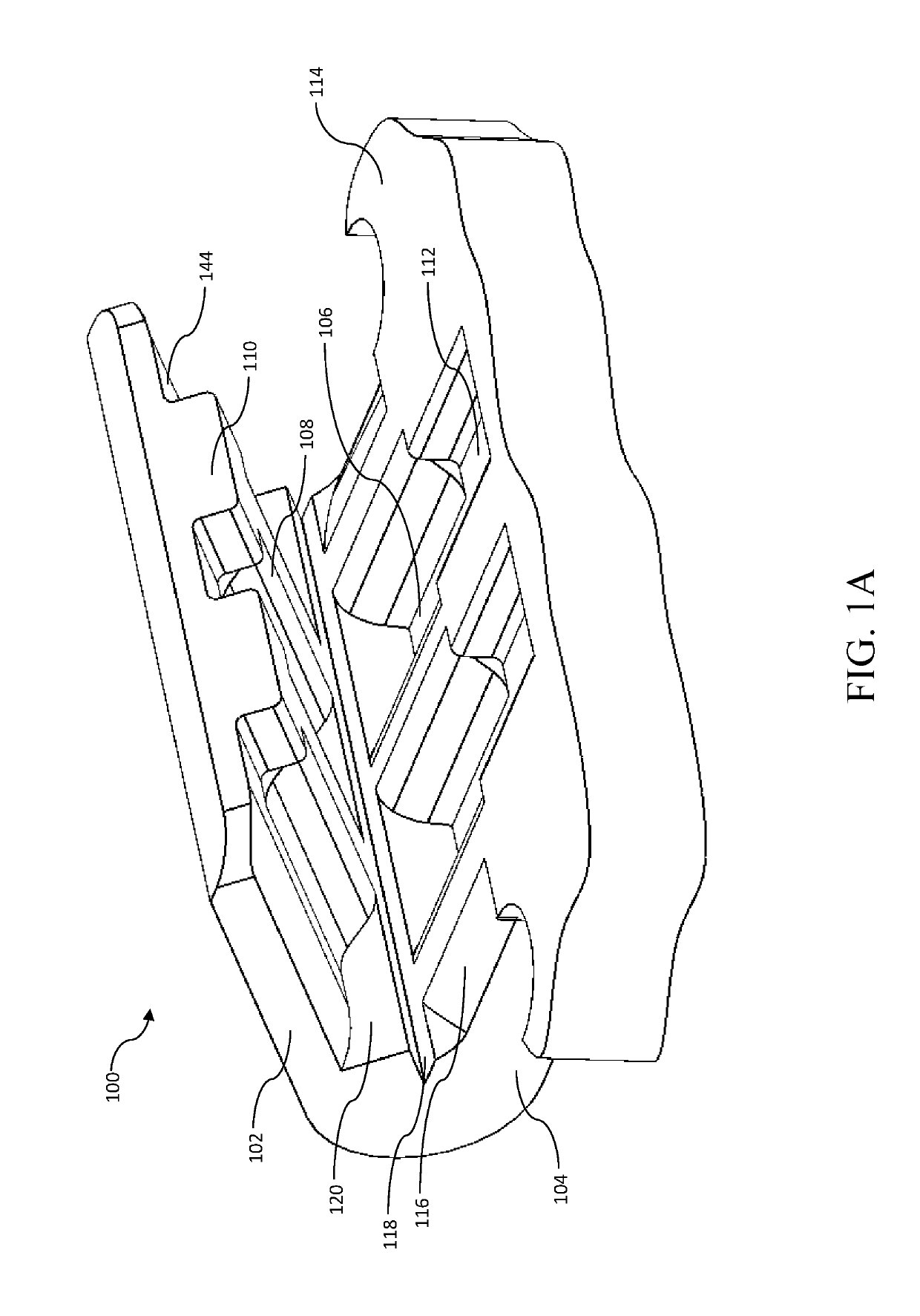

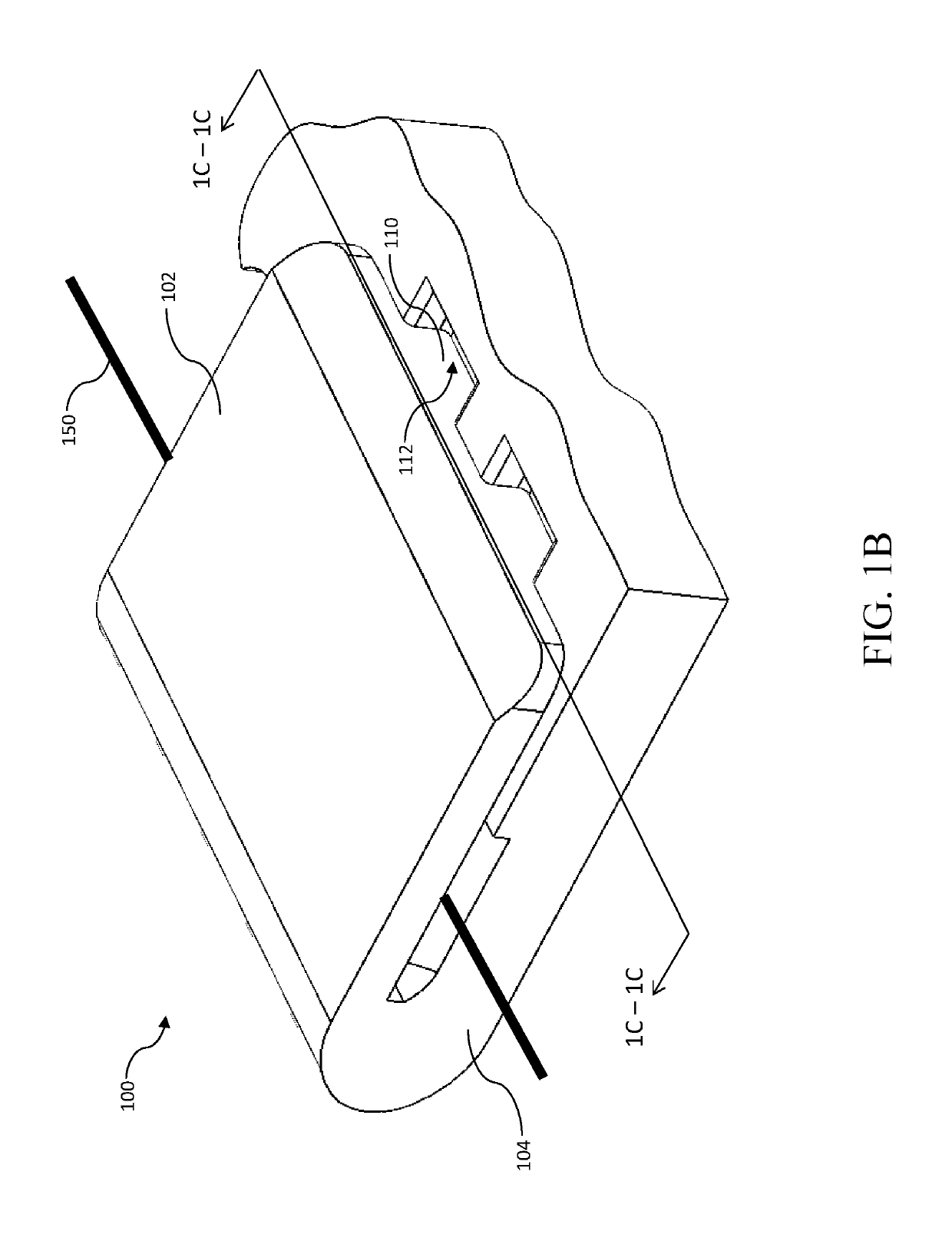

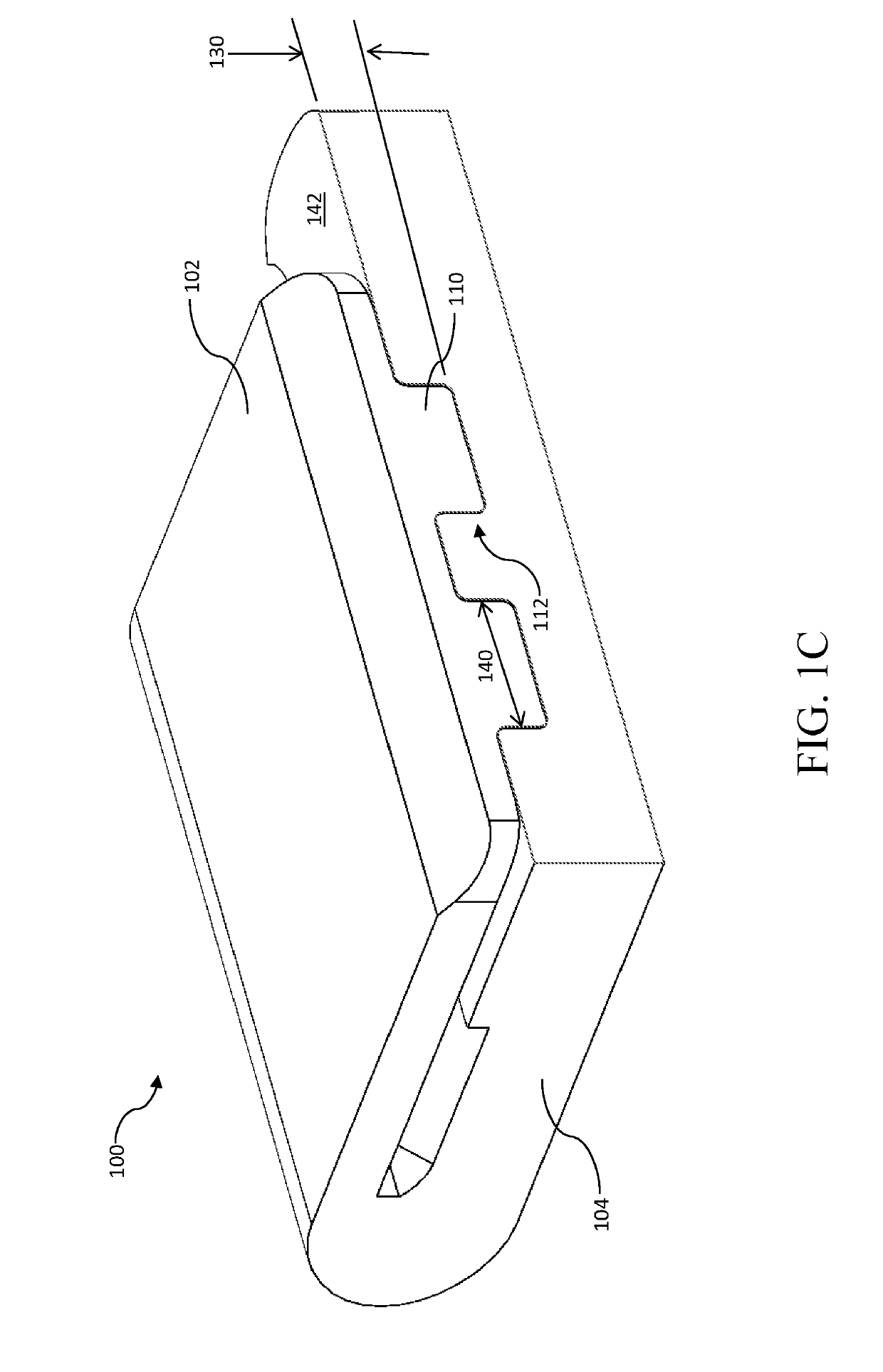

Apparatus and methods for filament crimping and manufacturing

ActiveUS7650914B2Reduce distortionContact member manufacturingShape memory alloy connectionsEngineeringMechanical engineering

Owner:AUTOSPLICE SYST

Semiconductor device contact resistant to deterioration due to heat and method for manufacturing contact

InactiveUS7527505B2Promote recoveryImprove heat resistanceElectrical measurement instrument detailsShape memory alloy connectionsResistSputtering

A Contact according to an aspect of the present invention is formed by laminating a shape memory alloy film on a surface of a metal spring film, and the shape thereof is a conical spiral. A manufacturing method therefor is composed of 11 steps including a step of preparing a sacrificial metal film, a step of forming a resist cone, a step of patterning a resist film, a step of preparing a shape memory alloy film, and the like. Since an organic resist material has poor heat resistance, the sacrificial metal film is formed in advance, the resist is removed before sputtering of the shape memory alloy film, the sacrificial metal film is removed after sputtering of a shape memory alloy and a heat treatment, which are performed at high temperatures, so as to lift off an excess shape memory alloy film.

Owner:ALPS ALPINE CO LTD

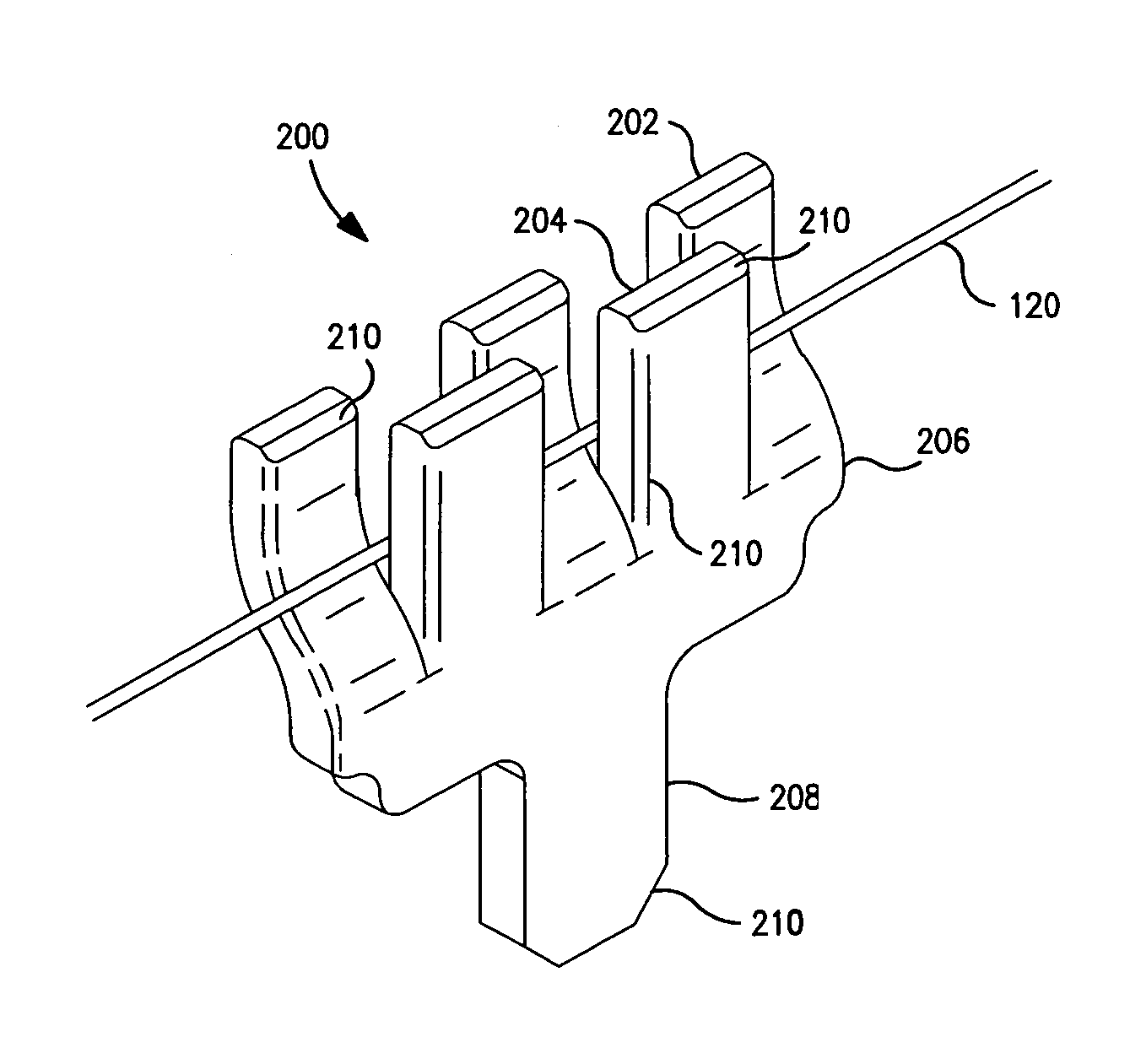

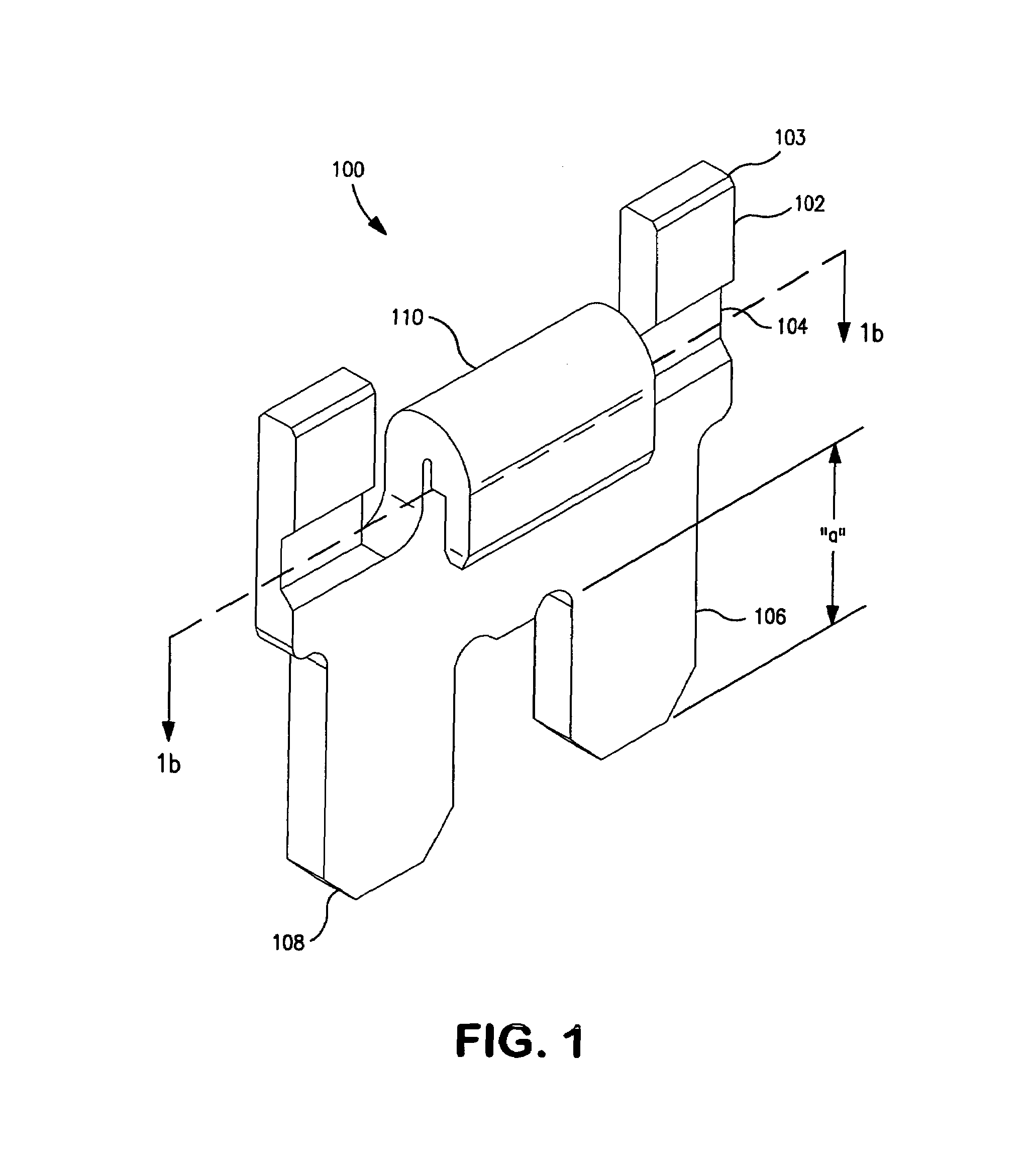

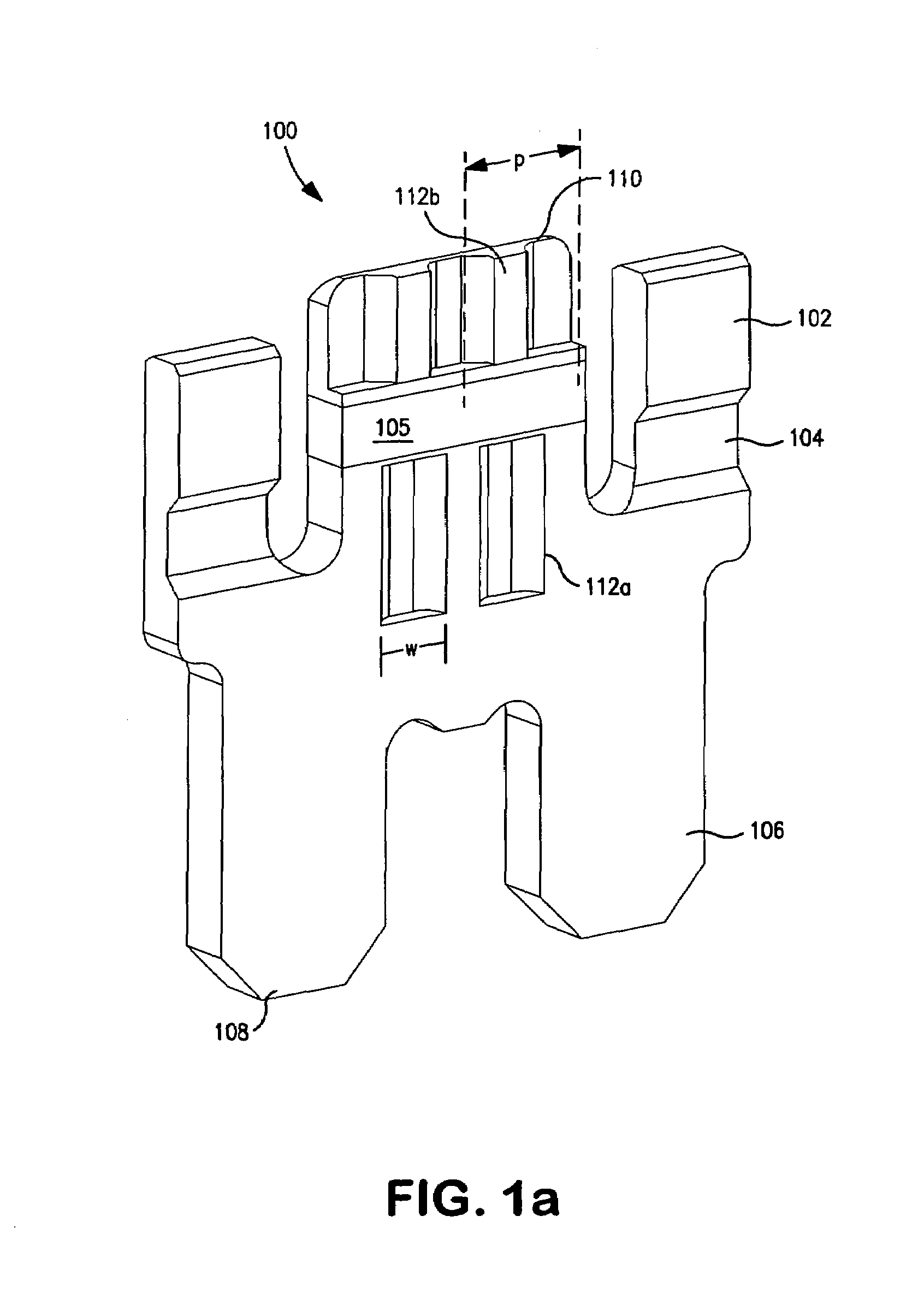

Apparatus and methods for filament crimping and manufacturing

ActiveUS20070294873A1Reduce distortionContact member manufacturingShape memory alloy connectionsEngineeringMechanical engineering

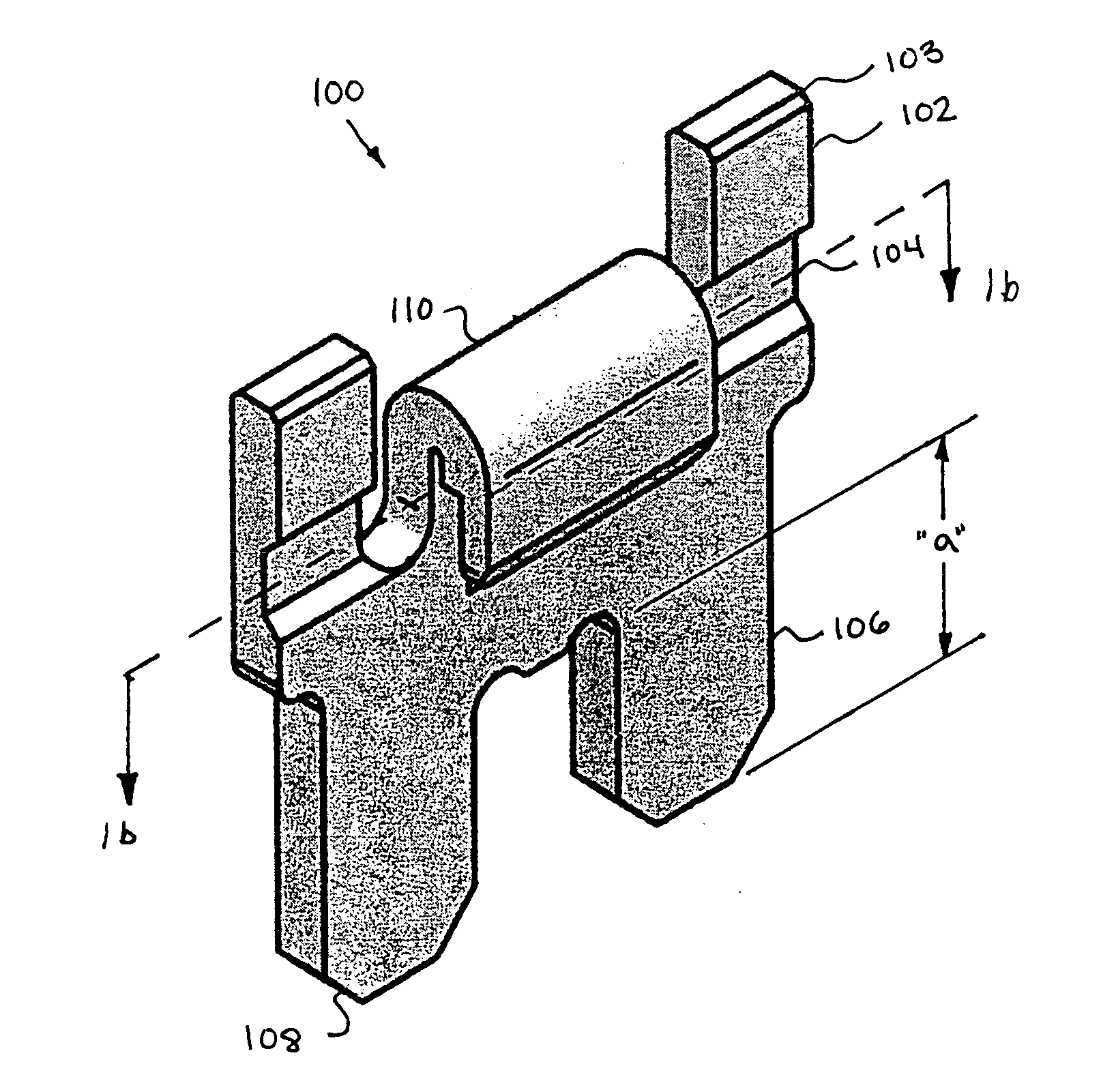

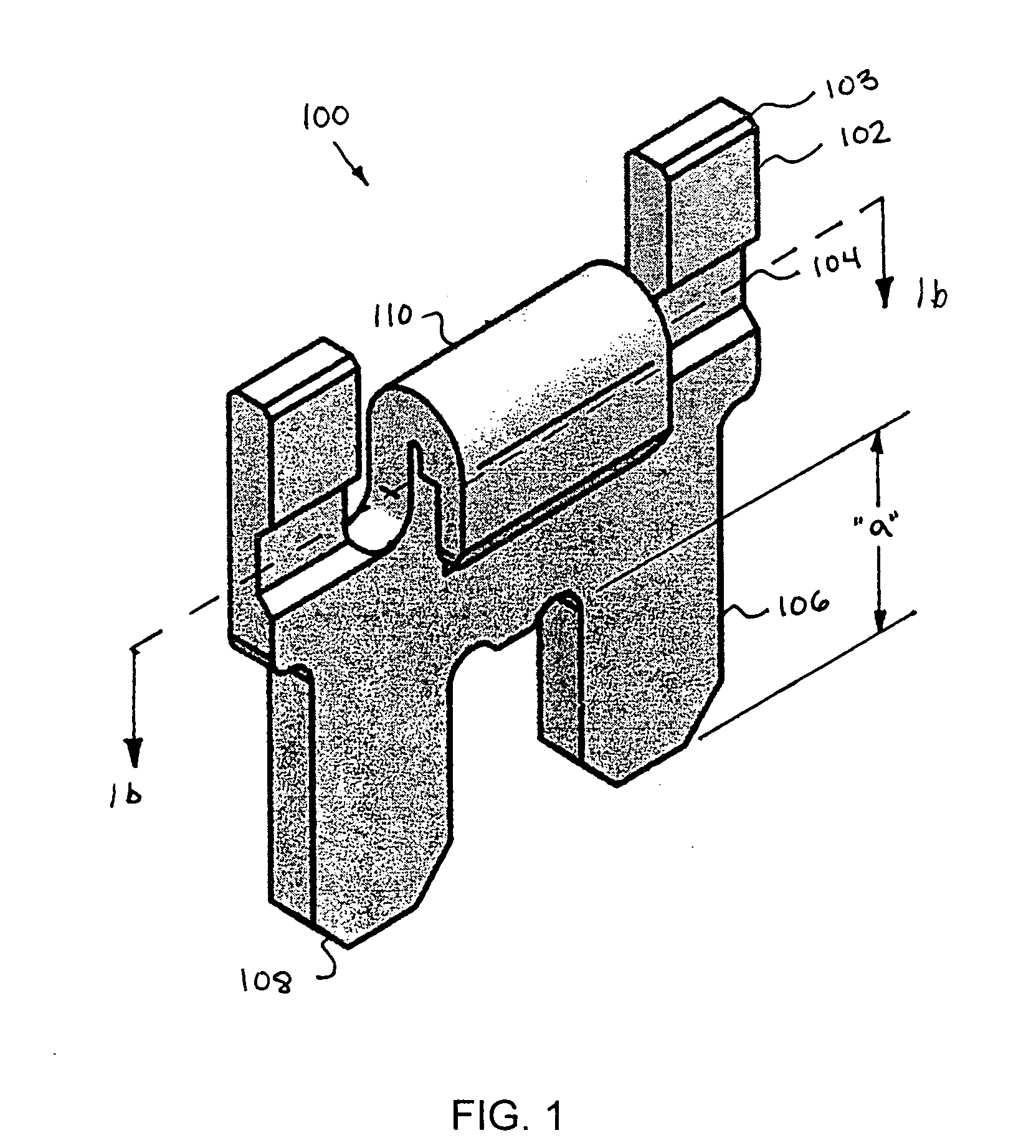

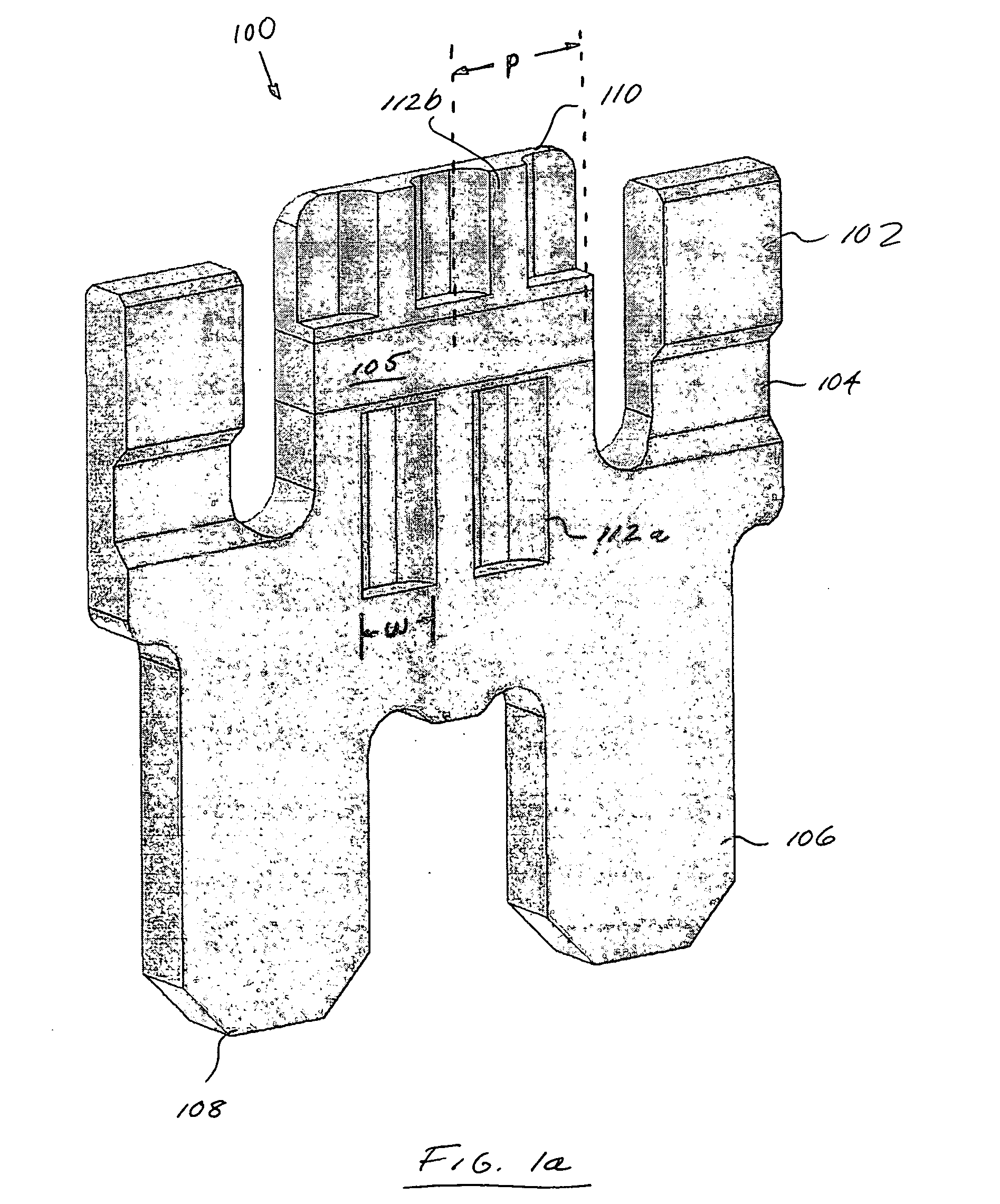

Apparatus and methods for filament crimping. In one embodiment, the apparatus comprises a body and a filament crimp element. The filament crimp element comprises a first set of cavities disposed at a spacing which creates a first set of features and a second set of cavities disposed at a spacing which creates a second set of features. The first and second set cavities are substantially opposite one another. The first set of features are adapted to be placed at least partially within the second set of cavities and the second set of features are adapted to be placed at least partially within the first set of cavities. Methods and apparatus for the manufacture of the device are also disclosed. In addition, methods for automated placement and manufacture of assemblies using the crimp elements are also disclosed.

Owner:AUTOSPLICE SYST

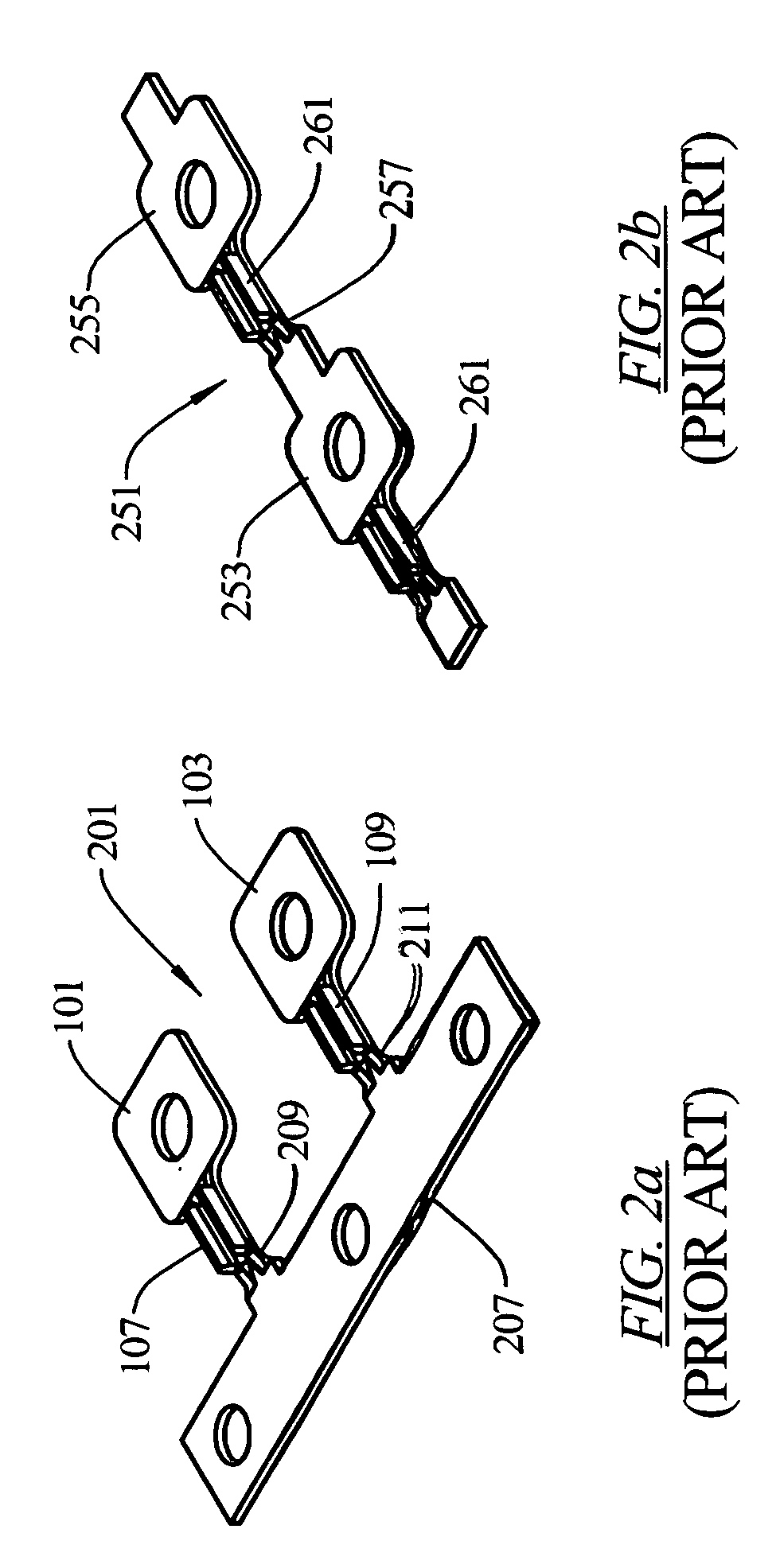

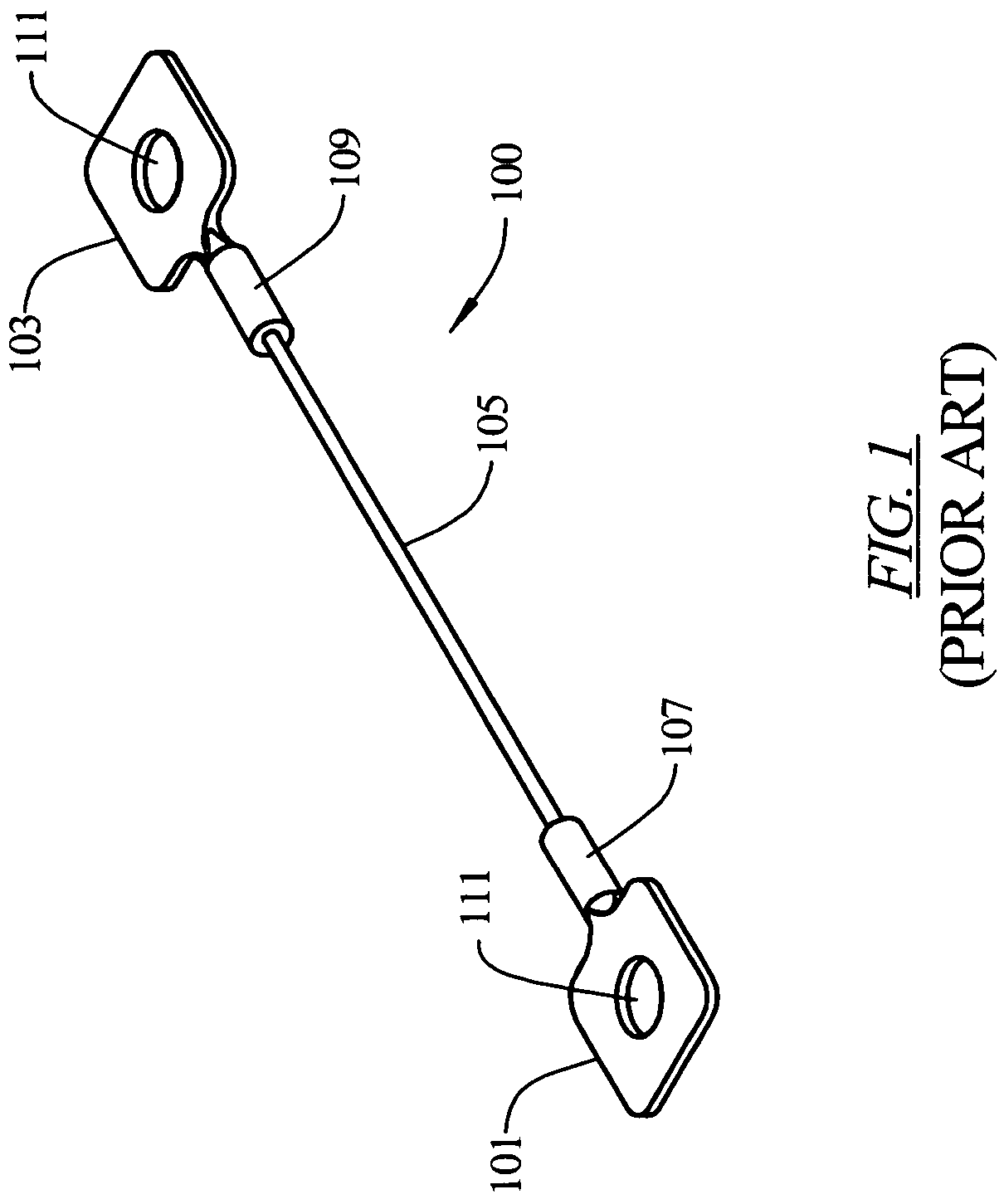

Self-locking wire terminal and shape memory wire termination system

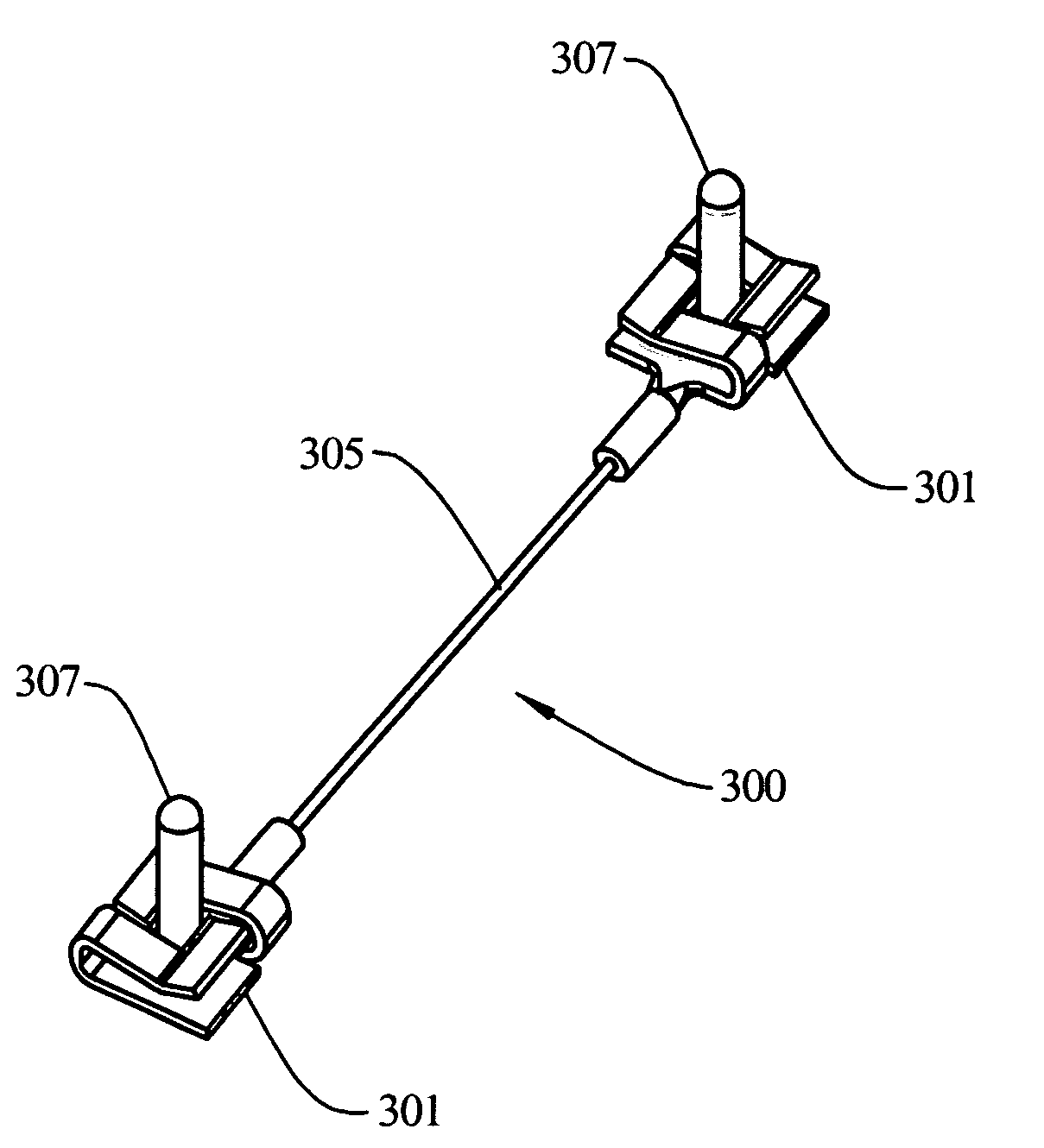

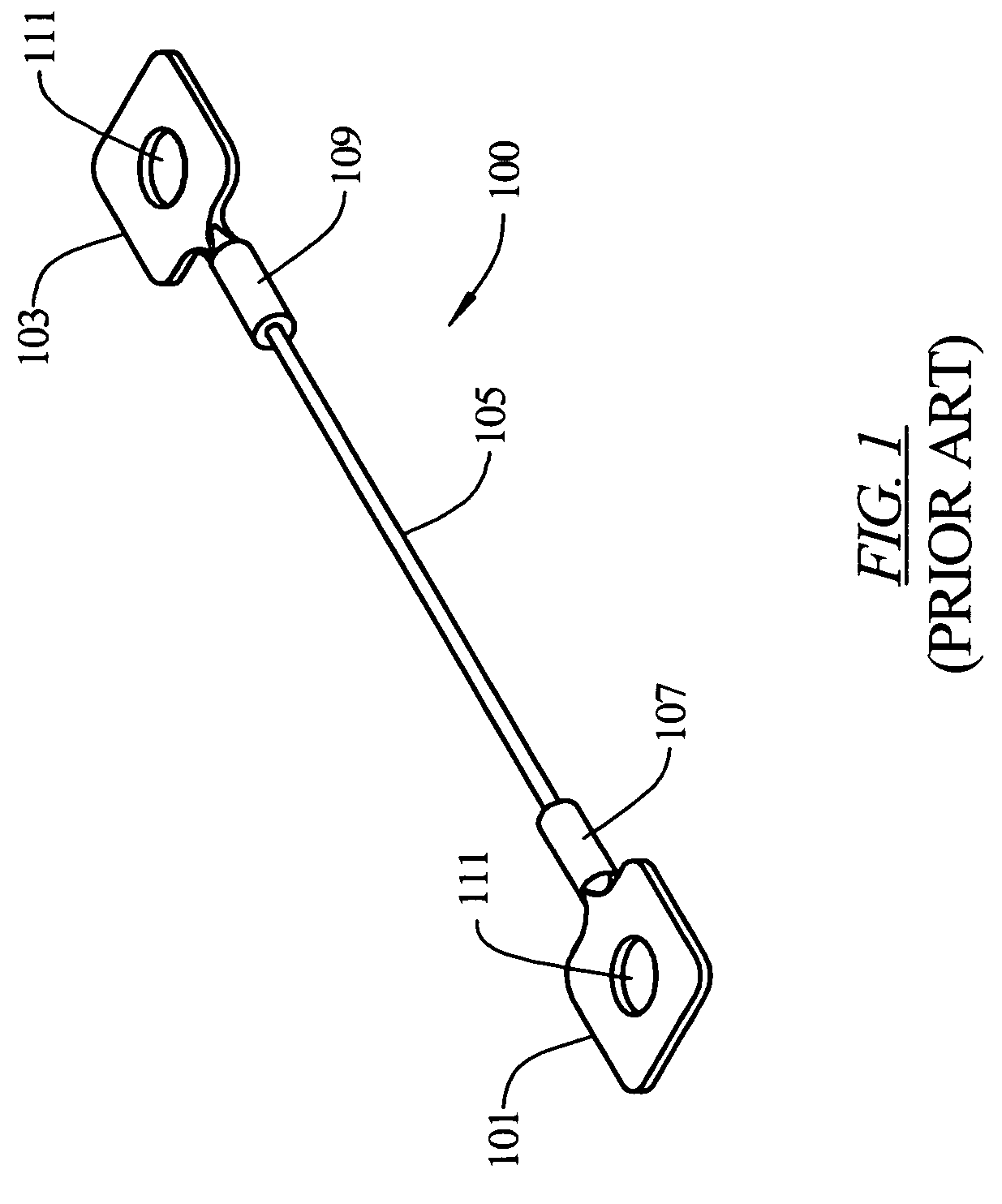

A self-locking wire terminal assembly and a shape memory wire termination system includes an electrical terminal constructed with spring legs which provide two opposing points of contact on a mating electrical conductive pin. The points of contact prevent the pin from being removed. The shape memory termination system is formed by electrically coupling a clip assembly to shape memory wire and to an electrical source. In one embodiment, the shape memory wire causes an actuator to activate when the shape memory wire dissipates electrical power. The terminal assemblies may be manufactured by assembling wire with conduction pads onto a continuous reel. The terminal assemblies may be formed from the reel by trimming wire and linkages between the conduction pads.

Owner:XEROX CORP +1

Electrode for recording and stimulation

ActiveUS8644903B1Fine surfaceImprove ductilityElectroencephalographyHead electrodesInterconnectionEngineering

Owner:PMT

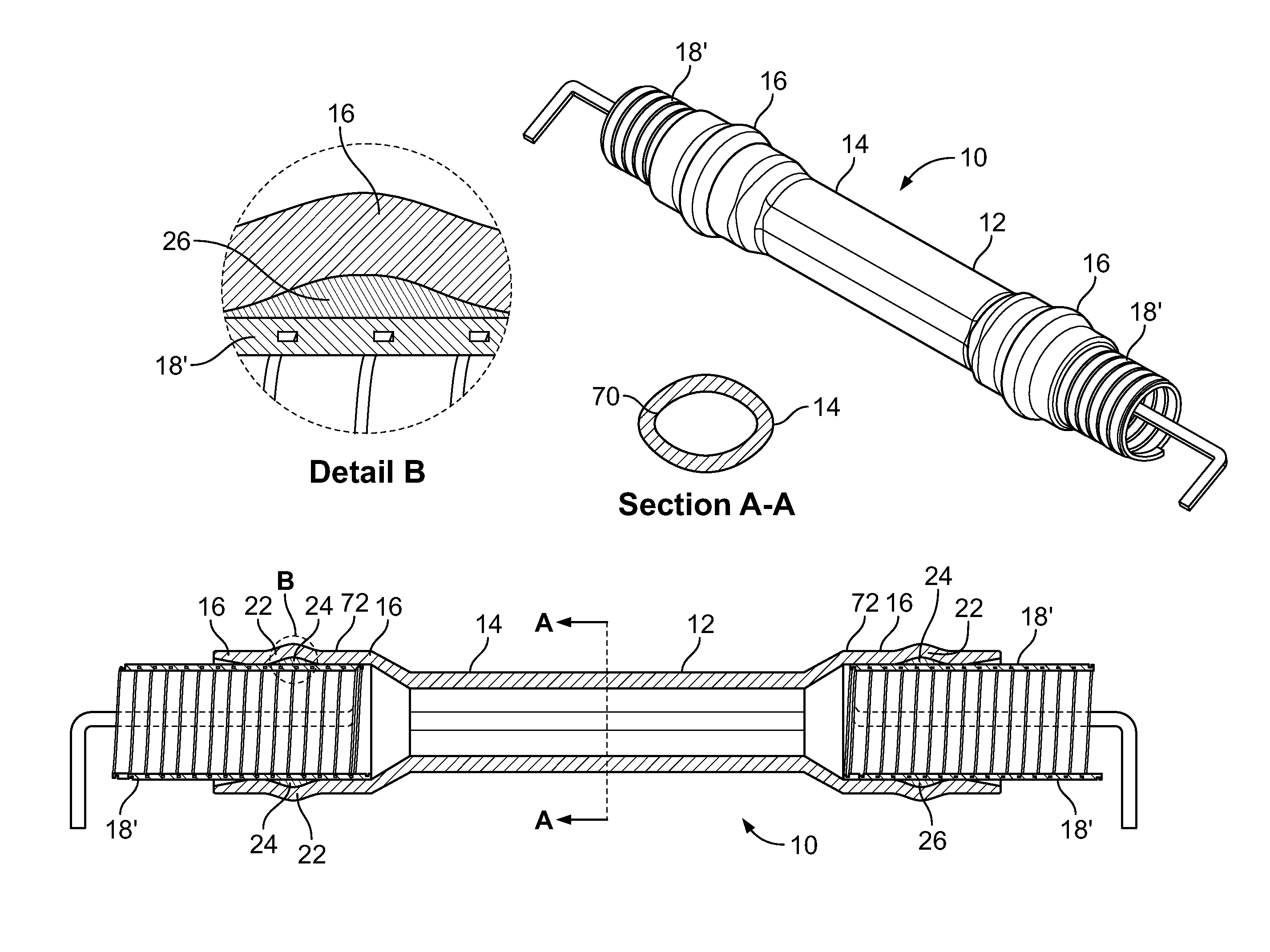

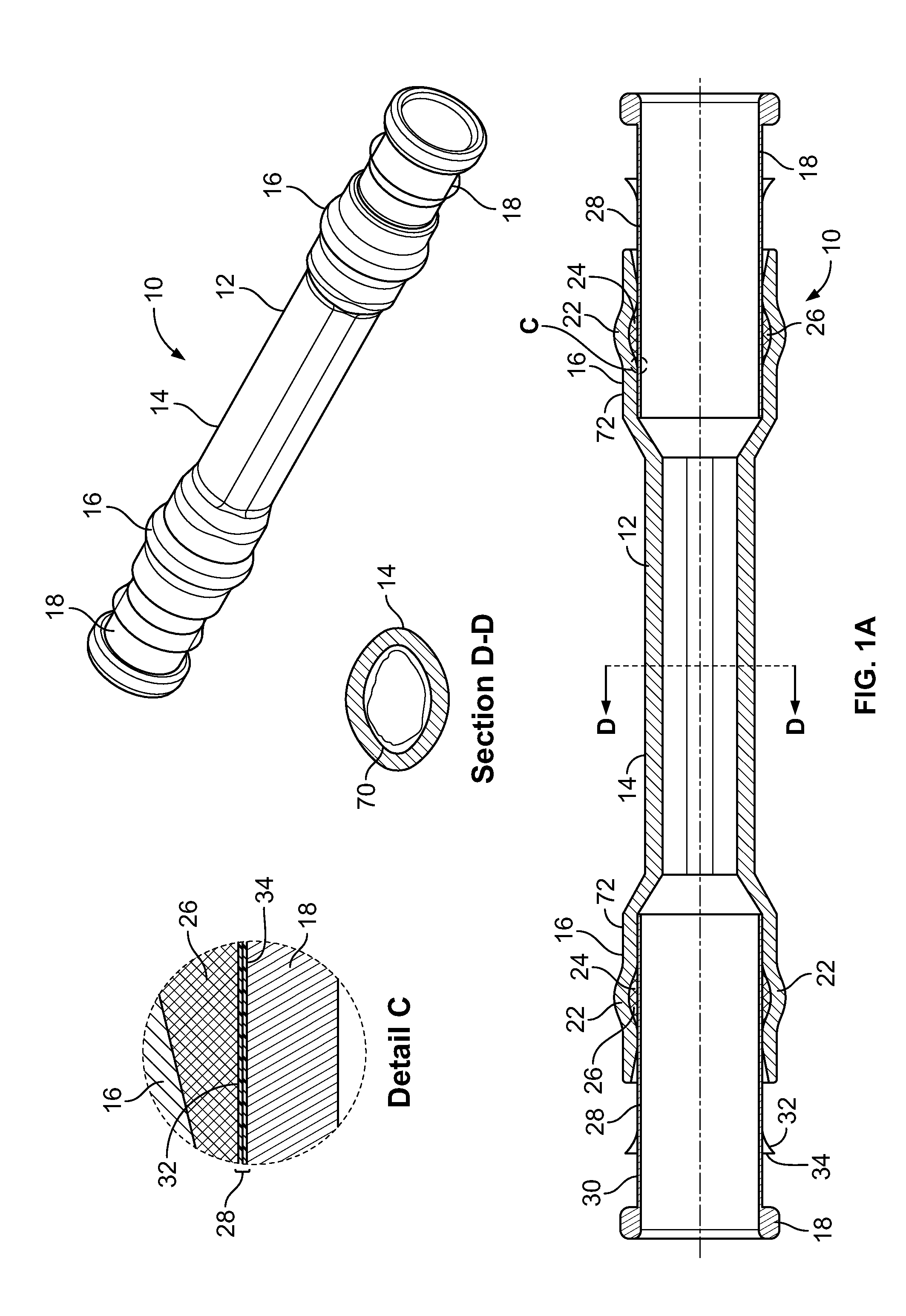

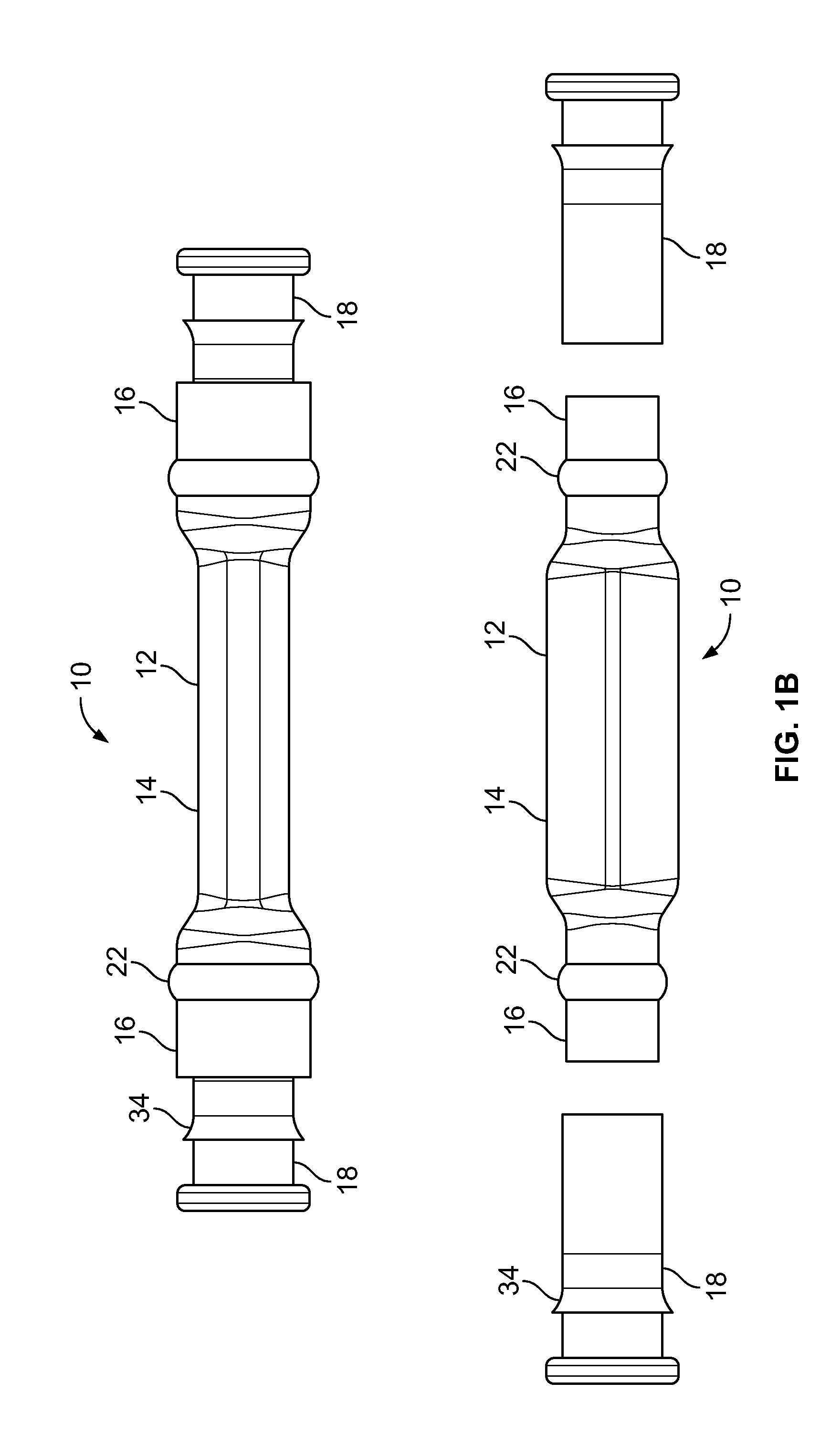

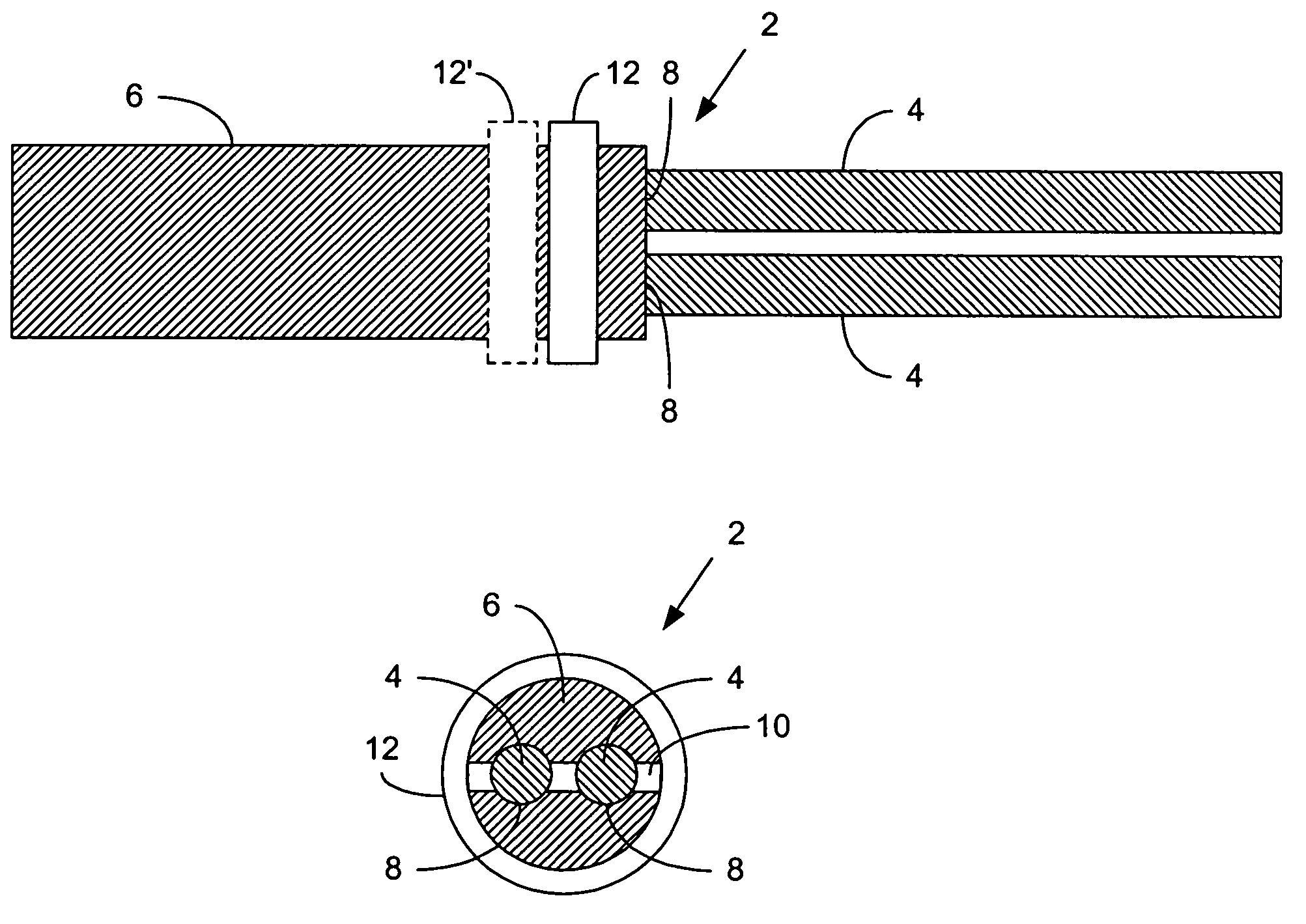

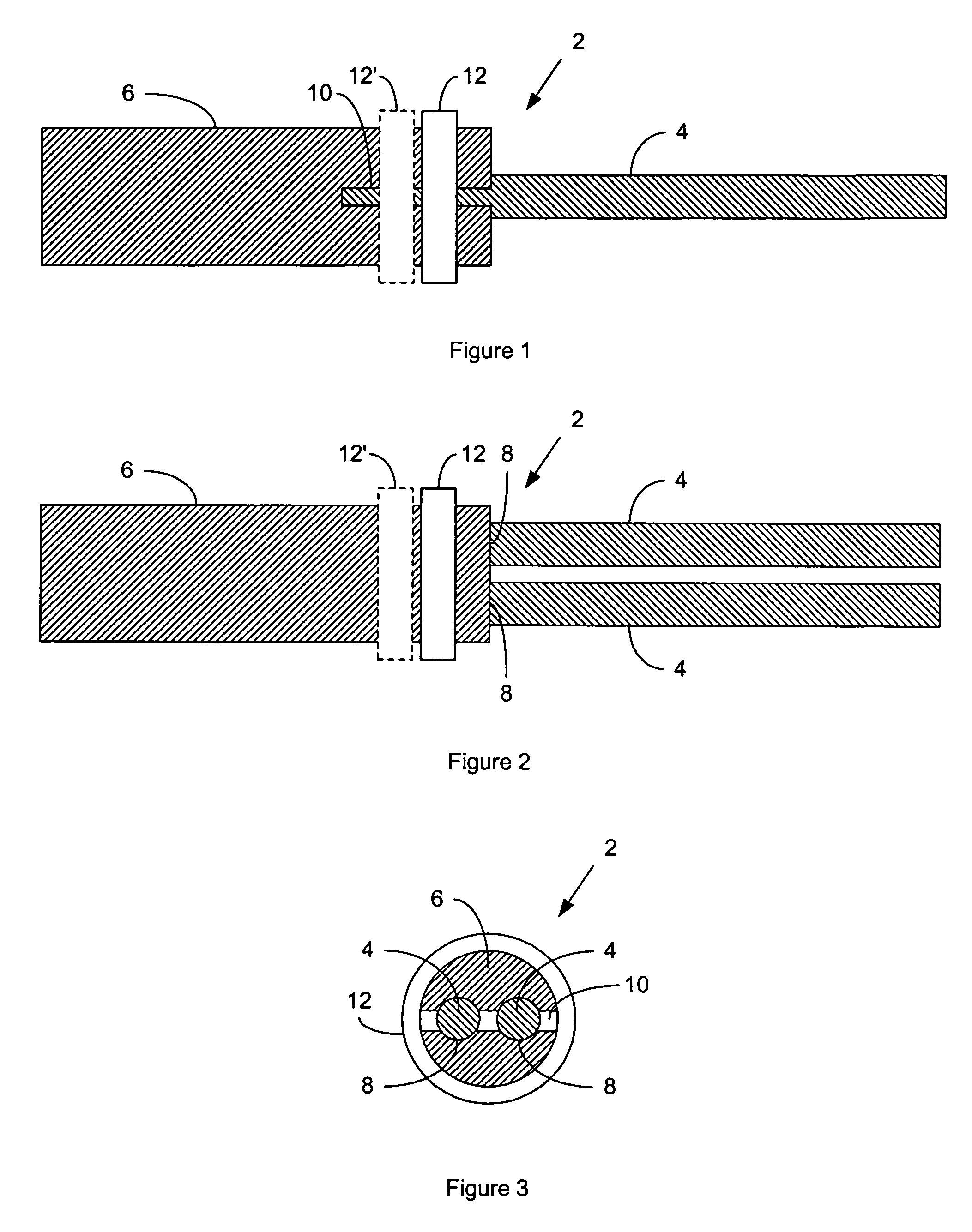

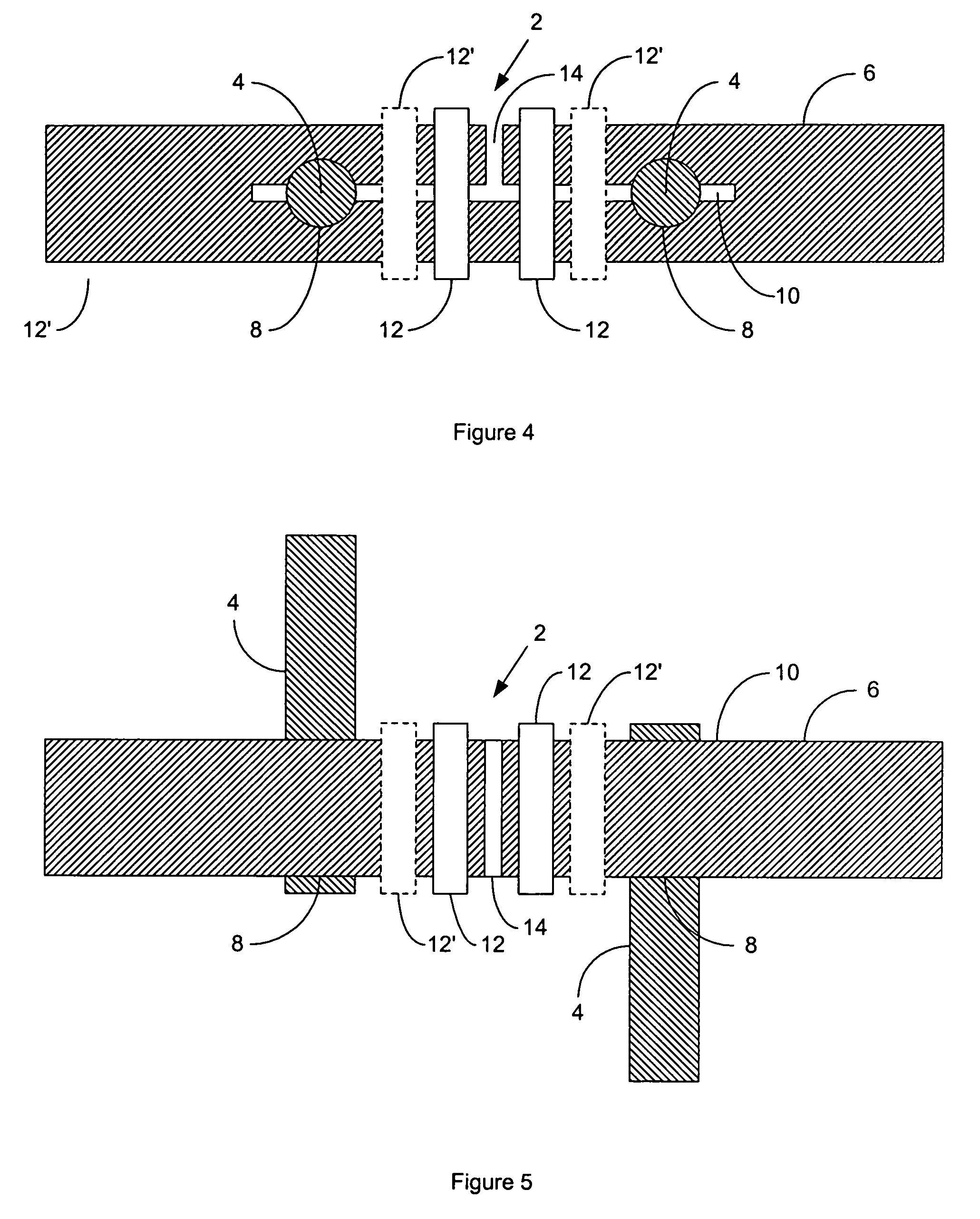

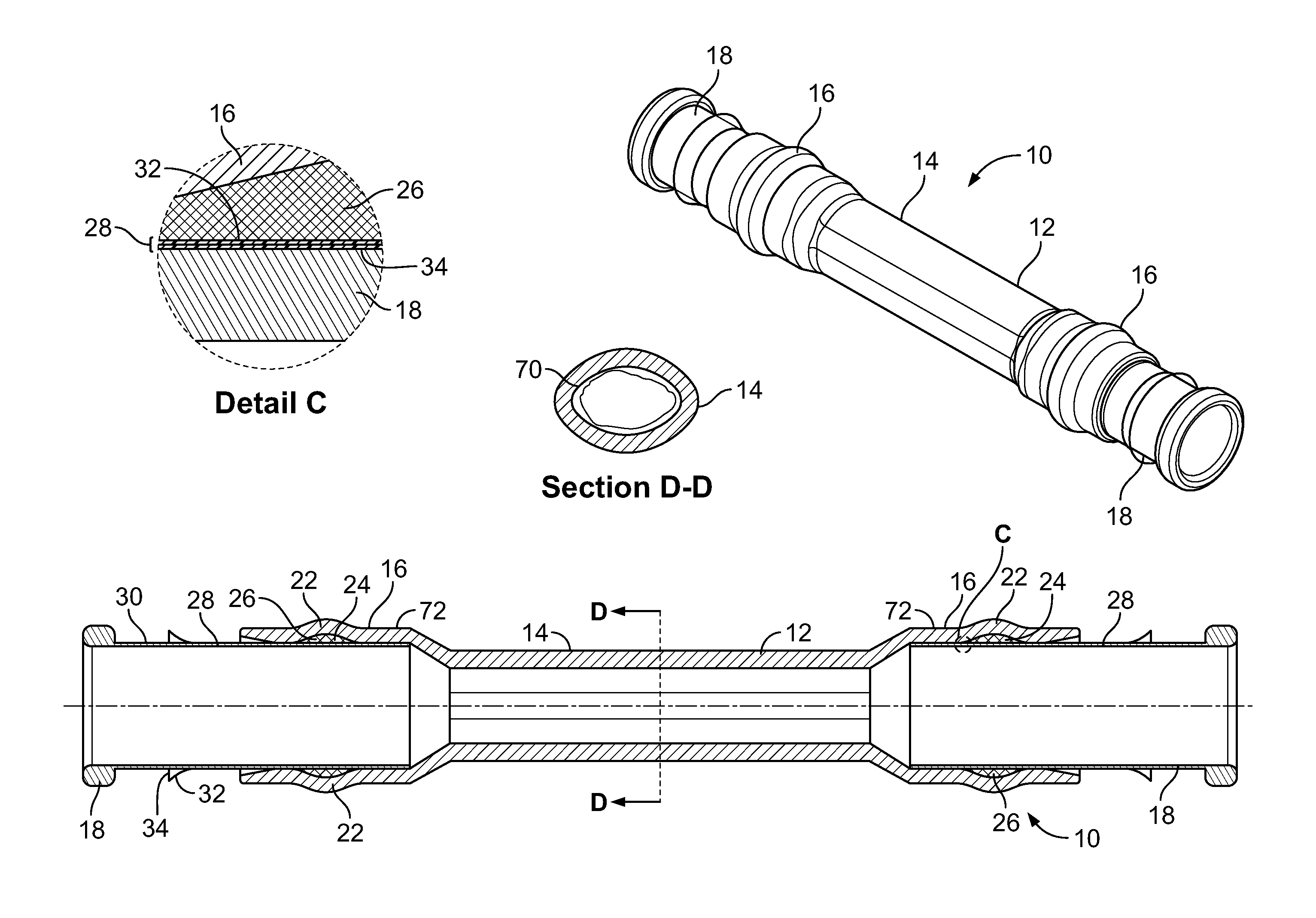

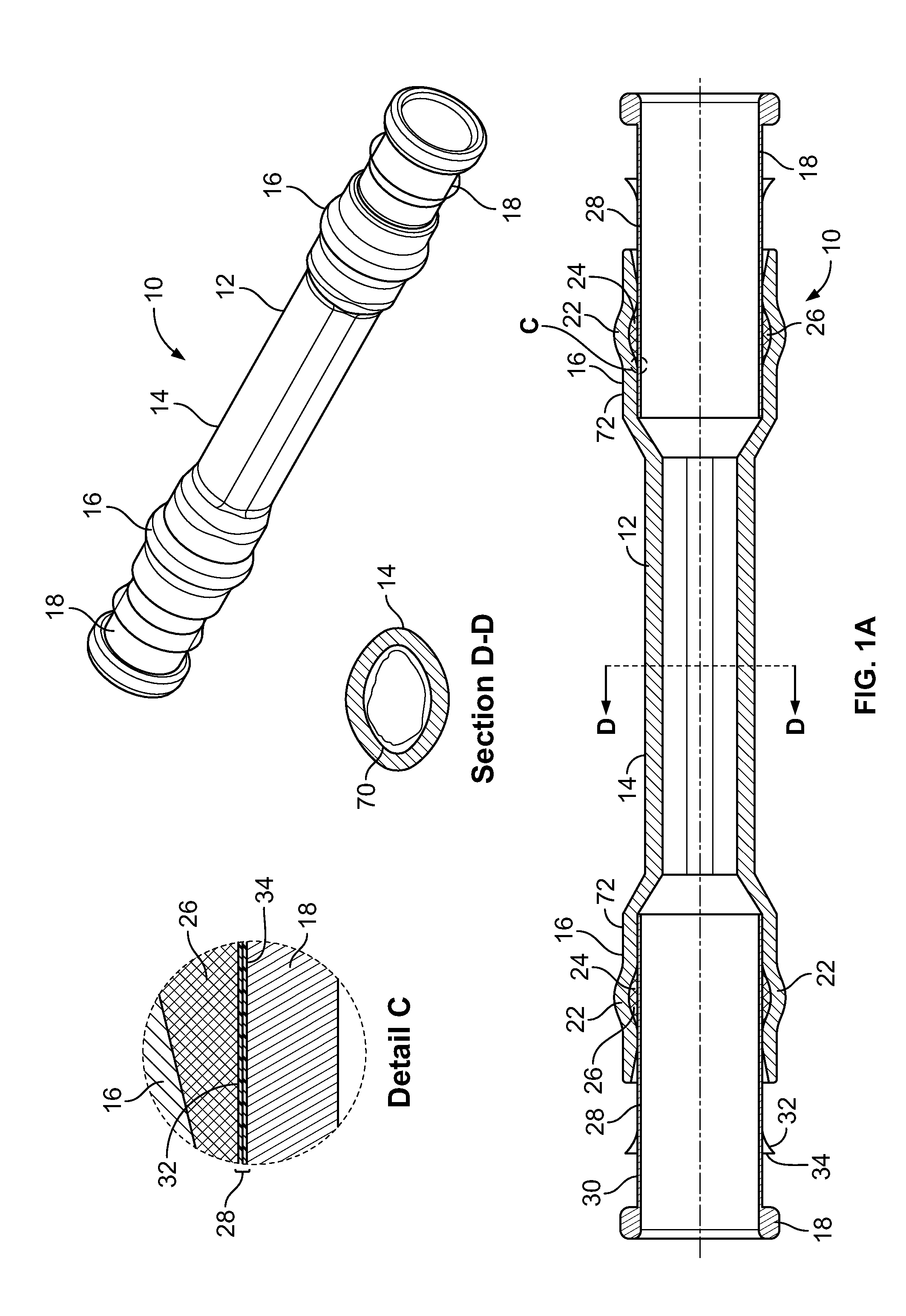

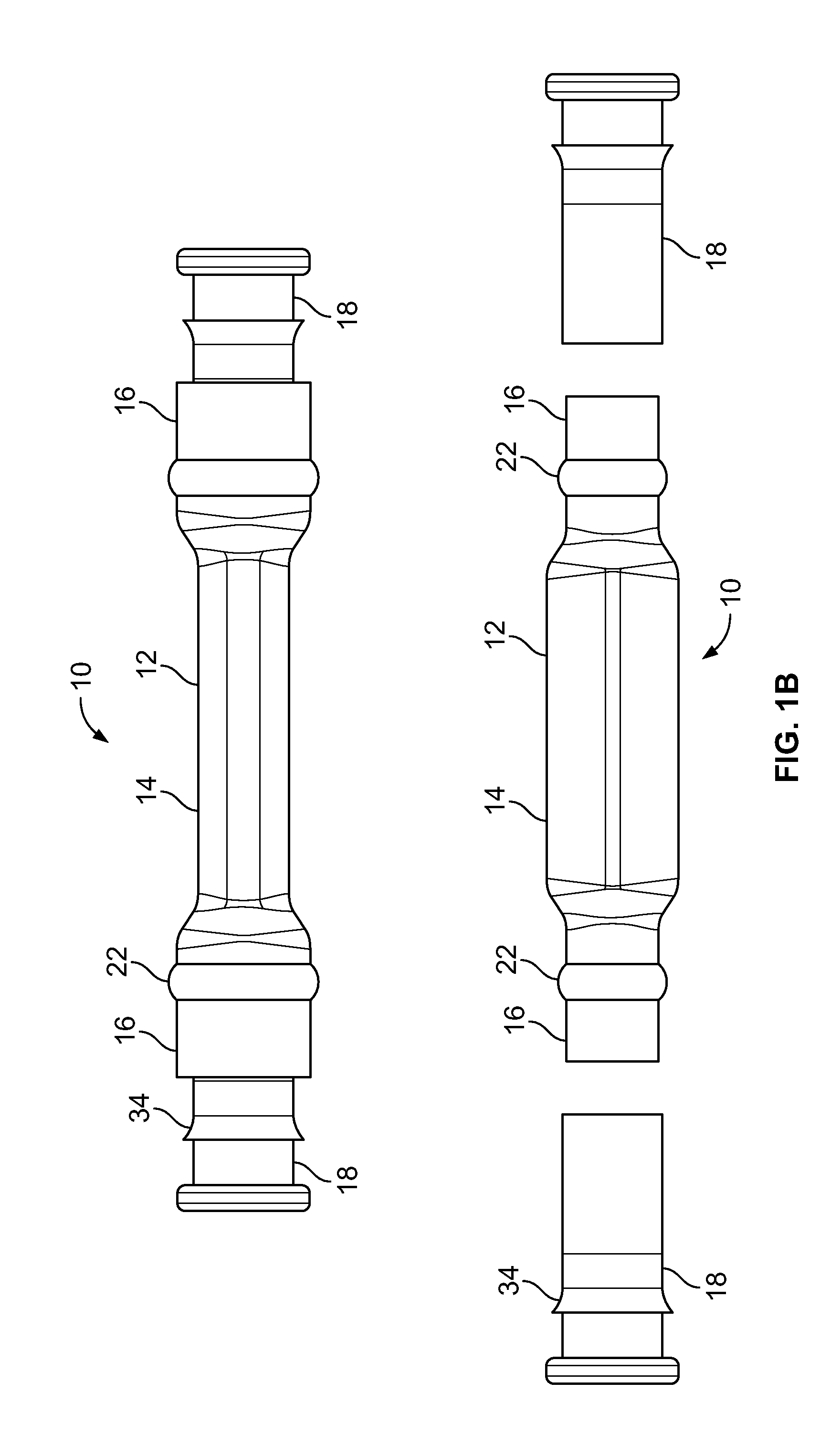

Cold shrinkable secondary splice

InactiveUS8502076B2Shape memory alloy connectionsDustproof/splashproof/drip-proof/waterproof/flameproof connectionInsulation systemBiomedical engineering

An insulating system for splicing a pair of cables having at least partially exposed non-insulating portions joined with a metallic connector is disclosed. The insulating system includes an insulating tube constructed from a shape memory material having a central section having a substantially elliptical cross-section and a pair of end sections with substantially circular cross-sections. A pair of support cores is removably insertable in each of the end sections for holding the end sections in a stretched configuration. When the insulating system is placed about the cables and the connector and the support cores are removed from the end sections, the end sections return to a pre-stretched configuration, thereby completing a splice of the cables.

Owner:RICHARDS MFG CO INC

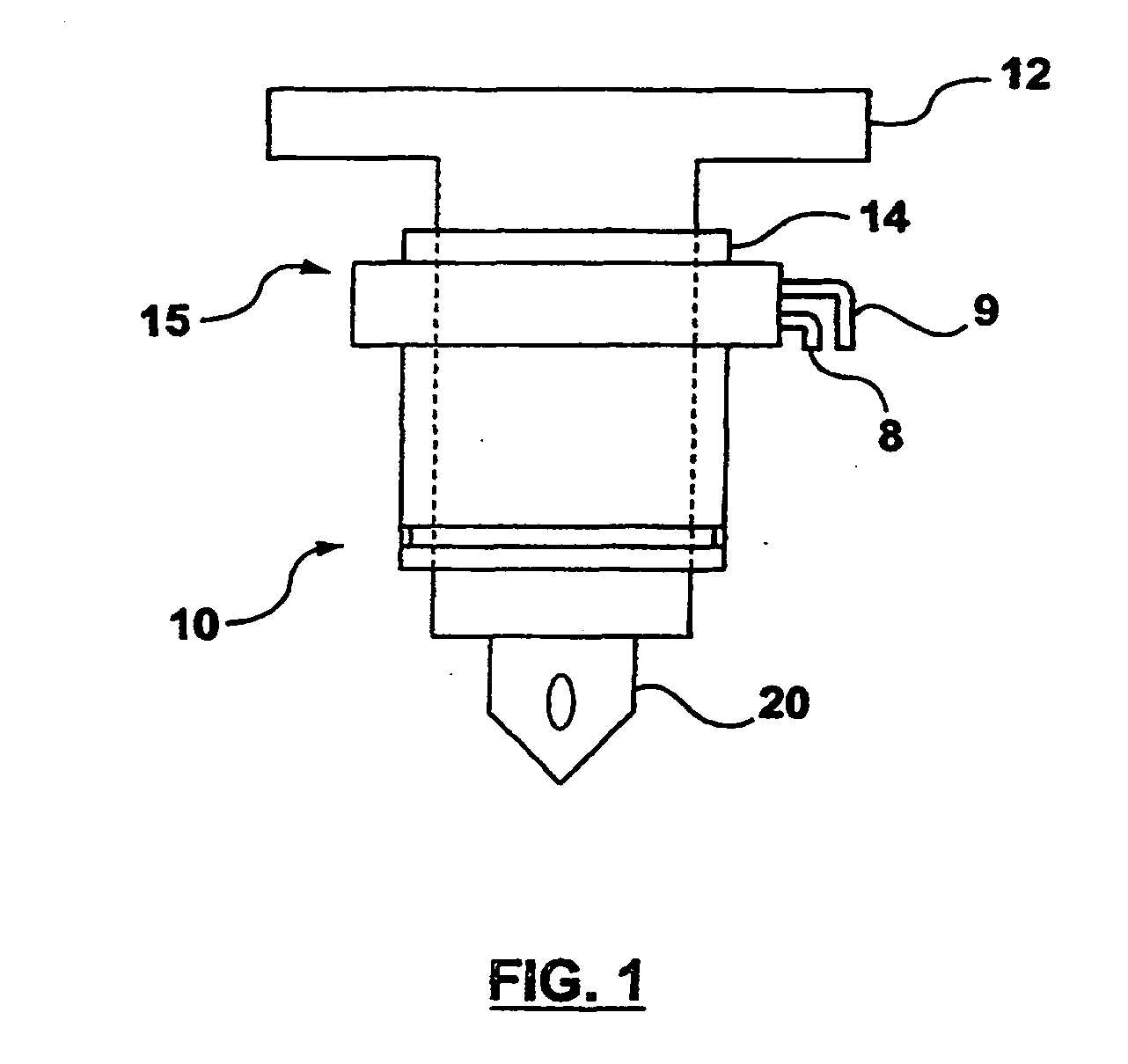

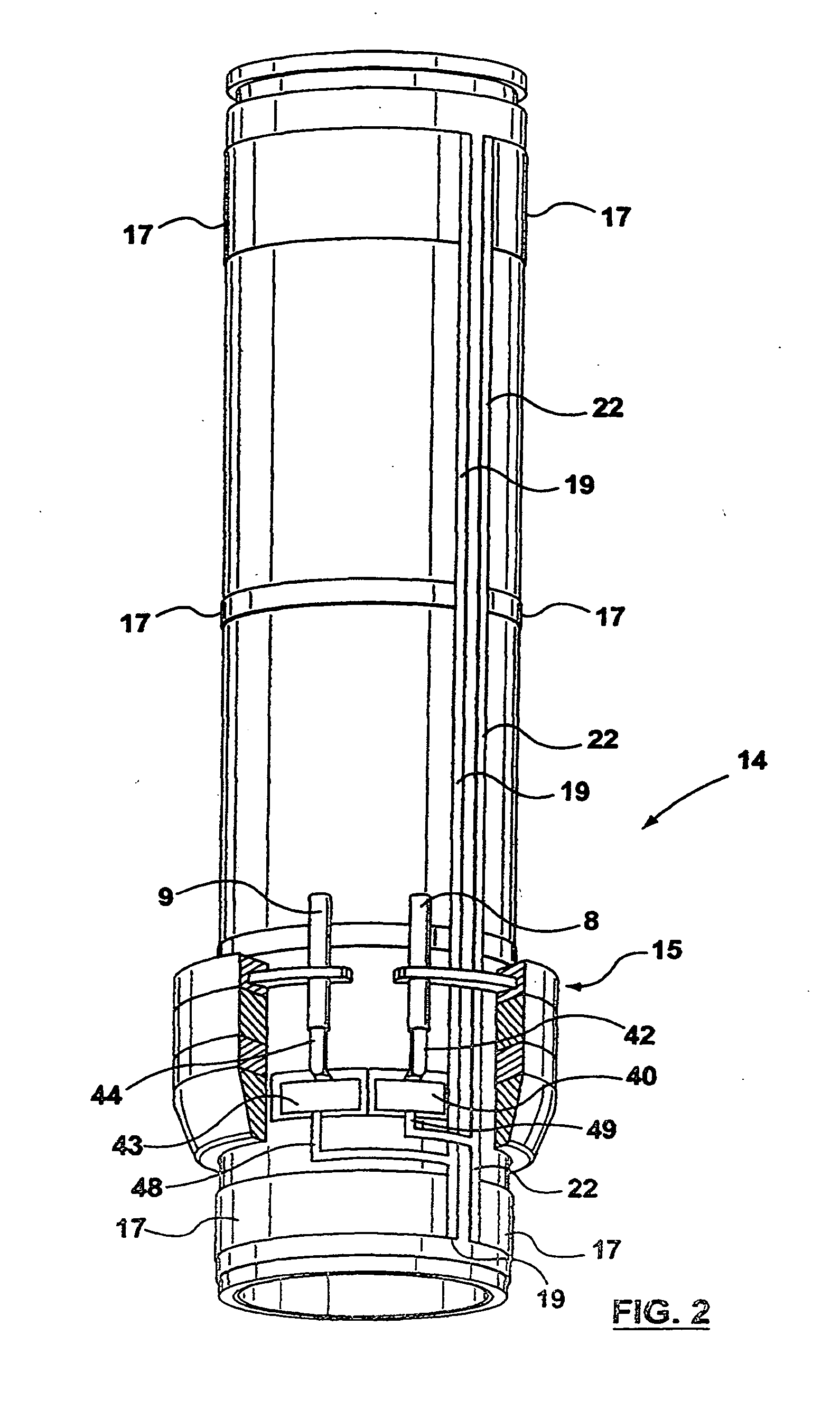

Electrical connector assembly for an arcuate surface in a high temperature environment and an associated method of use

InactiveUS20070077821A1Contact member assembly/disassemblyShape memory alloy connectionsElectrical conductorElectrical connection

An electrical connector assembly for an arcuate surface in a high temperature environment and associated method of use is disclosed for a variety of applications. This can include, but is not limited to, an injection molding heater assembly having at least one heater and an injection molding heater and nozzle assembly having at least one heater and a nozzle that is in thermal communication with the at least one heater. This at least one electrical connector, having a first electrical conductor that is electrically connectable to at least one first conductive portion at least one arcuate surface and a second electrical conductor that is electrically connectable to at least one second conductive portion on the at least one arcuate surface, and at least one disconnect mechanism positioned adjacent to the at least one electrical connector and in electrical connection with the first electrical conductor and the second electrical conductor.

Owner:HUSKY INJECTION MOLDING SYST LTD

Gas tight electrical connections with shape memory retainers

InactiveUS7207816B1Shape memory alloy connectionsCoupling contact membersElectrical connectionEngineering

A gas-tight electrical connection comprises a conductive substrate with at least one socket for receiving an associated wire, at least one slot in the conductive substrate that penetrates each socket and at least one SMA force ring that slides over the conductive substrate near each slot to clamp the electrical connection when heated to its austenitic state.

Owner:HAMILTON SUNDSTRAND CORP

Cold shrinkable secondary splice

InactiveUS20110180323A1Shape memory alloy connectionsDustproof/splashproof/drip-proof/waterproof/flameproof connectionInsulation systemBiomedical engineering

An insulating system for splicing a pair of cables having at least partially exposed non-insulating portions joined with a metallic connector is disclosed. The insulating system includes an insulating tube constructed from a shape memory material having a central section having a substantially elliptical cross-section and a pair of end sections with substantially circular cross-sections. A pair of support cores is removably insertable in each of the end sections for holding the end sections in a stretched configuration. When the insulating system is placed about the cables and the connector and the support cores are removed from the end sections, the end sections return to a pre-stretched configuration, thereby completing a splice of the cables.

Owner:RICHARDS MANUFACTURING COMPANY INC

Self-locking wire terminal and shape memory wire termination system

A self-locking wire terminal assembly and a shape memory wire termination system includes an electrical terminal constructed with spring legs which provide two opposing points of contact on a mating electrical conductive pin. The points of contact prevent the pin from being removed. The shape memory termination system is formed by electrically coupling a clip assembly to shape memory wire and to an electrical source. In one embodiment, the shape memory wire causes an actuator to activate when the shape memory wire dissipates electrical power. The terminal assemblies may be manufactured by assembling wire with conduction pads onto a continuous reel. The terminal assemblies may be formed from the reel by trimming wire and linkages between the conduction pads.

Owner:XEROX CORP +1

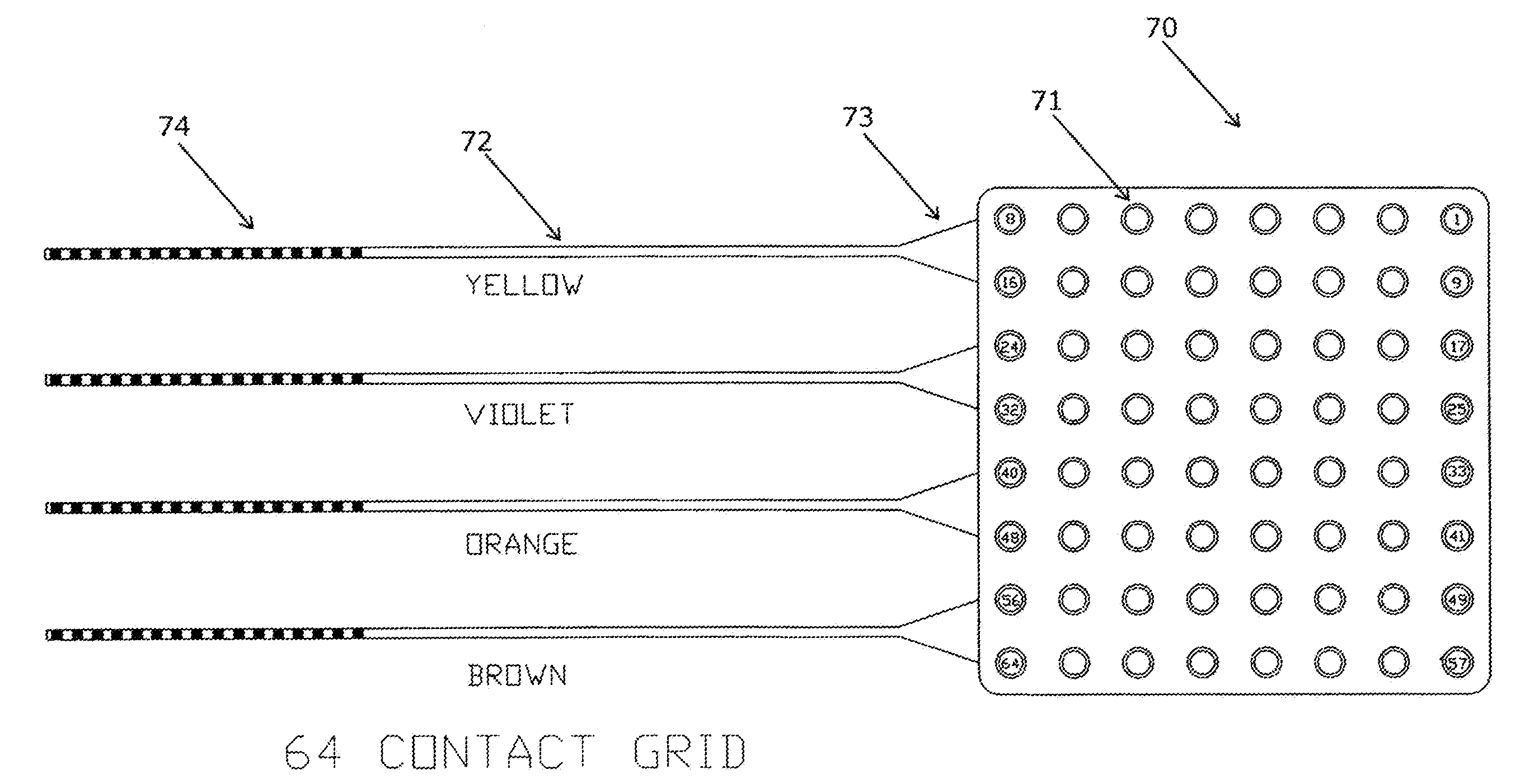

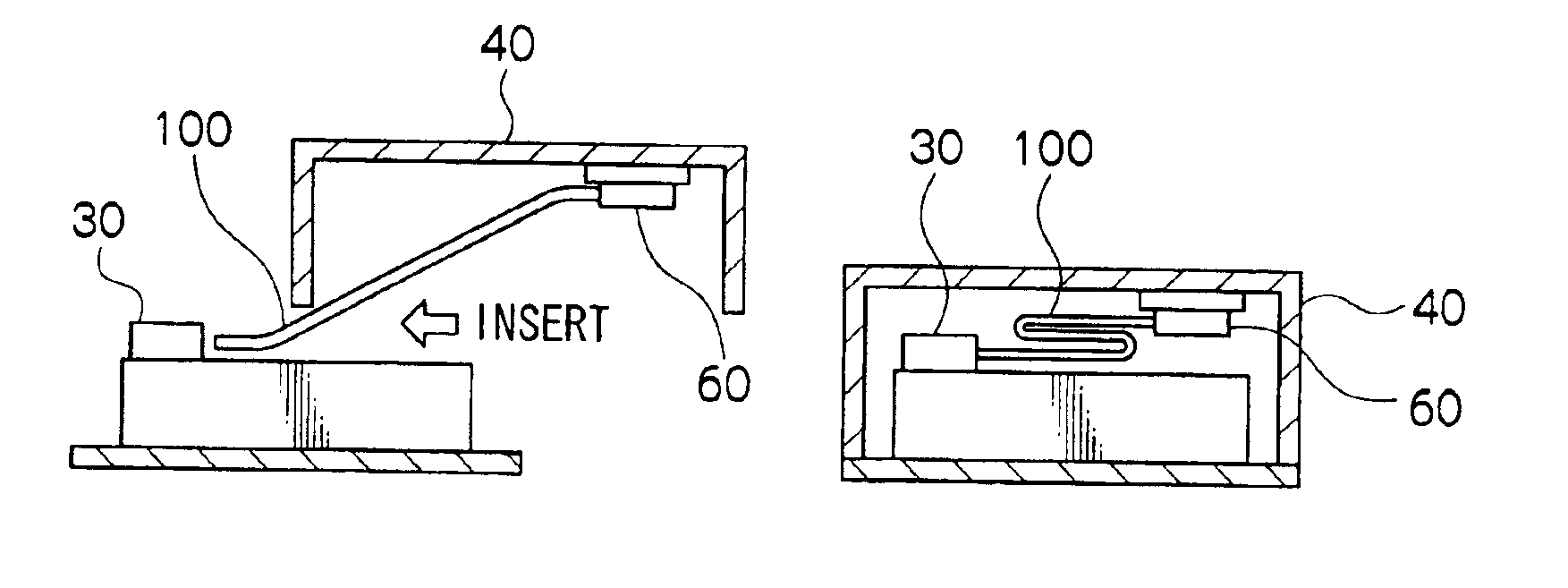

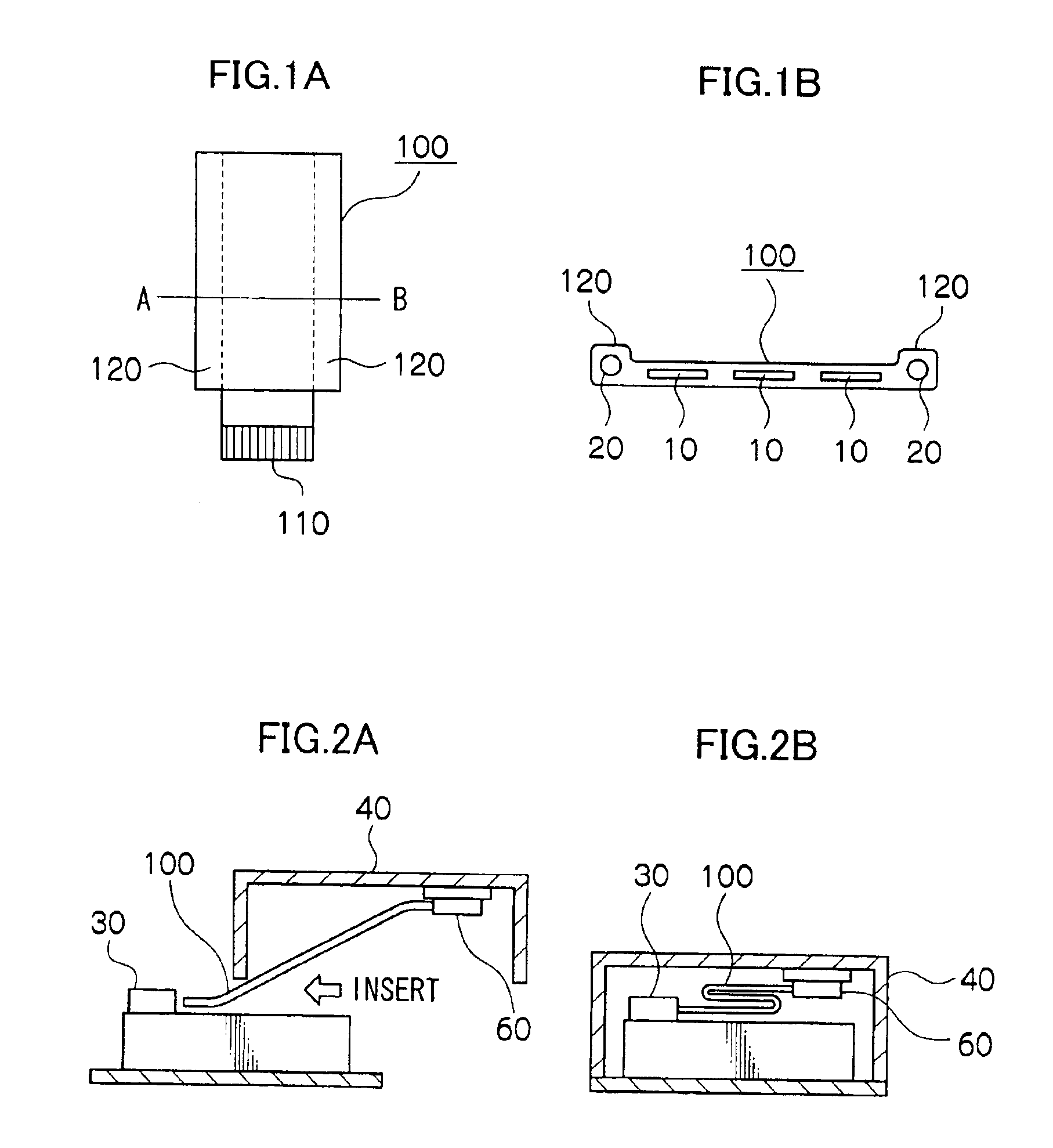

Flexible print circuit, wire harness, and wiring structure using shape memory material

InactiveUS6906262B2Reduce operating costsStable and reliableShape memory alloy connectionsPrinted circuit aspectsElectronic instrumentShape-memory alloy

In a flexible print circuit having a plurality of signal wires, core wires formed from a shape memory material are provided on the two end portions thereof in the direction of width, and are caused to memorize a wiring completion shape within an electronic instrument in advance. In a wire harness having a plurality of signal wires, core wires formed from a shape memory alloy are disposed on the two sides of the planar signal wire array, or positioned along the central axis of the signal wires which are bundled into circular form. A guide frame for guiding a wire harness having a plurality of signal wires and which is caused to memorize in advance a shape which removes the wire harness from the movement range of a movable component within the electronic instrument.

Owner:FUJIFILM CORP +1

Electrode for recording and stimulation

ActiveUS8435079B1Enhanced surface electrodeImprove ductilityElectroencephalographyHead electrodesEngineeringInterconnection

Improved electrode assemblies for recording and stimulation. Cortical and depth electrode structures are provided as well as inline interconnection systems. Methods of manufacture are further taught to provide enhanced surfaces for cortical electrodes. The inline interconnection systems include connector assembly embodiments for electrode leads which have structure providing ease of EEG recording as well as stimulation.

Owner:PMT

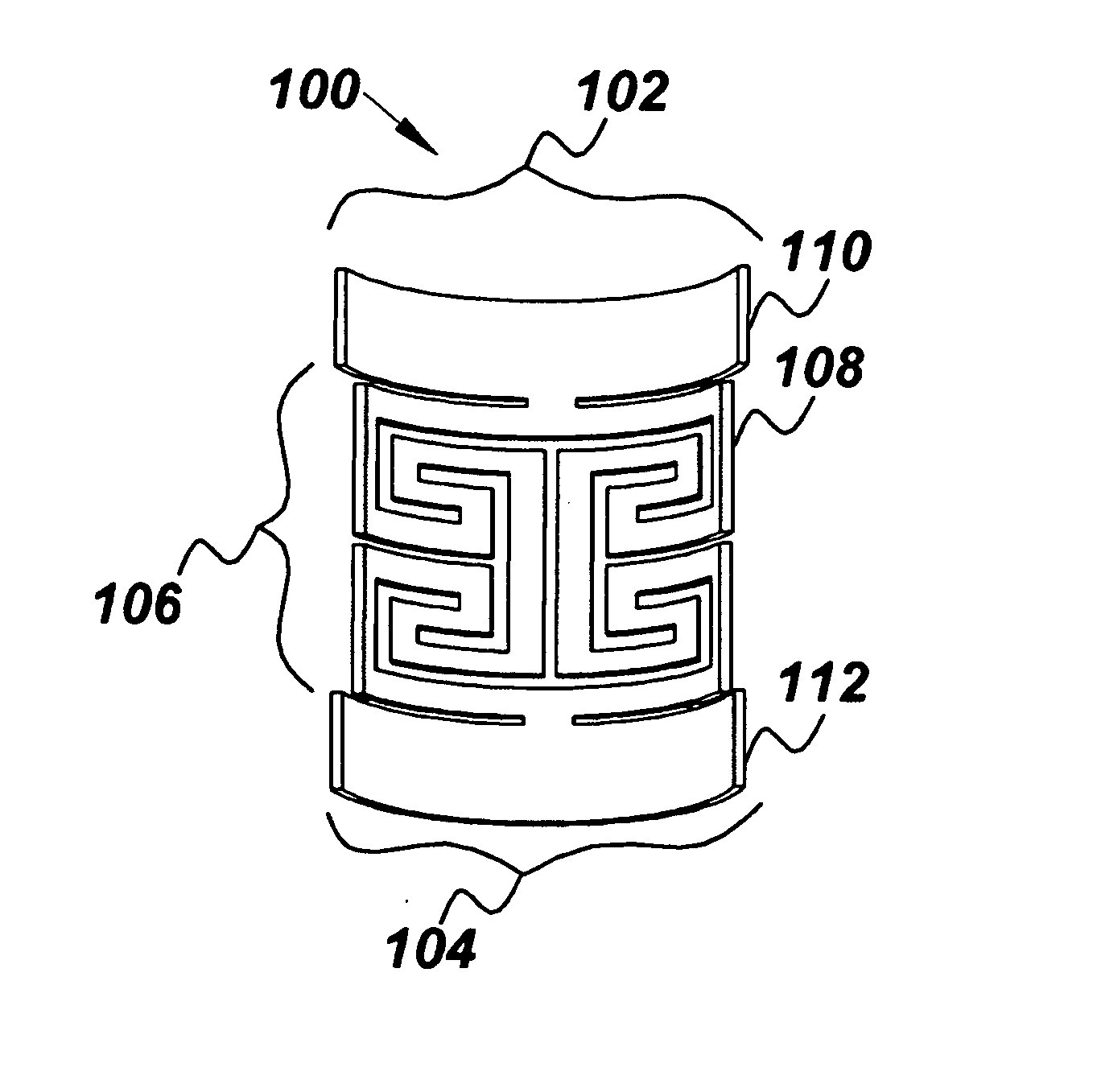

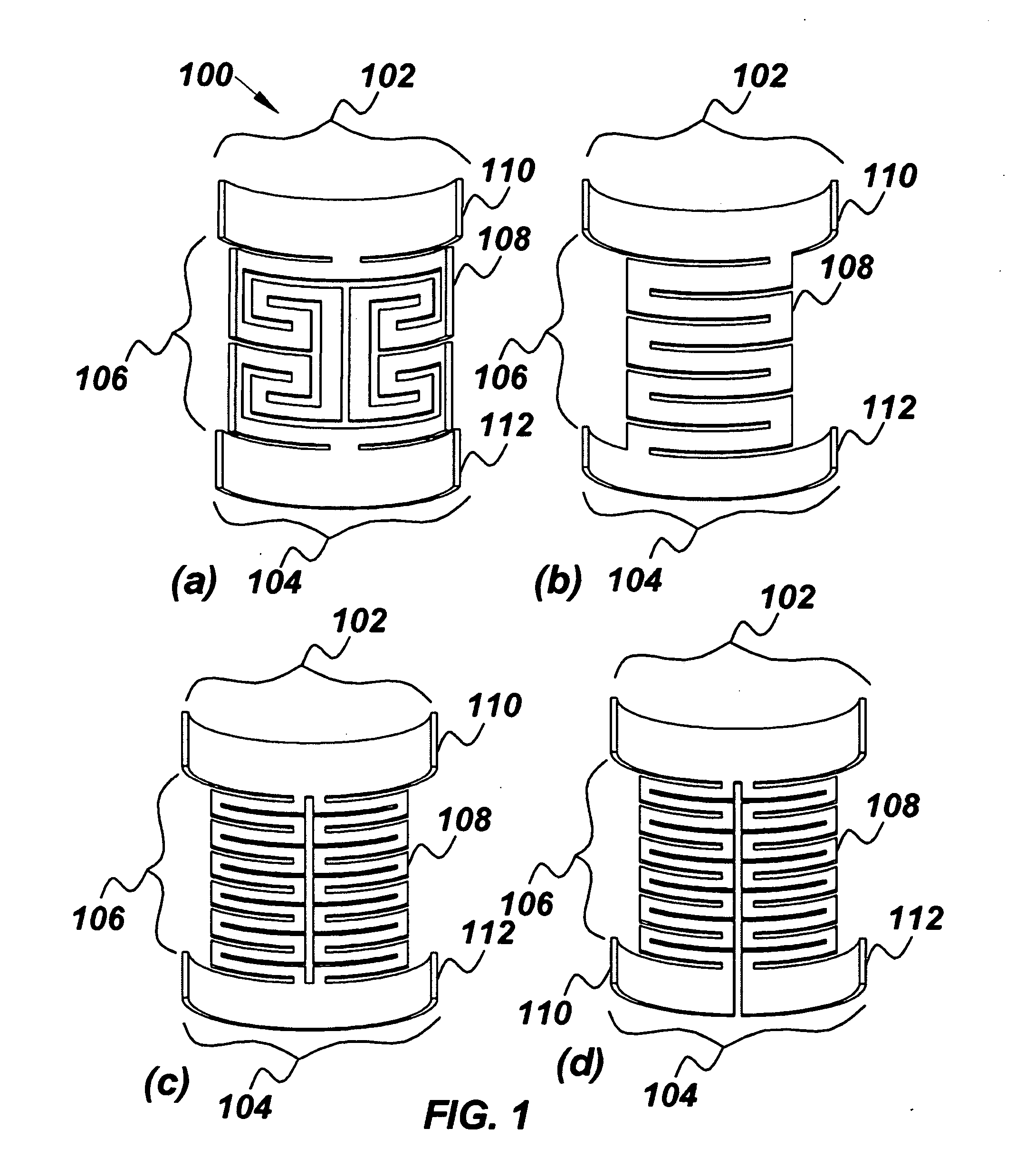

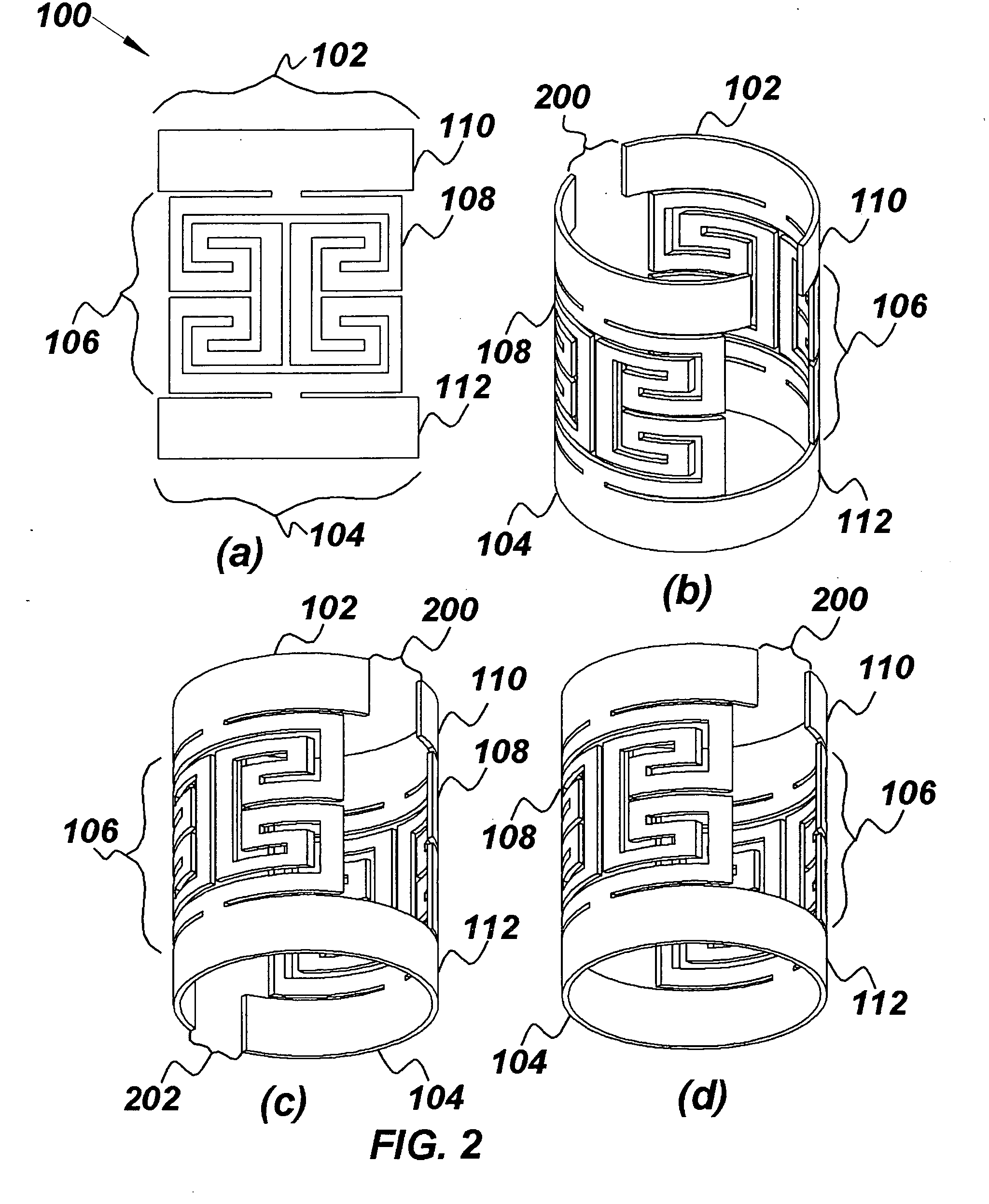

Tubular compliant shape memory alloy actuators

A shape memory alloy (SMA) actuator made from tubular structures is disclosed. The current invention is a tubular monolithic SMA actuator made from a tubular monolithic SMA substrate of NiTi, CuAlNi, CuAl, CuZnAl, TiV, or TiNb. The tubular monolithic SMA actuator has a first end, a second end and a middle portion, and can be made out or a substrate with a cross-section shape such as a circle, an ellipse, a rectangle or any irregular shape. The middle portion is formed into an actuator pattern that maintains unity and electrical continuity, along the path of the actuator pattern, with the first end and second end. The actuator pattern can be any number of patterns, for example, a Greek key pattern or a zigzag pattern. A first electrode is optionally formed in the first end and a second electrode is formed in the second end of the tubular monolithic SMA actuator.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

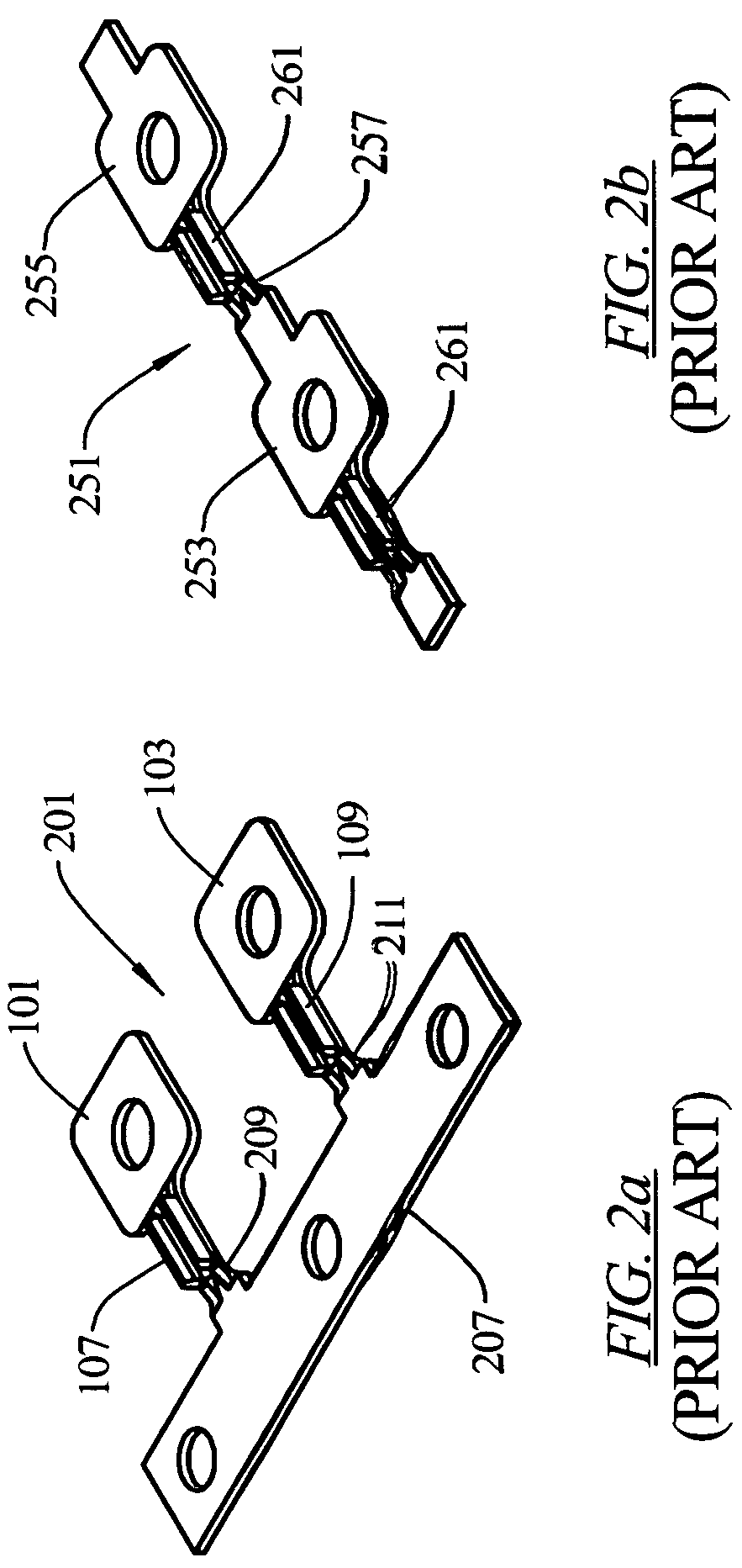

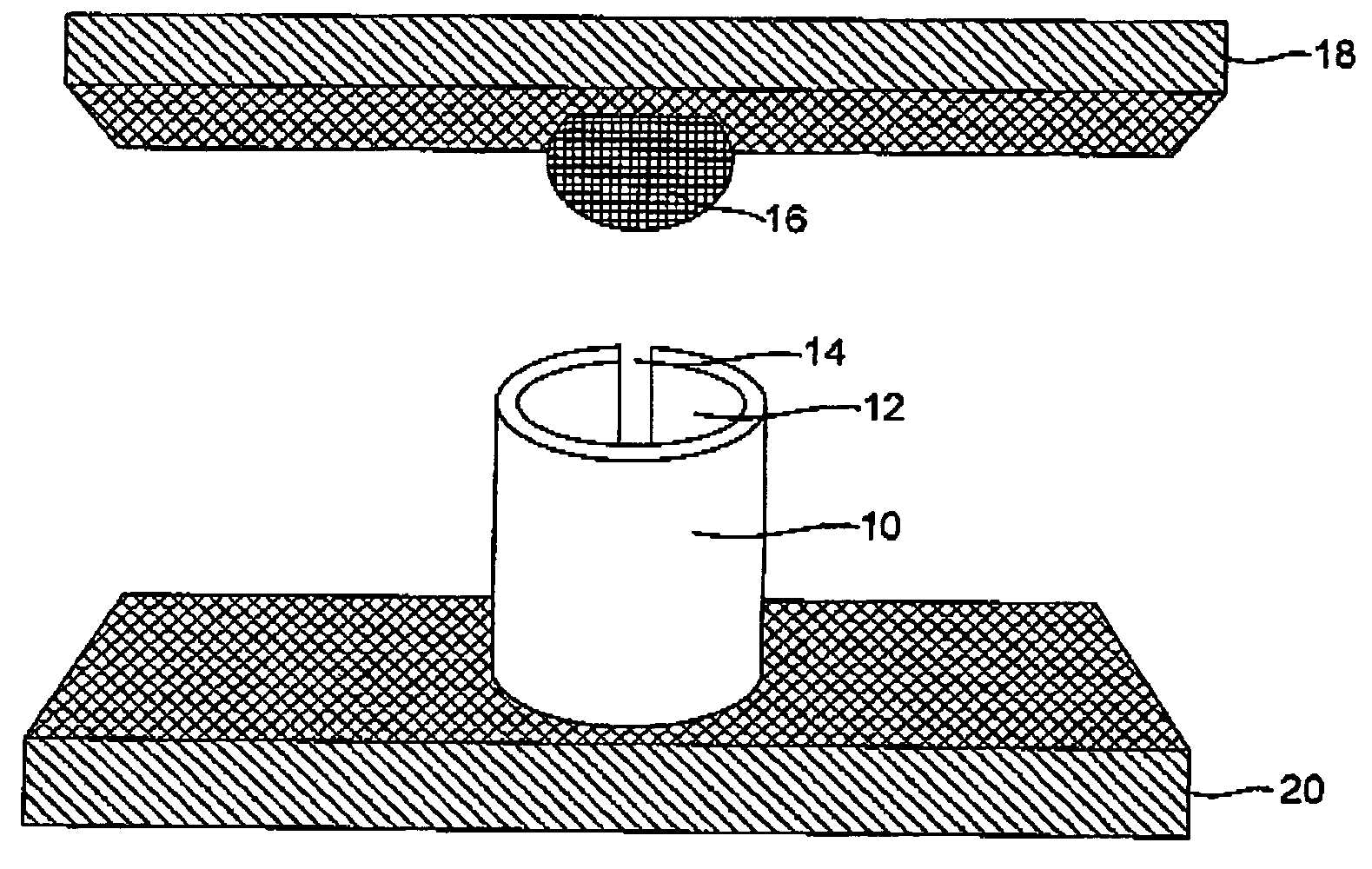

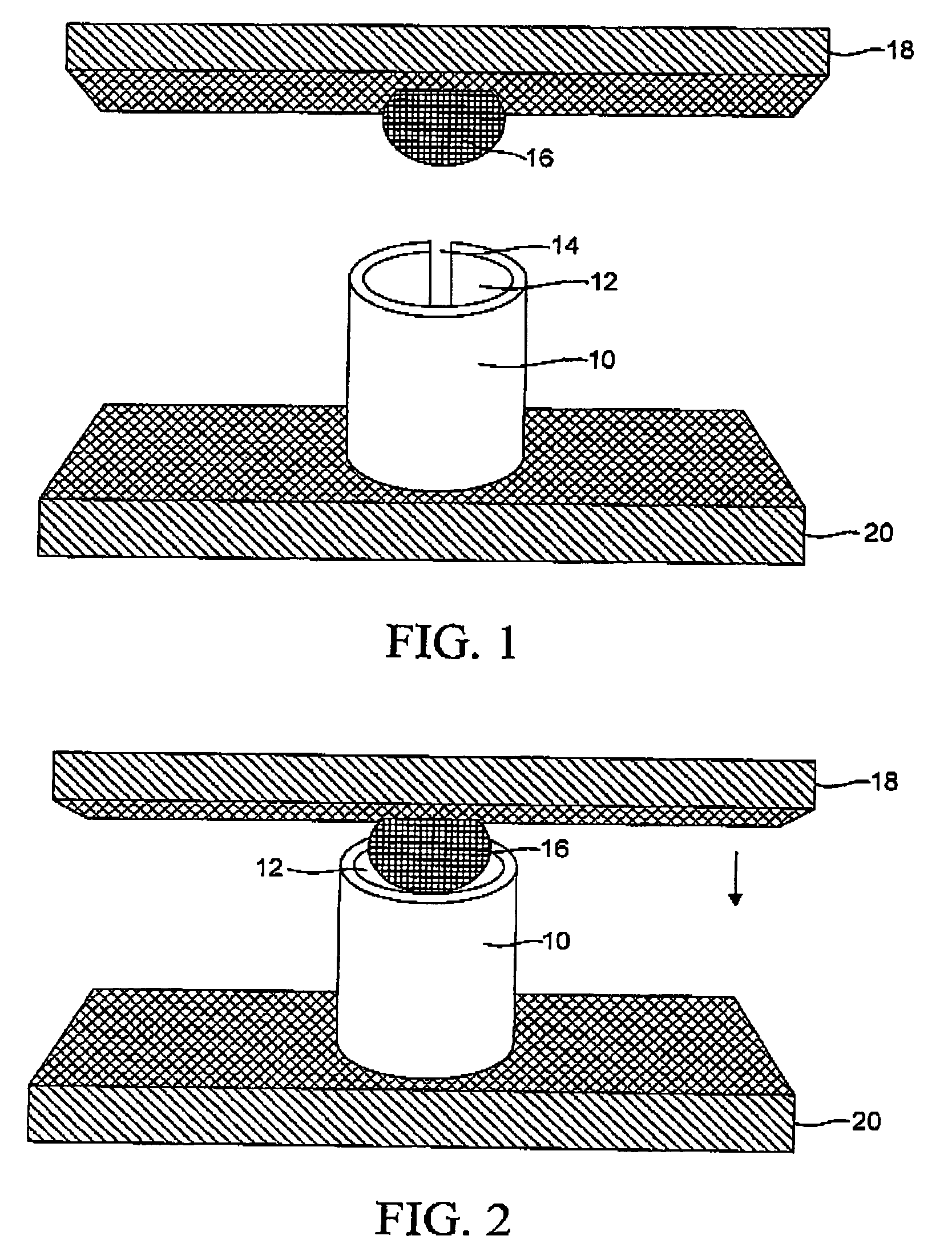

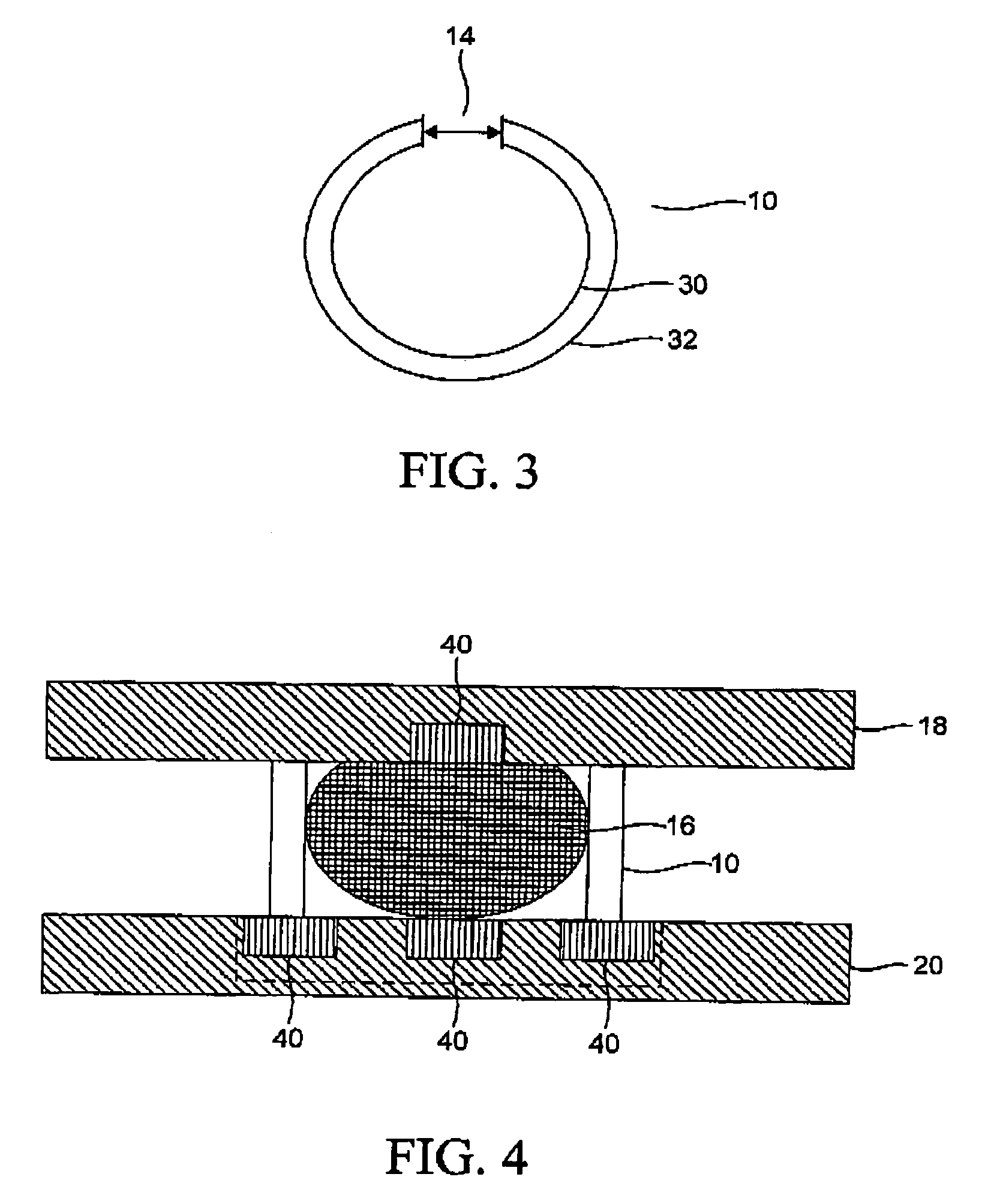

Temperature dependent semiconductor module connectors

InactiveUS7137826B2Semiconductor/solid-state device detailsShape memory alloy connectionsSemiconductor packageEngineering

A method and structure is disclosed for forming a removable interconnect for semiconductor packages, where the connector is adapted to repeatedly change from a first shape into a second shape upon being subjected to a temperature change and to repeatedly return to the first shape when not being subjected to the temperature change. The connector can be disconnected when the connector is in its second shape and the connector cannot be disconnected when the connector is in its first shape.

Owner:IBM CORP

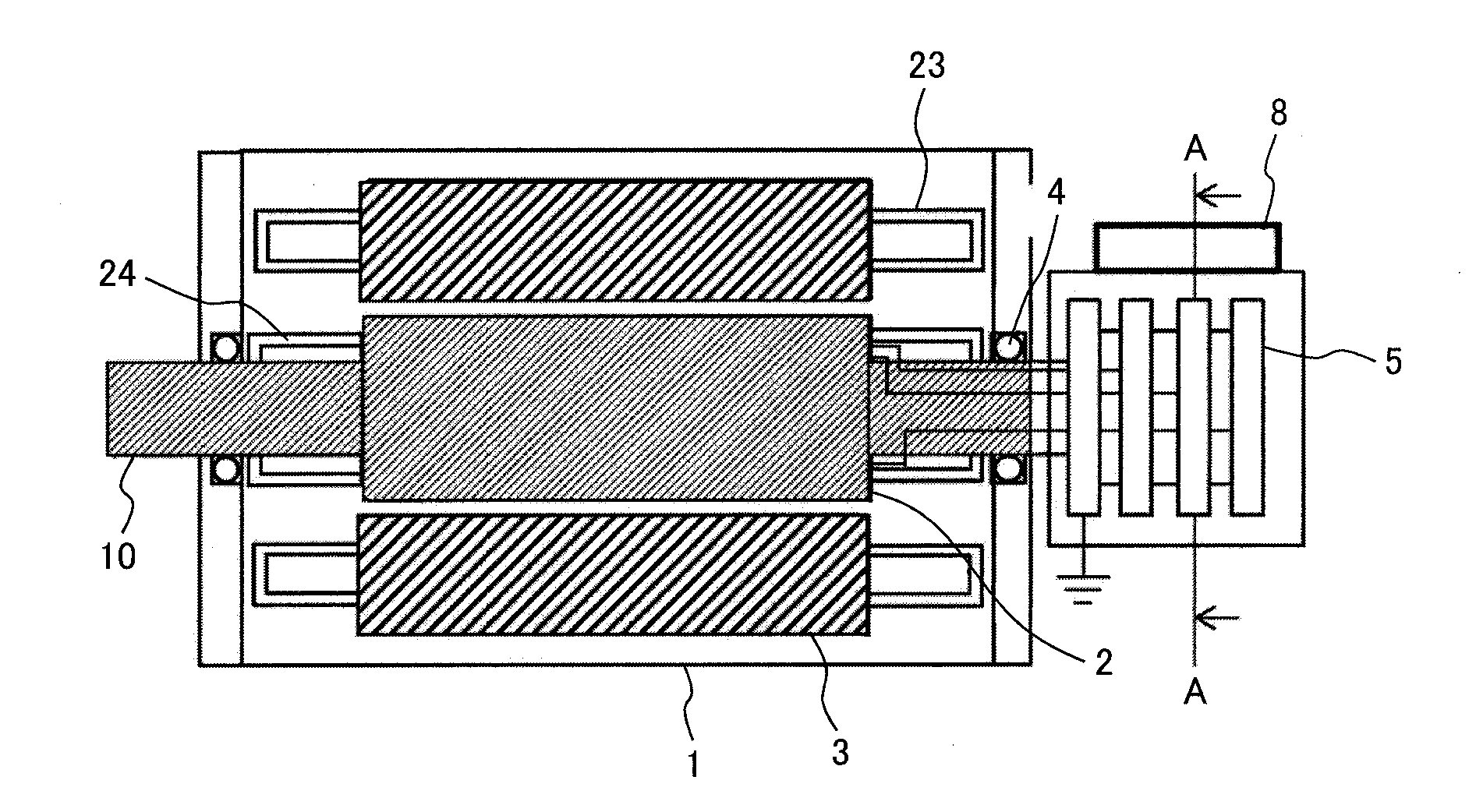

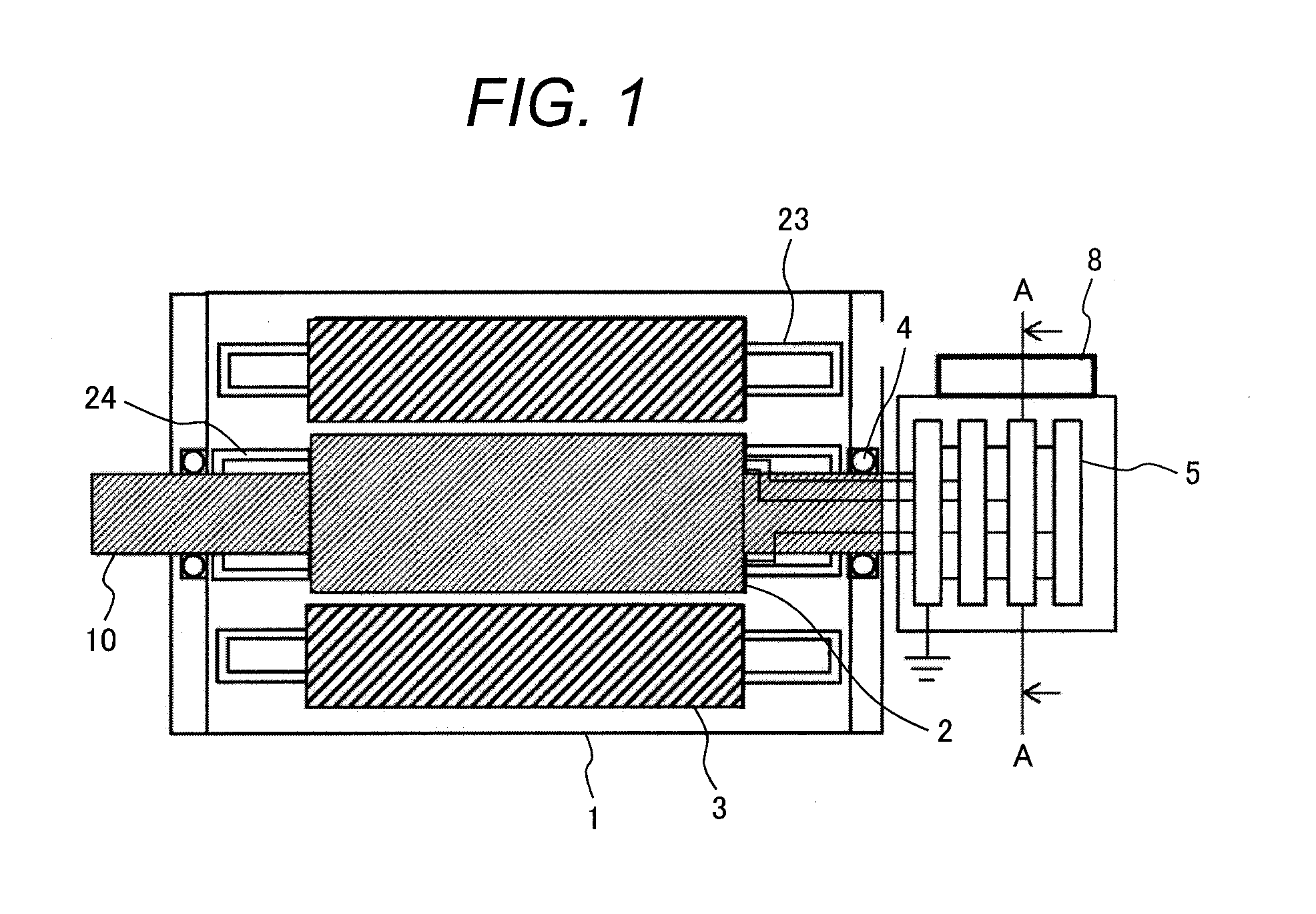

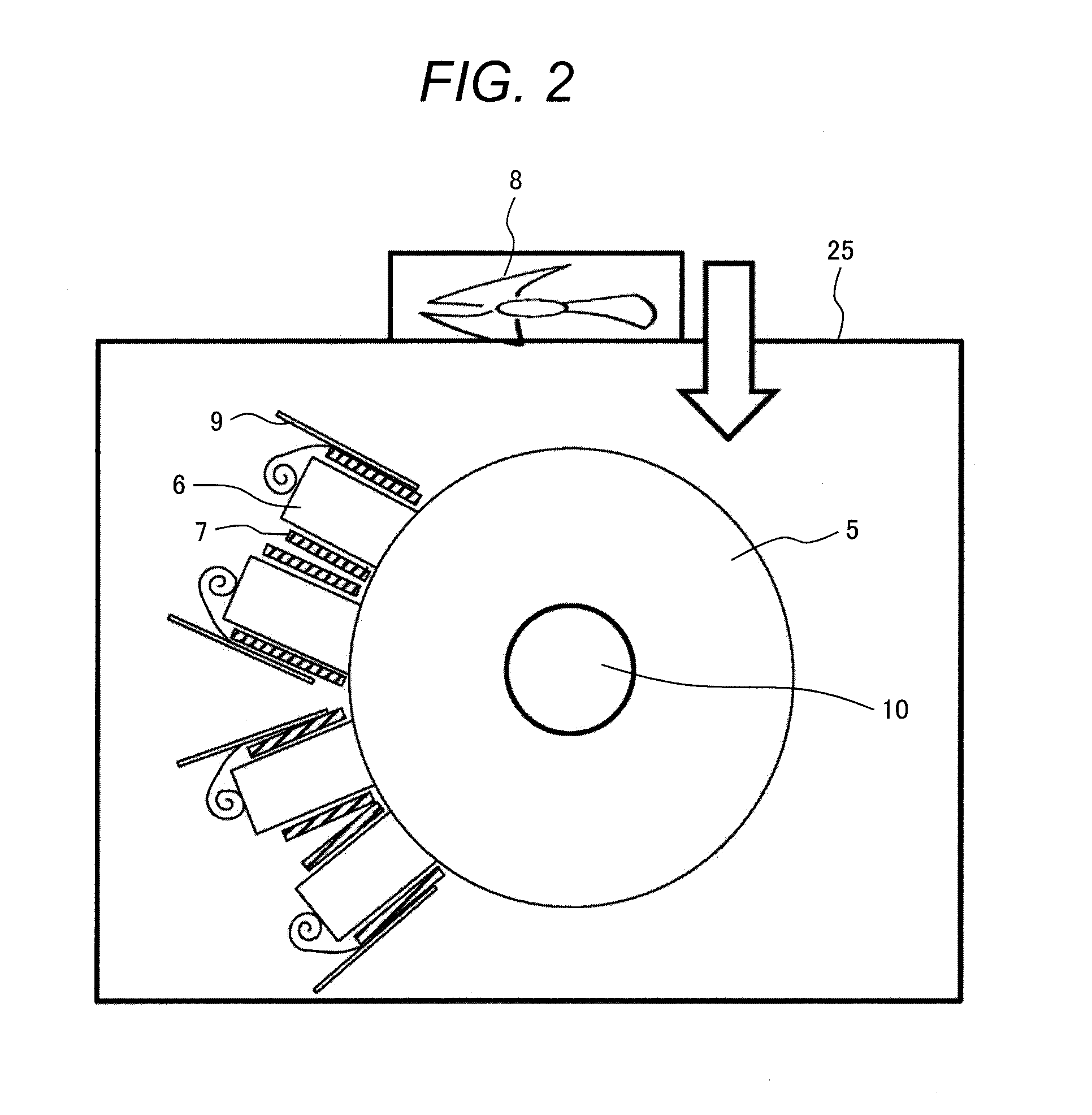

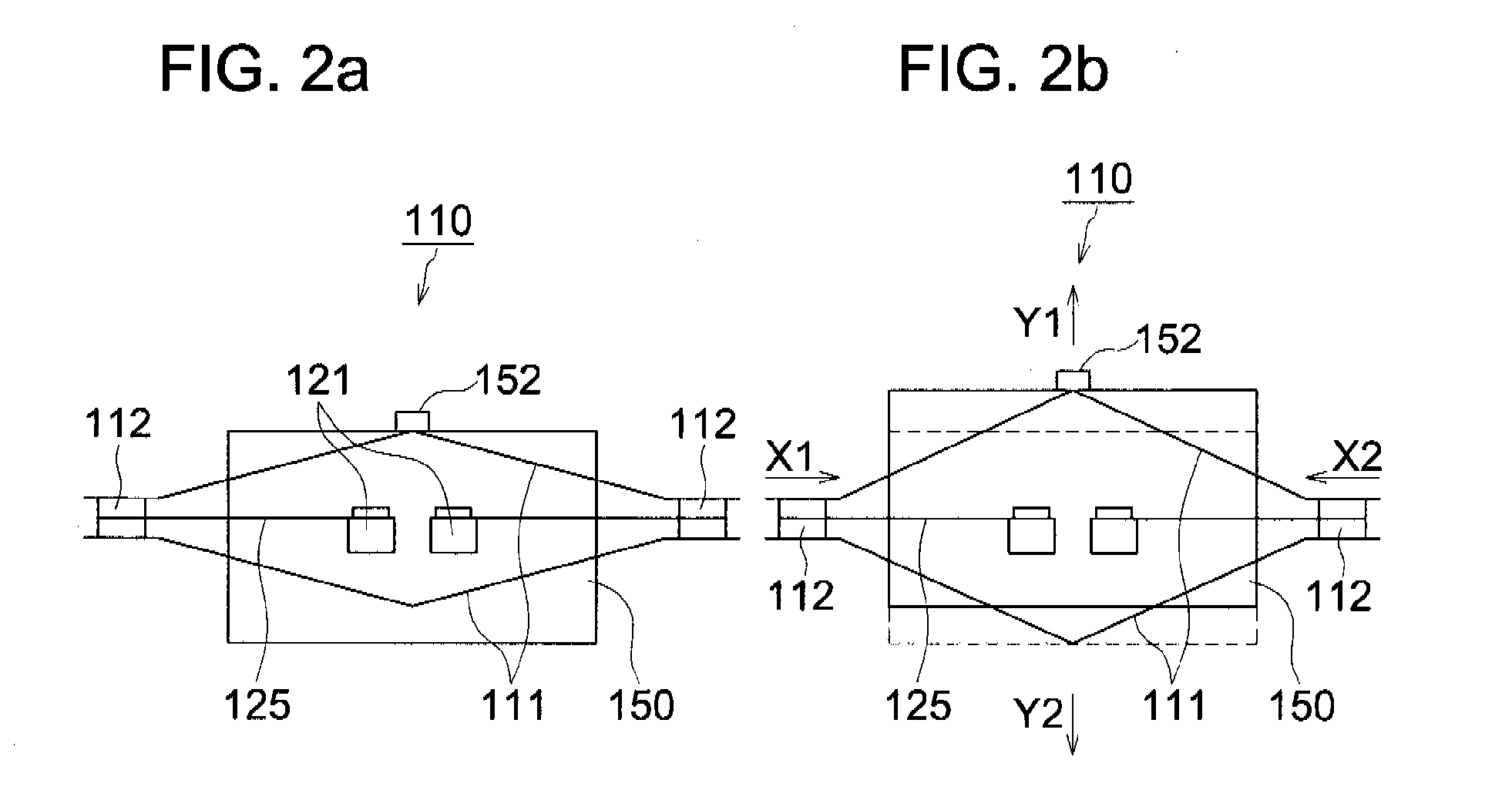

Rotating Machine

ActiveUS20160118867A1Improve contact statusRotary current collectorShape memory alloy connectionsContact failureConductor Coil

The present invention provides a rotating machine which can maintain good contact state between the brush and the metal rotating body. A rotating machine of the present invention includes a stator including a stator winding, a rotor including a rotor winding and rotatably disposed apart from the stator with a gap, a metal rotating body electrically coupled with the rotor winding, a brush in contact with the metal rotating body, and a pressing mechanism for increasing pressure to press the brush against the metal rotating body when contact failure occurs between the metal rotating body and the brush.

Owner:HITACHI LTD

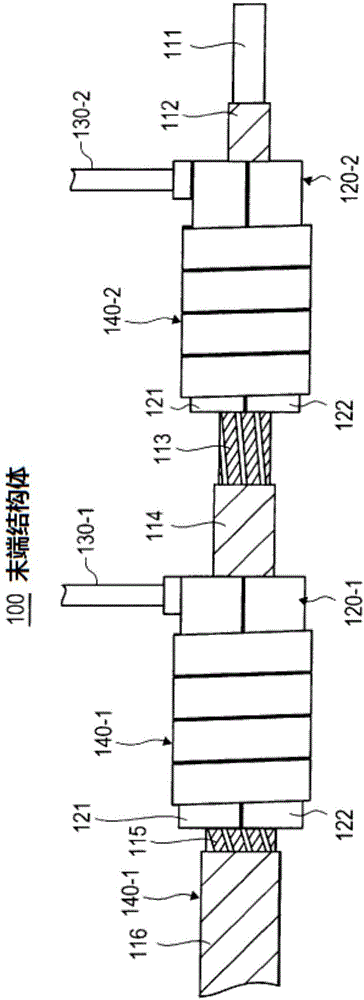

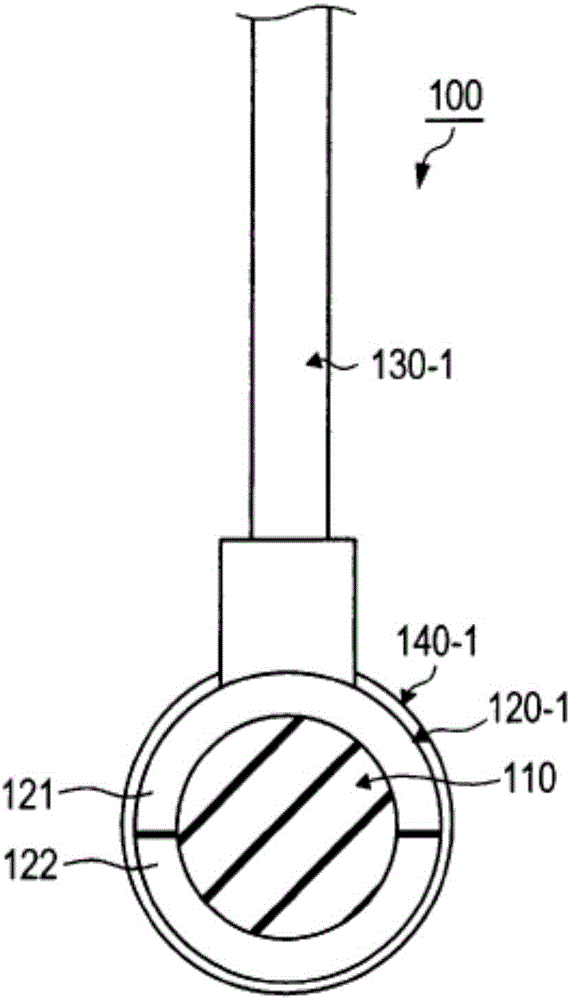

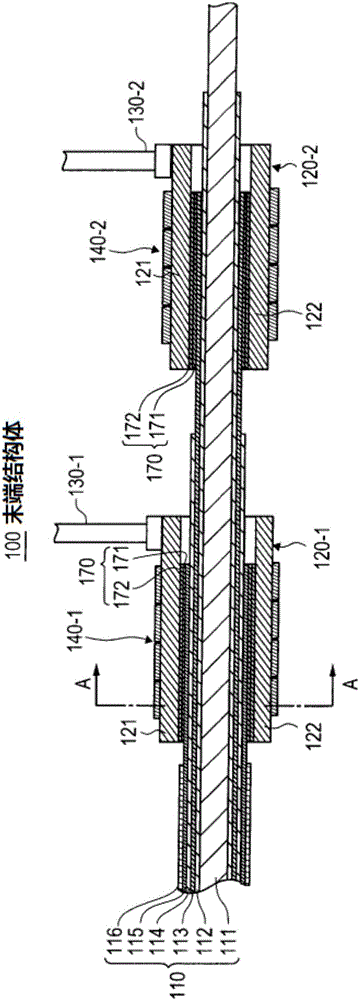

Terminal structure for superconducting cable and method for manufacturing same

ActiveCN106030909ARelocated and properly connectedLine/current collector detailsSuperconductors/hyperconductorsEngineeringContact resistance

Provided is a terminal structure for a superconducting cable that causes an electrode and a superconducting cable to be easily and favorably connected with reduced contact resistance. In the superconducting cable, a superconducting wire in which a superconducting layer is provided on a substrate interposed by an intermediate layer is wound around a core so that the superconducting layer becomes the inner periphery side and the substrate becomes the outer periphery side. In the terminal structure, the superconducting cable (110) has a plurality of superconducting wires (113, 115), in which a superconducting layer is provided on the substrate interposed by an intermediate layer, and the plurality of superconducting wires (113, 115) are arranged in multiple layers so as to be wound concentrically around a core (111) so that the superconducting layer becomes the inner periphery side and the substrate becomes the outer periphery side. The superconducting cable (110) is arranged inside a tubular electrode (120) and the inner surface of the tubular electrode (120) is soldered to the substrate-side surface of, among the plurality of superconducting wires (113, 115), the superconducting wire (113, 115) positioned at the outermost layer inside the tubular electrode (120).

Owner:SHOWA ELECTRIC WIRE & CABLE CO

Electrical connector assembly for an arcuate surface in a high temperature environment and an associated method of use

InactiveUS7714257B2Contact member assembly/disassemblyShape memory alloy connectionsElectrical conductorElectrical connector

Owner:HUSKY INJECTION MOLDING SYST LTD

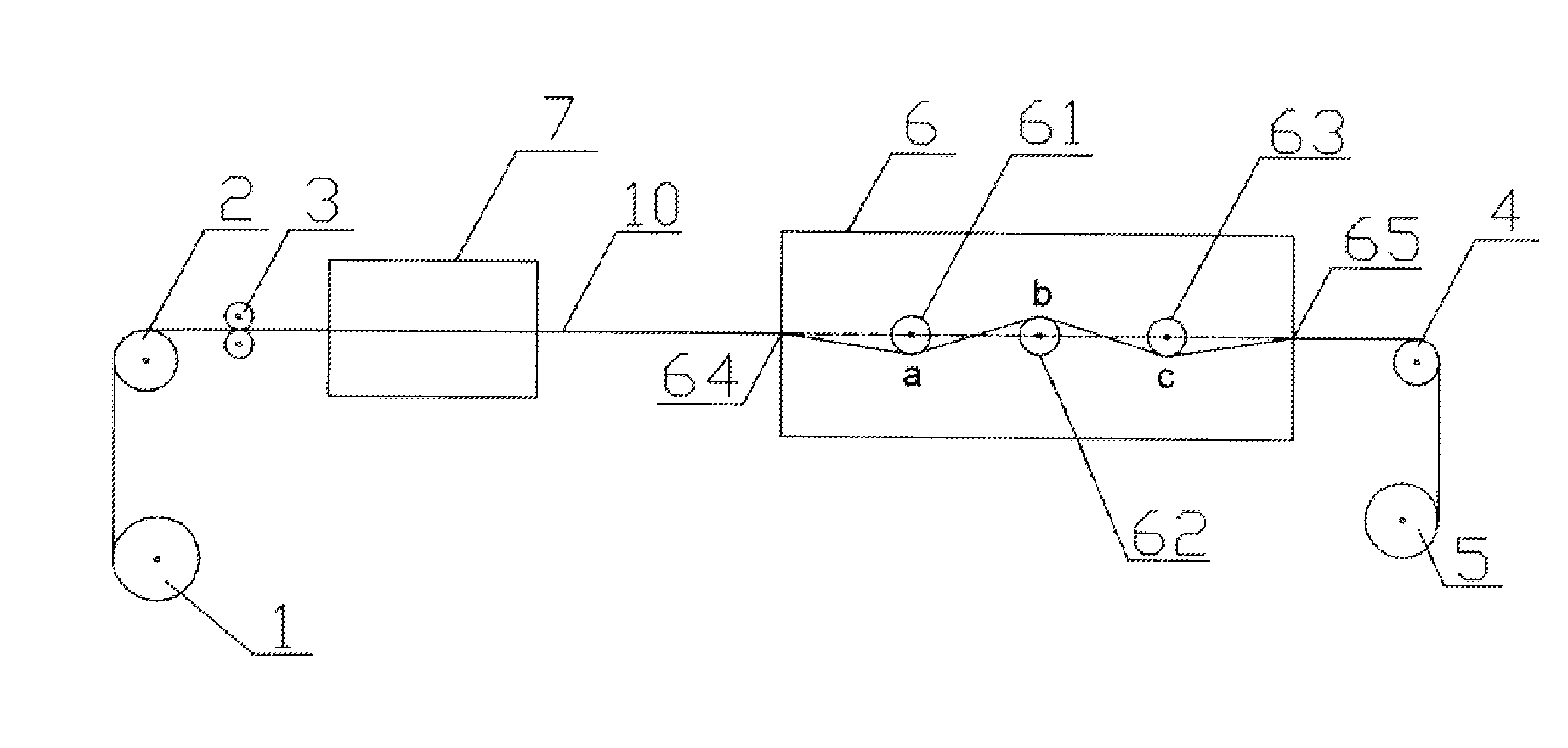

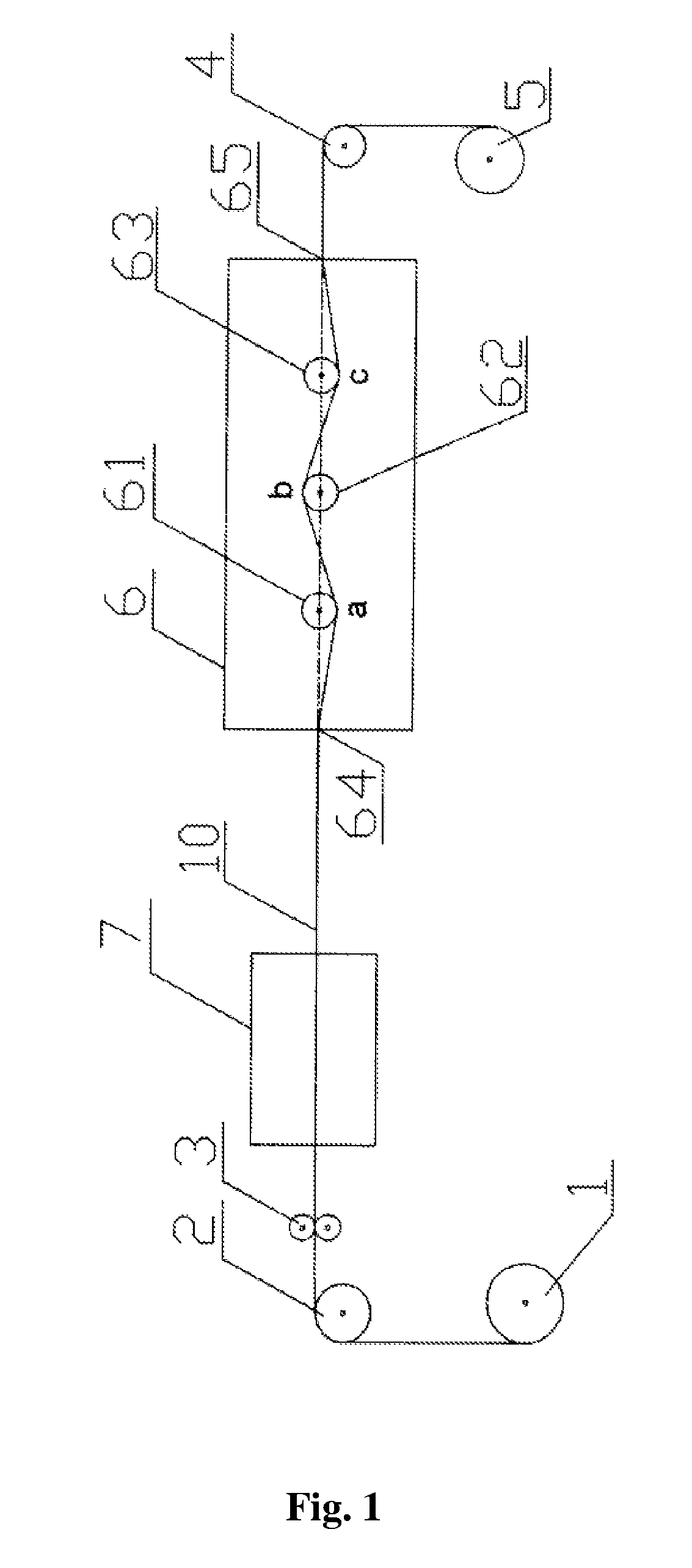

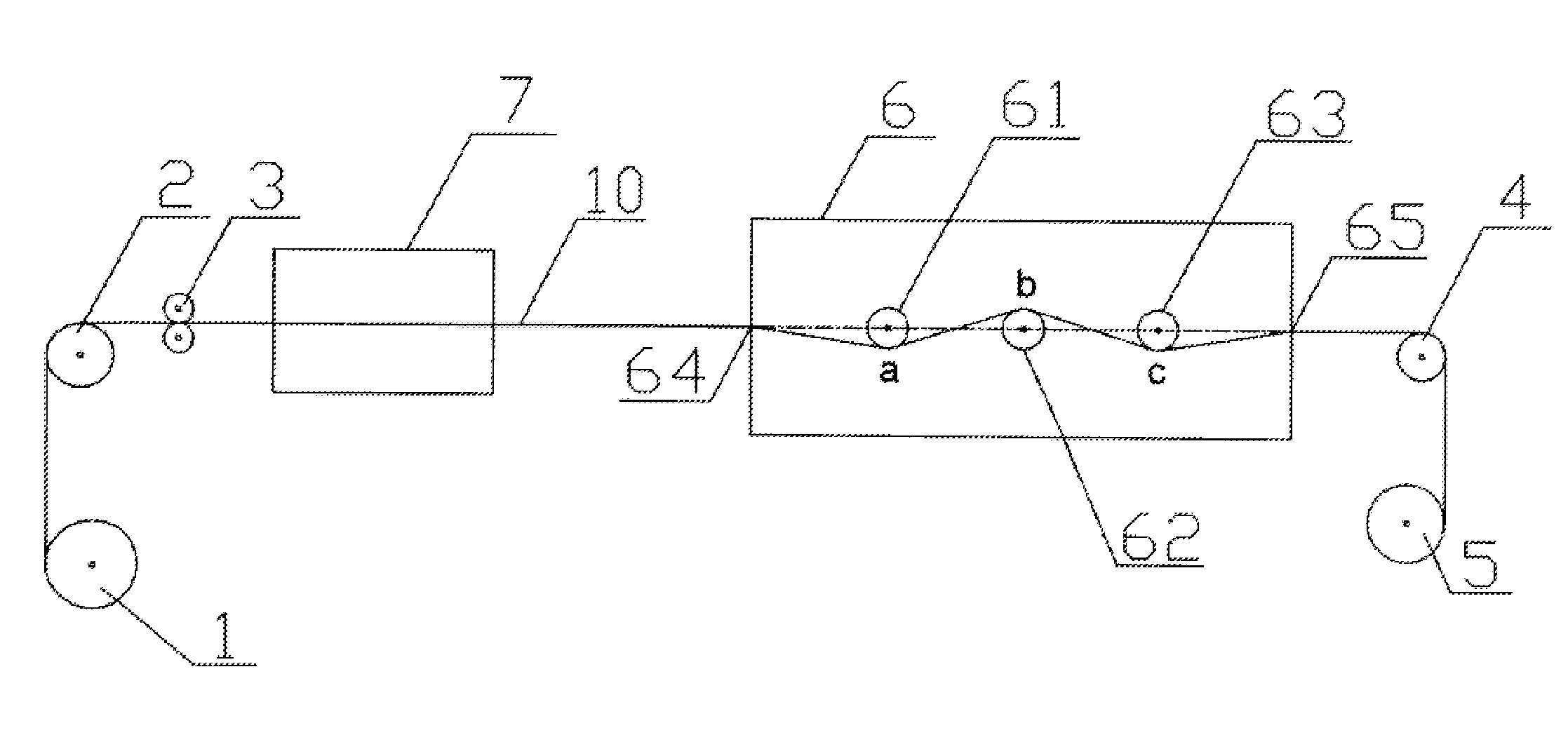

Device and method for molding bistable magnetic alloy wire

ActiveUS8099991B2Easy to controlEfficient productionContact member manufacturingWire articlesWire rodMaterials science

Taught herein is a method for molding a bistable magnetic alloy wire, comprising: processing an alloy wire by heat treatment; and processing the alloy wire by cold treatment of mechanical twisting, the mechanical twisting being a repeated twisting in a continuous state. Also taught herein is a device for molding a bistable magnetic alloy wire.

Owner:ZHANG NIANRONG +5

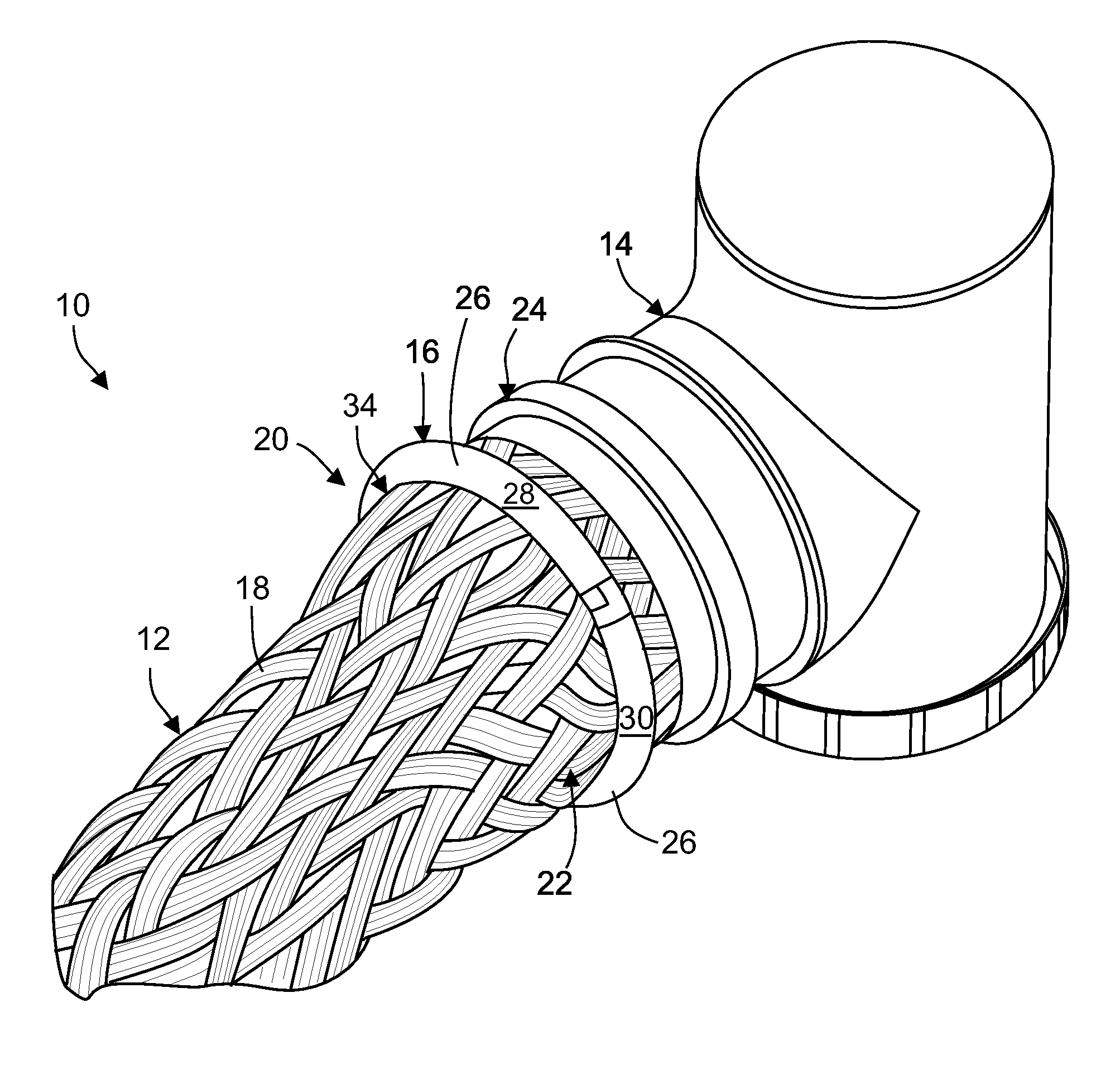

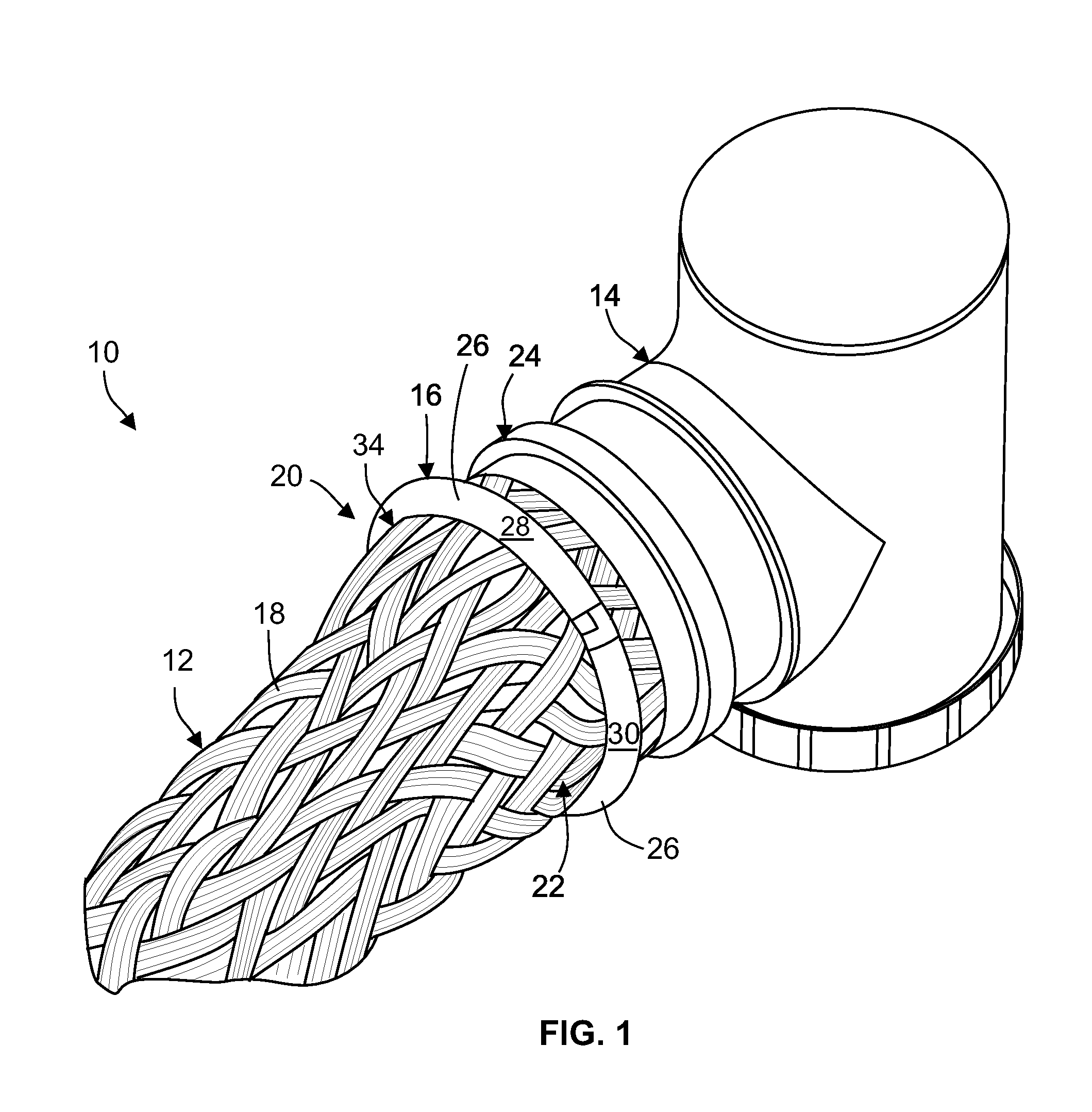

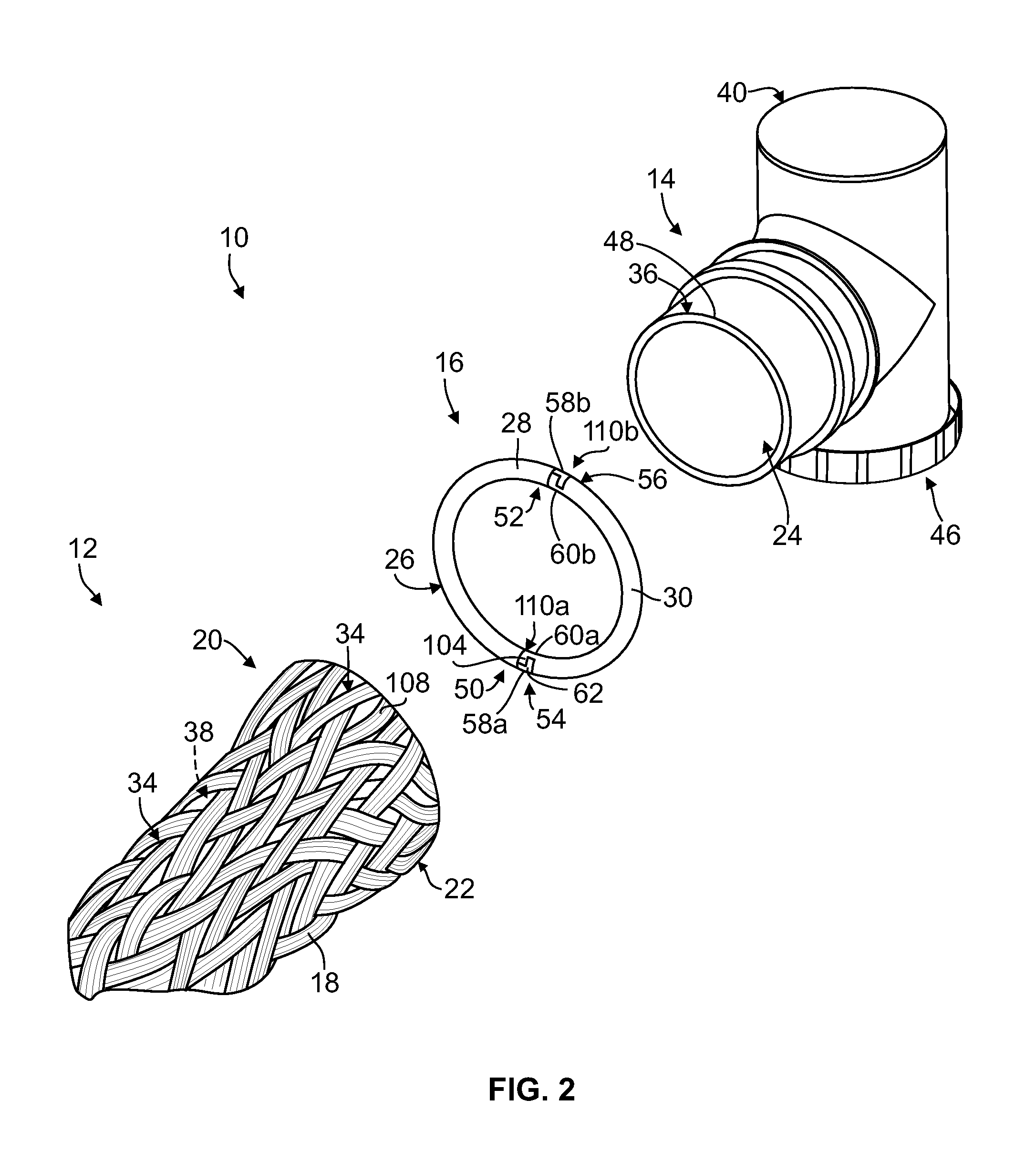

Attachment ring for attaching a shield of an electrical cable to a backshell

ActiveUS20120115363A1Relieving strain on wire connectionShape memory alloy connectionsElectrical and Electronics engineeringEngineering

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

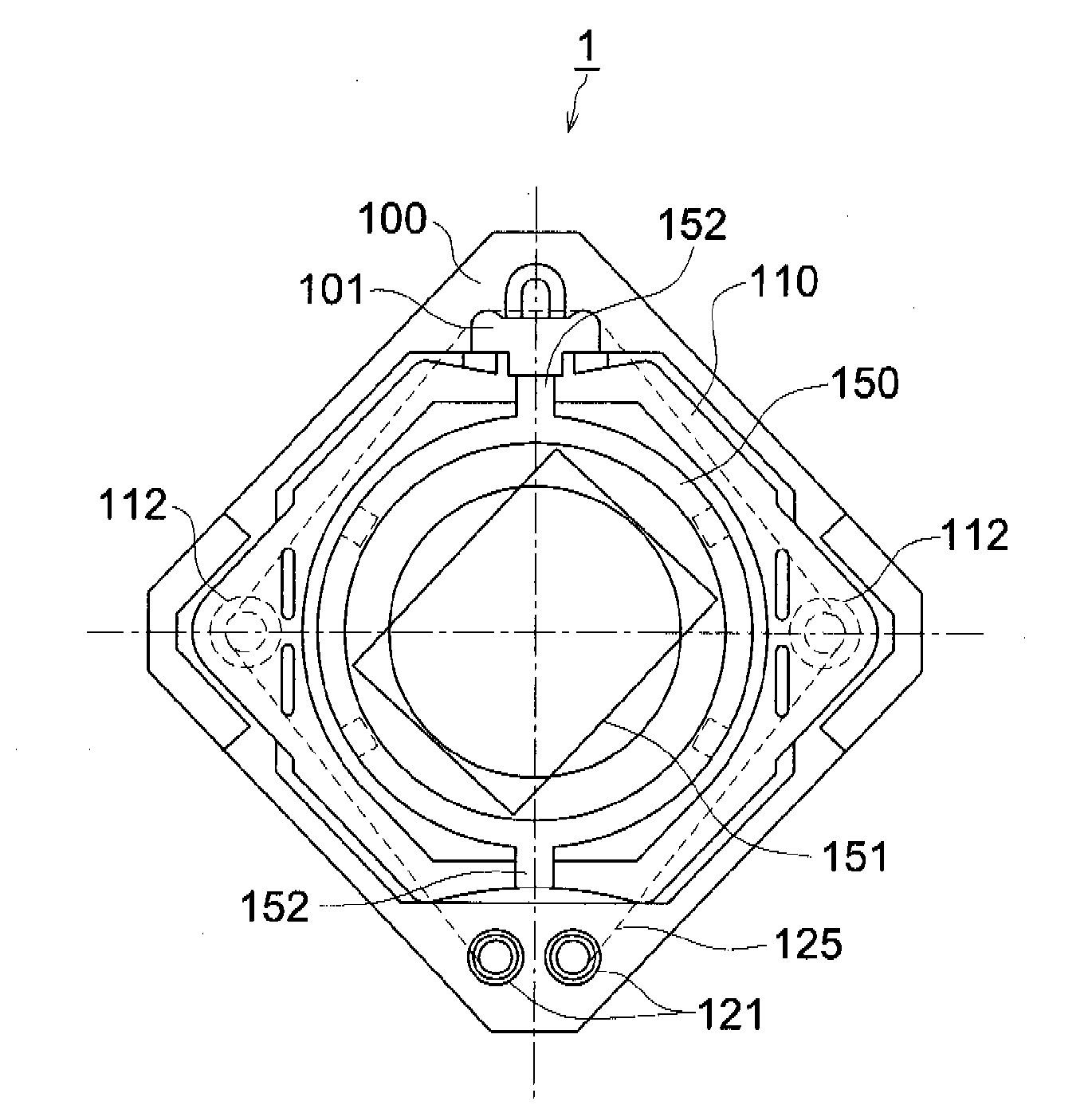

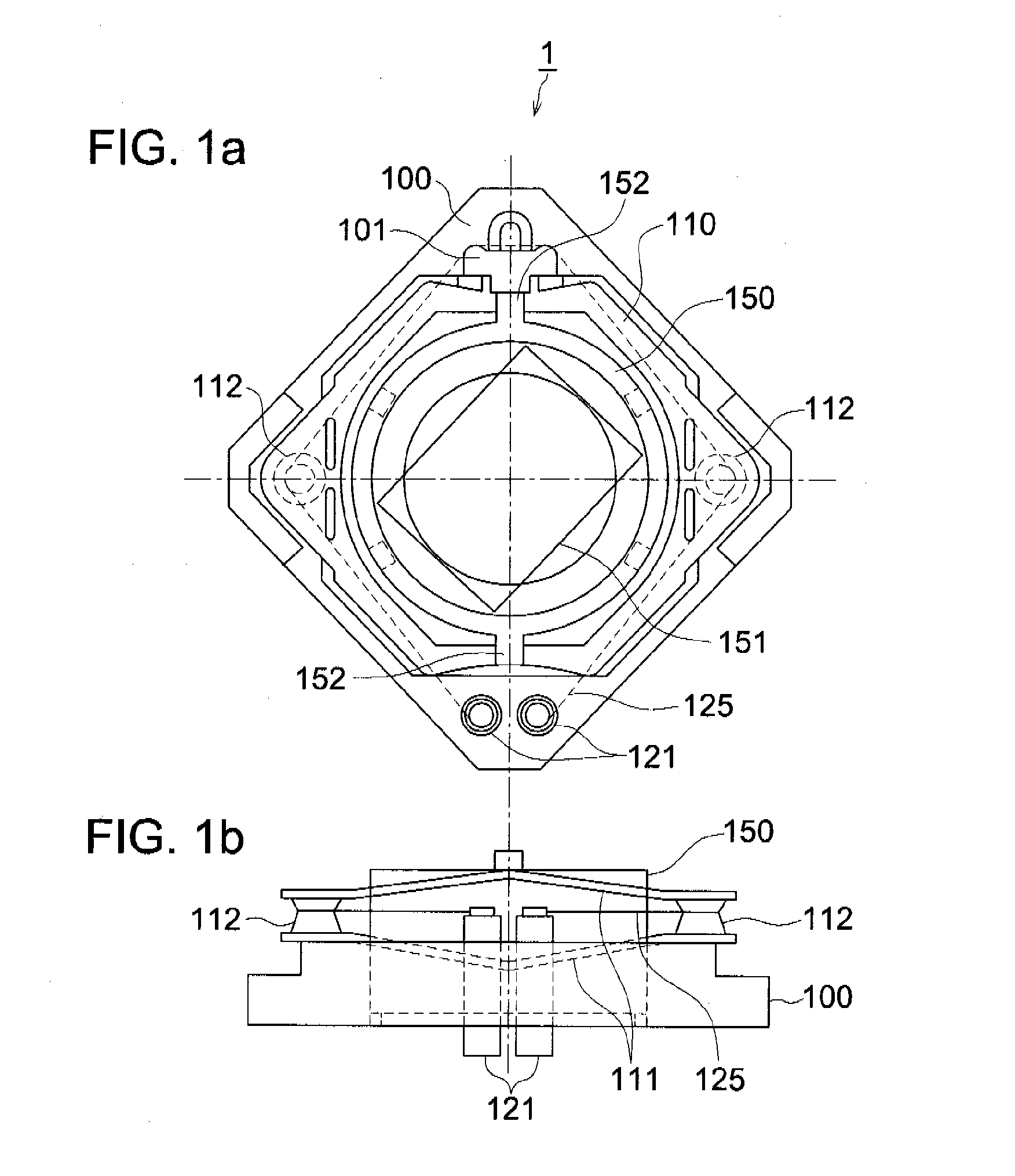

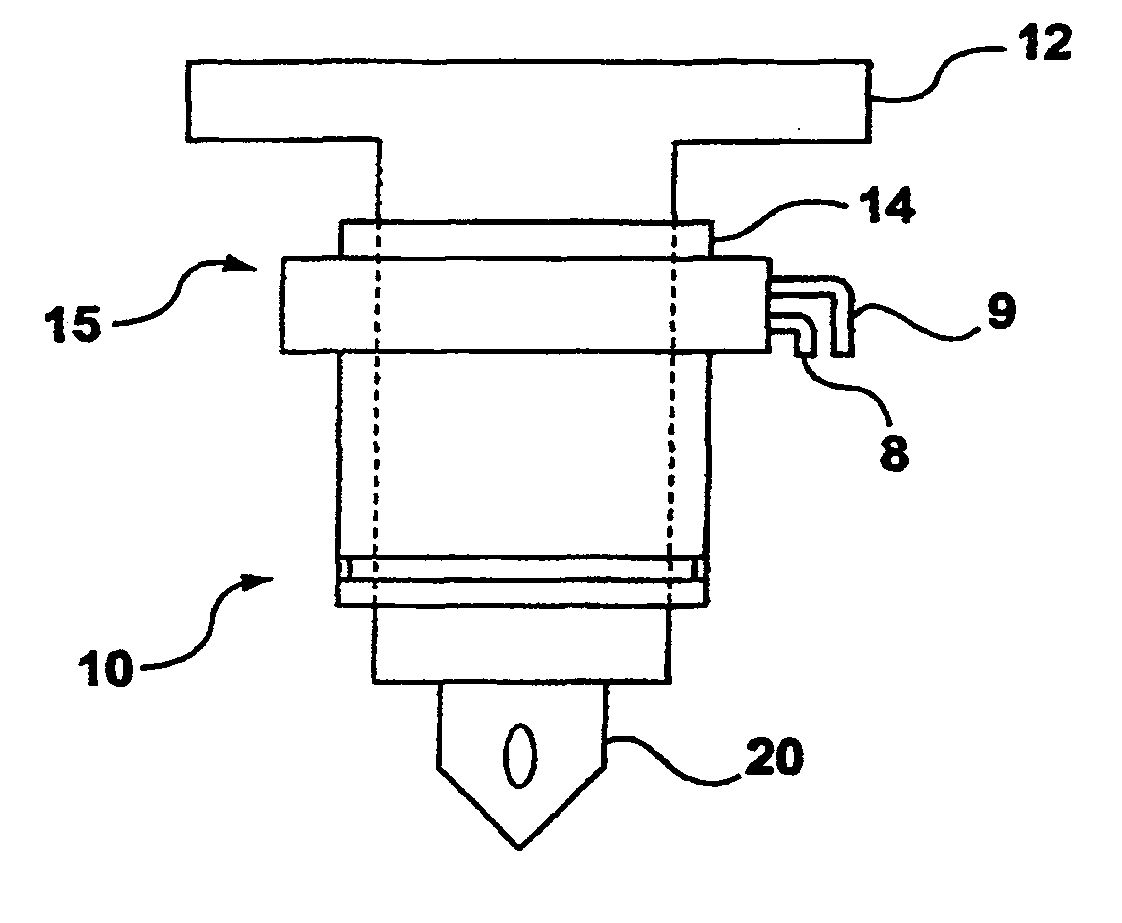

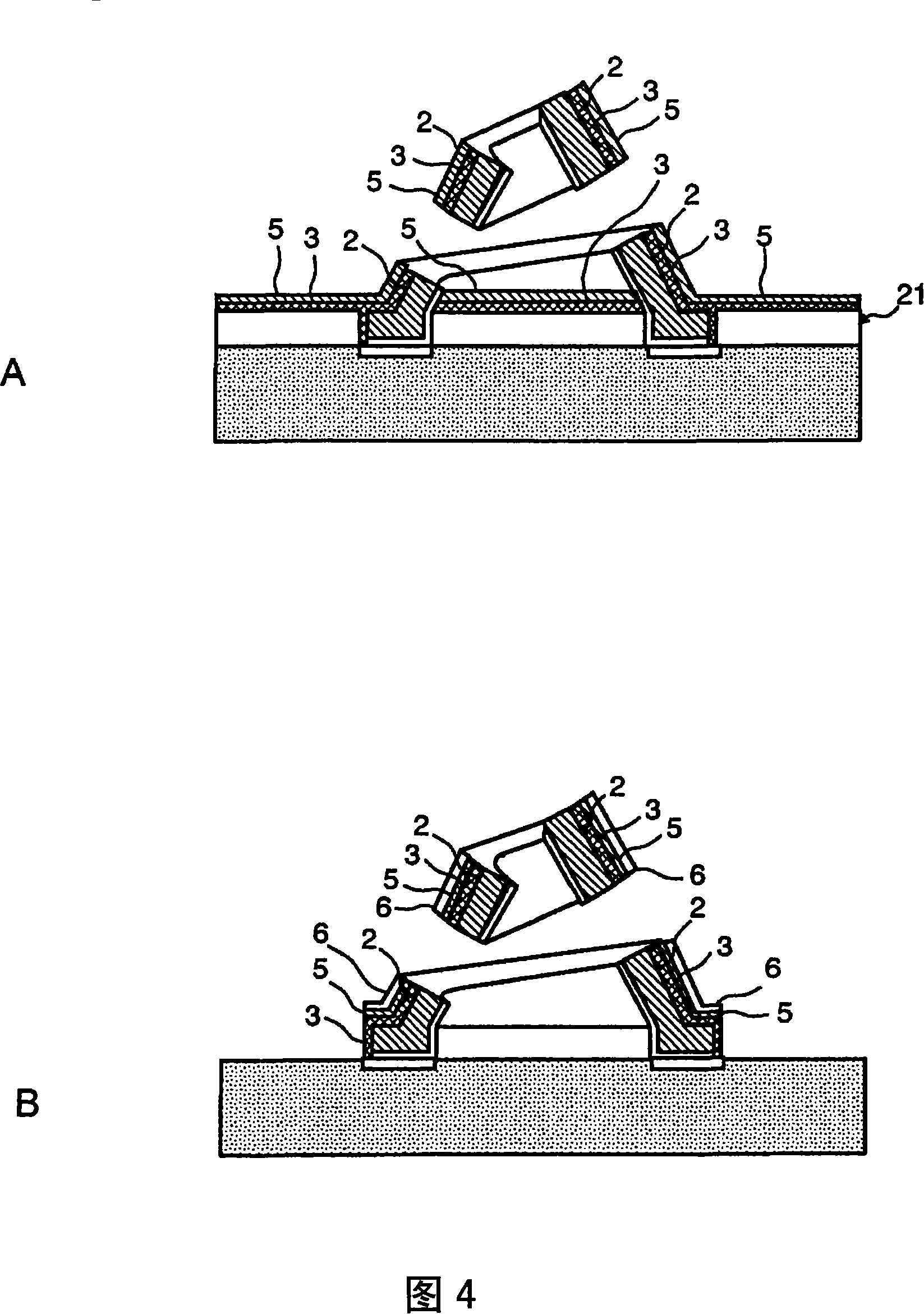

Driving device and method of manufacuring the same

InactiveUS20080256946A1Without affecting performanceEasy to fixLine/current collector detailsShape memory alloy connectionsMiniaturizationShape-memory alloy

A driving device and driving device manufacturing method that ensure stable fixing of an SMA, without causing difficulties in downsizing the device, and without adversely affecting the performance of the SMA. A driving device equipped with a string-shaped shape memory alloy as a drive source includes a base member constituting a basis of the driving device, and a rod-like member which penetrates the base member and is made of the metal fixed onto this base member. The rod-like member is caulked on one end of this rod-like member so that the aforementioned shape memory alloy is pinch-held in-between, whereas power-feeding members to apply current to the shape memory alloy are arranged on the other end of the rod-like member.

Owner:KONICA MINOLTA OPTO

Attachment Ring for Attaching a Shield of an Electrical Cable to a Backshell

ActiveUS20120282810A1Shape memory alloy connectionsCoupling device detailsEngineeringElectrical and Electronics engineering

An attachment ring is provided for attaching a shield of an electrical cable to a backshell. The attachment ring includes an annular body including a shape memory material that is heat recoverable. The body is configured to extend at least partially around the shield and a fitting of the backshell to hold the shield on the fitting in contact with the fitting. The body includes a single segment having a first end that includes a first connection member, and a second end that opposes the first end. The second end has a second connection member that is configured to be interlocked with the first connection member of the first end to connect the first and second ends together such that the single segment of the body defines a continuous ring.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

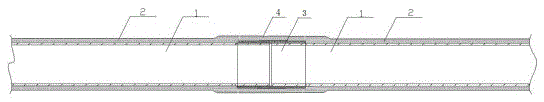

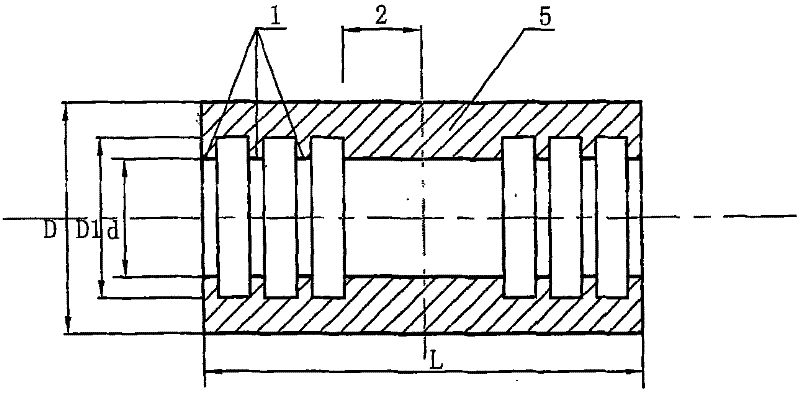

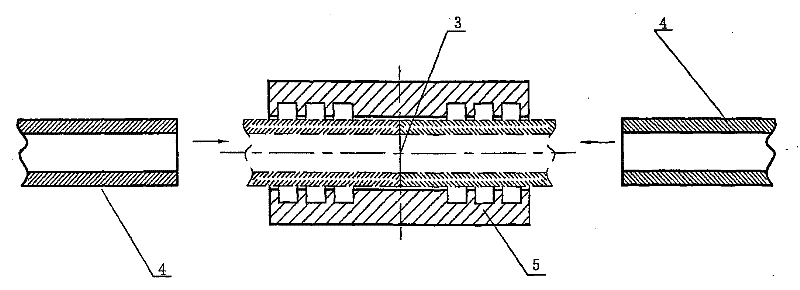

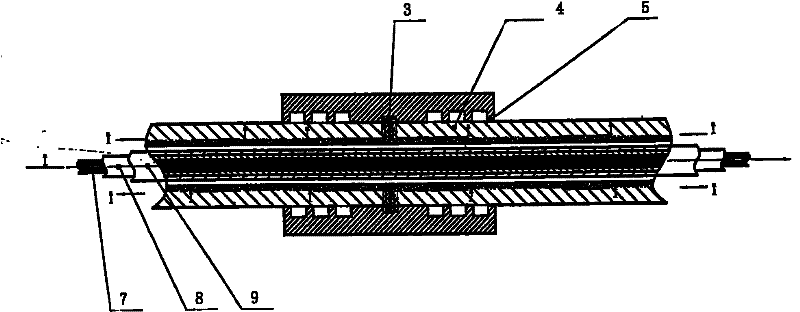

Insulating tube bus-bar connecting device and connecting method thereof

InactiveCN105655737AReduce volumeUniform contact surfaceShape memory alloy connectionsConnection contact member materialElectrical and Electronics engineering

The invention discloses an insulating tube bus-bar connecting device and a connecting method thereof. The connecting device comprises two insulating tube bus-bars and a tube bus-bar connector which is a tubular connector, the inner diameter of the tube bus-bar connector is small than the outer diameter of an insulating tube bus-bar core material, and the outer diameter of the tube bus-bar connector is larger than the outer diameter of the insulating tube bus-bar core material. The connecting method comprises the steps that 1, the connection parts of the two ends of the insulating tube bus-bars and the inner surface and outer surface of the tube bus-bar connector are polished clean and subjected to tinning treatment; 2, the tube bus-bar connector is subjected to heating and heat preservation treatment at certain temperature, and heating and heat preservation treatment are stopped when the inner diameter of the tube bus-bar connector is expanded to be larger than the outer diameter of the tube bus-bars under the action of heating and heat preservation treatment; 3, the middle of the tube bus-bar connector is fixedly clamped through a tool clamp, the connection parts of the insulating tube bus-bar ends are inserted into the tube bus-bar connector; 4, the joints of the tube bus-bar connector and the insulating tube bus-bar ends are cooled; 5, insulating treatment is conducted on the tube bus-bar connector and the joints of the tube bus-bar connector and the insulating tube bus-bar ends after cooling is conducted.

Owner:湖北兴和电力新材料股份有限公司

Pipe joint of skin-effect electric heating element

InactiveCN101752678AHas the "constraint recovery" featureWork reliablyShape memory alloy connectionsAlloyWeld seam

The invention relates to a pipe joint used for the connecting of a skin-effect electric heating element and a heating pipe; the pipe joint made of iron-based memory alloy material is provided with 'bound and restore' feature, and can generate a certain connected tightening force, and can be used for replacing the pipe joint made of general material; meanwhile, the problems that the pipe joint for connecting two heating pipes in heating pipe connection of long-distance pipeline electric heating pipe construction is submerged in underground water or accidental water seepage can lead the sealing of the welding seam to be unreliable, which can affect the skin-effect heating current channel, the number of the pipe joints at the heating pipe is large, the welding construction which clings to the long-distance pipeline is difficult, the difficulty of underground construction is large, the workers are more, the construction period is long, and the welding technology is low-efficient are solved; meanwhile, the invention has advantages that: the air tightness is reliable, the welding device and the corresponding personnel are not required, and the operating tool is simple.

Owner:赵放

Shape memory alloy crimp interlock apparatus and methods

ActiveUS20190242370A1Minimize degreeCost-effective assemblyLine/current collector detailsShape memory alloy connectionsShape-memory alloyEngineering

Apparatus and methods for filament crimping. In one embodiment, the apparatus comprises a body and a filament crimp element. The filament crimp element comprises a first set of cavities disposed at a spacing which creates a first set of features and a second set of cavities disposed at a spacing which creates a second set of features. The first and second set cavities are substantially opposite one another. The first set of features are adapted to be placed at least partially within the second set of cavities and the second set of features are adapted to be placed at least partially within the first set of cavities. Interlock features configured for cold welding are also included. Methods and apparatus for the manufacture of the device are also disclosed. In addition, methods for automated placement and manufacture of assemblies using the crimp elements are also disclosed.

Owner:AUTOSPLICE SYST

Electrical connector assembly for an arcuate surface in a high temperature environment and an associated method of use

An injection molding system injection molding system having at least one heater with an arcuate surface and a nozzle that is in thermal communication with the heater and an associated method of use. This injection molding system includes an electrical connector assembly for a heater having at least one electrical connector with a first electrical conductor that is electrically connectable to at least one first conductive portion on a heater and a second electrical conductor that is electrically connectable to at least one second conductive portion on the heater, and at least one disconnect mechanism positioned adjacent to the at least one electrical connector and in electrical connection with the first electrical conductor and the second electrical conductor. An injection molding system can include, but is not limited to, a hot runner system.

Owner:HUSKY INJECTION MOLDING SYST LTD

Semiconductor device contact resistant to deterioration due to heat and method for manufacturing contact

InactiveCN101118995APrevent collapseWill not deformContact member manufacturingElectric discharge tubesResistSputtering

A Contact according to an aspect of the present invention is formed by laminating a shape memory alloy film on a surface of a metal spring film, and the shape thereof is a conical spiral. A manufacturing method therefor is composed of 11 steps including a step of preparing a sacrificial metal film, a step of forming a resist cone, a step of patterning a resist film, a step of preparing a shape memory alloy film, and the like. Since an organic resist material has poor heat resistance, the sacrificial metal film is formed in advance, the resist is removed before sputtering of the shape memory alloy film, the sacrificial metal film is removed after sputtering of a shape memory alloy and a heat treatment, which are performed at high temperatures, so as to lift off an excess shape memory alloy film.

Owner:ALPS ALPINE CO LTD

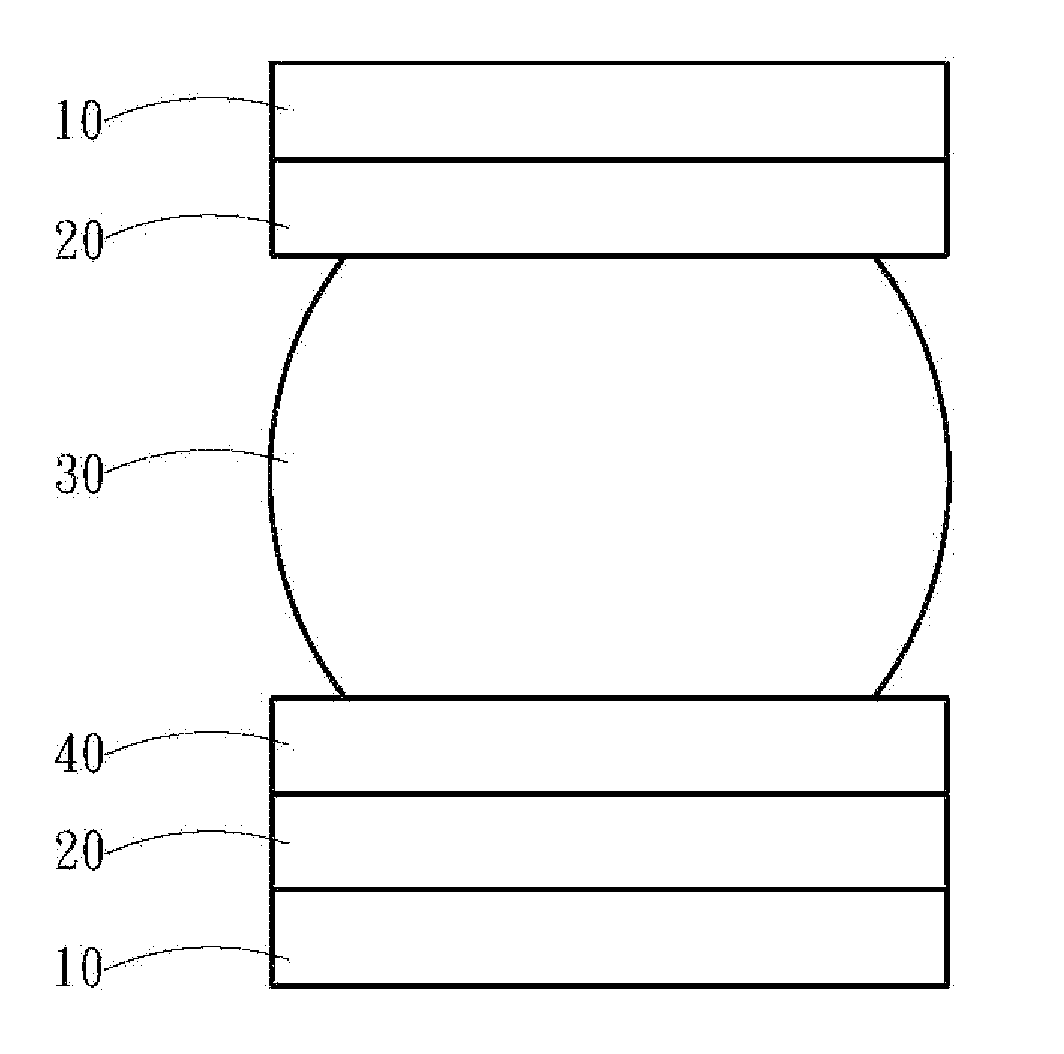

Electronic package structure

InactiveUS20100277880A1High integrity electronic packageReduce defective rateFinal product manufactureShape memory alloy connectionsElectronic structureShape-memory alloy

The present invention discloses an electronic package structure, which comprises an electronic element, a plurality of SMA (Shape Memory Alloy) connection portions, and a plurality of solder connection members. One side of the SMA connection portion is joined to the electronic element, and the solder connection member is arranged over the other side of the SMA connection portion. The SMA connection portions can comply with the strains caused by thermal stresses during the operation of the electronic product and can restore the original shape after the thermal stresses disappear. Therefore, the preset invention can prevent the junctions between the SMA connection portions and the electronic element / the solder connection members from the crack or disconnection caused by thermal stresses.

Owner:NATIONAL TSING HUA UNIVERSITY

Device and method for molding bistable magnetic alloy wire

ActiveUS20080052887A1Easy to controlEfficient productionContact member manufacturingWire articlesCold treatmentHeat treated

Taught herein is a method for molding a bistable magnetic alloy wire, comprising: processing an alloy wire by heat treatment; and processing the alloy wire by cold treatment of mechanical twisting, the mechanical twisting being a repeated twisting in a continuous state. Also taught herein is a device for molding a bistable magnetic alloy wire.

Owner:ZHANG NIANRONG +5

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com