Semiconductor device contact resistant to deterioration due to heat and method for manufacturing contact

一种制造方法、接触件的技术

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

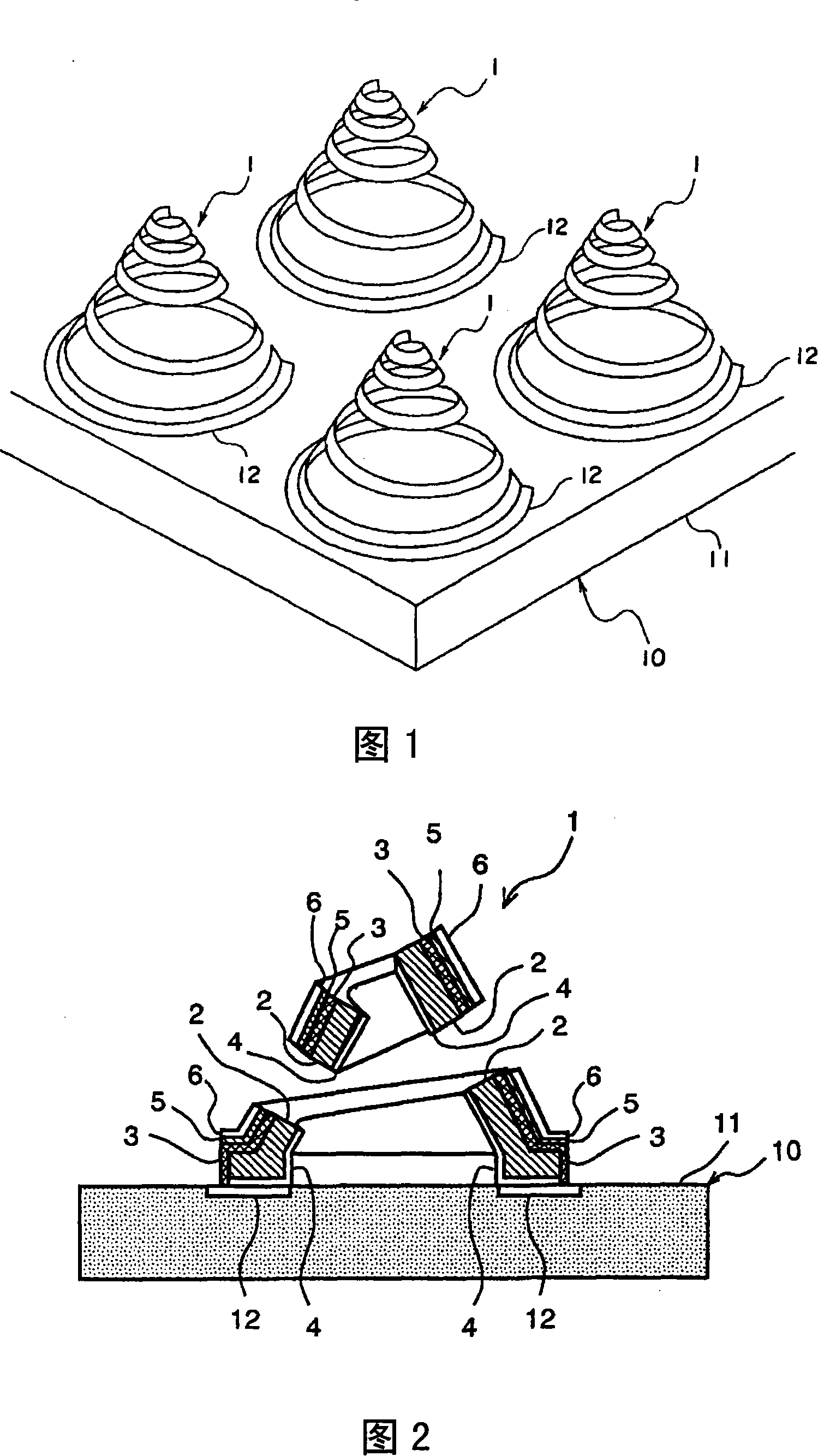

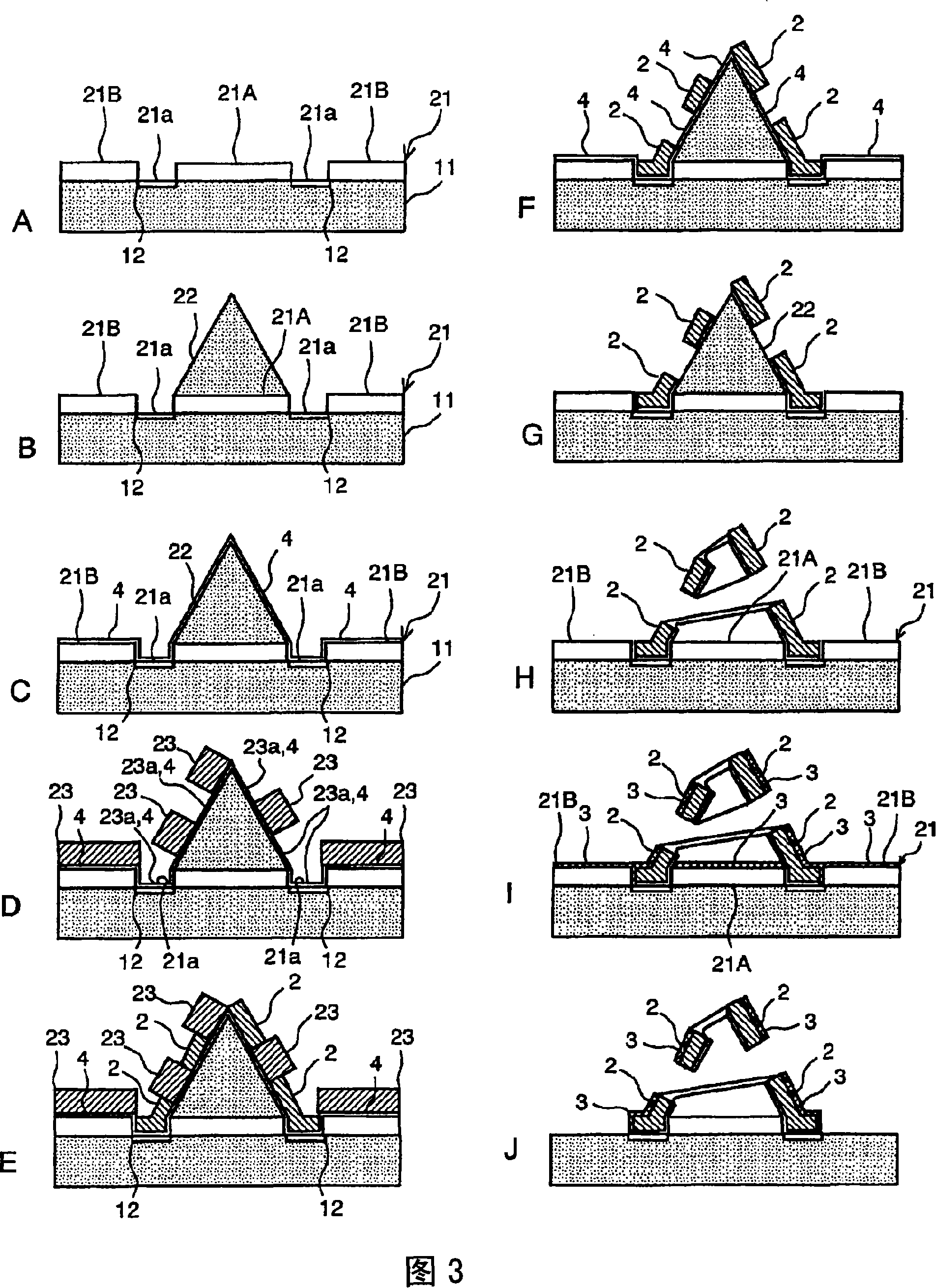

[0049] Next, an embodiment of the contact of the present invention will be described with reference to FIGS. 1 and 2 .

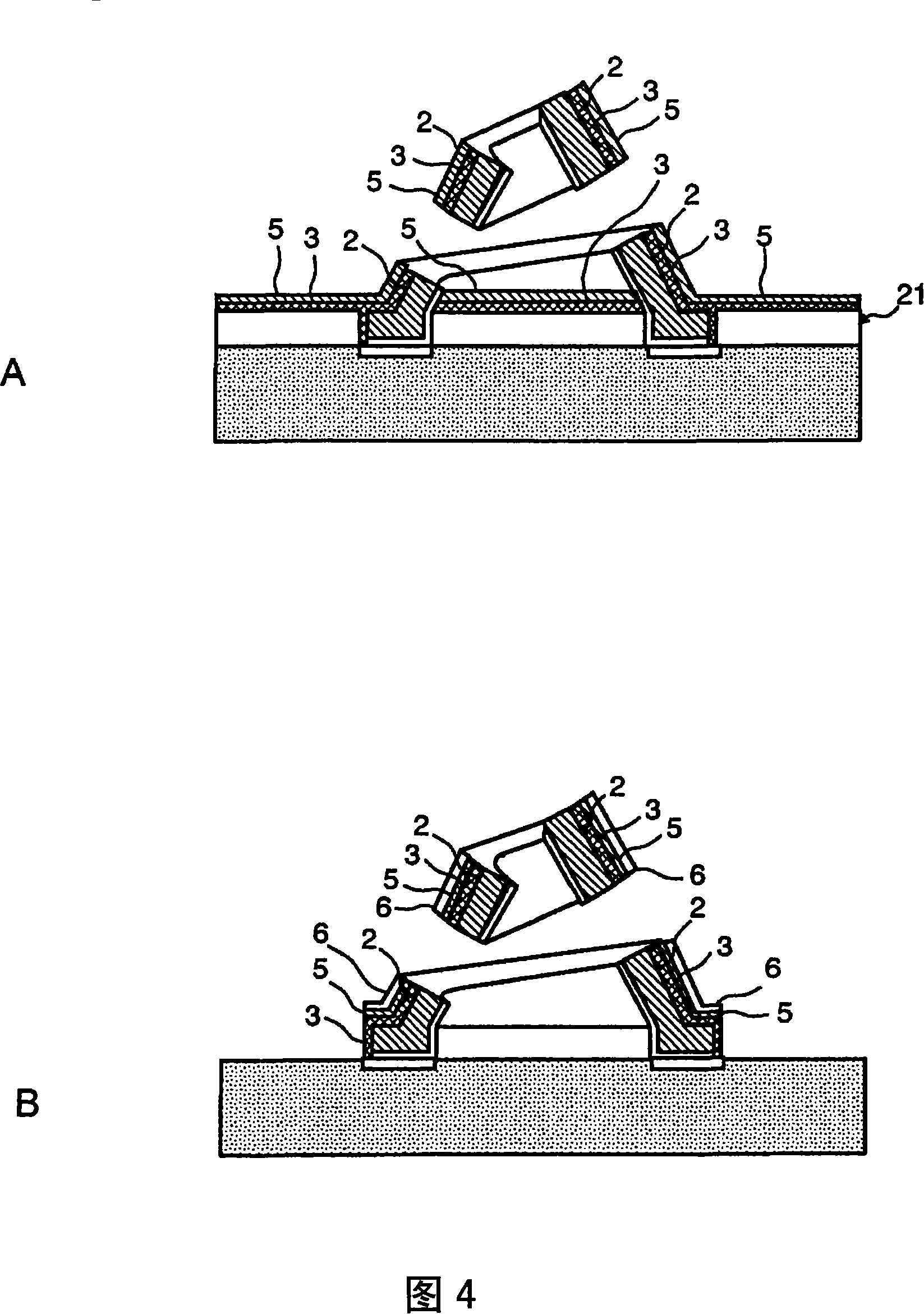

[0050] FIG. 1 is a perspective view showing a contact 1 according to the present embodiment, and FIG. 2 is a vertical cross-sectional view showing the contact 1 according to the present embodiment. As shown in FIG. 1 , the contact 1 of this embodiment is formed in a conical spiral shape with the center as the apex, and is connected to connection terminals 12 formed on an insulating substrate 11 of a probe card (wiring board for inspection) 10 . This contact 1 is formed by laminating a metal spring film 2 and a shape memory alloy film 3 as shown in FIG. 2 . Furthermore, the contact 1 of the present embodiment is formed by laminating the seed film 4 , the conduction auxiliary film 5 , and the conduction film 6 at predetermined positions as auxiliary films for the metal spring film 2 and the shape memory alloy film 3 .

[0051] The metal spring film 2 is forme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| martensitic transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com