Patents

Literature

43results about How to "Uniform contact surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

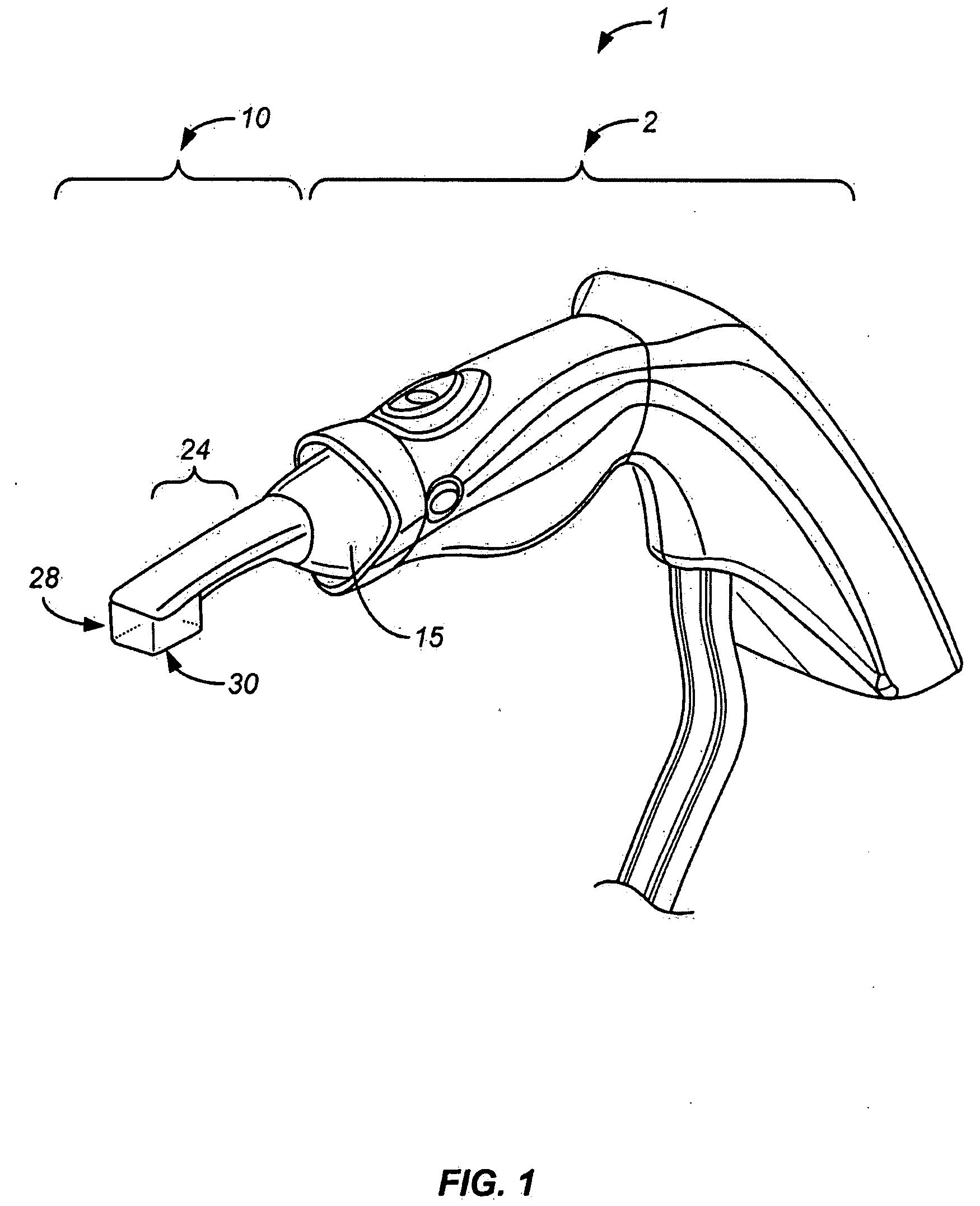

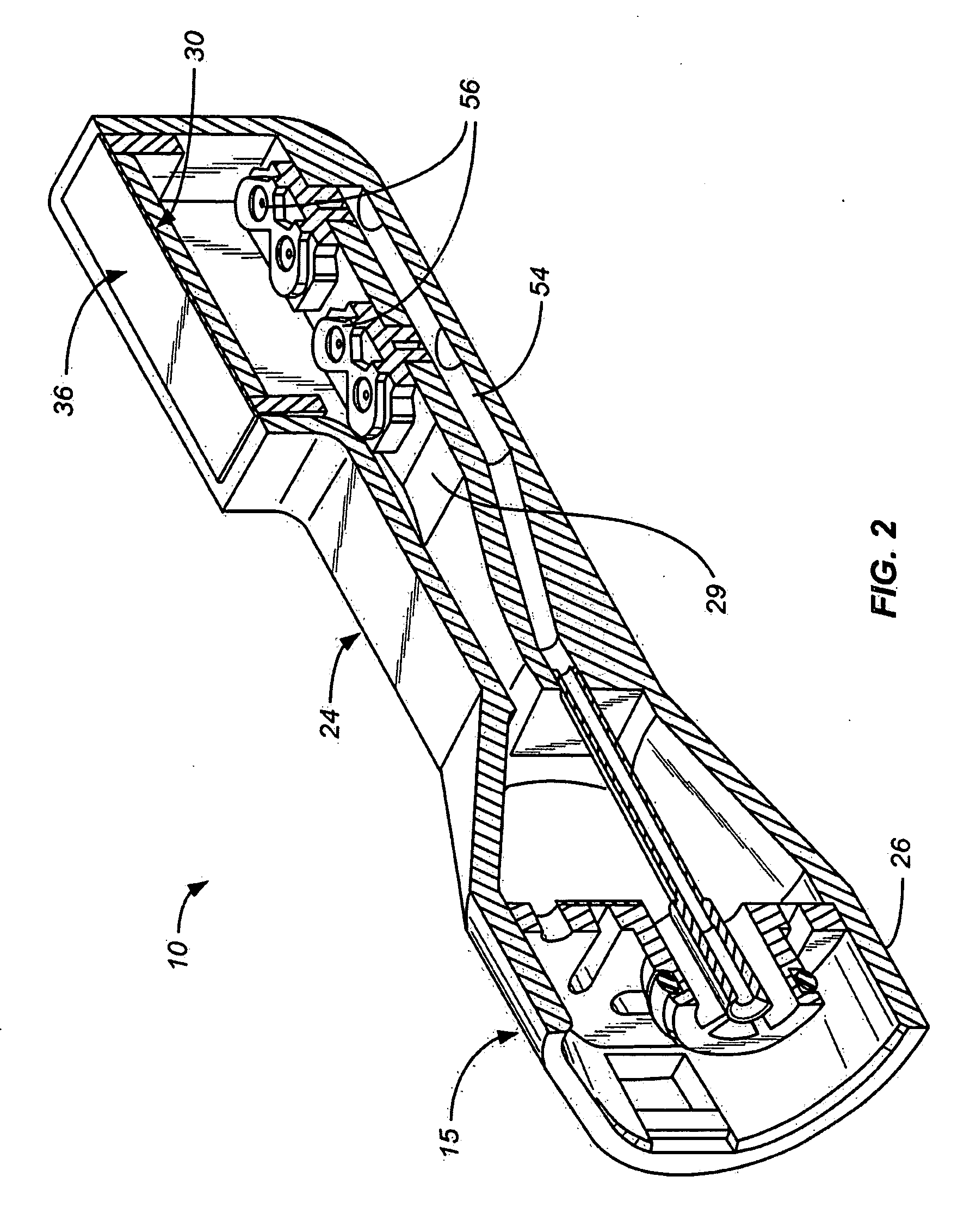

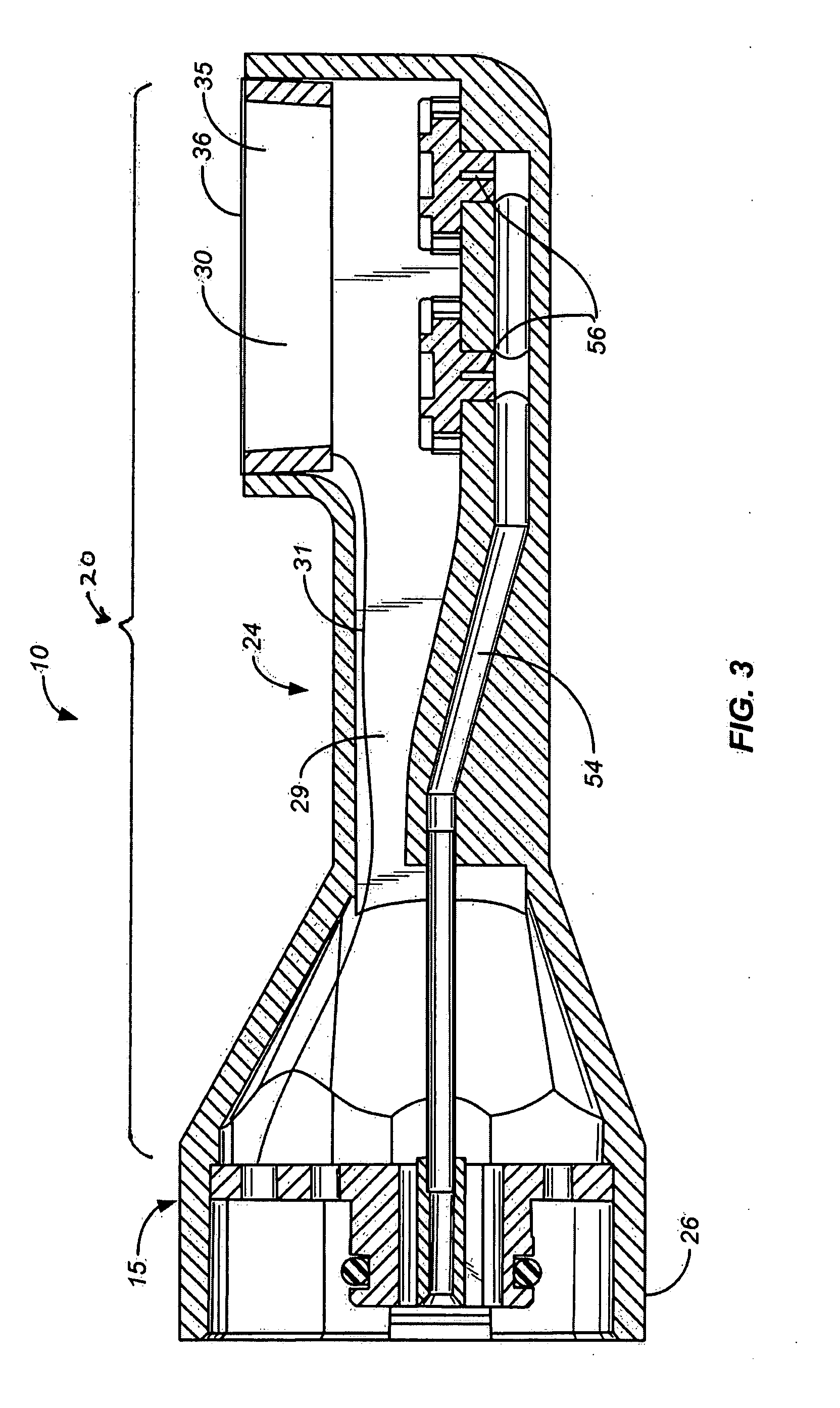

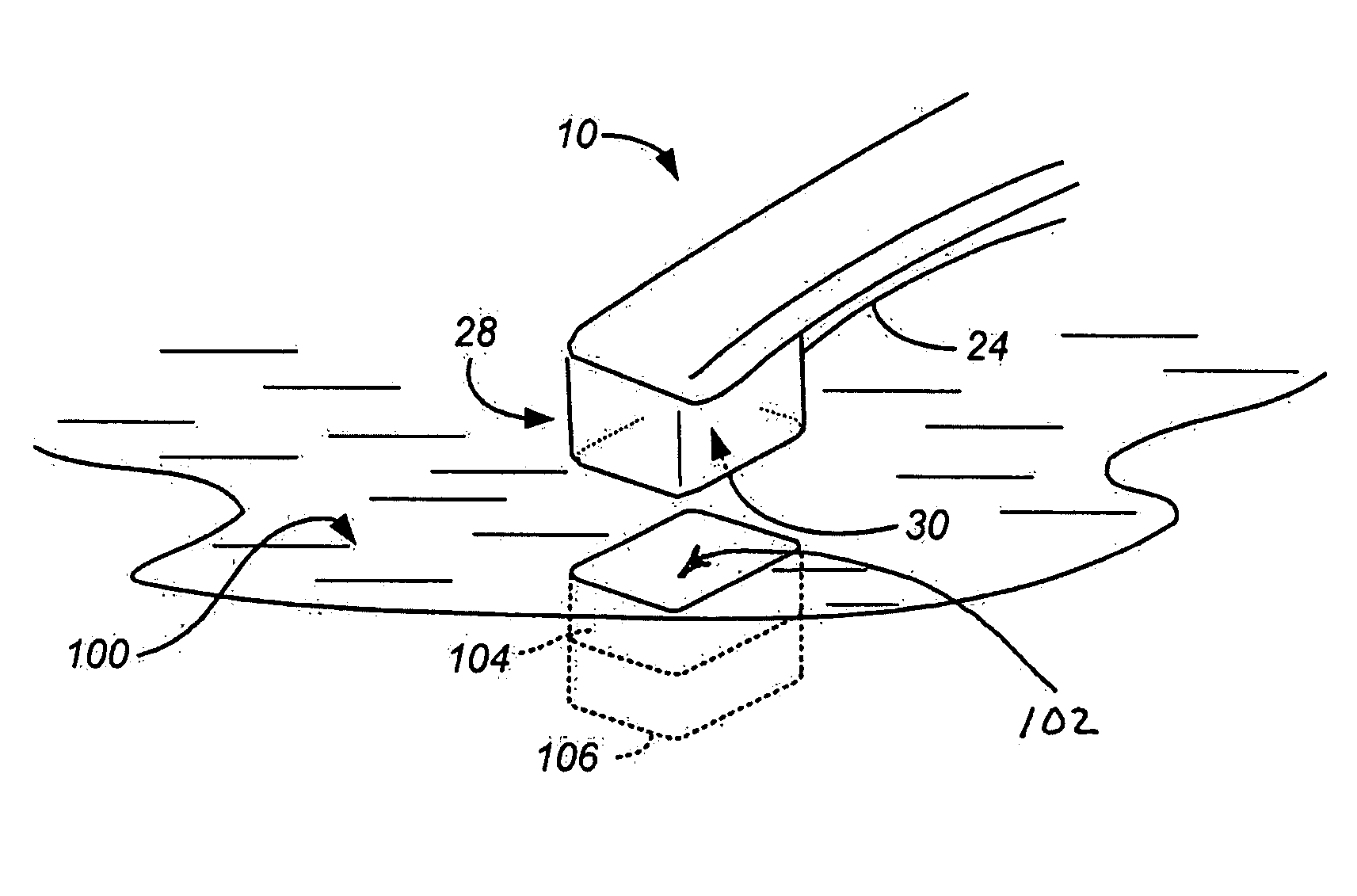

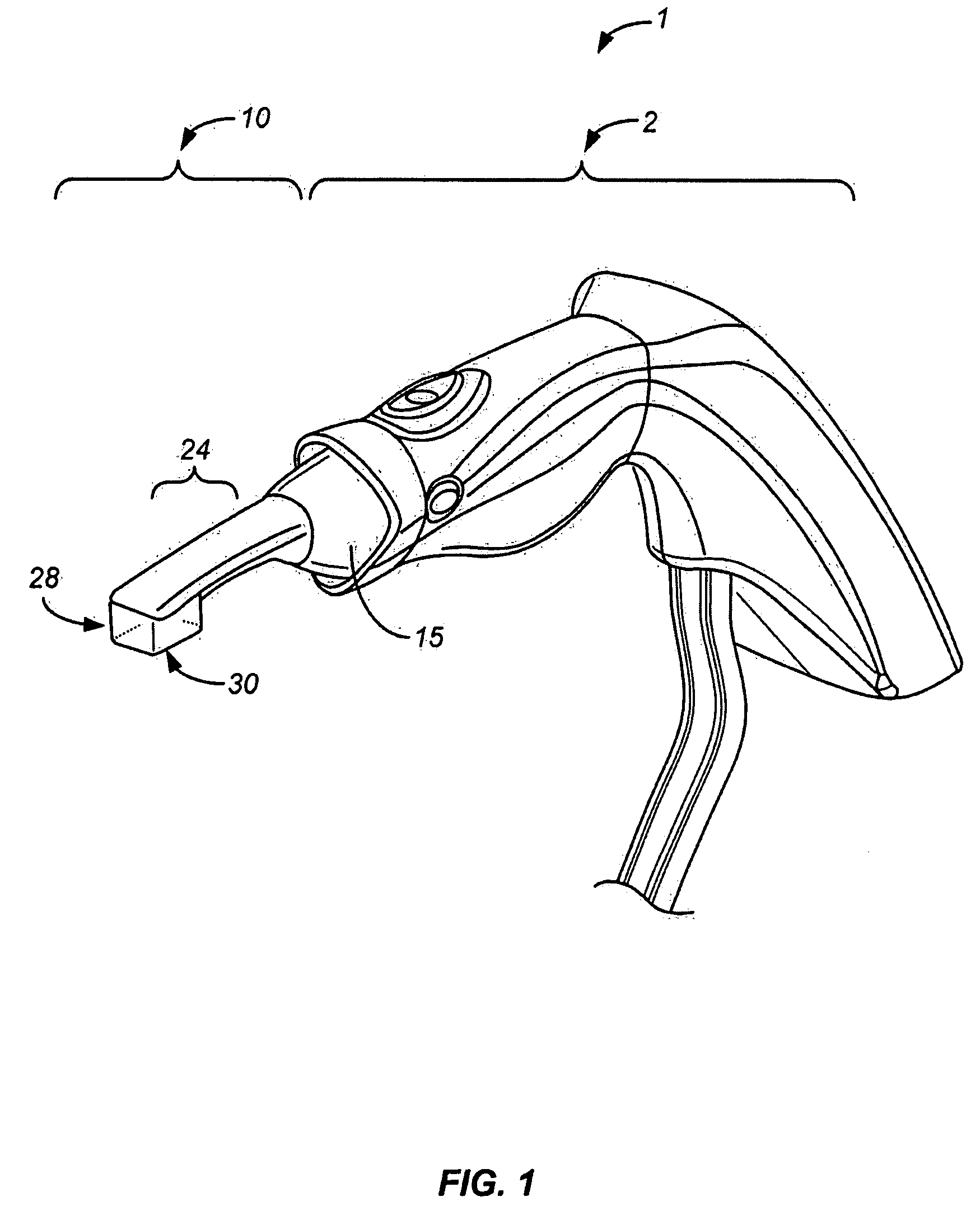

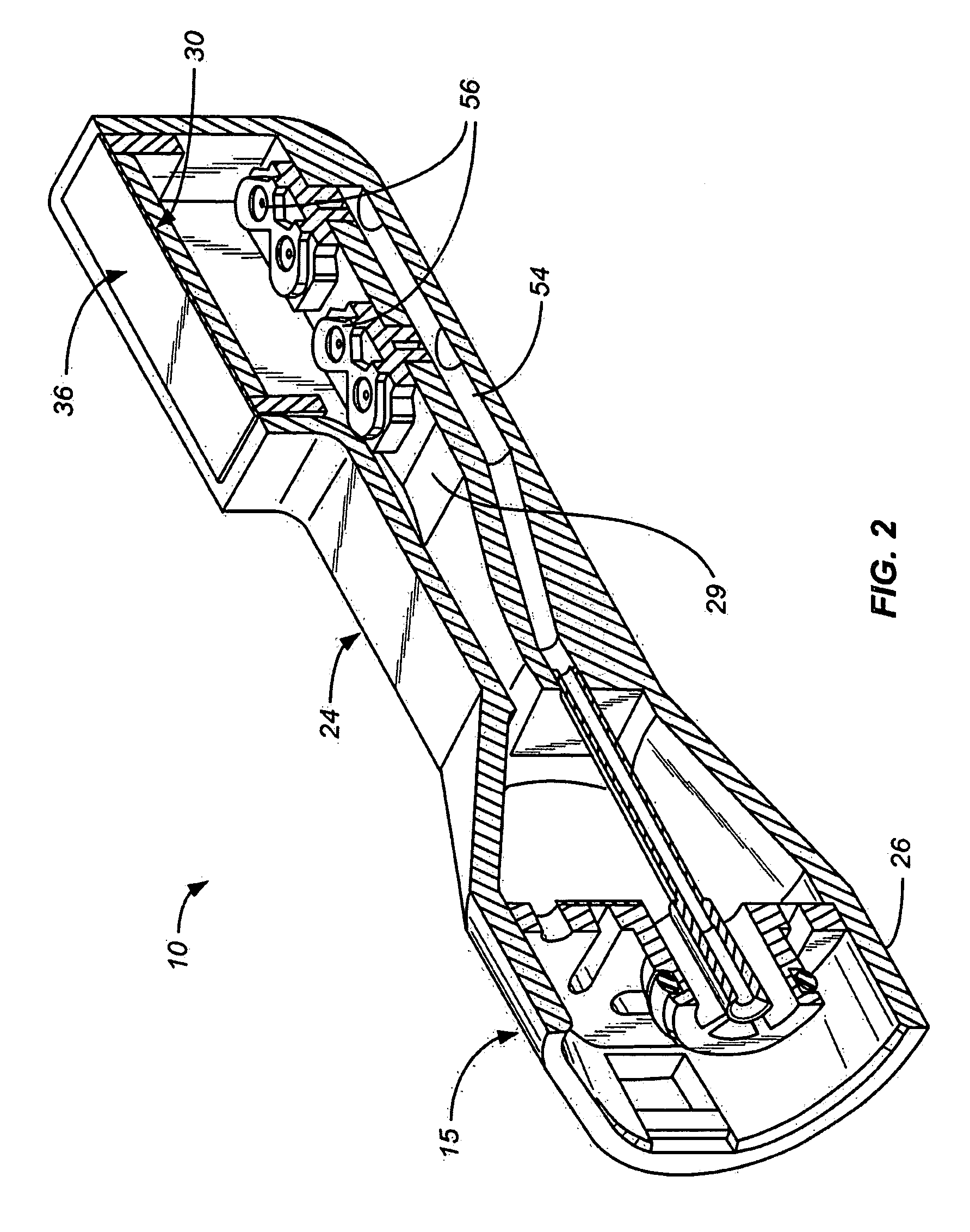

Vaginal remodeling device and methods

ActiveUS20070233191A1More accurate, deliberate, and visibleLevel of contacting pressure to be better controlledUltrasound therapyHeart defibrillatorsEpitheliumThermal denaturation

This invention relates generally to apparatus and methods for tightening tissue of the female genitalia by heating targeted connective tissue with radiant energy, while cooling the mucosal epithelial surface over the target tissue to protect it from the heat. Embodiments include a treatment tip that comprises both an energy delivery element and a cooling mechanism. As the treatment tip contacts the epithelial mucosa, the tip cools the mucosa by contact, and delivers energy thought the epithelium to the underlying tissue, thereby creating a reverse thermal gradient. The effect of the applied heat is to remodel genital tissue by tightening it. Such remodeling may include a tighter vagina and a tighter introitus. The tightening may be a consequence of thermal denaturation of collagen as well as a longer term healing response in the tissue that includes an increased deposition of collagen.

Owner:INMODE LTD

Vaginal remodeling device and methods

ActiveUS8961511B2More accurate, deliberate, and visibleLevel of contacting pressure to be better controlledUltrasound therapyHeart defibrillatorsEpitheliumThermal denaturation

This invention relates generally to apparatus and methods for tightening tissue of the female genitalia by heating targeted connective tissue with radiant energy, while cooling the mucosal epithelial surface over the target tissue to protect it from the heat. Embodiments include a treatment tip that comprises both an energy delivery element and a cooling mechanism. As the treatment tip contacts the epithelial mucosa, the tip cools the mucosa by contact, and delivers energy thought the epithelium to the underlying tissue, thereby creating a reverse thermal gradient. The effect of the applied heat is to remodel genital tissue by tightening it. Such remodeling may include a tighter vagina and a tighter introitus. The tightening may be a consequence of thermal denaturation of collagen as well as a longer term healing response in the tissue that includes an increased deposition of collagen.

Owner:INMODE LTD

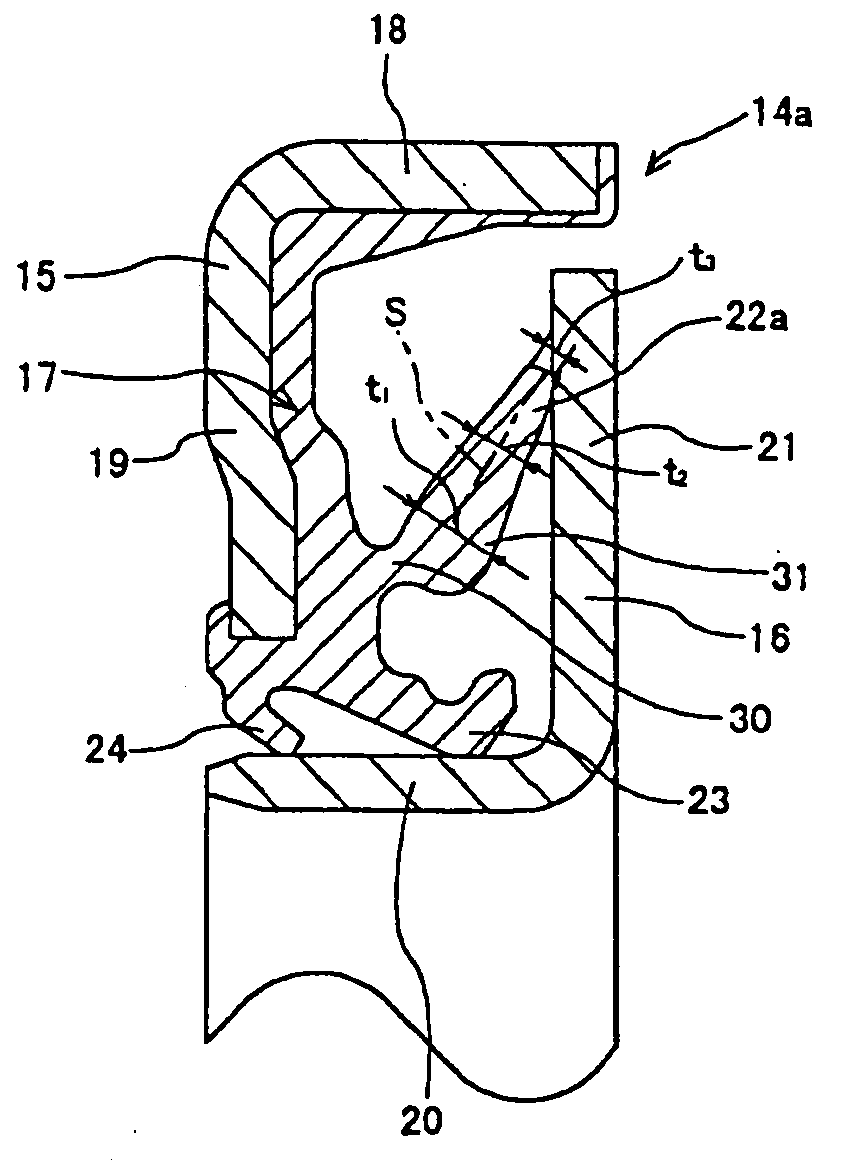

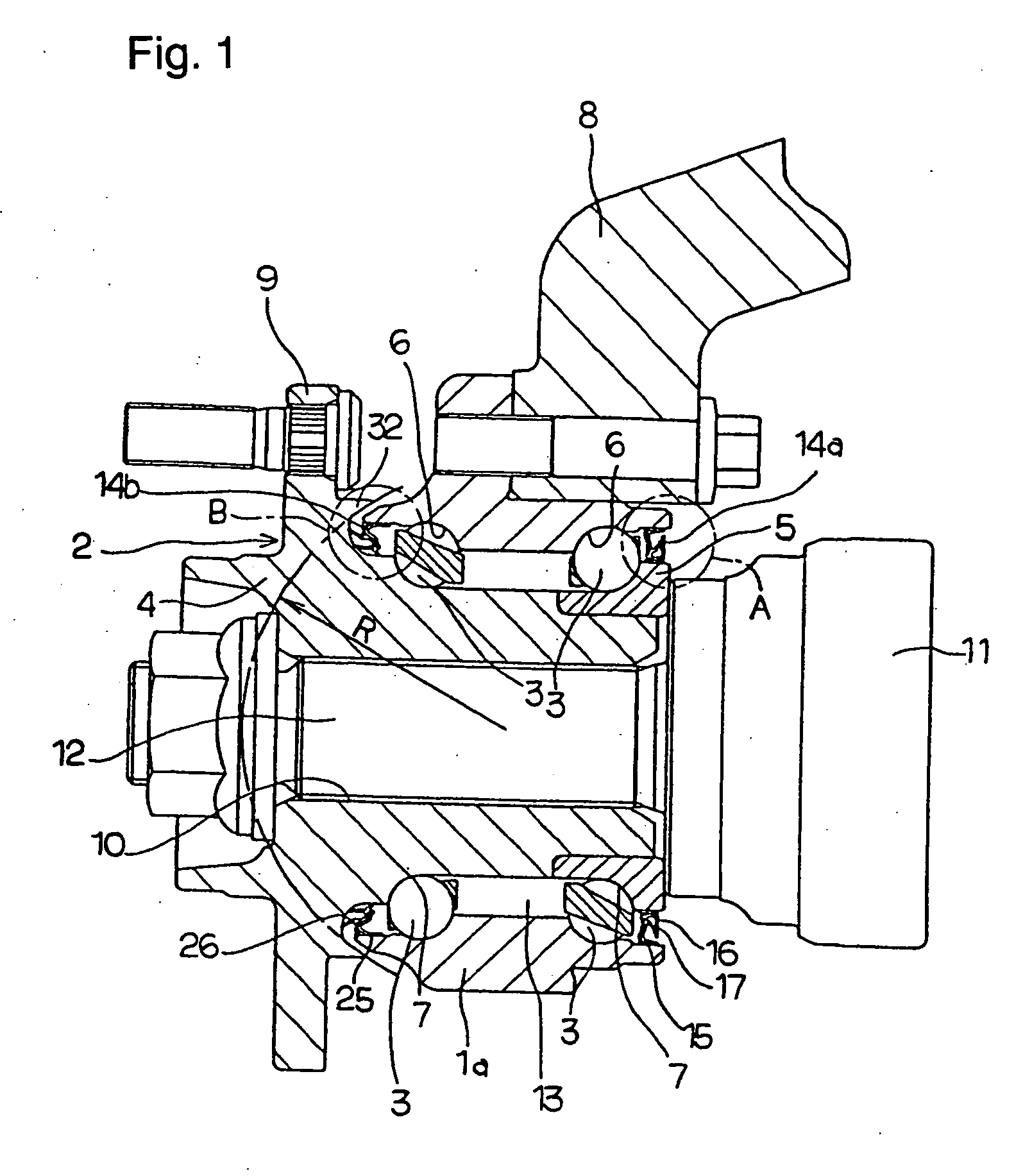

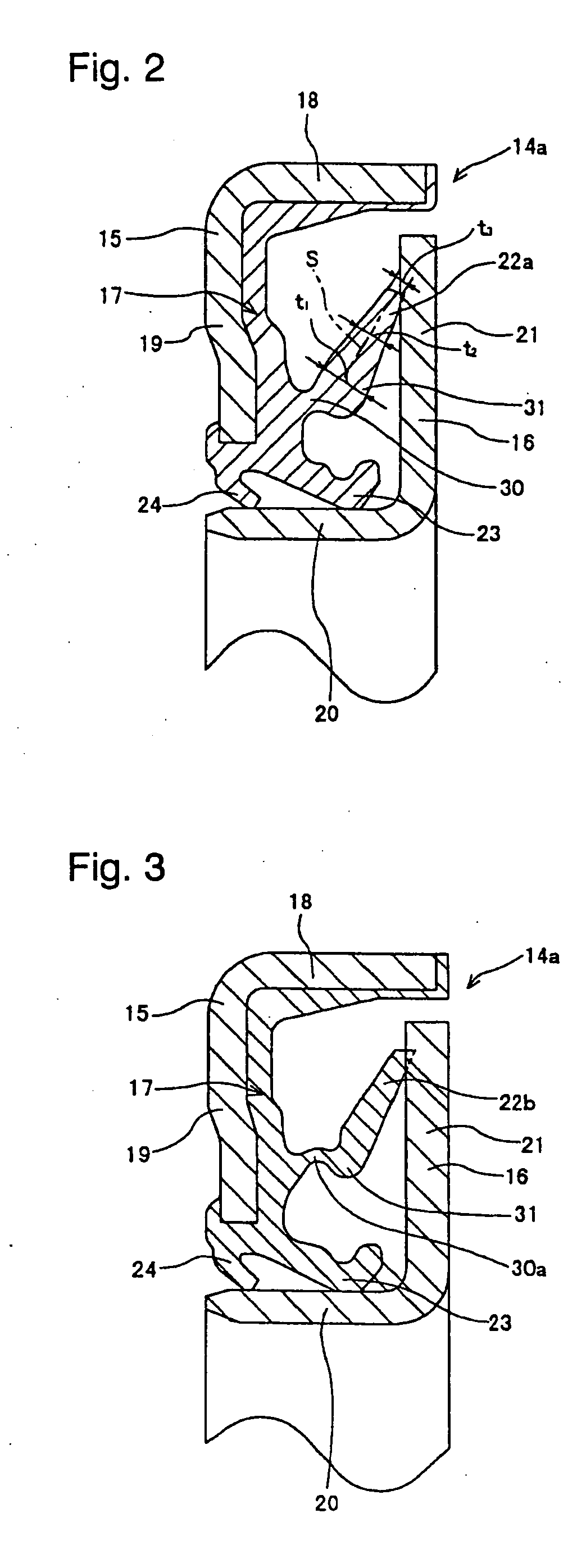

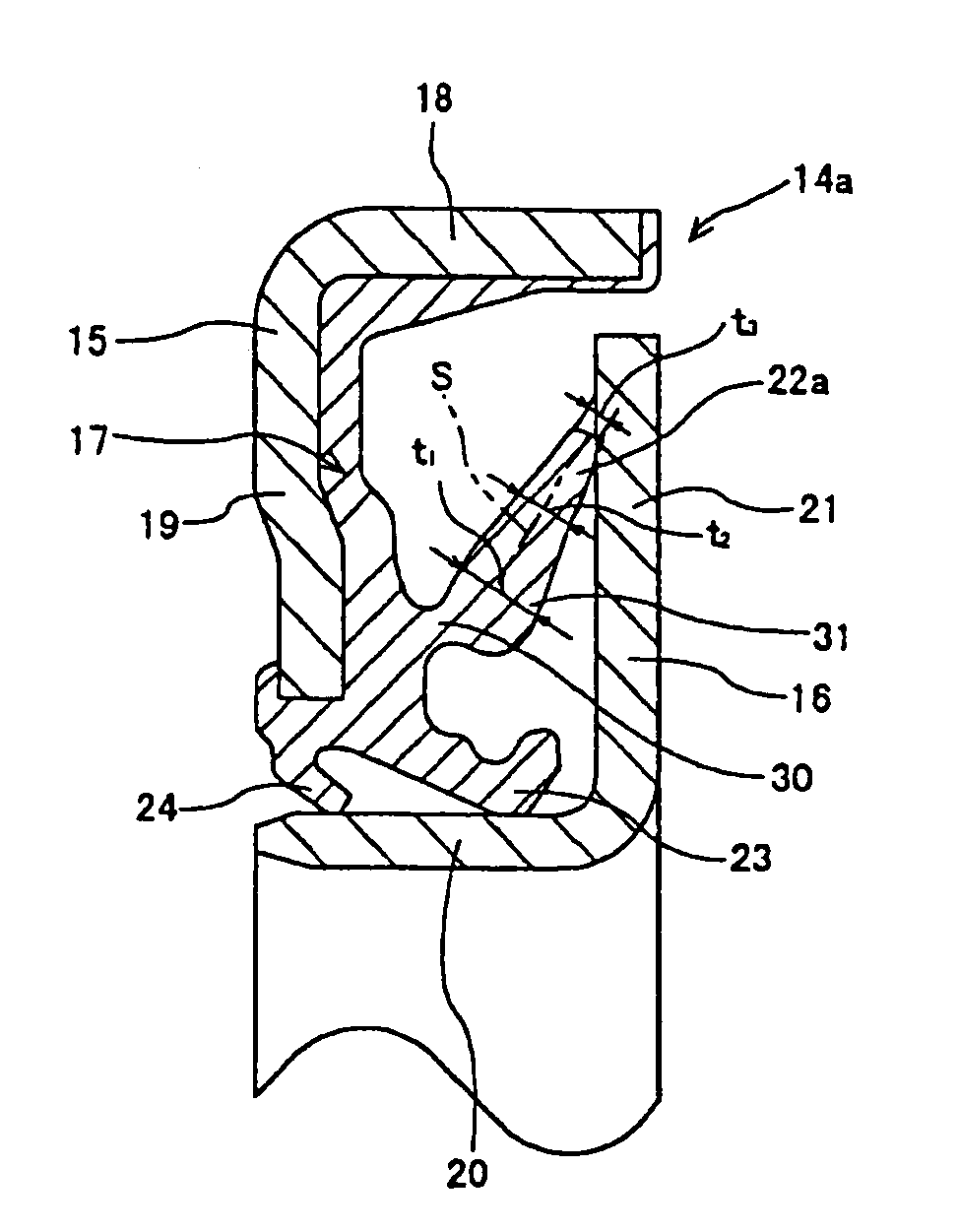

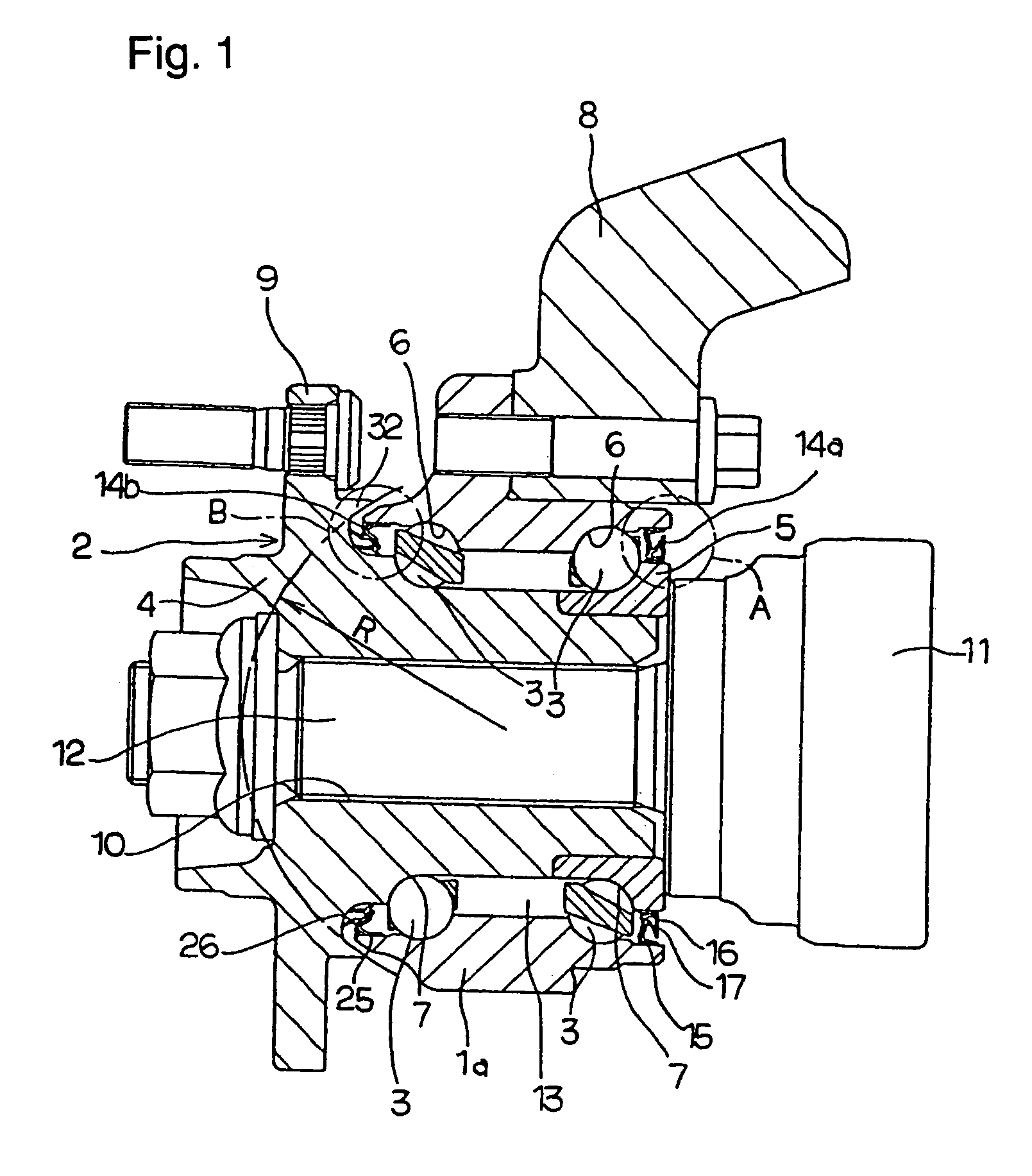

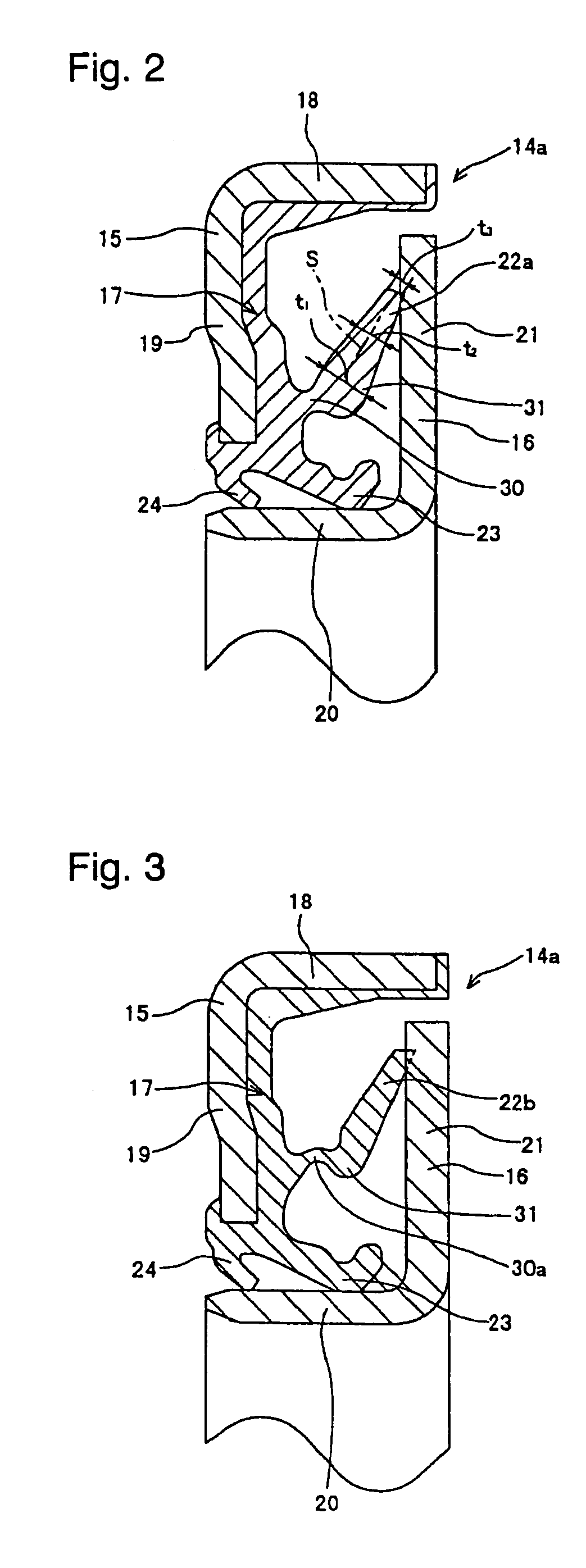

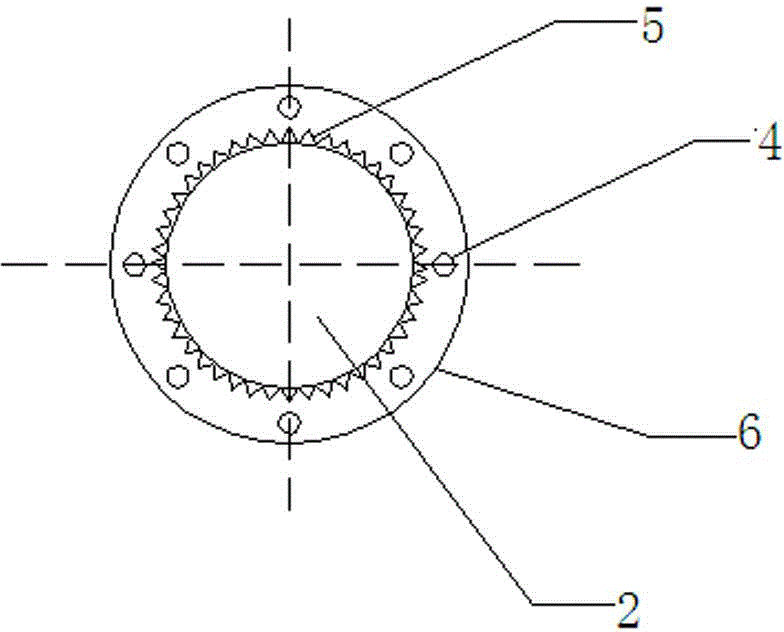

Seal ring and rolling bearing unit with seal ring

InactiveUS20050089254A1Reduce binding forcePromote generationEngine sealsRolling contact bearingsRolling-element bearingEngineering

It is intended that the rotation resistance is decreased while the durability and seal performance are kept in the rolling bearing unit with seal ring. The most thin wall-thickness portion 30 is provided in the vicinity of the base end of the seal lip 22a projecting laterally in sliding contact with the mating surface. The most thick wall thickness portion 31 is provided adjacent to the most thin wall thickness portion 30 on the tip end side. The thickness is gradually decreased from the most thick wall thickness portion 31 to the tip end. Further, the ratios of thickness in the respective portions 22a are properly controlled.

Owner:NSK LTD

Seal ring and rolling bearing unit with seal ring

InactiveUS7021830B2Reduce frictional resistanceImproved seal durabilityEngine sealsRolling contact bearingsRolling-element bearingThick wall

It is intended that the rotation resistance is decreased while the durability and seal performance are kept in the rolling bearing unit with seal ring.The most thin wall-thickness portion 30 is provided in the vicinity of the base end of the seal lip 22a projecting laterally in sliding contact with the mating surface. The most thick wall thickness portion 31 is provided adjacent to the most thin wall thickness portion 30 on the tip end side. The thickness is gradually decreased from the most thick wall thickness portion 31 to the tip end. Further, the ratios of thickness in the respective portions 22a are properly controlled.

Owner:NSK LTD

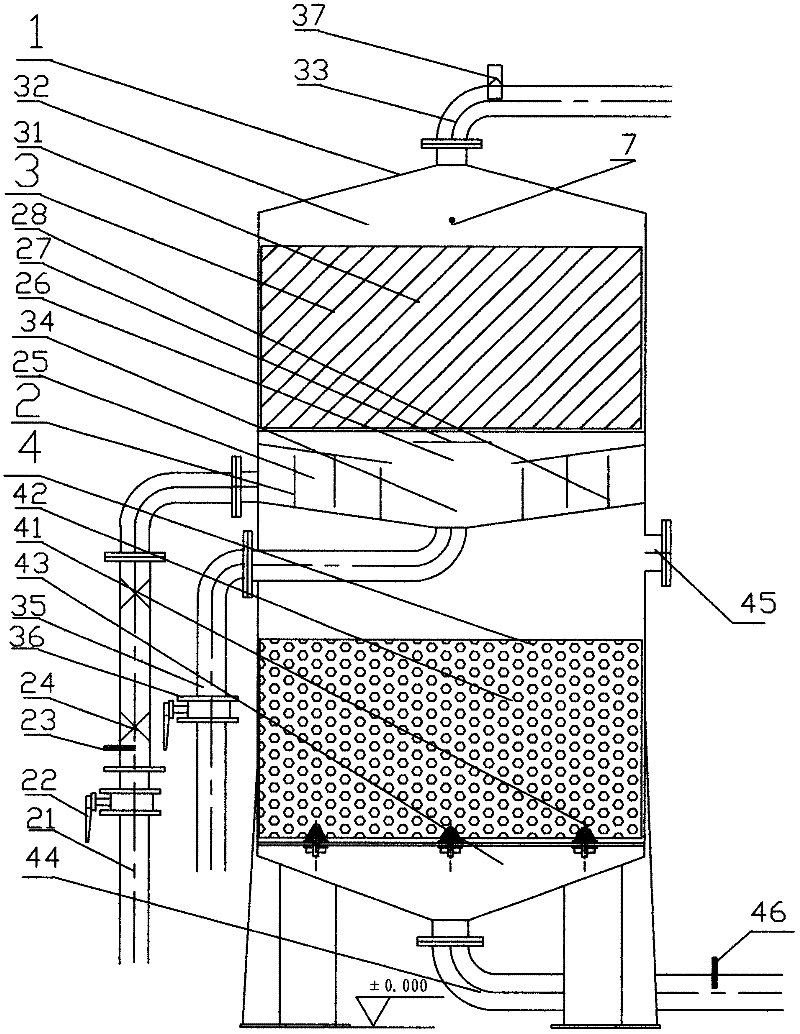

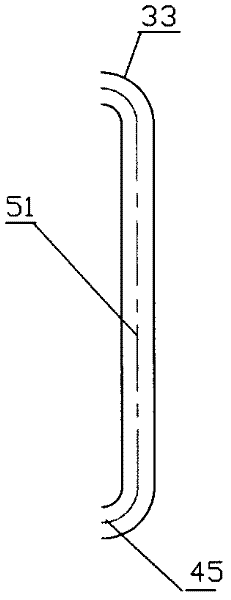

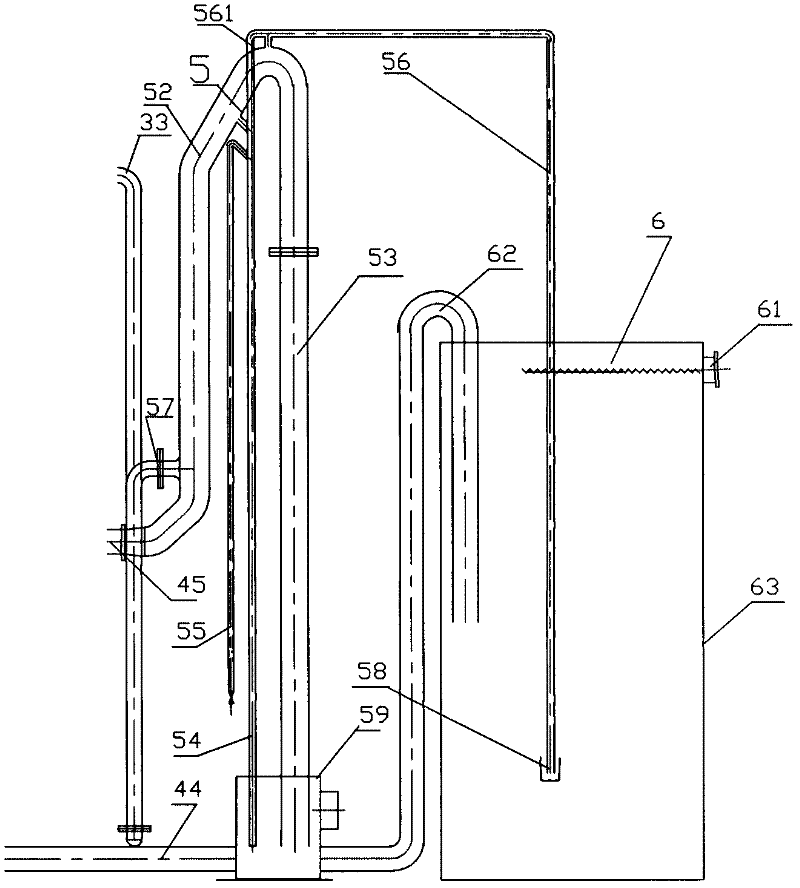

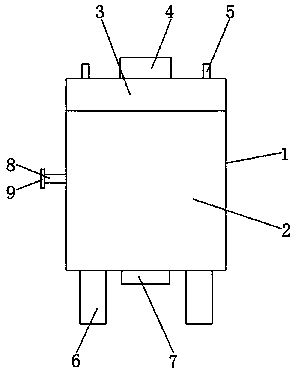

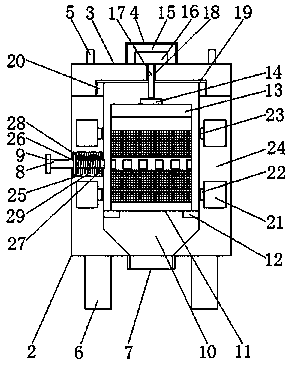

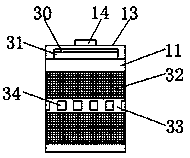

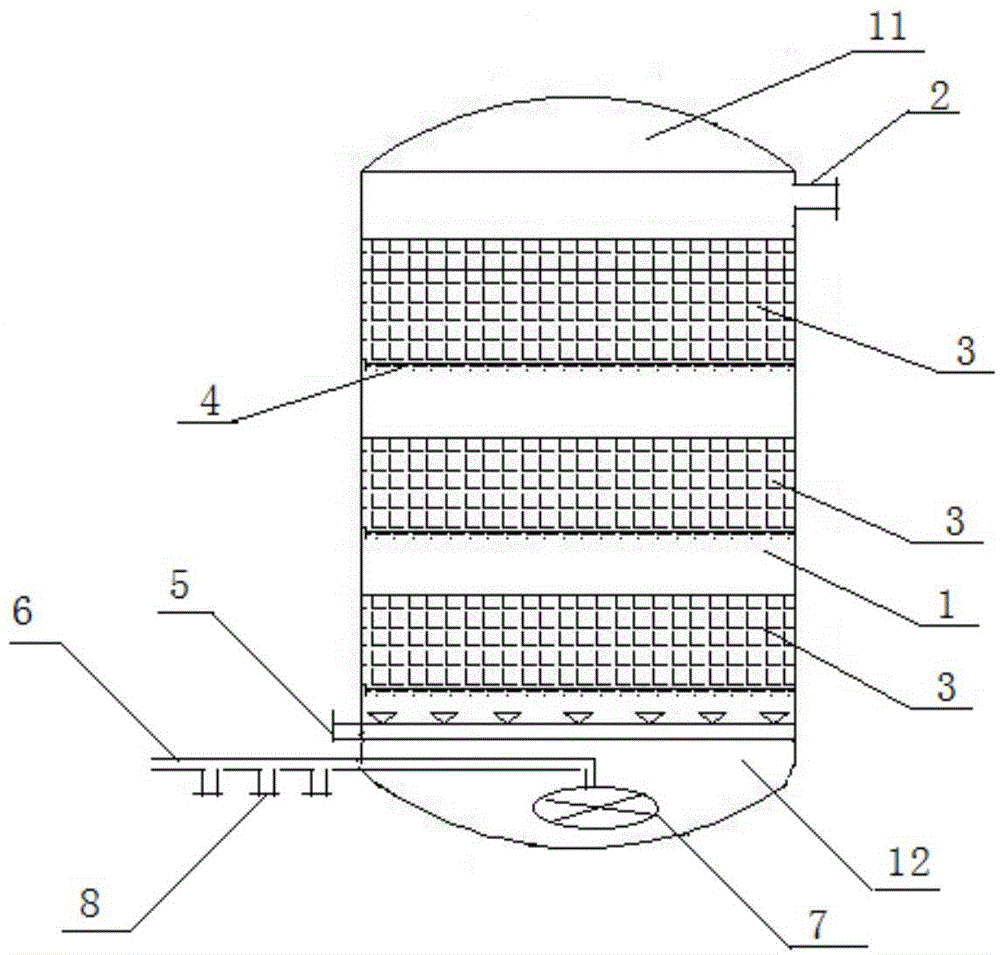

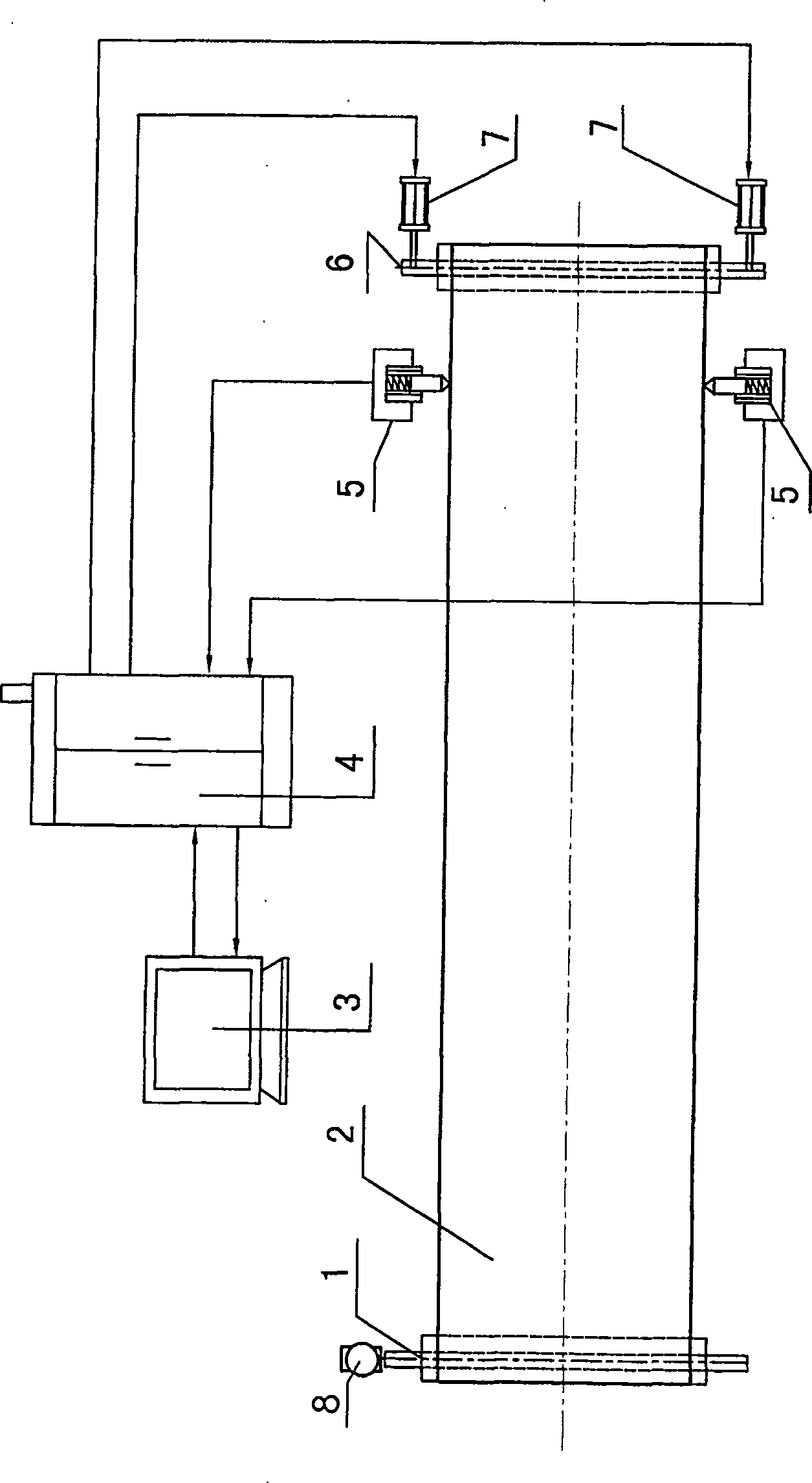

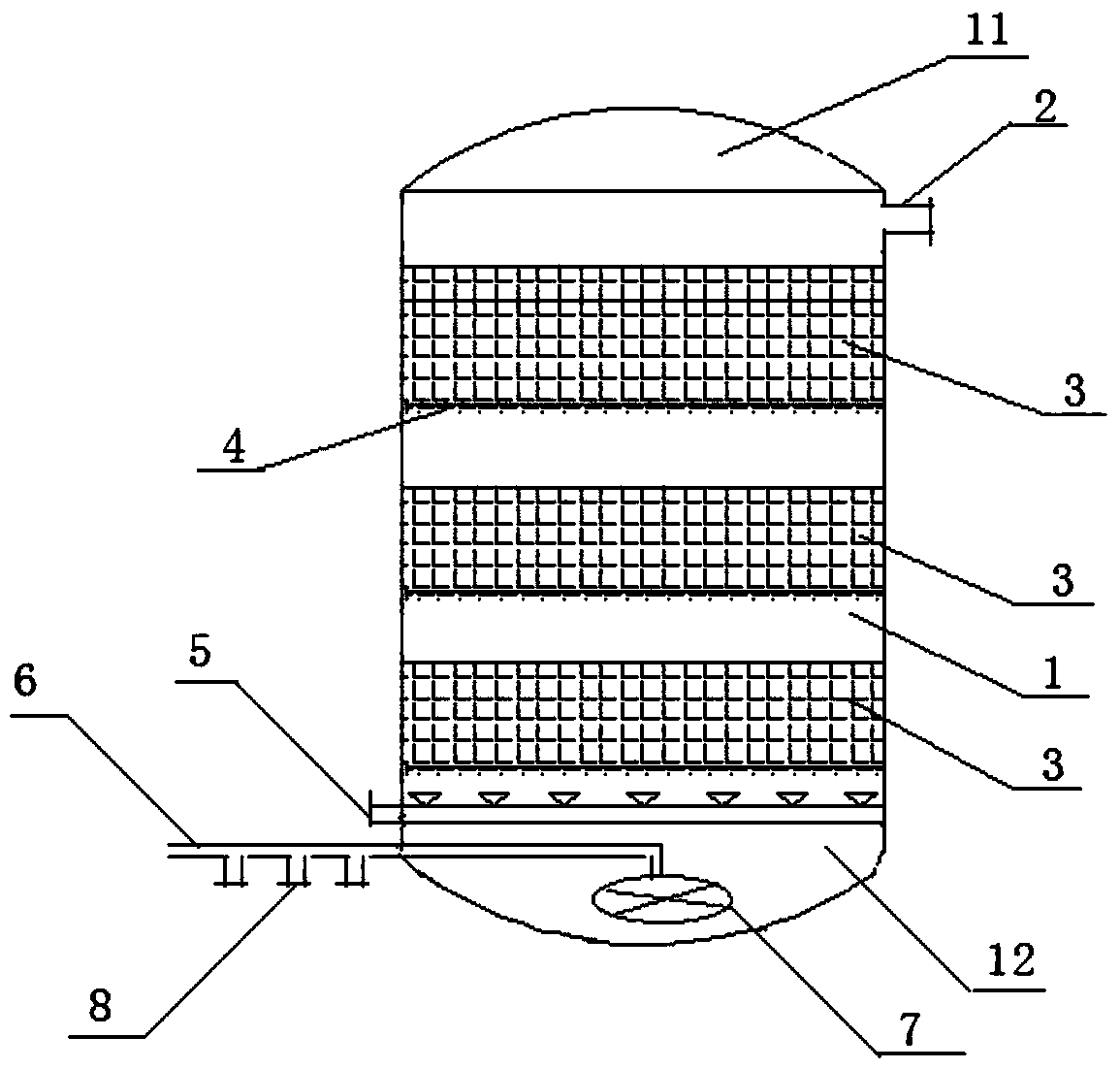

Multi-adaption pressure-type integral water purifier

InactiveCN102249446AOvercoming fixed structuresReduce lossesMultistage water/sewage treatmentSludgeWater source

The invention discloses a multi-adaption pressure-type integral water purifier, which relates to the technical field of water treatment, particularly relates to the problems that conventional small and medium-sized water plants are of complex structures and difficult to manage, and other integral water purification equipment has poor adaptability. The water purifier comprises a feedback-adjustable coagulant feeding device, a folded-plate reaction chamber, a uniform to-be-precipitated water dispenser, an inclined-tube sedimentation chamber, a sludge collection chamber, a sand-filtering chamber, and a connecting pipe or siphon back-washing piping system; and the water purifier is characterized in that the coagulation, precipitation, filtering and sludge disposal of conventional tap water are performed integrally in a pressure type tank; the operations of automatic water production and back washing are implemented by using the connecting pipe or siphon back-washing piping system; the whole water purification process is completed by using the original gravitational potentials of source water; and the discharged water also can be delivered to a high-level clear water reservoir by using original water pressures. The water purifier is manufactured into pressure-type tanks with proper size according to different water production amounts; and the multi-adaptable pressure-type integral water purifier disclosed by the invention is easy to transport, build, manage and low in cost, therefore, the integral water purifier can be used for solving the construction problems of water plants with different headwaters for the country, schools, troops and emergency water supply.

Owner:广州中科华康水处理技术有限公司

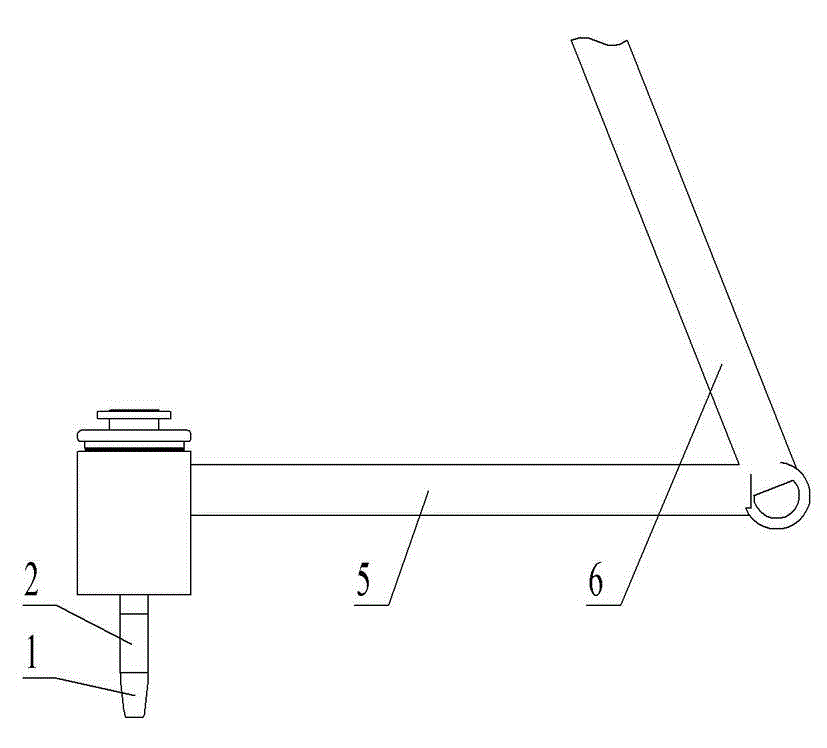

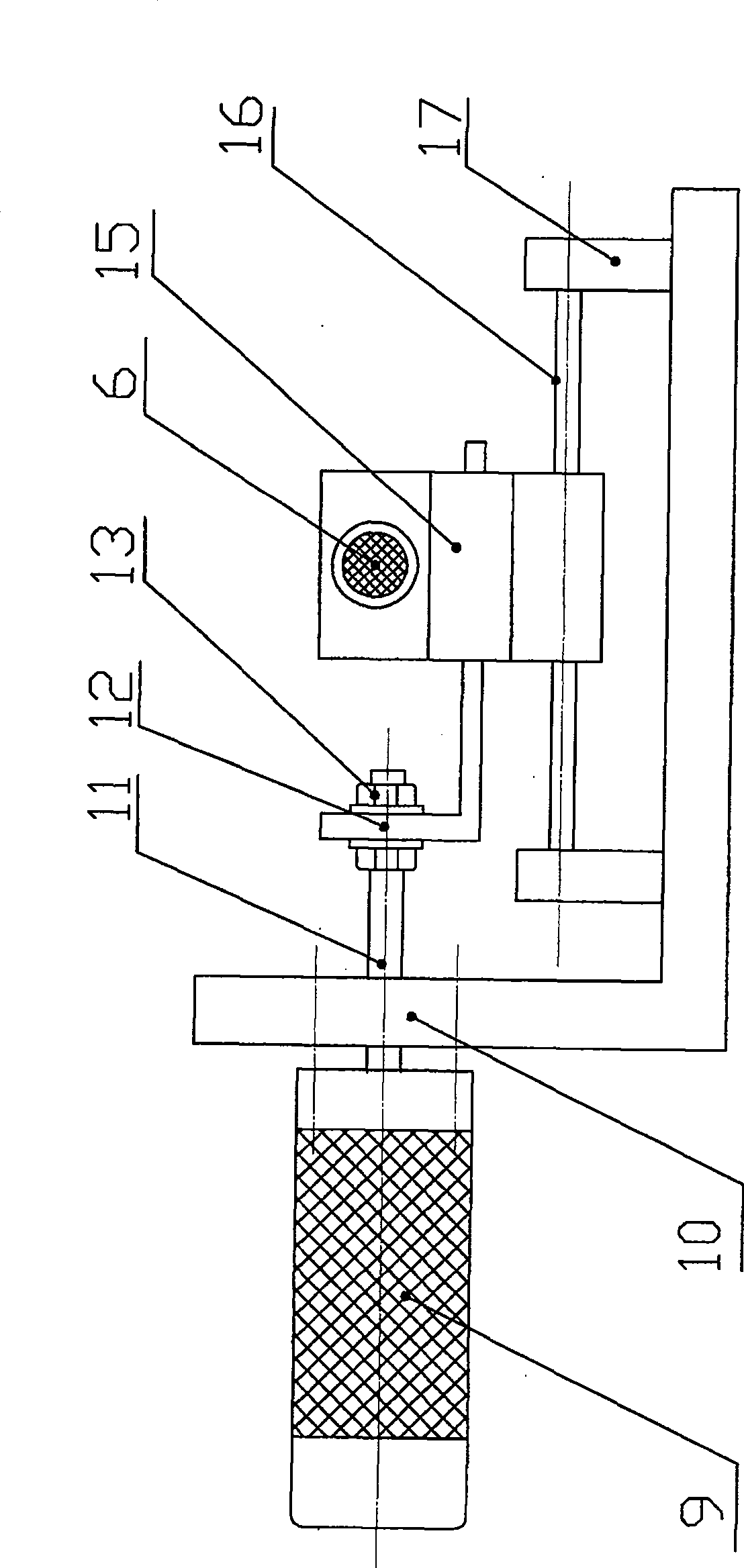

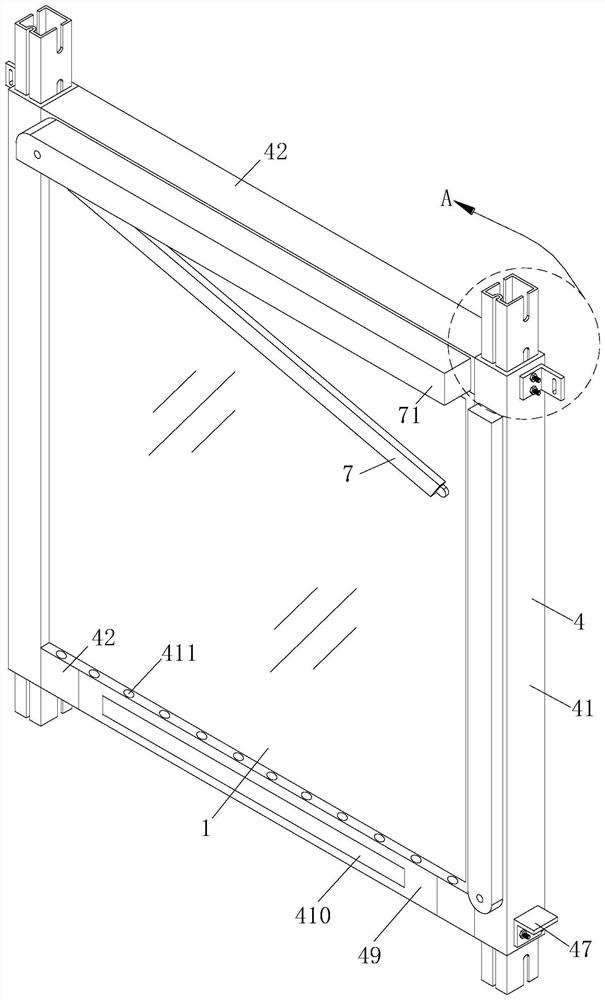

Scraper adjusting device

The invention discloses a scraper adjusting device and relates to the technical field of textile printing and dyeing machinery. The scraper adjusting device comprises a scraper holder for mounting a scraper. The scraper holder is slidably connected with a frame of a printing machine through a sliding arm. An elastic device is disposed between the scraper holder and the sliding arm. The elastic device is provided with a vertical rod disposed on the scraper holder. A spring and a sleeve are sleeved outside the vertical rod. The spring is disposed in the sleeve. The upper end of the sleeve is connected with a fastener used for adjusting pretension of the spring. A limit member fitting with the sleeve and the fastener is disposed on the vertical rod. The sleeve is fixedly connected with the sliding arm through a connecting rod. Compared with the prior art, the scraper adjusting device is simple for scrape pressure adjustment and high in operating efficiency. The elastic device is disposed on the scraper holder, so that the scraper is tightly pressed on a bedplate of the printing machine by the action of elasticity of the spring during motion, even force application and even contact area are achieved and printing quality is improved greatly.

Owner:SOUTHERN CHINA REGENERATED COTTON YARN WUZHOU CO LTD

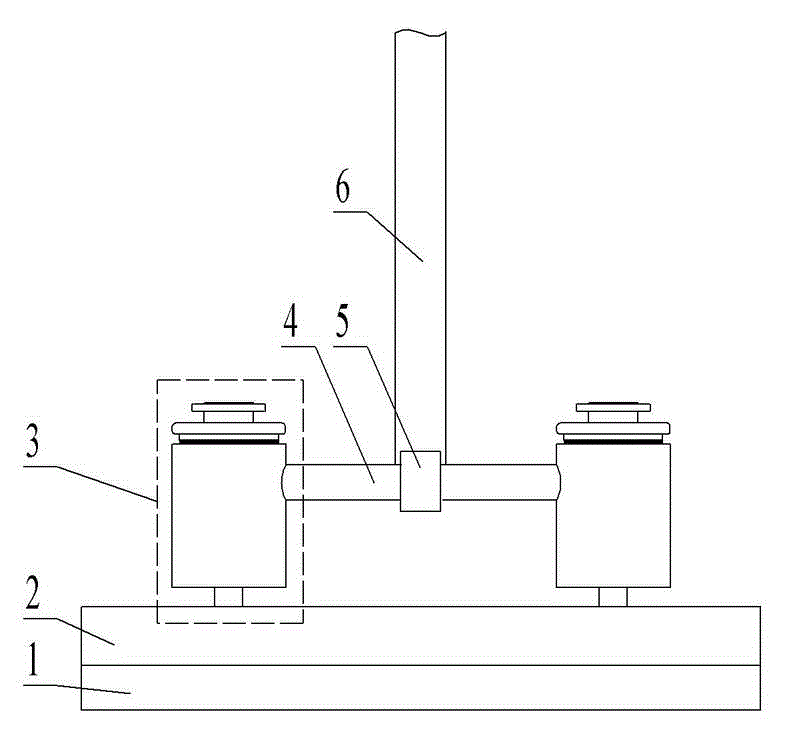

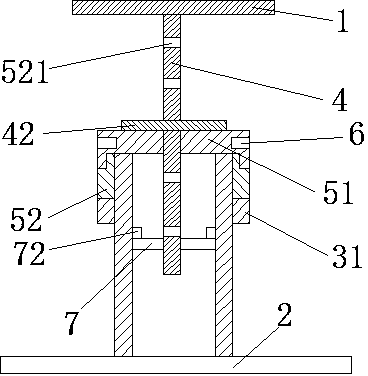

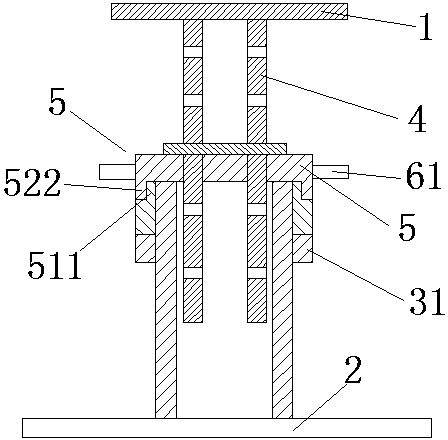

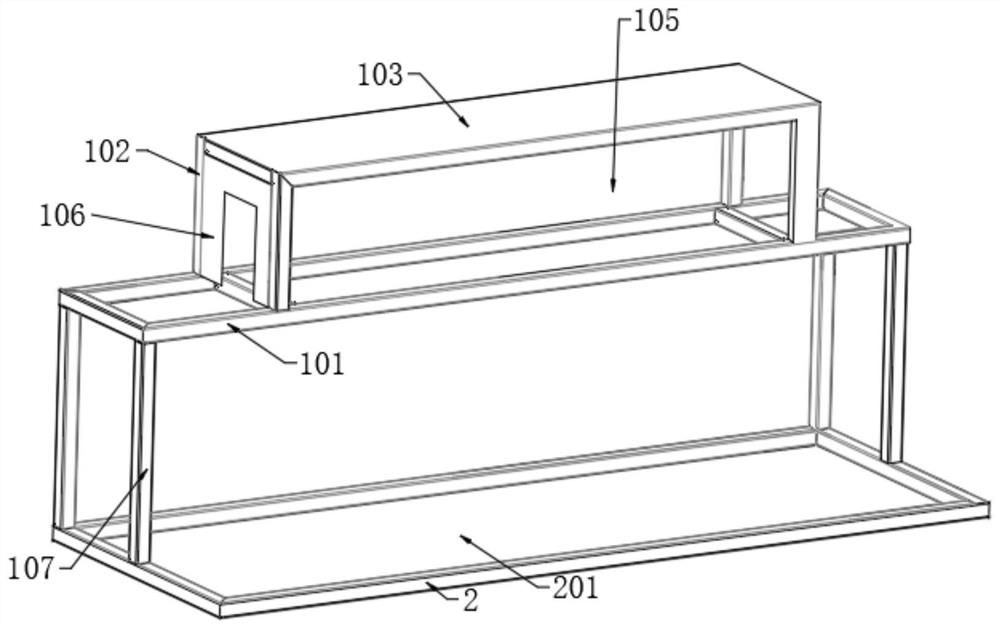

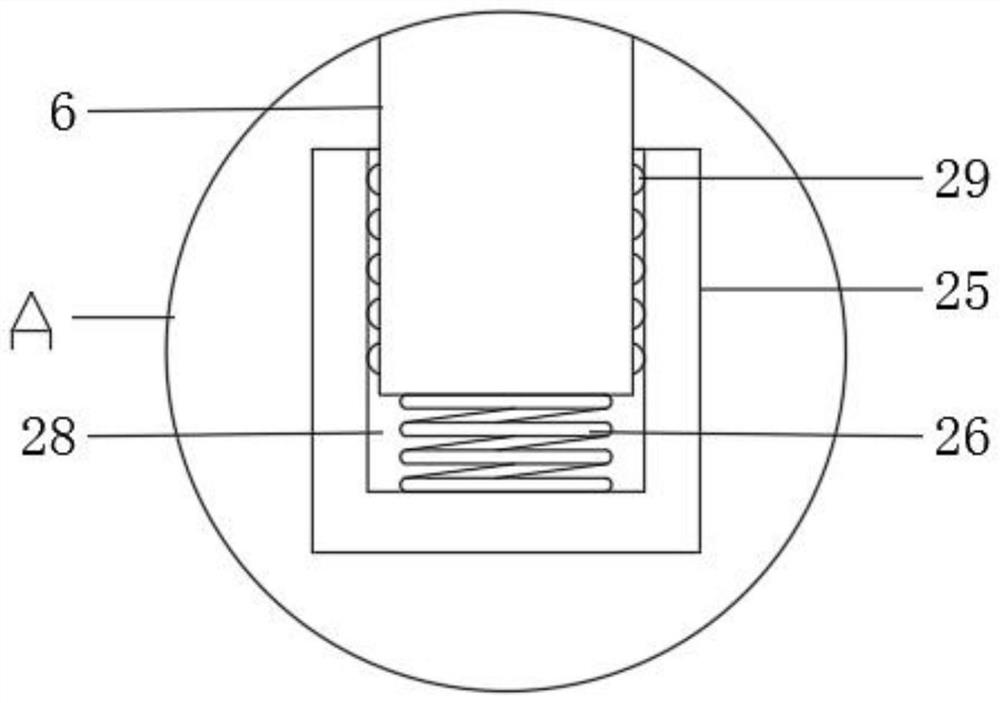

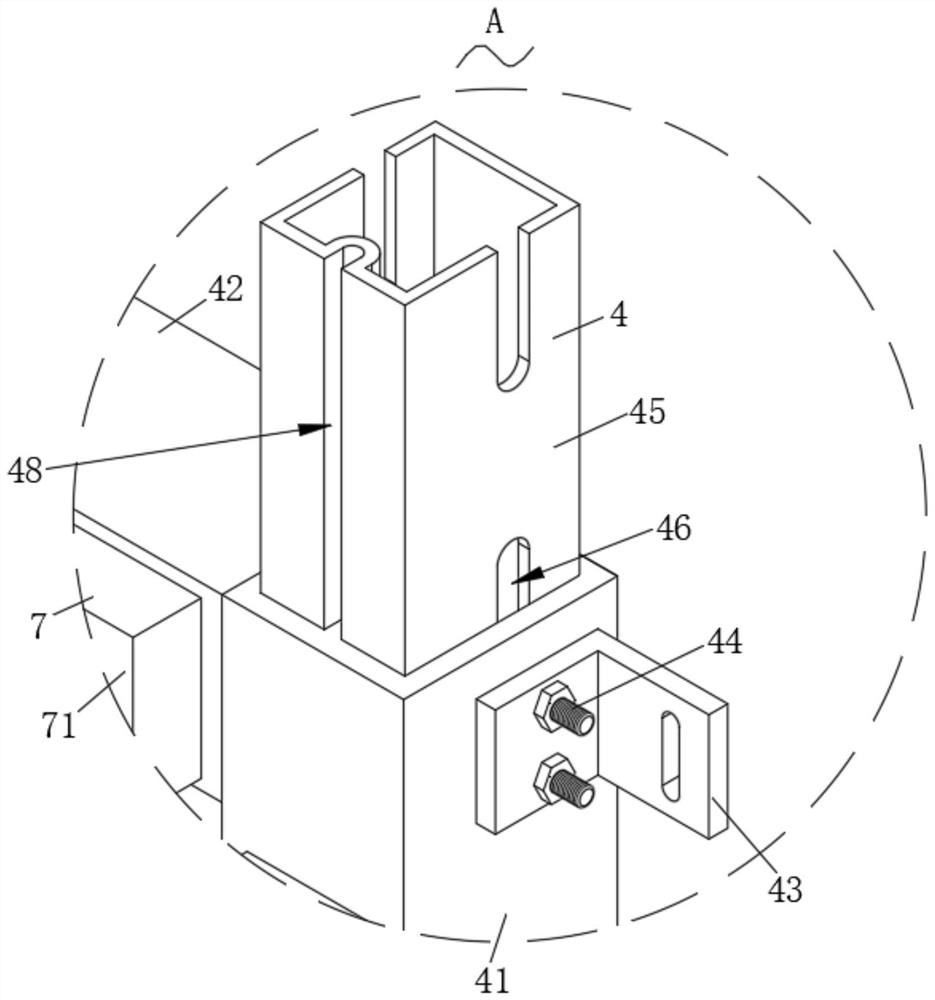

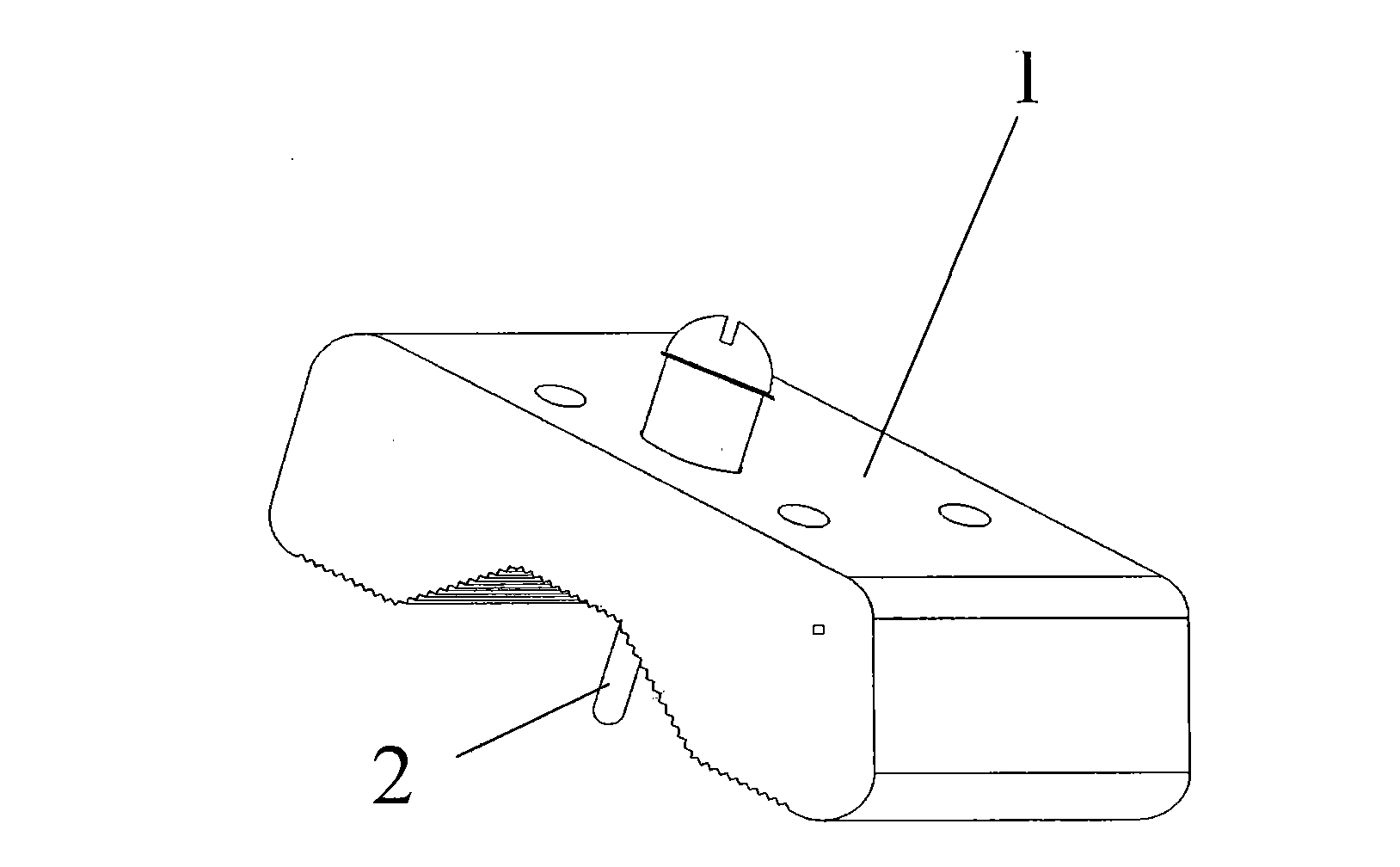

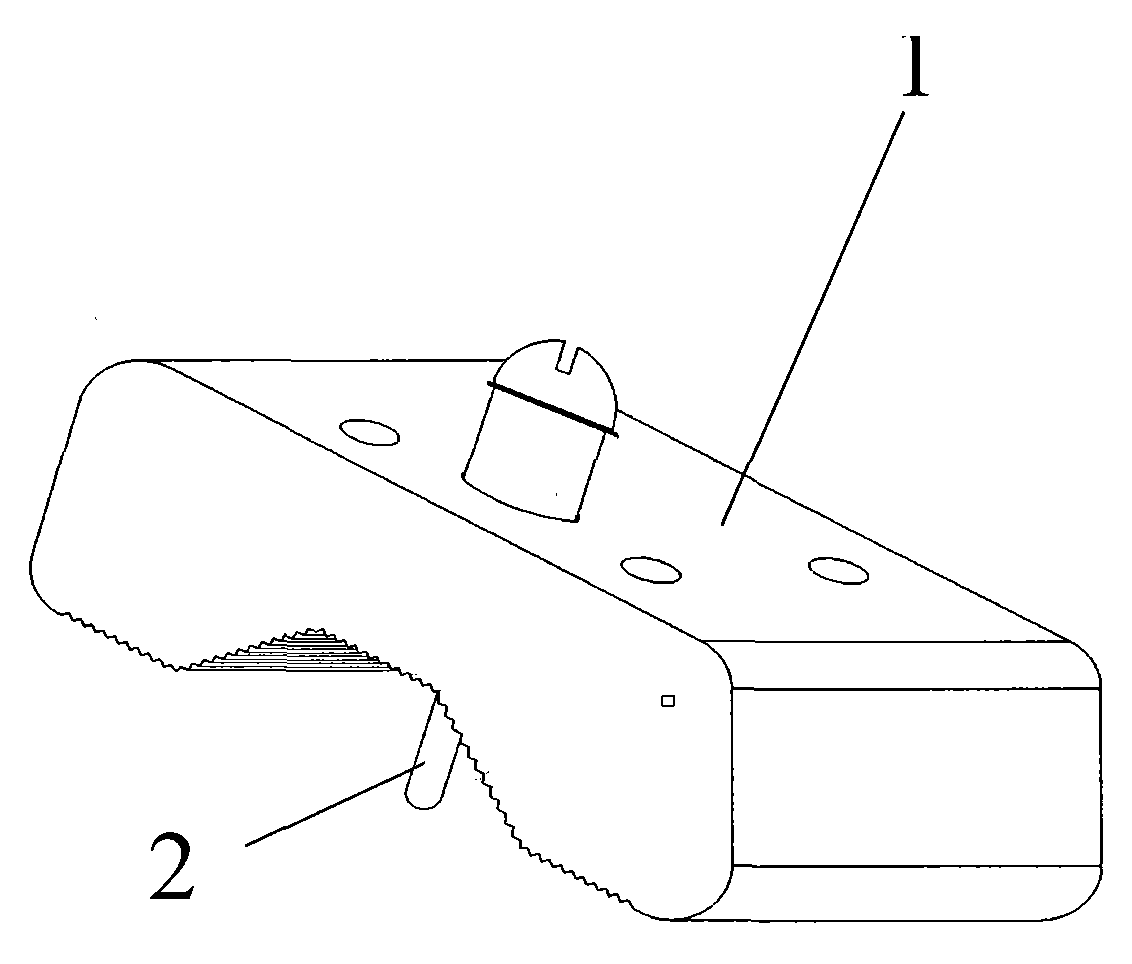

Building support for construction

ActiveCN104060852AIncrease contact areaUniform contact surfaceShoresArchitectural engineeringBuilding construction

The invention relates to the field of buildings, in particular to a building support for construction. The building support is high in supporting intensity and convenient to use. The building support comprises an upper supporting plate and a lower supporting plate. A guiding cylinder is arranged on the lower supporting plate. A supporting rod is arranged on the lower surface of the upper supporting plate. A supporting sleeve is arranged at the upper end of the guiding cylinder in a sleeved mode. The supporting sleeve comprises a sleeve body and a sleeve cover. The supporting rod penetrates through a through hole from top to bottom and is inserted into the guiding cylinder. A limiting part is arranged between the sleeve body and the sleeve cover. A position clamping part is arranged on the outer side of the sleeve cover. Outer threads are arranged on the outer cylinder wall of the guiding cylinder. Inner threads are arranged on the inner side of the lower portion of the sleeve body, or an adjusting ring is arranged at the bottom end of the sleeve body. A plurality of through grooves are formed in the supporting rod. The support further comprises locating inserting strips matched with through grooves. Parts of the building support are balanced in stress and stable in supporting and pushing, each operation action can be completed under a visible condition, visibility is achieved, the upper supporting plate and the supporting rod cannot rotate automatically, safety is high, supporting strength is high, and the angle of the upper supporting plate can be adjusted by adjusting the sleeve cover.

Owner:浙江升浙建设集团有限公司

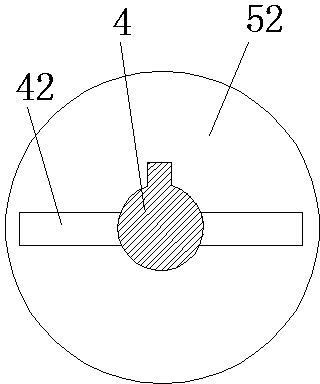

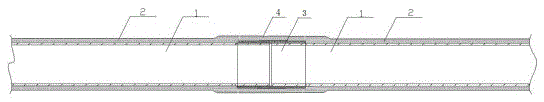

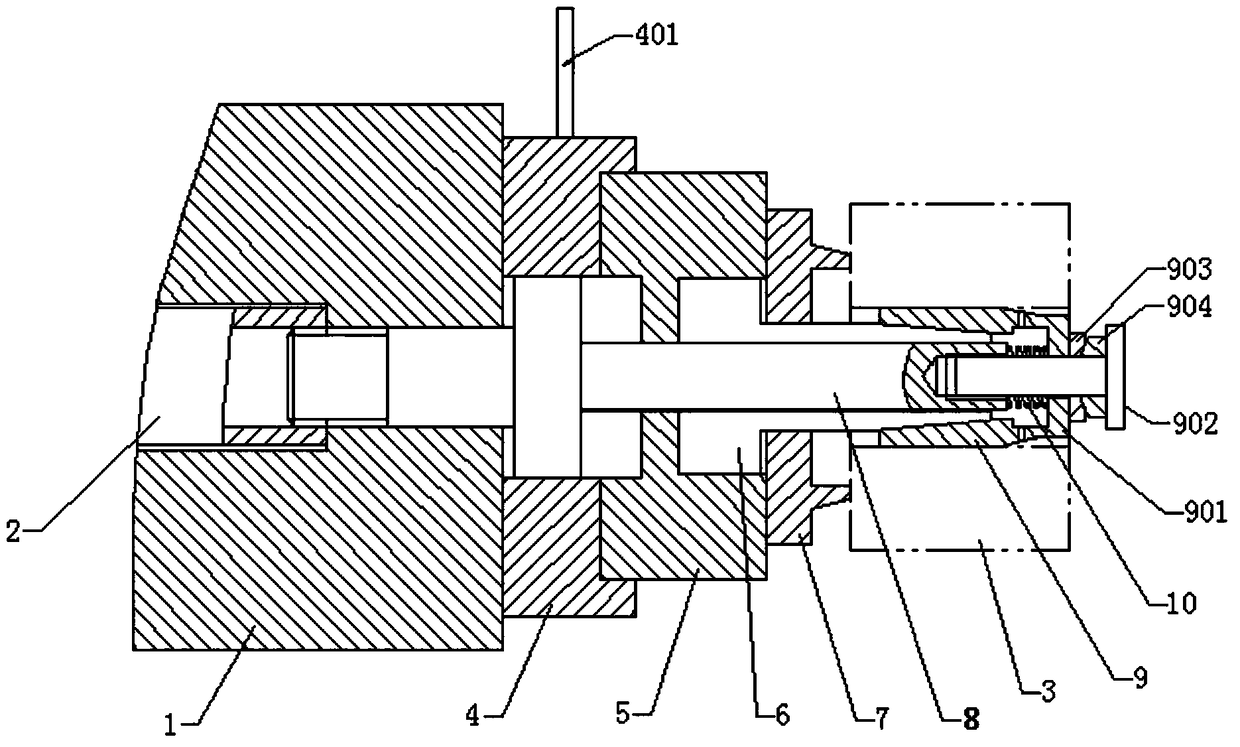

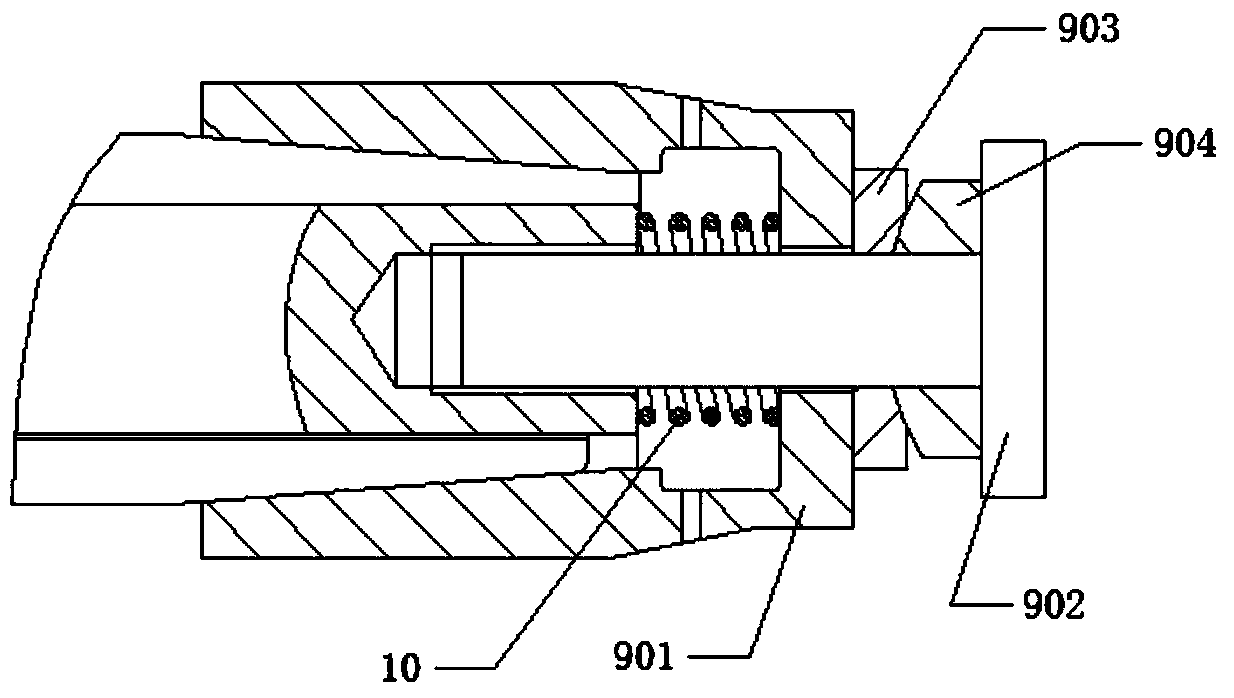

Insulating tube bus-bar connecting device and connecting method thereof

InactiveCN105655737AReduce volumeUniform contact surfaceShape memory alloy connectionsConnection contact member materialElectrical and Electronics engineering

The invention discloses an insulating tube bus-bar connecting device and a connecting method thereof. The connecting device comprises two insulating tube bus-bars and a tube bus-bar connector which is a tubular connector, the inner diameter of the tube bus-bar connector is small than the outer diameter of an insulating tube bus-bar core material, and the outer diameter of the tube bus-bar connector is larger than the outer diameter of the insulating tube bus-bar core material. The connecting method comprises the steps that 1, the connection parts of the two ends of the insulating tube bus-bars and the inner surface and outer surface of the tube bus-bar connector are polished clean and subjected to tinning treatment; 2, the tube bus-bar connector is subjected to heating and heat preservation treatment at certain temperature, and heating and heat preservation treatment are stopped when the inner diameter of the tube bus-bar connector is expanded to be larger than the outer diameter of the tube bus-bars under the action of heating and heat preservation treatment; 3, the middle of the tube bus-bar connector is fixedly clamped through a tool clamp, the connection parts of the insulating tube bus-bar ends are inserted into the tube bus-bar connector; 4, the joints of the tube bus-bar connector and the insulating tube bus-bar ends are cooled; 5, insulating treatment is conducted on the tube bus-bar connector and the joints of the tube bus-bar connector and the insulating tube bus-bar ends after cooling is conducted.

Owner:湖北兴和电力新材料股份有限公司

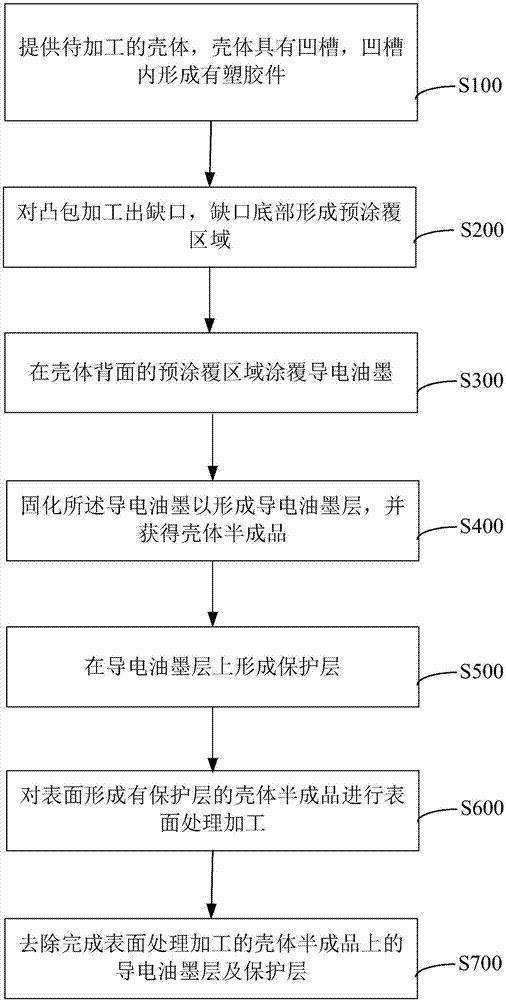

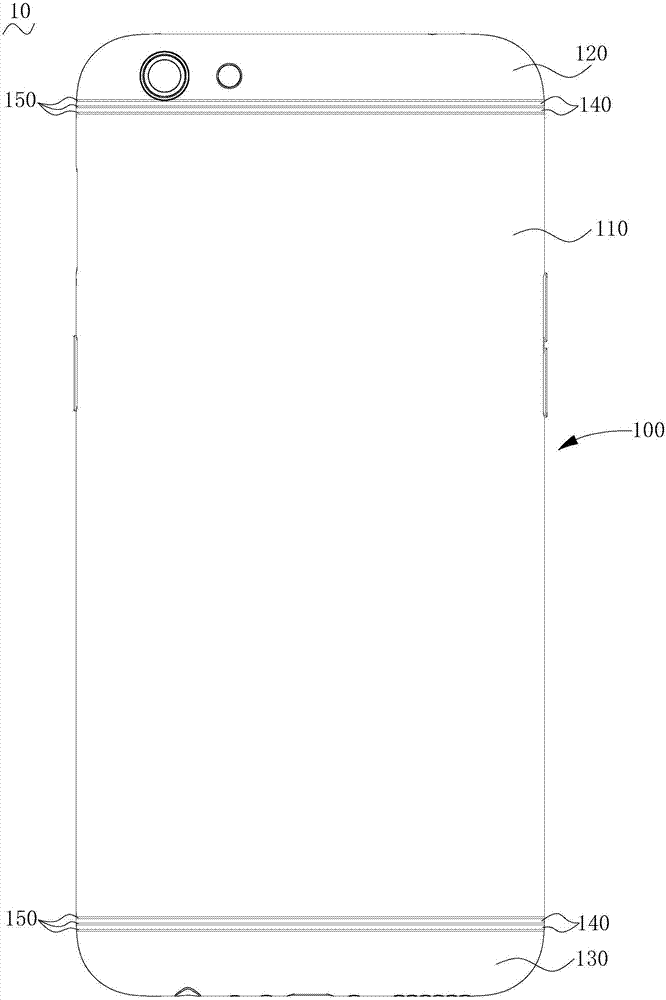

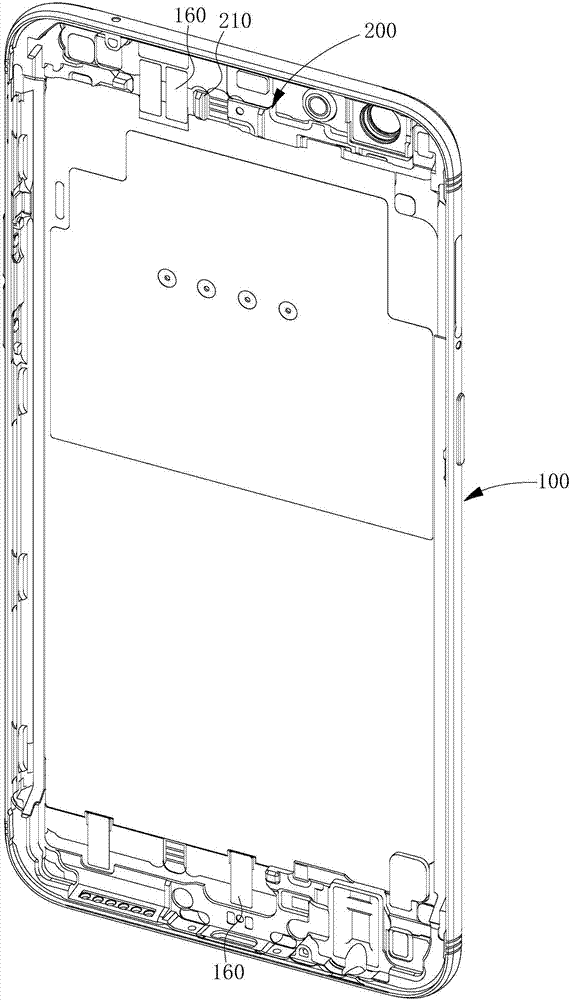

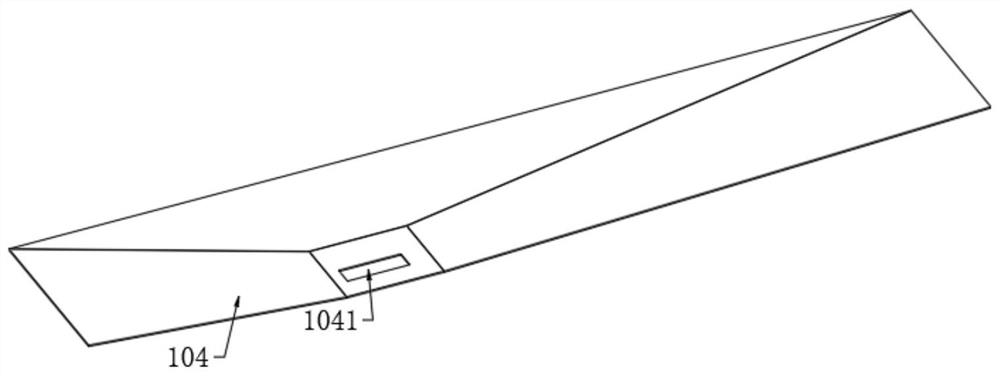

Terminal shell and preparing method thereof

ActiveCN106968005AImprove yieldImprove conductivityAnodisationPortable casingsEngineeringWork in process

The invention relates to a terminal shell and a preparing method thereof. The preparing method of the terminal shell includes the steps that a to-be-machined shell is provided, the shell is provided with a groove, and plastic parts are formed in the groove; the plastic parts are coated with conductive ink so that the parts, on the two sides of the groove, of the shell are conductive; the conductive ink is cured to form an conductive ink layer, and a semi-finished product of the shell is obtained; a protection layer is formed on the conductive ink layer; the semi-finished product, with the surface coated with the protection layer, of the shell is subject to surface treating and machining; and the conductive ink layer and the protection layer of the semi-finished product, completing surface treating and machining, of the shell are removed. By means of the preparing method of the terminal shell, as the conductive ink has mobility, the shell can have good electrical conductivity, the overall preparing process is simple in operation, efficiency is high, and the machining cost is low.

Owner:GUANGDONG EVERWIN PRECISION TECH

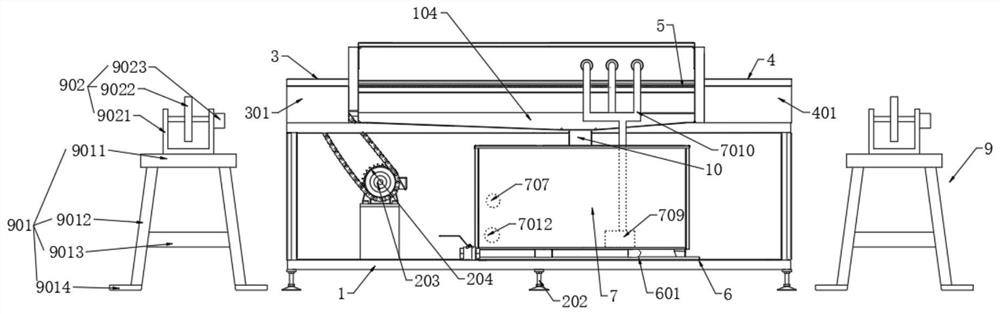

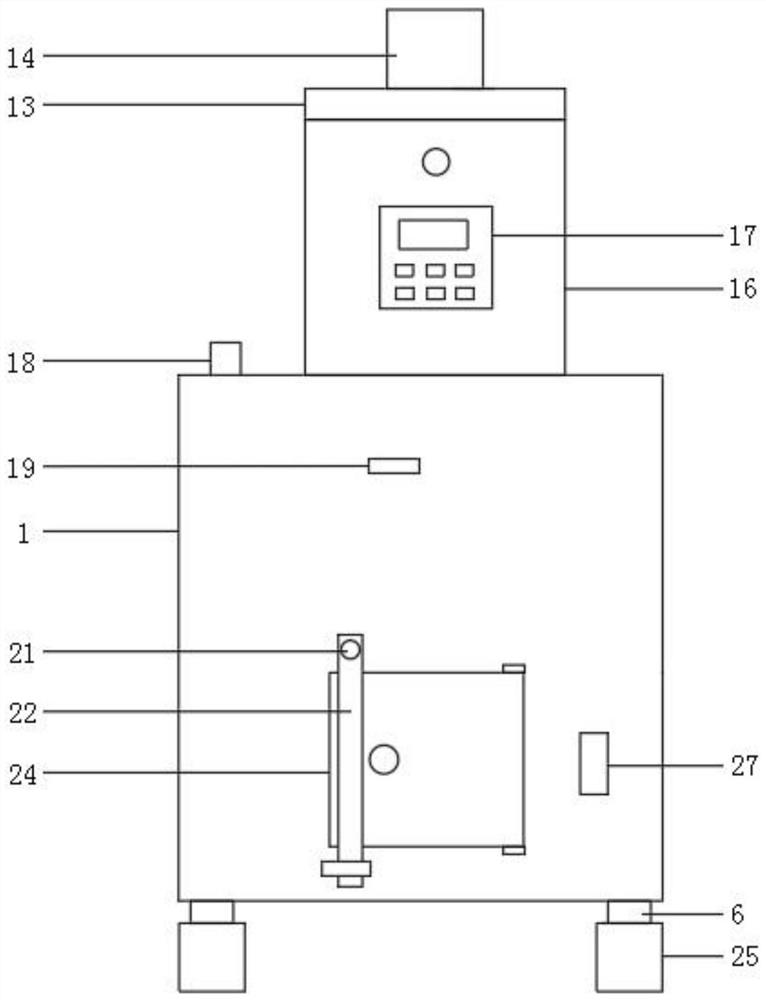

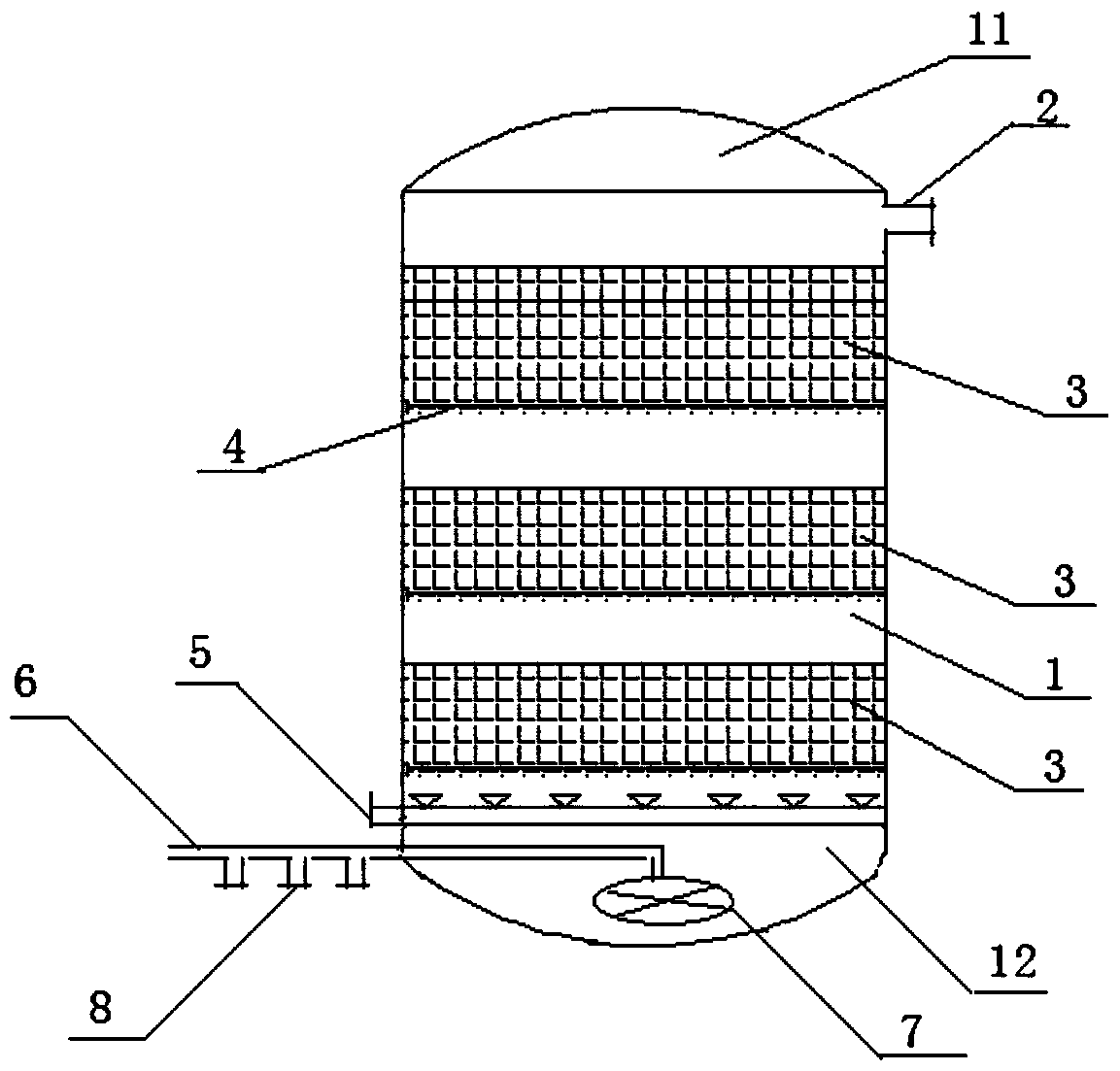

Grain dryer with rotary drying function

InactiveCN109566731AUniform contact surfaceEasy to drySeed preservation by dryingMotor driveAgricultural engineering

The invention discloses a grain dryer with a rotary drying function. The grain dryer comprises a grain dryer body, the grain dryer body comprises a drying machine barrel, and the top of the drying machine barrel is connected with a machine cover. The interior of the drying machine barrel comprises a machine shell, and the machine shell is internally provided with a grain drying chamber. The graindrying chamber is internally provided with a grain drying inner cylinder, and the top of the grain drying inner cylinder is connected with a sealed drying cover. A motor protective cover is fixedly connected to the top of the machine cover. According to the grain dryer with the rotary drying function, power is provided by a working motor, the working motor drives the internal grain drying inner cylinder to rotate through an output rotating shaft, and the drying contact surfaces of internal grains are relatively uniform by the fact that the drying inner cylinder is driven to rotate, so that all-round drying treatment is facilitated, the advantage of the rotary drying function is achieved, and the problem that grain drying treatment operation is affected due to the fact that an existing grain dryer has a poor drying effect and non-uniform drying is effectively solved.

Owner:冯冰琦

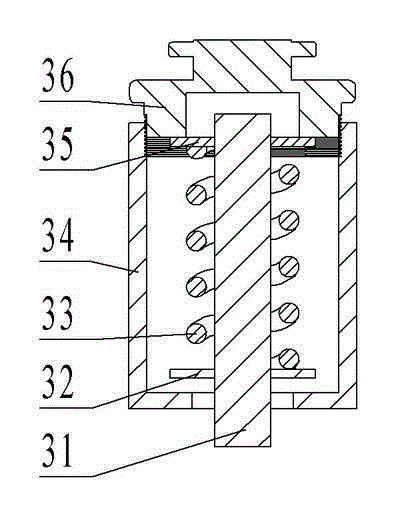

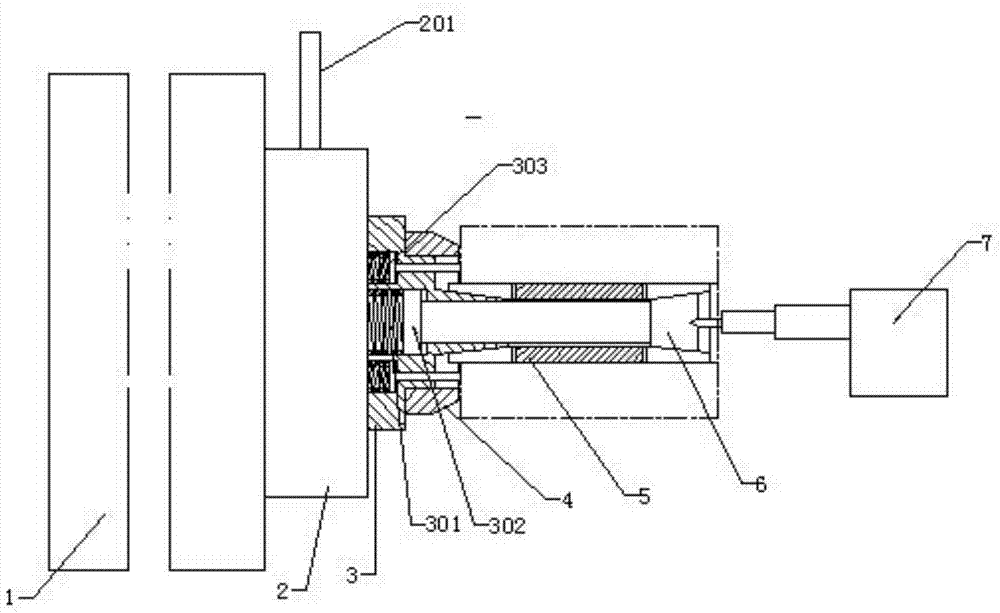

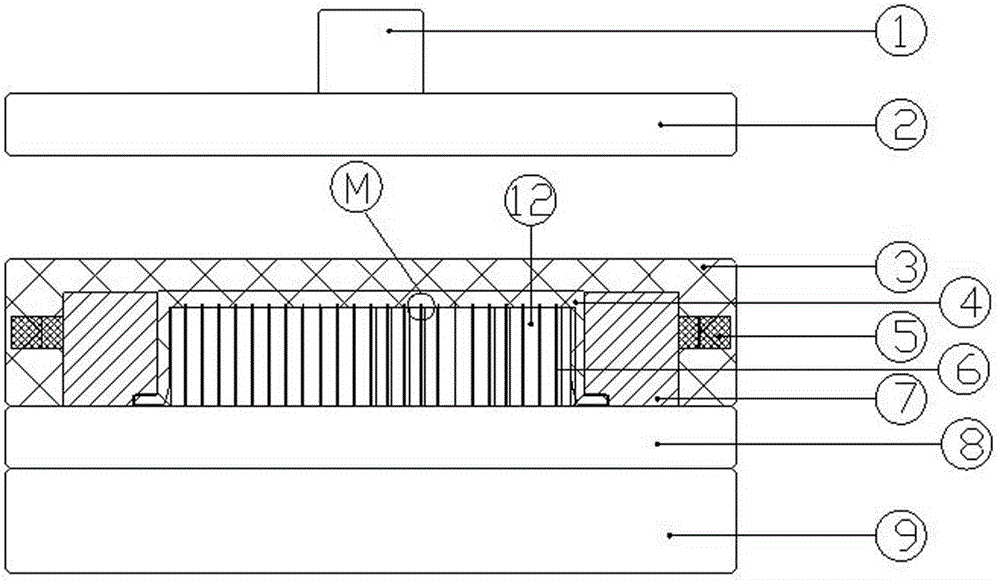

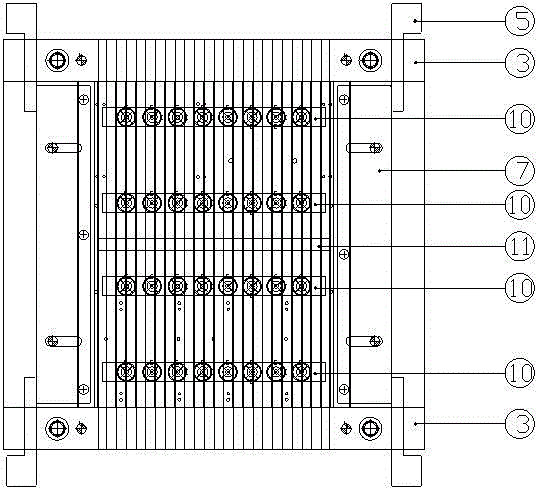

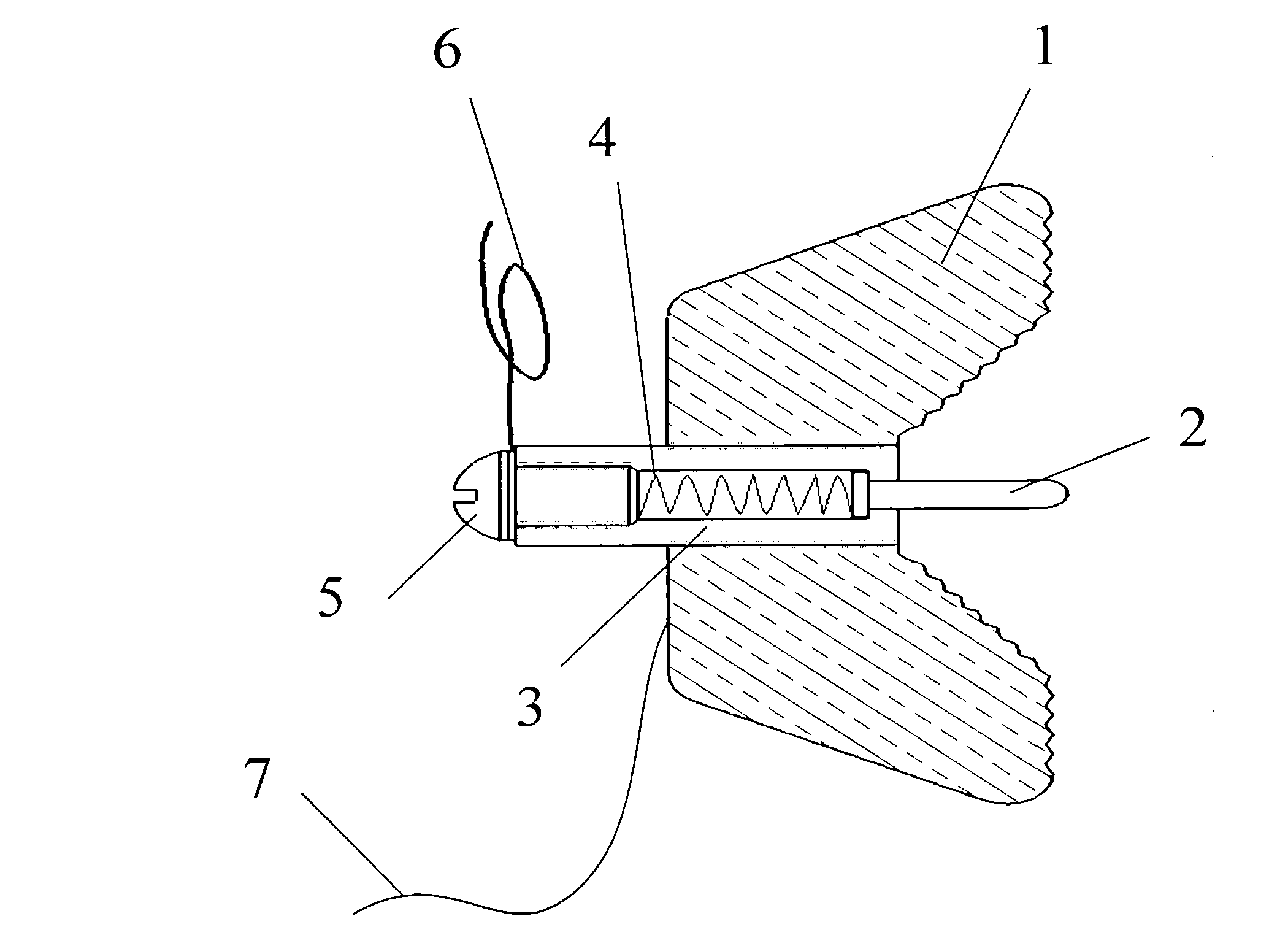

Pneumatic bidirectional clamping device for turning

InactiveCN104493226AUniform contact surfaceUniform force distributionTailstocks/centresExpansion mandrelsEngineeringScrew thread

The invention discloses a pneumatic bidirectional clamping device for turning. The pneumatic bidirectional clamping device for turning comprises a spindle, a reverser, a positioning centre, a positioning plate, a bidirectional inner support sleeve, an ejector rod and a pneumatic tail jack. The reverser is positioned at the center of the front end of the spindle, and the reverser and the spindle are in threaded connection; the positioning centre is positioned at the center of the front end of the reverser, and the positioning centre and the reverser are in slide fit and threaded connection; the positioning plate is positioned at the center of the front end of the positioning centre, and the positioning plate and the positioning centre are in slide fit and threaded connection; the bidirectional inner support sleeve is positioned at the center of the front end of the positioning centre, and the bidirectional inner support sleeve and the positioning centre are in slide fit and movable connection; the ejector rod is positioned at the inner center of the bidirectional inner support sleeve and is in threaded connection with the positioning centre; the pneumatic tail jack is positioned at the center of the front end of the ejector rod and is movably connected with a lathe guide rail. By the pneumatic bidirectional clamping device for turning, clamping efficiency is improved, product quality is guaranteed, and product scrappage is prevented.

Owner:池州共康汽车零部件有限公司

Exhaust heat recovery device of textile printing and dyeing forming machine

ActiveCN102944128AIncrease contact timeIncrease contact surfaceStationary conduit assembliesTextile printerThermal energy

The invention discloses an exhaust heat recovery device of a textile printing and dyeing forming machine. The device comprises a recovery pool, wherein a gas-washing heat-conducting liquid is arranged in the recovery pool, a waste gas inlet is arranged at the bottom of the recovery pool, a waste gas outlet is arranged at the top of the recovery pool, a coil is arranged in the recovery pool, one end of the coil extends out of the recovery pool to form a water inlet, the other end of the coil extends out of the recovery pool to form a water outlet, the waste gas inlet is connected to a gas inlet pipeline and the waste gas outlet is connected to a gas outlet pipeline. By the aid of the device, the waste gas can be subjected heat recovery further, harmful substances in waste gas can be cleaned, the heat recovery can be improved, and the exhausted waste gas meet environment protection requirements.

Owner:ZHANGJIAGANG DATANG TEXTILE PROD

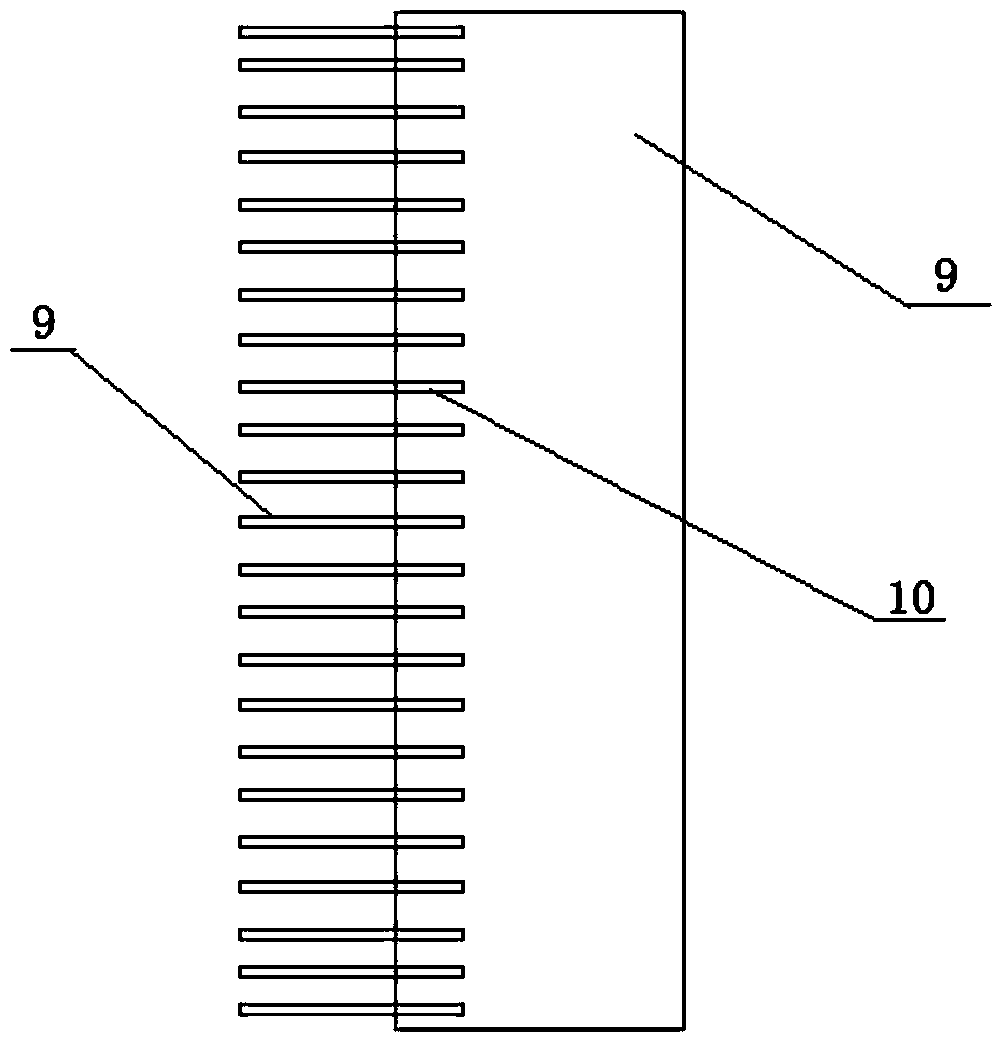

Deformed steel bar quenching process and quenching equipment

ActiveCN112575150AEasy to disassemble and cleanUniform contact surfaceFurnace typesHeat treatment furnacesLiquid storage tankSteel bar

The invention discloses a deformed steel bar quenching process. The deformed steel bar quenching process is characterized by comprising the following steps that S1, a deformed steel bar forge piece isheated to 700-900 DEG C, and the temperature is kept for 50-100 minutes; S2, the time for transferring the deformed steel bar forge piece to any deformed steel bar quenching equipment in the claim 2-9 for rapid cooling is not longer than 45 s; and S3, the temperature of a liquid storage tank (7) is not higher than 45 DEG C.

Owner:JIANGSU BINXIN STEEL GRP

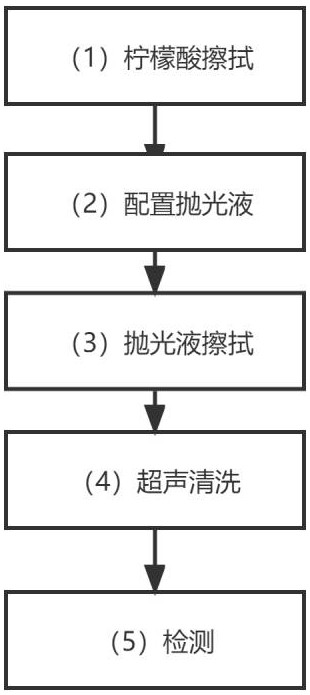

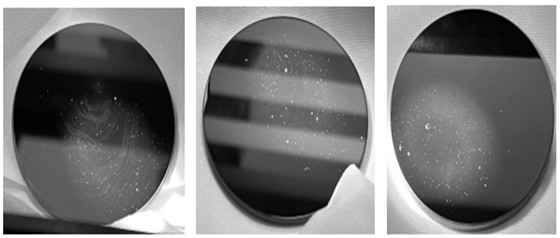

Surface treatment process for zinc sulfide lens

PendingCN114798589AImprove yieldAvoid the problem of dirty whiteningCleaning using toolsCleaning using liquidsPhysicsChemistry

The invention belongs to the field of lens surface treatment, and discloses a surface treatment process of a zinc sulfide lens, which comprises the following steps: (1) citric acid wiping; (2) preparing a polishing solution; (3) wiping with a polishing solution; (4) ultrasonic cleaning; and (5) entering a subsequent film coating procedure after the inspection is qualified. According to the zinc sulfide lens surface treatment process, the zinc sulfide lens can be better cleaned, the appearance problems that the surface of the zinc sulfide lens is dirty and white after film coating and the like are solved, and the yield of the zinc sulfide lens in the production process is increased.

Owner:安徽光智科技有限公司

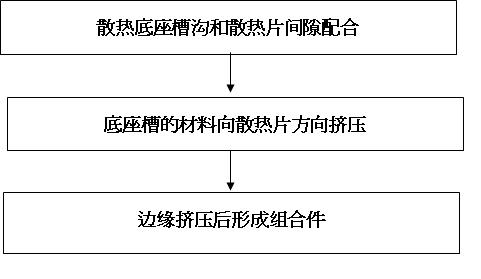

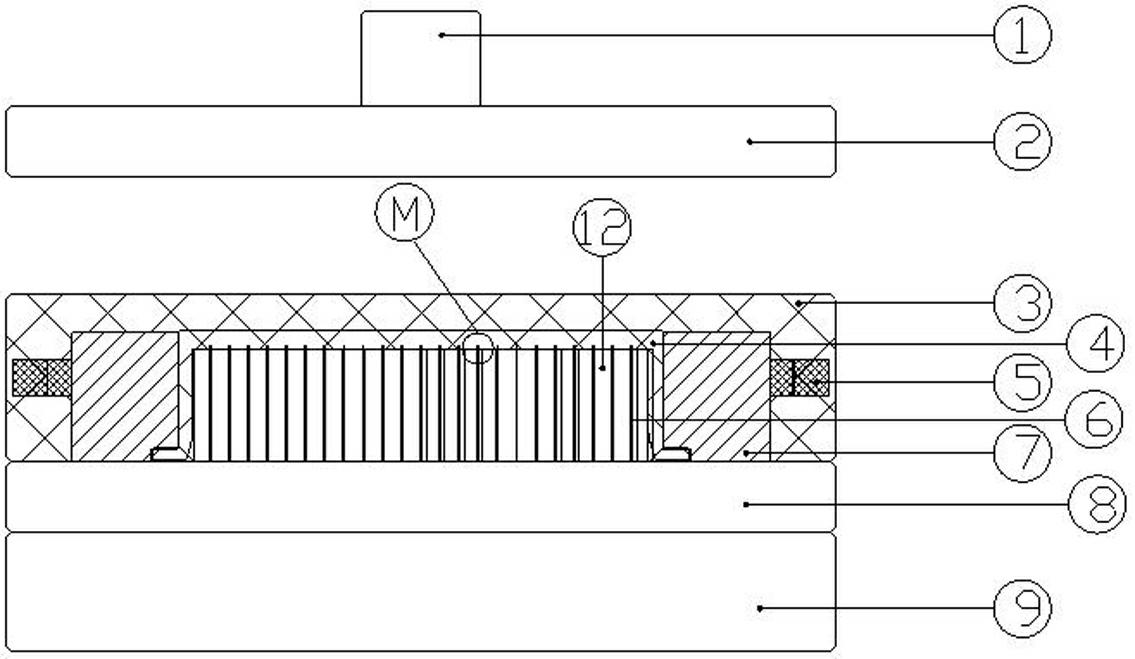

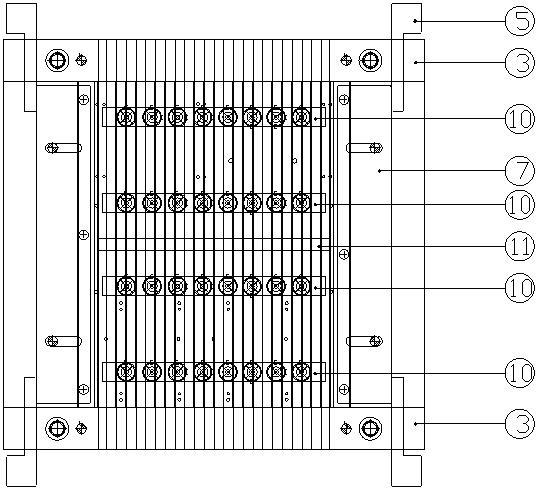

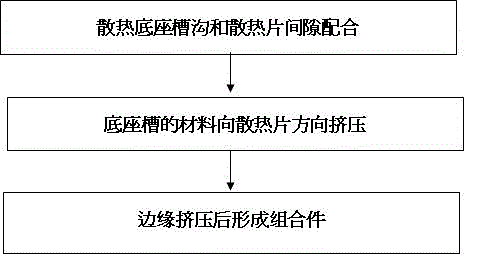

Edge extrusion riveting process of solar energy heat radiation base plate and riveting mold for edge extrusion riveting process

The invention discloses an edge extrusion riveting process of a solar energy heat radiation base plate and a riveting mold for the process. The process comprises: performing clearance fit between a trough and a heat radiating fin of the heat radiation base; and extruding two side walls of the trough of the heat radiation base towards the heat radiating fin, and forming an assembling piece through edge extrusion; the pivoting mold comprises an upper template, a lower mold base and a lower template; a plurality of stripping floating blocks are arranged in the lower template; a plurality of lower mold punches, a punch fixing sleeve plate and a material choking sleeve plate are arranged on the lower template, wherein the material choking sleeve plate is arranged in the punch fixing sleeve plate; and heat radiation base plates to be combined are arranged between the punch fixing sleeve plate and the lower template. According to the edge extrusion riveting process provided by the invention, welding is replaced by punching, the machining cost is saved, the manufacturing cost is reduced greatly, and the production efficiency is improved; the edge extrusion riveting process has the advantages of short mold-opening period, low cost, high production efficiency, stable quality, beautiful structure, strong holding capability of the heat radiation fin, uniform contact plane and good thermal conduction; the product manufacturing competitiveness is improved, and the edge extrusion riveting process has a wide popularization application value.

Owner:昆山能缇精密电子有限公司

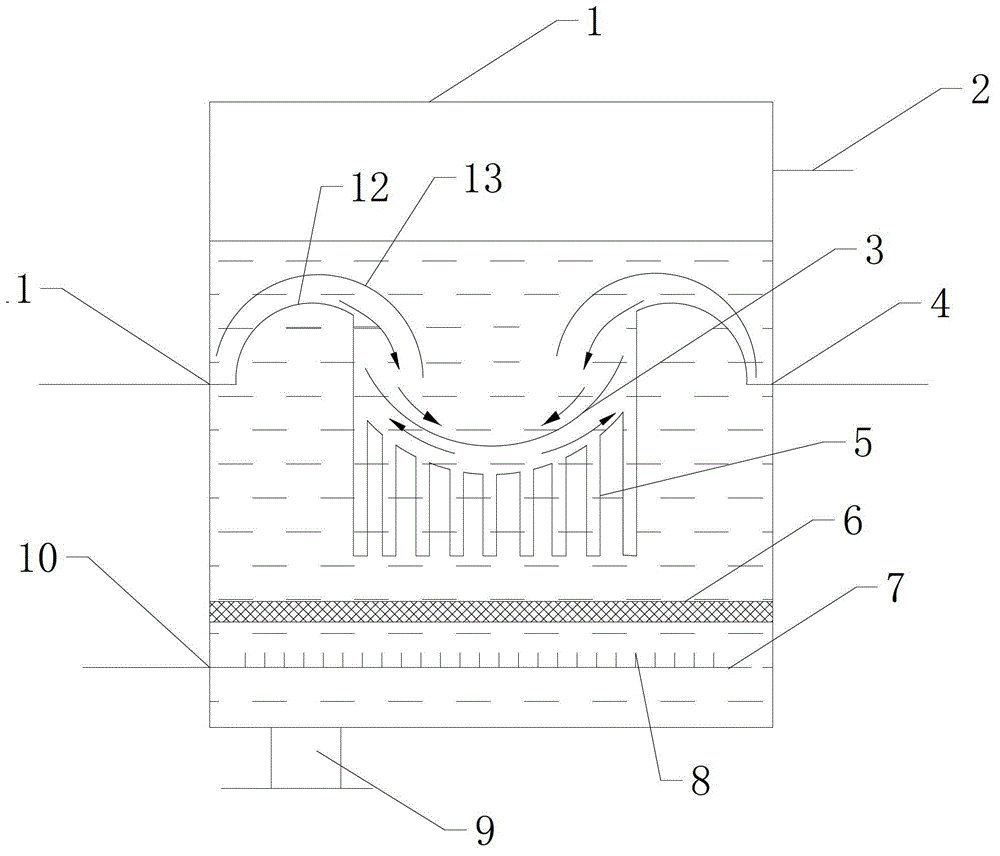

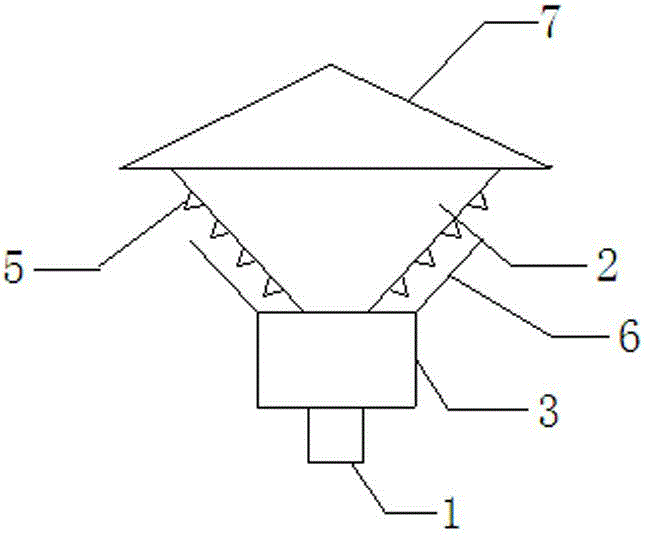

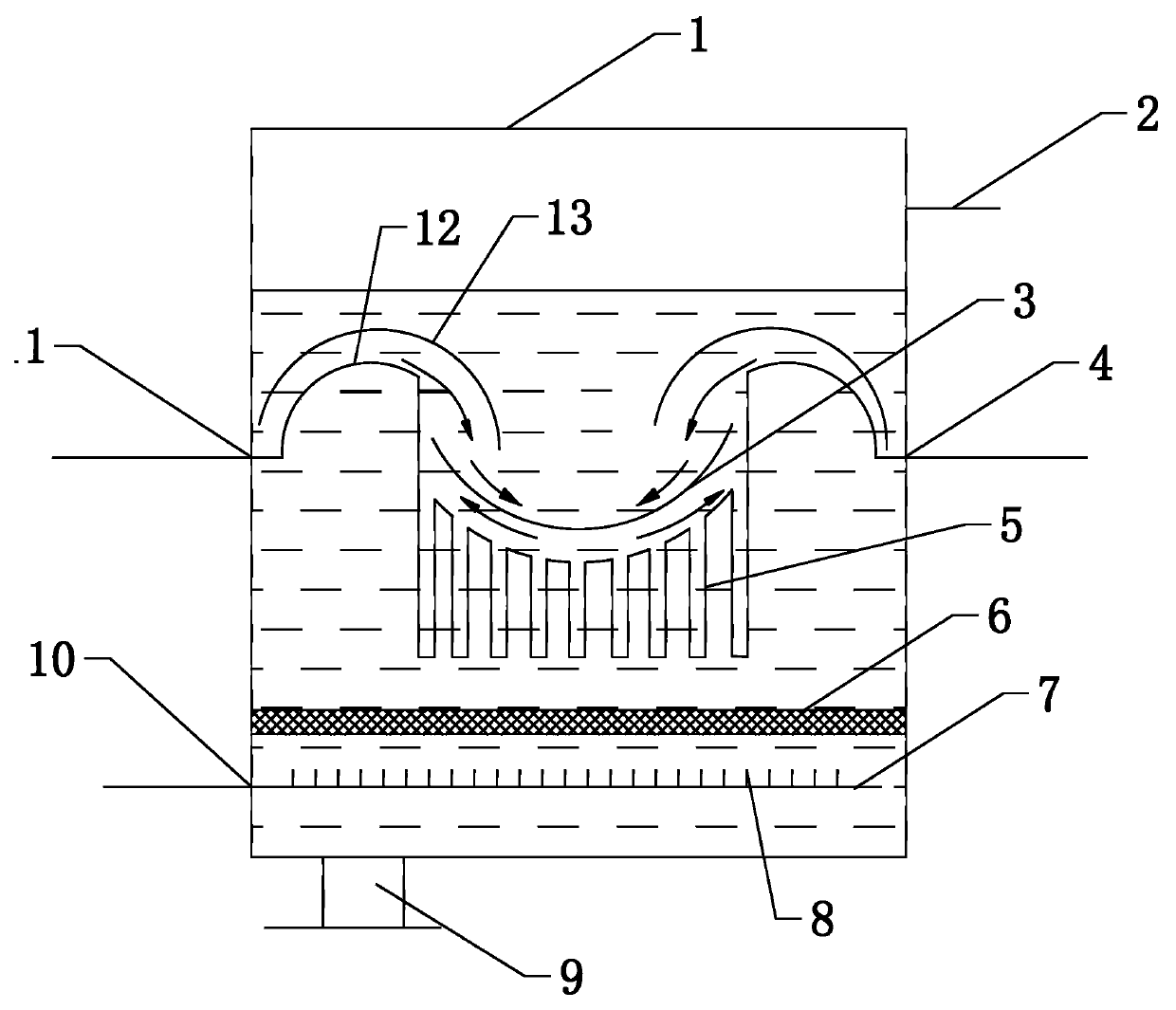

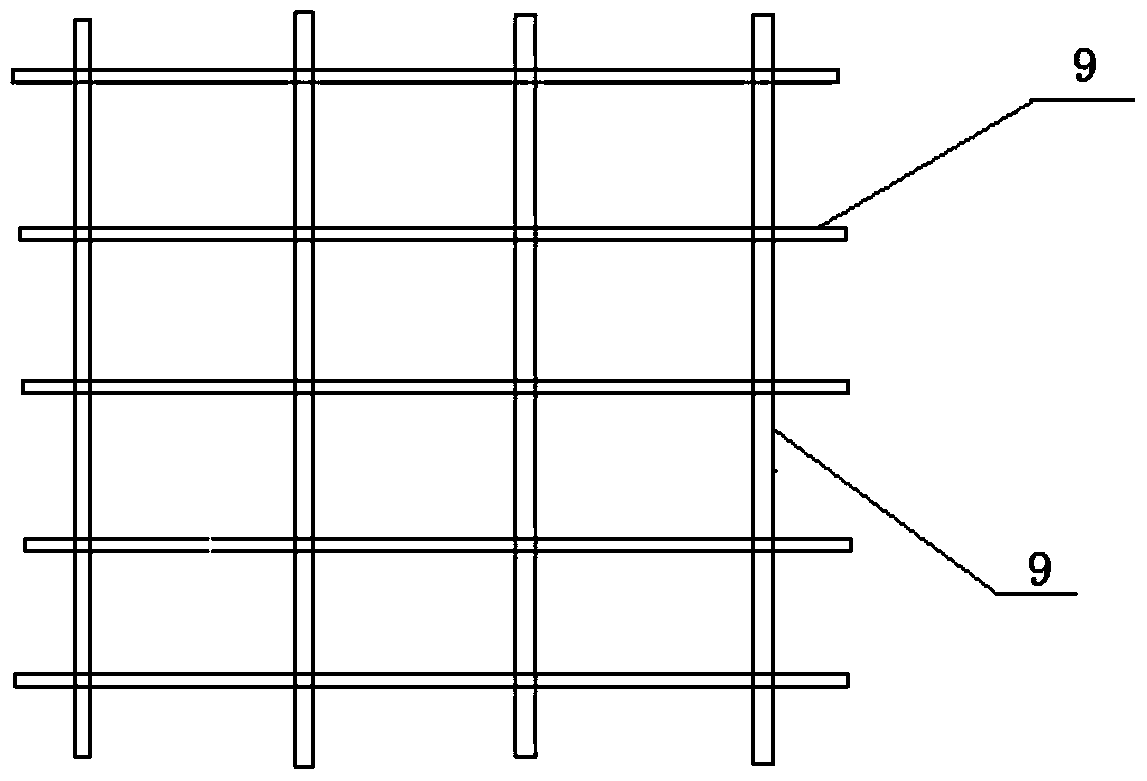

Pressure-equalizing turbulent type water distributor

ActiveCN104058502AUniform contact surfaceEven distribution of waterTreatment with anaerobic digestion processesSewage treatmentWater treatment

The invention relates to a pressure-equalizing turbulent type water distributor, and belongs to the technical field of sewage treatment equipment. The pressure-equalizing turbulent type water distributor comprises a water distributing interface and a water distributing plate, wherein a water inlet of the water distributing interface is connected with a water outlet of an inlet water pressure pump of the water distributor. The pressure-equalizing turbulent type water distributor further comprises a water equalizing room, wherein the water inlet of the water equalizing room is communicated with the water outlet of the water distributing interface; the water distributing plate is fixedly arranged on the top surface of the water equalizing room; the top surface of the water equalizing room is equipped with at least three water distributing holes around the water distributing plate; water distributing stabs are arranged on the side wall of the water distributing plate; the water distributing stabs surrounds the water distributing plate in a spiral manner. The pressure-equalizing turbulent type water distributor disclosed by the invention balances pressure of each water distributor, sufficiently distributes water, disperses water at the periphery of the water distributor, realizes uniform water distribution at the periphery of the plate, prevents mud deposition, greatly increases mud water contact area, so that metabolism efficiency of sludge is improved.

Owner:江苏海澜正和环境科技有限公司

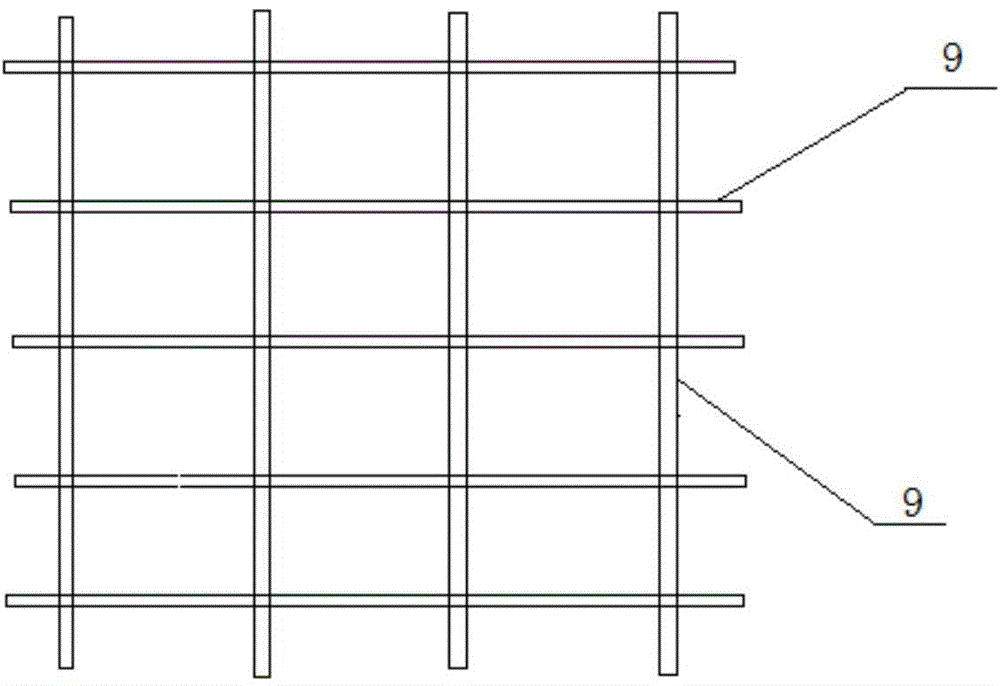

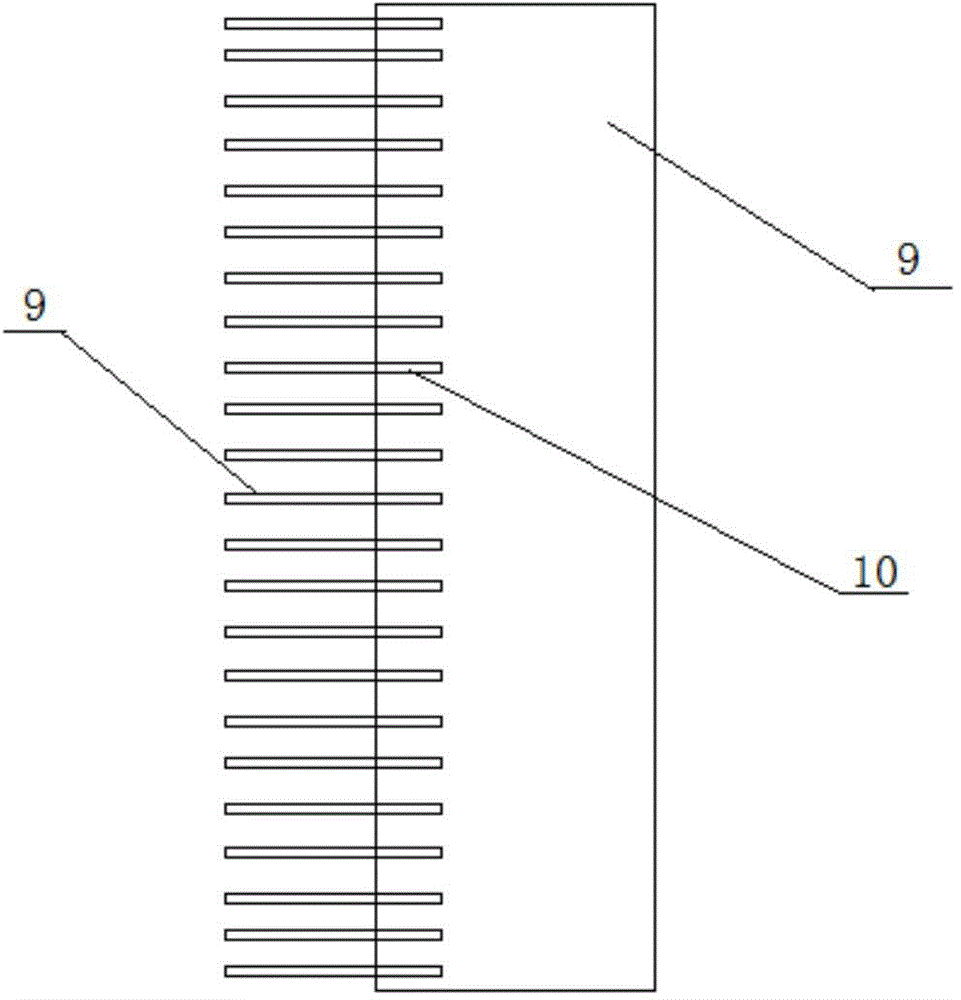

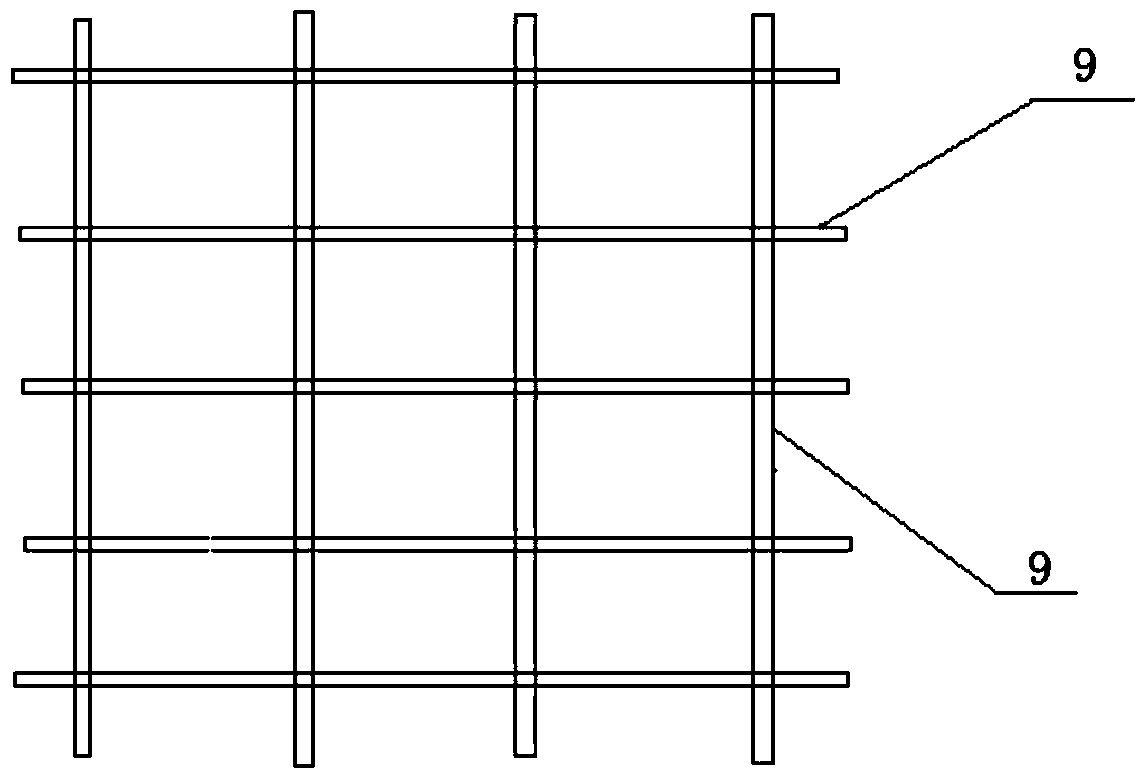

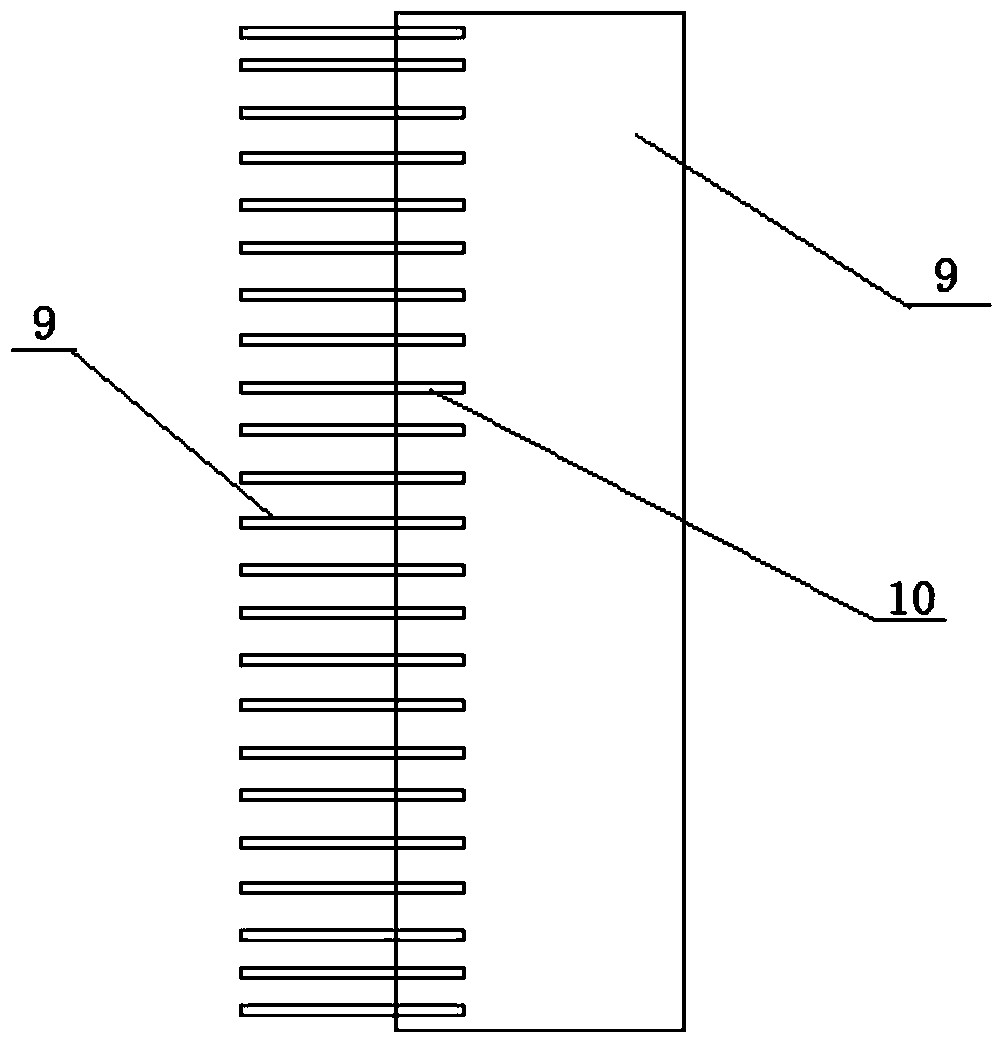

Noble-metal iron-carbon-filler sewage reactor

The invention discloses a noble-metal iron-carbon-filler sewage reactor. According to the reactor, a tank body is inside provided with a stainless-steel porous filtration plate, three layers of an insertion type noble-metal iron carbon filler are arranged on the stainless-steel porous filtration plate from top to bottom, the filler is composed of a plurality of specially-prepared steel plate single bodies through mutual socket connection via slots, the slots are arranged at one side of each specially-prepared steel plate single body, and the width of each slot is same to the thickness of the specially-prepared steel plate single body. The insertion type noble-metal iron carbon filler of the reactor can slowly uniformly precipitate various metal metastable ions which are uniform and not easy to lose. The filler truly realizes no passivation, no obstruction and no demand of replacing, and only need maintaining for 1-3 times every year, and the maintenance time each time is about 4 h. COD removal rate is high, water secondary pollution is not caused, and the sewage removal efficiency is improved by 20%-30% compared with that of a common iron carbon micro-electrolysis technology.

Owner:江苏元捷环境科技有限公司

Towel production equipment and production process thereof

PendingCN112458655AUniform contact surfaceShorten mixing timeTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentControl powerHeater Rod

The invention relates to the technical field of towels, and particularly discloses towel production equipment and a production process thereof. The towel production equipment comprises a sand washingtank body; a heating rod is fixedly installed at the top of an inner cavity of the sand washing tank body; the heating rod is electrically connected with a control power source; and a feeding pipe, awater inlet pipe, a pair of supporting plates and two pairs of supporting sliding rods are fixedly installed at the top of the sand washing tank body. By starting a driving motor and an air cylinder,a rotating shaft and stirring blades can move up and down while rotating in the inner cavity of the sand washing tank body, towels and mixed liquid can move up and down while being stirred, the contact surface of the towels and the mixed liquid is more uniform, the stirring time can be effectively shortened, and energy consumption is reduced; and the towels are made of pure cotton and are high instrength and toughness, do not deform after being washed with water for multiple times, can be used for early education of pattern colors for development of sensory recognition capacity of 0-6-year-old children, do not mildew or rot after being used even if the towels are not dried in the sun, and do not turn yellow or hard after being used for multiple times, and the service life of the towels isremarkably prolonged.

Owner:江苏梦妃丝织造有限公司

Preparation method for anti-slip coating of floating clamp

InactiveCN107541695AExtended replacement cycleReduce use and maintenance costsMolten spray coatingSand blastingFree cooling

The invention relates to a preparation method for an anti-slip coating of a floating clamp. The preparation method comprises the following steps that sand-blasting roughening treatment is conducted ona working face of the floating clamp with brown fused alumina, metal ceramic powder is sprayed on the surface of a base body of the working face of the floating clamp with adoption of a supersonic flame spraying technology, the anti-slip and abrasion-resistant coating is prepared, and sprayed workpieces are wrapped with asbestos and are placed in air for natural cooling. According to the preparation method for the anti-slip coating of the floating clamp, defects which exist in a previous dovetail groove structure are overcome; metal ceramics are used as spraying materials, commercial powder can be directly purchased and used for the spraying materials, quality of the coating is higher, the service life is longer, spraying efficiency is high, and cost is low; and the heat influence on thebase body of the floating clamp in the spraying process is small, and texture and the shape of the base body are not changed.

Owner:YANGZHOU UNIV

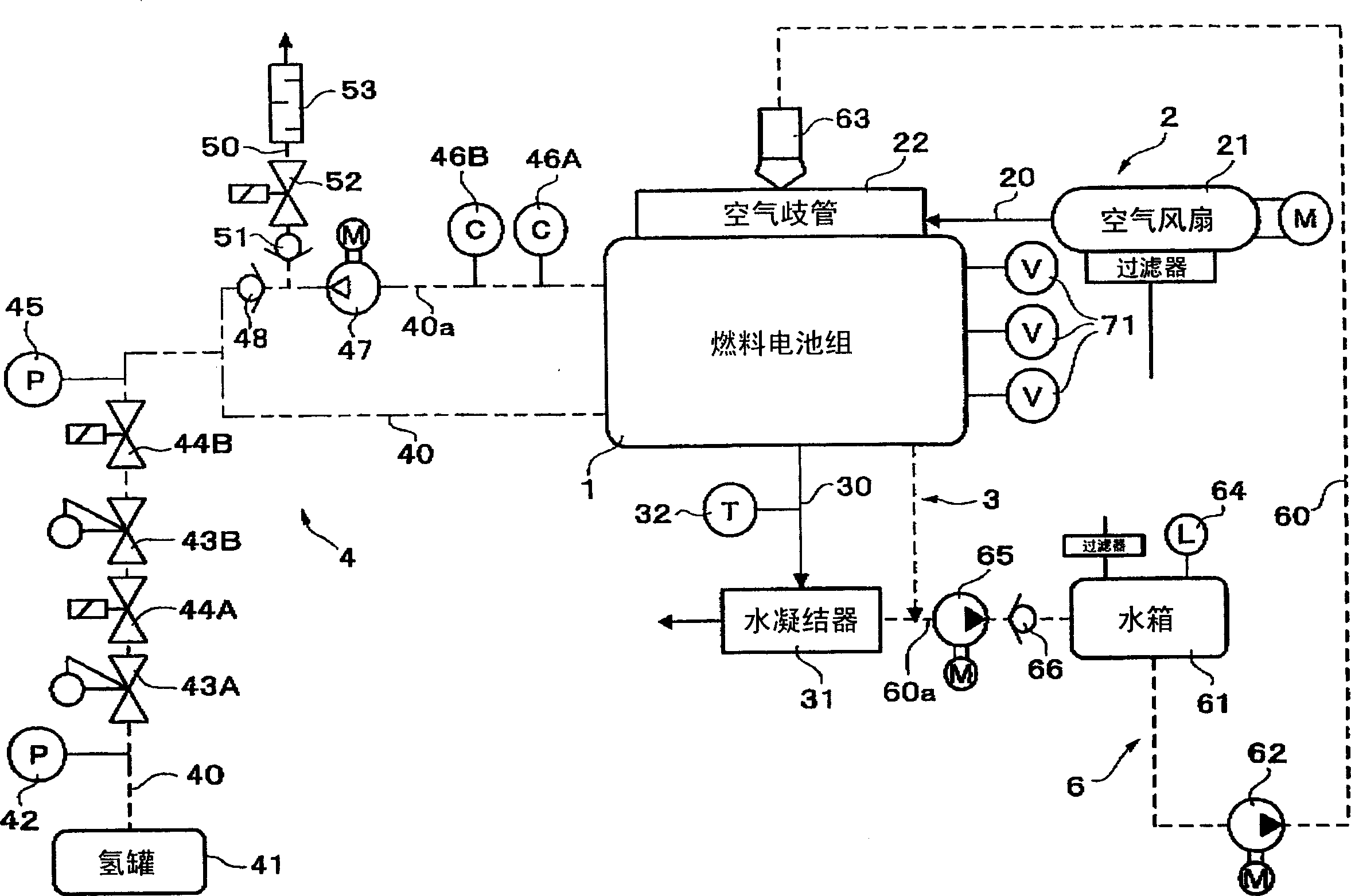

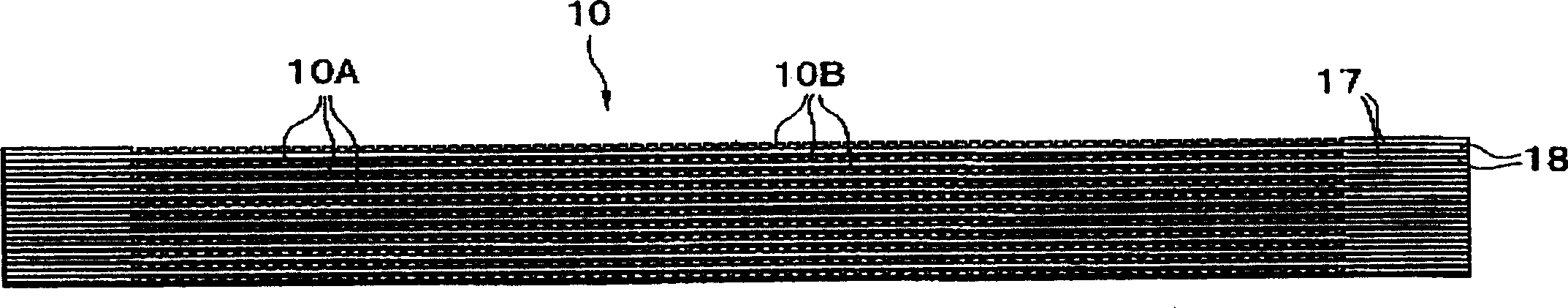

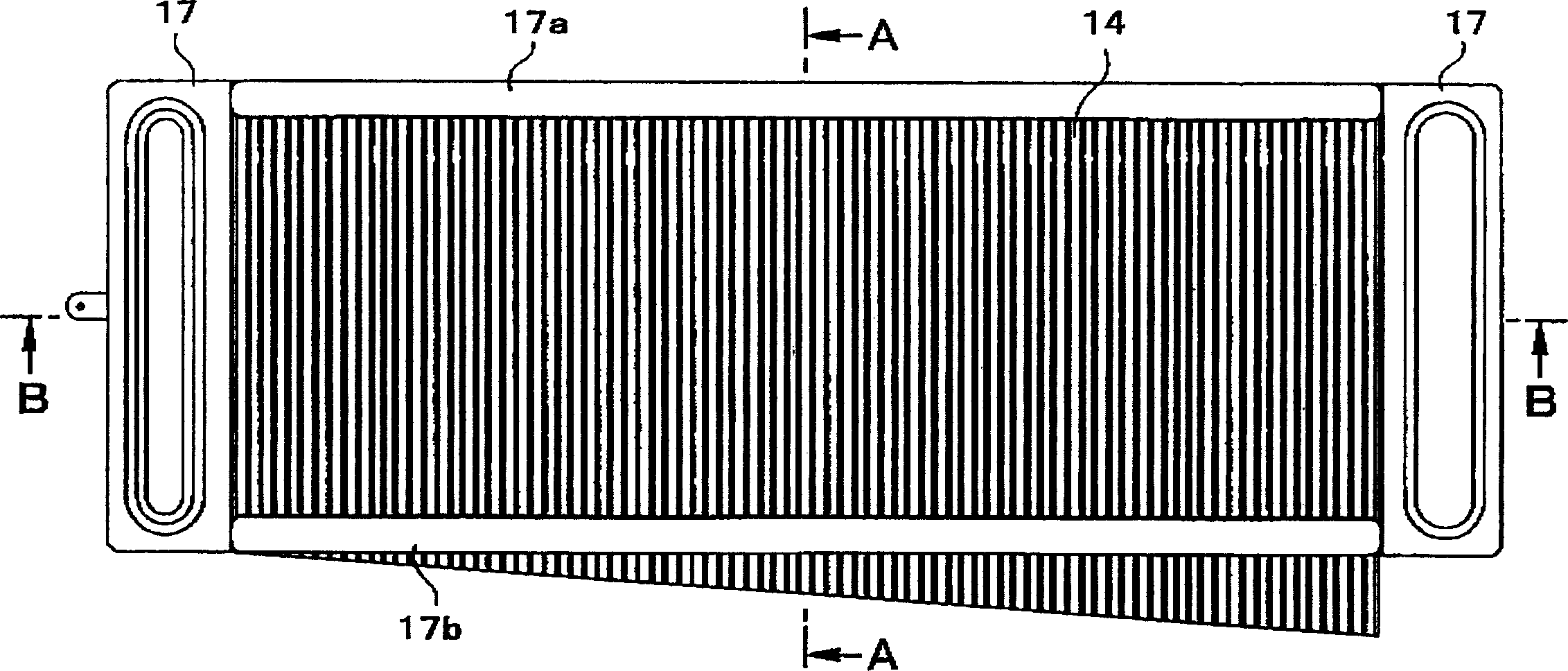

Separator and fuel cell using that separator

InactiveCN1691368AEasy to spreadSpread evenlyMechanical apparatusLighting support devicesFuel cellsWave shape

A separator includes an imperforate separator substrate and spacer plates that are interposed between electrodes and the separator substrate. The spacer plates are formed of mesh and have rectangular wave-shaped cross-sections. Top portions of the rectangular waves that abut against the electrodes serve as gas diffusion portions. Adjacent side portions and portions between waves together are rectangular and serve as spacer portions which define gas passages between the gas diffusion portions and the separator substrate. Air holes that provide intercommunication between adjacent gas passages are provided in the spacer portions. As a result, gas can be supplied downstream of a gas passage that has become narrow or blocked due to a water droplet remaining in the passage.

Owner:EQUOS RES

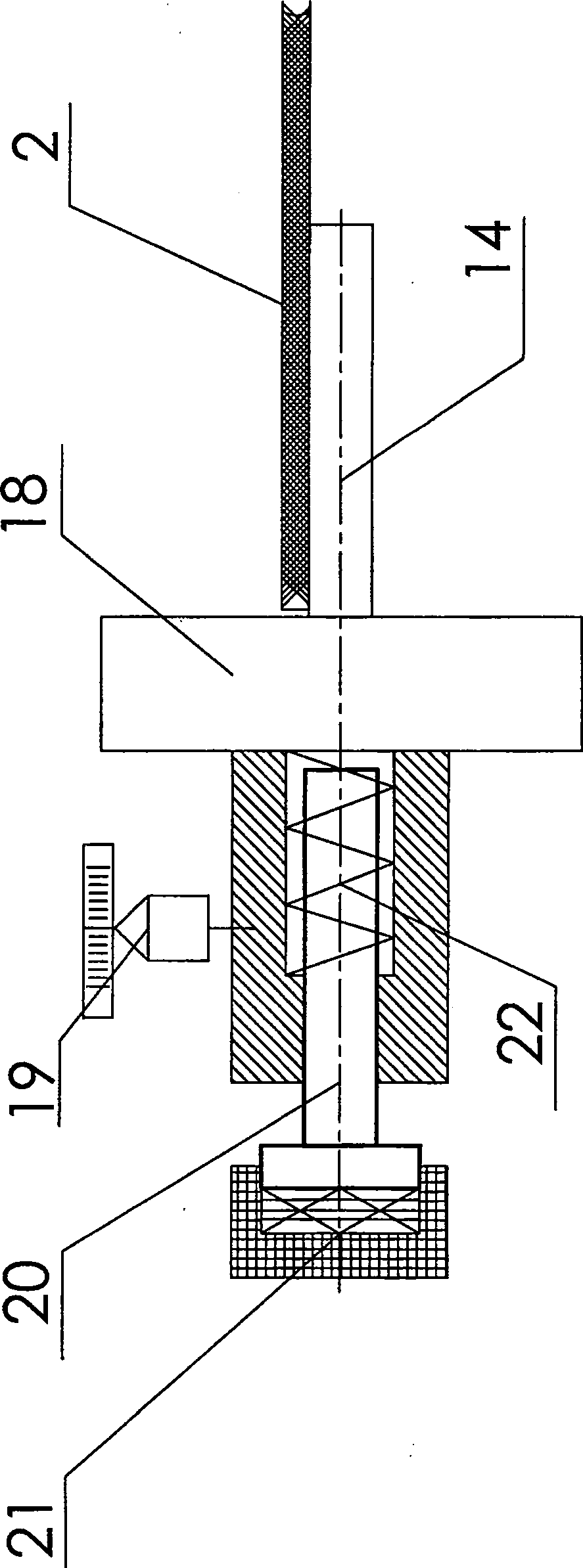

Automatic position correcting system for material carrying belt of vacuum belt type drying machine

ActiveCN100510593CExtended service lifeLong-term continuous working statusDrying solid materialsComputer control systemDrive shaft

Owner:温州市金榜轻工机械有限公司

Exhaust heat recovery device of textile printing and dyeing forming machine

ActiveCN102944128BIncrease contact timeIncrease contact surfaceStationary conduit assembliesTextile printerHazardous substance

Owner:ZHANGJIAGANG DATANG TEXTILE PROD

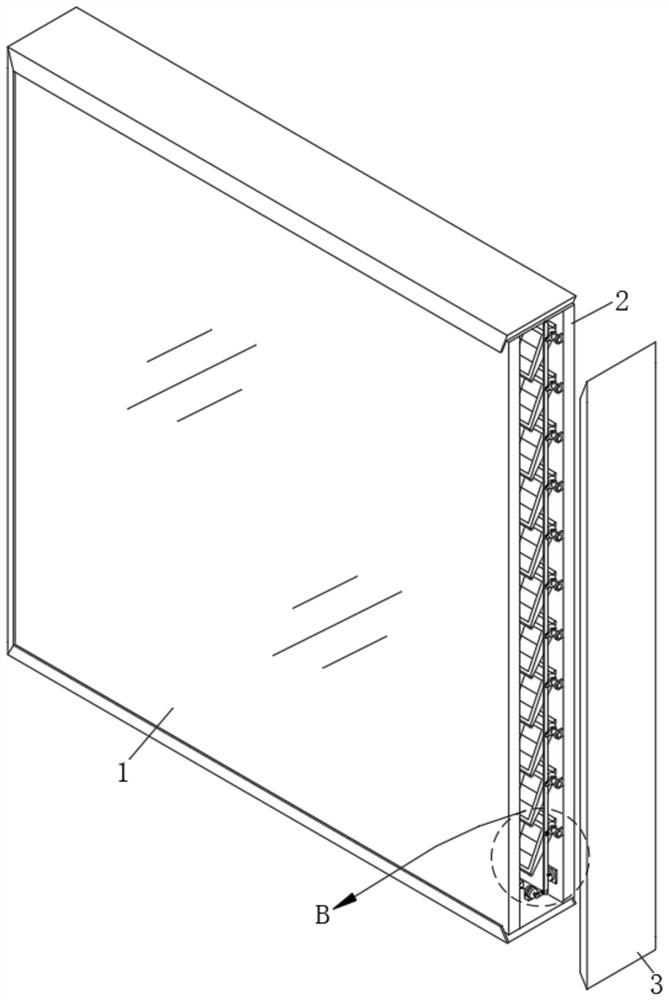

Component type heat preservation fireproof curtain wall structure and method thereof

PendingCN114439138AGood luminous fluxEasy to adjust the anglePhotovoltaic supportsSolar heating energyLight fluxCooling effect

The invention relates to the field of building curtain walls, in particular to a component type heat preservation fireproof curtain wall structure which comprises outer-layer glass, inner-layer glass is arranged on one side of the outer-layer glass, and a sealing piece is connected between the outer-layer glass and the inner-layer glass in a sealed mode. The angle of the photovoltaic mechanism is conveniently adjusted through the adjusting mechanism, so that the luminous flux of the curtain wall reaches the optimal state, and the comfort level of indoor personnel is improved; through the cleaning mechanism, the outer-layer glass easily contaminated with dirt can be conveniently cleaned, the permeability and attractiveness of the curtain wall are improved, and manual cleaning is avoided; the reciprocating mechanism facilitates repeated rubbing of the swinging cleaning component, so that the contact surface of the cleaning component and the glass is more uniform, less dust is collected, meanwhile, the noise is lower, and the cleaning effect of the curtain wall is better; through the cooperation of the water spraying mechanism and the cleaning mechanism, when a fire disaster occurs, only a thin plate arranged on the bottom beam needs to be crushed, water flows out of the bottom beam, and therefore the fire extinguishing and cooling effects are achieved.

Owner:张严

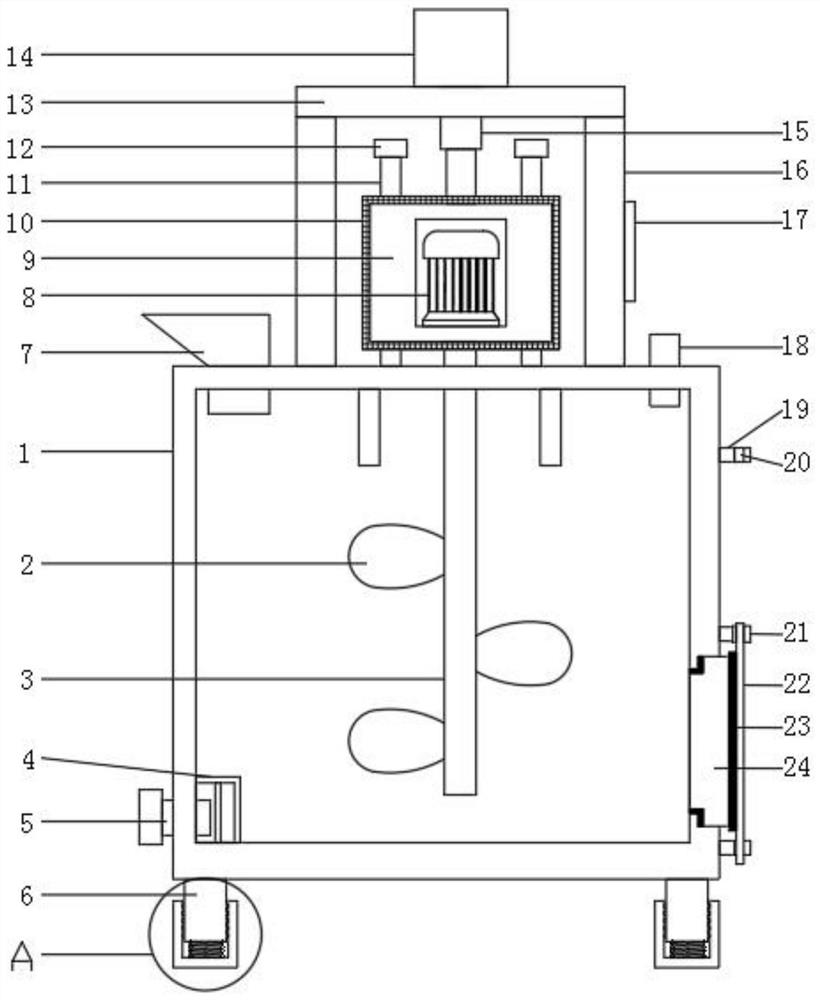

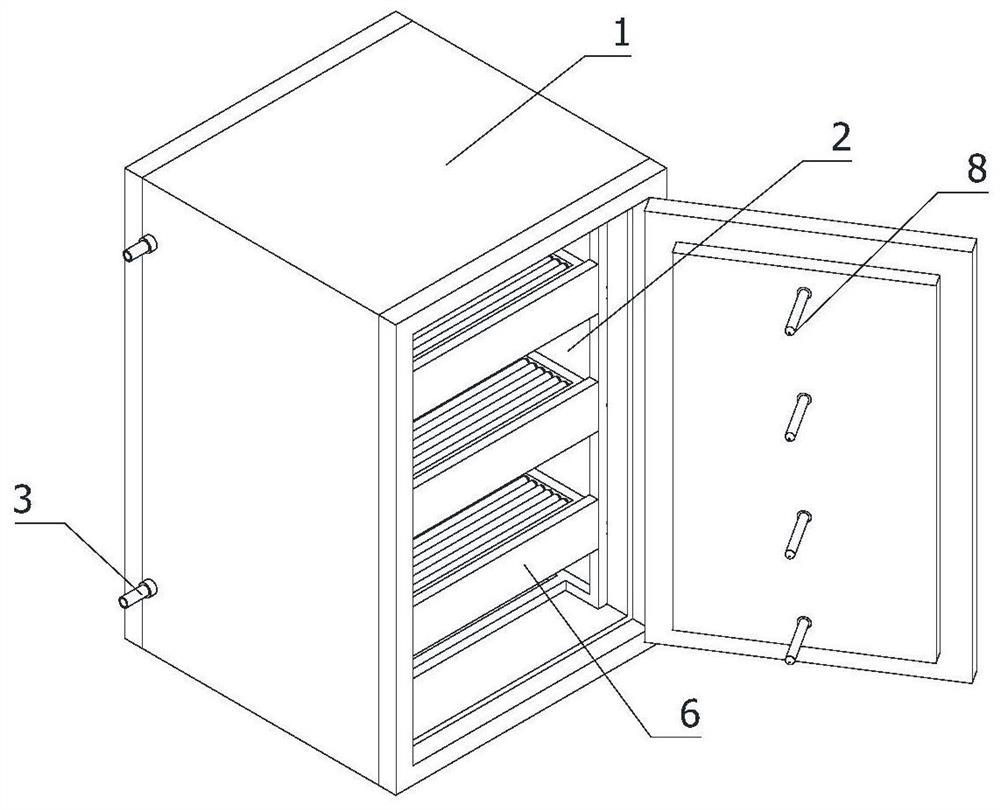

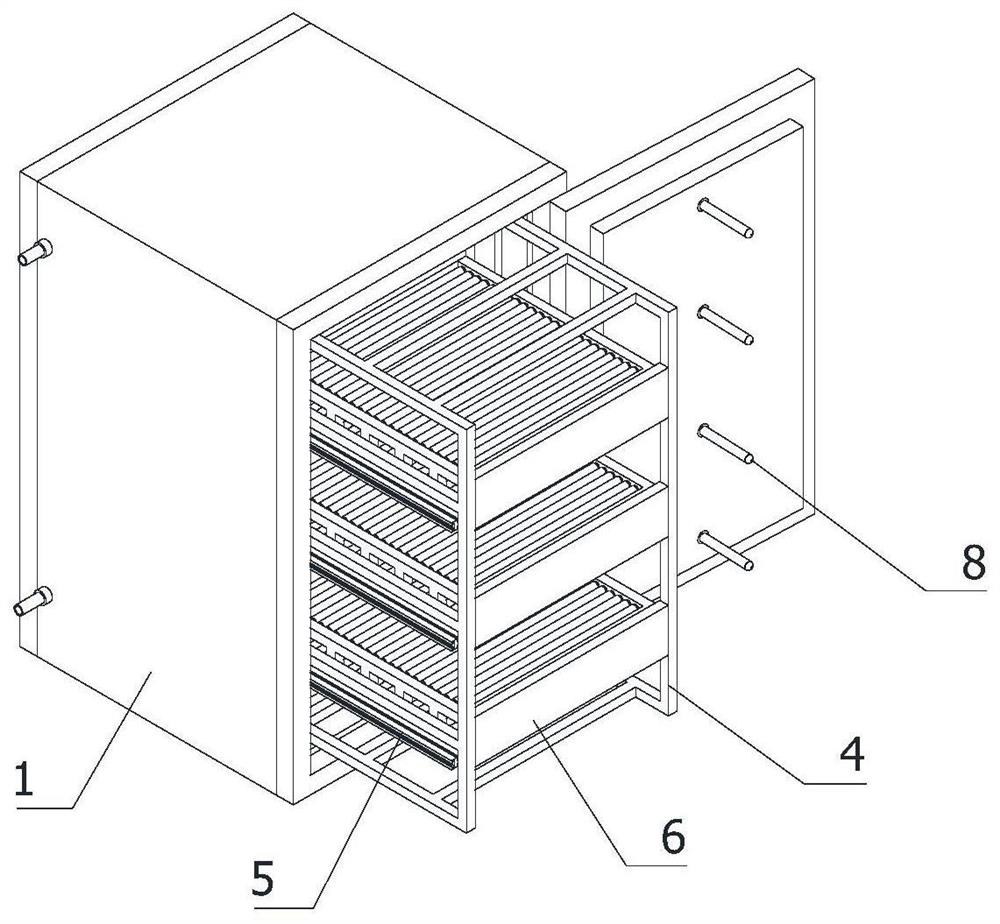

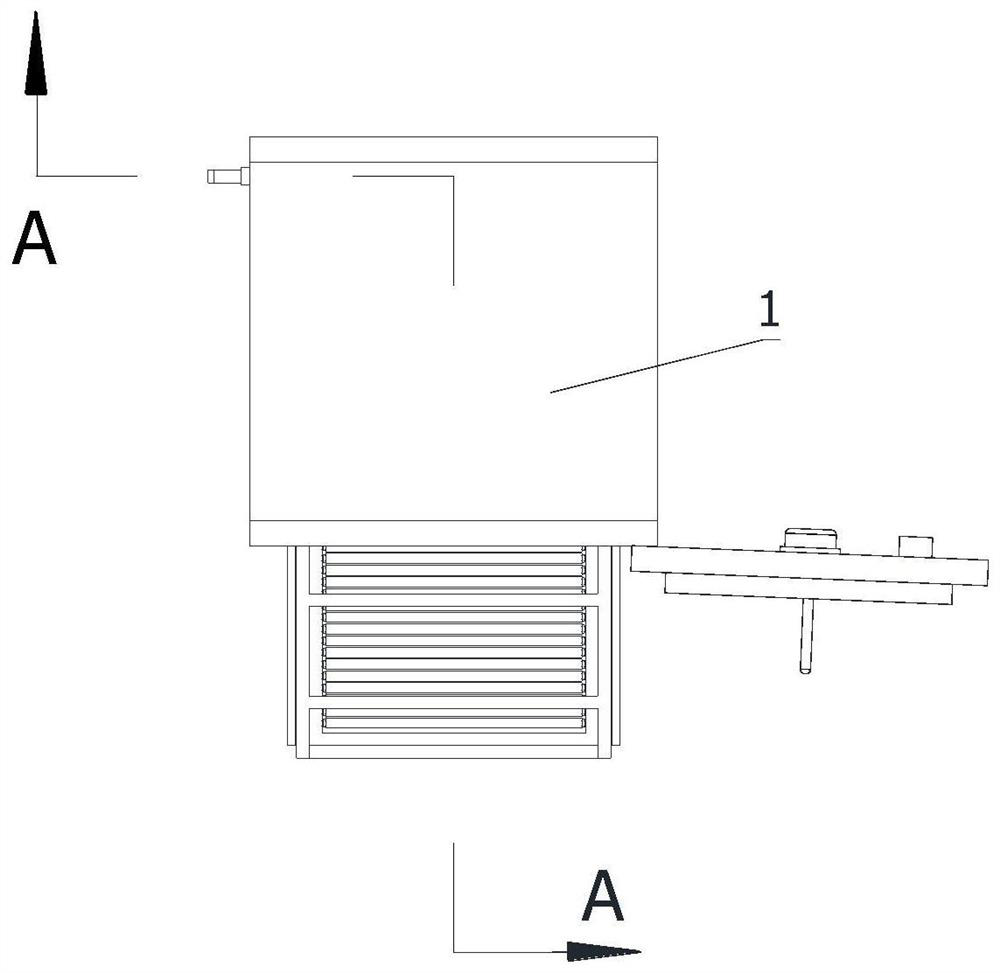

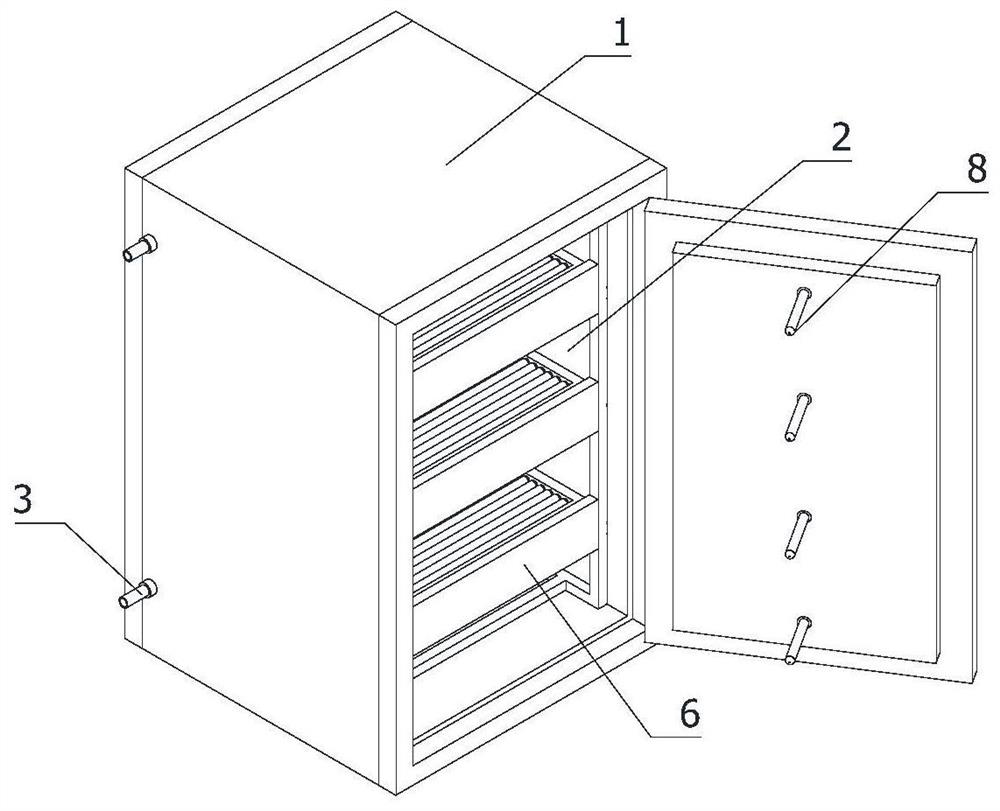

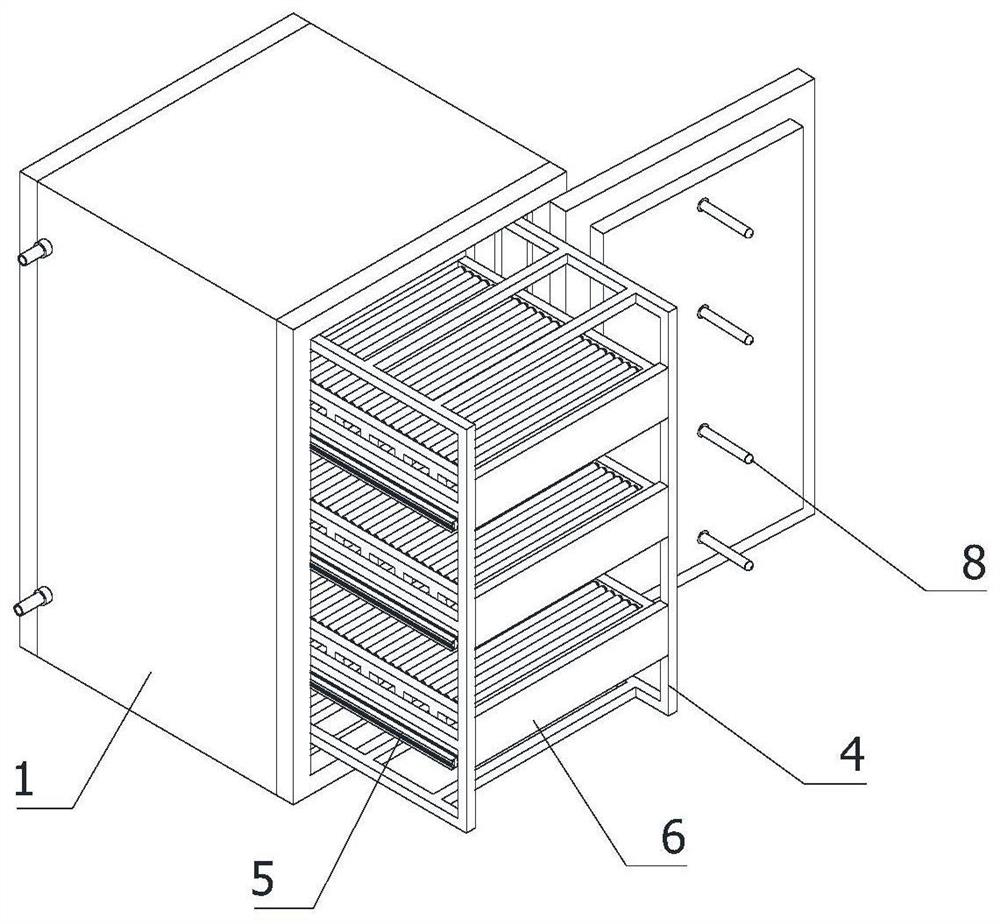

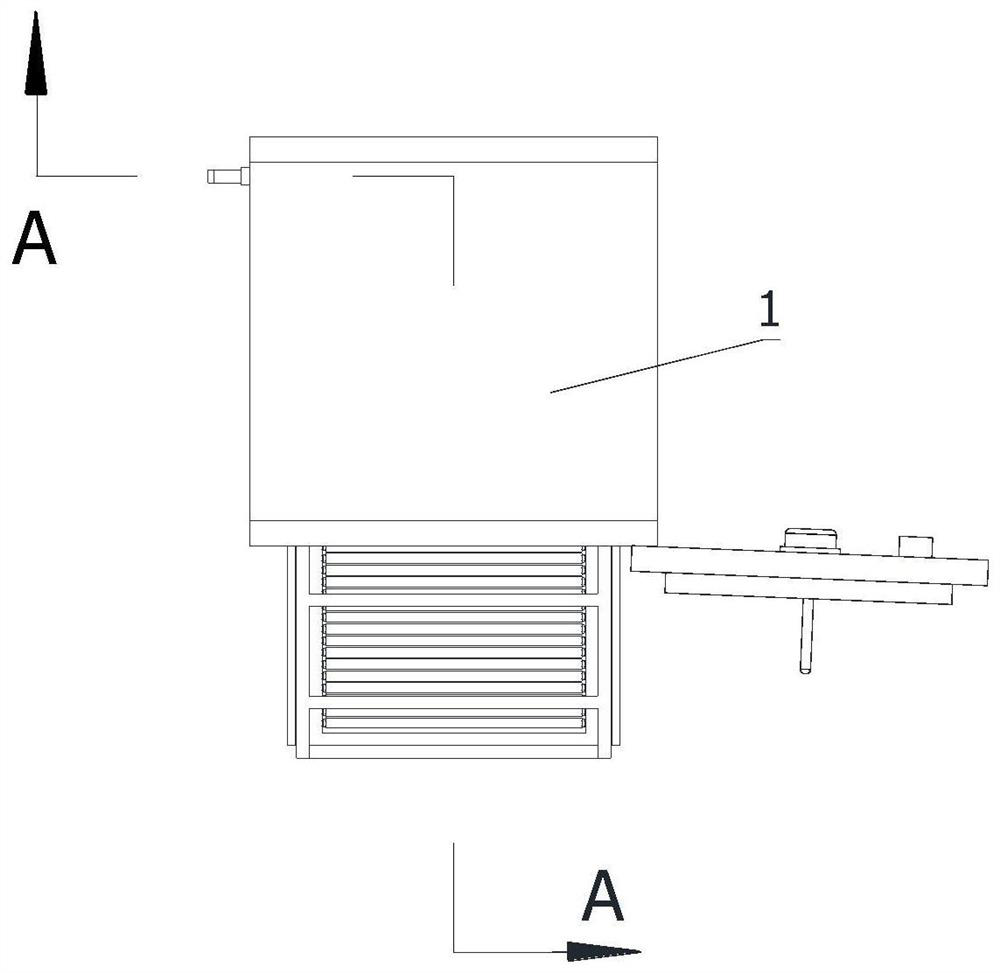

An aging furnace for alloy forging heat treatment process and its control method

ActiveCN112029975BEasy to control temperatureReduce the temperatureFurnace typesHeat treatment process controlElectrical connectionEngineering

The present invention relates to the technical field of alloy aging furnace equipment, in particular to an aging furnace for alloy forging heat treatment process and its control method, comprising: Connection; the electric heating plate is fixed horizontally on the inner side of the furnace body at equal intervals in the vertical direction and is matched with the electric heating layer on both sides and electrically connected to the controller; the U-shaped heat exchange tube runs through the side wall of the furnace body at both ends and passes through the electric heating layer The gap on both sides of the plate is arranged on the fixed side of the electric heating plate, and the bottom and top of the U-shaped heat exchange tube are connected to the water inlet and the water outlet respectively; Placement frame, the opening facing the electric heating plate is vertically and equidistantly arranged on the inner frame connecting frame; the connecting closing plate is vertically arranged on both sides of the U-shaped placing frame; the thermometer is vertically opened and closed through the furnace body at equal intervals along the vertical direction The door, the device can conveniently place the alloy and can store the heat in the furnace after aging.

Owner:浦夕特种合金(上海)有限公司

Edge extrusion riveting mold of solar energy heat radiation base plate

The invention discloses an edge extrusion riveting process of a solar energy heat radiation base plate and a riveting mold for the process. The process comprises: performing clearance fit between a trough and a heat radiating fin of the heat radiation base; and extruding two side walls of the trough of the heat radiation base towards the heat radiating fin, and forming an assembling piece through edge extrusion; the pivoting mold comprises an upper template, a lower mold base and a lower template; a plurality of stripping floating blocks are arranged in the lower template; a plurality of lower mold punches, a punch fixing sleeve plate and a material choking sleeve plate are arranged on the lower template, wherein the material choking sleeve plate is arranged in the punch fixing sleeve plate; and heat radiation base plates to be combined are arranged between the punch fixing sleeve plate and the lower template. According to the edge extrusion riveting process provided by the invention, welding is replaced by punching, the machining cost is saved, the manufacturing cost is reduced greatly, and the production efficiency is improved; the edge extrusion riveting process has the advantages of short mold-opening period, low cost, high production efficiency, stable quality, beautiful structure, strong holding capability of the heat radiation fin, uniform contact plane and good thermal conduction; the product manufacturing competitiveness is improved, and the edge extrusion riveting process has a wide popularization application value.

Owner:昆山能缇精密电子有限公司

A process for treating sewage in a piece-type precious metal iron-carbon filled sewage reactor

ActiveCN105461158BAvoid passivationPassivation NoneWater/sewage treatmentMultistage water/sewage treatmentElectrolysisNiobium

The invention discloses a process for treating sewage in a piece-type precious metal iron-carbon filled sewage reactor. The invention discloses a sewage treatment process. After pretreatment, the organic waste water enters the tank body together with the air, and meets the insert-type precious metal filler. The filler evenly releases metal sub-ions to start a micro-electrolysis reaction. The plug-in type precious metal filler is composed of several special steel plate monomers inserted into each other through slots. The special steel plate is made of 0.1-2g of palladium, 0.1-4g of ruthenium, 0.1-2g of niobium, and silver per 10,000 grams of carbon steel. 0.3 ~ 7g, platinum 0.1 ~ 3g, rhodium 0.1 ~ 2g, cast. The sewage treatment process of the present invention has simple steps, is easy to control, truly achieves no passivation, no clogging, and no replacement, and only needs to be maintained once to three times a year, and the maintenance time is about 4 hours each time. The COD removal rate is high and will not Cause secondary pollution to water.

Owner:HUAINAN BAIBANG PNEUMATIC TECH CO LTD

Aging furnace for alloy forging heat treatment process and control method of aging furnace

ActiveCN112029975AEasy to control temperatureReduce the temperatureFurnace typesHeat treatment process controlEngineeringAlloy

The invention relates to the technical field of alloy aging furnace equipment, in particular to an aging furnace for an alloy forging heat treatment process and a control method of the aging furnace.The aging furnace comprises a furnace body, wherein a heat preservation layer and electric heating layers are arranged on the inner wall of the furnace body, and the electric heating layers are electrically connected with a controller; electric heating plates, wherein the electric heating plates are horizontally and fixedly arranged on the inner side of the furnace body in the vertical direction at equal intervals, are in clearance fit with the electric heating layers on the two sides and are electrically connected with the controller; U-shaped heat exchange pipes, wherein the two ends of theU-shaped heat exchange pipes penetrate through the side wall of the furnace body and penetrate through gaps in the two sides of the electric heating plates to be arranged on the fixed sides of the electric heating plates in a surrounding manner, and the bottom ends and the top ends of the U-shaped heat exchange pipes communicate with a water inlet and a water outlet correspondingly; an inner frameconnecting frame, wherein the two sides of the inner frame connecting frame are horizontally and slidably arranged in the furnace body through guide rails; U-shaped containing frames, wherein openings of the U-shaped containing frames face the electric heating plates, and the U-shaped containing frames are vertically arranged on the inner frame connecting frame at equal intervals; connecting closing plates, wherein the connecting closing plates are vertically arranged on the two sides of the U-shaped containing frames; and thermometers, wherein the thermometers vertically penetrate through anopening and closing door of the furnace body in the vertical direction at equal intervals. The device can be used for conveniently containing alloys and storing heat in the furnace after aging is finished.

Owner:浦夕特种合金(上海)有限公司

Current-voltage electrode

InactiveCN102109545AIncrease contact areaEven contactCurrent/voltage measurementCurrent voltageMedia layer

The invention relates to a current-voltage electrode, comprising a current electrode and a voltage electrode, wherein the voltage electrode is a metal probe, and a voltage signal line terminal is led out from one end of the voltage electrode; the current voltage is internally provided with an insulating medium which wraps the voltage electrode; the current electrode is provided with a current line leading-out terminal; and the voltage electrode has an elastic and telescopic structure and is used for compacting structural testing points when the testing points of a tested object sample voltage signals. In the current-voltage electrode disclosed by the invention, an insulating medium layer is arranged between the voltage electrode and the current electrode; when in test, the voltage electrode and the current electrode are separated, voltage signal sampling points are accurate, the current electrode samples current signals, the contact area is large and the contact is uniform; and for a tested object with a large volume and irregular shape, the shape of the contact surface between the current electrode and the tested object can be changed according to the shape and the size of the tested object, so that the contact is good, the testing accuracy is high and the use is convenient.

Owner:WUHAN SIWEI TECH INVESTMENT

A turning belt automatic rebound floating inner support clamping device

ActiveCN104588714BEasy to take outUniform contact surfaceTransportation and packagingExpansion mandrelsEngineeringScrew thread

Owner:博瑞孚曼机械科技(苏州)有限公司

A precious metal iron-carbon filled sewage reactor

The invention discloses a sewage reactor with precious metal iron-carbon filler. The tank body is provided with a stainless steel porous filter plate, and the stainless steel porous filter plate is provided with a three-layer inserted precious metal iron-carbon filler from top to bottom. The filler is composed of several special steel plates. The single cells are formed by inserting slots into each other, and the slots are arranged on one side of the special steel plate single body, and the groove width of the slot is the same as the thickness of the special special steel plate single body. The insert-type precious metal iron-carbon filler of the reactor of the present invention can slowly and uniformly precipitate sub-ions of various metals, which is uniform and not easy to be lost. The maintenance time is about 4 hours, the COD removal rate is high, and it will not cause secondary pollution to the water, which is 20% to 30% higher than the sewage removal efficiency of the ordinary iron-carbon micro-electrolysis process.

Owner:江苏元捷环境科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com