Patents

Literature

40results about How to "Improved seal durability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

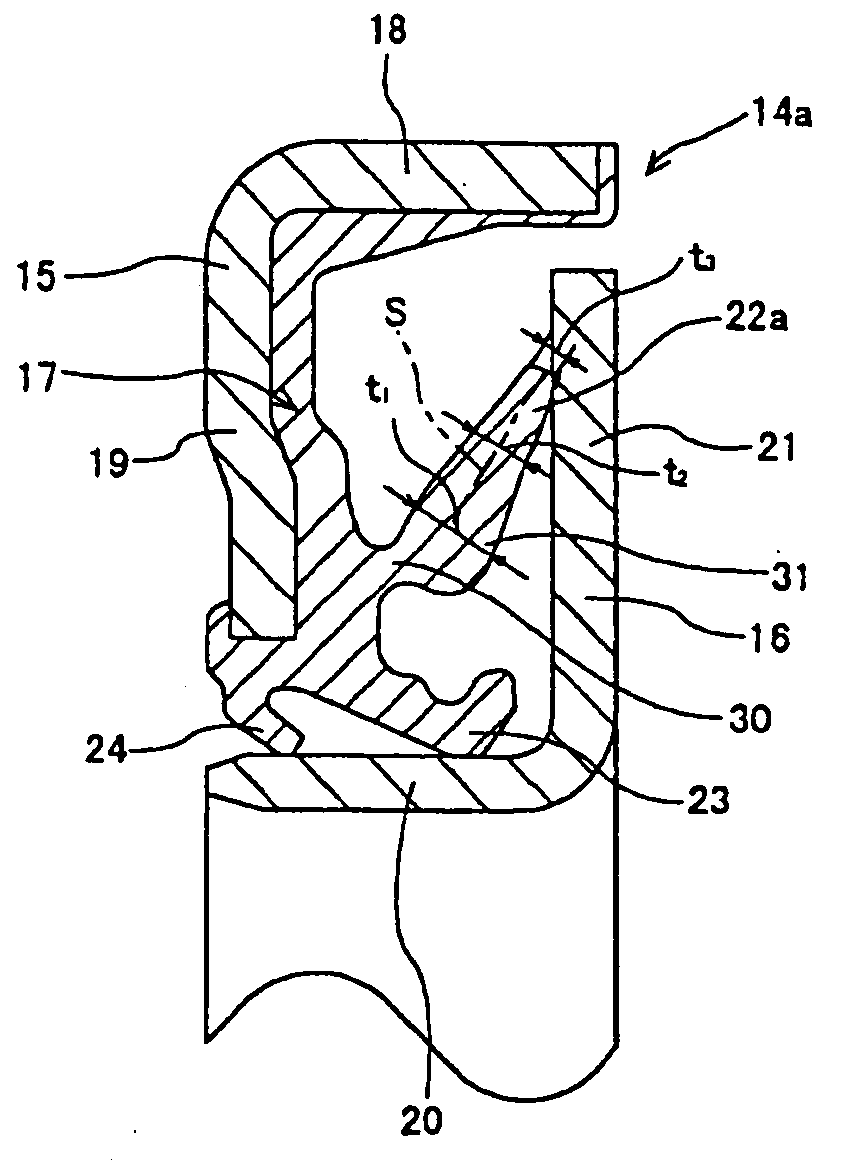

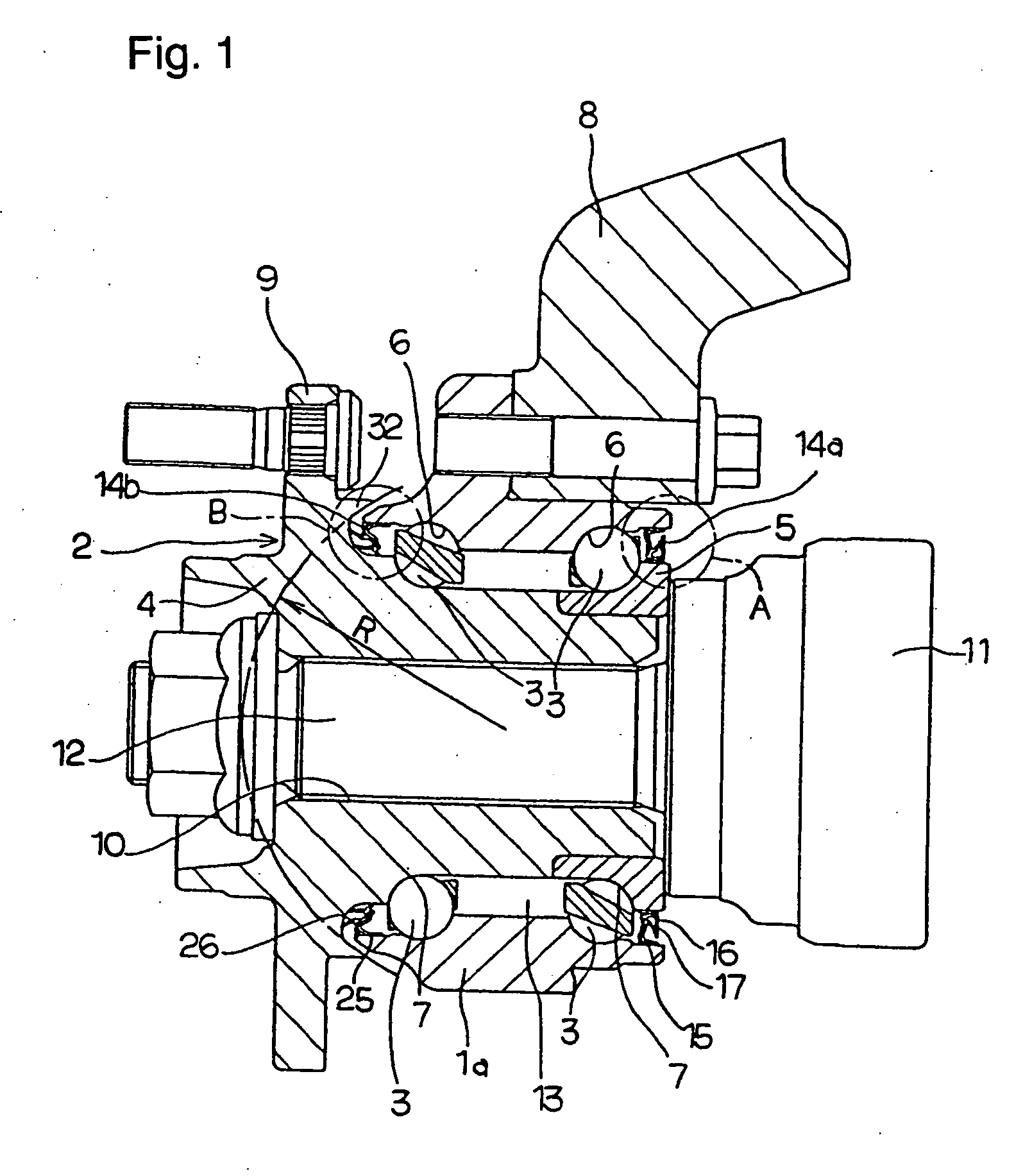

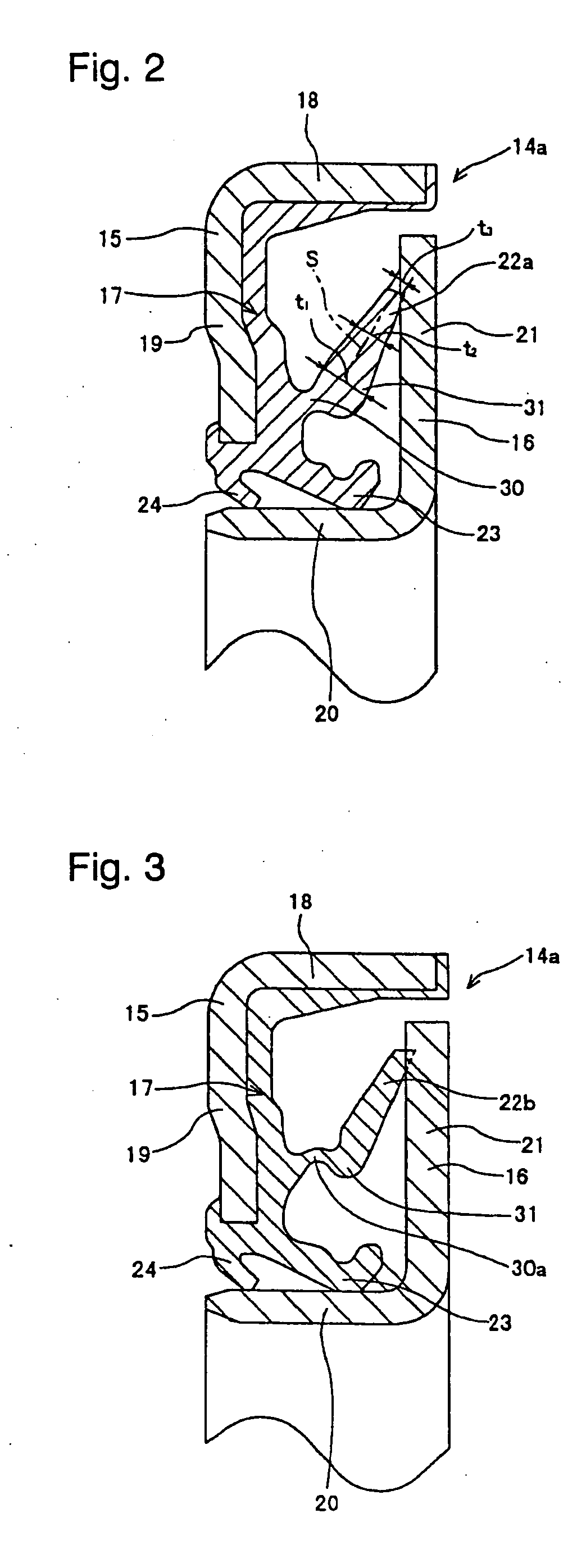

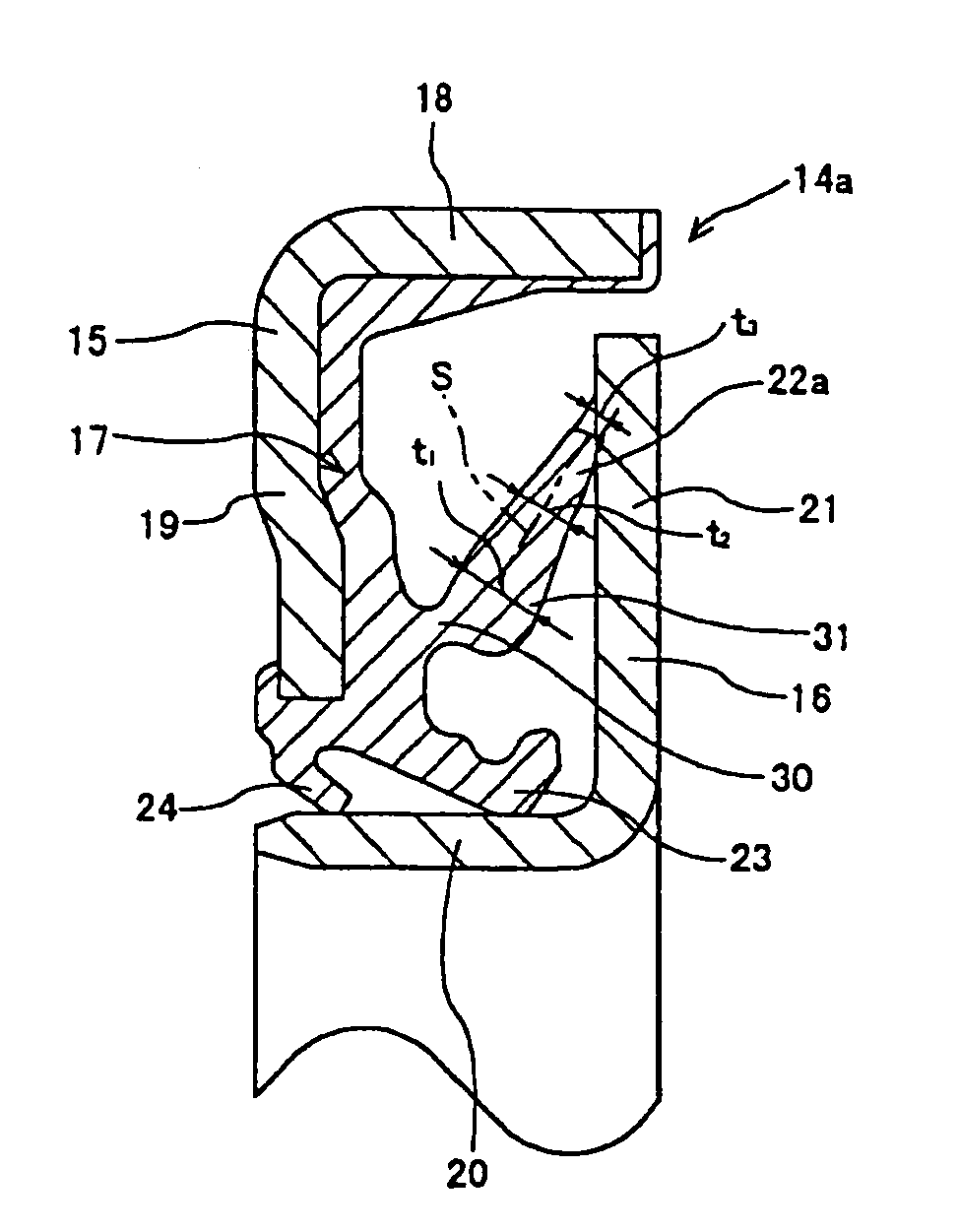

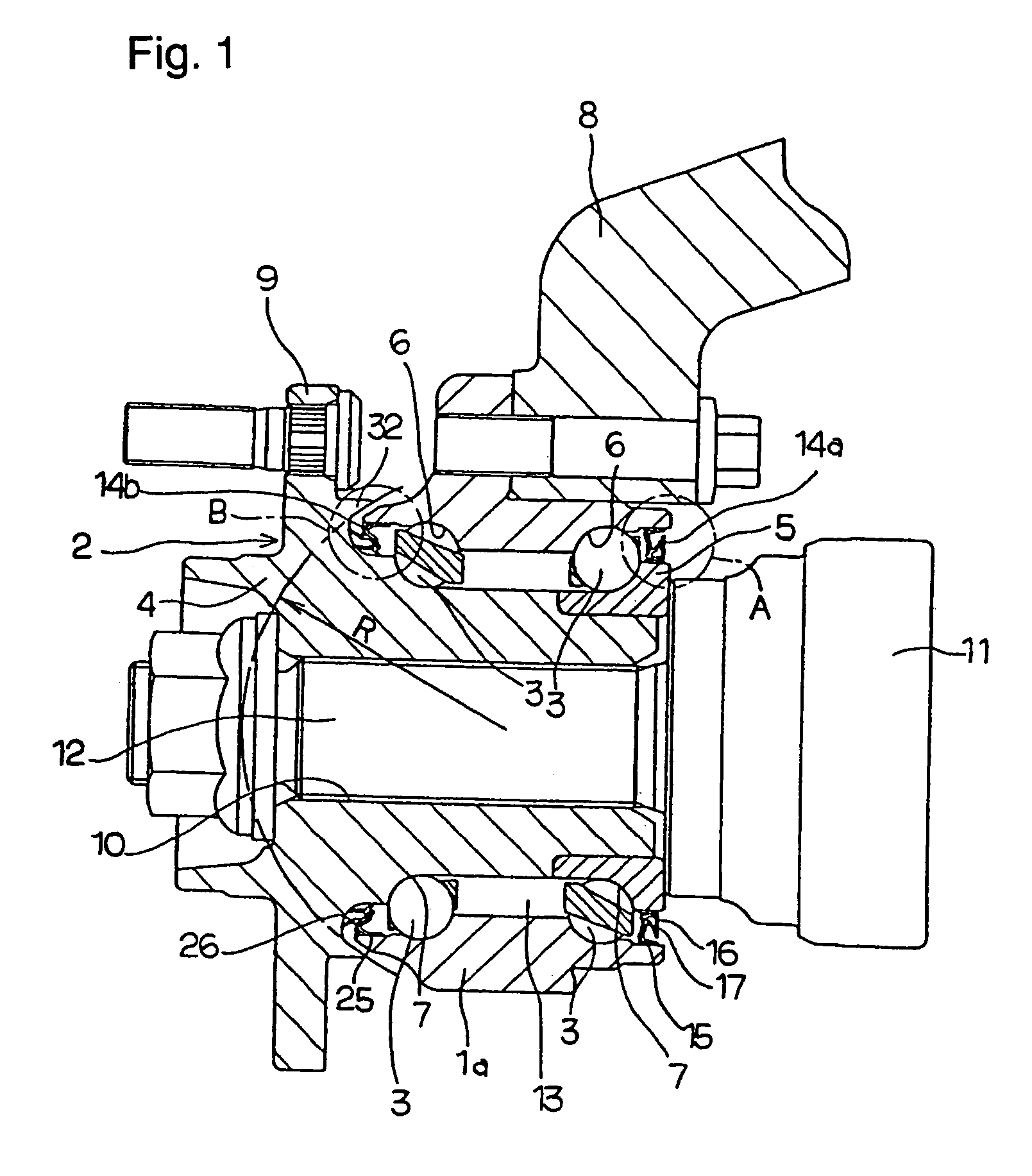

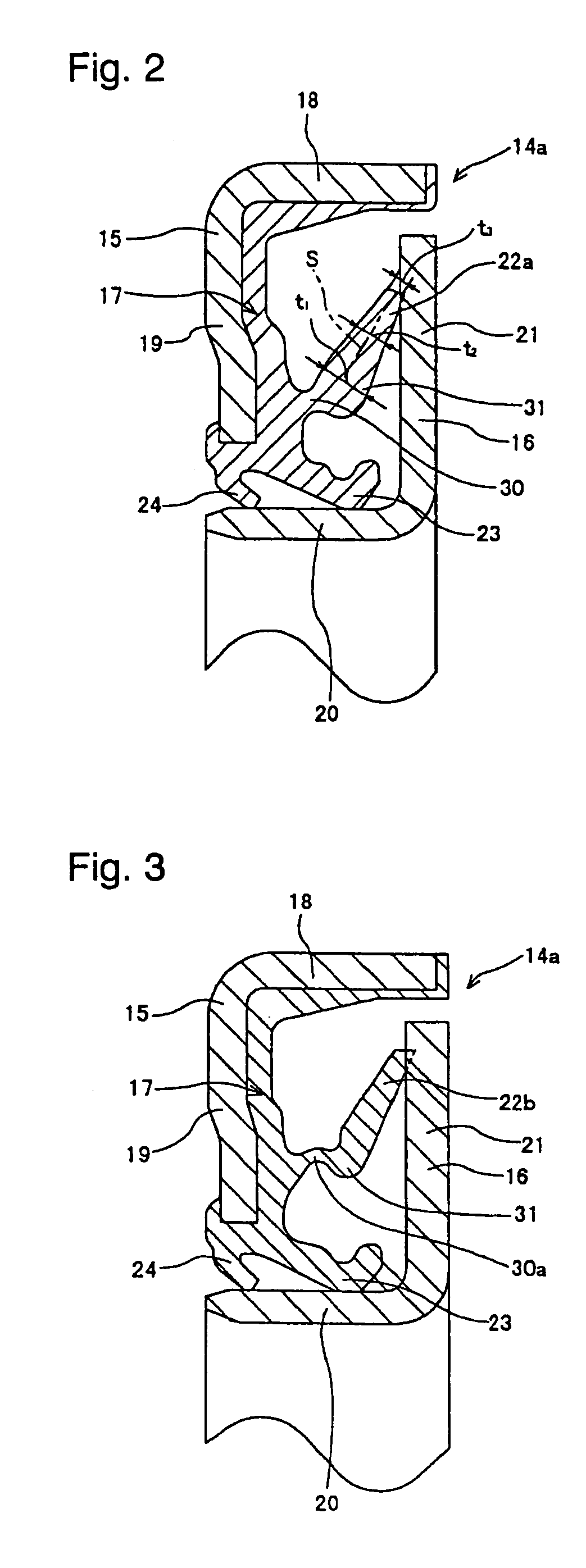

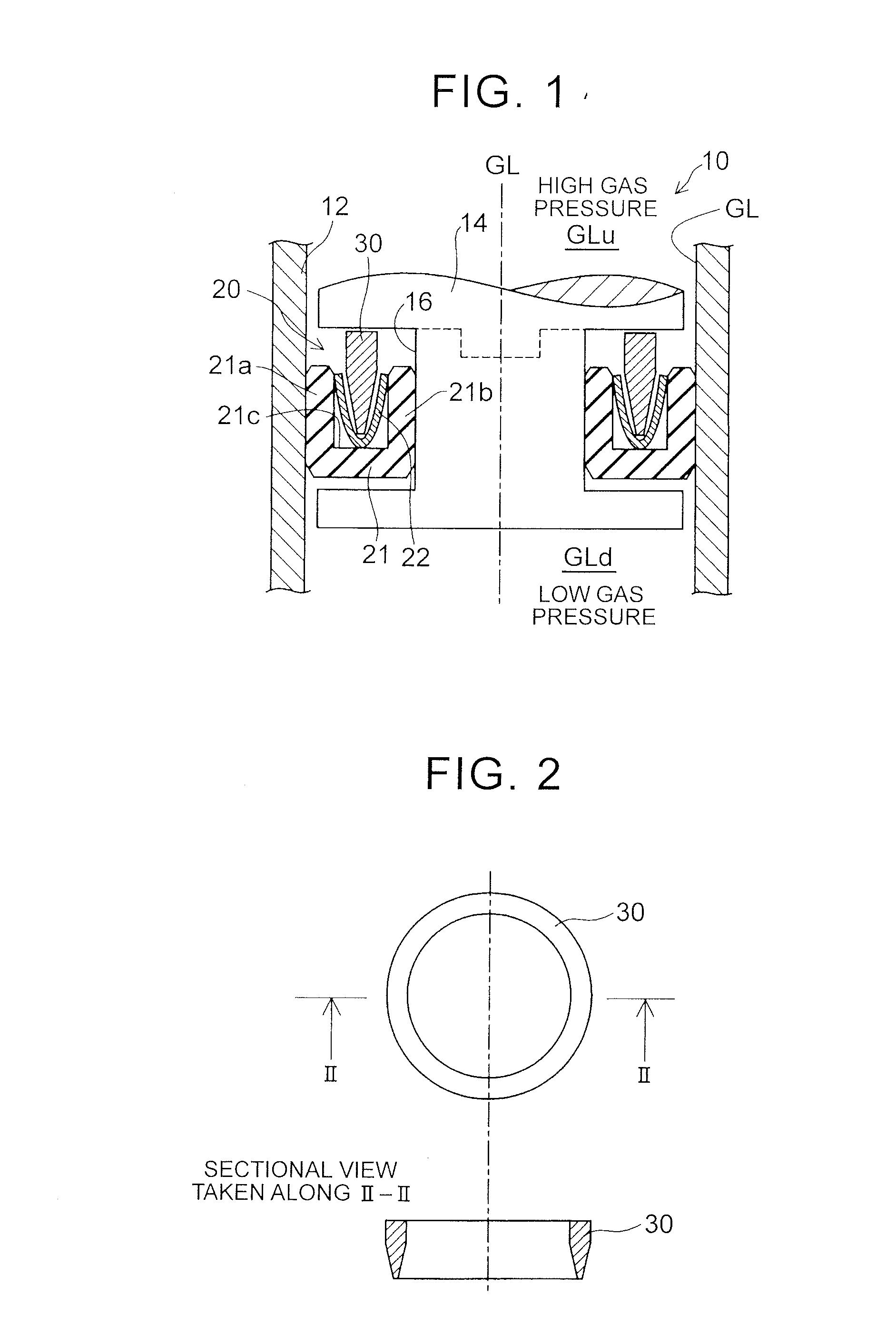

Seal ring and rolling bearing unit with seal ring

InactiveUS20050089254A1Reduce binding forcePromote generationEngine sealsRolling contact bearingsRolling-element bearingEngineering

It is intended that the rotation resistance is decreased while the durability and seal performance are kept in the rolling bearing unit with seal ring. The most thin wall-thickness portion 30 is provided in the vicinity of the base end of the seal lip 22a projecting laterally in sliding contact with the mating surface. The most thick wall thickness portion 31 is provided adjacent to the most thin wall thickness portion 30 on the tip end side. The thickness is gradually decreased from the most thick wall thickness portion 31 to the tip end. Further, the ratios of thickness in the respective portions 22a are properly controlled.

Owner:NSK LTD

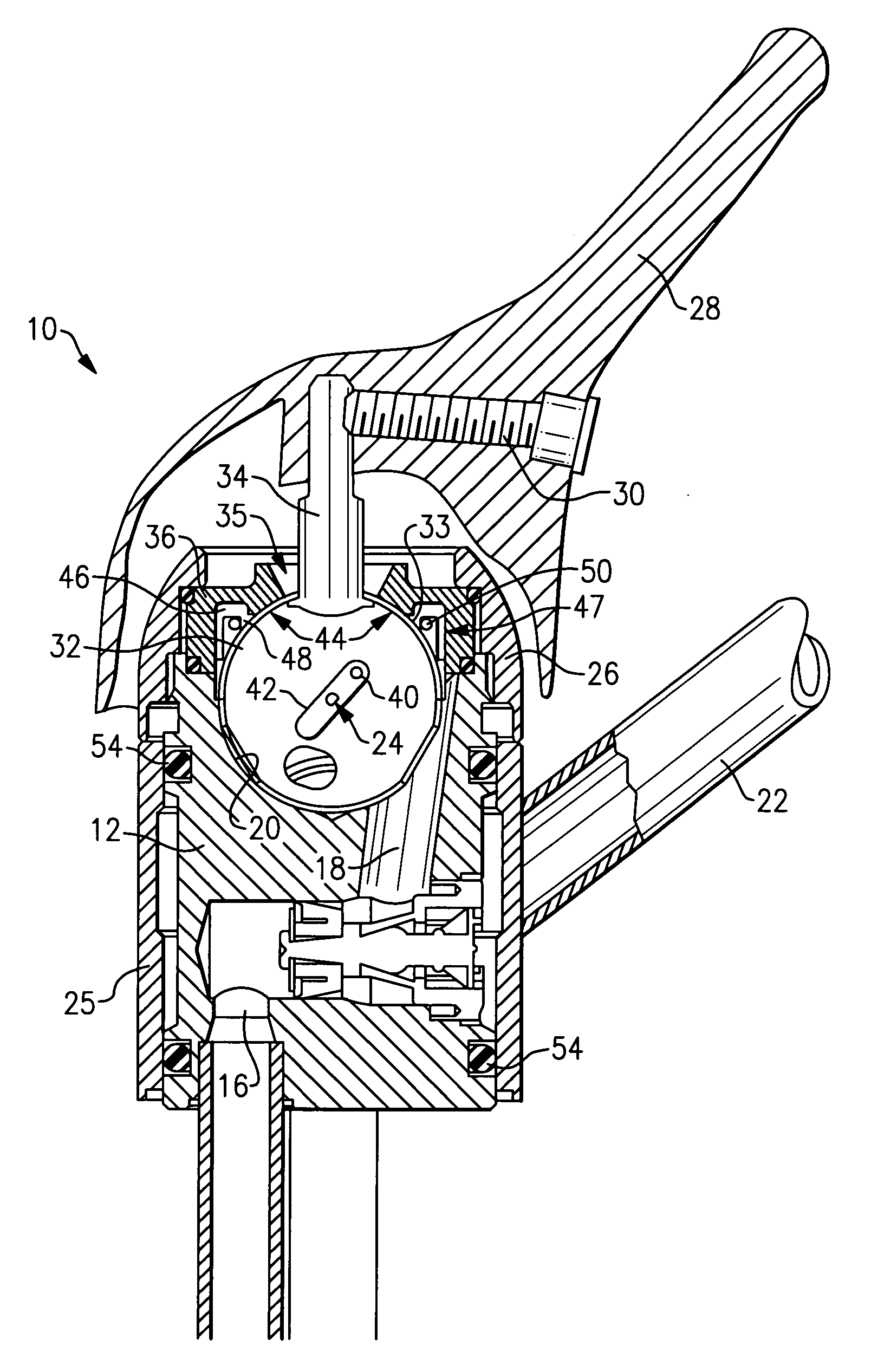

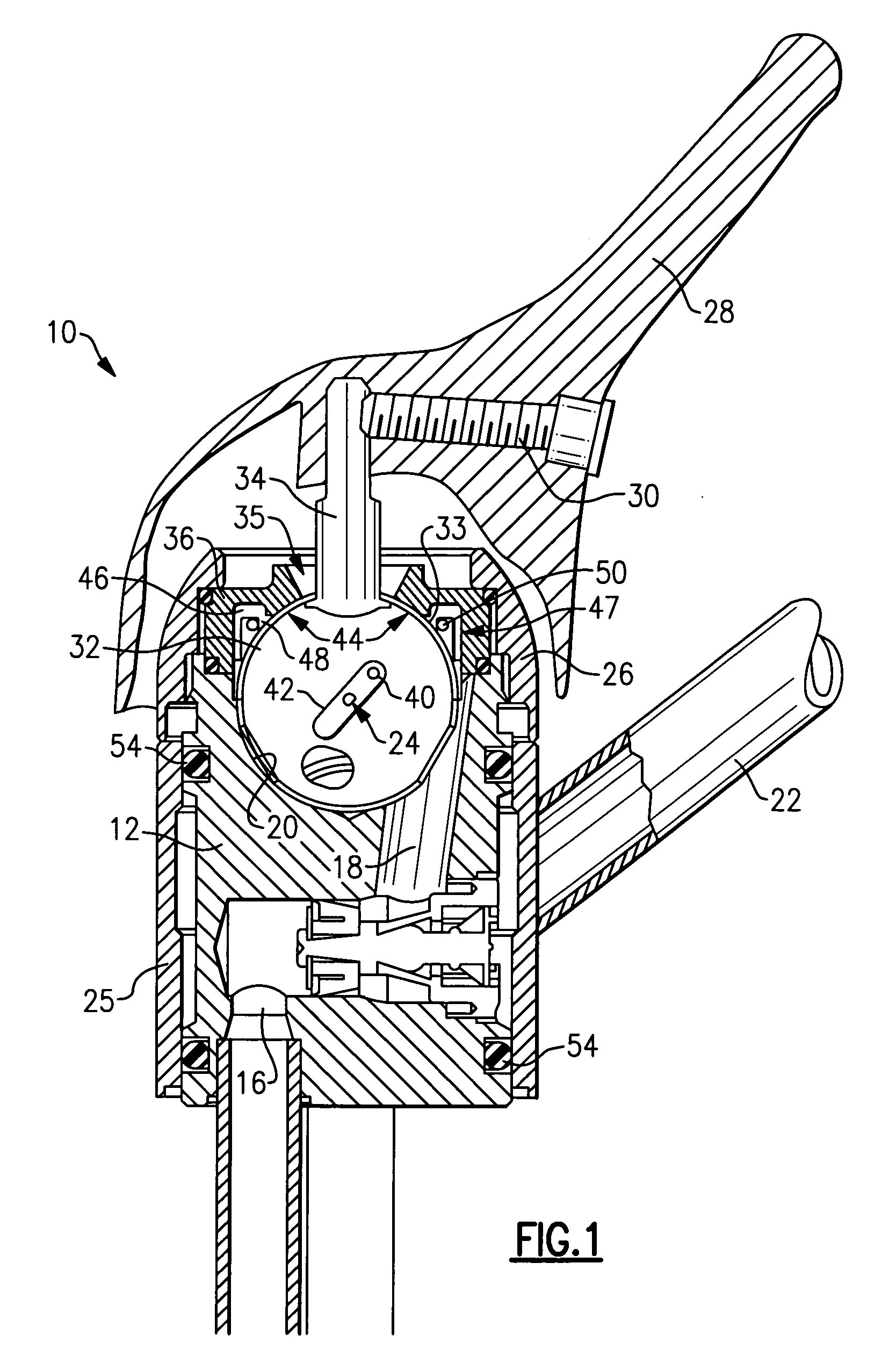

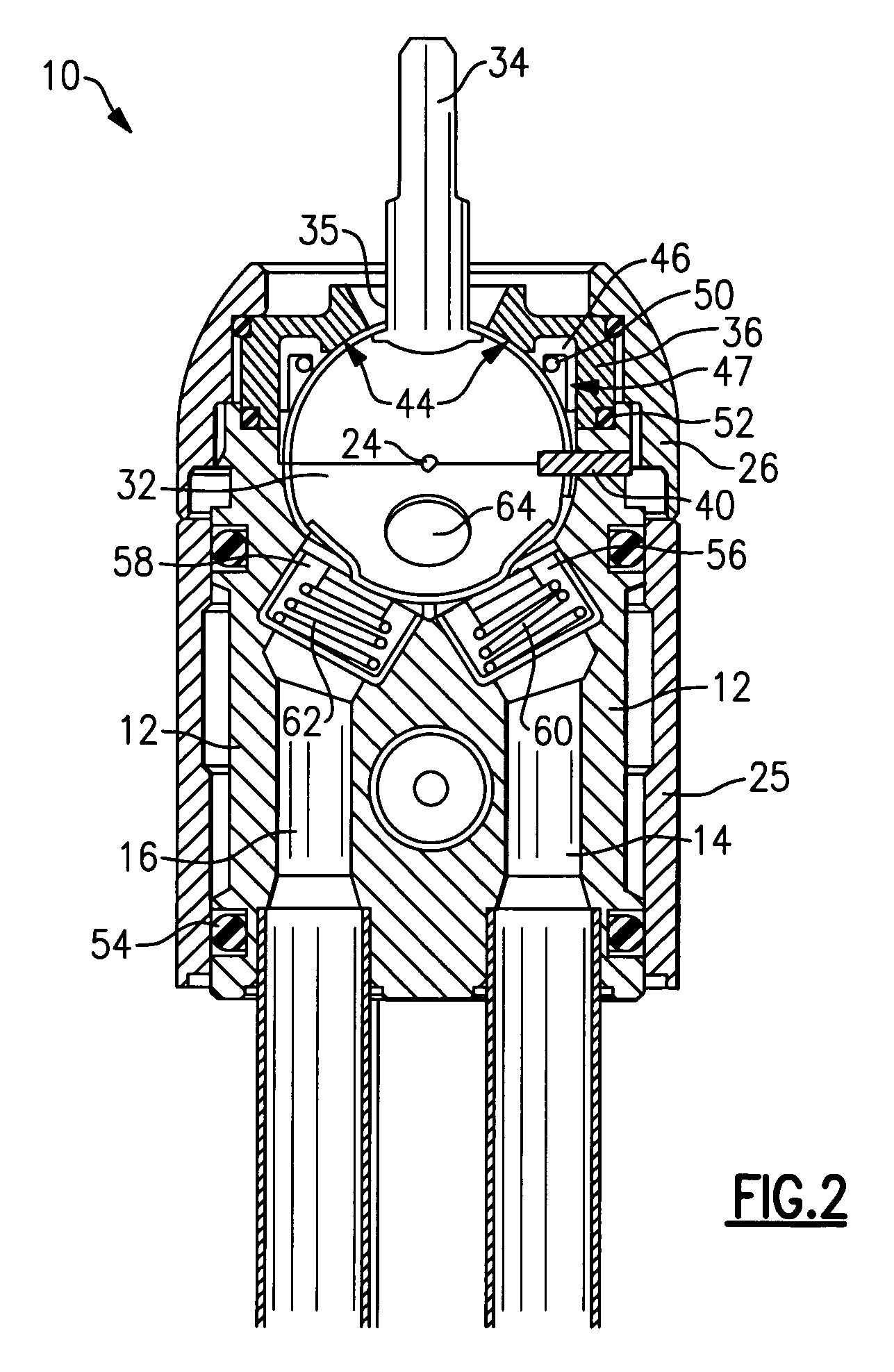

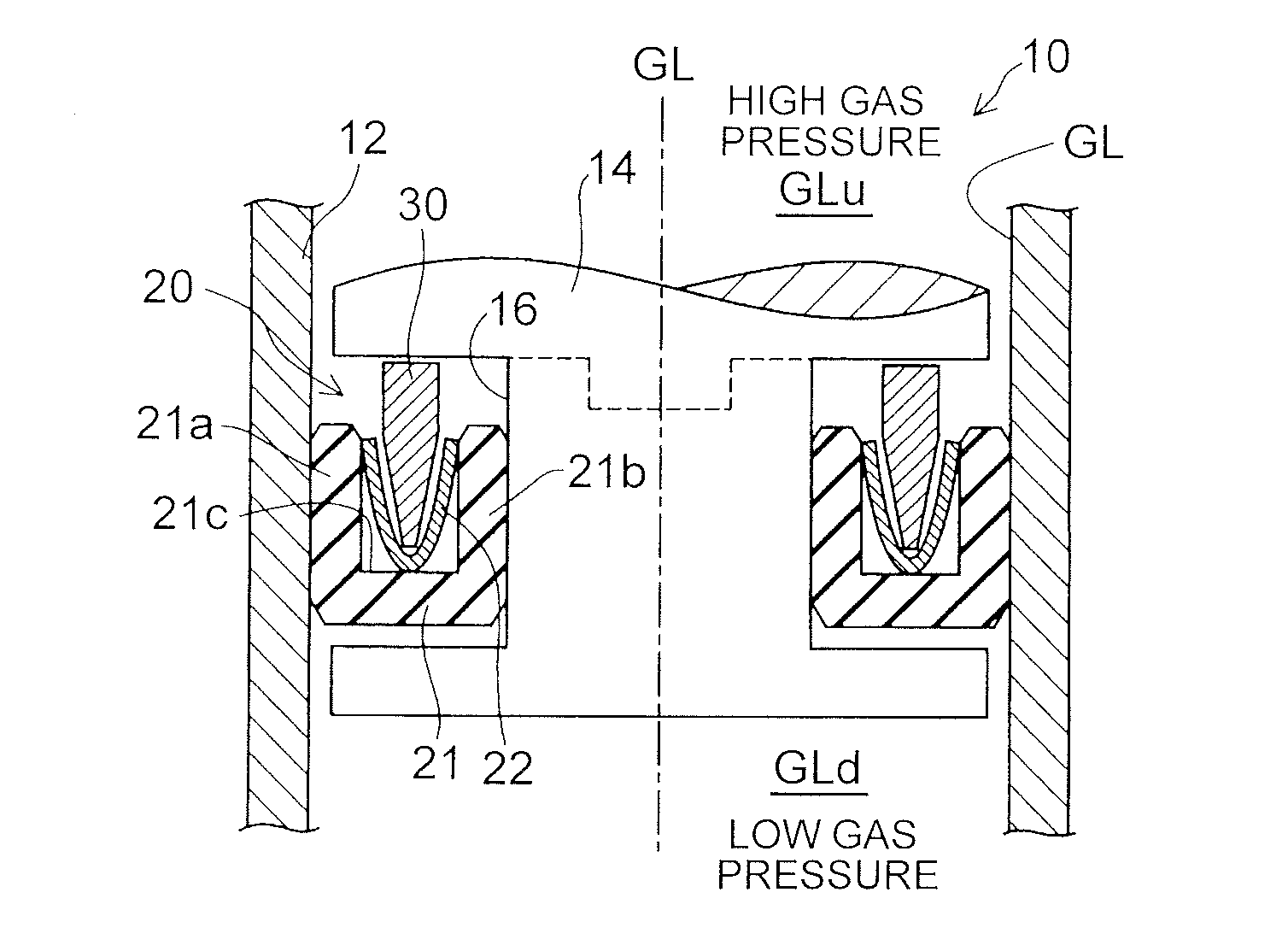

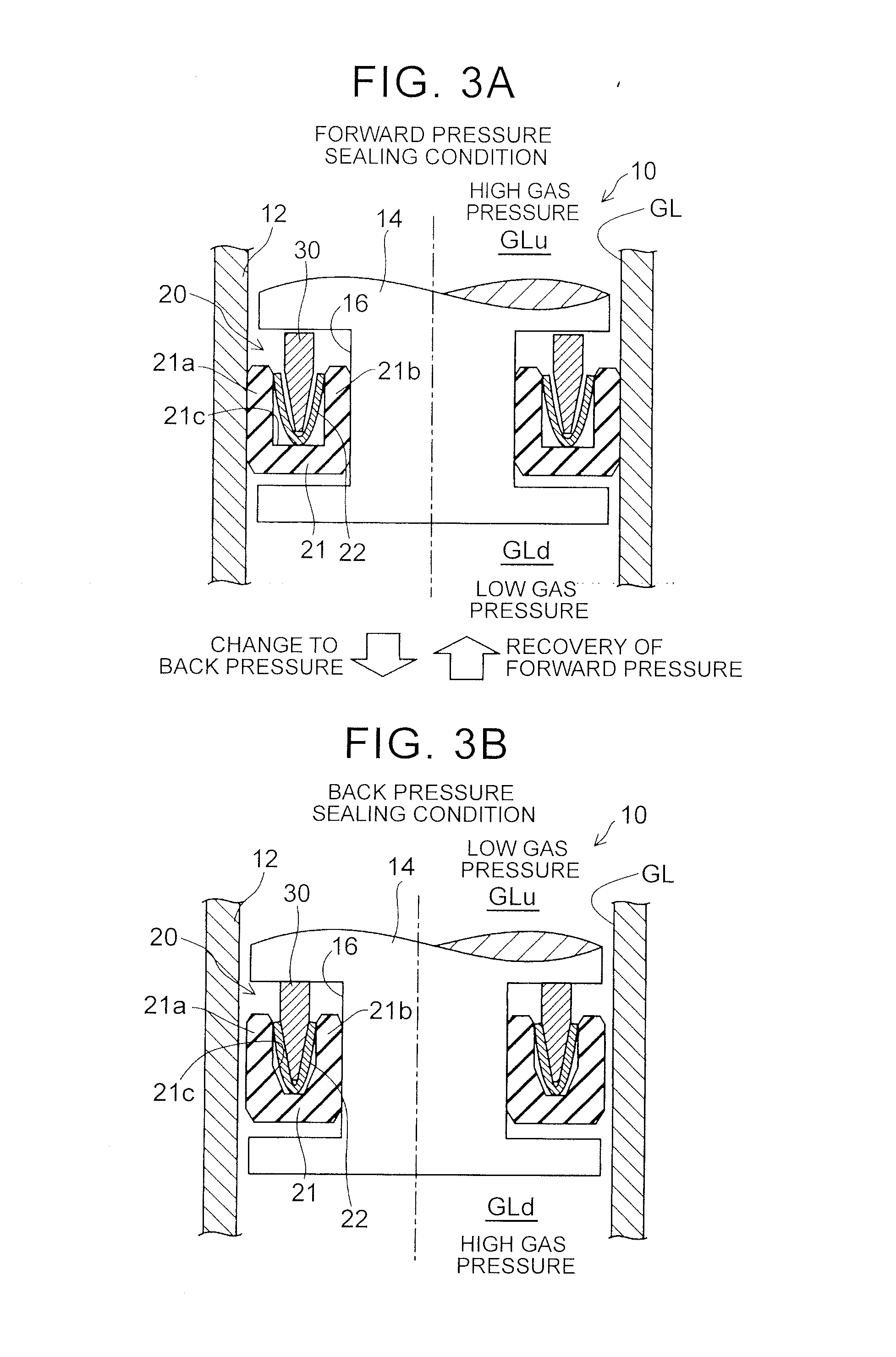

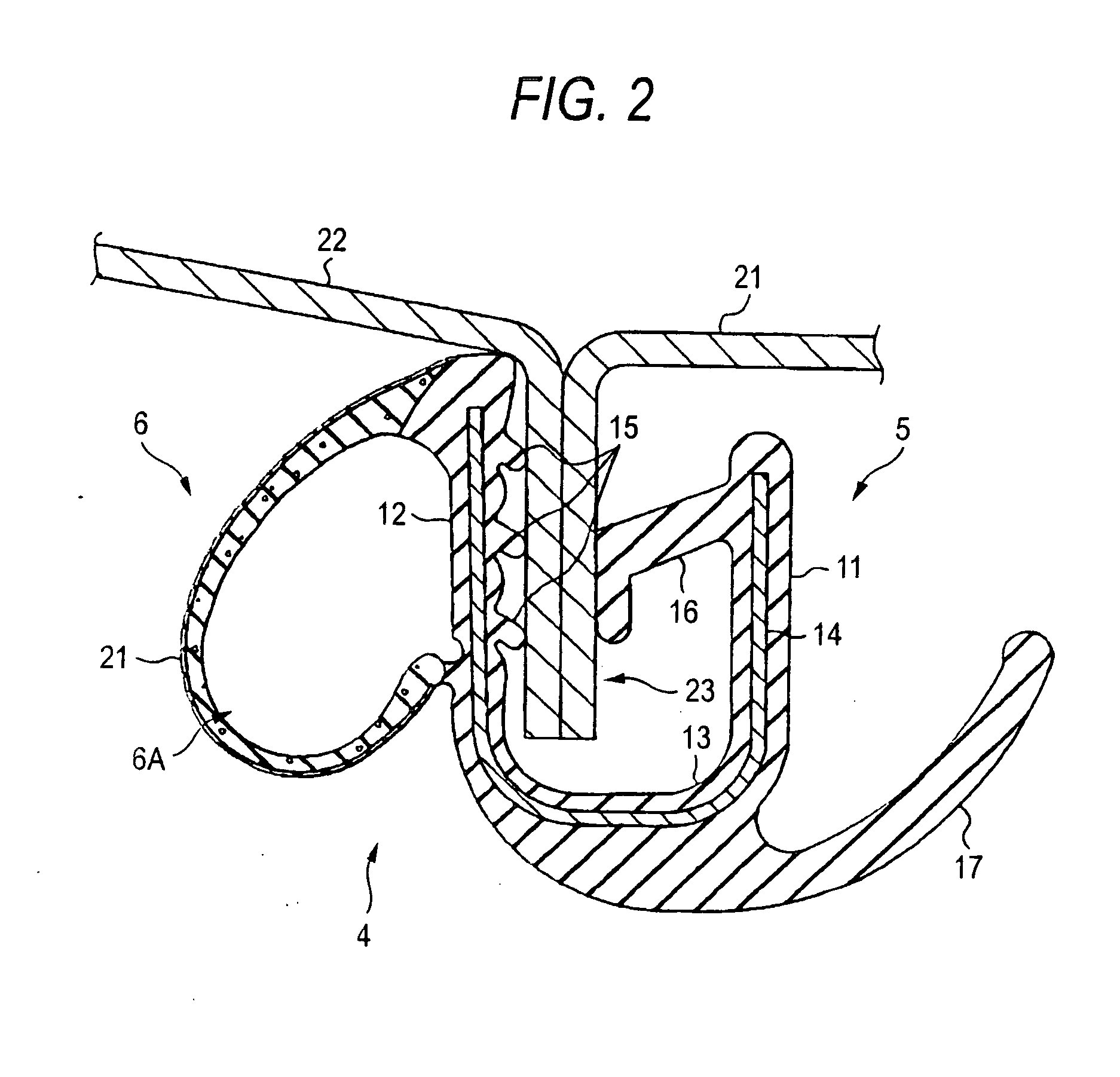

Plunger type master cylinder

InactiveUS7181911B2Improved seal durabilityInvalid stroke can be reducedPiston ringsRotary clutchesWorking fluidMaster cylinder

Owner:BOSCH CORP

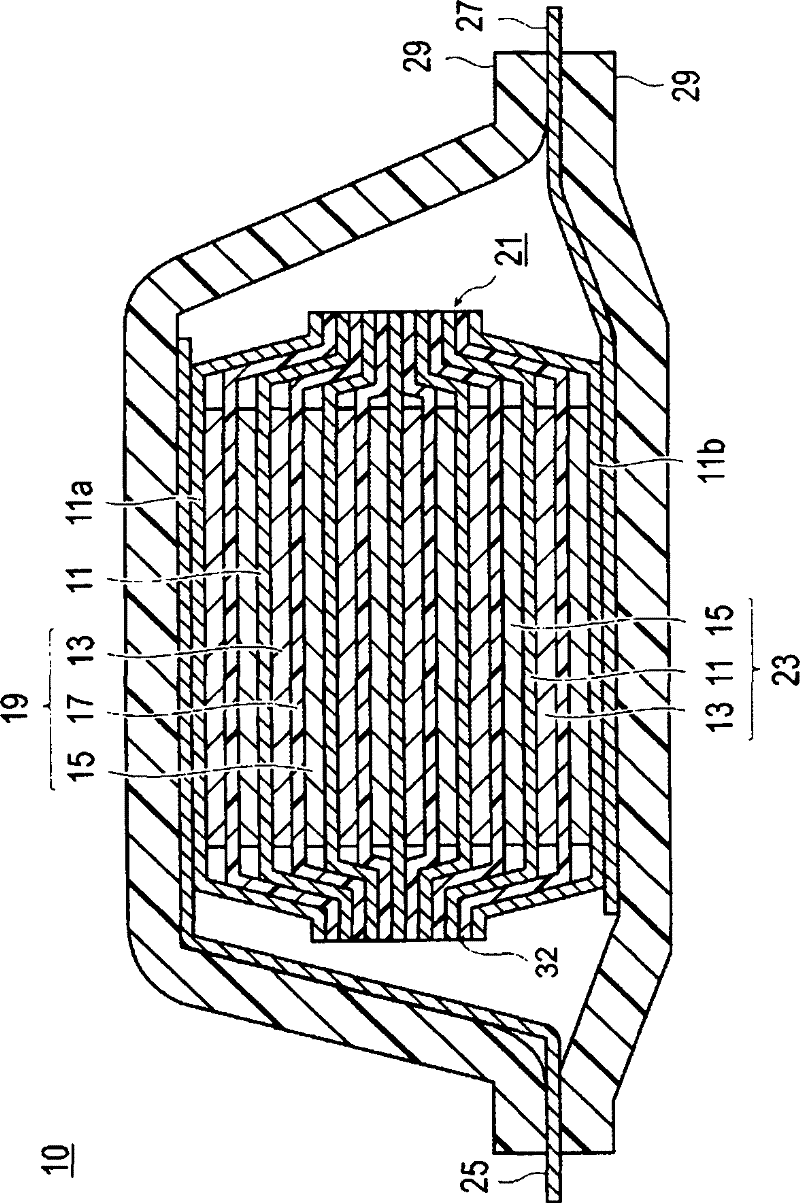

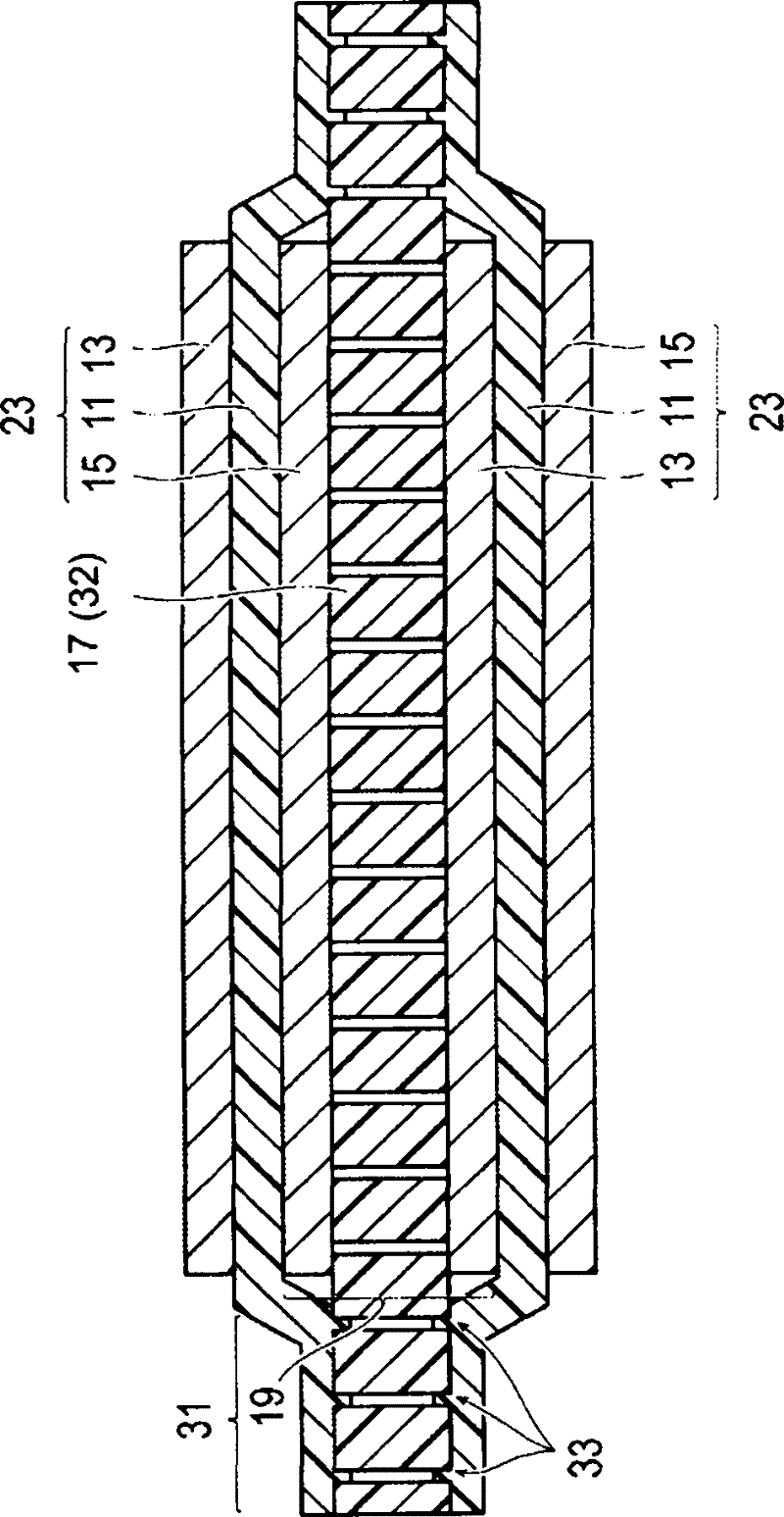

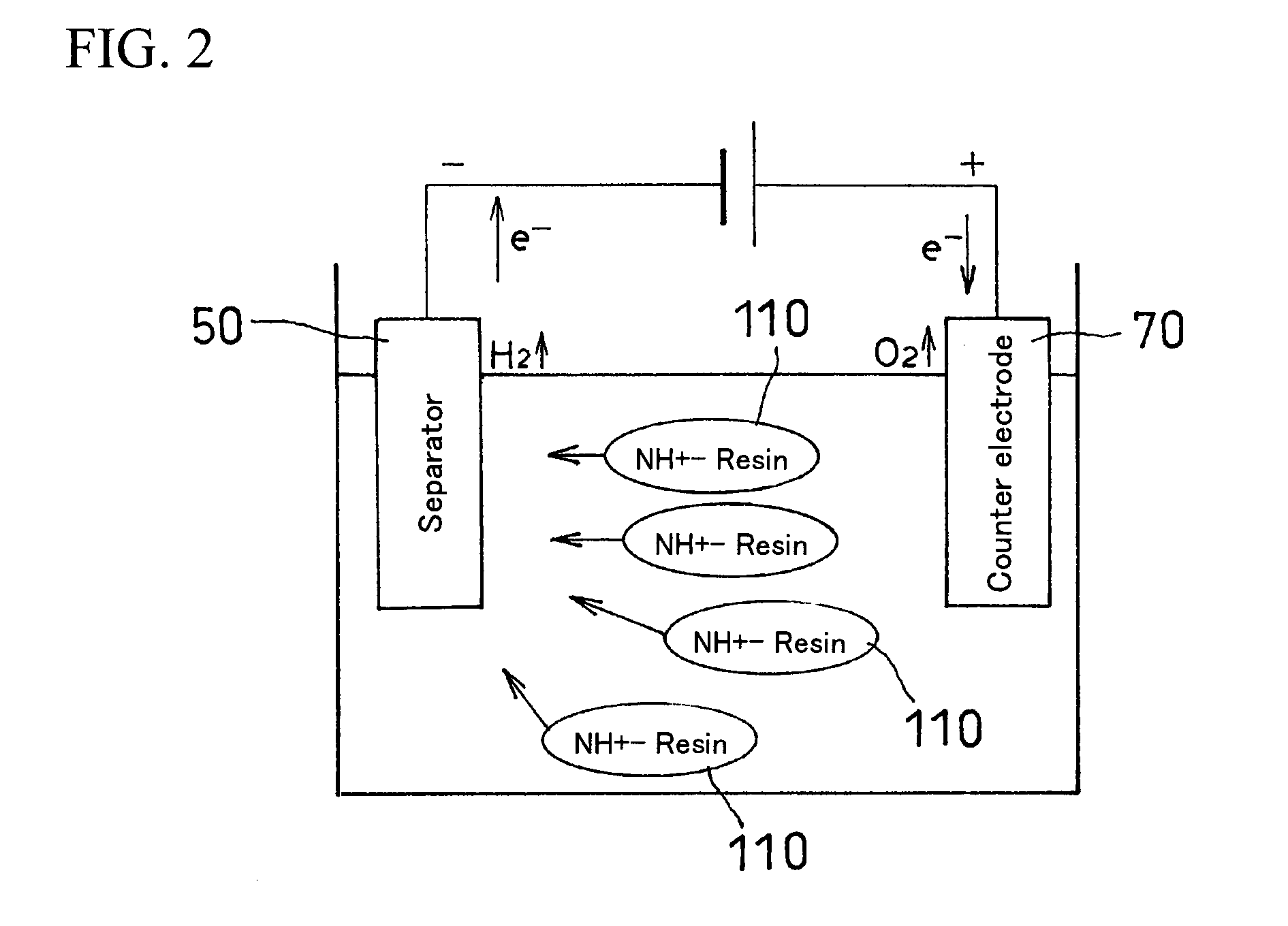

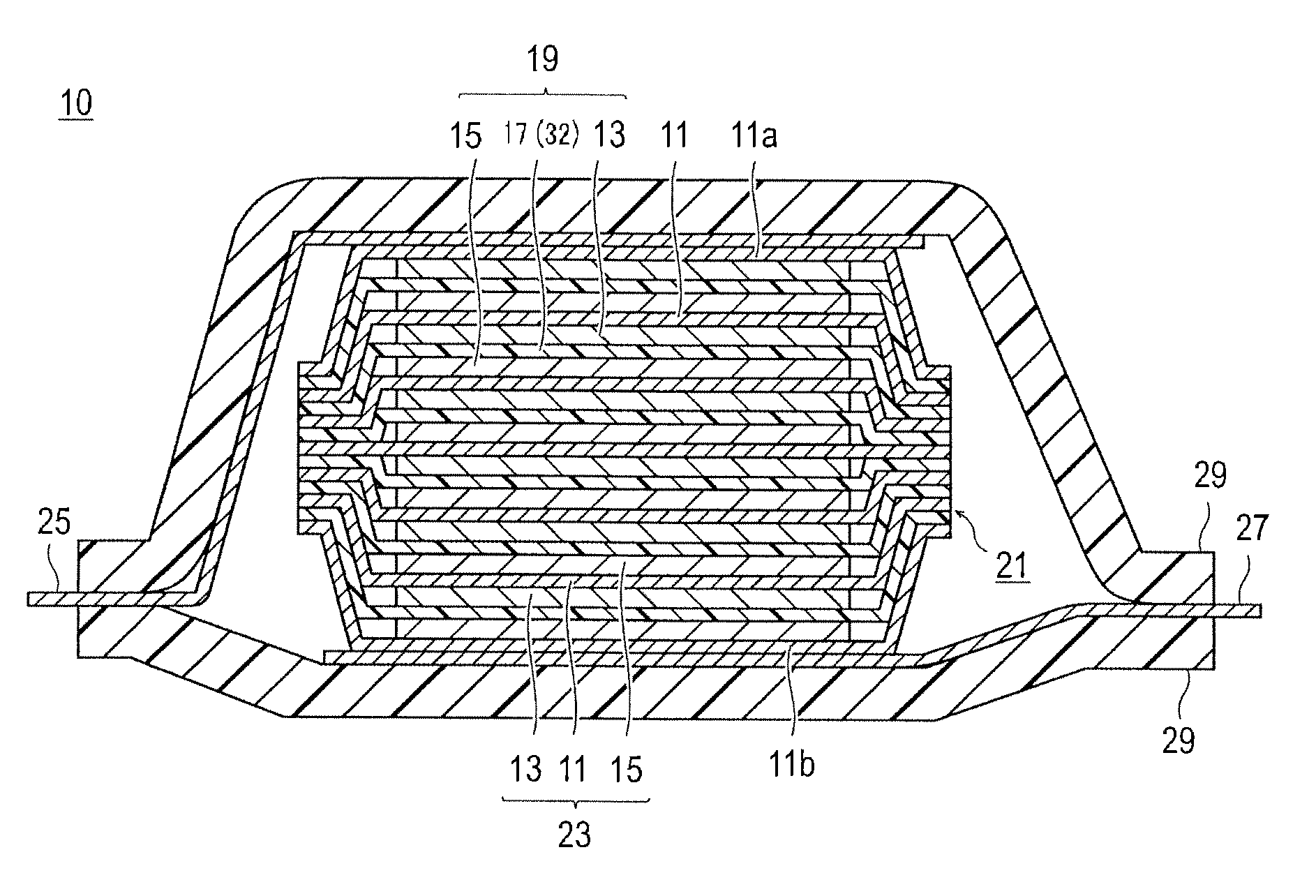

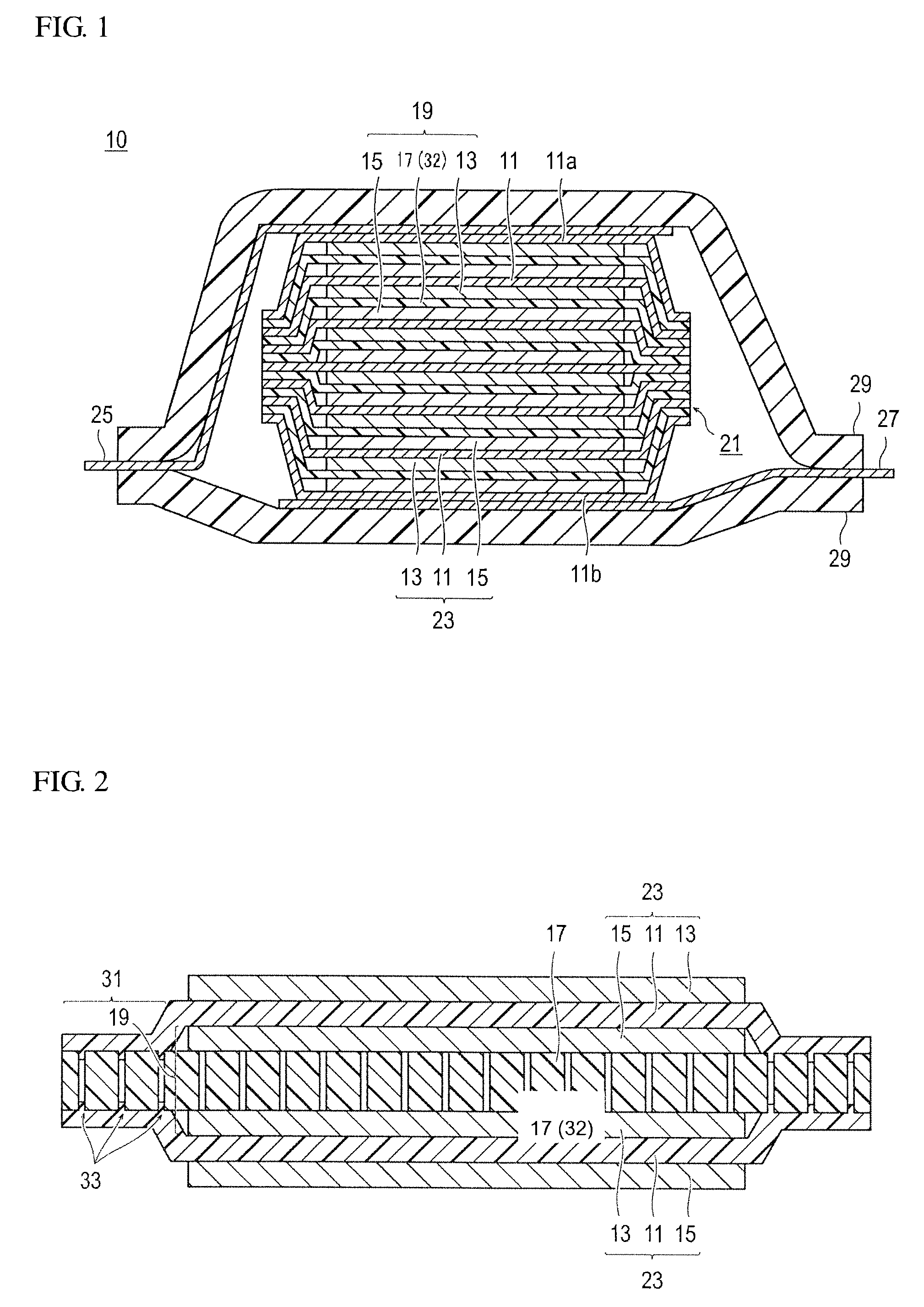

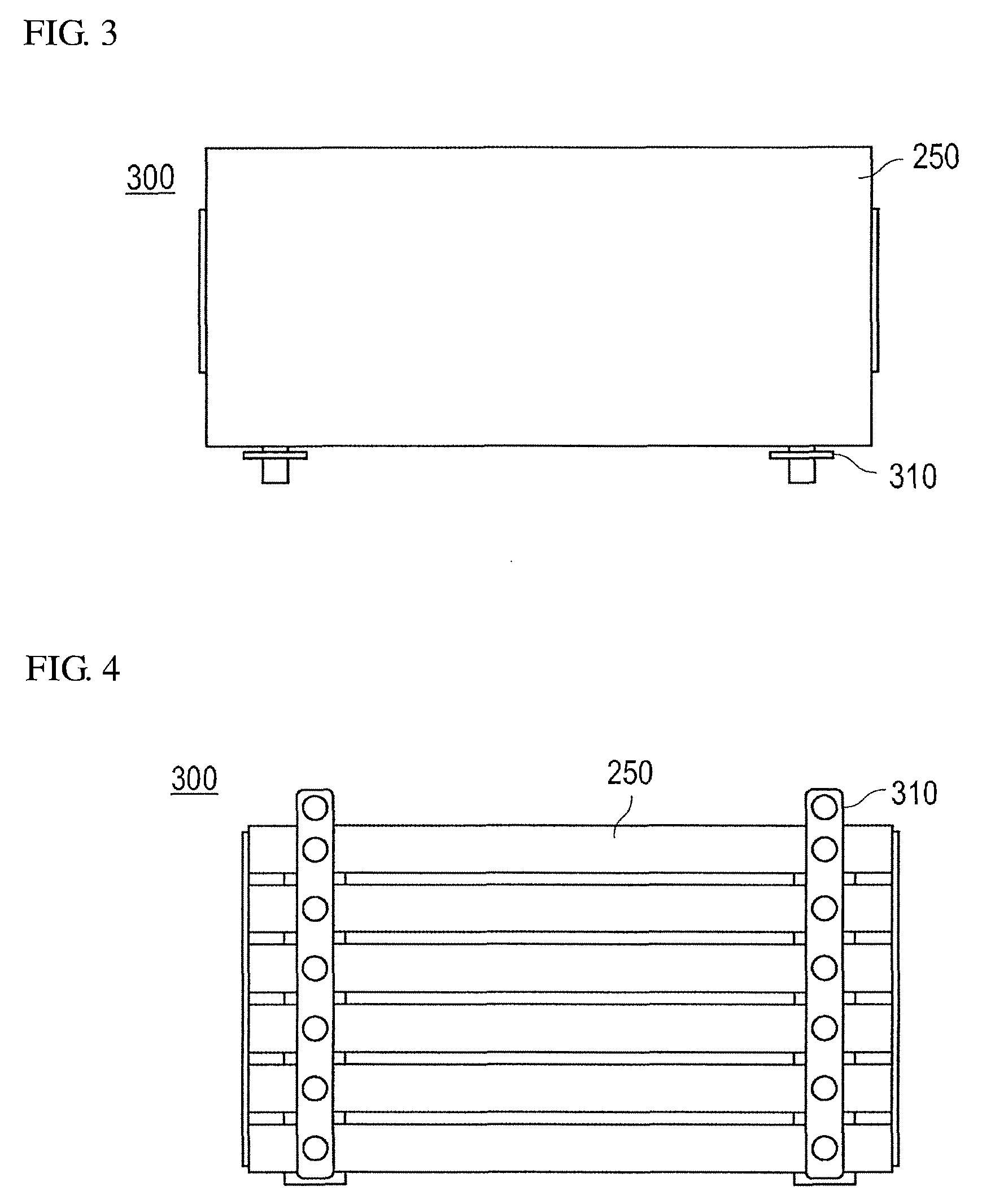

Bipolar secondary cell and method for producing the same

ActiveCN102341948AImproved seal durabilityLarge-sized flat cells/batteriesFinal product manufactureCell layerElectrolyte

Provided is a bipolar secondary cell comprised of first and second bipolar electrodes and a separator. The first and second bipolar electrodes are provided with a power collecting element composed of a first resin as a base material and a conductive resin layer; a positive-electrode active material layer formed on one surface of the power collecting element; and a negative-electrode active material layer formed on the other surface of the power collecting element. The separator is disposed between the first and second bipolar electrodes and composed of a second resin as a base material, and holds electrolyte to form an electrolyte layer. The bipolar secondary cell is comprised of a power generating element provided with an electric cell layer composed of the positive-electrode active material layer of the first bipolar electrode, the electrolyte layer, and the negative-electrode active material layer of the second bipolar electrode. The melting point of the first resin is not more than that of the second resin. The peripheral edges of the power collecting elements of the first and second bipolar electrodes are fusion-bonded to the peripheral edge of the separator, to seal the outer periphery of the electric cell layer.

Owner:NISSAN MOTOR CO LTD

Seal ring and rolling bearing unit with seal ring

InactiveUS7021830B2Reduce frictional resistanceImproved seal durabilityEngine sealsRolling contact bearingsRolling-element bearingThick wall

It is intended that the rotation resistance is decreased while the durability and seal performance are kept in the rolling bearing unit with seal ring.The most thin wall-thickness portion 30 is provided in the vicinity of the base end of the seal lip 22a projecting laterally in sliding contact with the mating surface. The most thick wall thickness portion 31 is provided adjacent to the most thin wall thickness portion 30 on the tip end side. The thickness is gradually decreased from the most thick wall thickness portion 31 to the tip end. Further, the ratios of thickness in the respective portions 22a are properly controlled.

Owner:NSK LTD

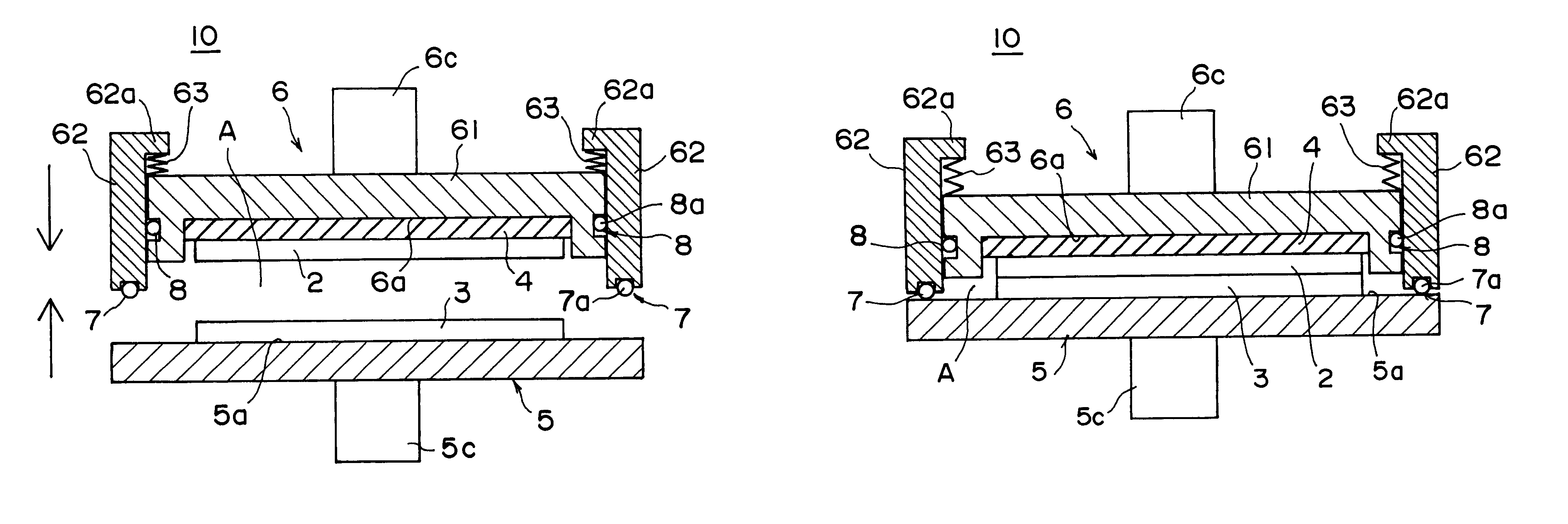

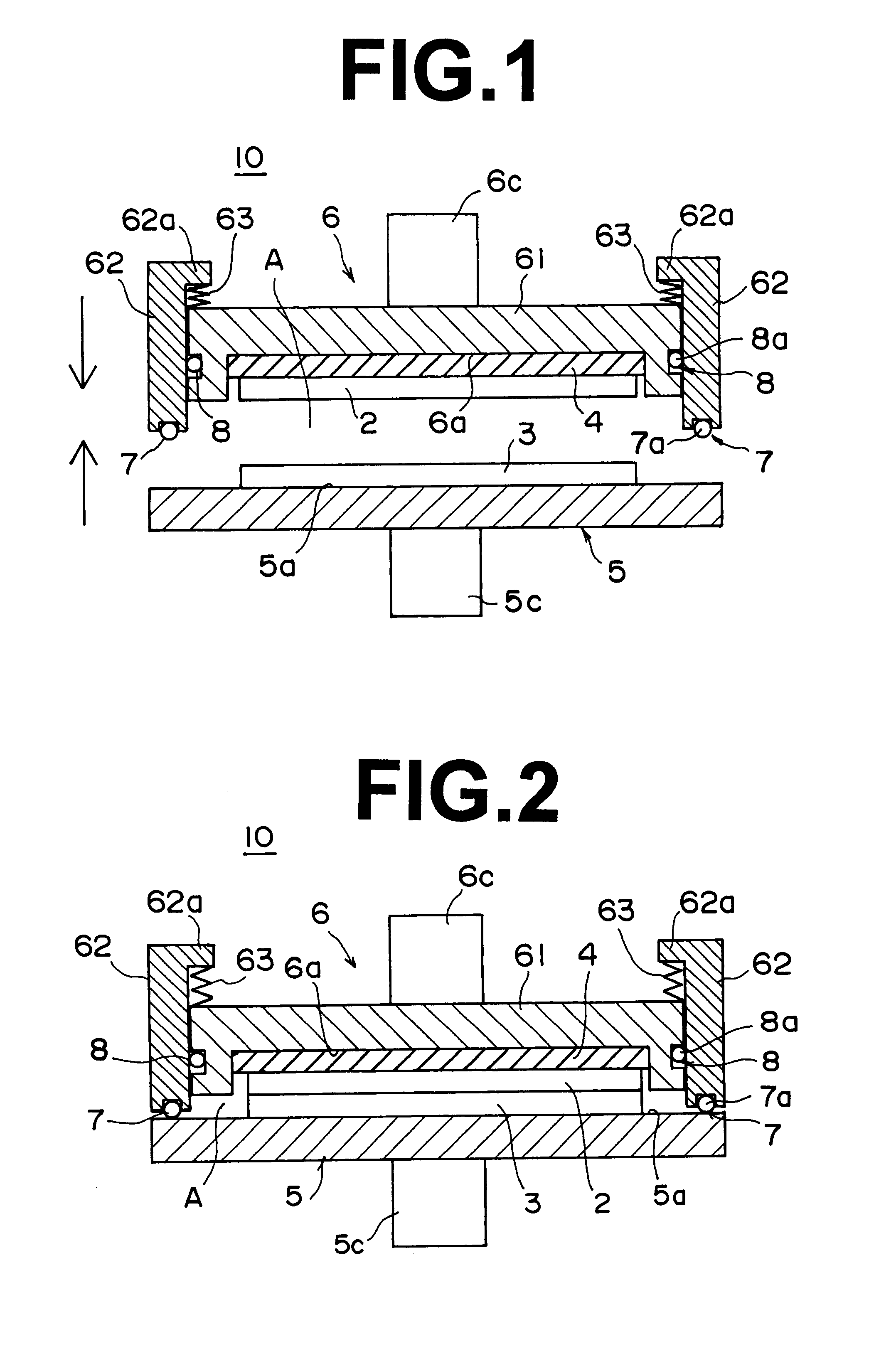

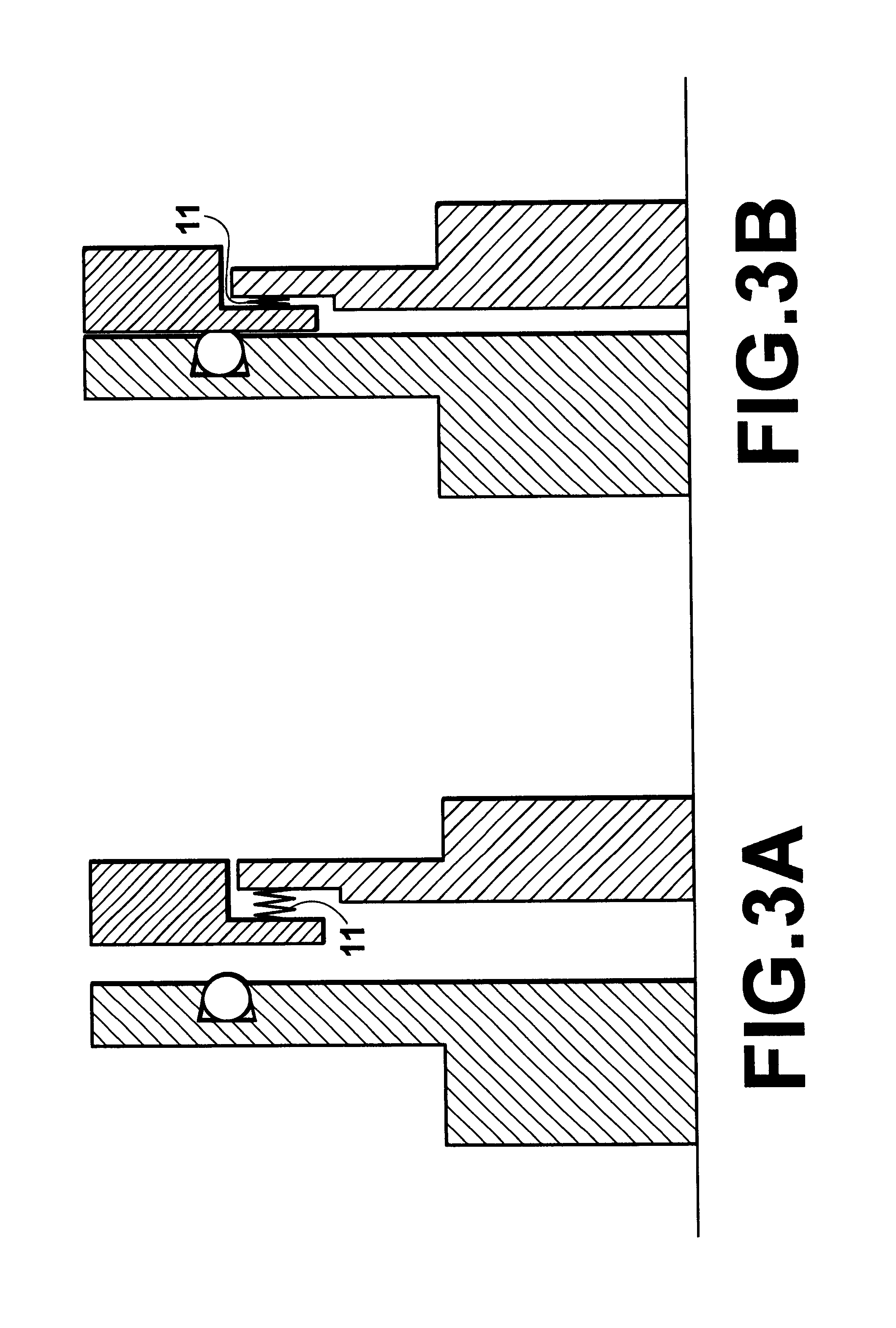

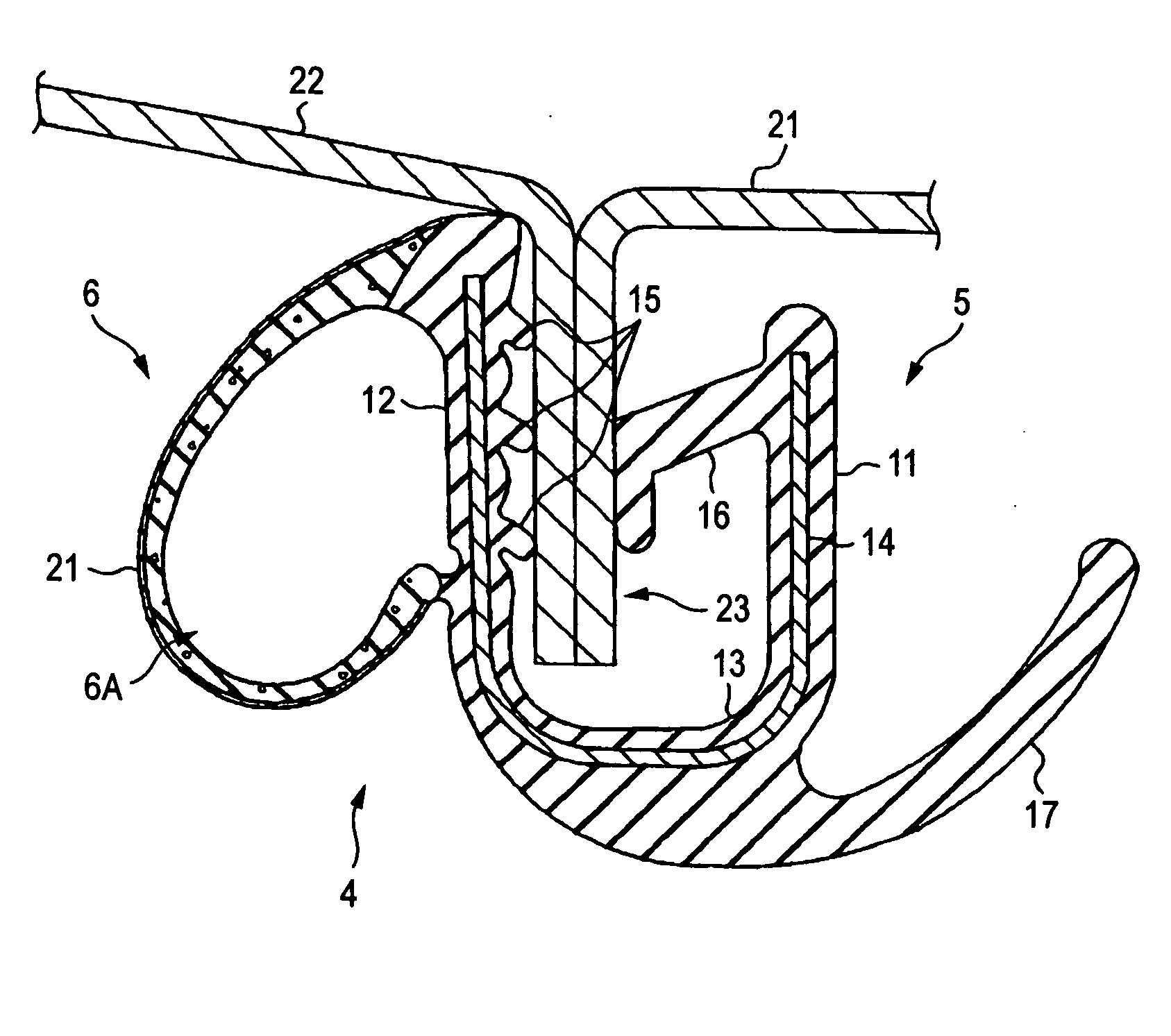

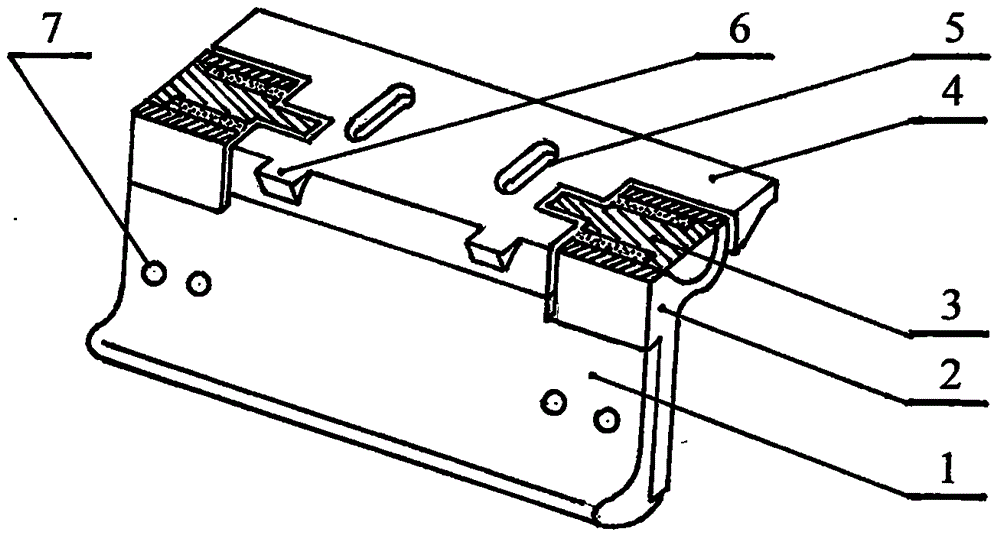

Holder for magnetic transfer apparatus

InactiveUS6839192B2Increased durabilityReduced seal wearMechanical record carriersRecord information storageInterior spaceEngineering

A holder for magnetic transfer is formed by a chamber base and a chamber body which are moved toward and away from each other and form therebetween an inner space in which a master information carrier and a slave medium are accommodated and held in close contact with each other. The holder is provided at different parts with a first sealing portion for sealing the inner space between the chamber base and the chamber body and a second sealing portion allowing the pressing faces of the chamber base and the chamber body to move toward each other to press the master information carrier and the slave medium against each other with the inner space kept sealed.

Owner:FUJIFILM CORP +1

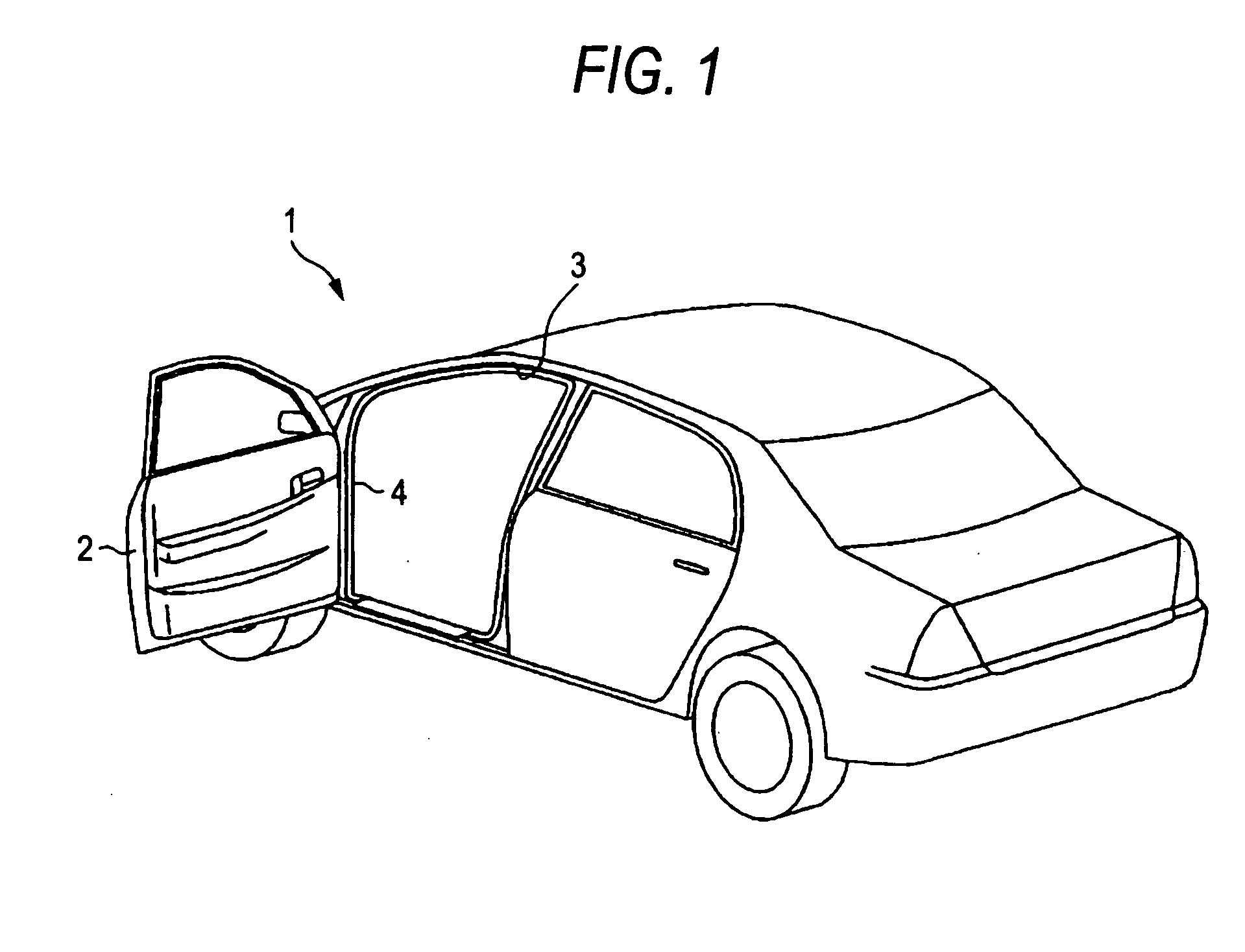

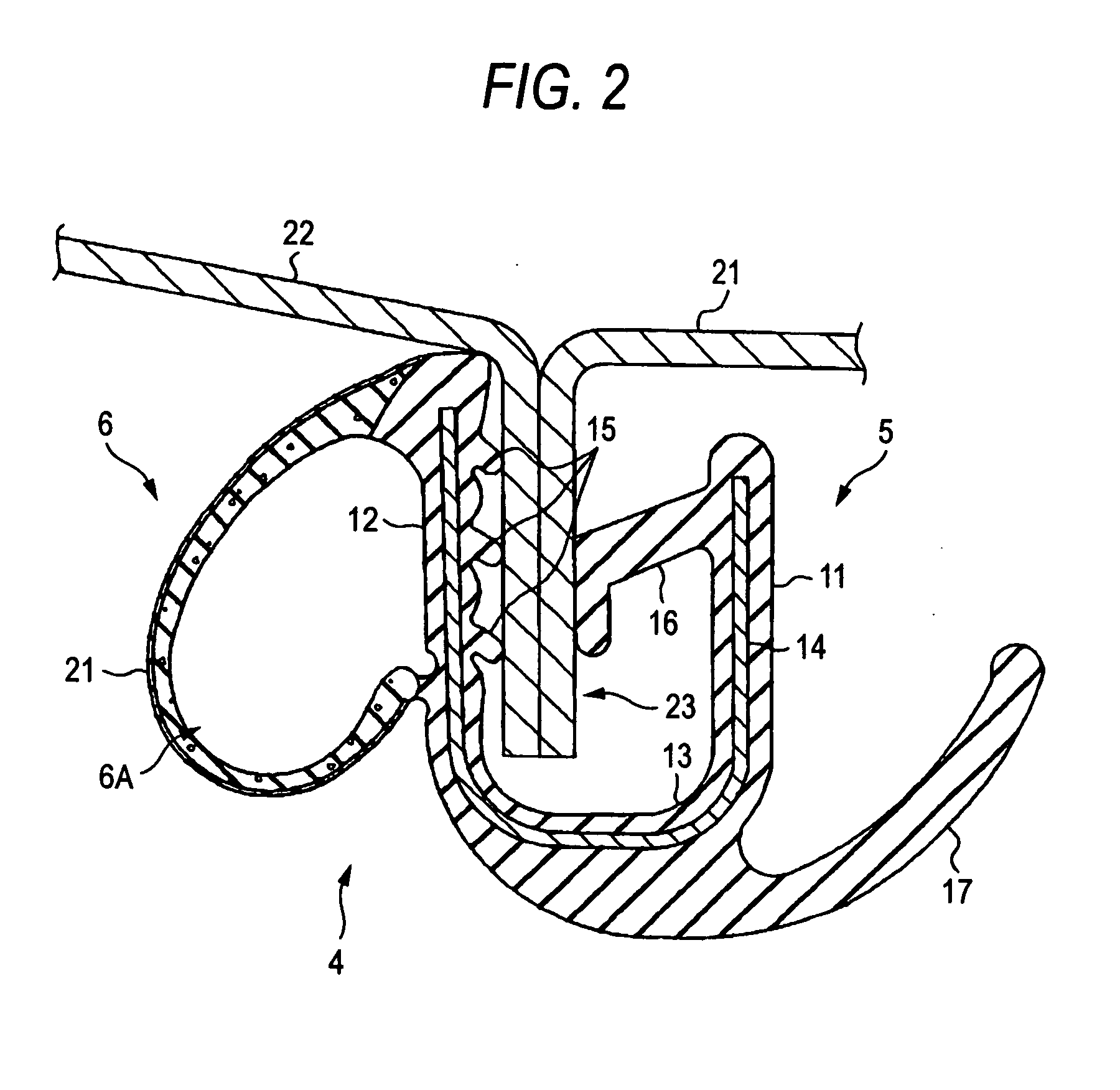

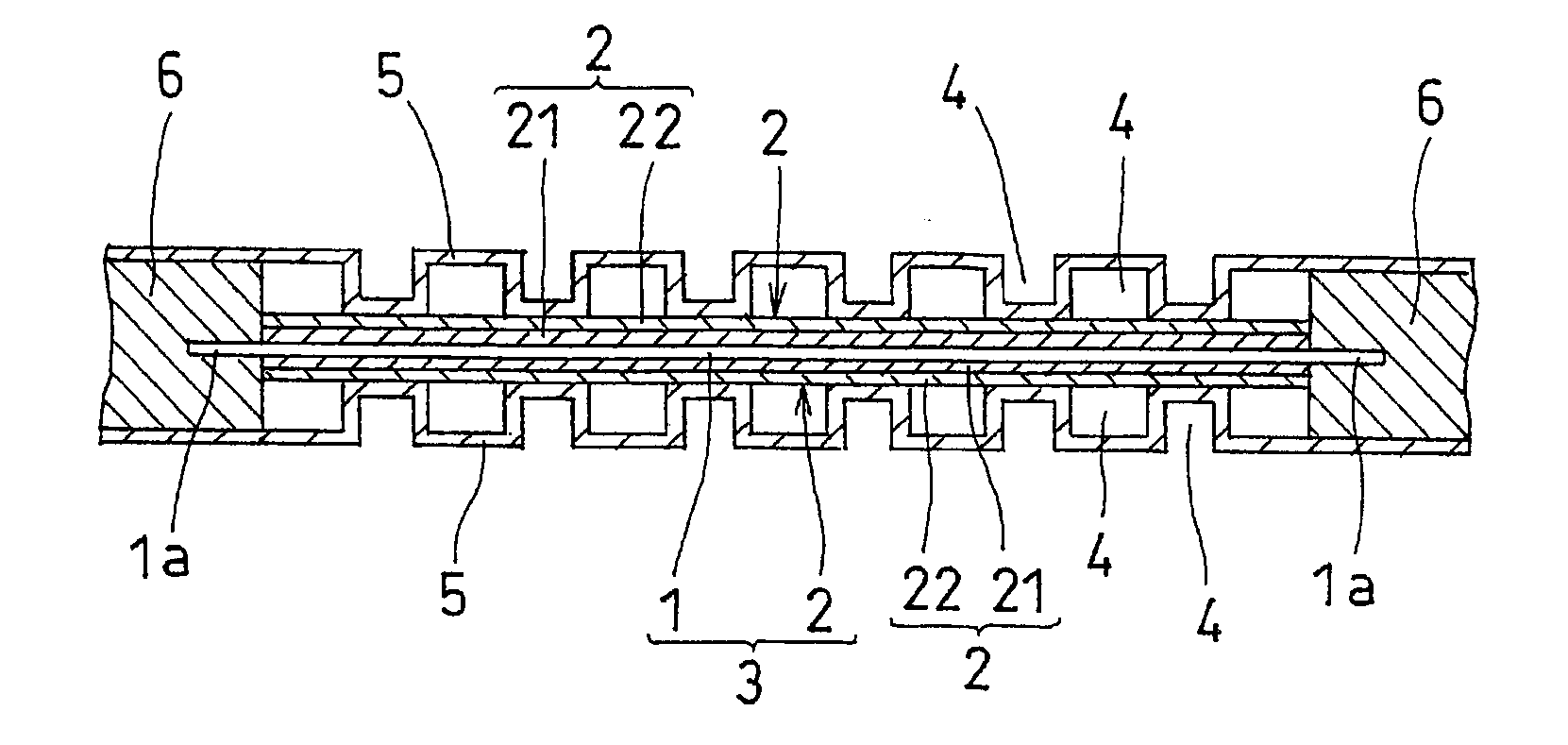

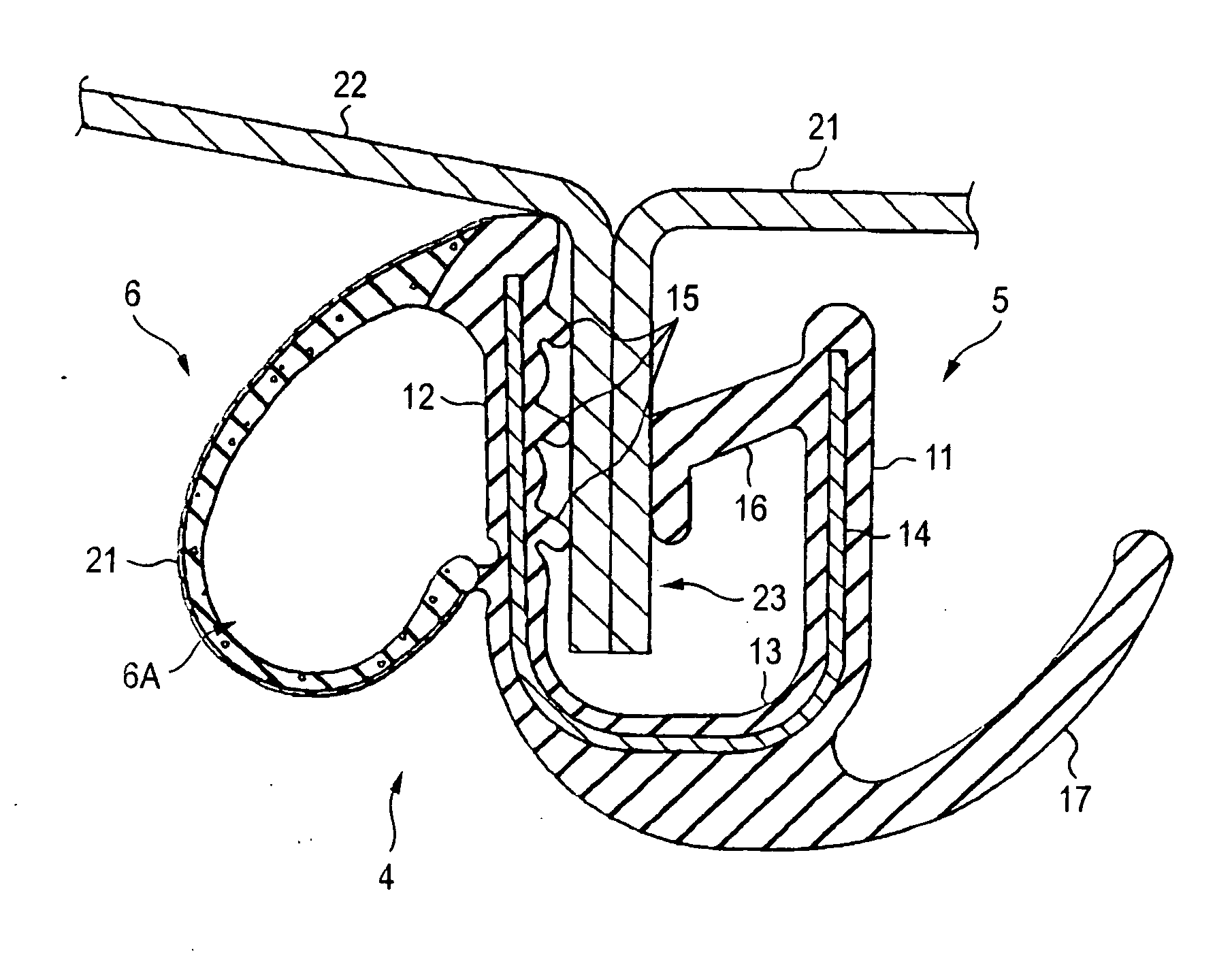

Weather strip and production method for the same

InactiveUS20080110102A1Reduce work efficiencyAvoid probabilitySealing arrangementsVehicle sealing arrangementsSulfurEngineering

A weather strip has a trim part 5 to be attached to a peripheral part of a door opening corresponding to a door and a sealing part projecting from the trim part 5 and having a hollow part. The weather strip is obtainable by coating a treatment liquid containing a simple sulfur, a sulfur compound, or both of the simple sulfur and the sulfur compound on an outer surface of the sealing part of an extruded, non-vulcanized, and non-foamed intermediate molded body and vulcanizing and foaming the intermediate molded body by passing the intermediate molded body through a heating zone. By the above production steps, in the trim part, a skin layer that is harder than a sponge layer is formed on the sponge layer and a superficial part of the trim part. The skin layer has a width of 10 mm or more in a width direction and a uniform thickness set in a range of 0.04 mm to 0.15 mm.

Owner:TOYODA GOSEI CO LTD

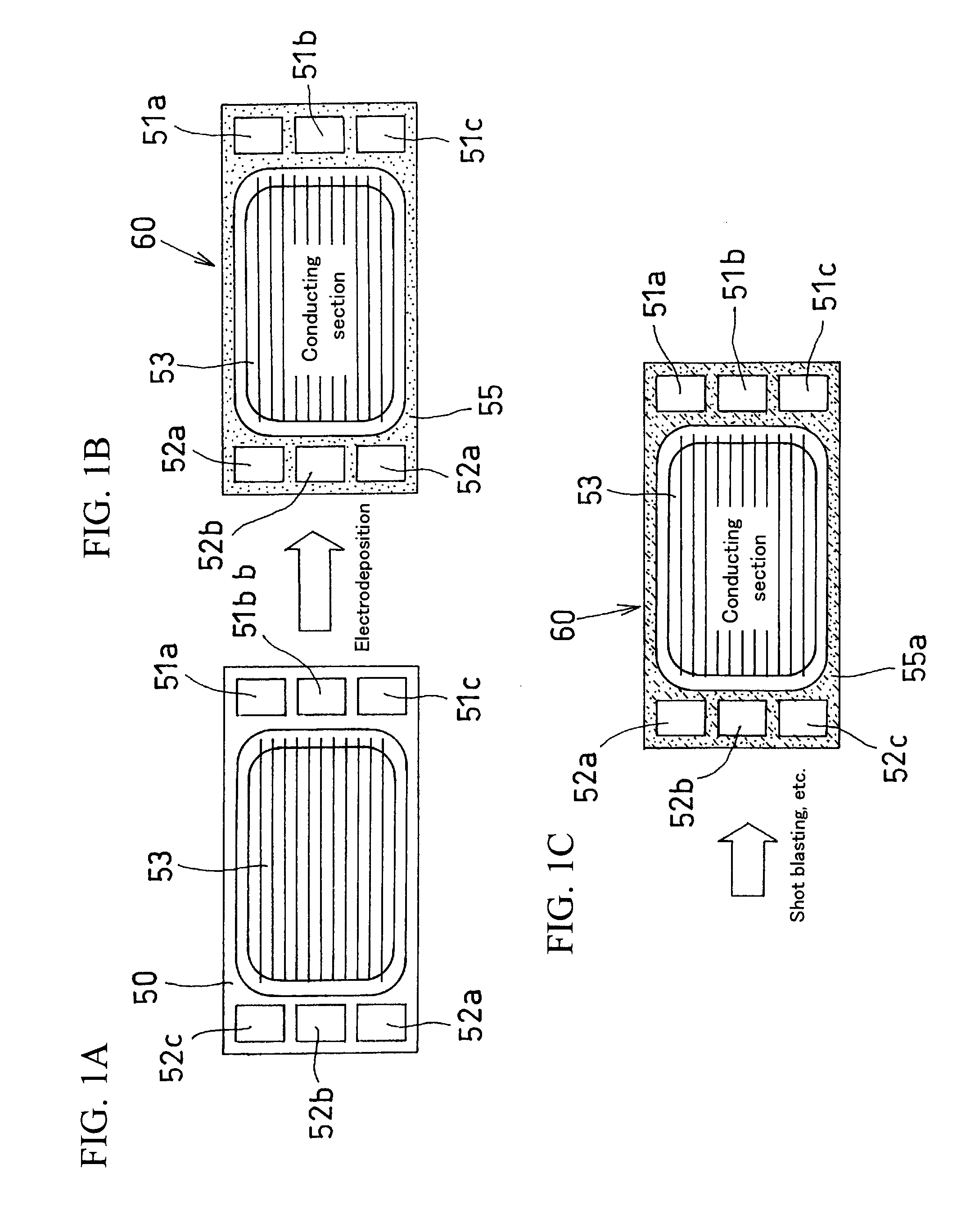

Fuel cell separator and method for manufacturing the same

ActiveUS20090297921A1Improved seal durabilityIncreased durabilityFinal product manufacturePrimary cellsPeeningEngineering

A fuel cell separator 60 having a metal plate and an anticorrosion resin coating layer 55 formed thereon is provided, with which adhesion between the resin coating layer 55 and its counterpart member is further increased and the durability of a fuel cell unit is improved. In forming the fuel cell separator 60 having a separator substrate 50 that is a metal plate and an anticorrosion resin coating layer 55 formed thereon, the resin coating layer 55 is formed such that it has a surface roughness Ra of 0.5 to 13.5 μm. Increasing the surface roughness will produce an anchoring effect, which will improve the adhesive force at the interface. The aforementioned surface roughness Ra can be obtained either with the use of fillers that are mixed into the resin coating layer 55 or with external force applied to the surface of the resin coating layer 55 by means of shot blasting, for example.

Owner:TOYOTA JIDOSHA KK

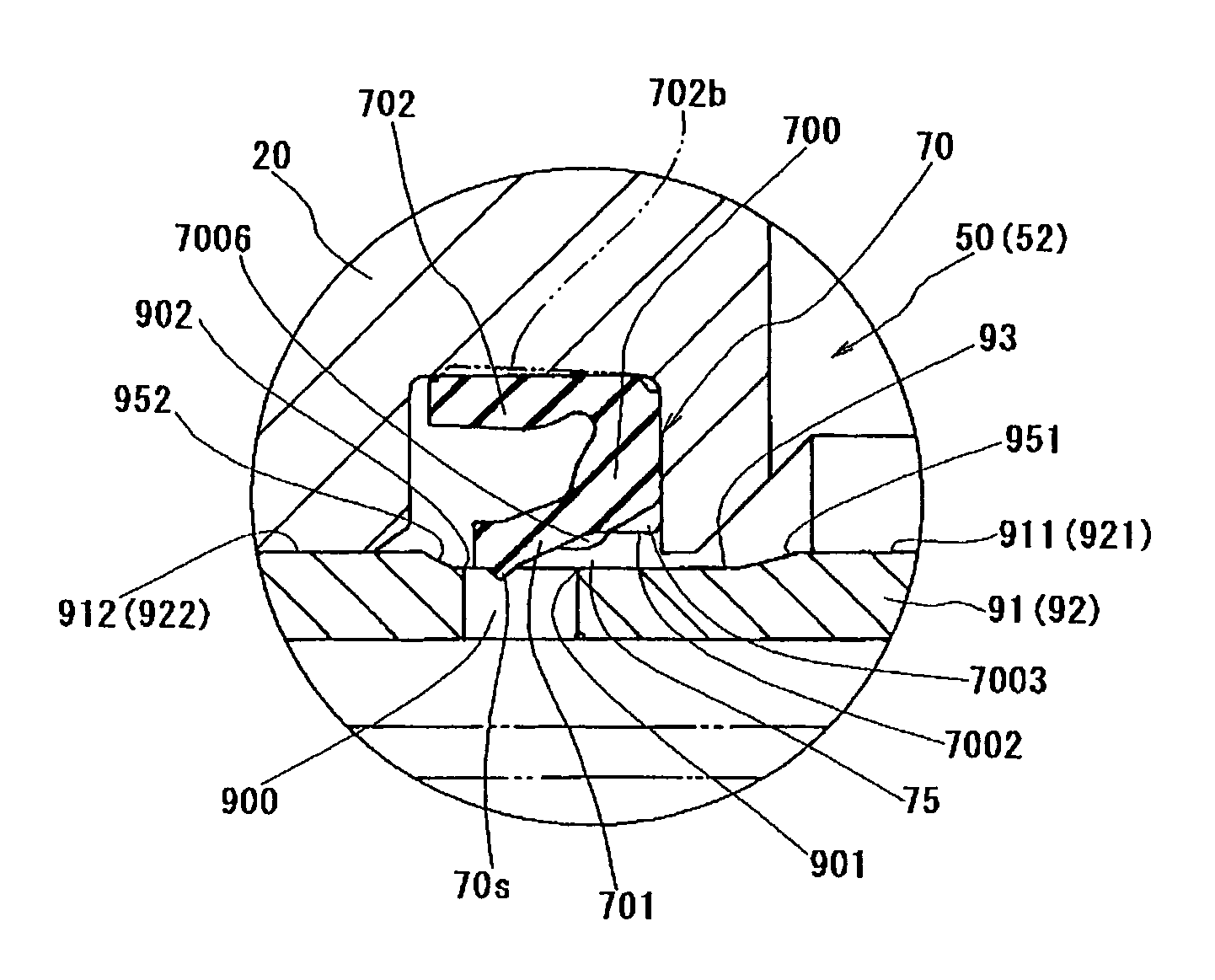

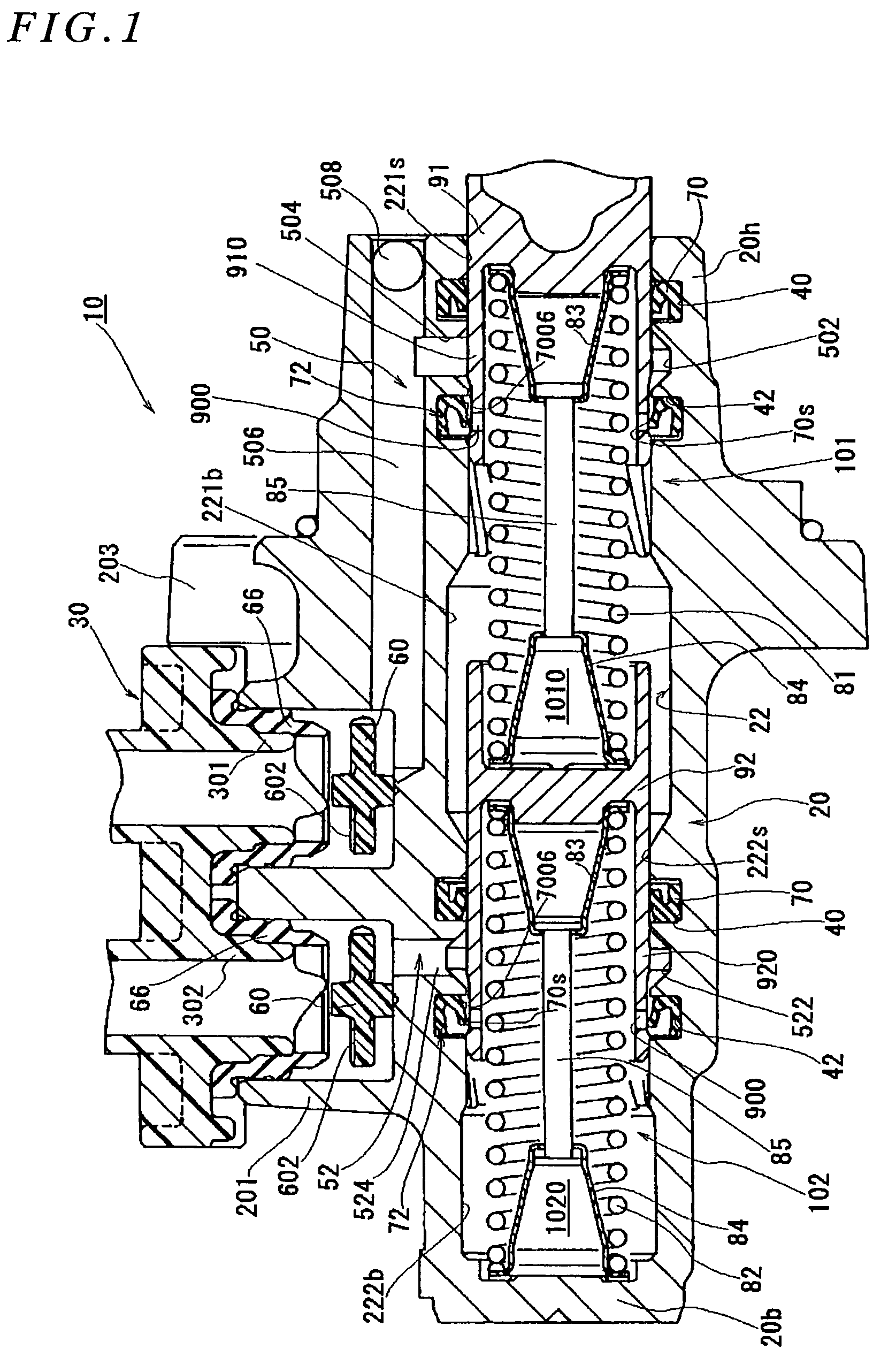

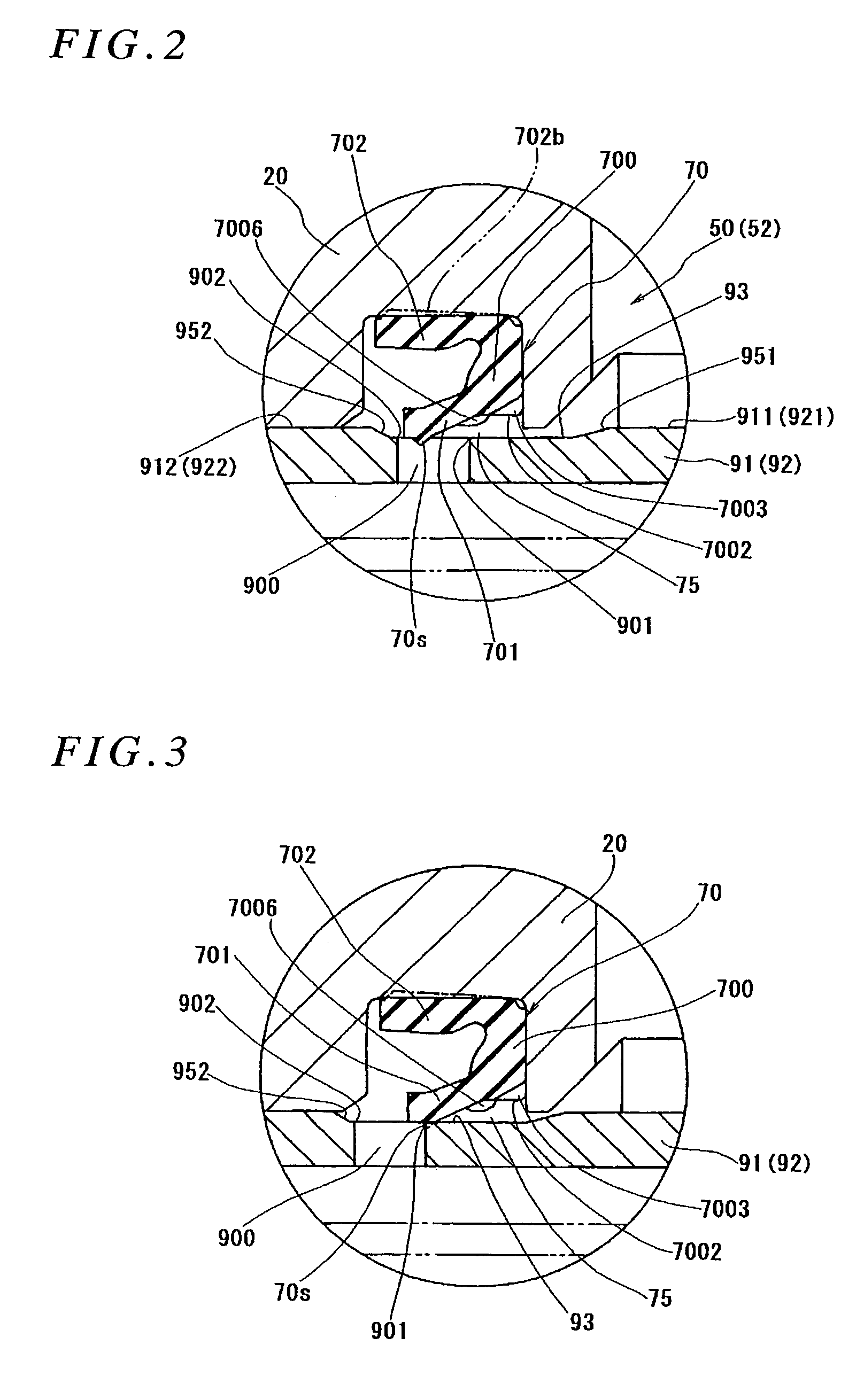

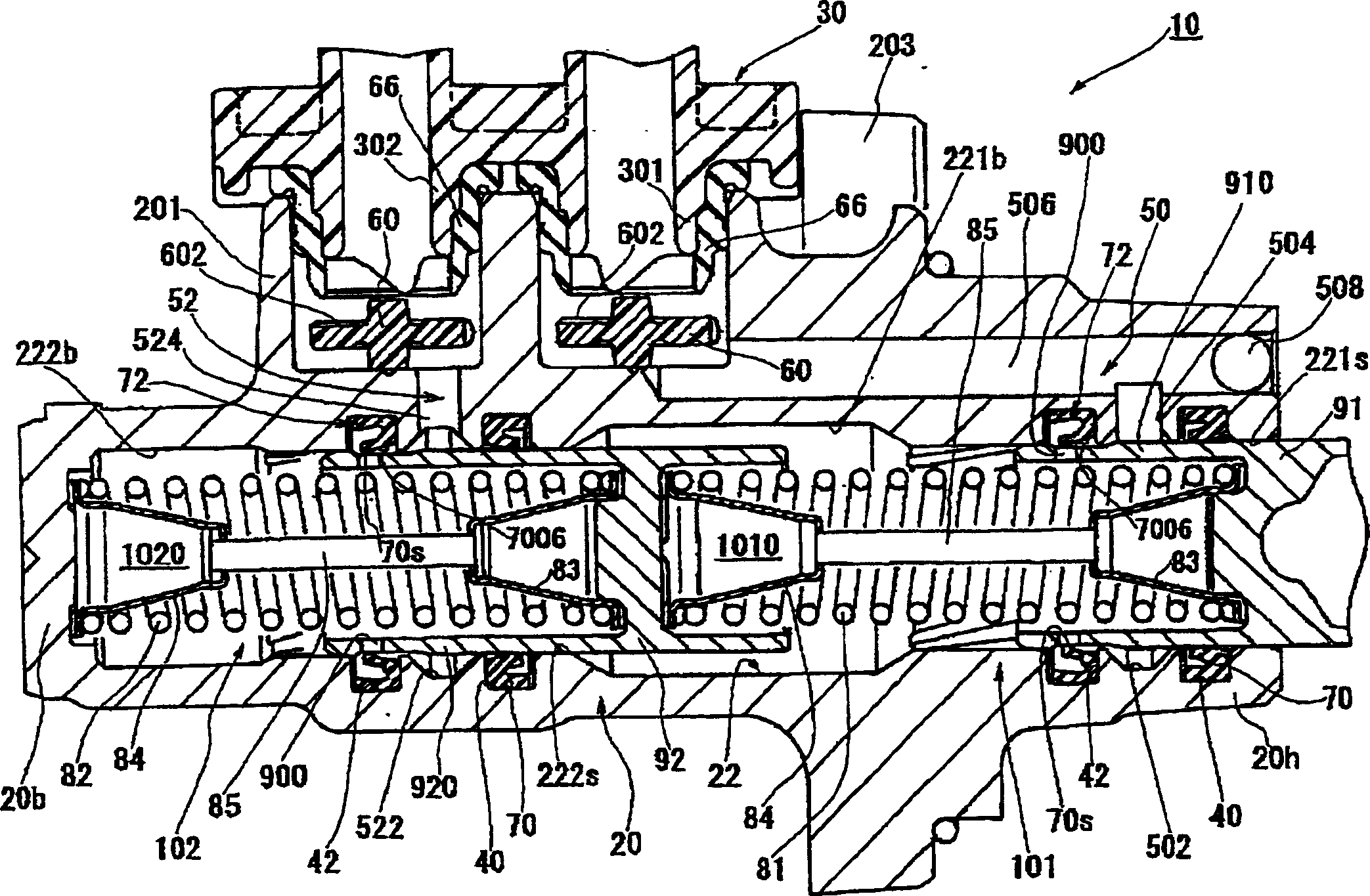

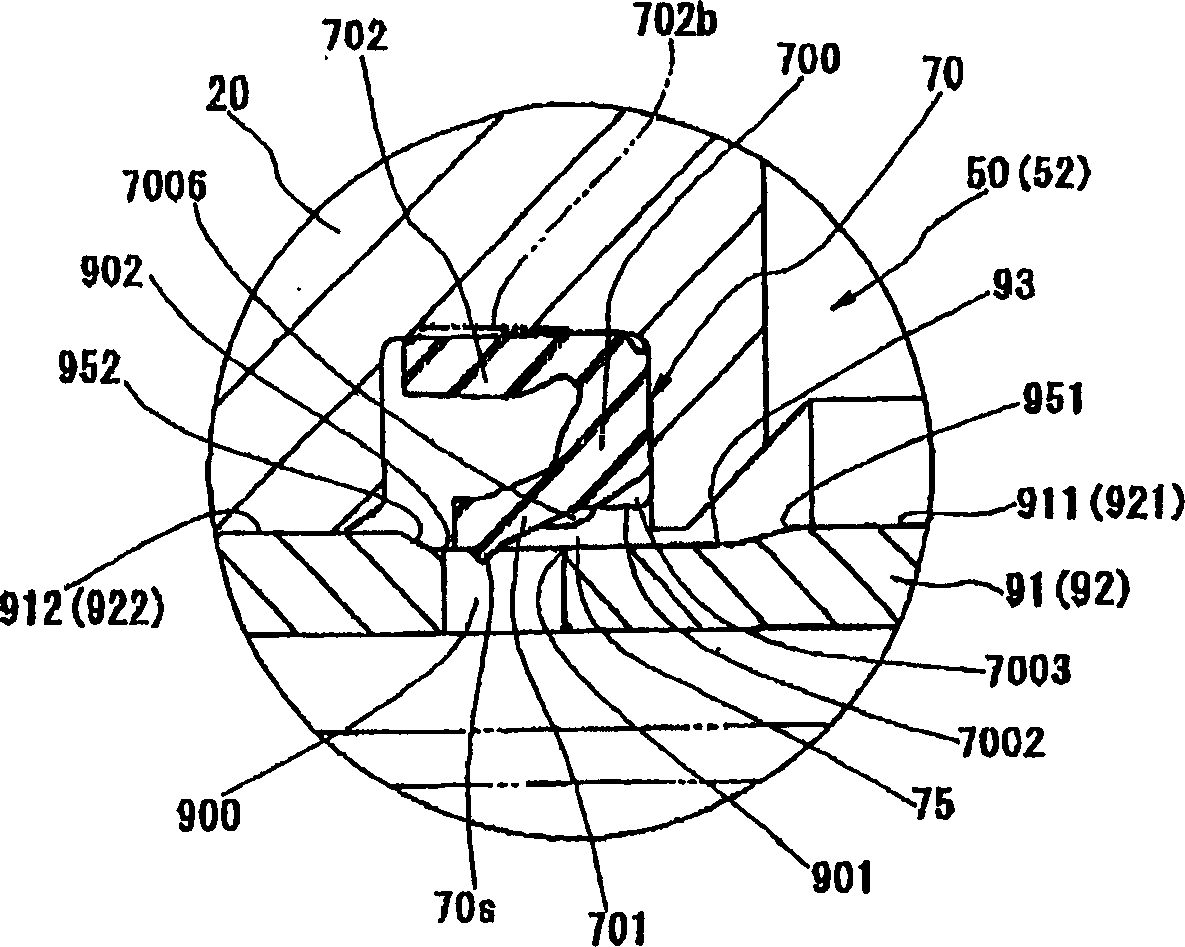

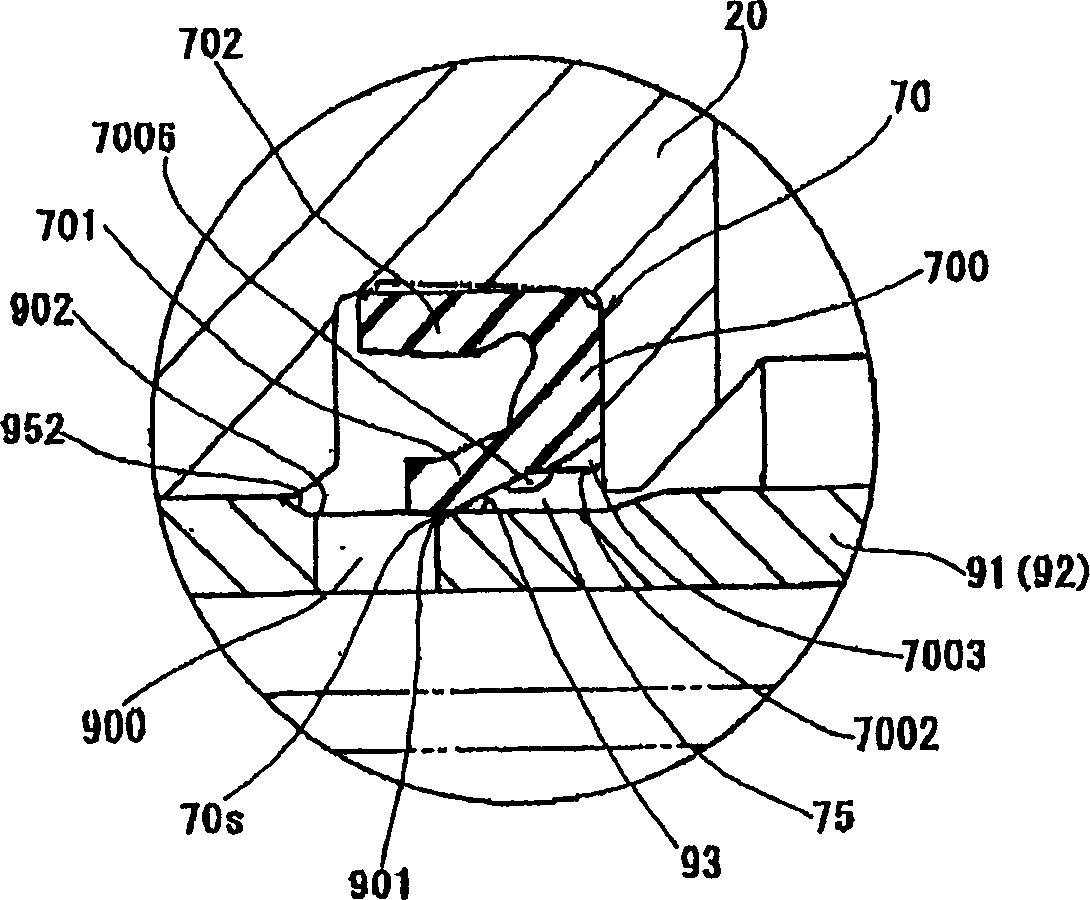

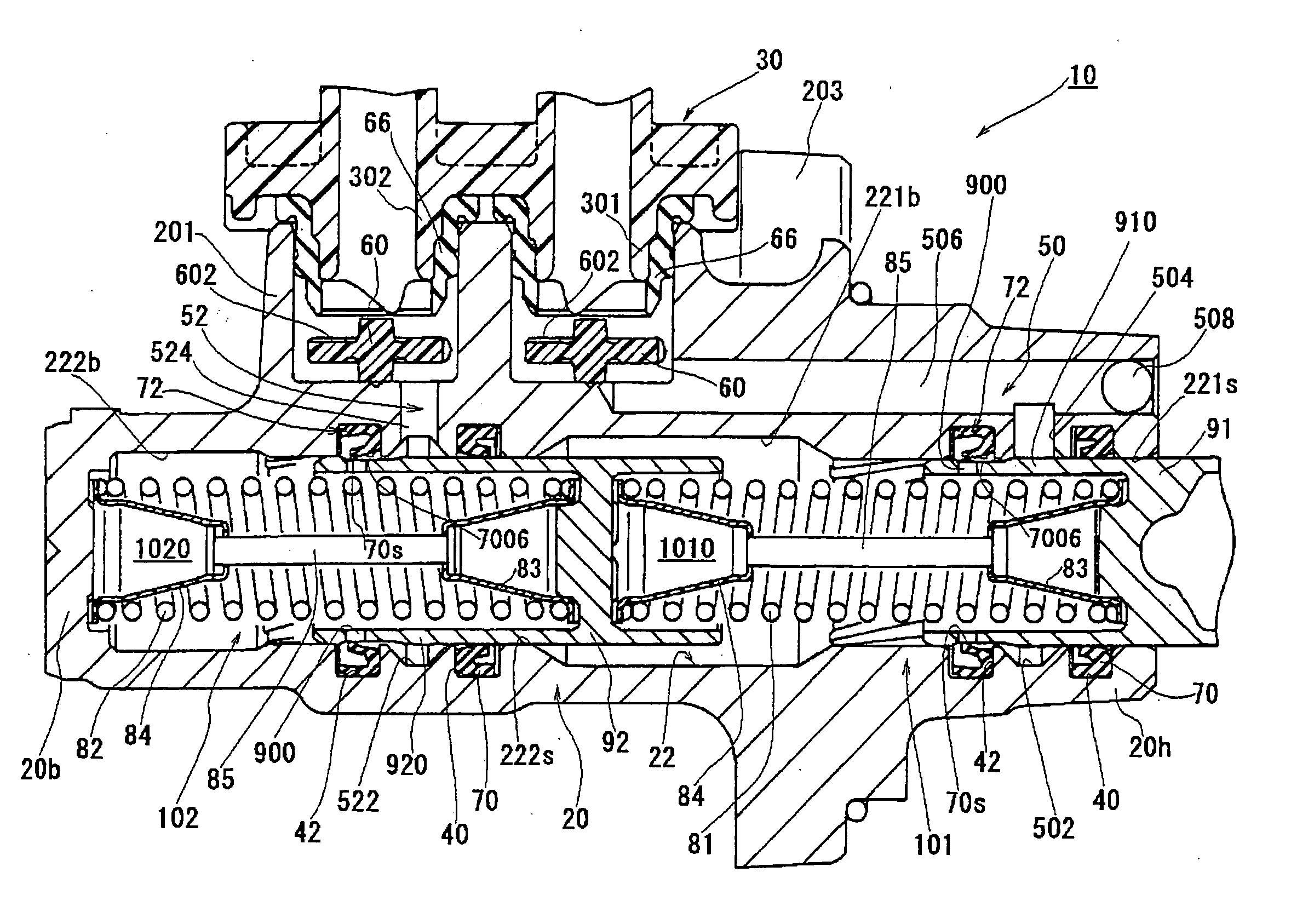

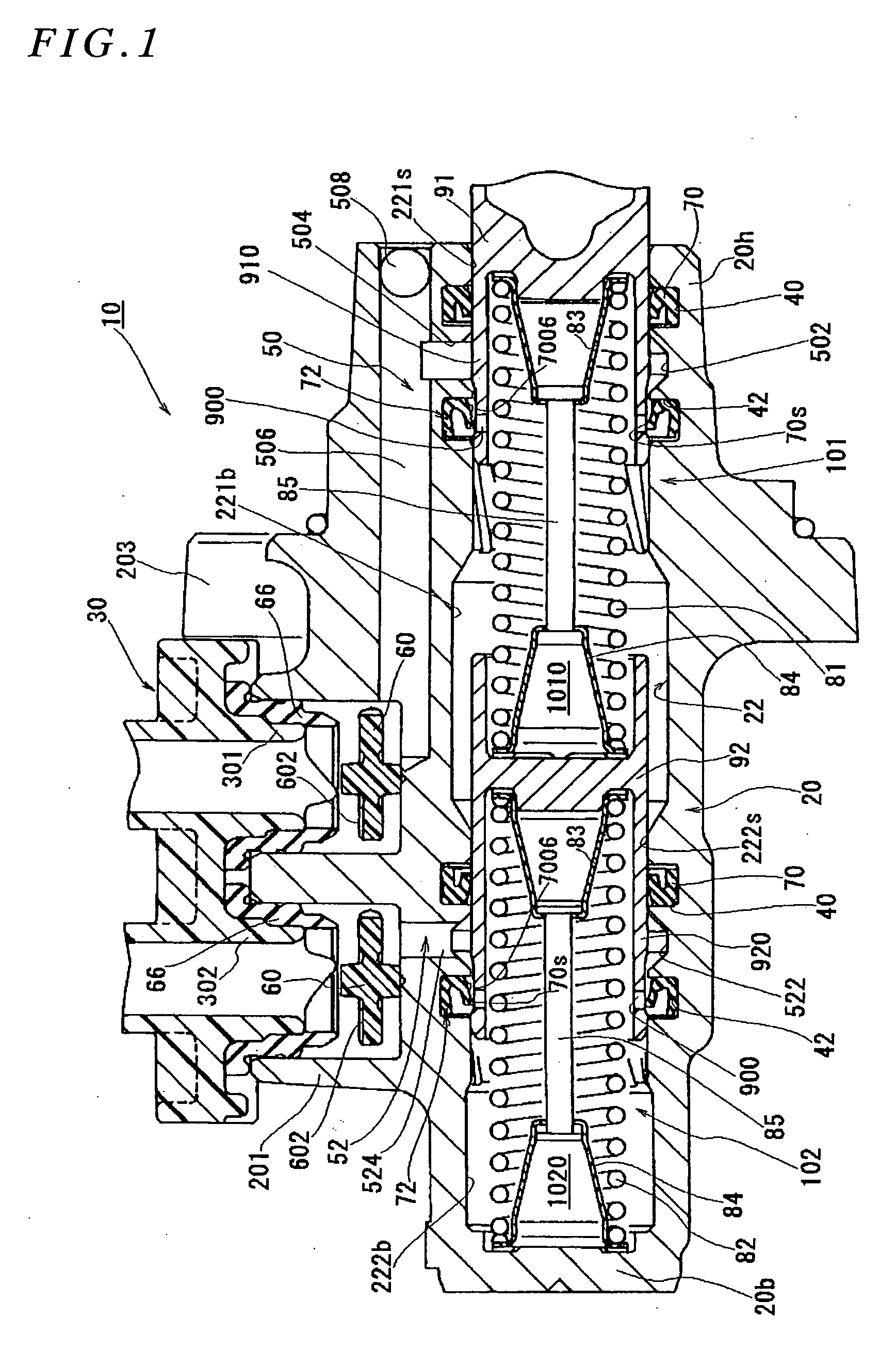

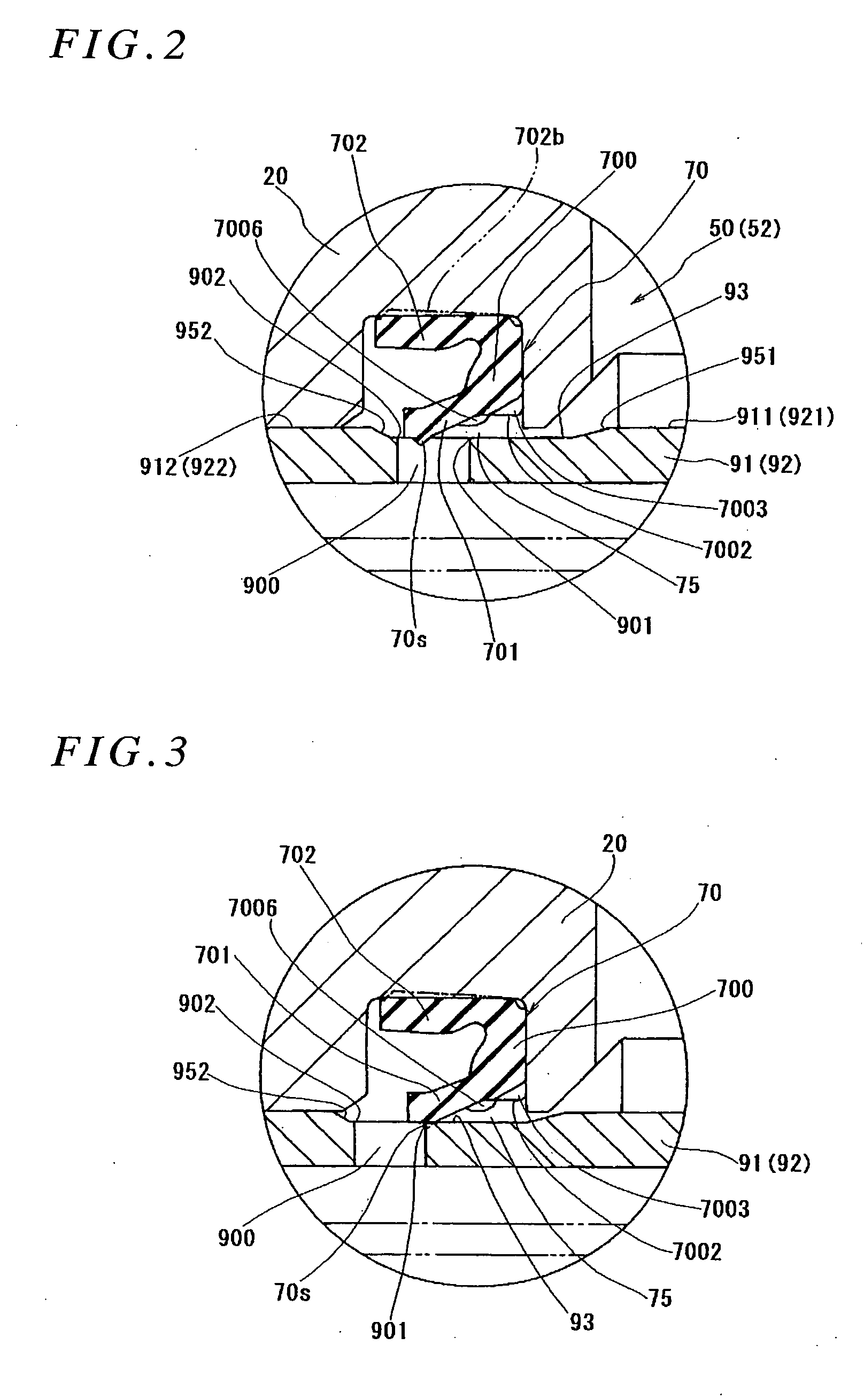

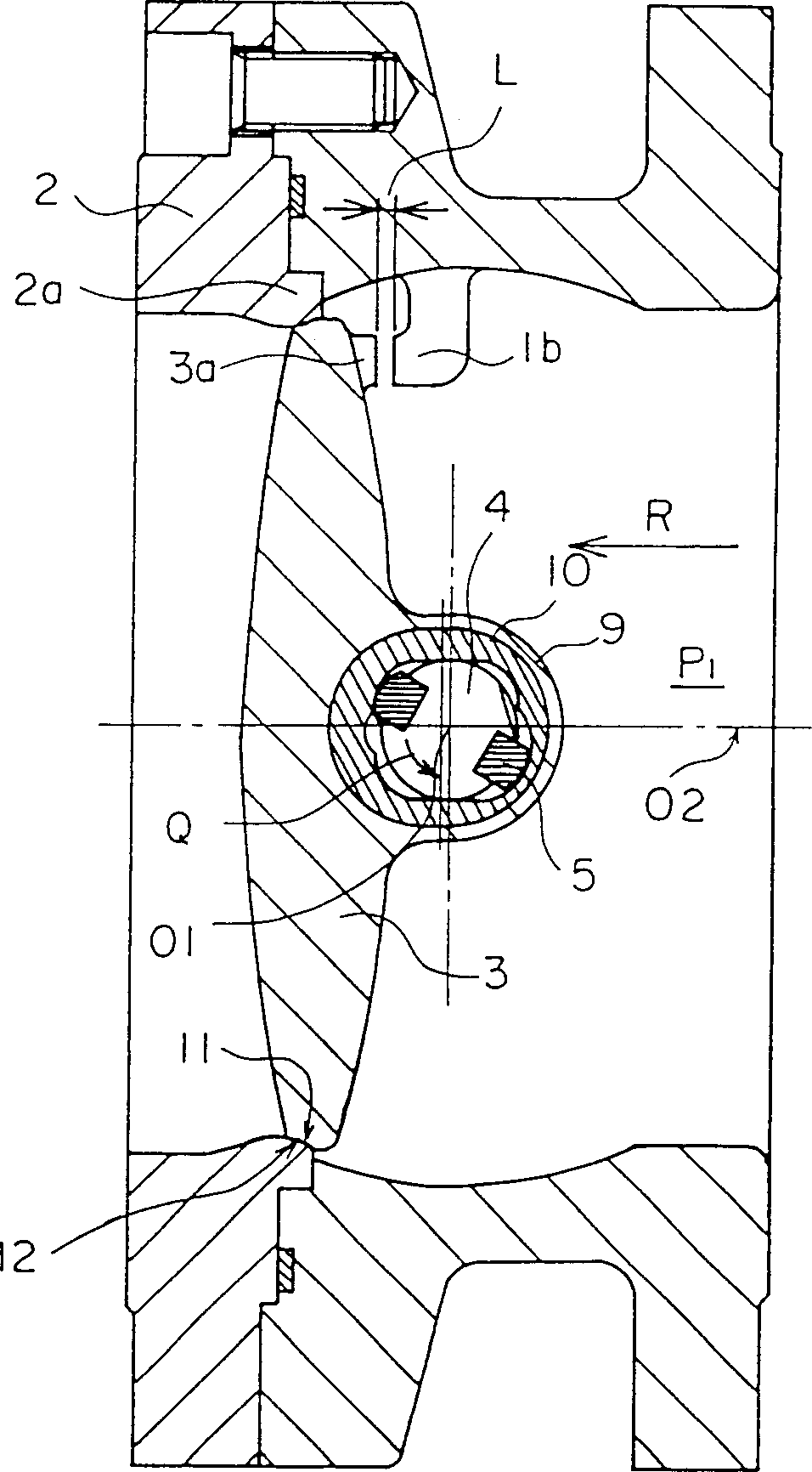

Plunger-type master cylinder

InactiveCN1777529AImproved seal durabilityLost stroke reductionFluid braking transmissionWorking fluidMaster cylinder

The present invention provides a plunger-type master cylinder capable of reducing lost strokes and preventing residual pressure without impairing the durability of a seal ring (70). The piston (91) of the master cylinder is provided with a recess (93) on the outer peripheral surface, and an overflow port (900) is provided in the recess (93). The seal ring (70) is provided with a seal joint (70s) on the inner periphery of the front end portion of the inner peripheral lip (701). The sealing junction (70s) is located at the opening of the overflow port (900) on the side of the piston (91) when the brake is not working. The distance from the sealing joint (70s) to the overflow opening (900) is small. Furthermore, the sealing ring (70) is provided with first and second protrusions (7006, 7002) on the inner peripheral surface of the inner peripheral lip (701), so that the working fluid on the inner peripheral side of the inner peripheral lip (701) can be ensured. flow path.

Owner:BOSCH CORP

Plunger type master cylinder

InactiveUS20060179836A1Efficiently obtainedReduce the number of partsPiston ringsRotary clutchesWorking fluidMaster cylinder

To provide a plunger type master cylinder capable of reducing invalid stroke and preventing residual pressure without impairing durability of a seal ling (70). A piston (91) of the master cylinder has a recess (93) at its outer peripheral surface and a relief port (900) in its recess (93). The seal ring (70) has a seal coupling part (70s) on the inner periphery of the distal end part of an inner peripheral lip (701). The seal coupling part (70s) is located at the opening of the relief portion (900) on the piston (91) side when the brake is in a non-operating position. The distance between said seal coupling part (70s) and said relief port (900) is short. The seal ring (70) additionally has first and second projection parts (7006, 7002) on the inner peripheral surface of the inner peripheral lip (701). By this, a flow passage for working fluid can be obtained on the inner periphery side of the inner peripheral lip (701).

Owner:BOSCH CORP

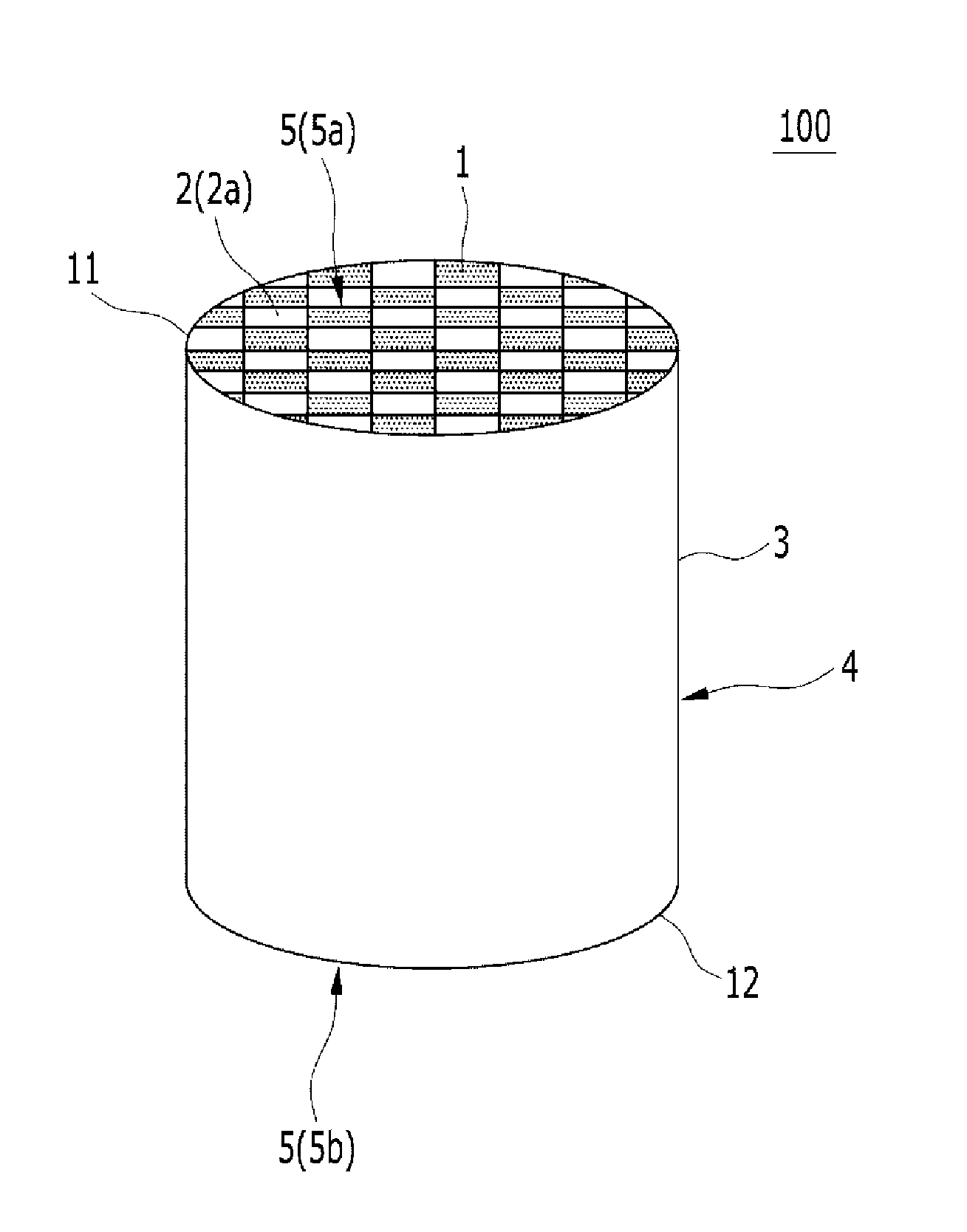

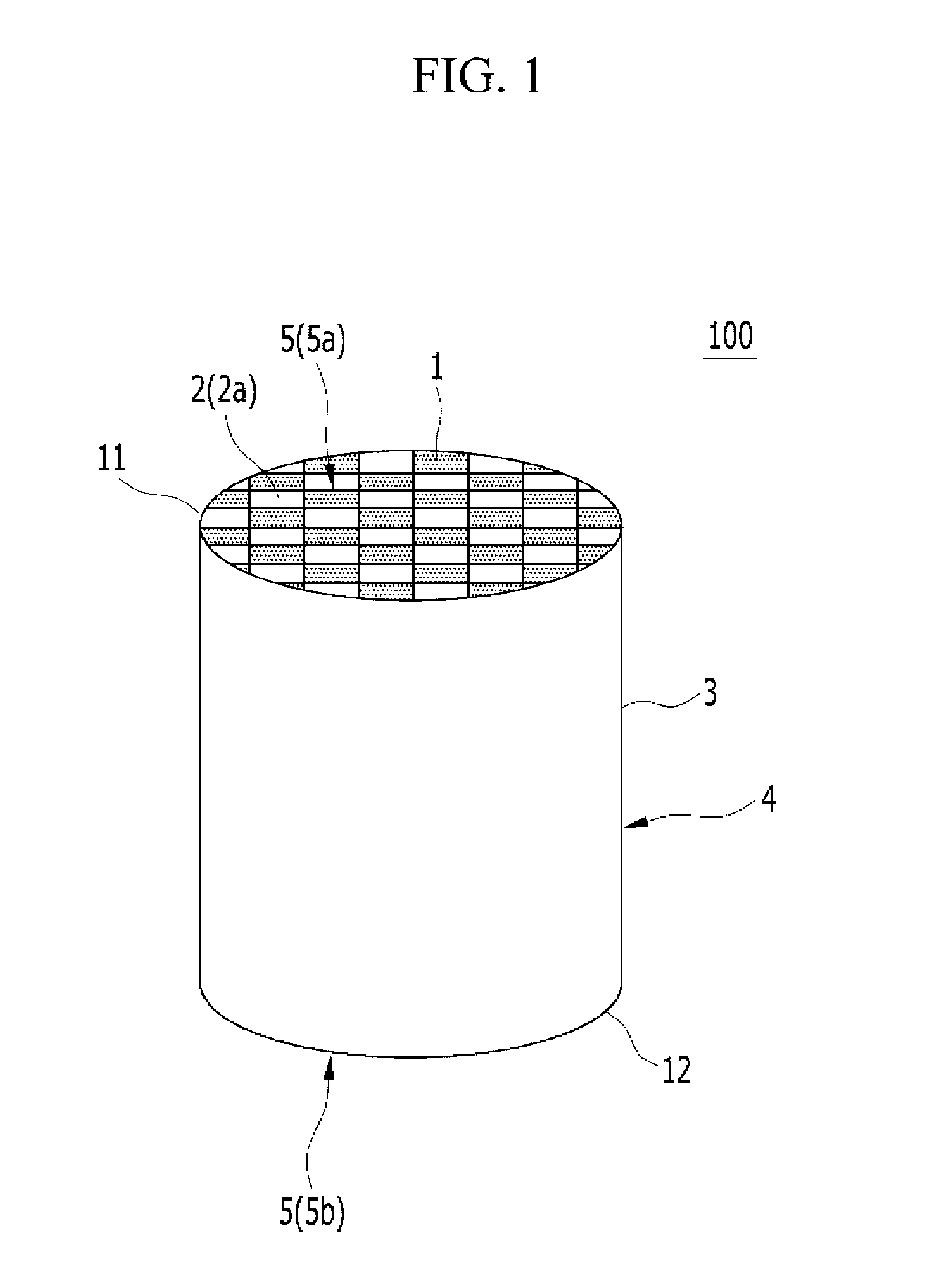

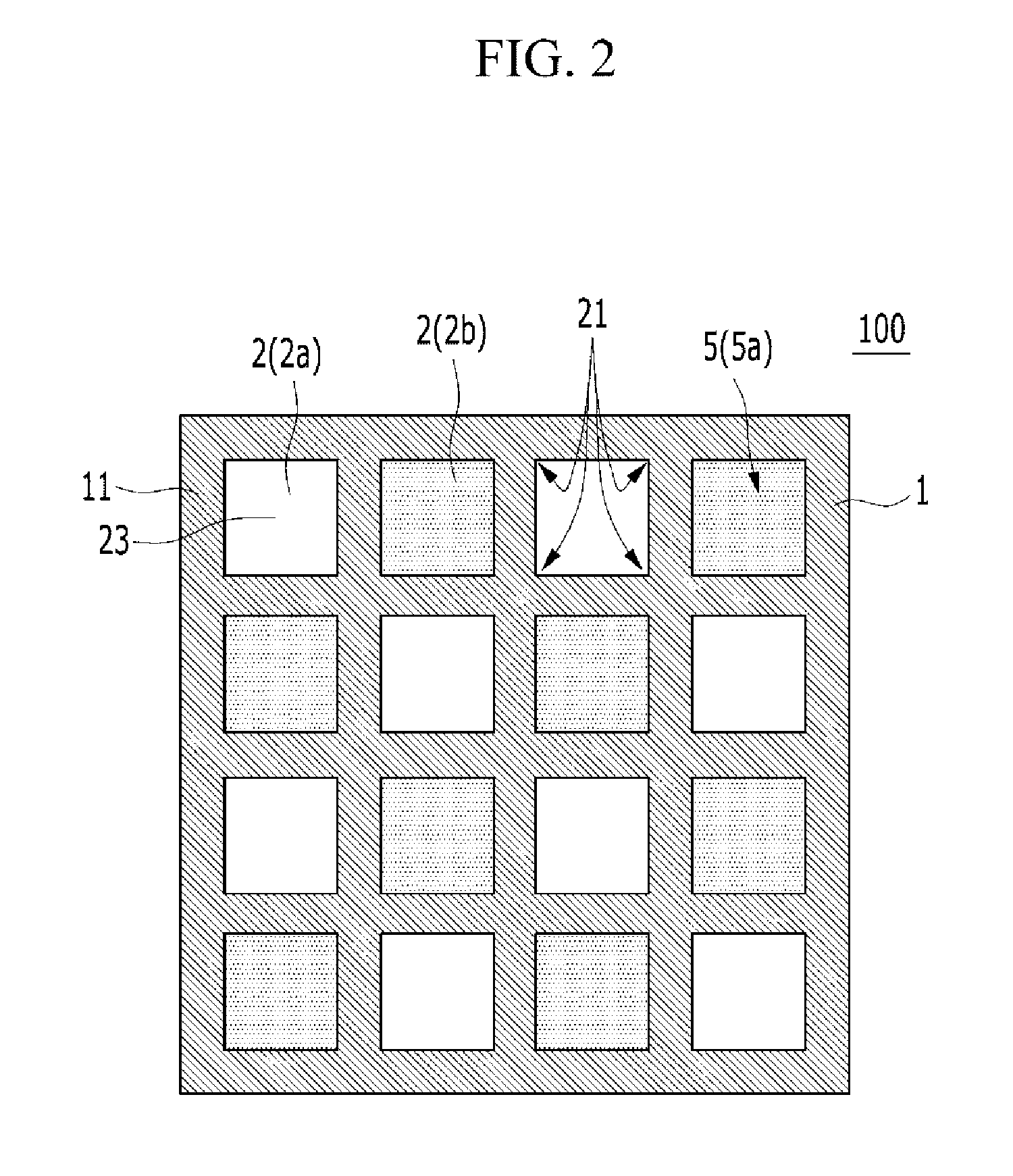

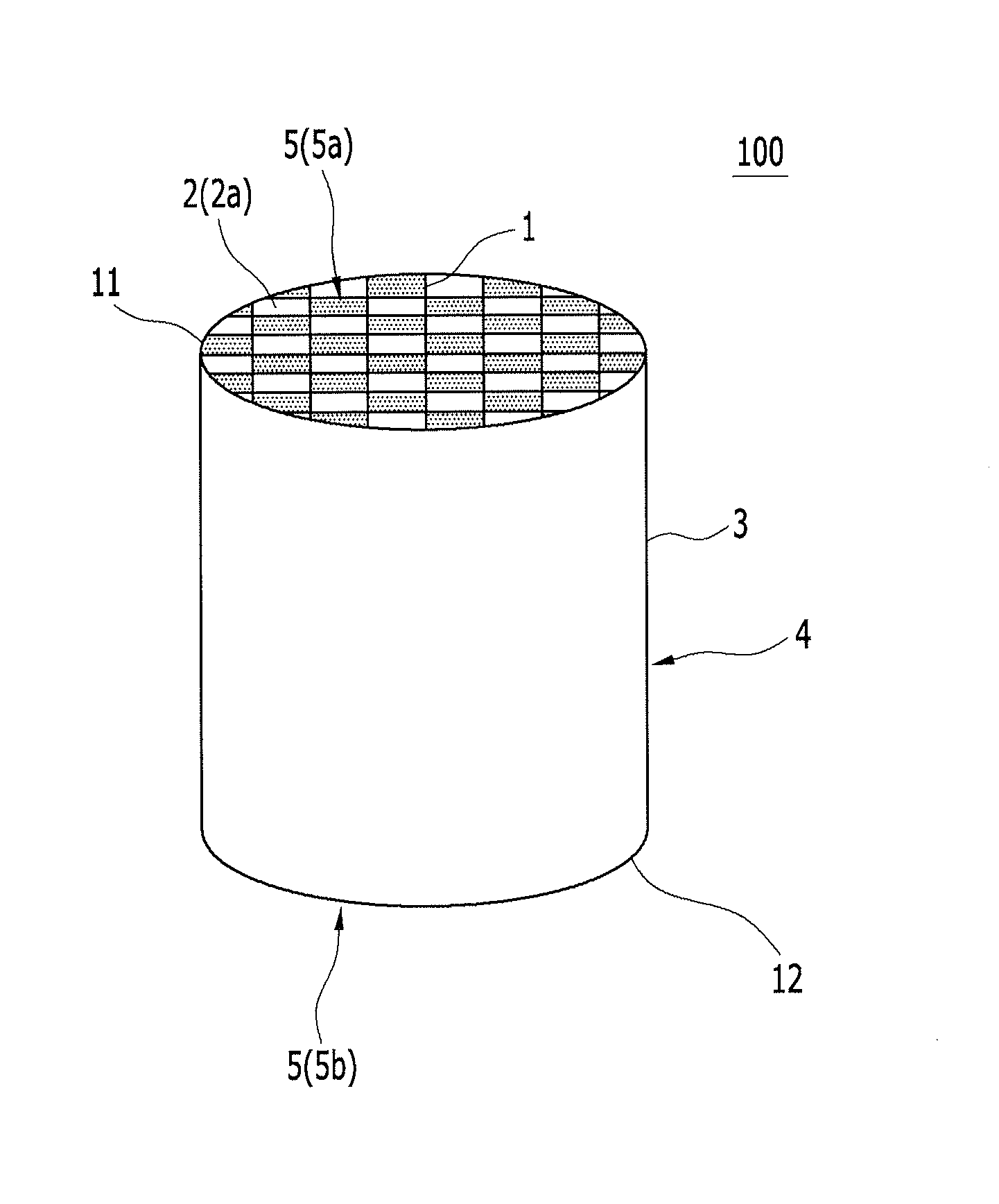

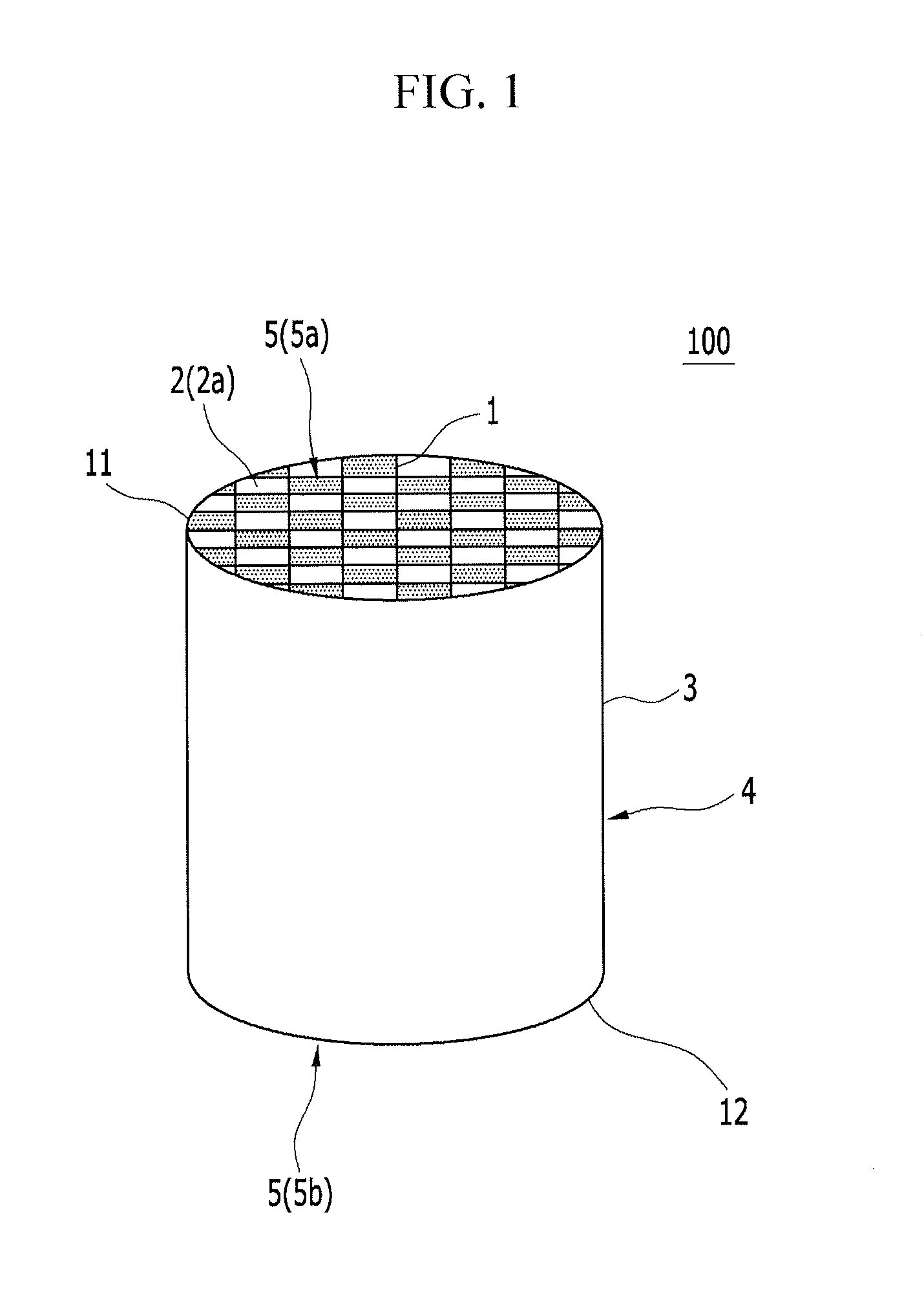

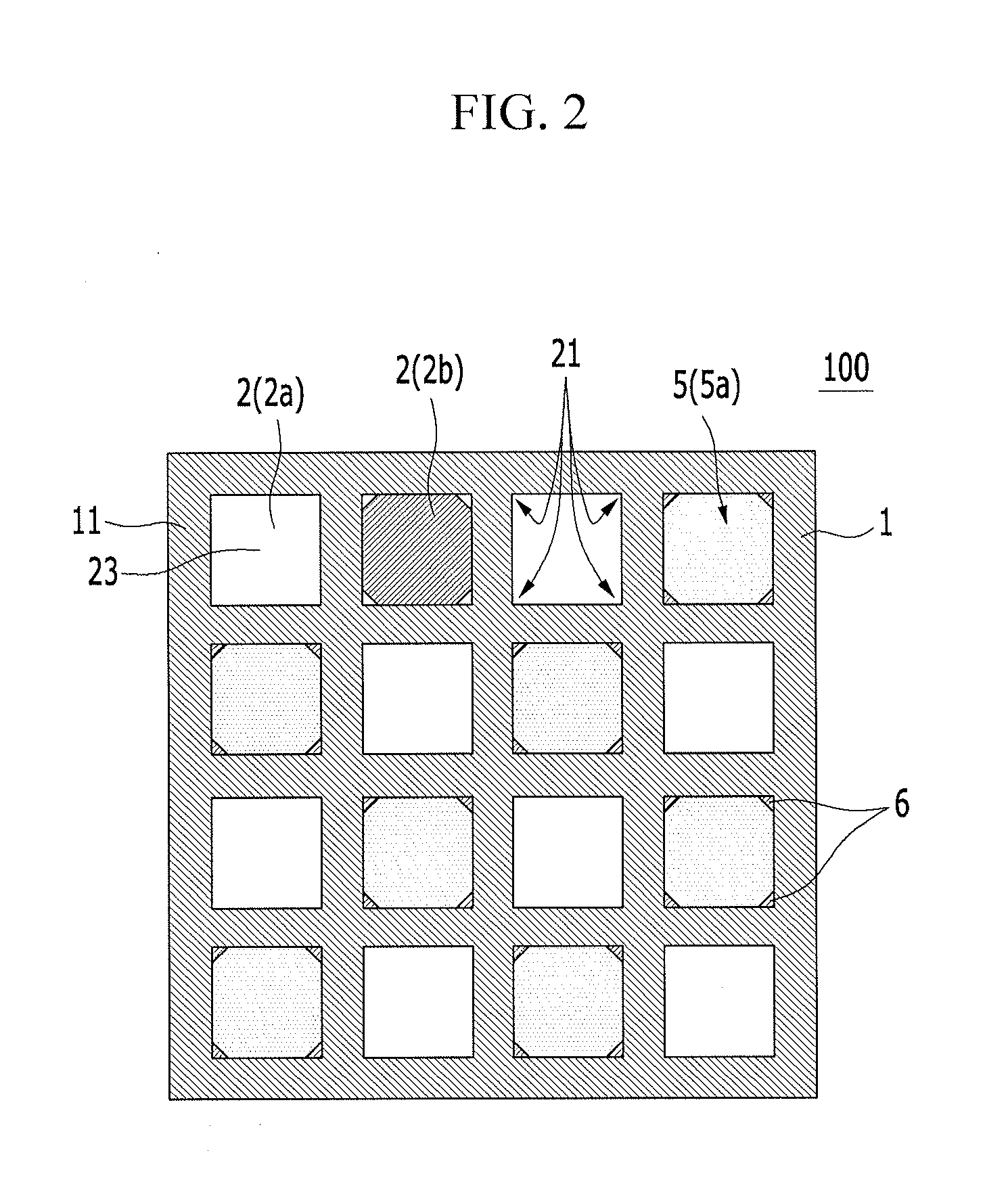

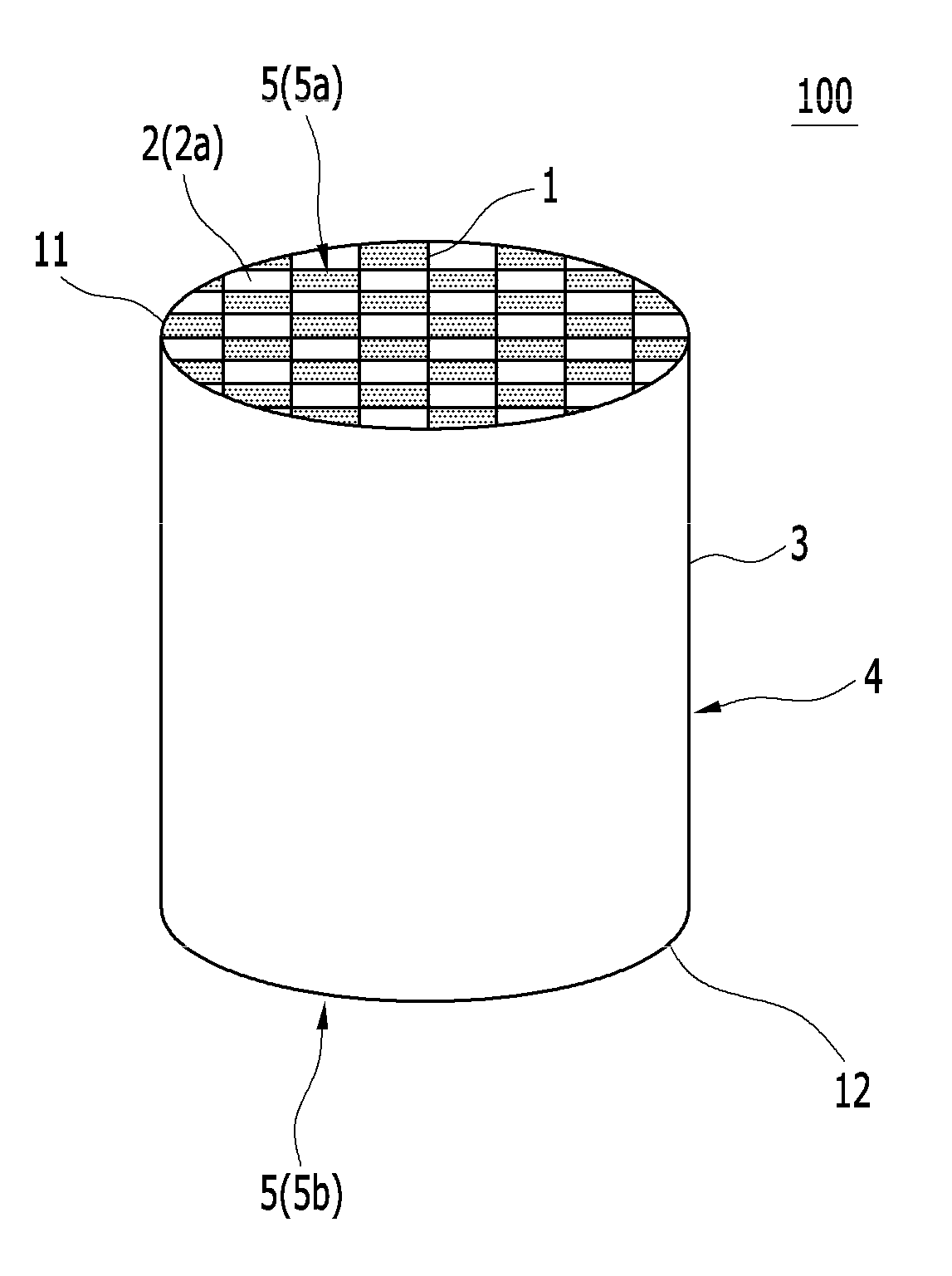

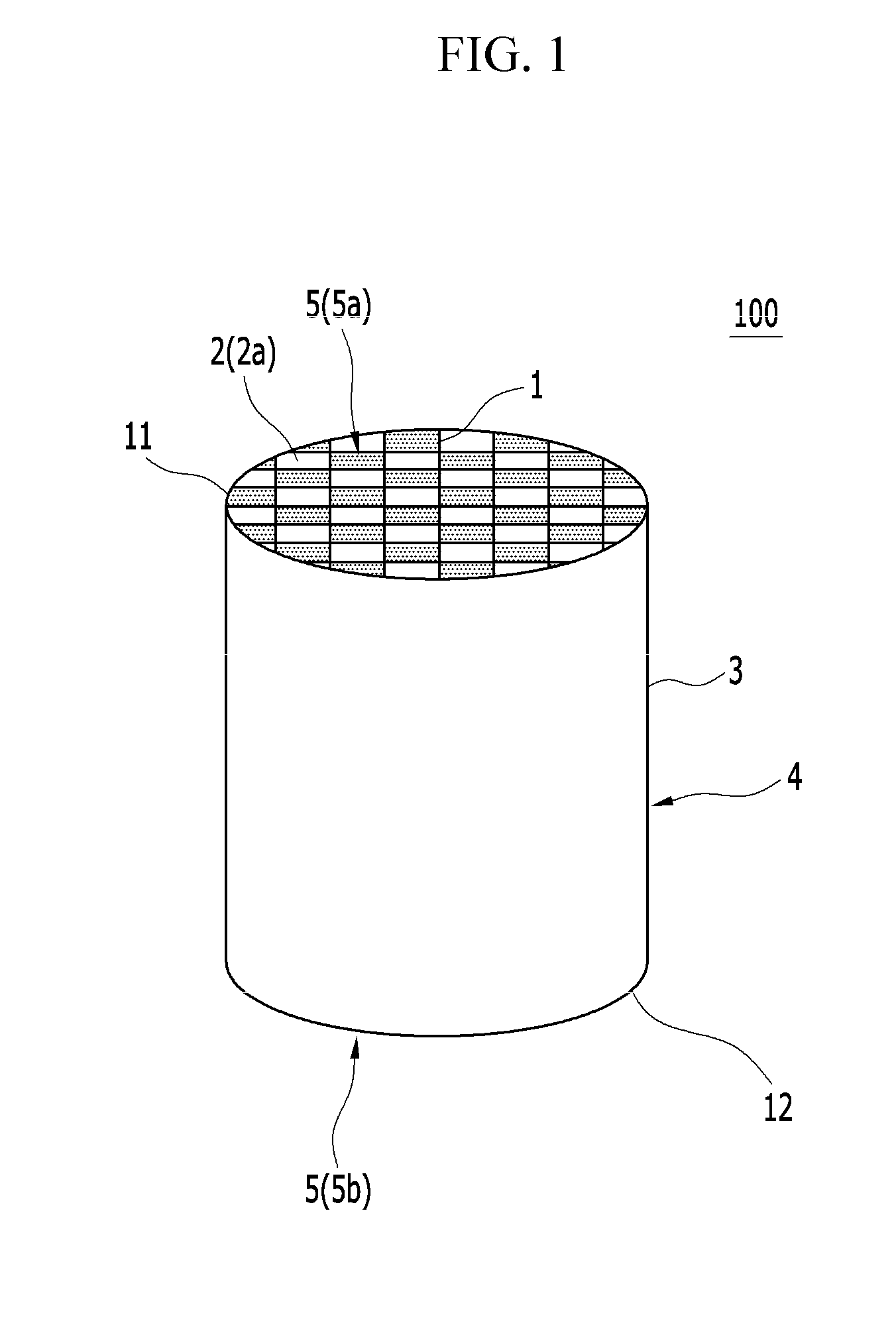

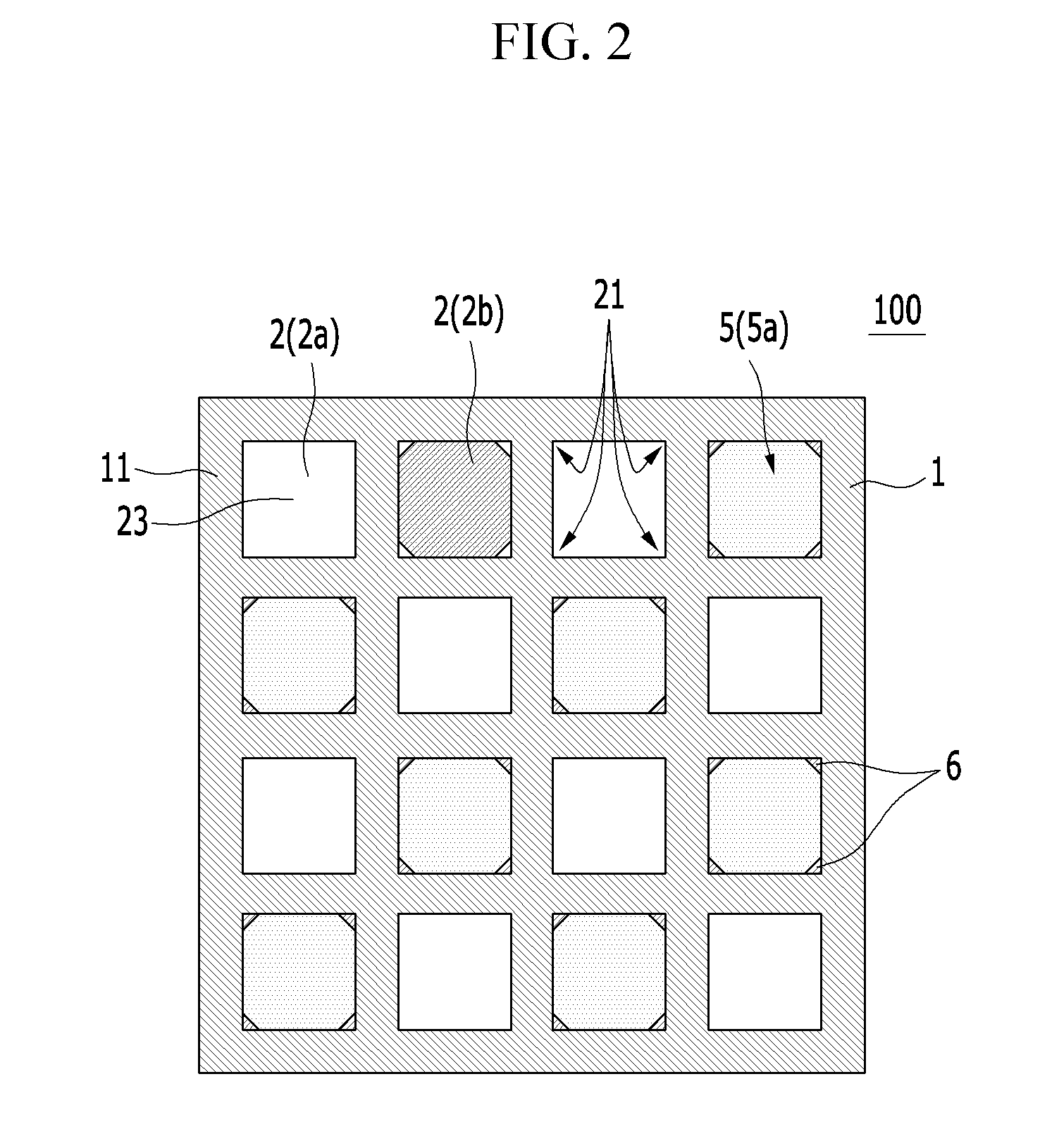

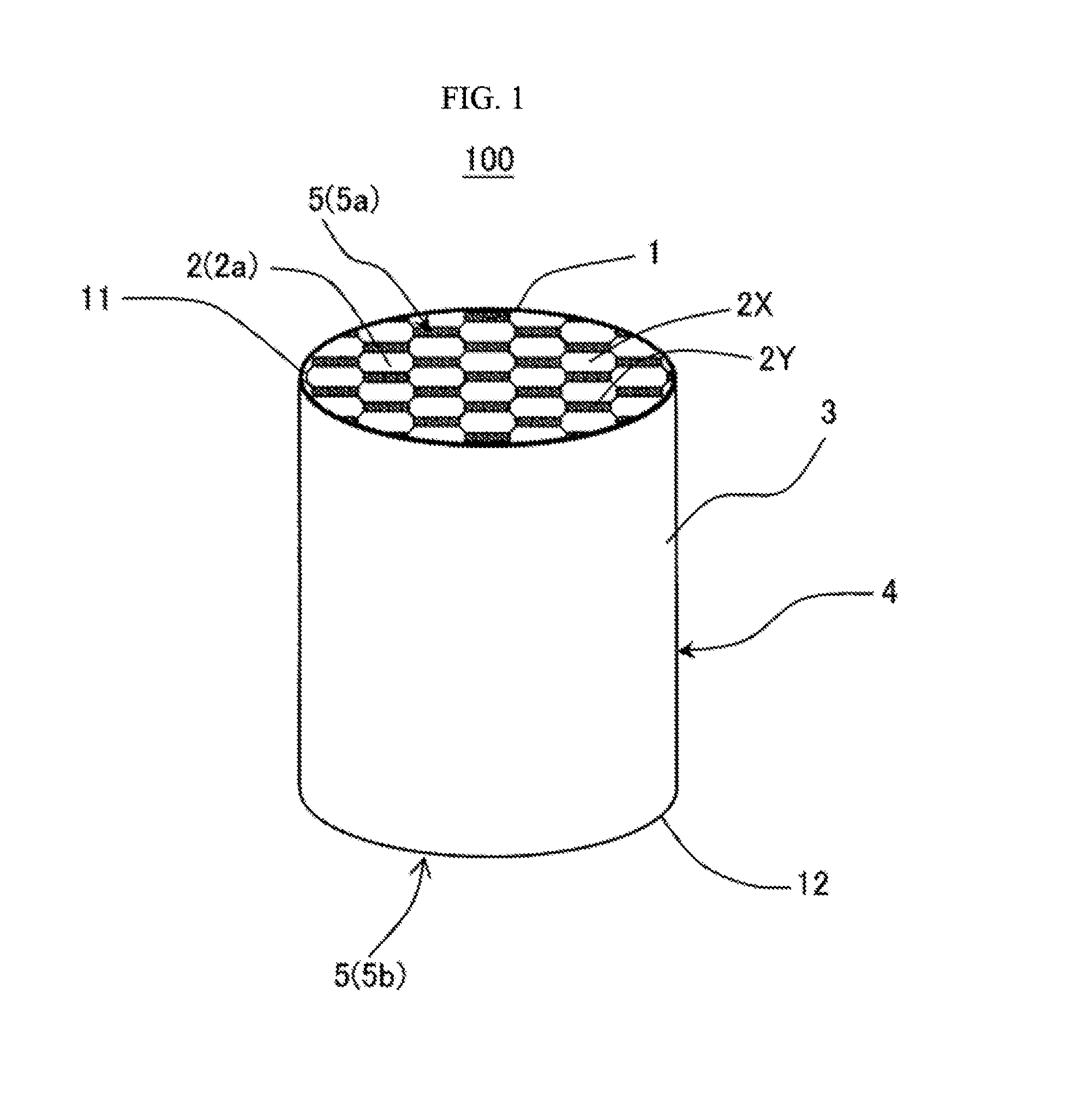

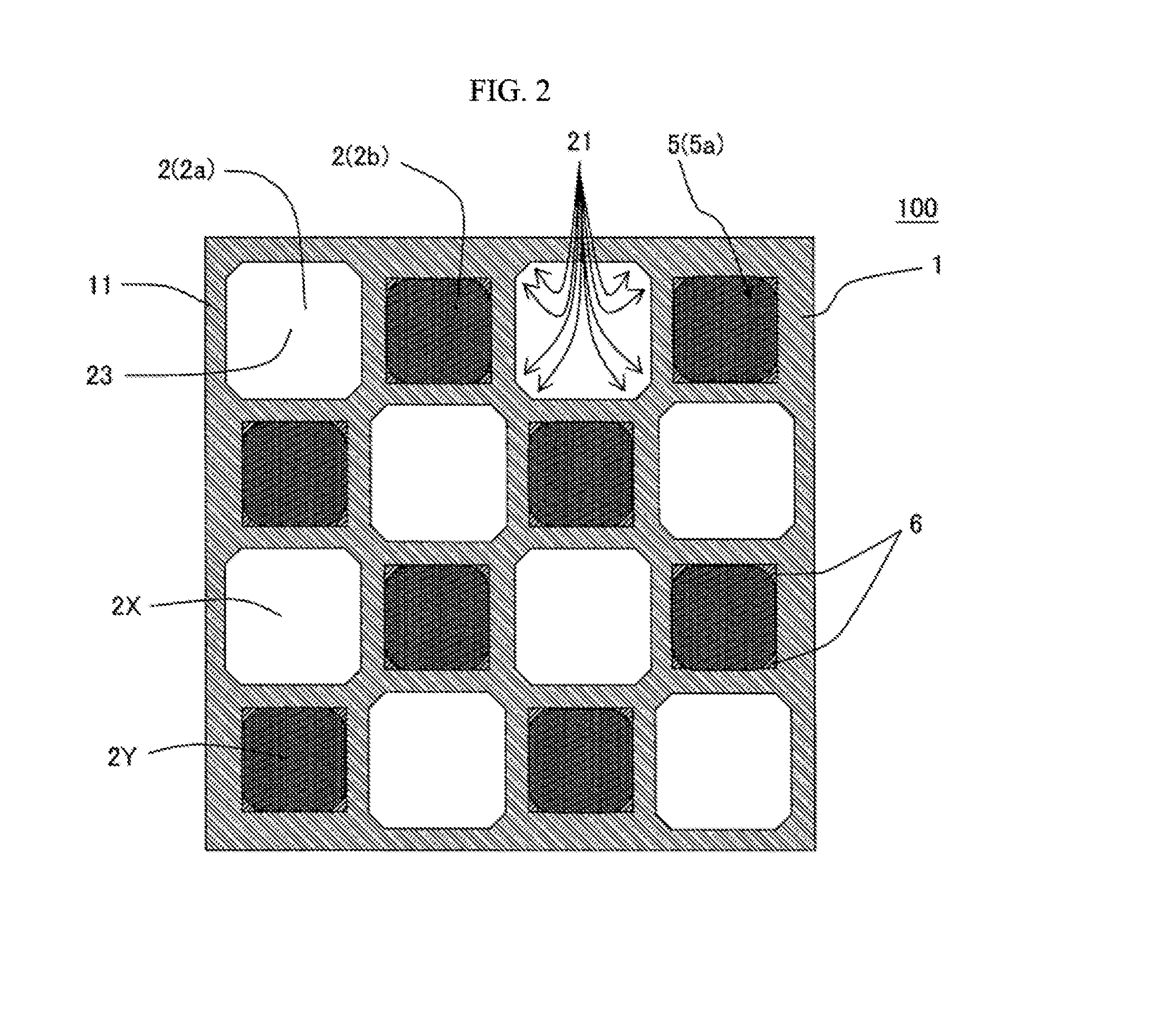

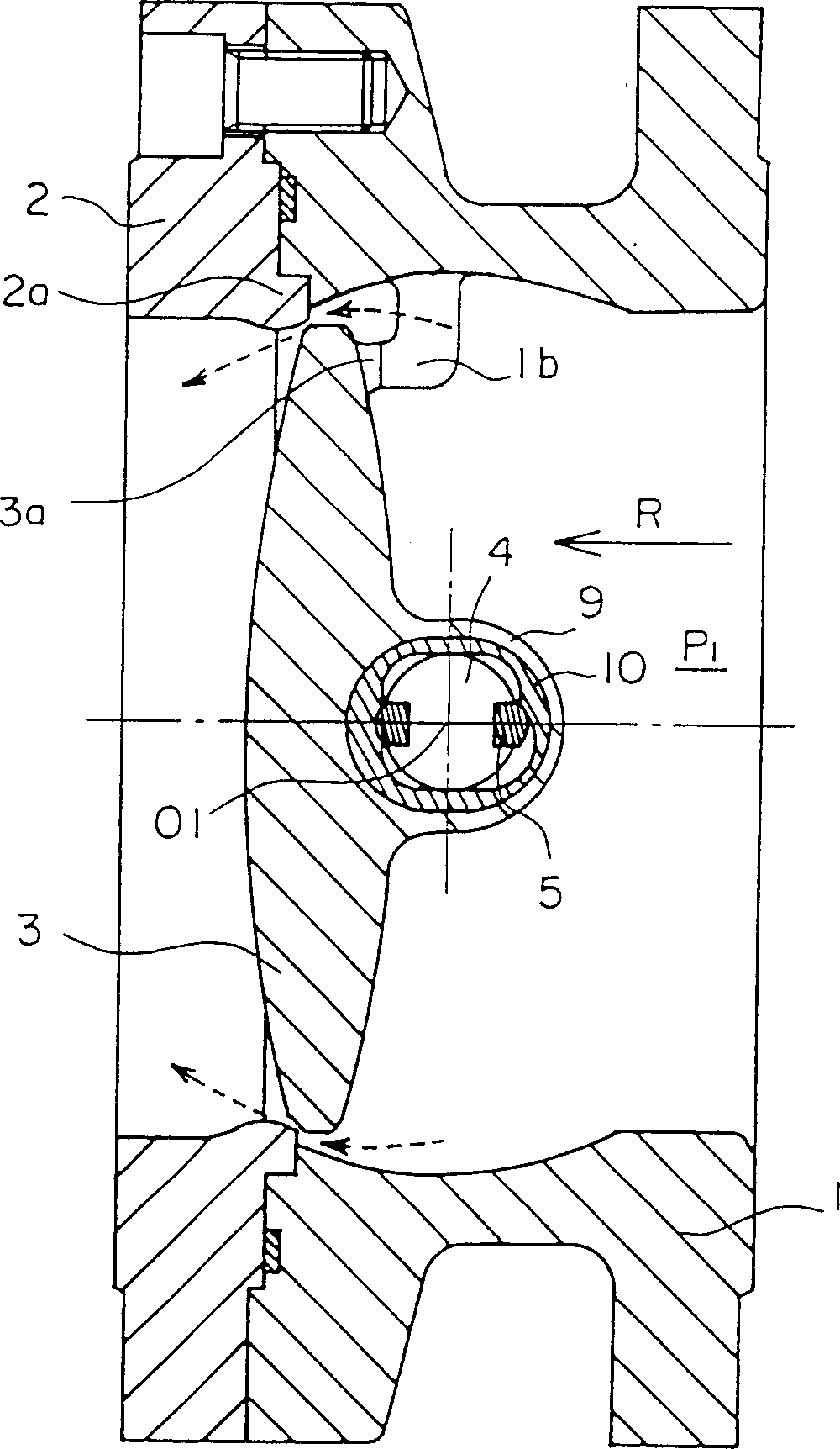

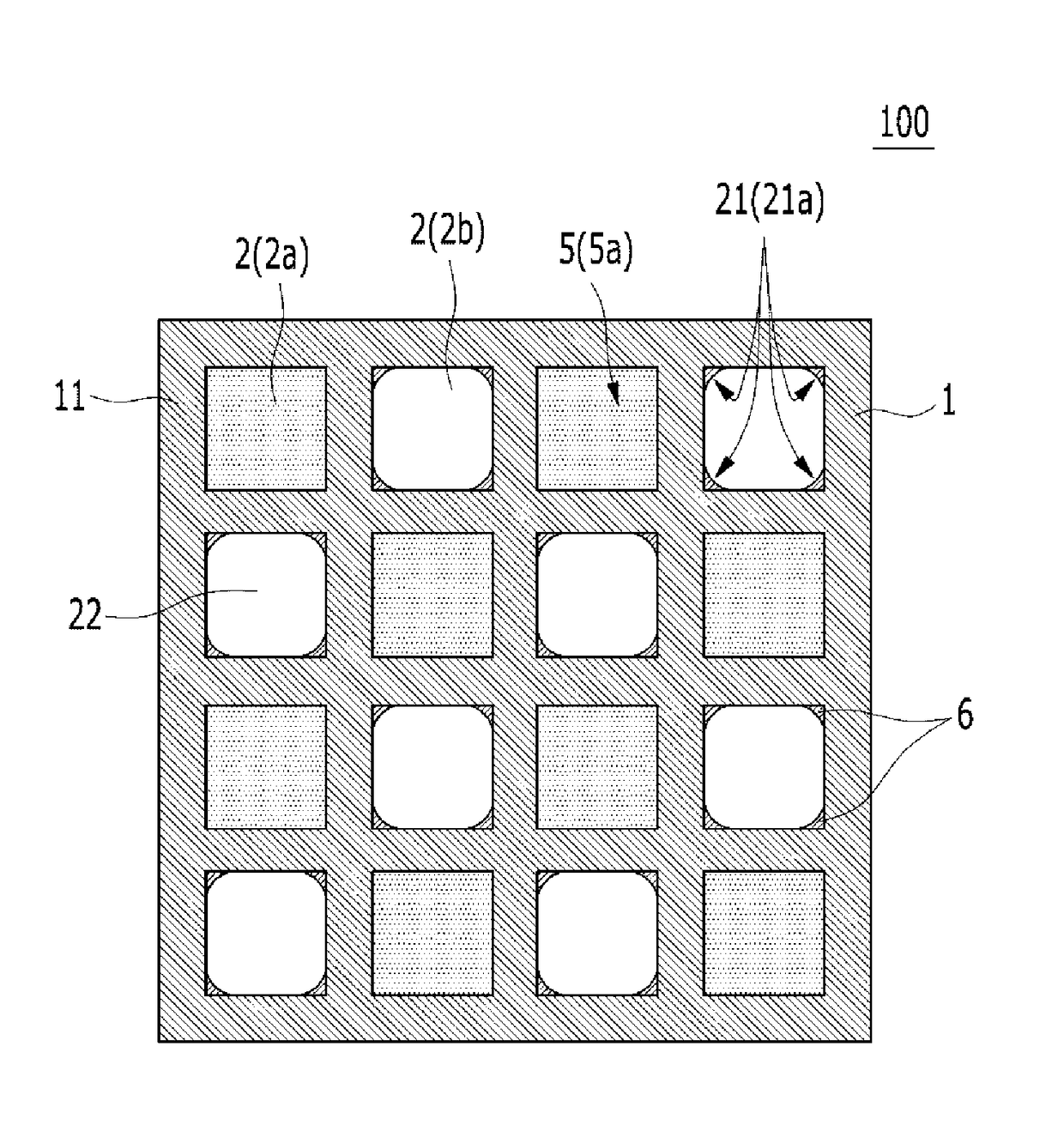

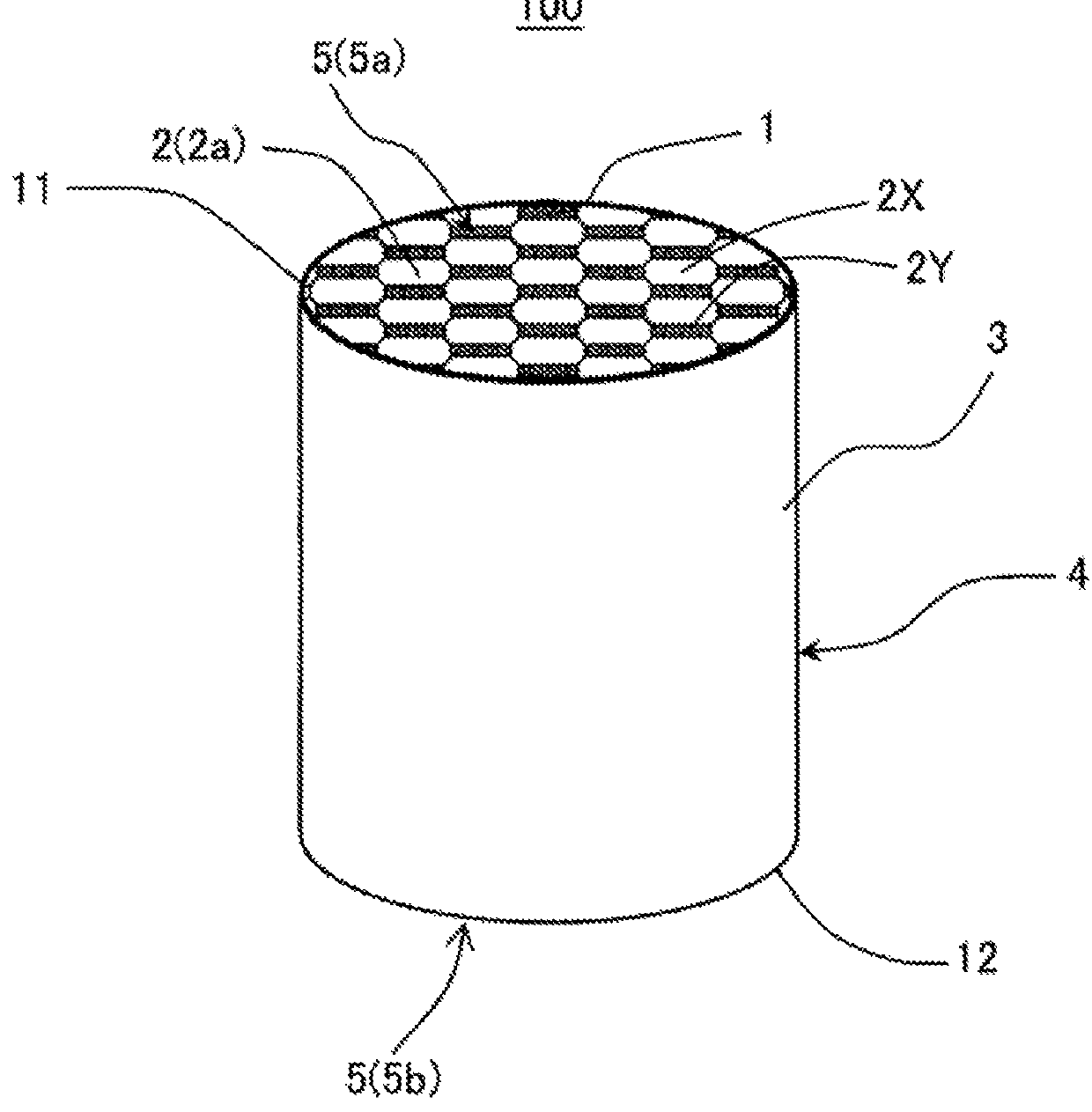

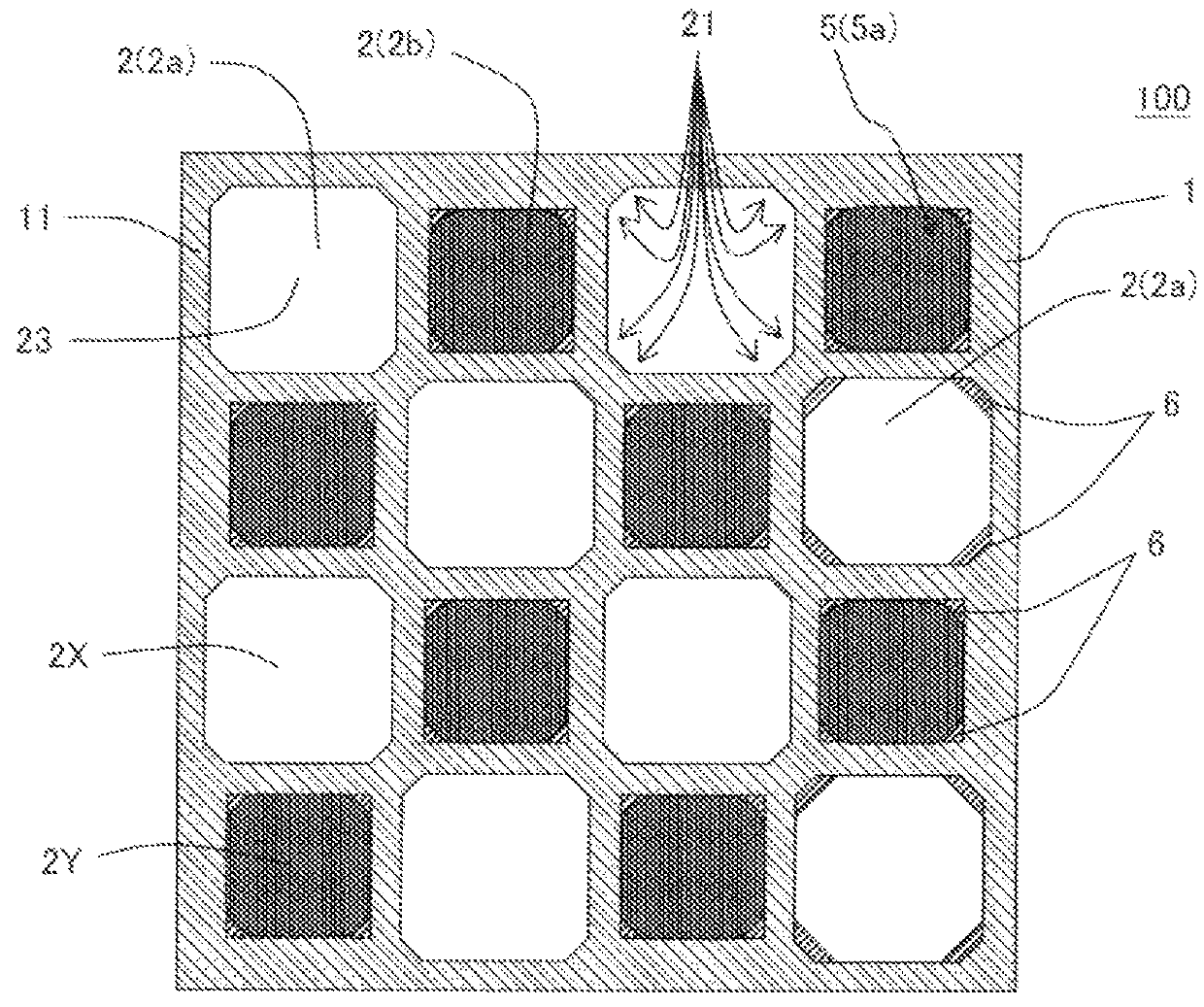

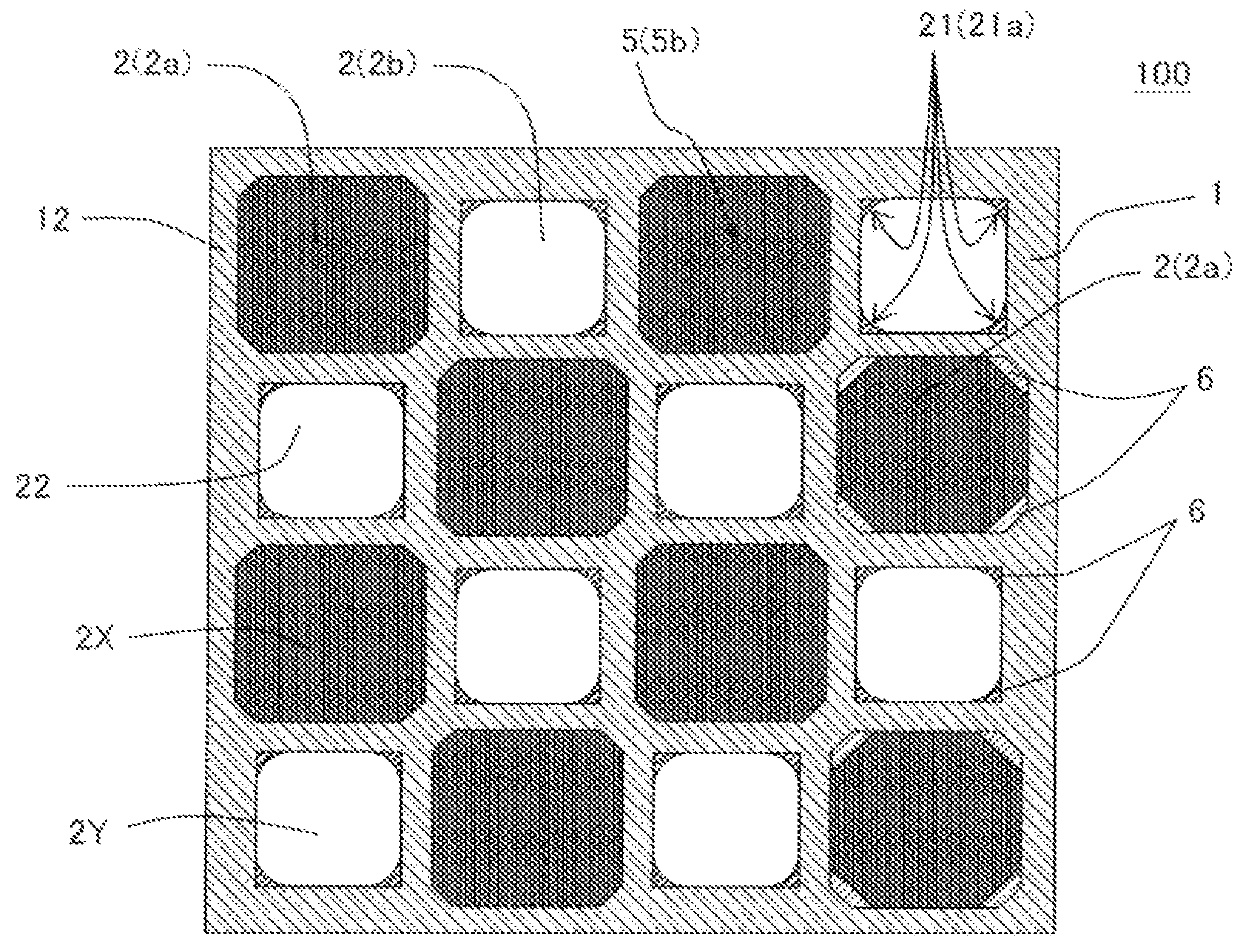

Sealed honeycomb structure

ActiveUS20140311112A1Increased durabilityIncrease of pressure loss can be suppressedDispersed particle filtrationExhaust apparatusEngineeringMechanical engineering

A sealed honeycomb structure may include porous walls dividedly forming inlet cells and outlet cells extending from an end surface of an inlet side to an end surface of an outlet side, inlet and outlet side sealing portion 5b, and an inlet side sealing portion, wherein at least one outlet cell is a reinforced cell where a reinforcing part 6 for reinforcing the outlet cell 2b is formed at at least one corner portion 21a at which the walls on a cross-section vertical to an extending direction of the cell cross each other, wherein the inlet cell is a non-reinforced cell where the reinforcing part is not formed at all the corner portions at which the walls on the cross-section vertical to the extending direction of the cell cross each other, and wherein the reinforcing parts 6 of the reinforced cells 22 are formed at a section of the honeycomb structure from the end surface of the outlet side in the extending direction of the cell.

Owner:HYUNDAI MOTOR CO LTD +2

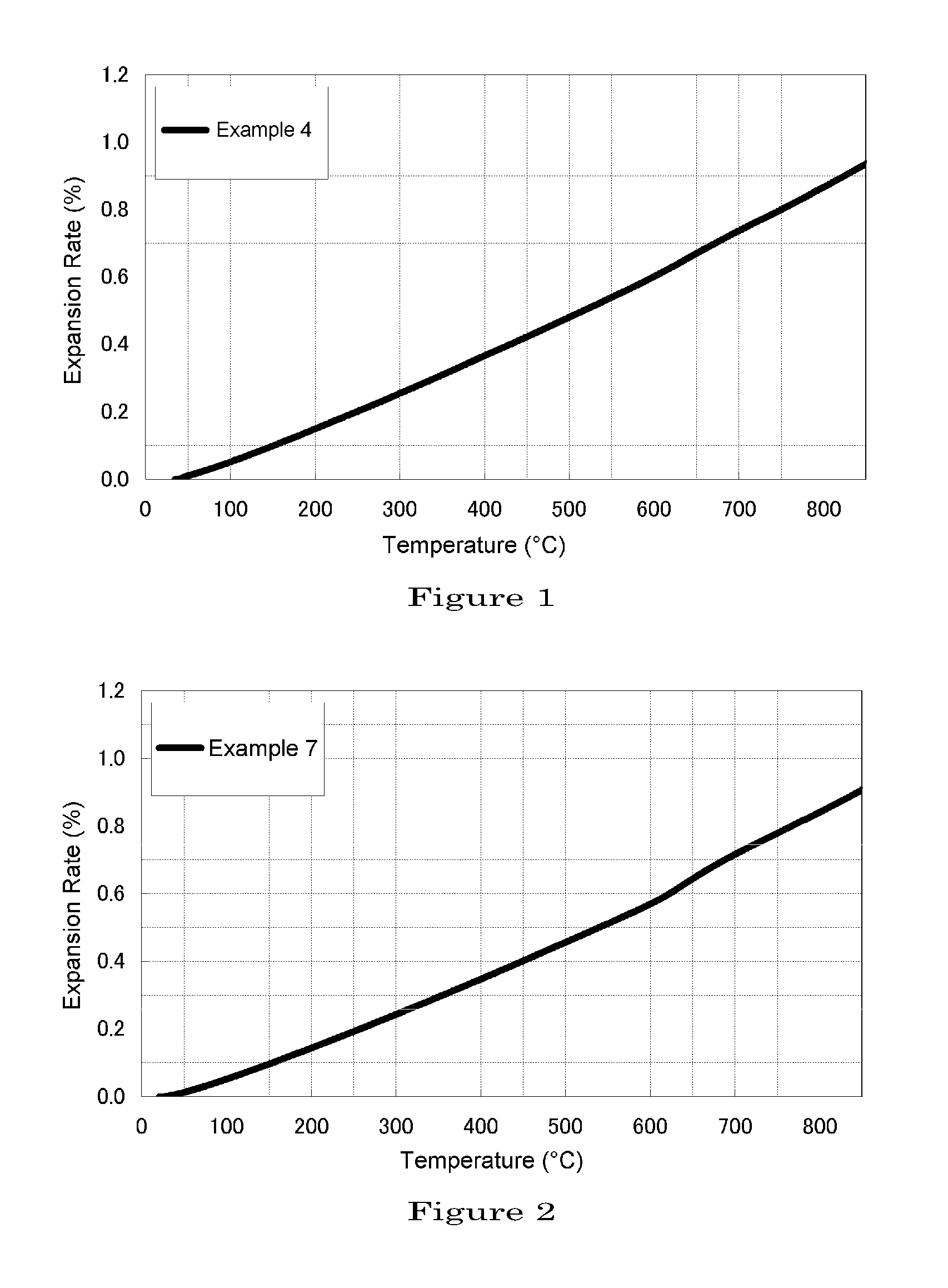

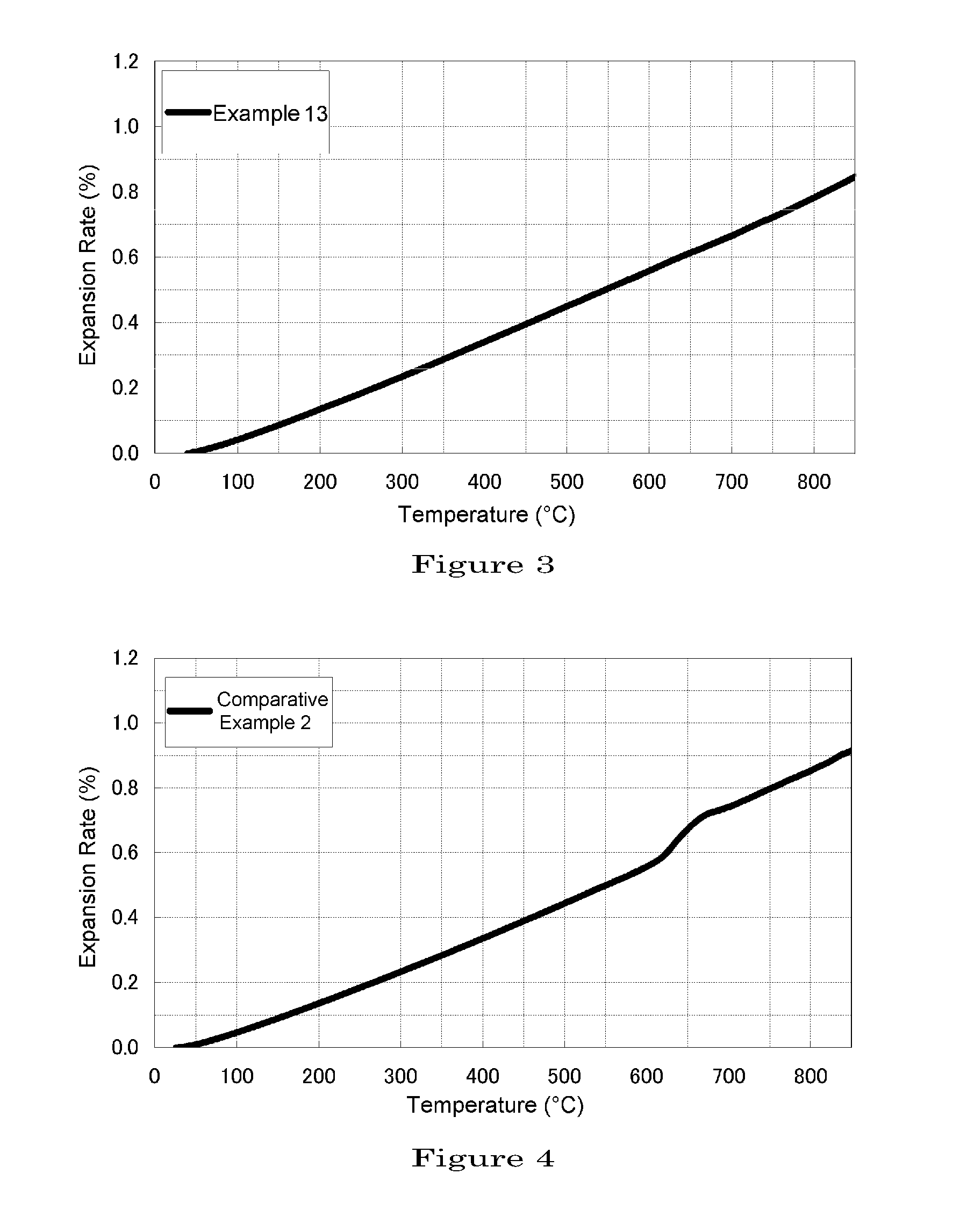

Glass composition for sealing

ActiveUS20110053753A1Improvement factorMaintain good propertiesSynthetic resin layered productsCellulosic plastic layered productsHermetic sealFlexural strength

Disclosed is a glass composition which is adapted to use in providing a hermetic seal between a metal and a ceramic, a metal and a metal, and a ceramic and a ceramic, to form crystallized glass having high strength and high thermal expansion which allow it to be used at high temperatures of 950° C. and over. The glass composition is substantially free of alkali metals, and contains, as calculated as oxide, 15-30 mass % of SiO2, 0-5 mass % of Al2O3, 20-35 mass % of B2O3, 10-25 mass % of CaO, 25-40 mass % of MgO, 3-8 mass % (3.0% excluded) of ZrO2, and 0-3 mass % of CeO2, wherein the crystallized glass which is formed by firing a glass powder made of the glass composition at a temperature of 850-1050° C. has a thermal expansion coefficient of 90-110×10−7 / ° C. at 50-550° C. and flexural strength of not less than 80 MPa.

Owner:NIHON YAMAMURA GLASS CO LTD

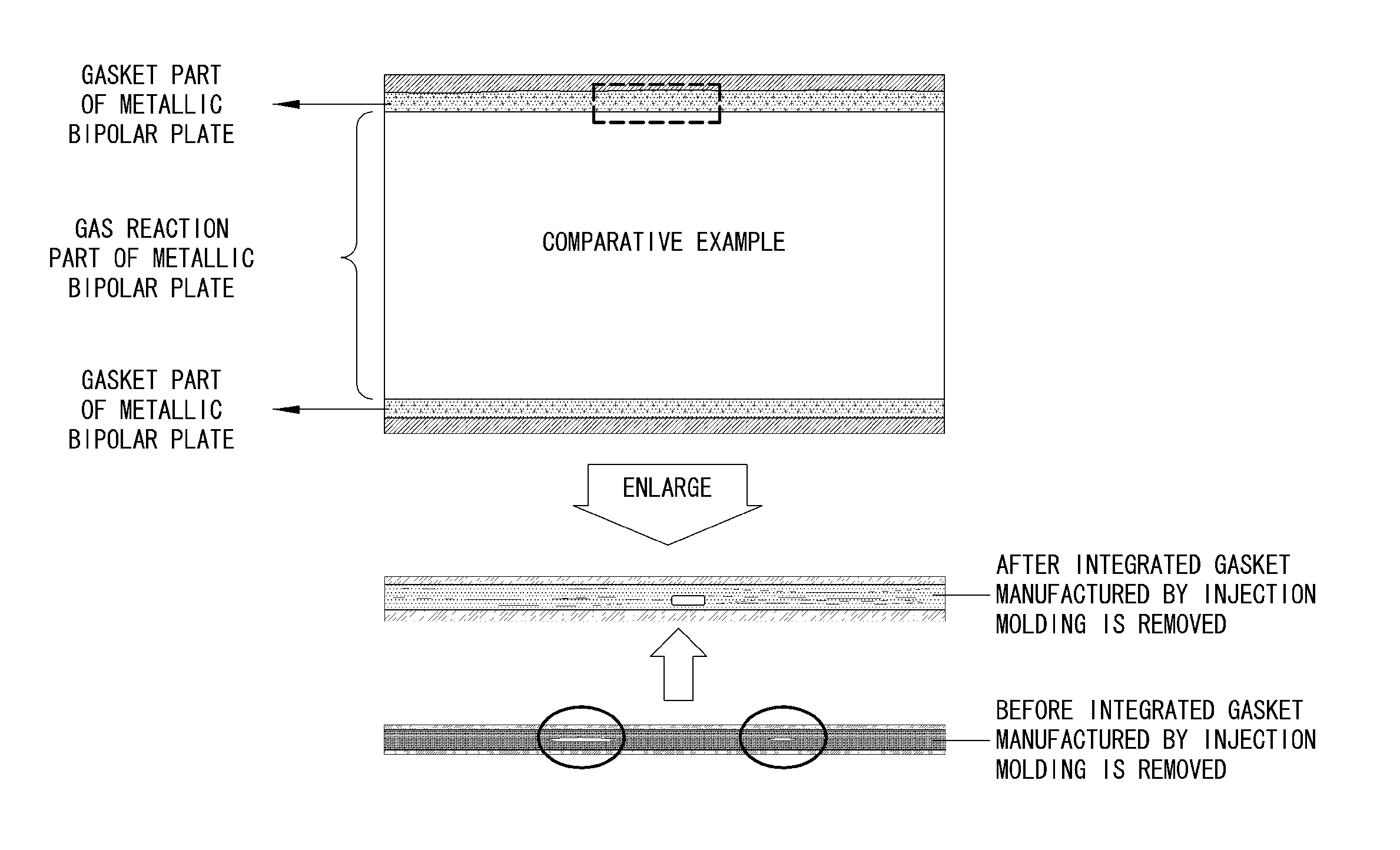

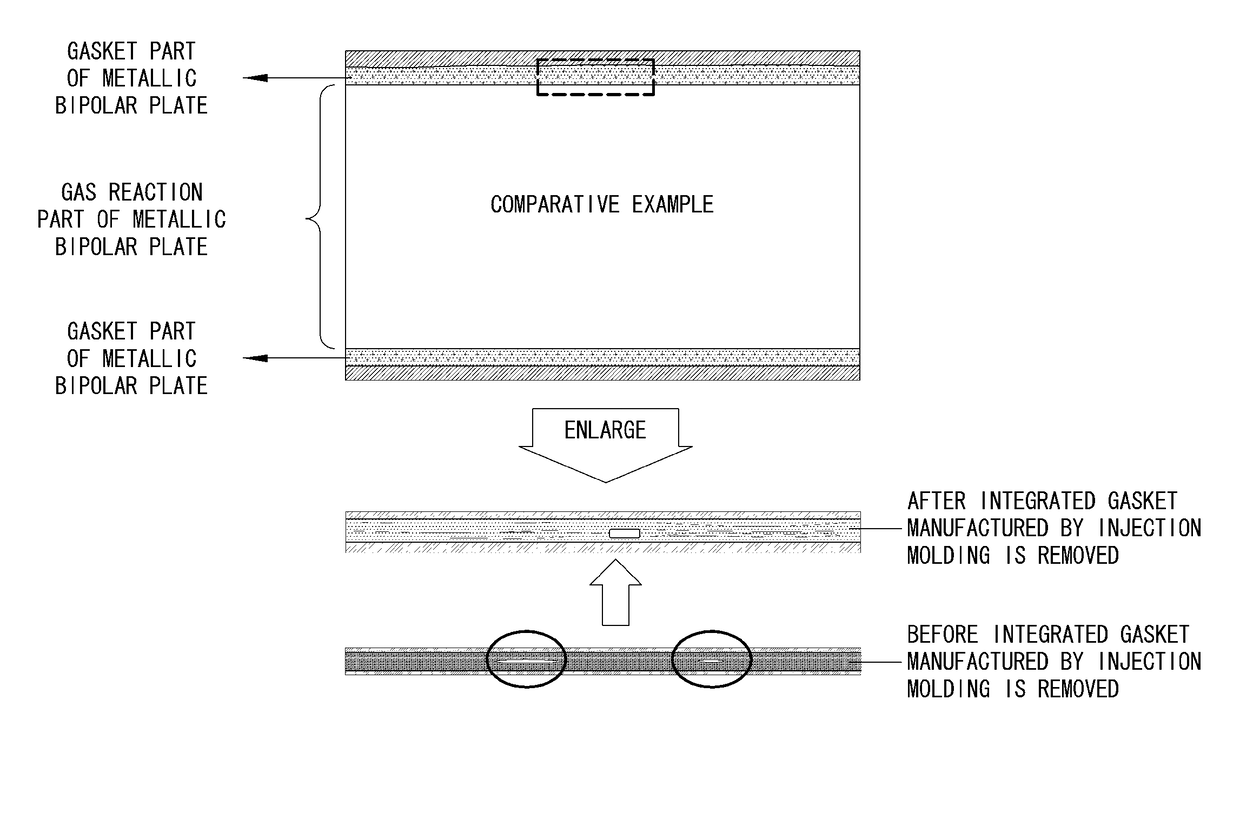

Integrated fluorine gasket manufactured by injection molding for hydrogen fuel cells

ActiveUS20140077462A1Lower Mooney ViscosityIncrease elasticityDomestic sealsEngine sealsHydrogen fuel cellEngineering

Disclosed is an integrated fluorine gasket manufactured by injection molding for hydrogen fuel cells. In particular, a fluorine compound having a fluorine content of about 60 to 75 parts by weight based on 100 parts by weight of a fluoroelastomer is disposed in a gasket. The resulting fluorine gasket is integrated with a thin bipolar plate having a thickness of about 200 μm or less to have a thickness of about 750 μm or less by injection molding on the thin bipolar plate and by cross-linking.

Owner:THE CHEMOURS CO FC LLC +2

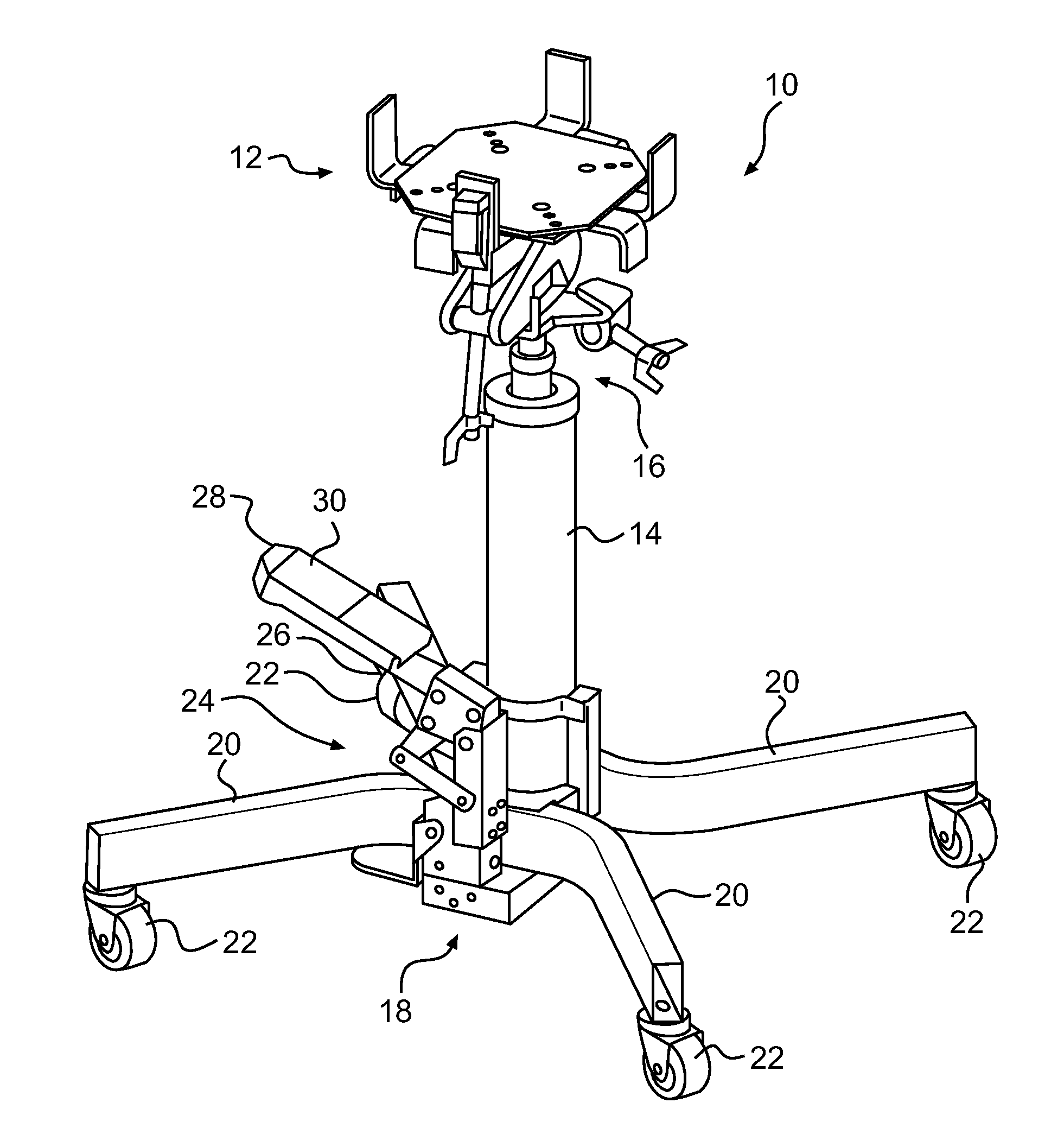

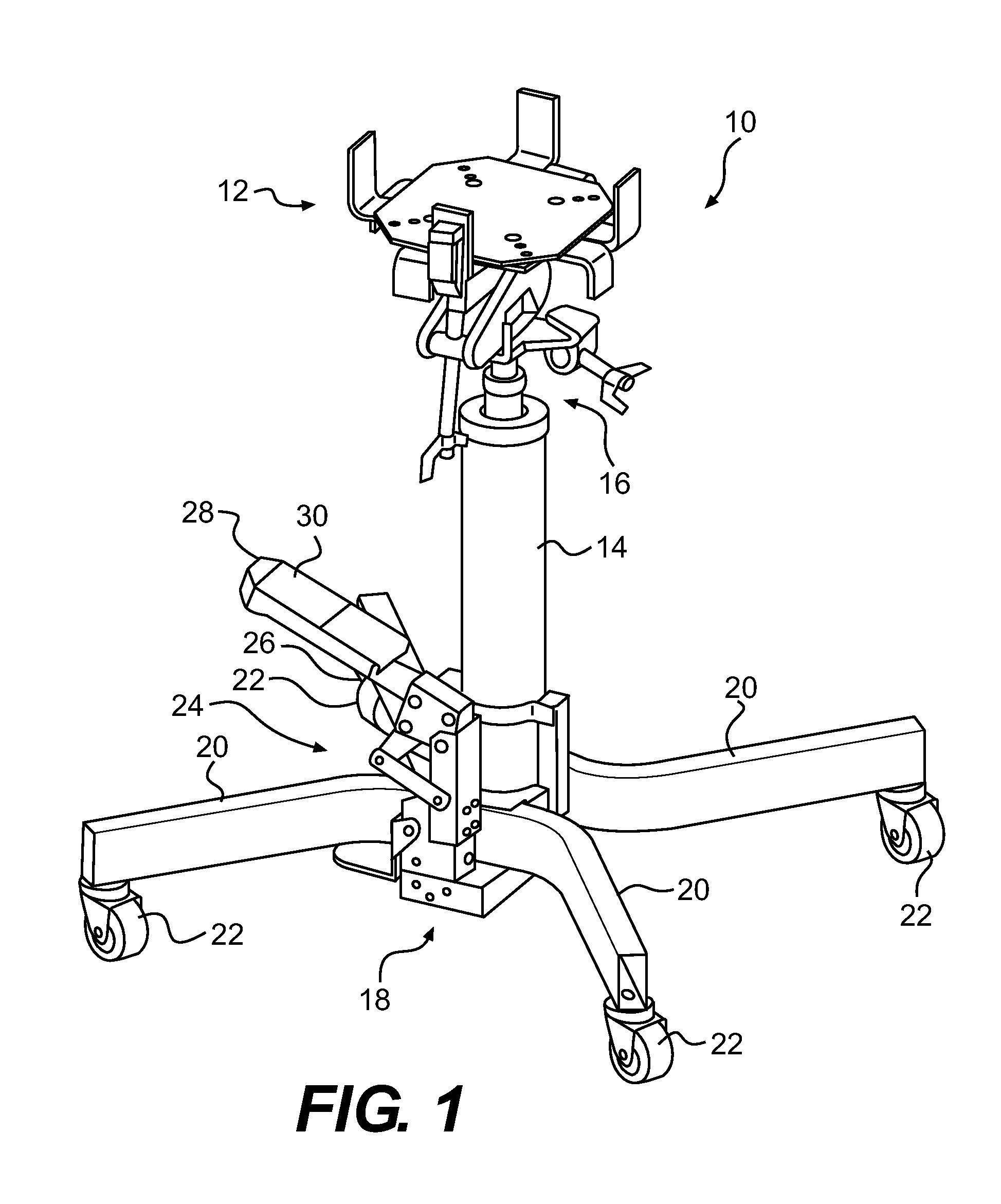

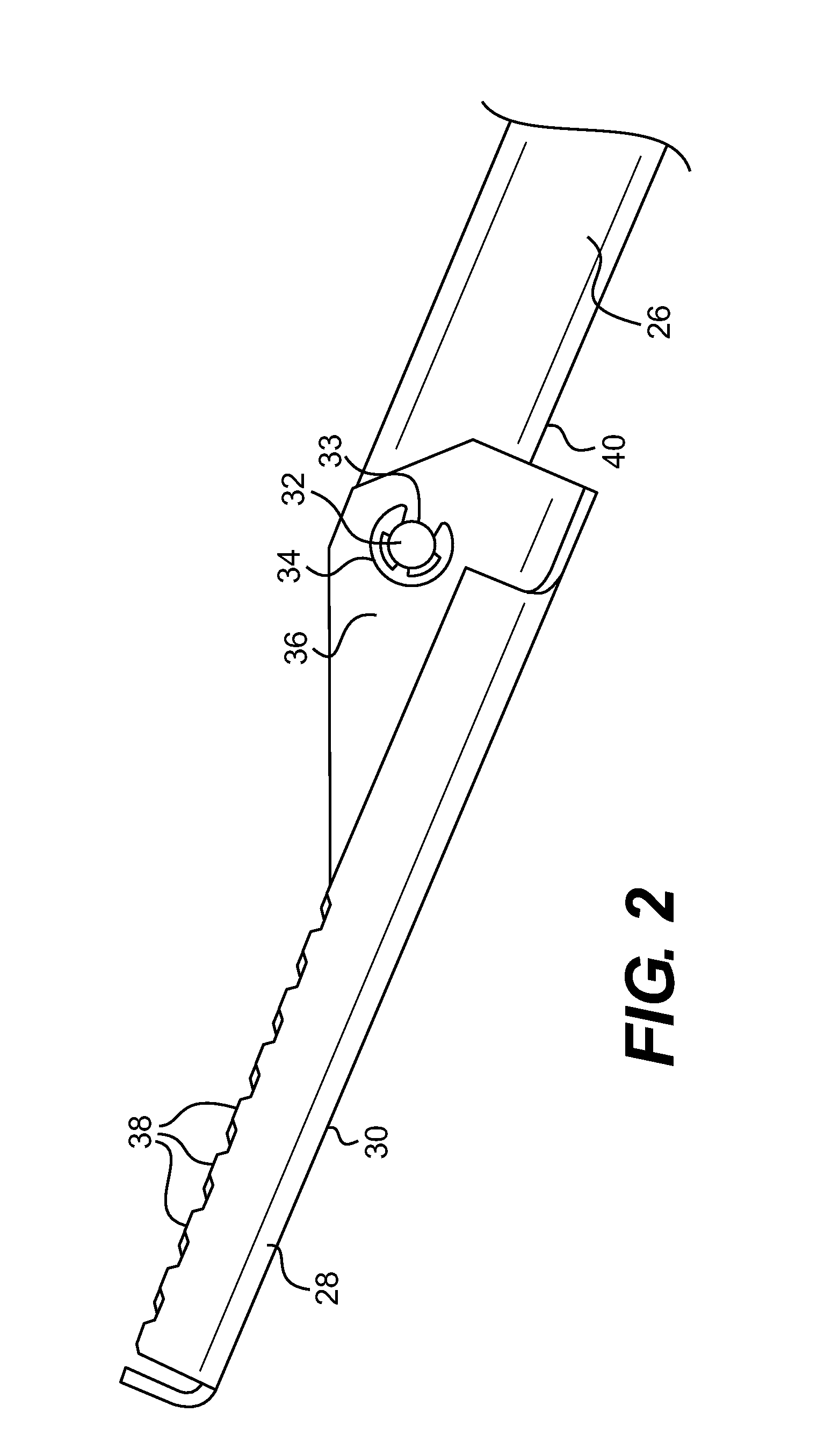

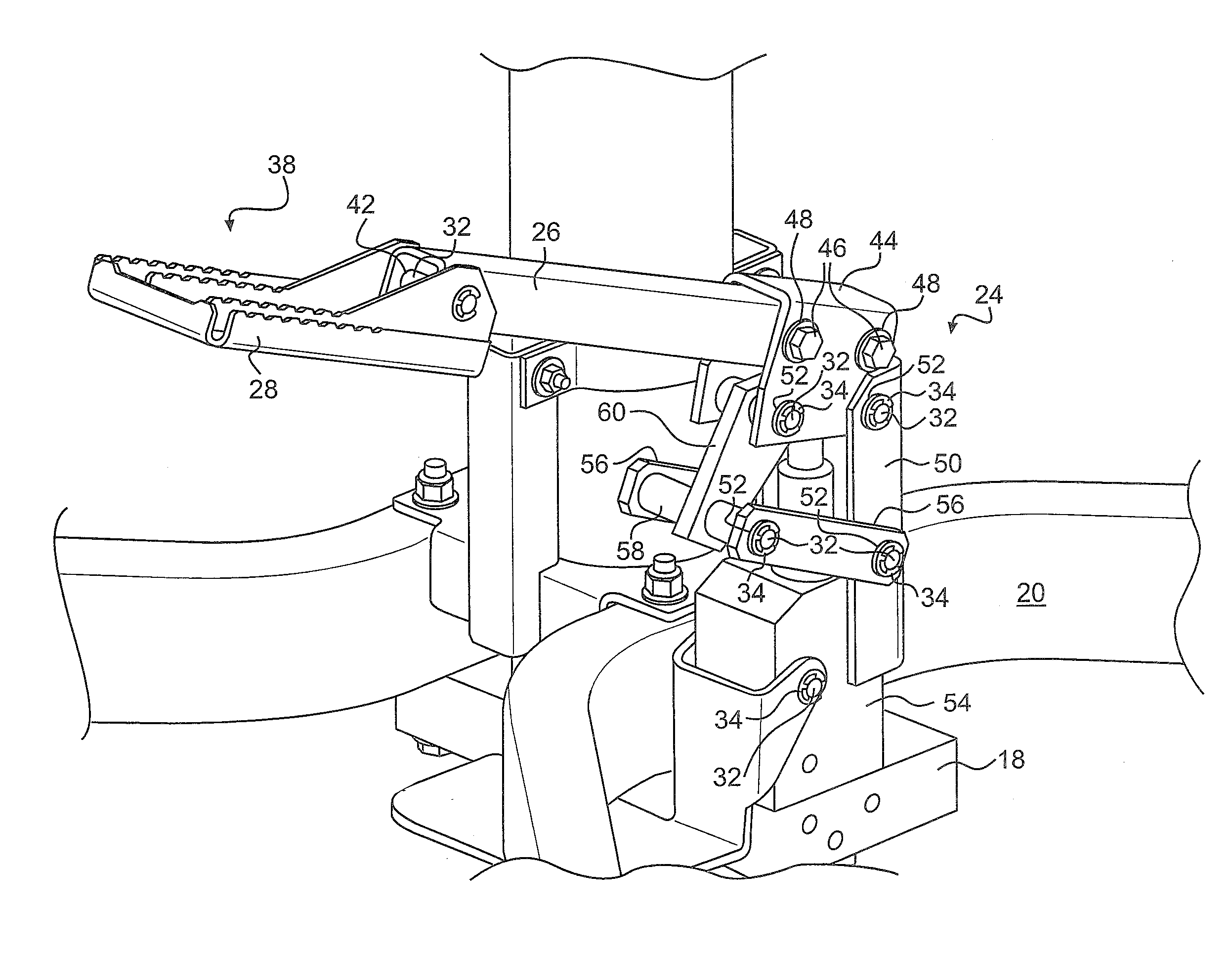

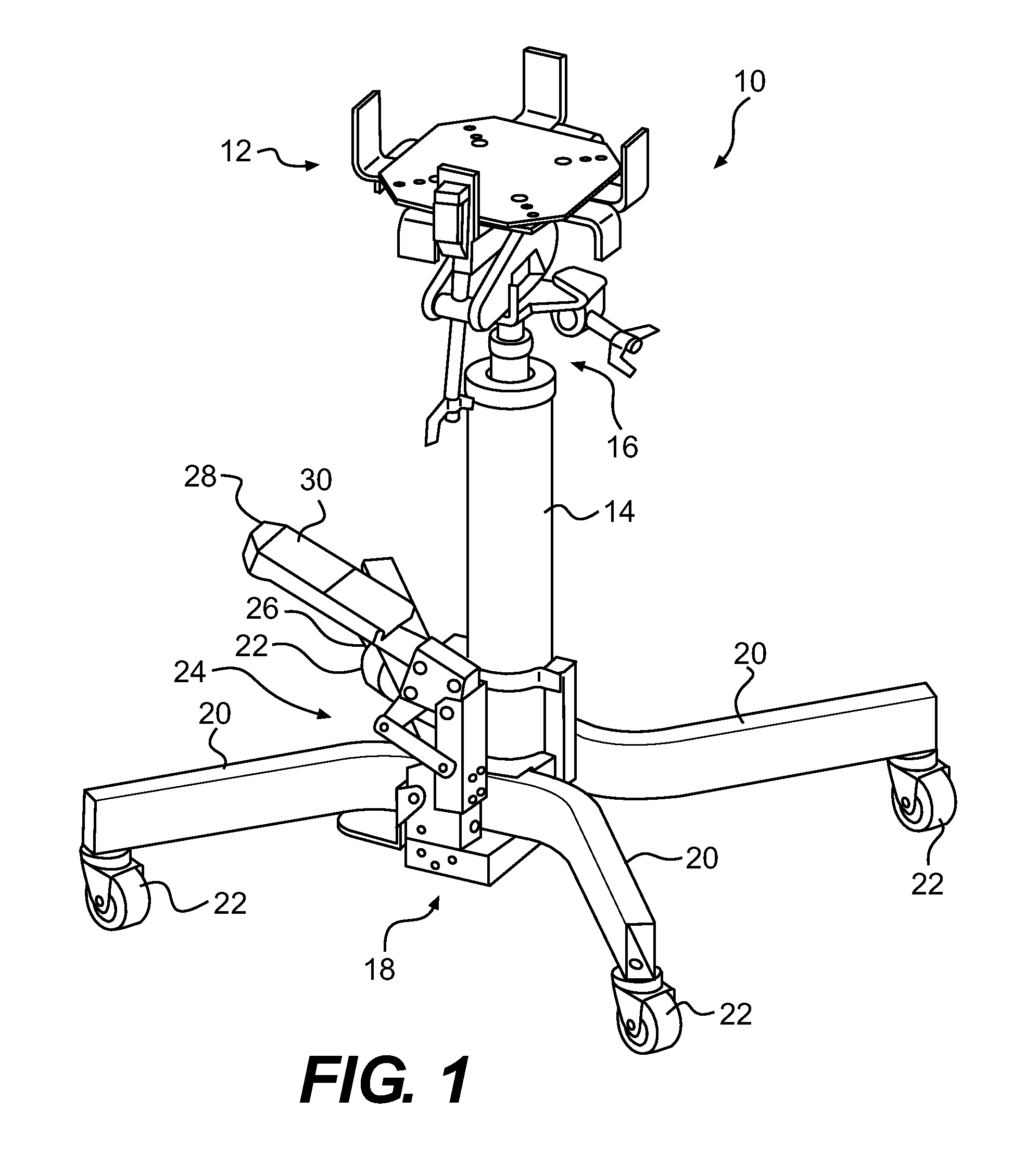

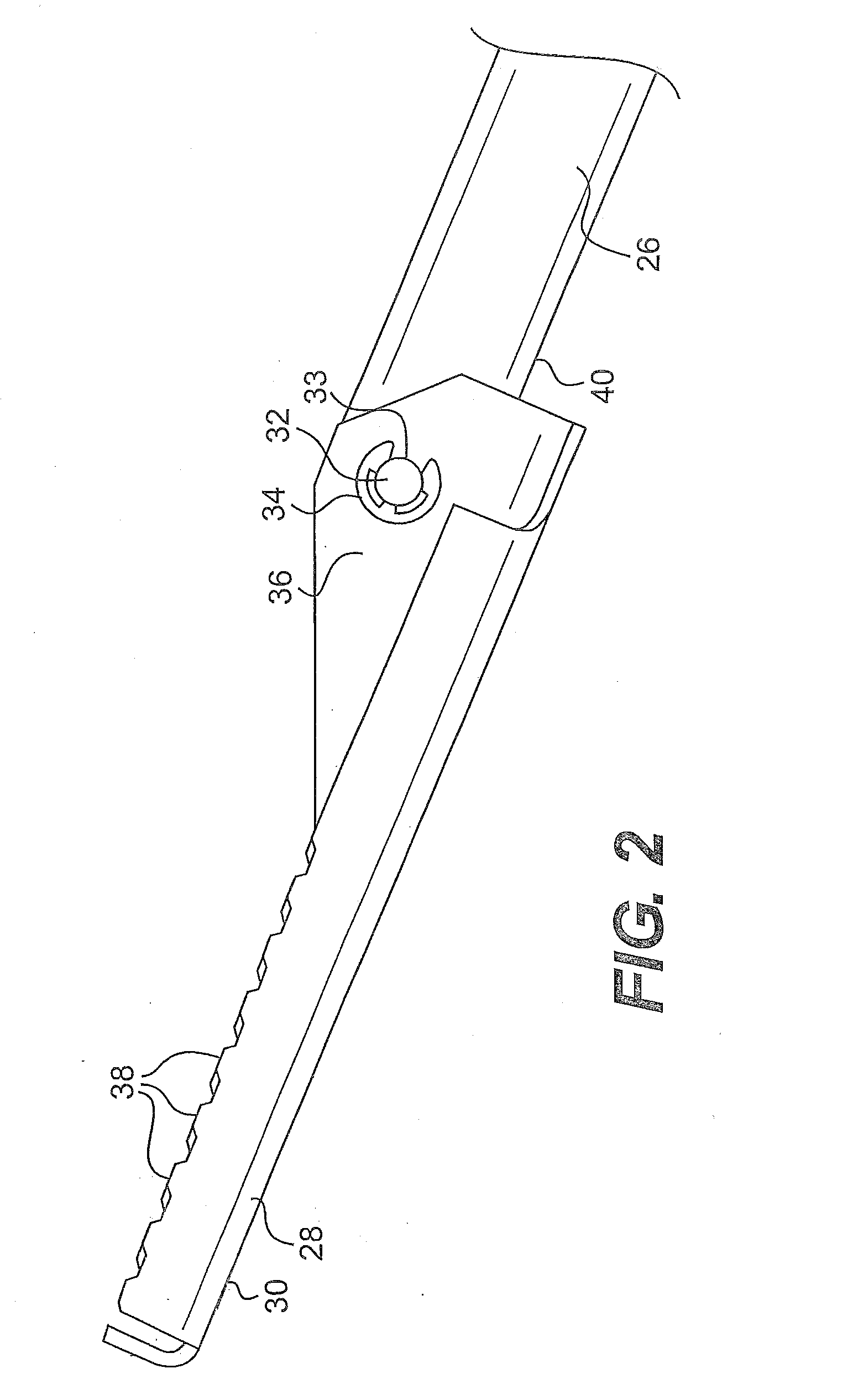

Adjustable Foot Pedal, Linkage, and Method for Actuating a Hydraulic Cylinder

ActiveUS20130104695A1Enhanced advantageLift heavier loadsControlling membersGearingHydraulic cylinderEngineering

A foot actuated pivoting lever is provided. The lever may include: a lever member having two ends, one end configured to attach to a mechanism configured to receive an input from the lever member; and a pedal pivotally attached proximate to the other end of the lever member, wherein the pedal is configured to pivot between a first and a second position, wherein in the first position, the pedal lies on top of a section of the lever member and, in the second position, the pedal extends beyond the lever member. A mechanism for actuating a piston may be provided.

Owner:BOSCH AUTOMOTIVE SERVICE SOLUTIONS

Sealed honeycomb structure

ActiveUS20160375395A1Volume andLower the volumeDispersed particle filtrationSilencing apparatusEngineeringMechanical engineering

Owner:HYUNDAI MOTOR CO LTD +2

Spring energized lip seal faucet ball valve

InactiveUS20070039654A1Increase durabilityImproved seal durabilityMultiple way valvesThin material handlingBall valveCam

A faucet assembly includes a housing that defines a cavity. Within the cavity there is a ball valve that is held in place by cam surfaces of a cam. The cam surfaces positively and directly contact the ball valve without a pliable seal member disposed there between. The possible location of the ball valve eliminates linear movement. Further, a seal assembly is disposed between the cam and the ball valve in locations that are not in direct contact with the cam surfaces. The cam surfaces hold the ball valve in place separately from the seal resulting in less load on the seal to provide lengthened seal life.

Owner:MASCO CORP

Sealed honeycomb structrure

InactiveUS20140127453A1Increase of pressure loss can be suppressedImproved seal durabilityDispersed particle filtrationLayered productsHoneycomb structureEngineering

A sealed honeycomb structure may include porous walls dividedly forming inlet cells and outlet cells extending from an end surface of an inlet side to an end surface of an outlet side, an outlet side sealing portion, and an inlet side sealing portion, wherein at least one outlet cell is a reinforced cell, where a reinforced part for reinforcing the outlet cell is formed at at least one corner portion at which the walls on a cross-section vertical to an extending direction of the cell cross each other, and wherein the inlet cell is a non-reinforced cell where the reinforced part is not formed at all the corner portions at which the walls on the cross-section vertical to the extending direction of the cell cross each other.

Owner:HYUNDAI MOTOR CO LTD +2

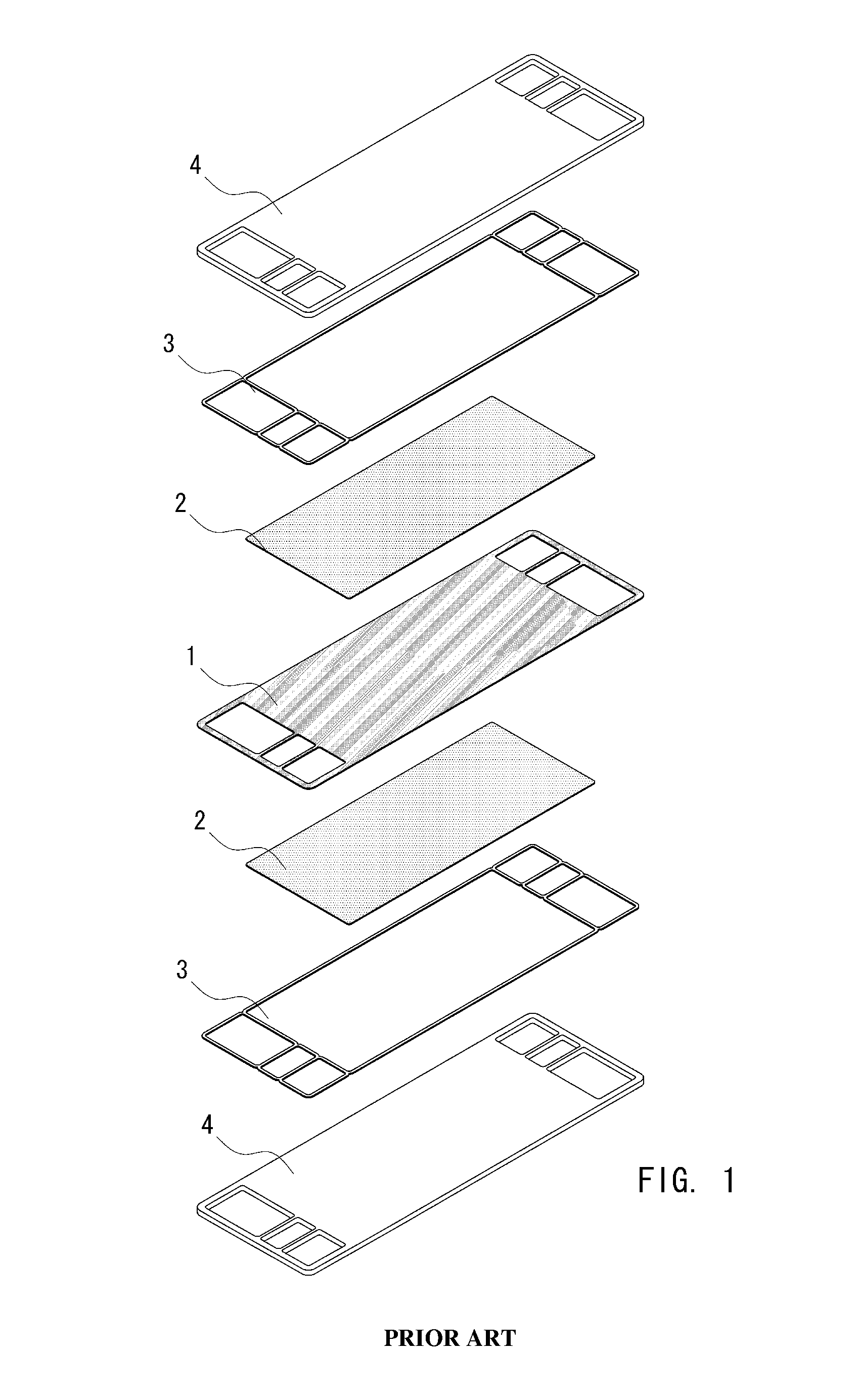

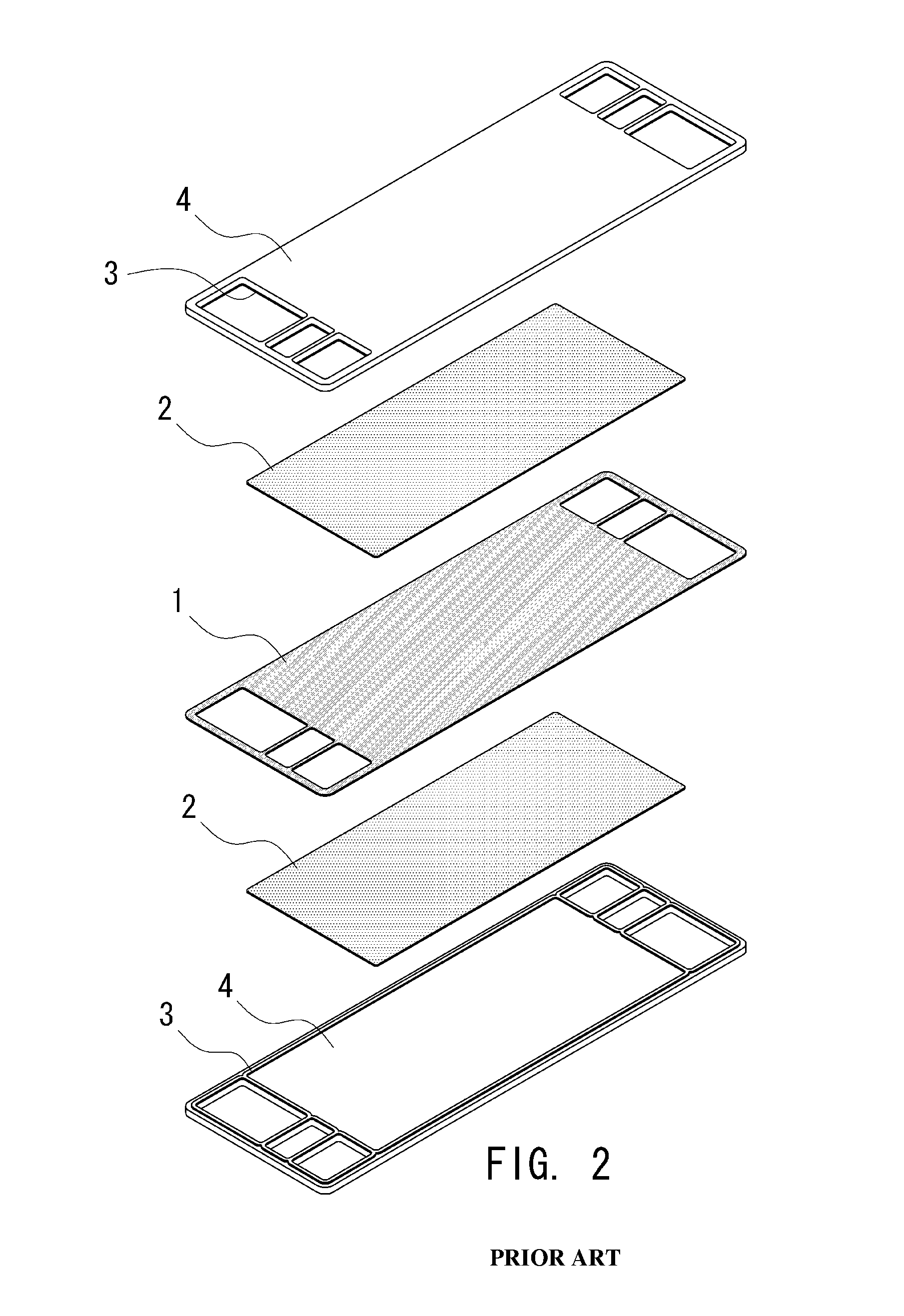

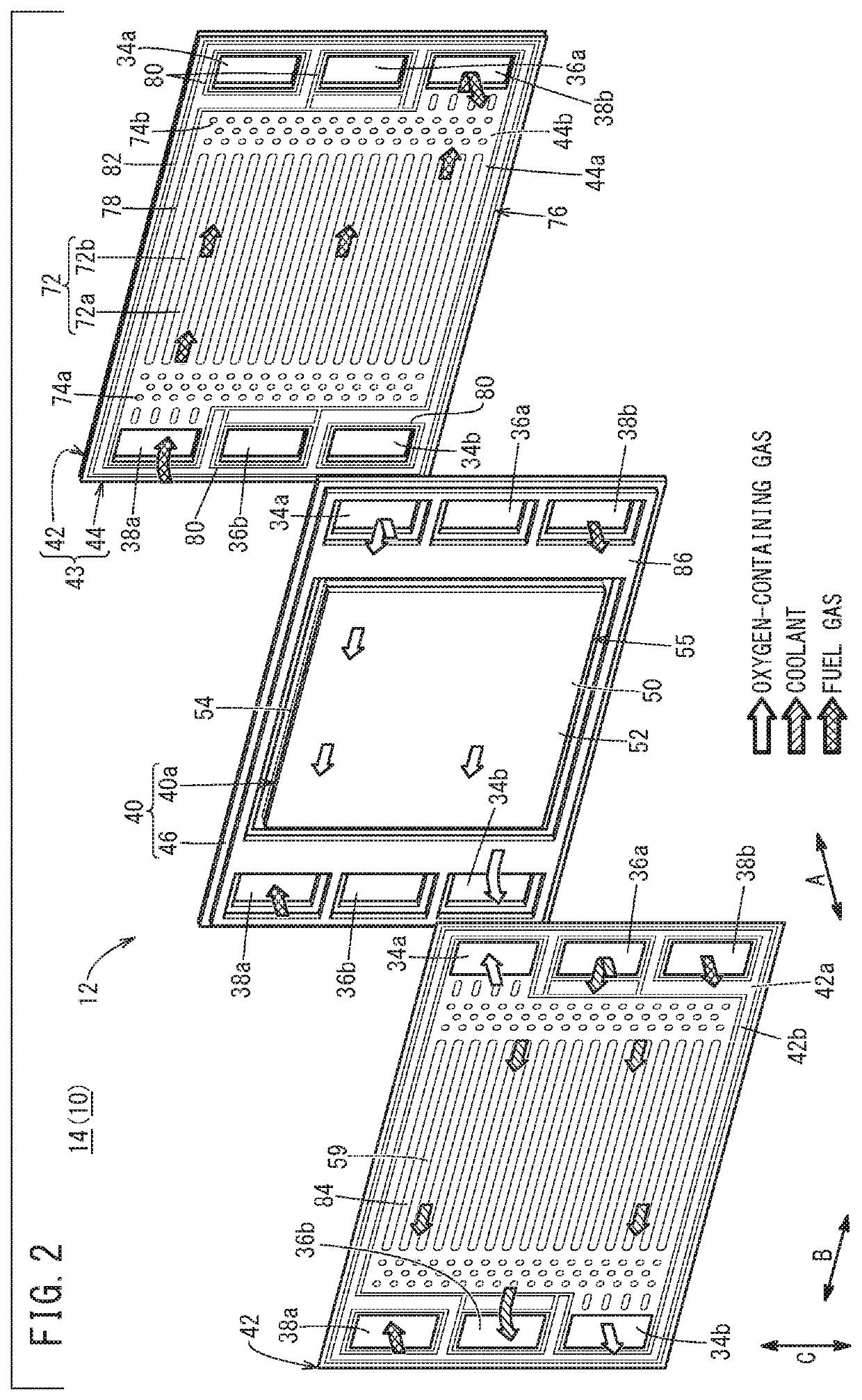

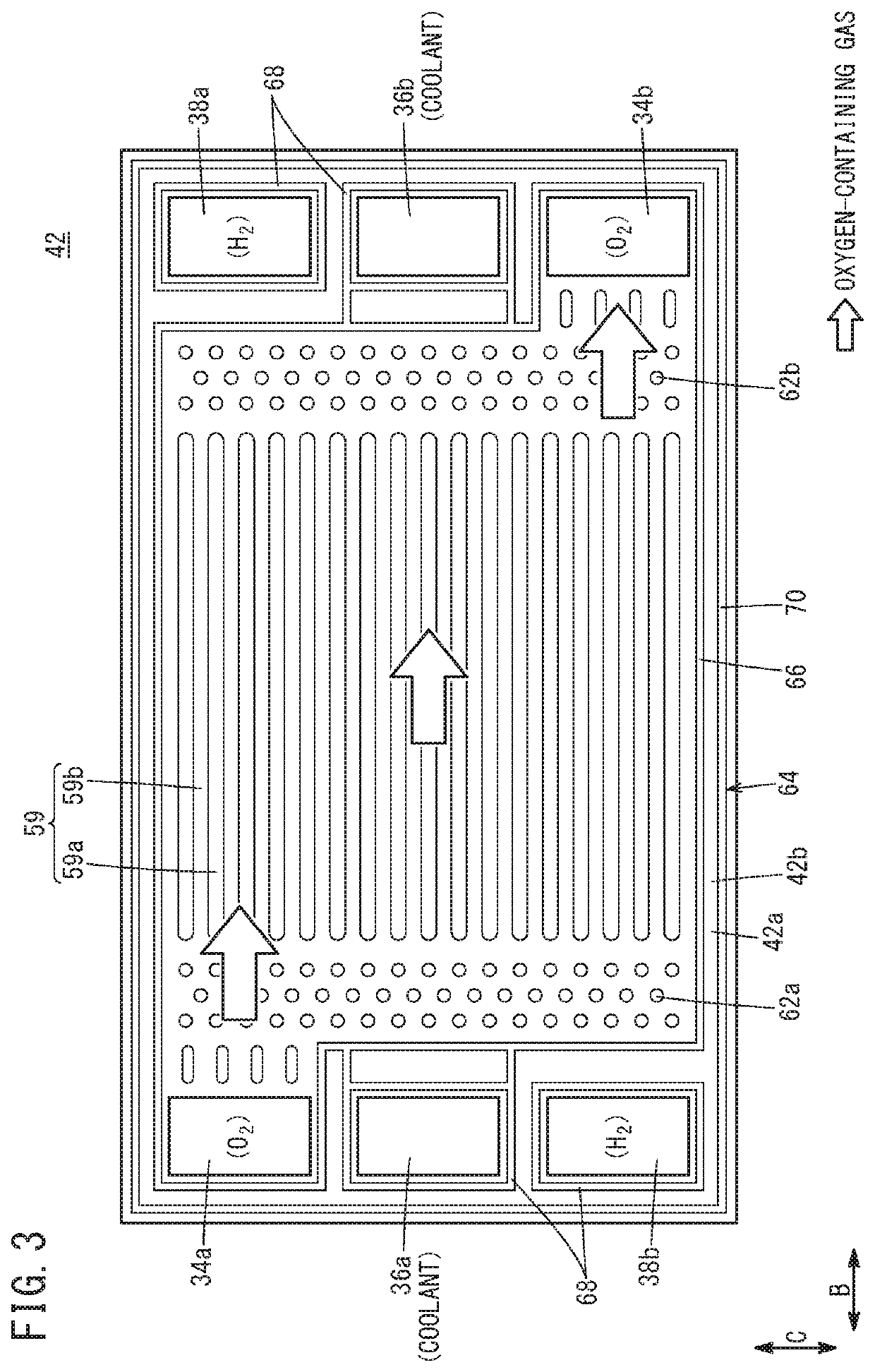

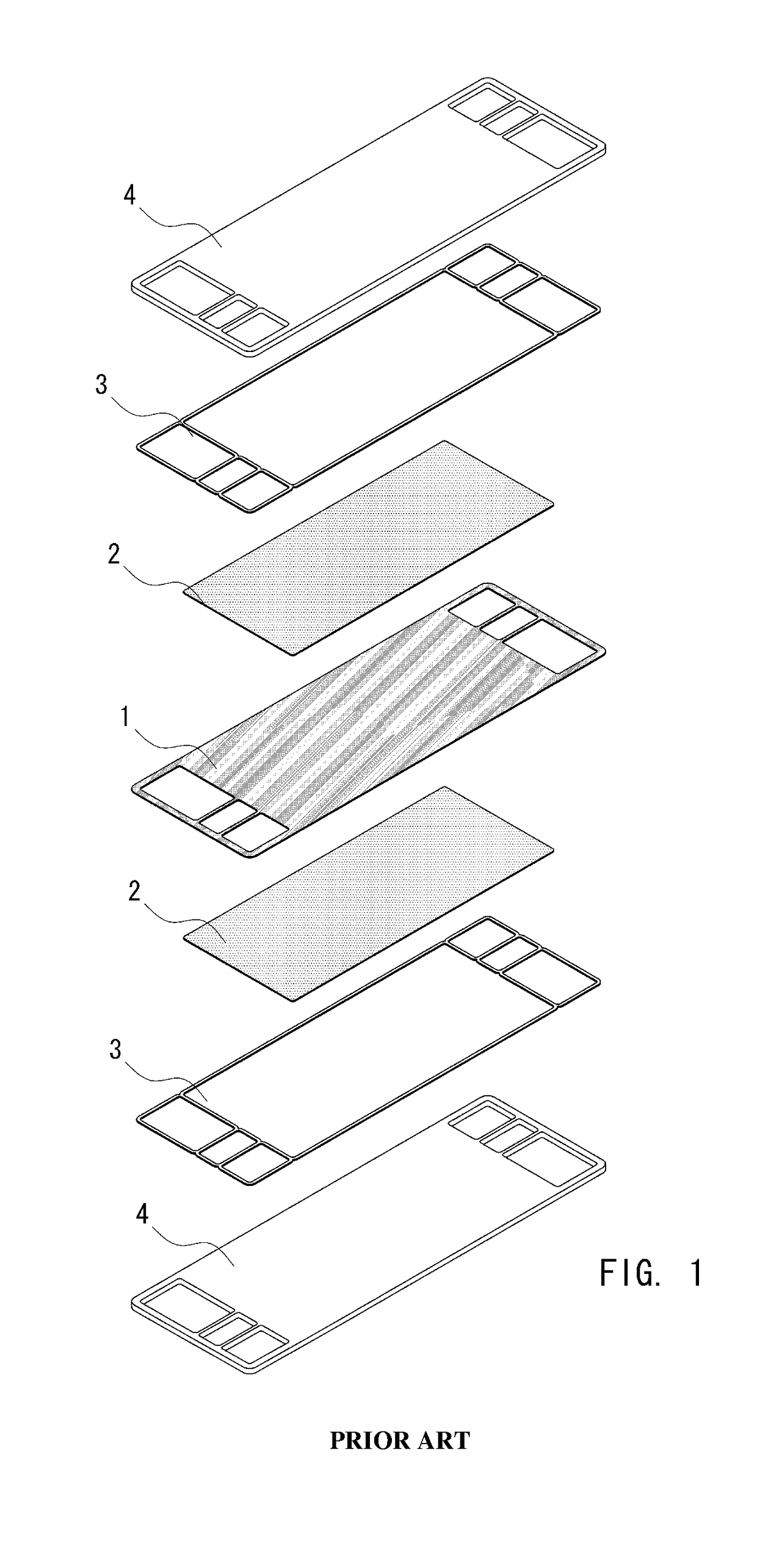

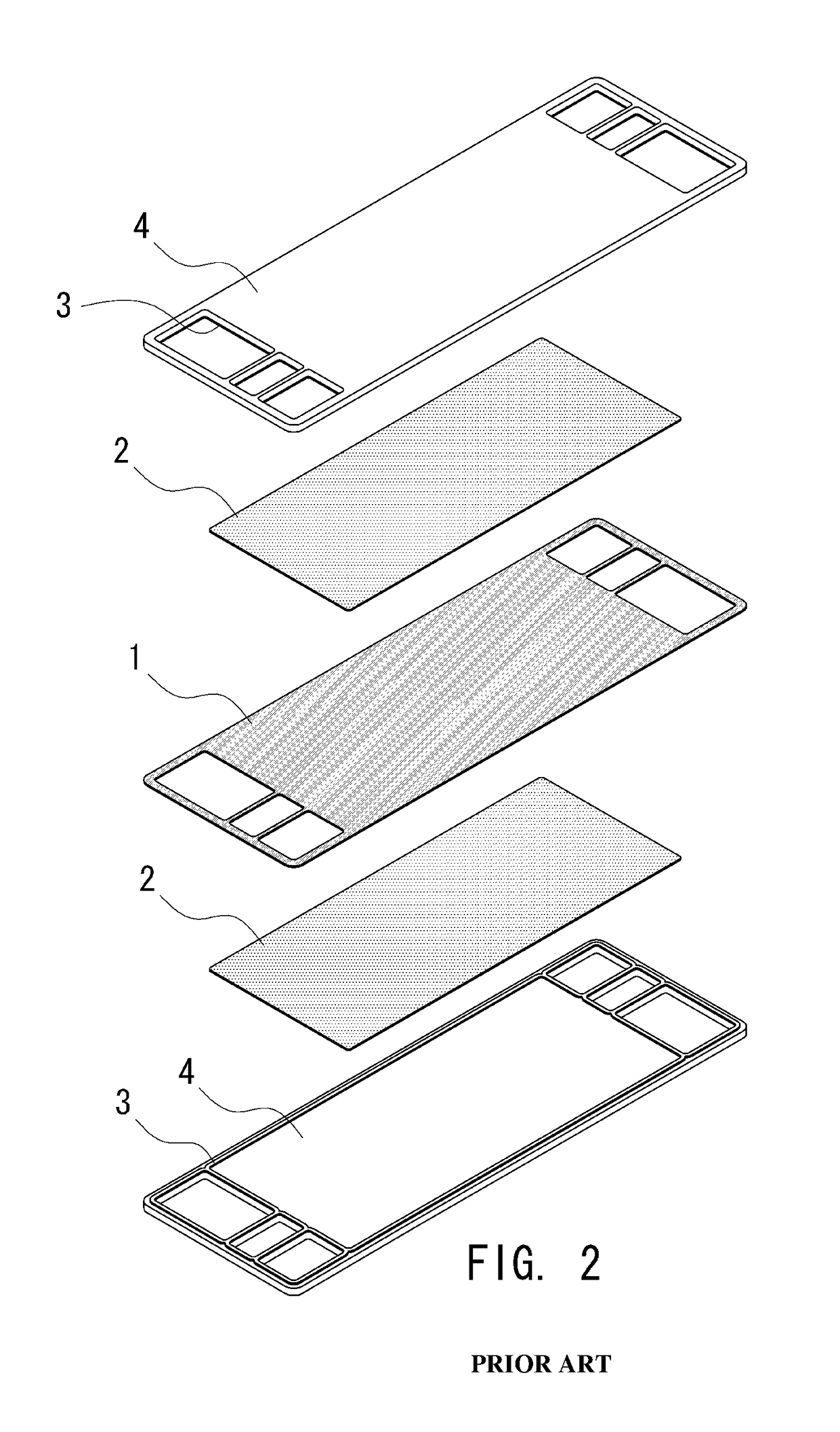

Fuel cell and fuel cell stack

InactiveUS20200388860A1Small creepHigh constantFuel cell shape/formCollectors/separatorsFuel cellsEngineering

An electrically insulating resin frame is provided on an outer peripheral side of a power generation section of a membrane electrode assembly forming a fuel cell of a fuel cell stack. A seal bead protruding toward the resin frame is formed on a metal separator. A metal sheet is provided in a portion of the resin frame overlapped with the seal bead as viewed in the stacking direction.

Owner:HONDA MOTOR CO LTD

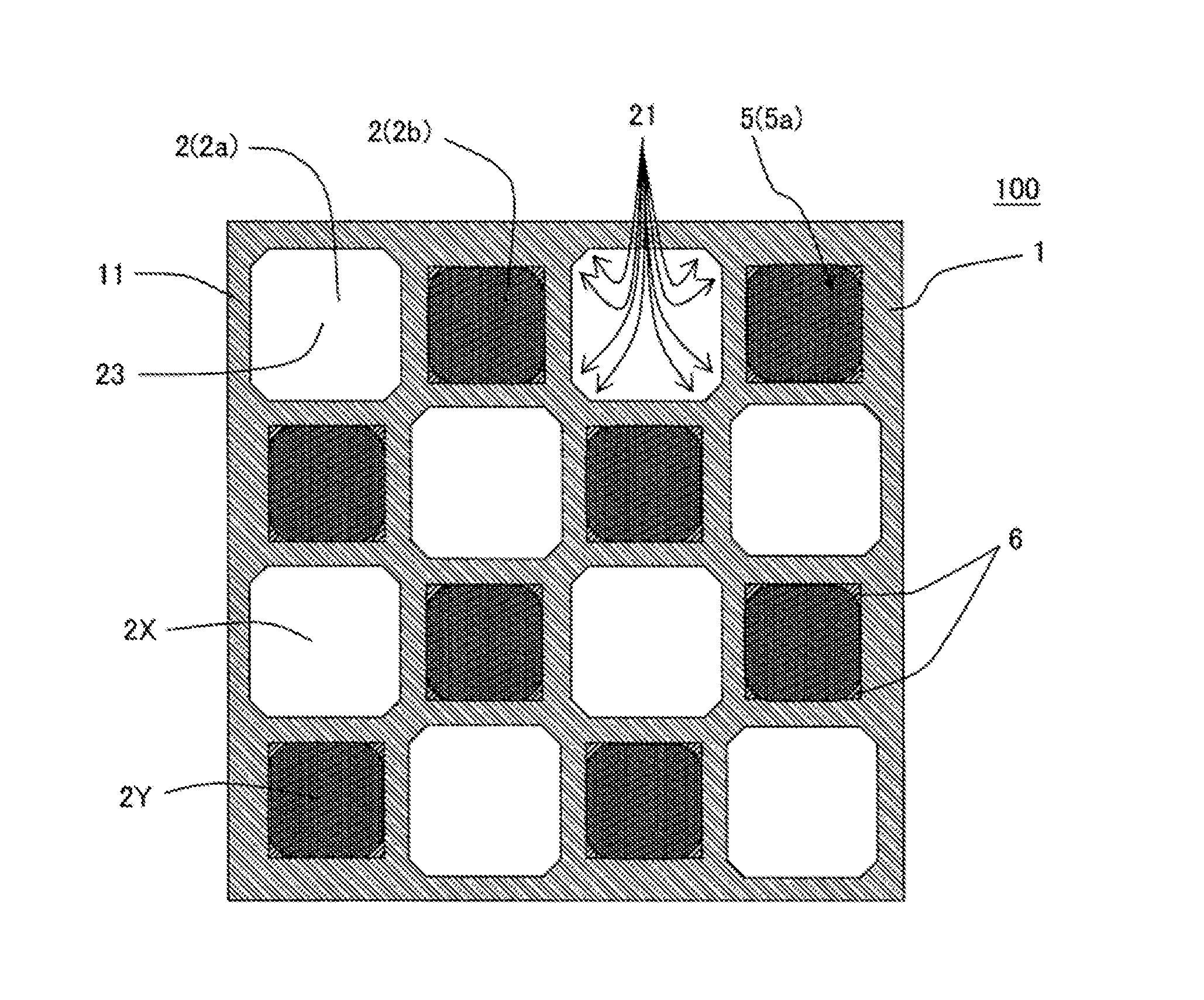

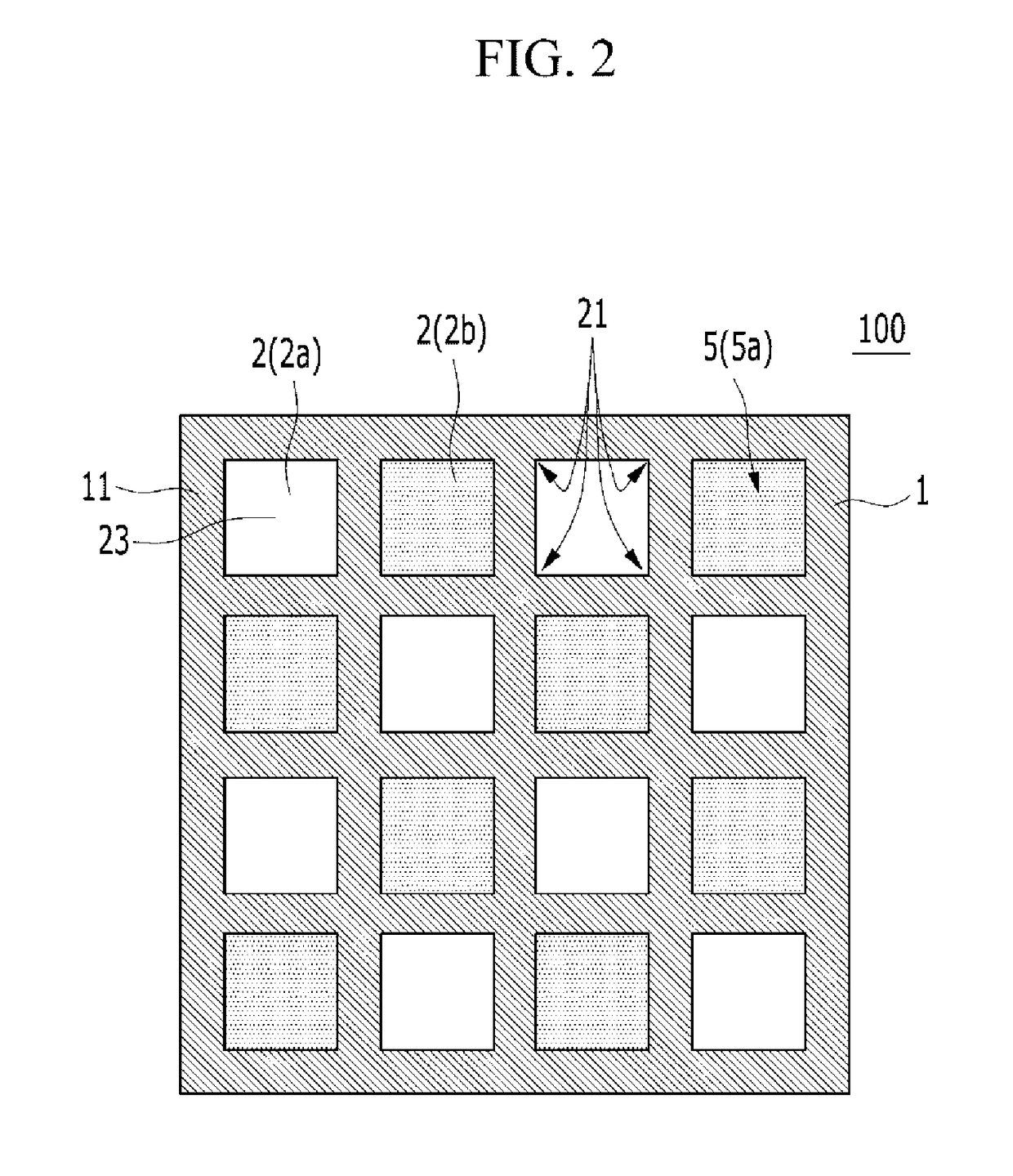

Sealed honeycomb structure and device for cleaning exhaust

ActiveUS20140123611A1Pressure loss increaseImprove seal durabilityDispersed particle filtrationExhaust apparatusHoneycomb structureEngineering

A sealed honeycomb structure which can suppress increase of pressure loss and improve durability favorably is disclosed. A sealed honeycomb structure 100 including includes a honeycomb structure having porous walls dividedly forming inlet cells and outlet cells, an outlet side sealing portion, and an inlet side sealing portion, wherein an opening area of the inlet cell is larger than an opening area of an outlet cell on a cross-section of the honeycomb structure, wherein at least one outlet cell is a reinforced cell where a reinforcing part for reinforcing the outlet cell is formed at at least one corner portion at which the walls on a cross-section vertical to an extending direction of the cell cross each other, and wherein the inlet cell is a non-reinforced cell where the reinforcing part is not formed at all the corner portions at which the walls on the cross-section vertical to the extending direction of the cell cross each other.

Owner:HYUNDAI MOTOR CO LTD +2

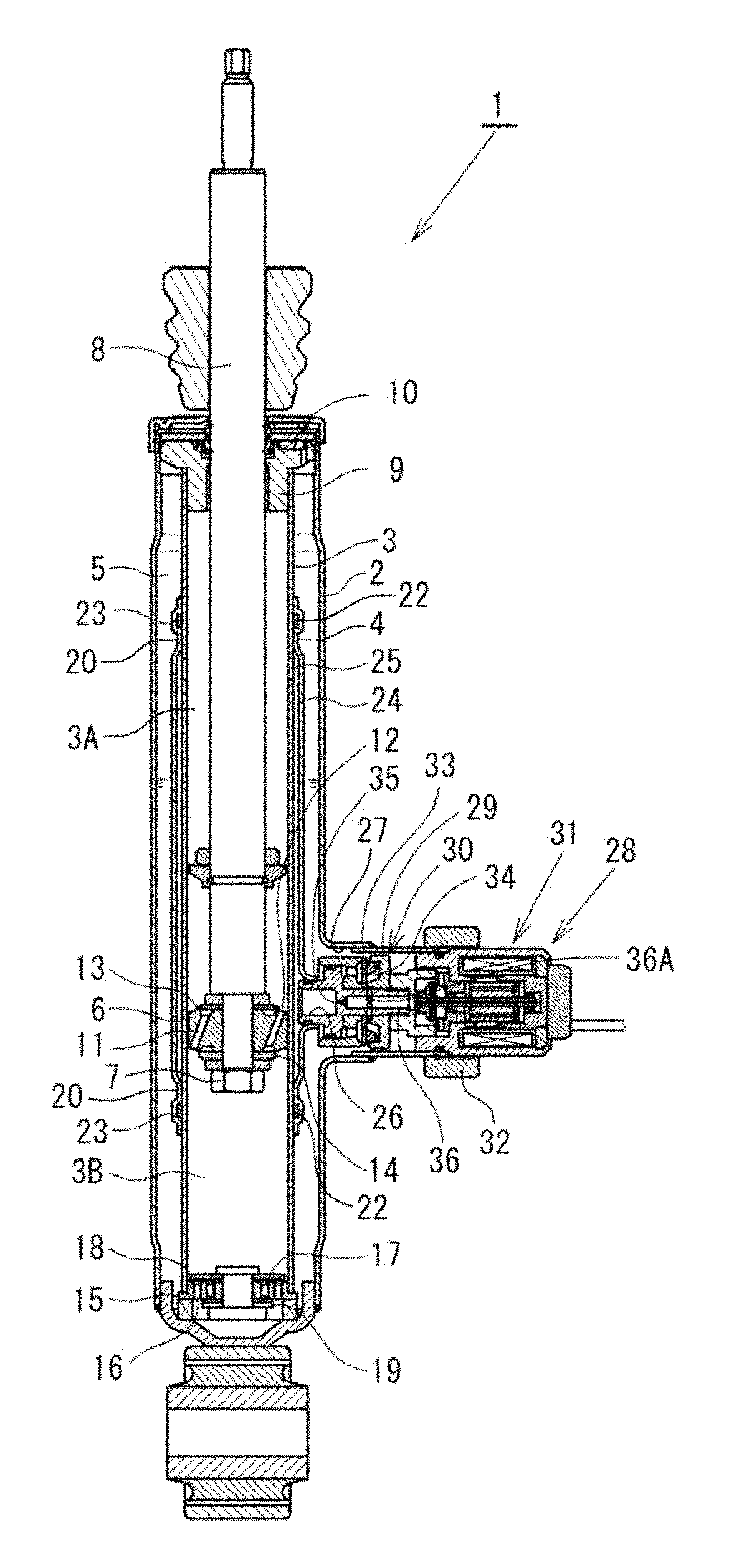

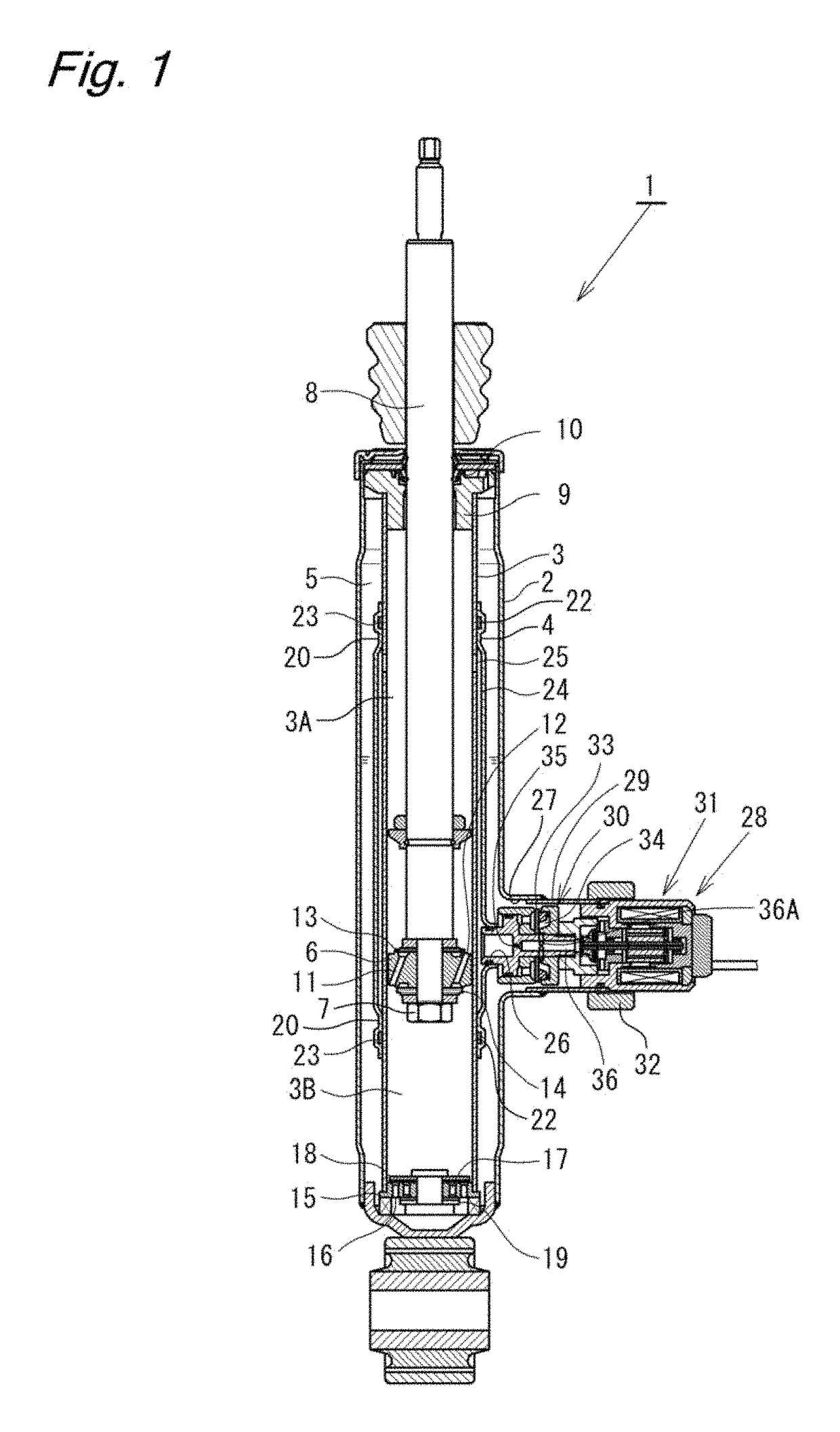

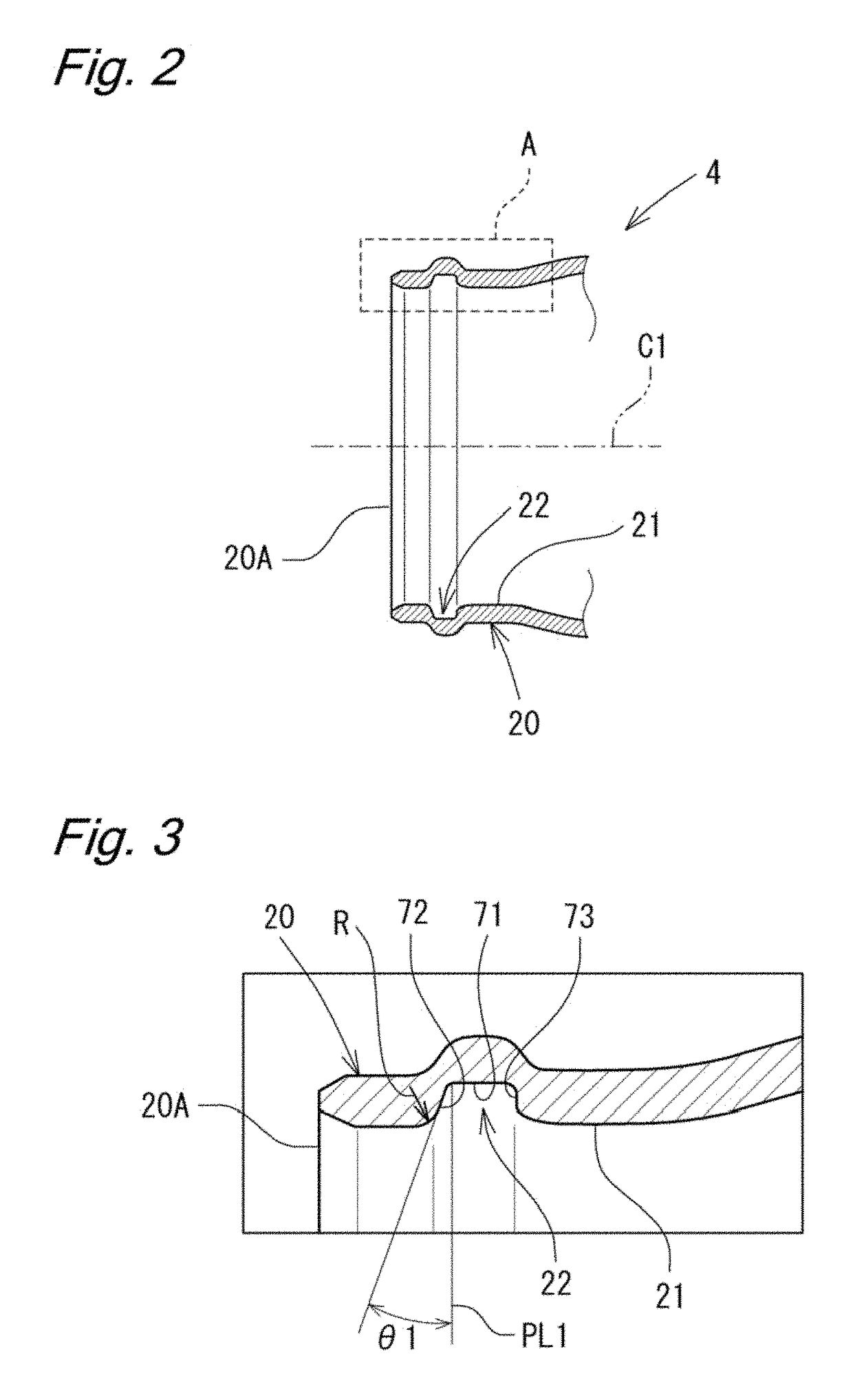

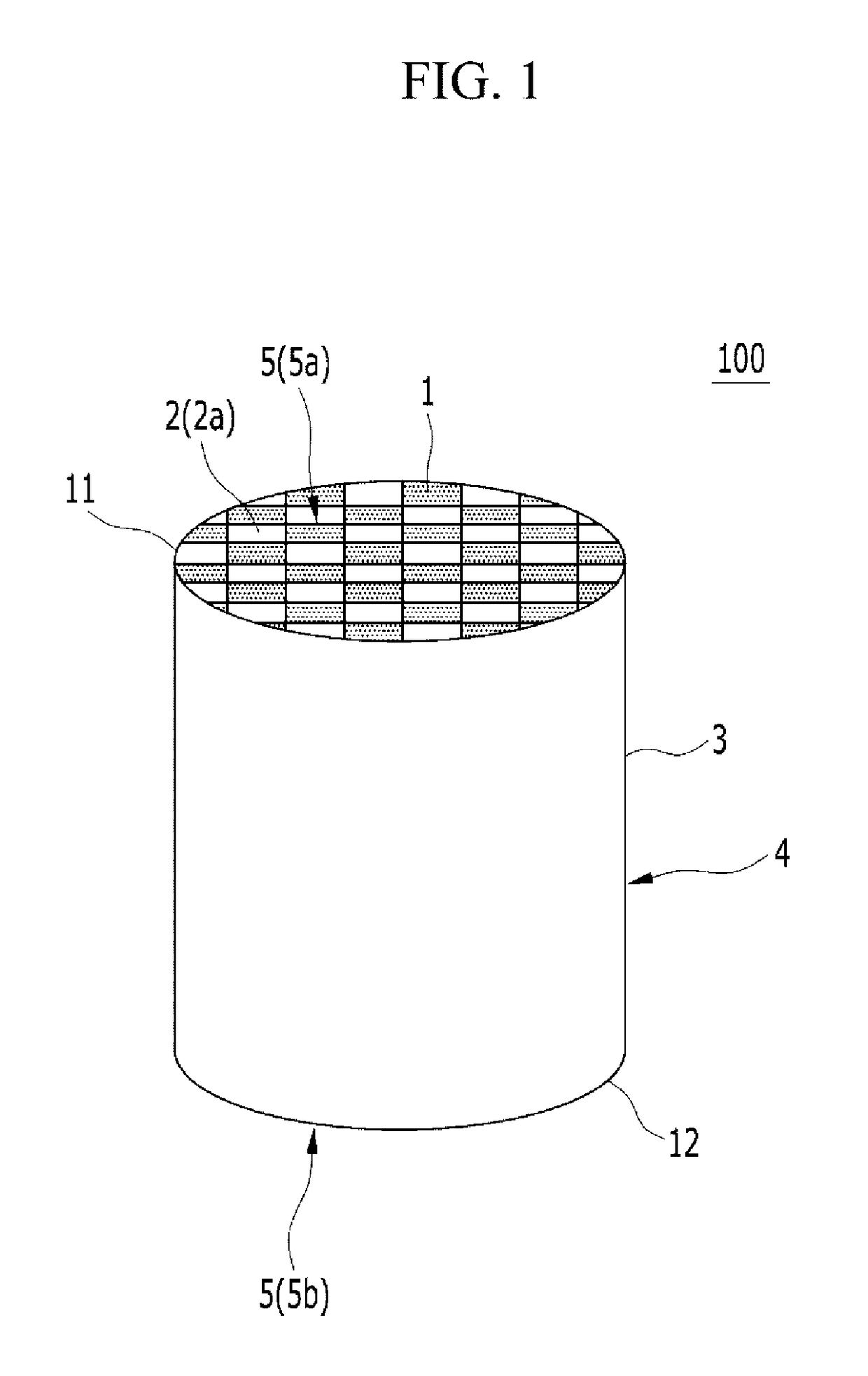

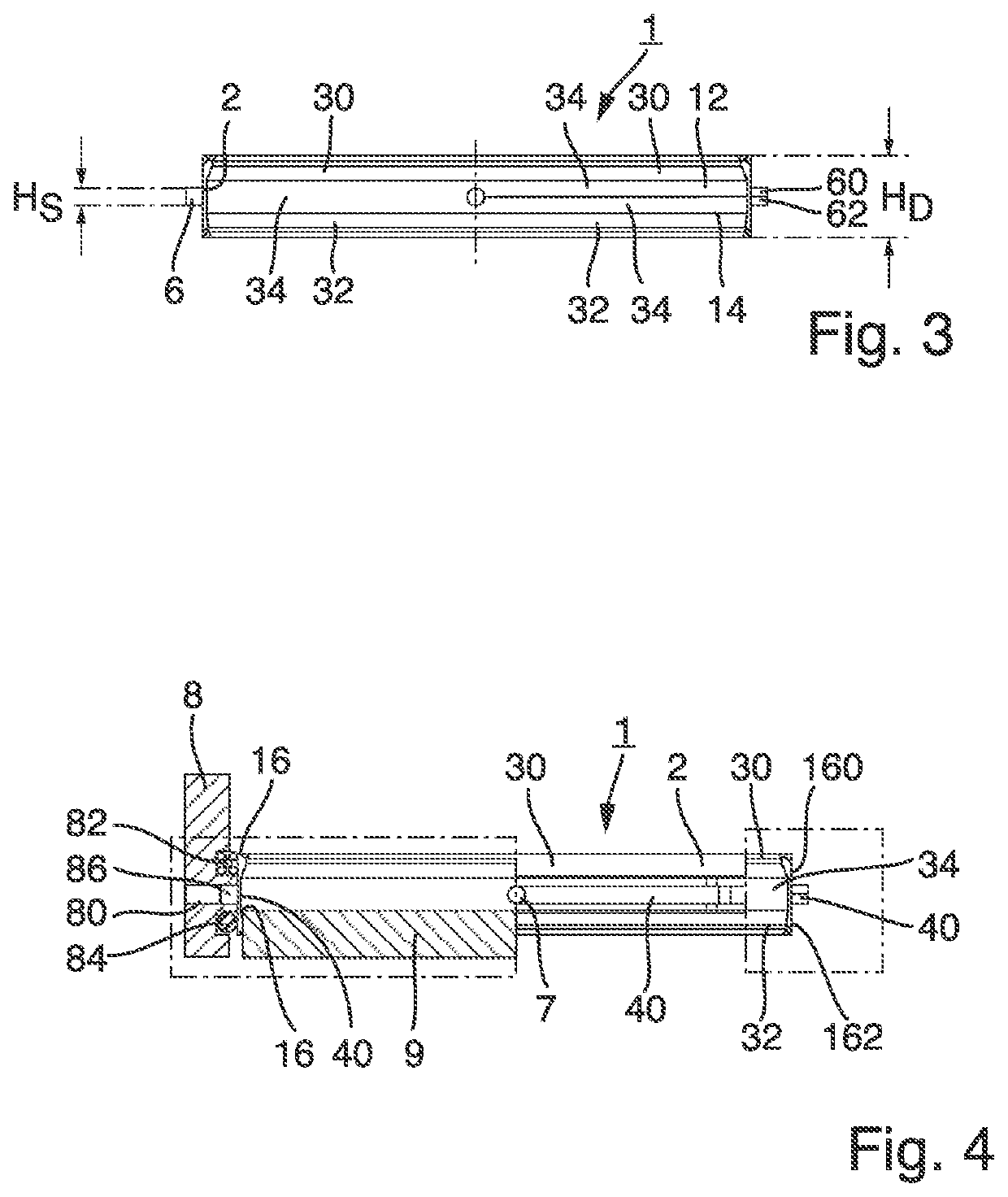

Tube and shock absorber

ActiveUS9707820B2Improved seal durabilityIncreased durabilityEngine sealsSpringsTension stressShock absorber

A tube having sealing ring grooves formed by a sequential rotational process and a shock absorber including the tube, in which durability of a sealing ring fitted in each of the sealing ring grooves is enhanced. An inclination angle (θ1) formed with respect to a plane (PL1) perpendicular to an axis of a separator tube by a side surface of the sealing ring groove, which is located on an opening end side of the separator tube, is set to 8° or more. With this, a maximum tensile stress to be applied to an O-ring can be reduced to be smaller than a maximum tensile stress in a case of using a backup ring. As a result, the durability of the O-ring can be set equivalent to or enhanced to be higher than durability in the case of using the backup ring.

Owner:HITACHI ASTEMO LTD

Integrated fluorine gasket manufactured by injection molding for hydrogen fuel cells

ActiveUS9640807B2Lower Mooney ViscosityIncrease elasticityDomestic sealsCell seperators/membranes/diaphragms/spacersHydrogen fuel cellHydrogen fuel

Disclosed is an integrated fluorine gasket manufactured by injection molding for hydrogen fuel cells. In particular, a fluorine compound having a fluorine content of about 60 to 75 parts by weight based on 100 parts by weight of a fluoroelastomer is disposed in a gasket. The resulting fluorine gasket is integrated with a thin bipolar plate having a thickness of about 200 μm or less to have a thickness of about 750 μm or less by injection molding on the thin bipolar plate and by cross-linking.

Owner:THE CHEMOURS CO FC LLC +2

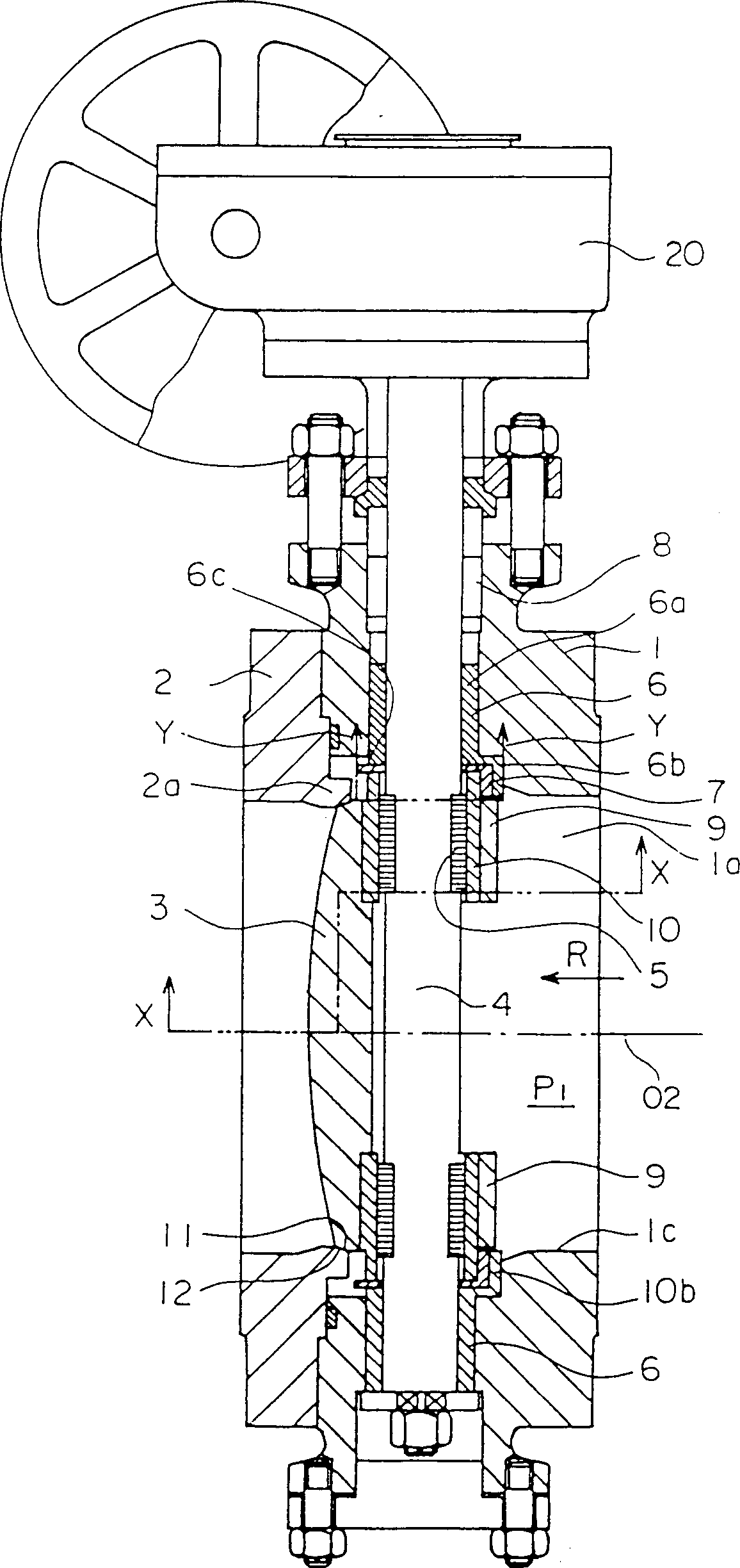

Valve device

InactiveCN1121566CReduce operating forceImproved seal durabilityOperating means/releasing devices for valvesLift valveEngineeringValve seat

PROBLEM TO BE SOLVED: To keep the seal durability of a valve seat without any difficult work of excellent accuracy in machining the valve seat, and to reduce the operation force in opening a valve. SOLUTION: In a this valve device, a disk bush 10 to be integratedly connected to a boss part is arranged between a slide key 5 provided in a rod 4 and a boss part 9 of a valve element 3. A washer 7 is arranged around the disk bush 10, and the disk bush 10 and the washer 7 form a cylindrical assembly when they are closely fitted to each other. A bush 6 having a notch 6c in which the disk bush 10 can be locally projected on a seat ring 2a side is arranged around the washer 7. While the disk bush 10 is projected from the notch, the valve element 3 is moved straight. While the disk bush is retracted from the notch, the cylindrical assembly is turnably supported by the bush 6, and the valve element 3 is turned together with the rod 4.

Owner:OKANO VALVE MFG

Sealed honeycomb structure

ActiveUS9623359B2Volume andLower the volumeCombination devicesDispersed particle filtrationEngineeringMechanical engineering

A sealed honeycomb structure may include porous walls dividedly forming inlet cells and outlet cells extending from an end surface of an inlet side to an end surface of an outlet side, inlet and outlet side sealing portion 5b, and an inlet side sealing portion, wherein at least one outlet cell is a reinforced cell where a reinforcing part 6 for reinforcing the outlet cell 2b is formed at at least one corner portion 21a at which the walls on a cross-section vertical to an extending direction of the cell cross each other, wherein the inlet cell is a non-reinforced cell where the reinforcing part is not formed at all the corner portions at which the walls on the cross-section vertical to the extending direction of the cell cross each other, and wherein the reinforcing parts 6 of the reinforced cells 22 are formed at a section of the honeycomb structure from the end surface of the outlet side in the extending direction of the cell.

Owner:HYUNDAI MOTOR CO LTD +2

Seal body and gas seal mechanism

A seal body that is used for gas seal includes a seal main body in which a recessed groove is formed by arranging a pair of lips so that the lips face each other; an elastic body that is inserted in the recessed groove and expands the lips; and a rigid body that is installed in the elastic body, and restricts deformation of the elastic body, due to narrowing of the recessed groove, within an elastic deformation range.

Owner:TOYOTA JIDOSHA KK

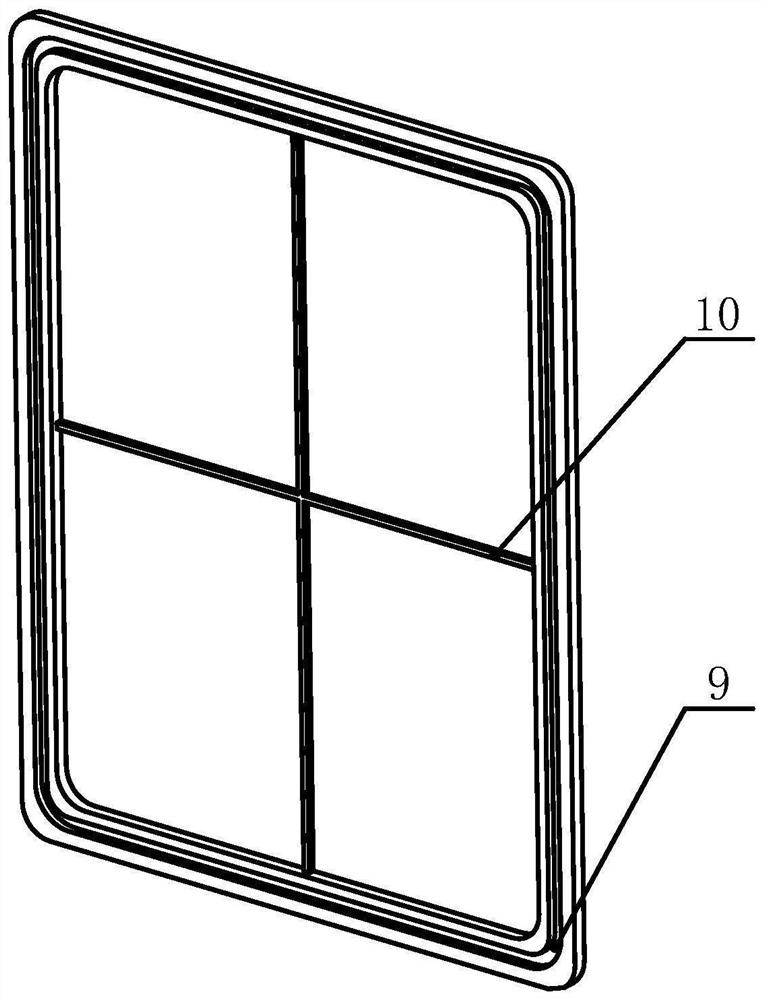

Metal-air fuel cell with self-sealing cathode easy to fix

ActiveCN112382775AImproved seal durabilityEasy to fixFuel and primary cellsSealing/support meansFuel cellsStructural engineering

The invention discloses a metal-air fuel cell with a self-sealing cathode easy to fix. The metal-air fuel cell comprises a battery shell, a metal anode assembly, a cathode, a cathode pressing plate, an anode leading-out piece and a cathode leading-out piece. The battery shell comprises two opposite open type end faces, a first sealing groove is formed in a frame of each open type end face, a firstsealing piece is arranged in each first sealing groove, and a cathode maintaining structure is arranged in each open type end face. The metal anode is inserted into the battery shell through the anode through groove, and the anode base is fixed to the end face of the battery shell. The cathode pressing plate covers the open end surface and is clamped through a buckle, the cathode pressing plate is of a frame structure, a second sealing groove is formed in the outer frame of the cathode pressing plate, a second sealing piece is arranged in the second sealing groove, and the cathode is clampedbetween the first sealing piece and the second sealing piece. And the open end surface is hermetically connected with the cathode through a sealing groove and a sealing piece. The cathode material disclosed by the invention can be simply and quickly fixed, can be used for multiple times, and is durable in sealing.

Owner:TRANSLATIONAL RES CENT SCHOOL OF MECHANICAL & VEHICLE BEIJING INST OF TECH TANGSHAN PORT ECONOMIC DEV ZONE

Bipolar secondary battery and method for producing the same

ActiveUS8852785B2Improved seal durabilityImprove sealingLarge-sized flat cells/batteriesFinal product manufactureEngineeringBattery cell

A bipolar secondary battery has a battery element that includes first and second bipolar electrodes each having a collector disposed with a conductive resin layer containing a first resin as a base material and positive and negative electrode active material layers formed on opposite sides of the collector and a separator containing a second resin as a base material, arranged between the first and second bipolar electrodes and retaining an electrolyte material to form an electrolyte layer. The positive electrode active material layer of the first bipolar electrode, the electrolyte layer and the negative electrode active material layer of the second bipolar electrode constitute a unit cell. A melting point of the first resin is lower than or equal to a melting point of the second resin. Outer peripheries of the collectors of the first and second bipolar electrodes and an outer periphery of the separator are fused together to thereby seal an outer peripheral portion of the unit cell.

Owner:NISSAN MOTOR CO LTD

Weather strip and production method for the same

InactiveUS20110277388A1Improved seal durabilitySuppressing troubleEngine sealsDoors/windowsPolymer scienceShell molding

A method for producing a weather strip, includes an extrusion step for extruding a non-vulcanized and non-foamed rubber into a predetermined shape, a coating step for coating a treatment liquid containing a simple sulfur, a sulfur compound, or both of the simple sulfur and the sulfur compound on an outer surface of a sealing part of a non-vulcanized and non-foamed intermediate molded body that is molded by the extrusion step, and a vulcanizing and foaming step for forming a skin layer in a non-foamed state by heating and vulcanizing a surface of the treatment liquid, and forming a sponge layer by vulcanizing and foaming the non-vulcanized and non-foamed rubber that is internal from the skin layer by passing the intermediate molded body on which the treatment liquid has been coated during the coating step through a heating zone, the steps being performed when molding the extruded part.

Owner:TOYODA GOSEI CO LTD +1

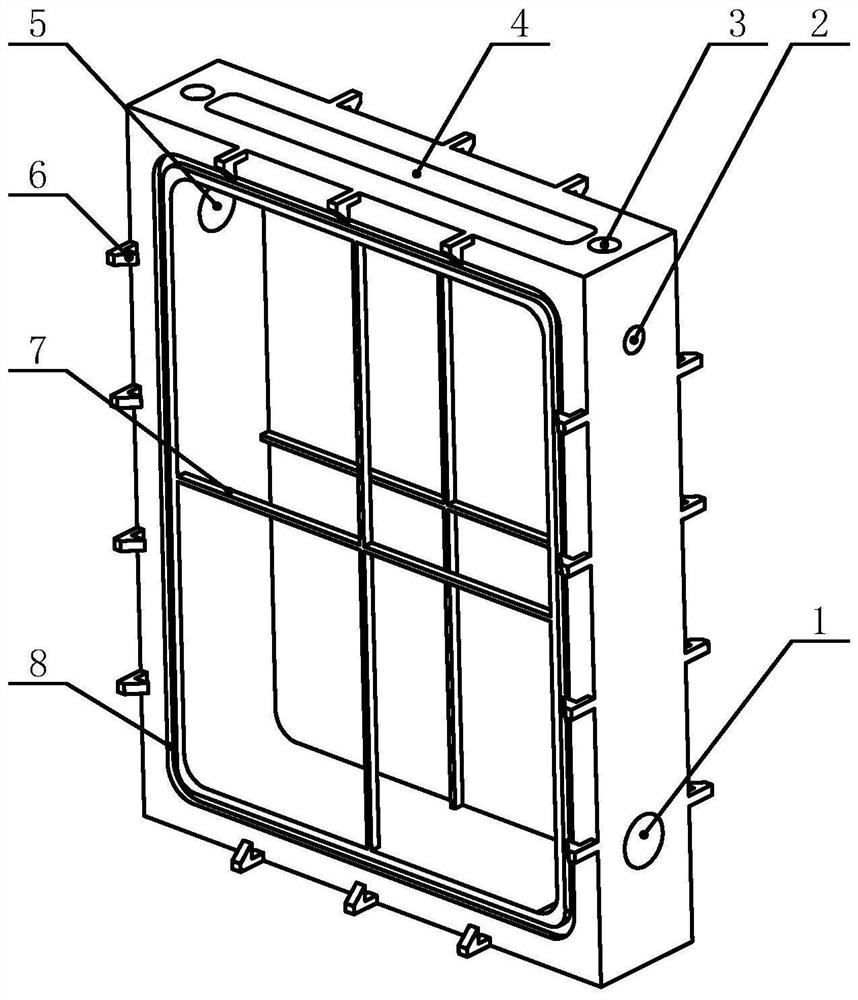

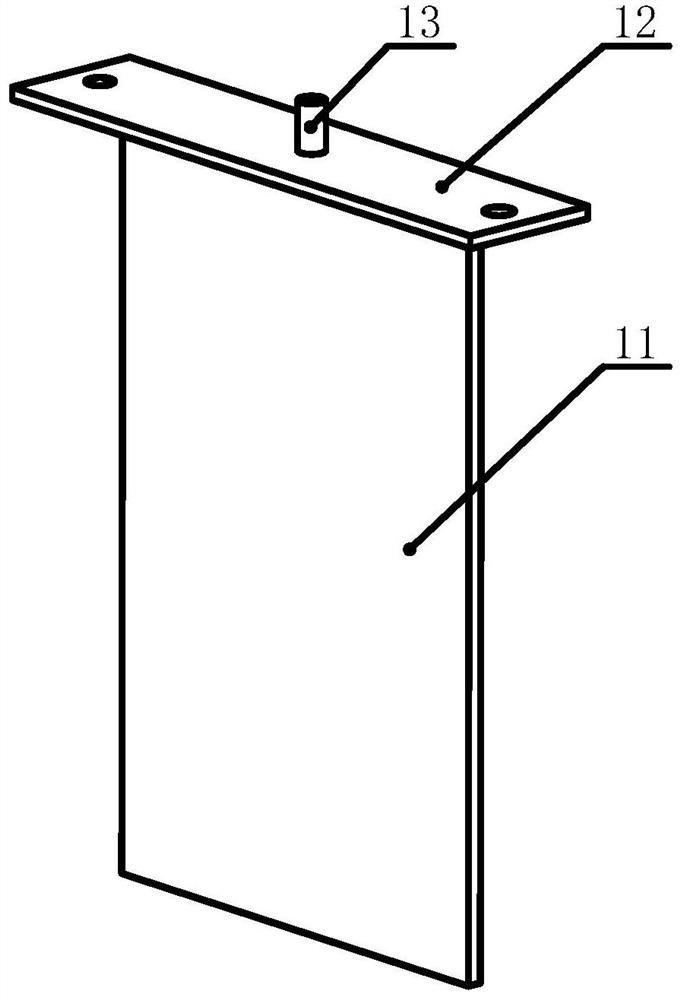

Vertical plate gravity sealer used for air pre-heater of thermal power station

InactiveCN105889520AReduce power consumptionImprove dynamic response characteristicsEngine sealsCombustion processAir preheaterHeat resistance

A vertical plate gravity sealer used for an air pre-heater of a thermal power station belongs to the field of thermal power generation technology. The vertical plate gravity sealer used for the air pre-heater of the thermal power station is composed of a sealing plate (1), two shaft seats (2), two swinging shafts (3) and a connecting seat (4). Shaft holes are formed in the two longitudinal ends of the connecting seat (4) and the swinging shafts (3) are mounted in the shaft holes. The swinging shafts (3) penetrate outwards the shaft seats (2). Two holes are formed in each shaft seat (2) and each shaft seat (2) is connected with the sealing plate (1) through the two holes. A lubricant cavity is located between each swinging shaft (3) and each shaft seat (2). The lubricant cavities are filled with heat resistance lubricant. The connecting seat (4) is mounted on a rotor of the air pre-heater. The sealing plate (1) droops by self-weight and attaches to a sector plate of the air pre-heater to form attached sealing. The sealer is good in sealing stability and sealing durability, flexible to swing, small in friction resistance, low in power loss, simple in structure, convenient for installation and maintenance.

Owner:吴天顺

Sealed honeycomb structure and device for cleaning exhaust

ActiveUS9358487B2Volume andLower the volumeCombination devicesDispersed particle filtrationEngineeringHoneycomb structure

A sealed honeycomb structure which can suppress increase of pressure loss and improve durability favorably is disclosed. A sealed honeycomb structure 100 including includes a honeycomb structure having porous walls dividedly forming inlet cells and outlet cells, an outlet side sealing portion, and an inlet side sealing portion, wherein an opening area of the inlet cell is larger than an opening area of an outlet cell on a cross-section of the honeycomb structure, wherein at least one outlet cell is a reinforced cell where a reinforcing part for reinforcing the outlet cell is formed at at least one corner portion at which the walls on a cross-section vertical to an extending direction of the cell cross each other, and wherein the inlet cell is a non-reinforced cell where the reinforcing part is not formed at all the corner portions at which the walls on the cross-section vertical to the extending direction of the cell cross each other.

Owner:HYUNDAI MOTOR CO LTD +2

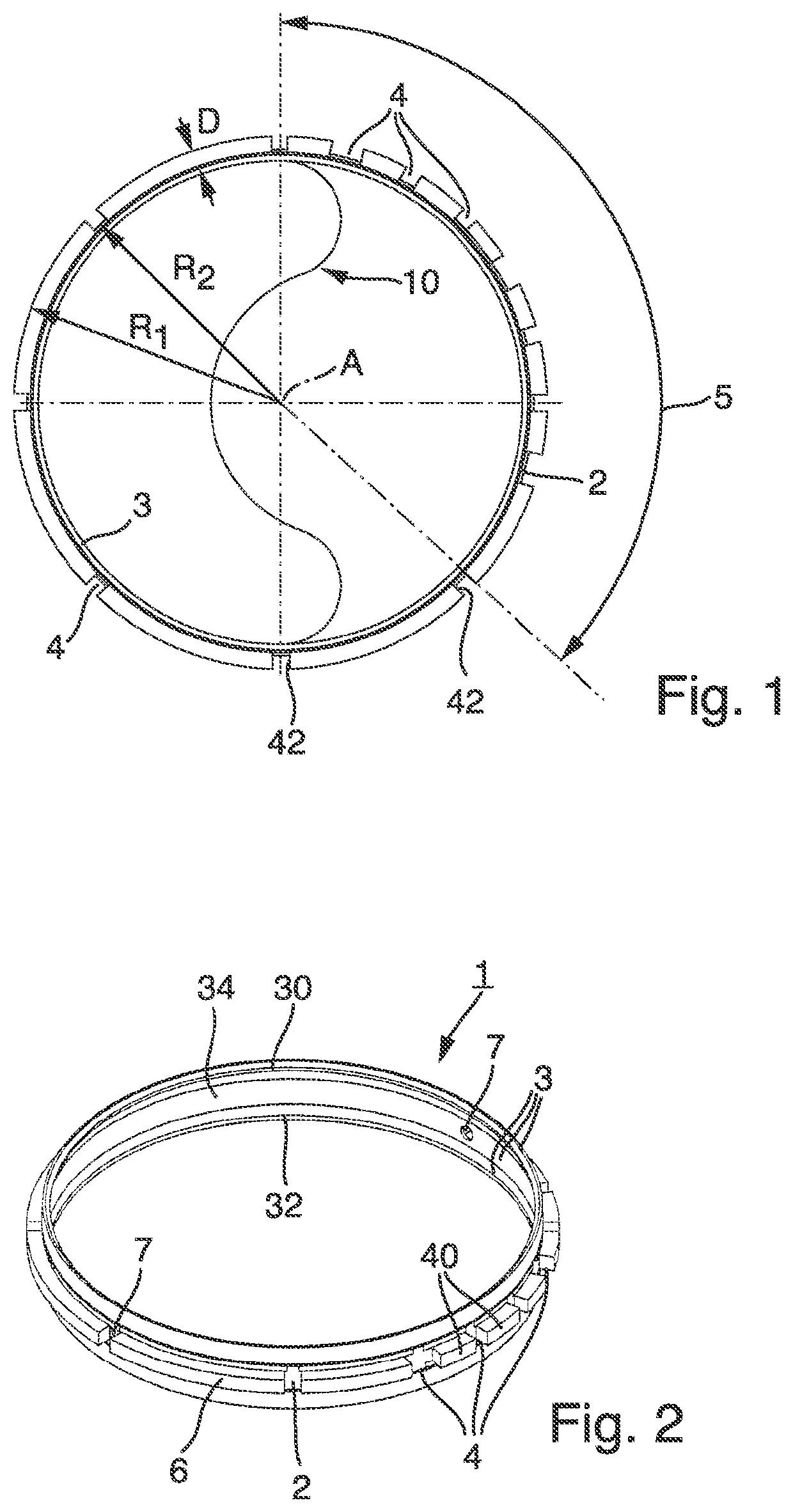

Sealing ring

A sealing ring for sealing a second component, which rotates in relation to a first component, for example for sealing a distribution channel of a rotary media distributor in a beverage filling system is described. The sealing ring includes an annular seal main body to be accommodated on the first component and a wear profiled element arranged radially within the seal main body for contacting the second component in a sealing manner, wherein the seal main body has at least one region of reduced radius in order to enable deformation of the seal main body as the seal main body is assembled with the first component.

Owner:KRONES AG

Adjustable foot pedal, linkage, and method for actuating a hydraulic cylinder

ActiveUS8991281B2Enhanced advantageLift heavier loadsControlling membersVehicle with pivoted armsHydraulic cylinderMechanical engineering

Owner:BOSCH AUTOMOTIVE SERVICE SOLUTIONS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com