Patents

Literature

34results about How to "Suppresses generation of dust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

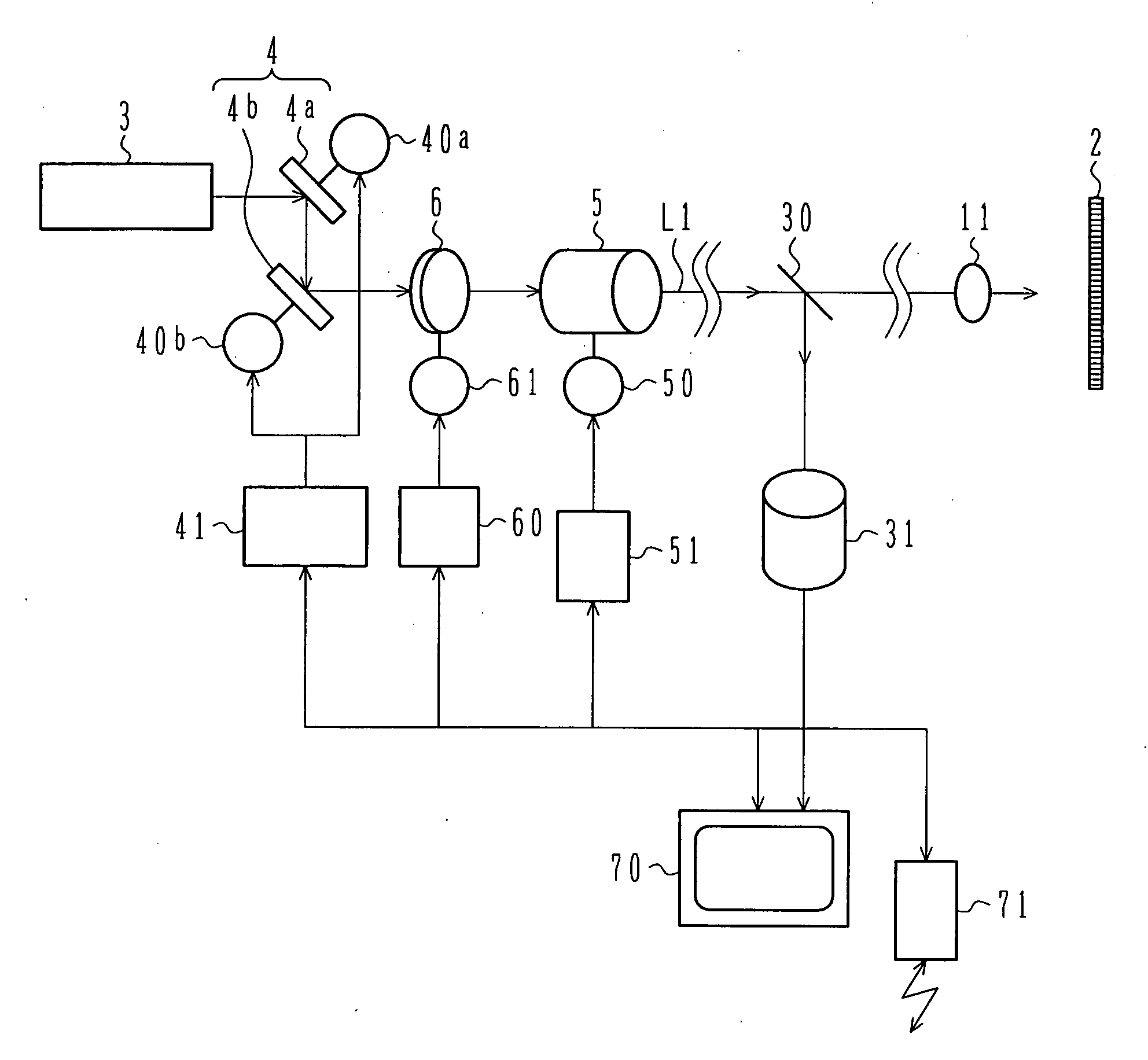

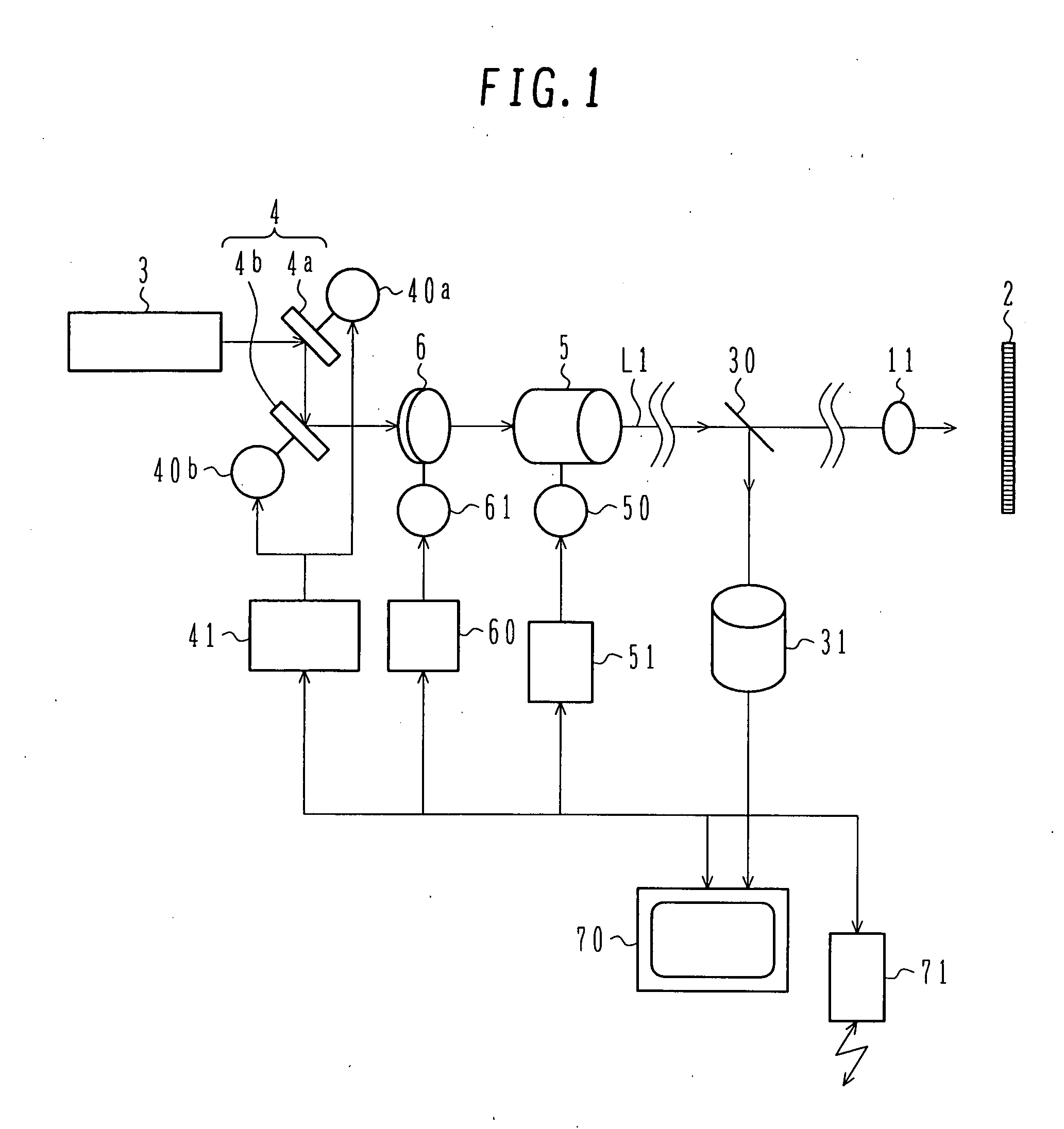

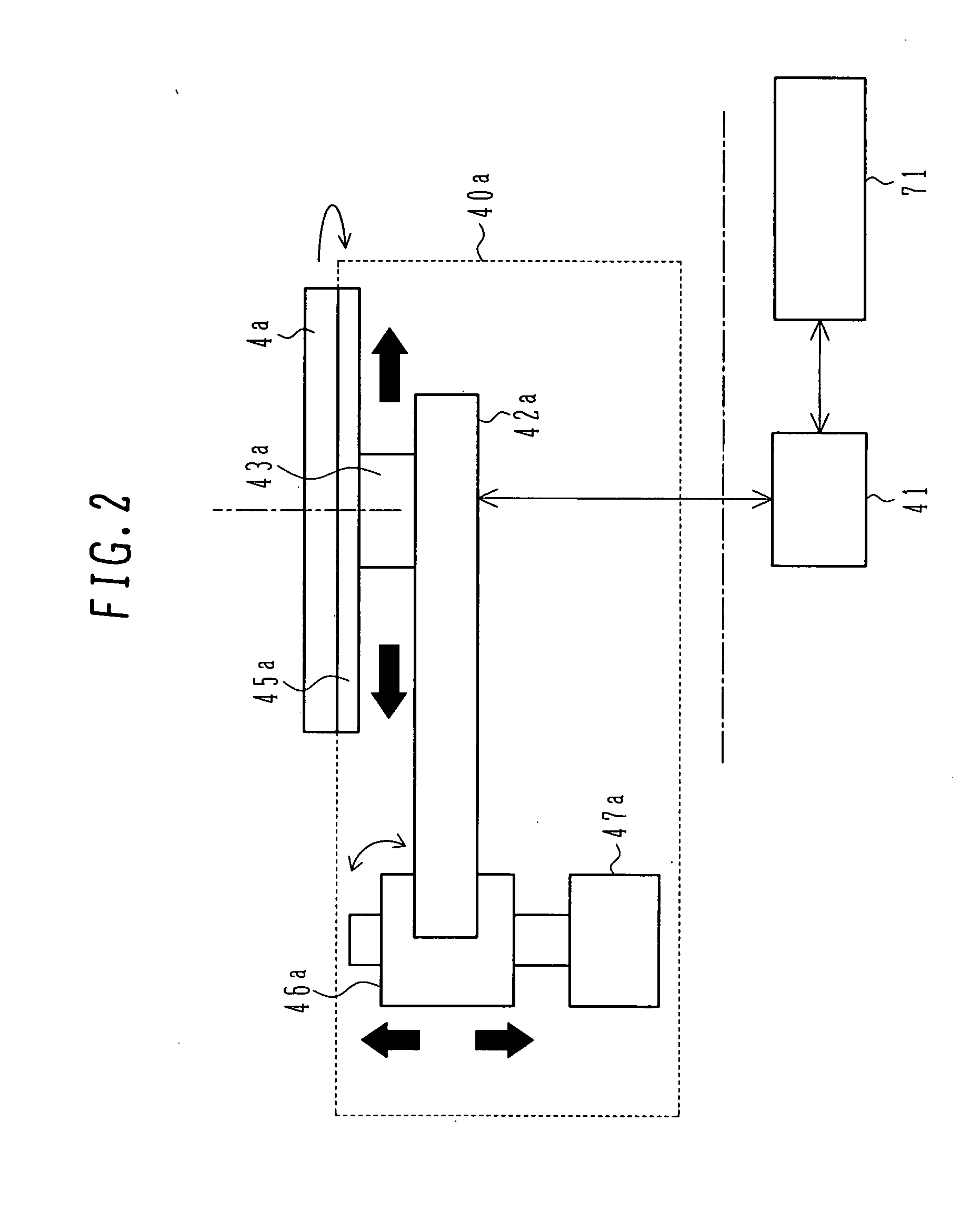

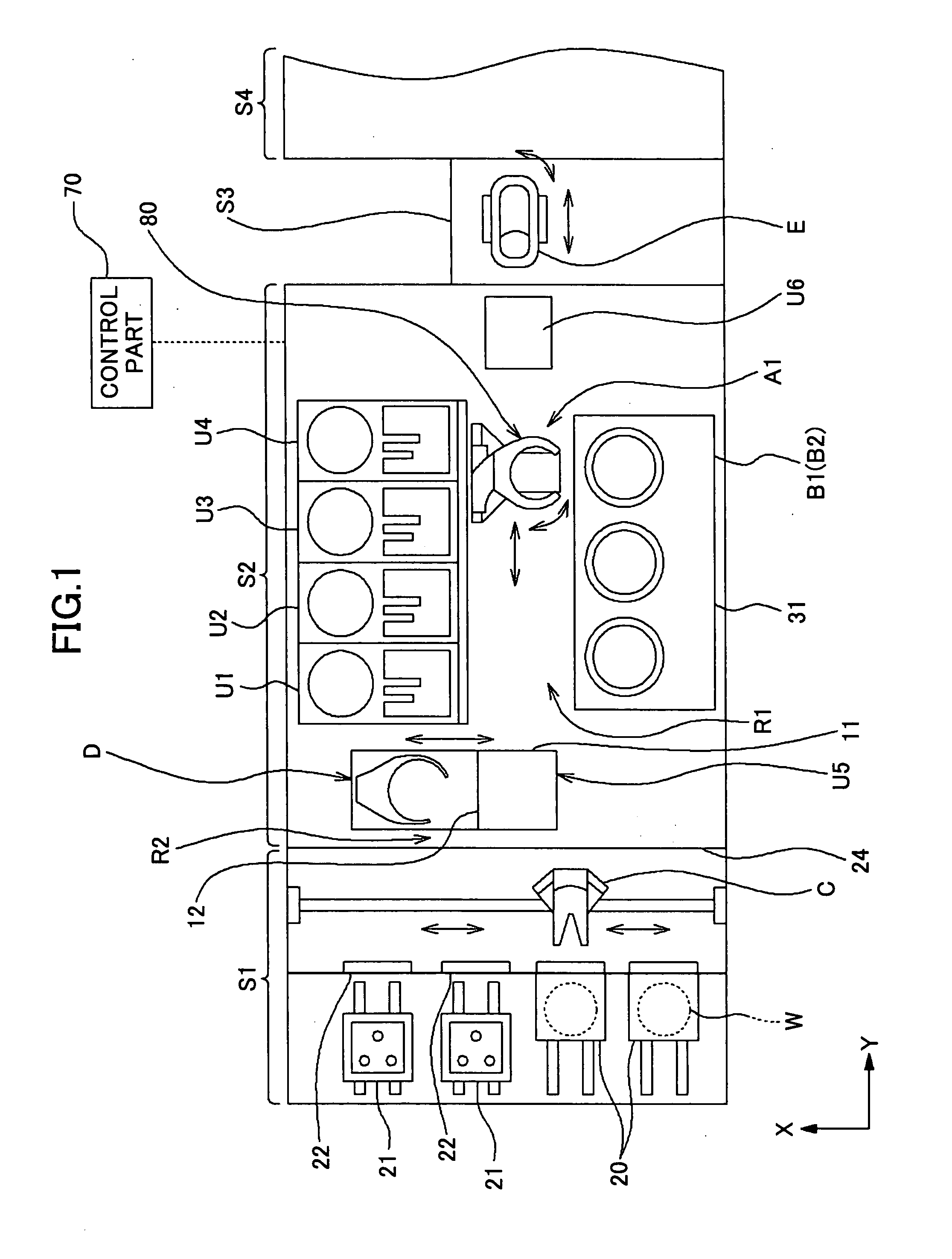

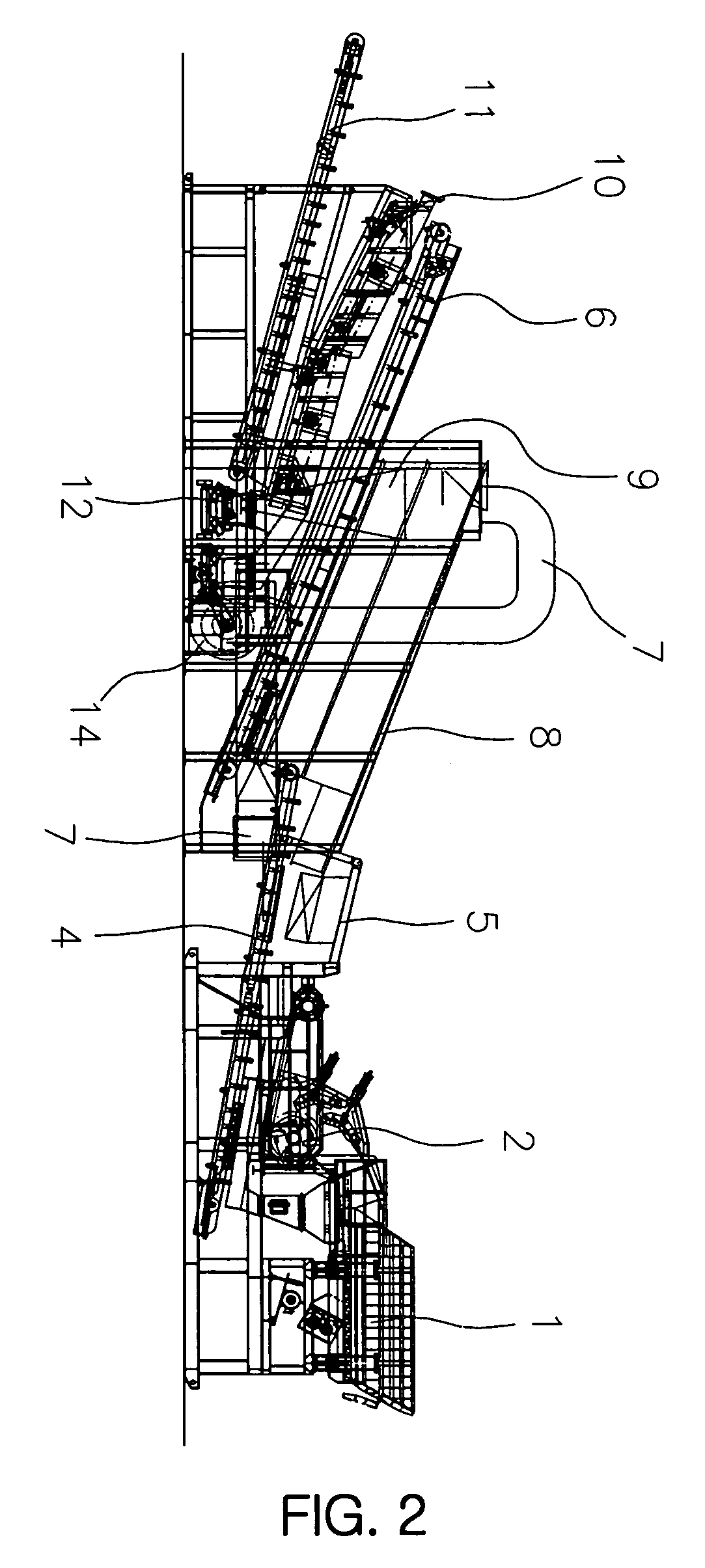

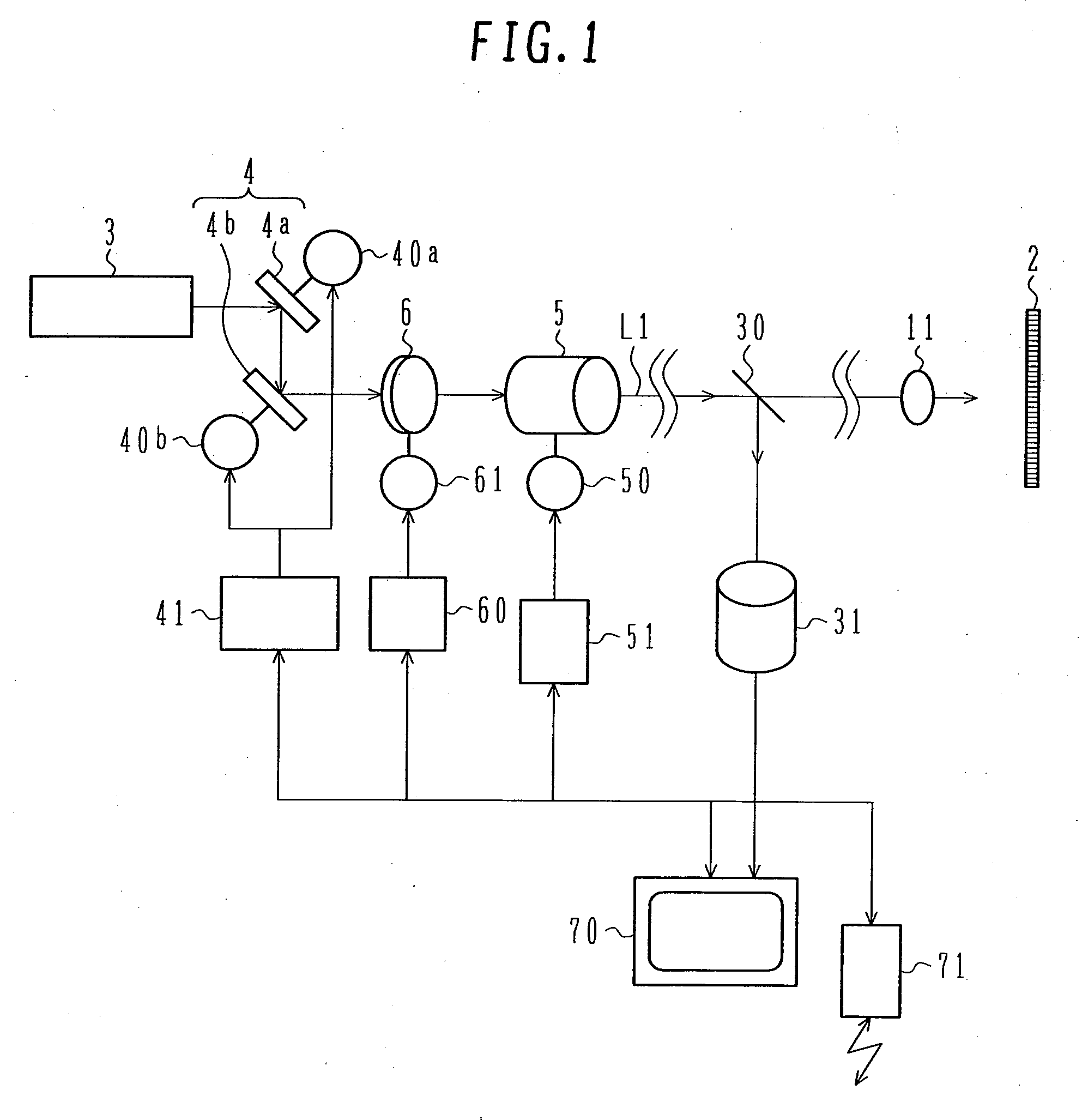

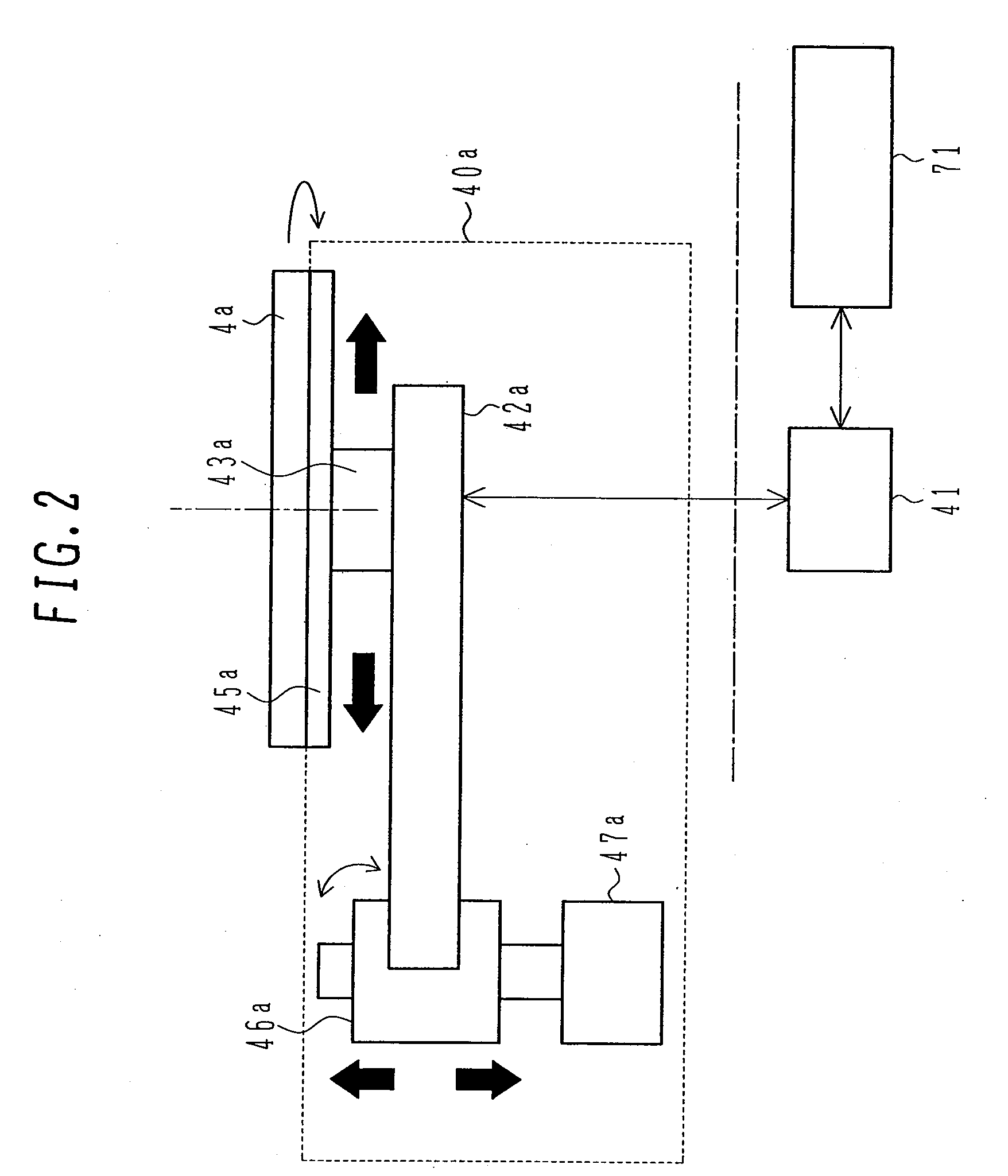

Optical defect inspection apparatus

InactiveUS20070211241A1Reduce frequencyExtended service lifeSemiconductor/solid-state device testing/measurementOptically investigating flaws/contaminationBeam expanderIlluminance

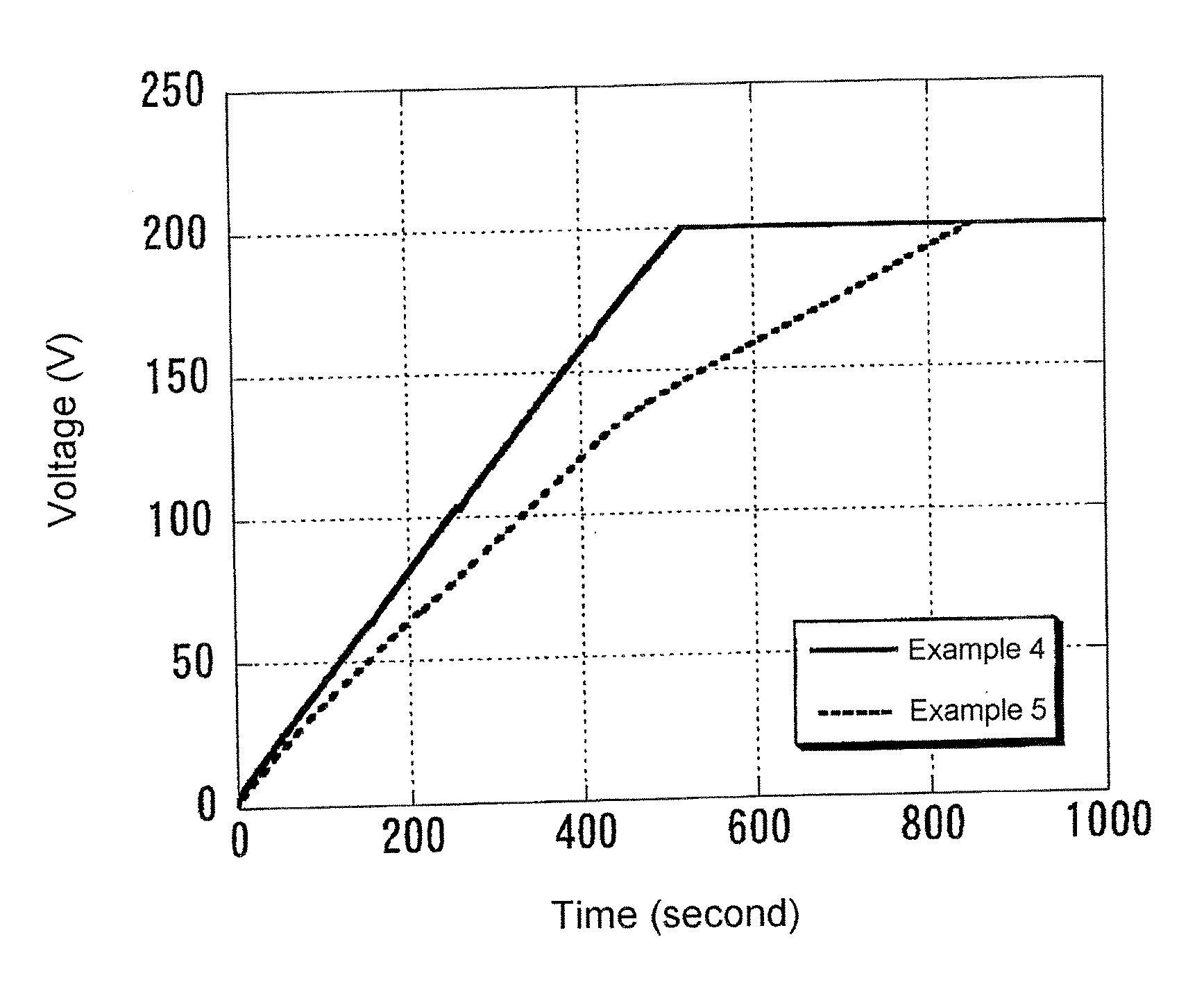

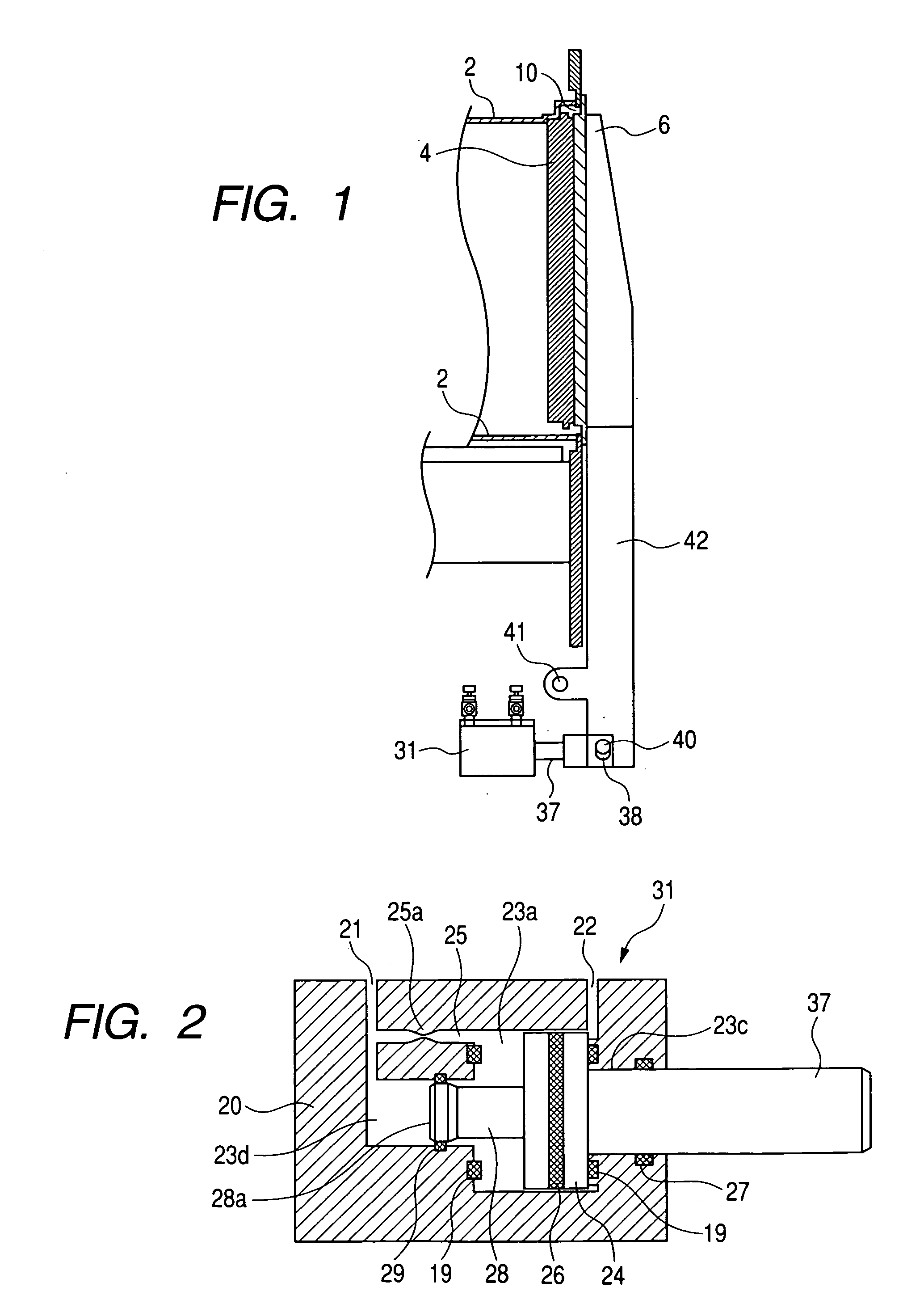

A laser beam oscillated from a laser source is folded in its path by first and second plane mirrors and enters a beam expander. The surface of each plane mirror is deteriorated with illumination by the laser beam and the reflectance is reduced. To avoid a light quantity of the laser beam entering the beam expander from being reduced below a reference value, when the laser beam is illuminated over a certain time, a position on each of the first and second plane mirrors at which the laser beam is illuminated is changed by a structure for rotating and / or translating a reflecting surface of each plane mirror on a plane, which includes the plane mirror, while an optical axis is kept same. The useful life of each plane mirror can be prolonged without displacing the optical axis itself by overcoming the problem that when the laser beam is employed as the light source and a thin beam with a high illumination density is illuminated to the same position on each of the first and second plane mirrors for a long time, the surface of the plane mirror is deteriorated, the reflectance is reduced, and the light quantity cannot be held at a required level.

Owner:HITACHI HIGH-TECH CORP

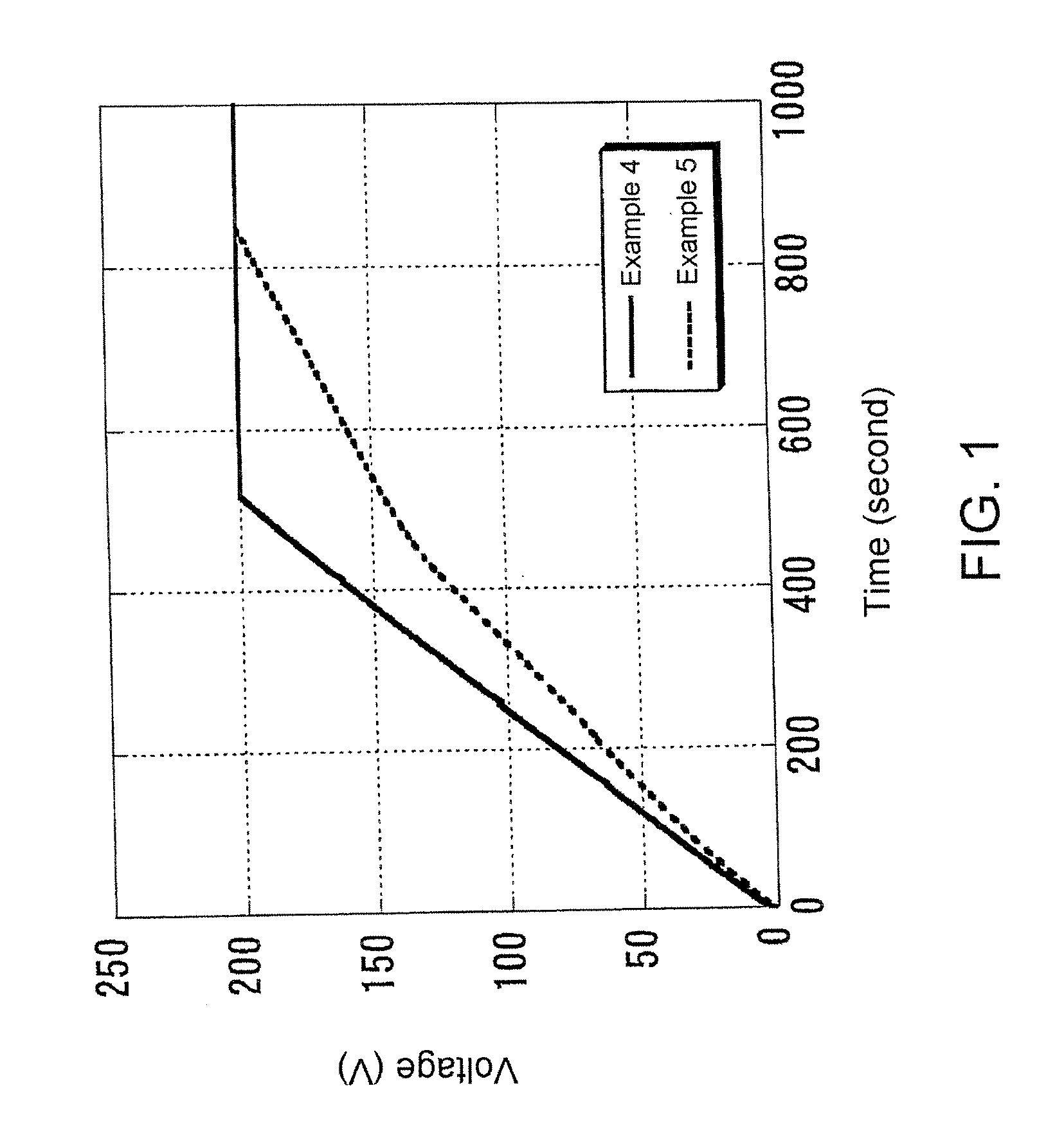

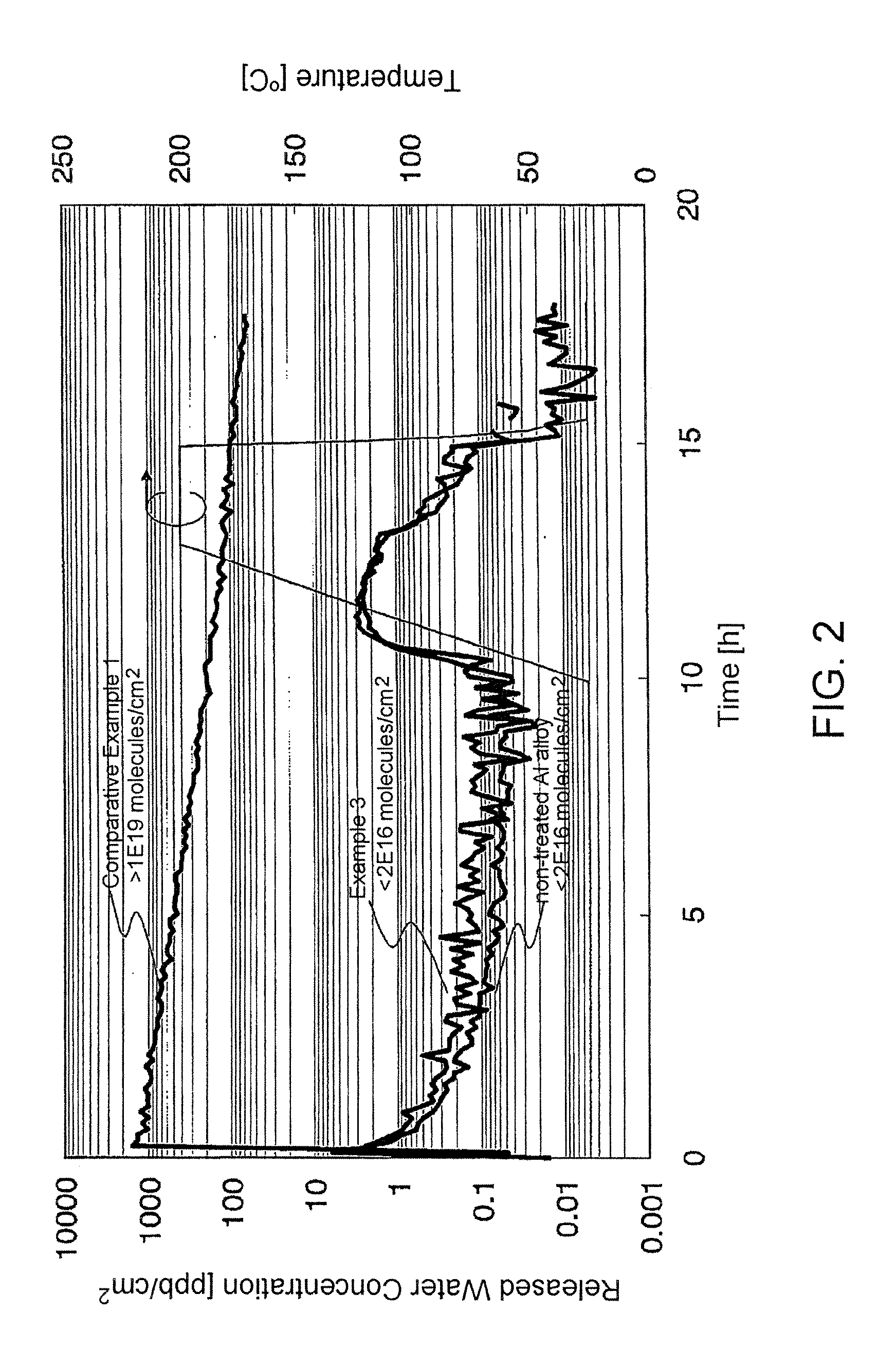

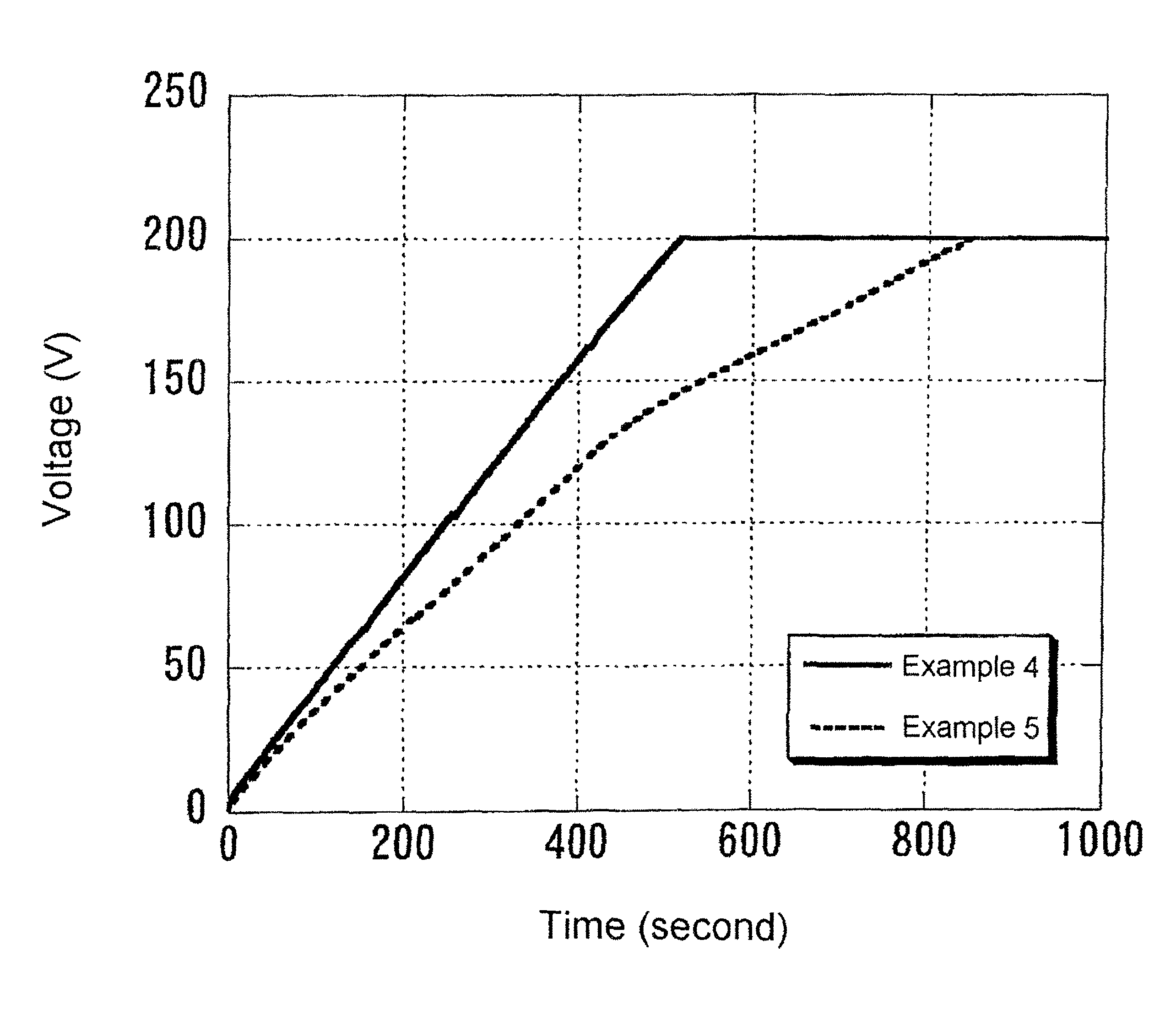

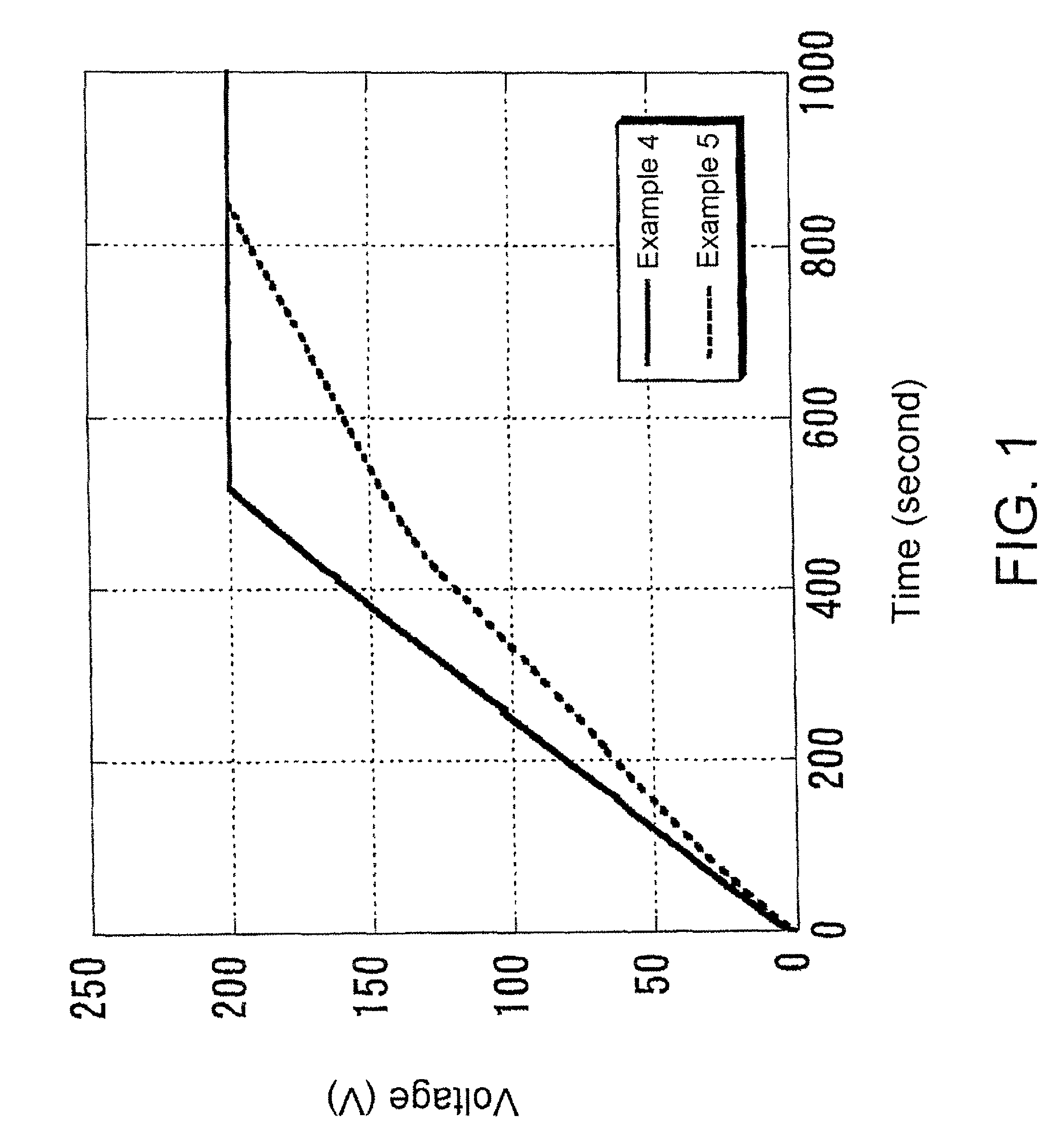

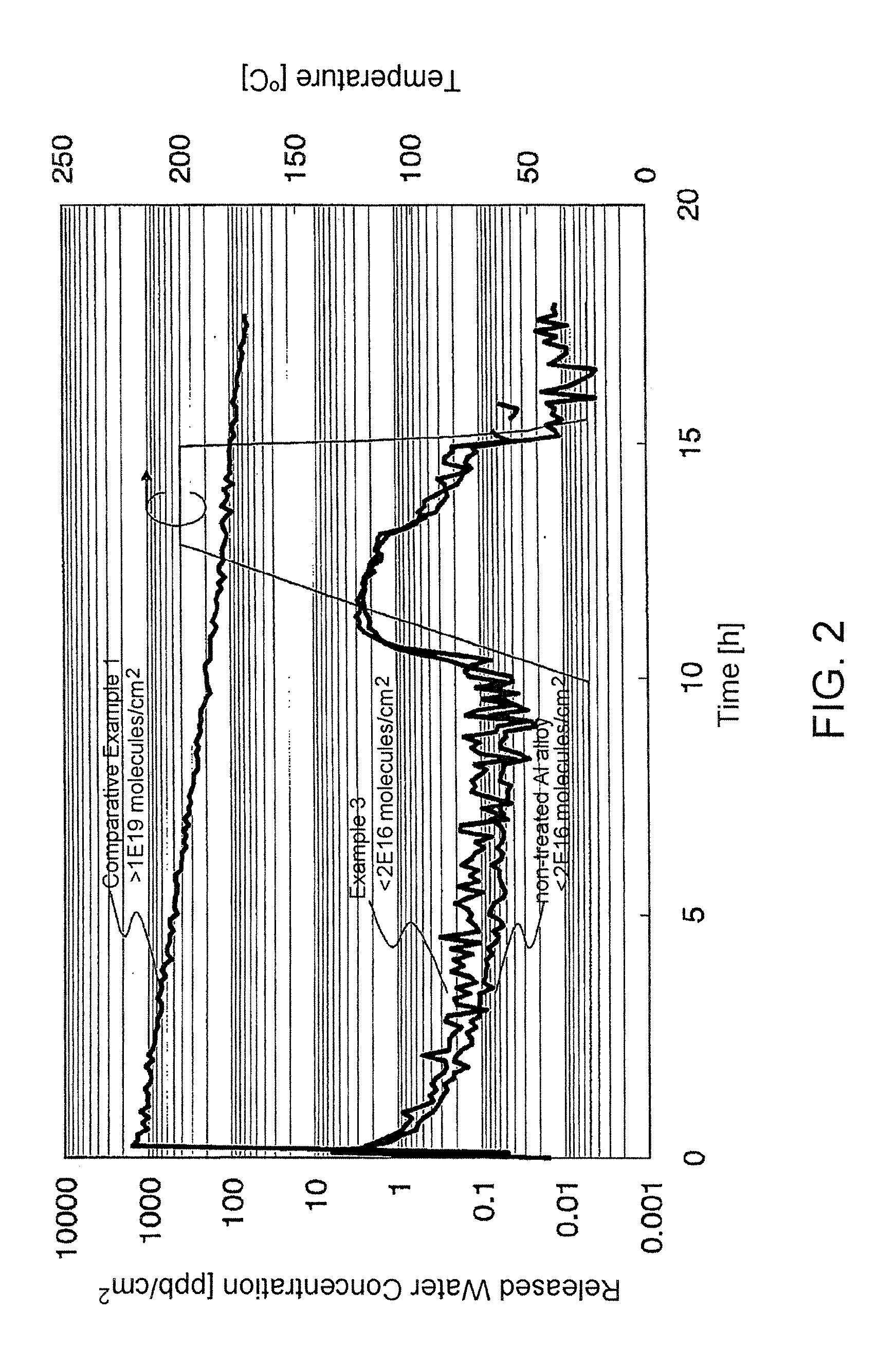

Metal oxide film, laminate, metal member and process for producing the same

InactiveUS20090038946A1Improve corrosion resistanceImprove the immunityAnodisationSynthetic resin layered productsChemical solutionMoisture

A metal oxide film suitable for protection of metals, composed mainly of aluminum. A metal oxide film includes a film of an oxide of a metal composed mainly of aluminum, having a thickness of 10 nm or greater, and exhibiting a moisture release rate from the film of 1E18 mol. / cm2 or less. Further, there is provided a process for producing a metal oxide film, wherein a metal composed mainly of aluminum is subjected to anodic oxidation in a chemical solution of 4 to 10 pH value so as to obtain a metal oxide film.

Owner:TOHOKU UNIV +1

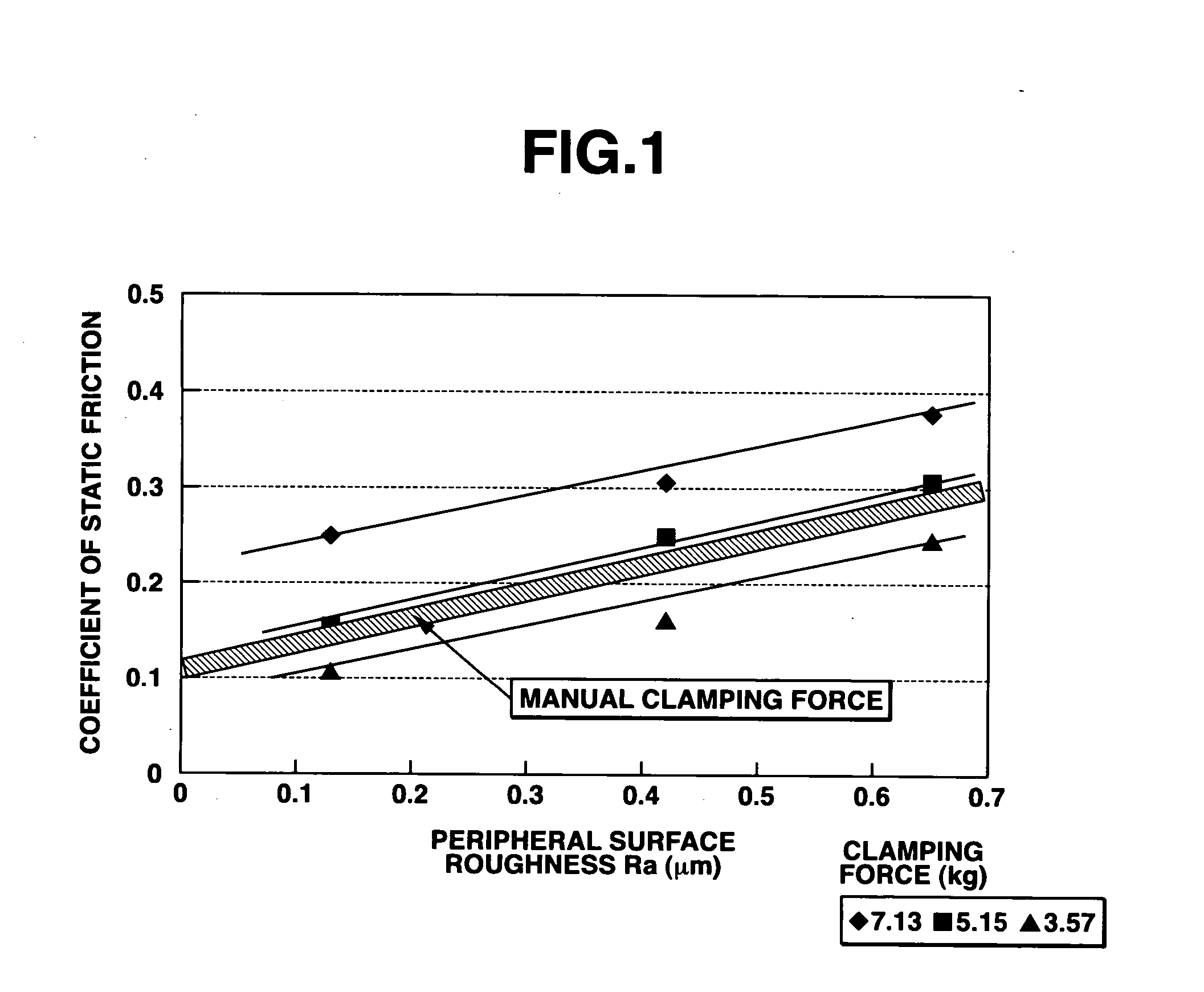

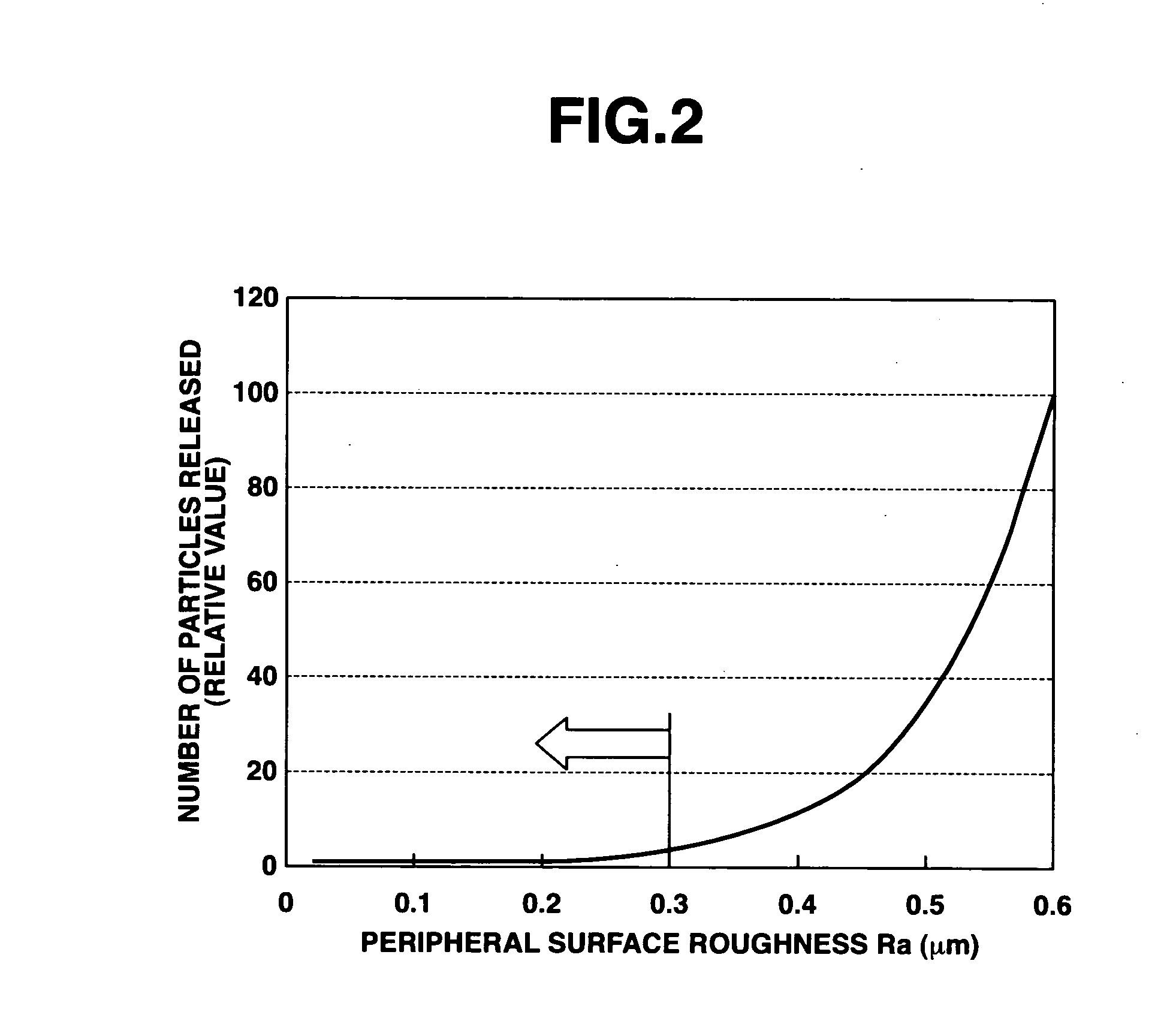

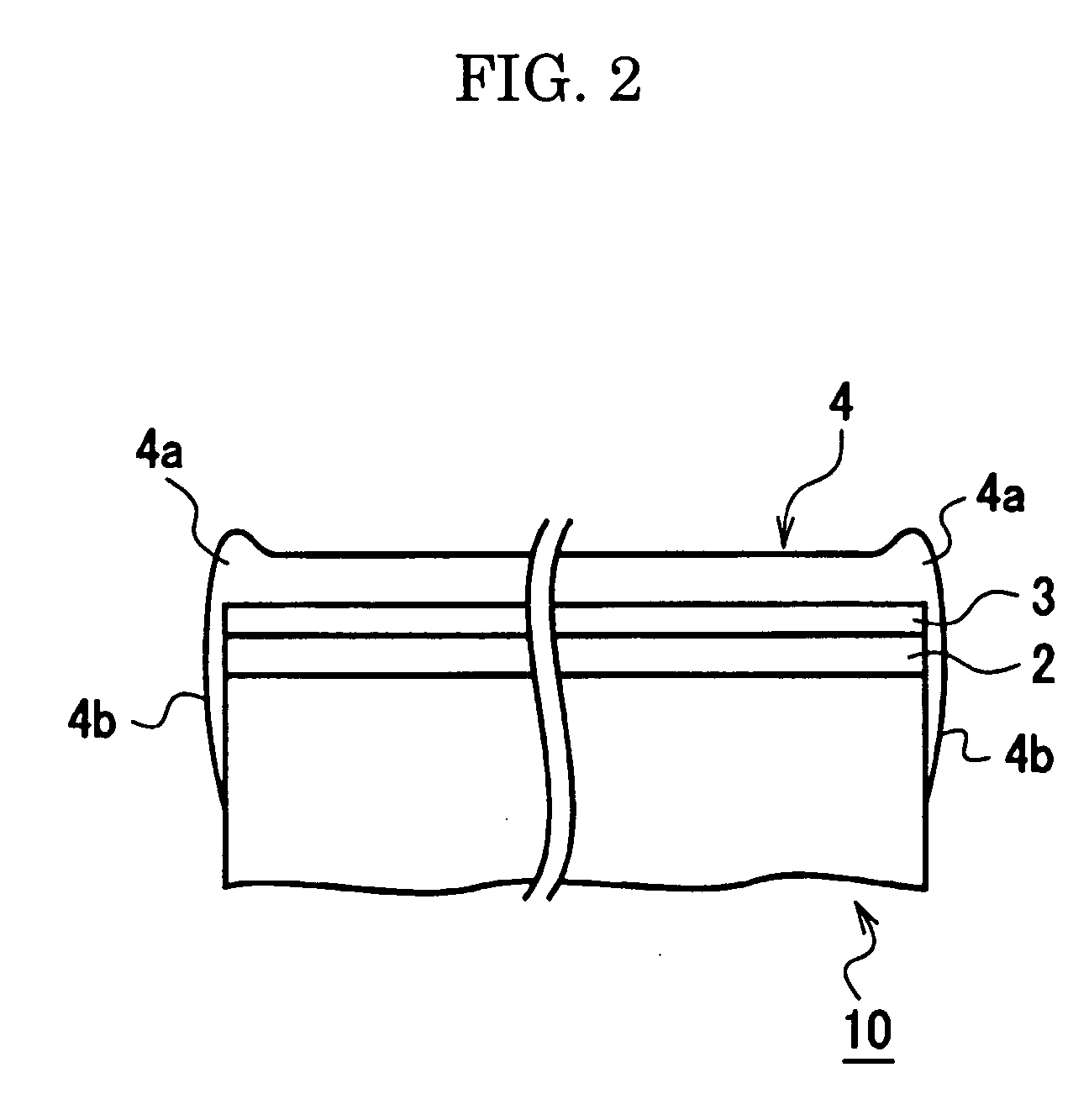

Large-size substrate

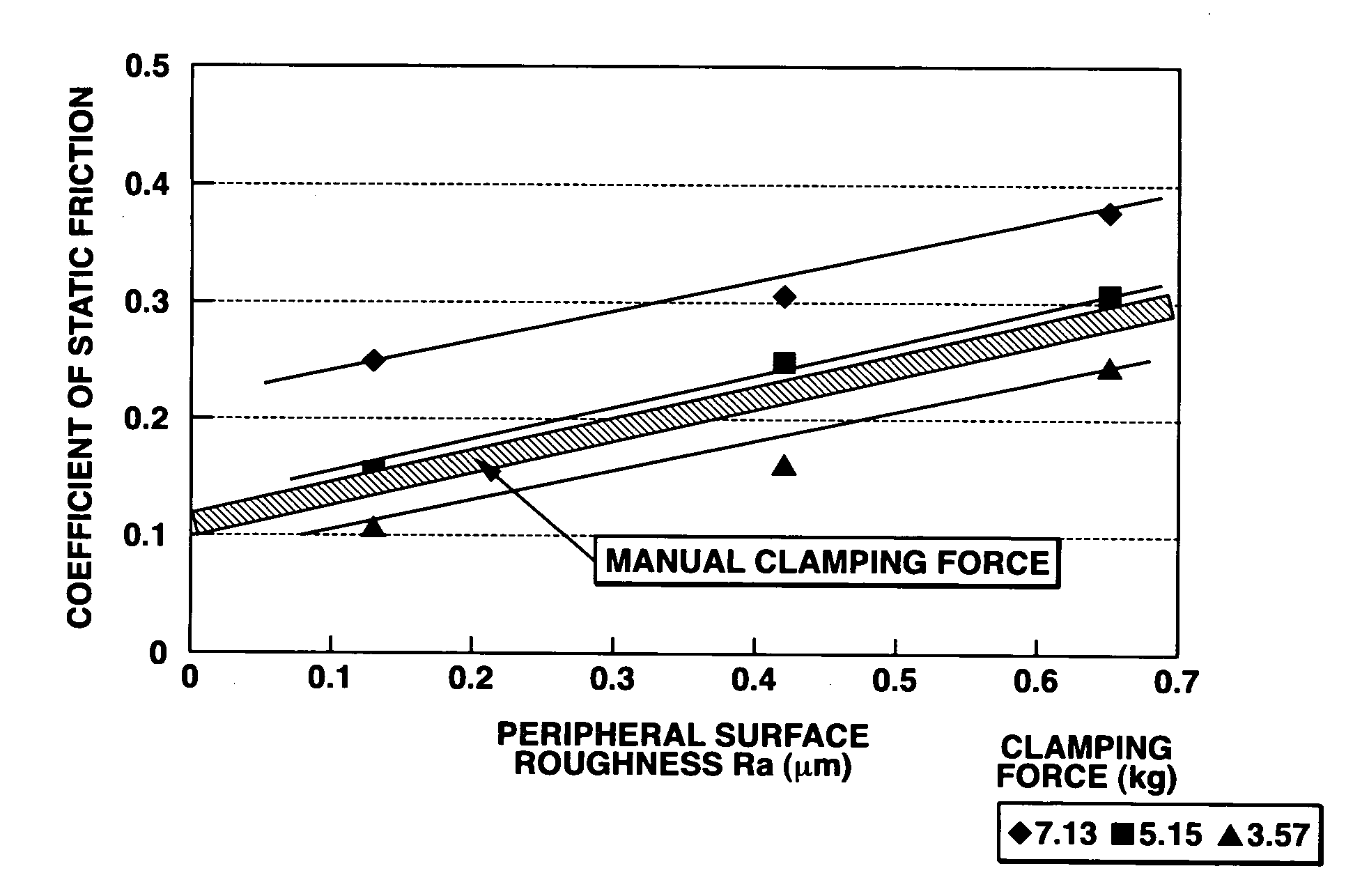

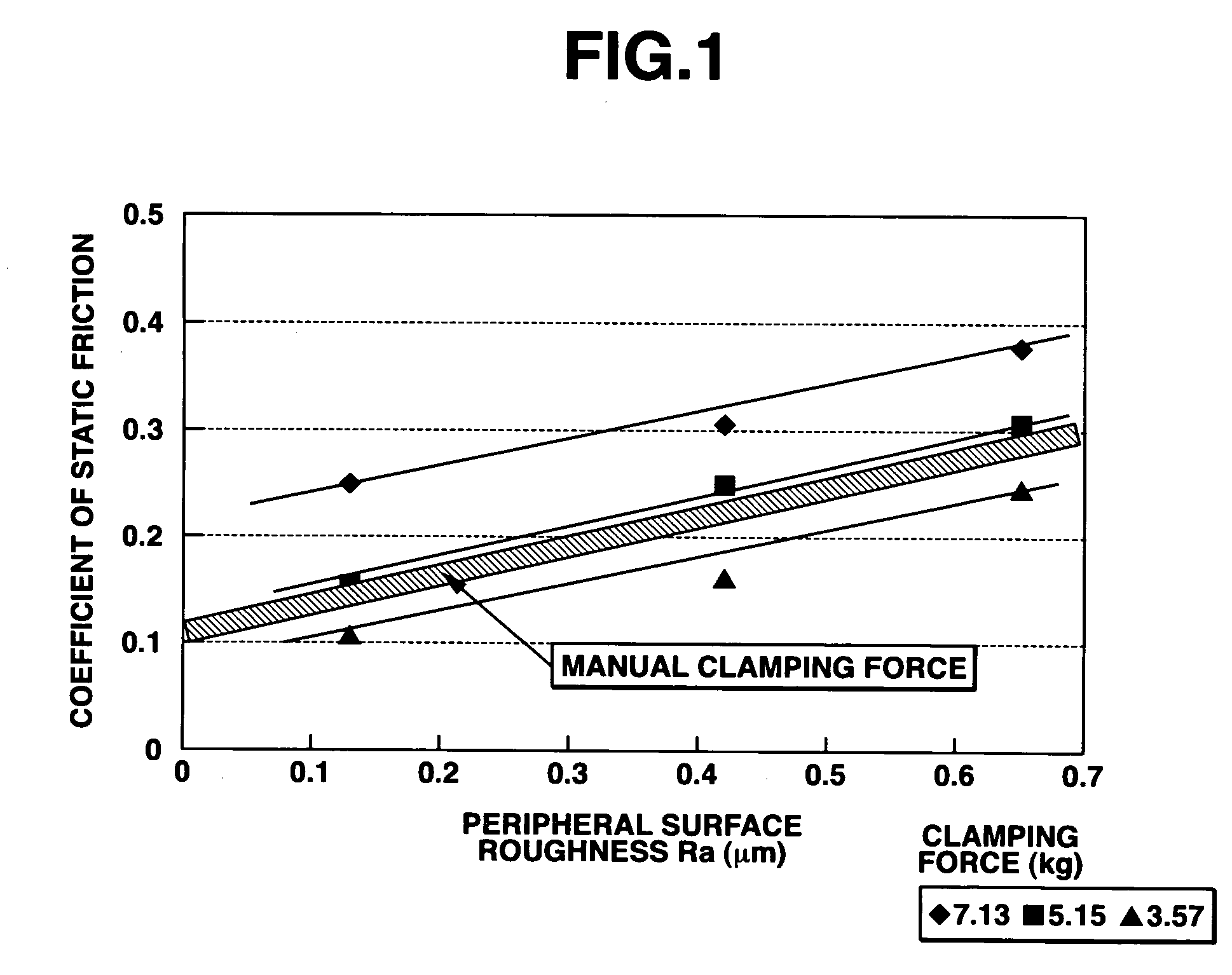

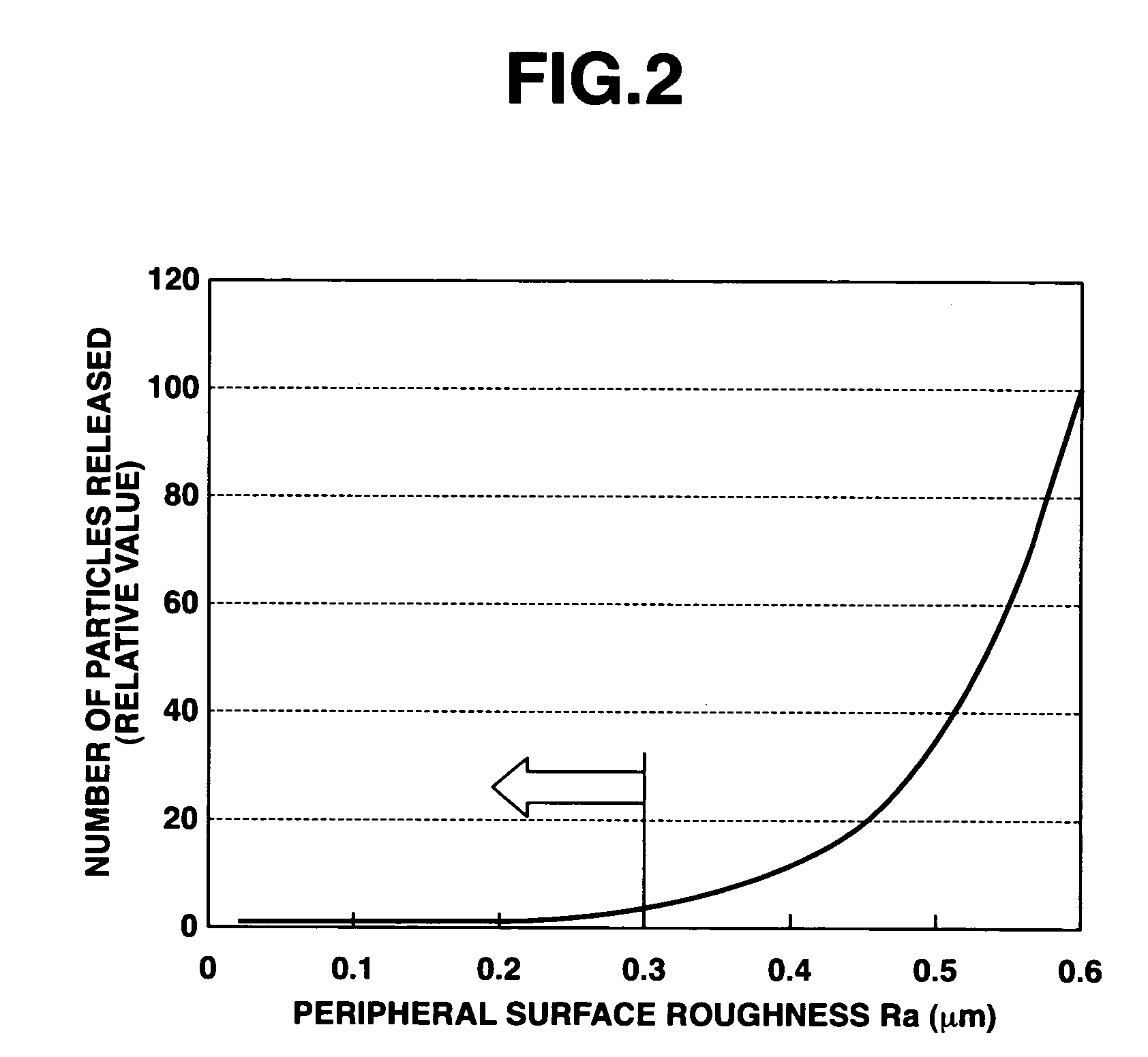

ActiveUS20050013972A1Suppresses generation of dustLiquid crystal compositionsFlexible-parts wheelsSurface roughnessDiagonal

A large-size substrate adapted for light exposure is of a plate shape having a diagonal length or diameter of 500-2,000 mm, a thickness of 1-20 mm, and a peripheral surface with a roughness Ra of 0.05-0.4 μm. The number of particles released from the substrate periphery during cleaning is minimized, leading to an improved yield in the cleaning step. The substrate can be manually handled, achieving an improvement in substrate quality without a need for a handling mechanism.

Owner:SHIN ETSU CHEM IND CO LTD

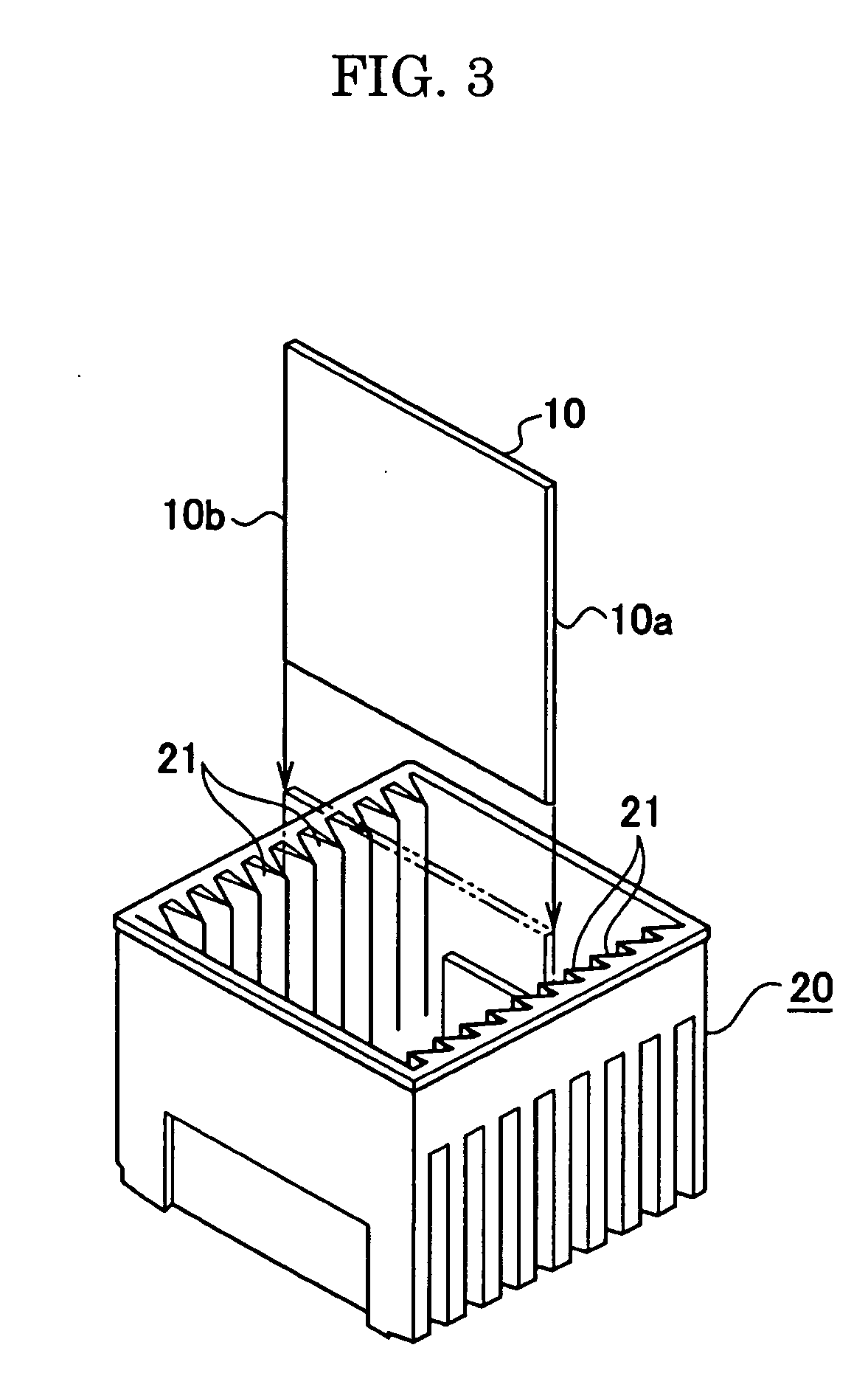

Display device

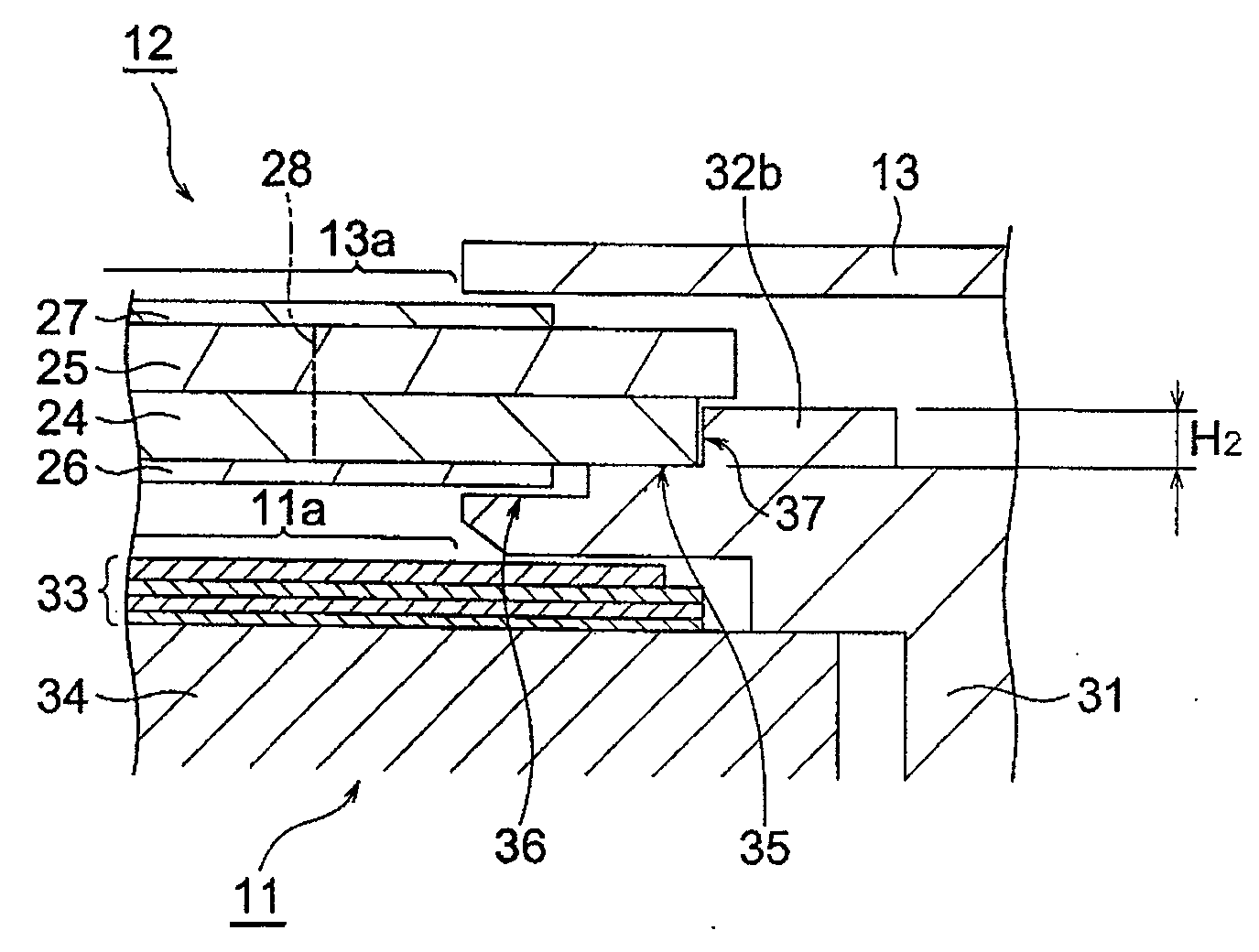

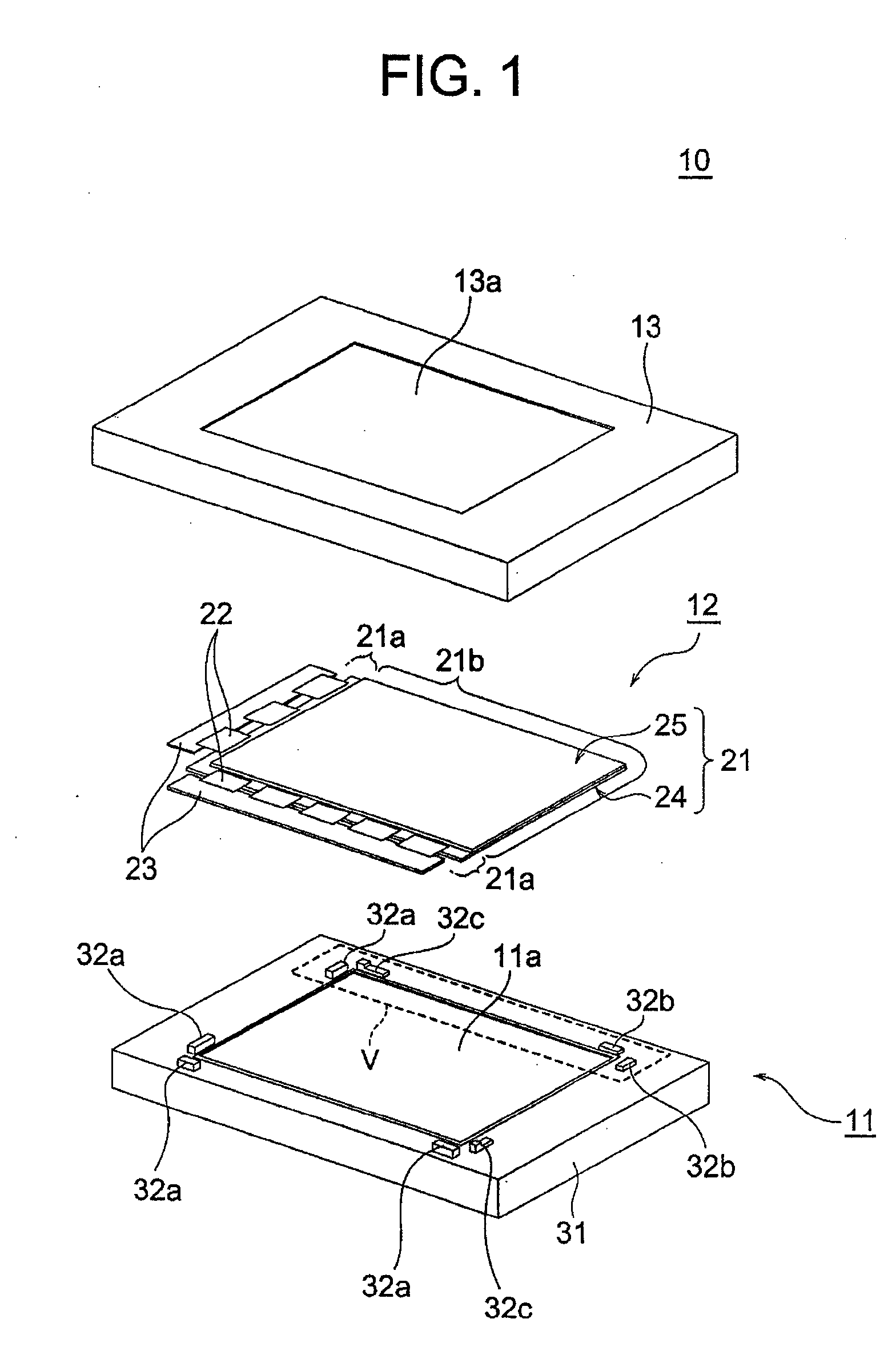

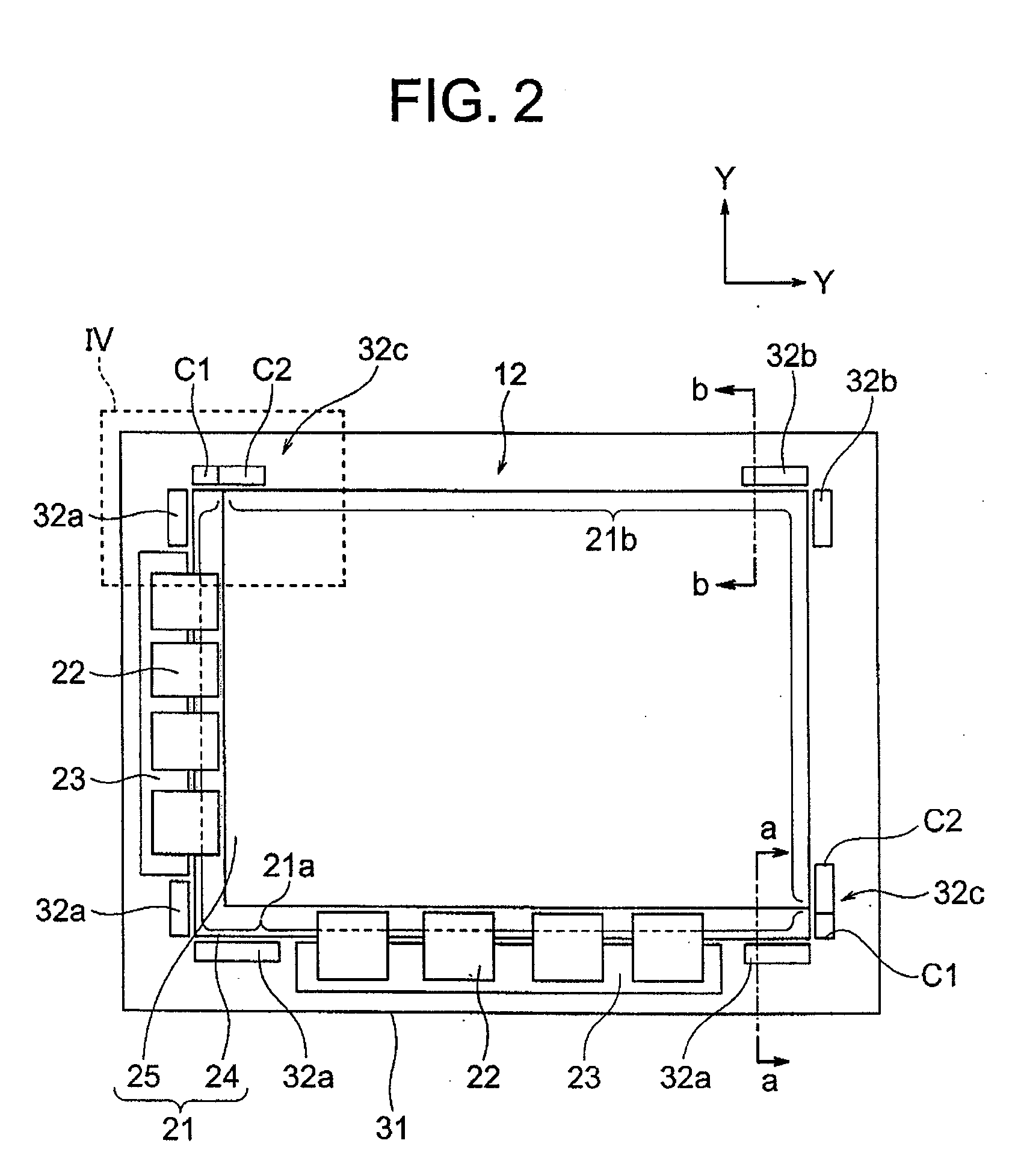

ActiveUS20070195220A1Improve image qualitySuppresses generation of dustTelevision system detailsColor television detailsDisplay deviceEngineering

Owner:NEC LCD TECH CORP

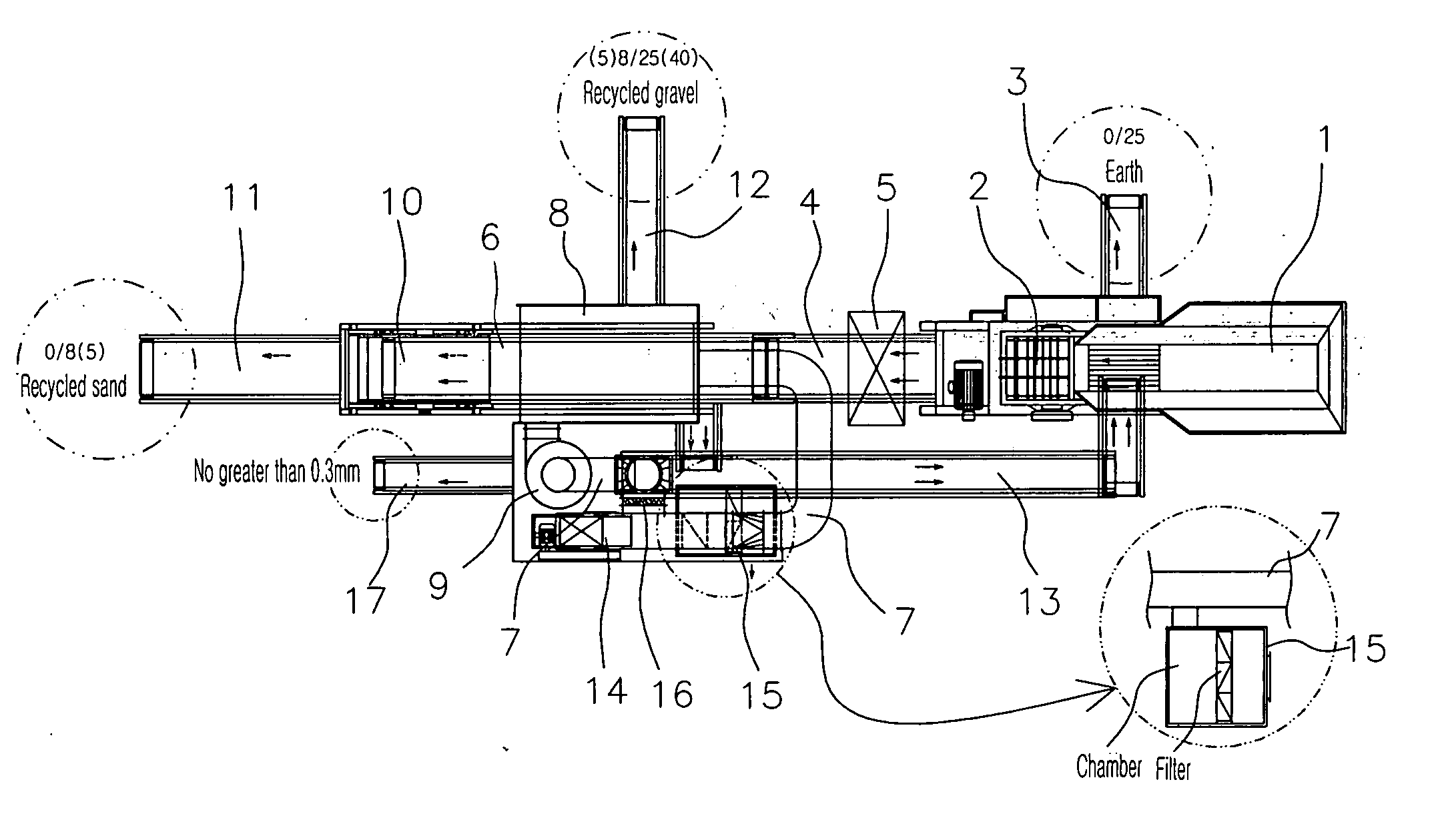

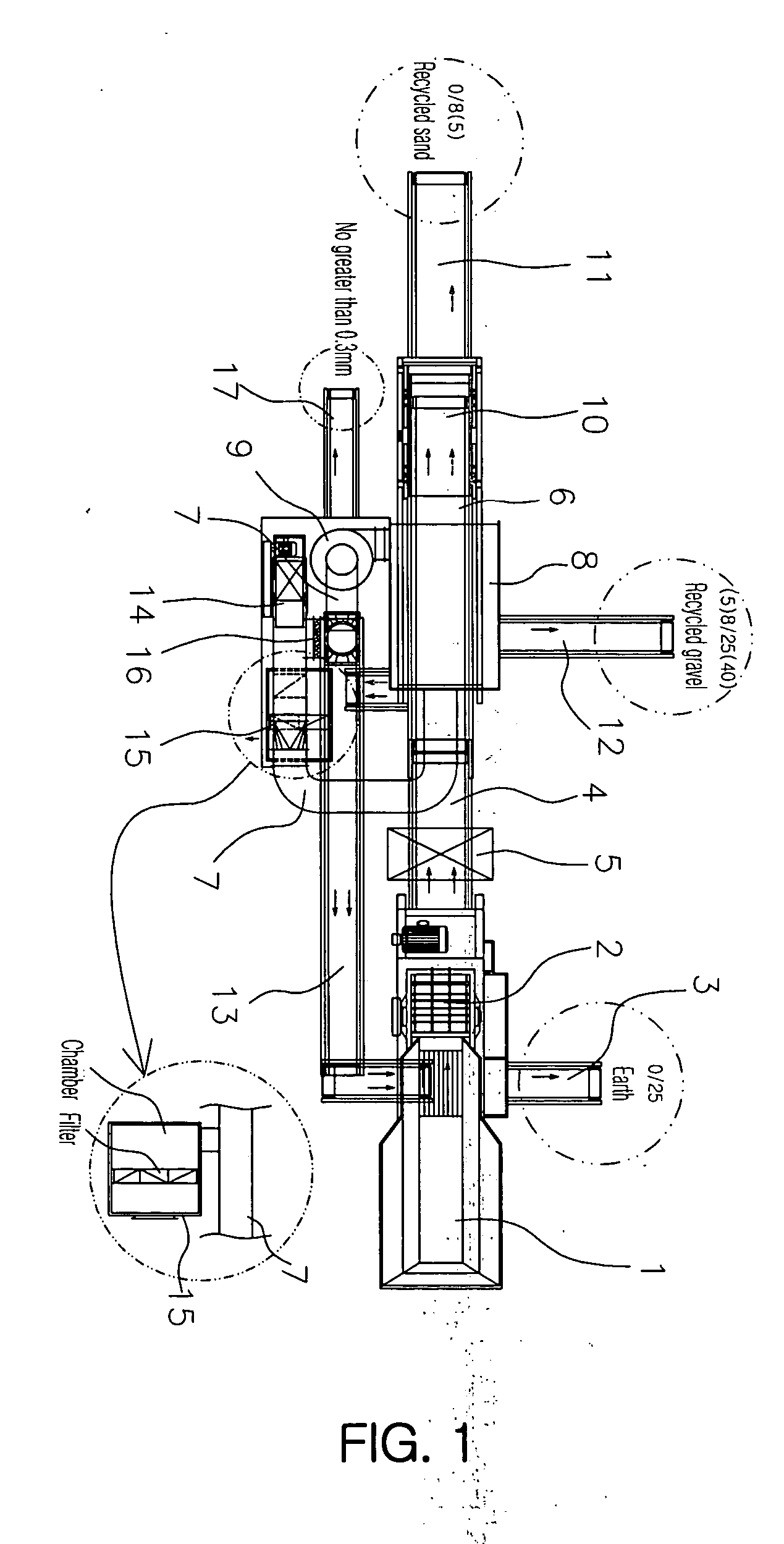

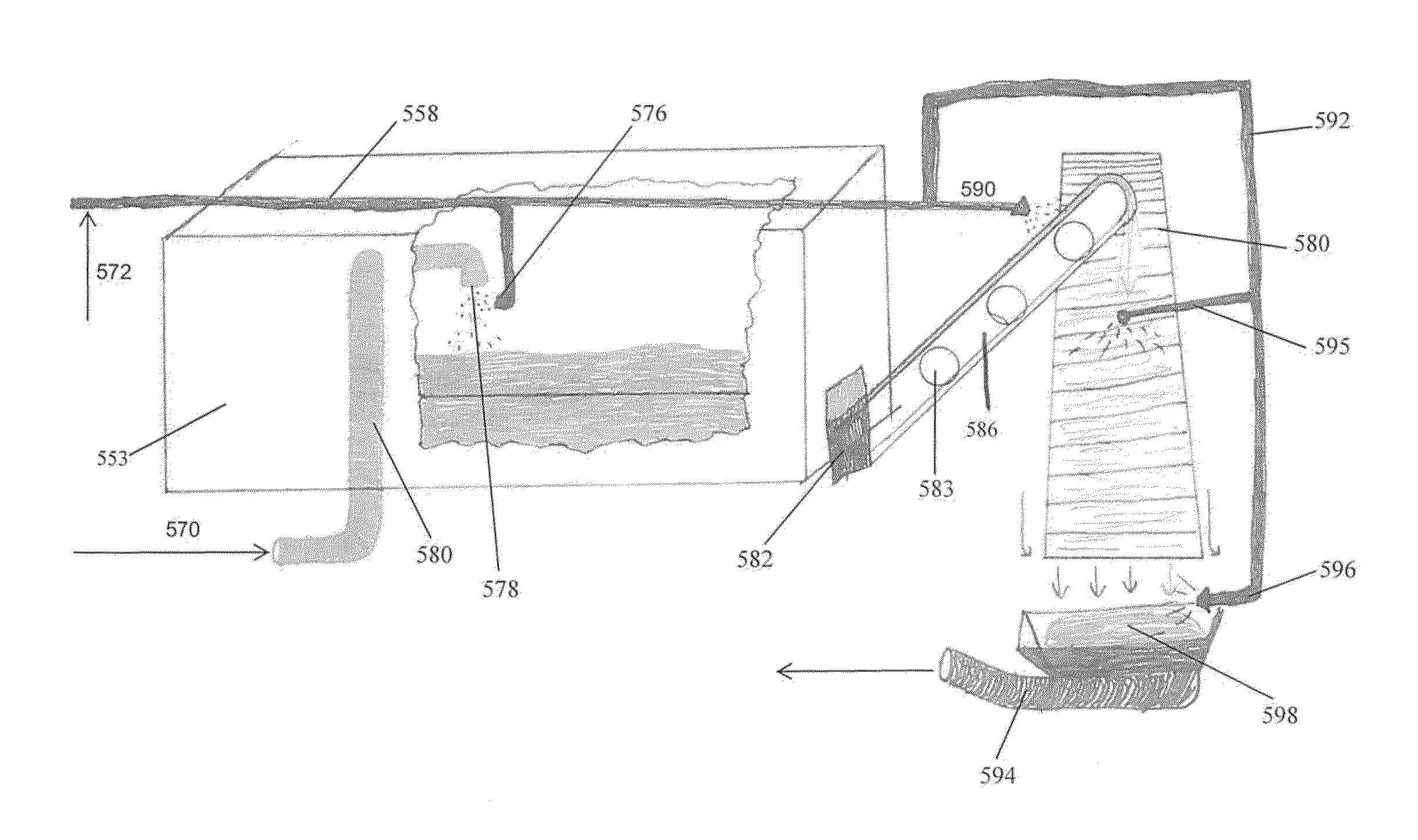

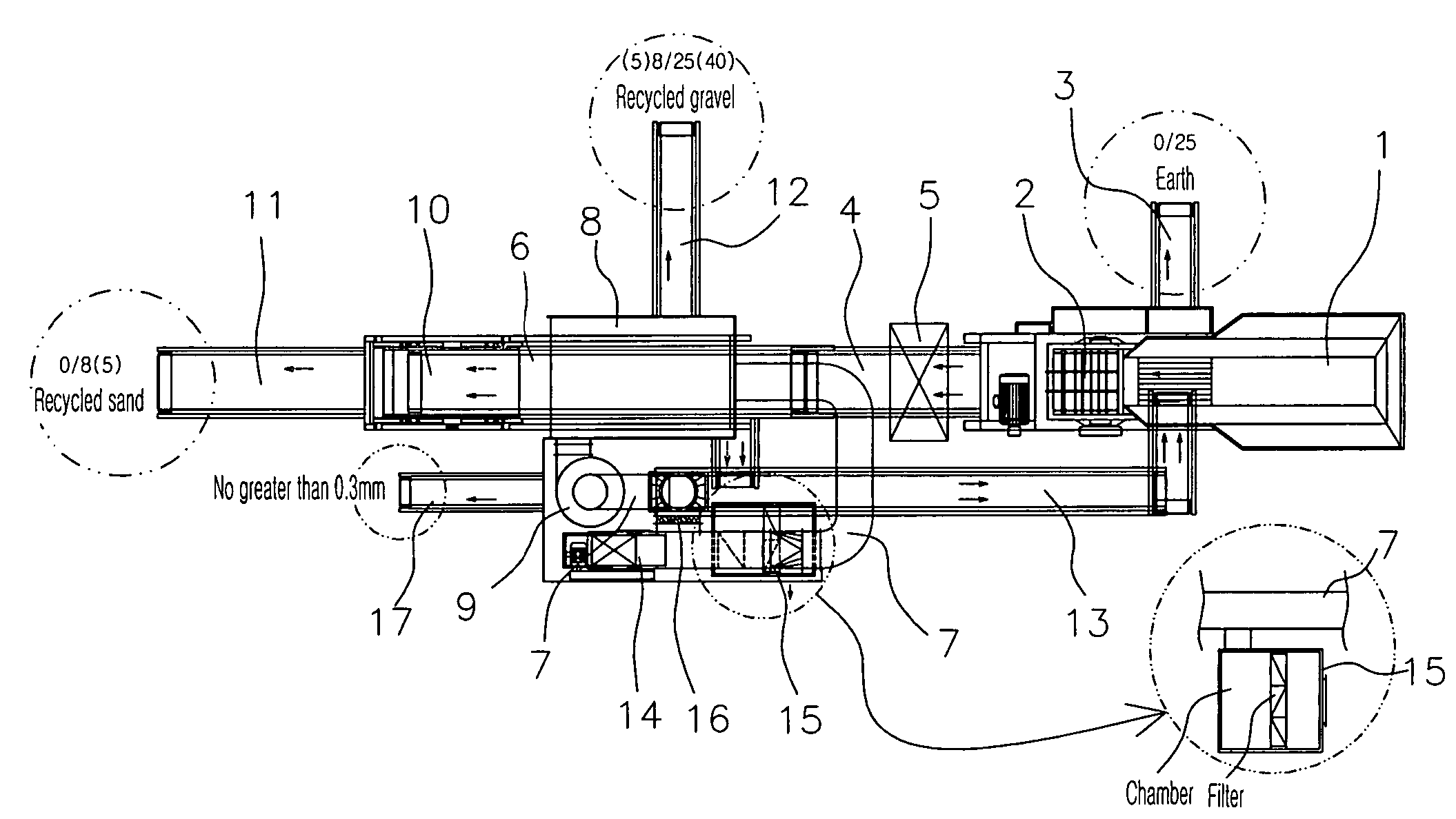

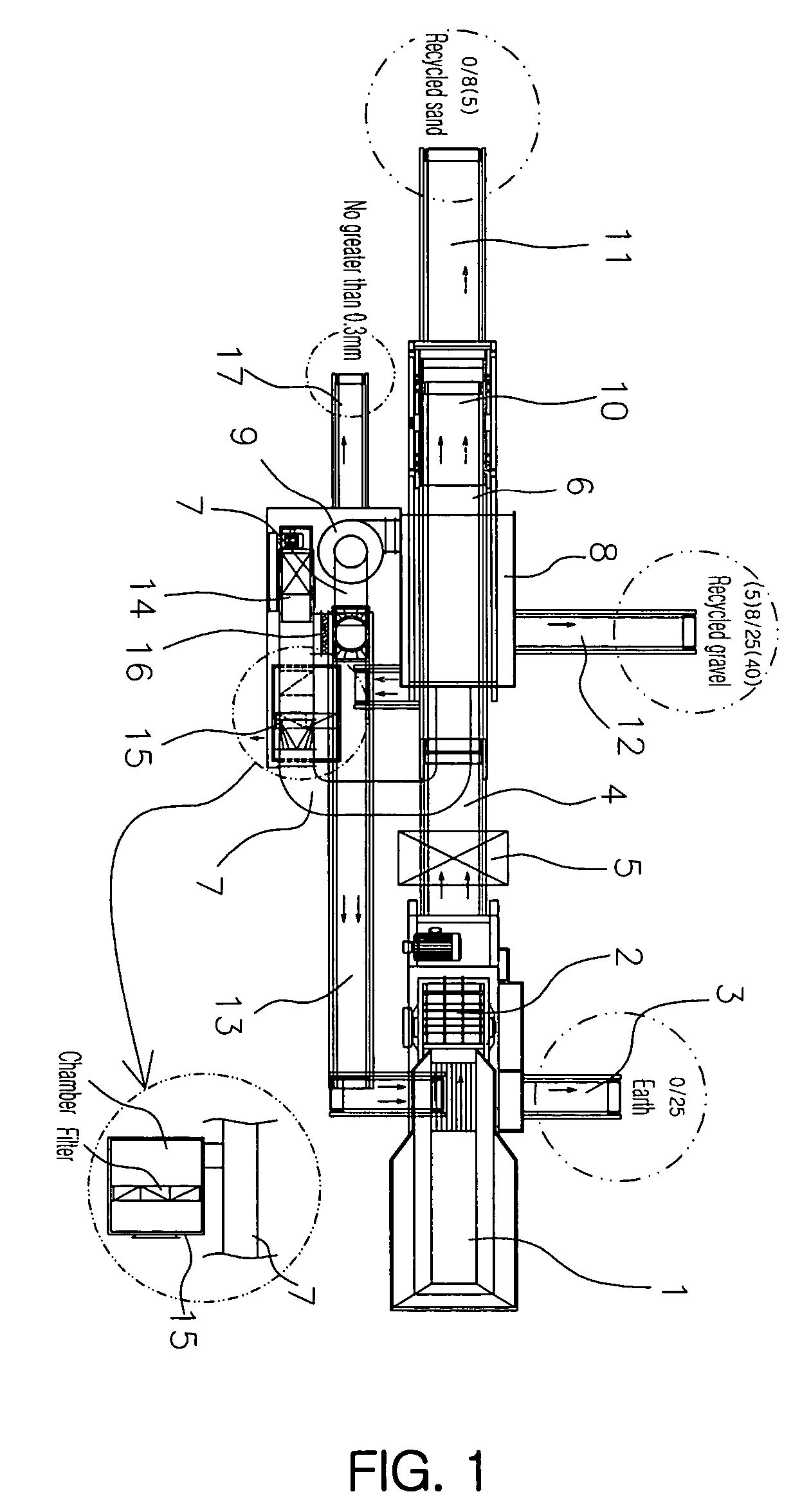

Aggregate recycling apparatus having air circulation type foreign substance and fine particle separation means, and method thereof

InactiveUS20060266857A1Efficient separationAvoid air pollutionSievingConstruction waste recoveryForeign matterAir cycle

Disclosed is an aggregate recycling apparatus having an air circulation type foreign substance and fine particle separation means which directs a blast of air, circulated in a dry state, toward waste having passed through a crushing process immediately after the crushing of the waste and removes fine particles and foreign substances using a cyclone, thereby removing dust generated in the course of separating and screening the waste, and a method thereof. The aggregate recycling apparatus includes a crushing device for crushing waste, an air circulation type fine particle and foreign substance separation device for directing re-circulated air to crushed products received from the crushing device, scattering fine particles and foreign substances and collecting dust in a cyclone, an air conveyor for conveying crushed products deprived of the fine particles and foreign substances, and a double vibration screen for screening the crushed products received from the air conveyor.

Owner:SHINTEK

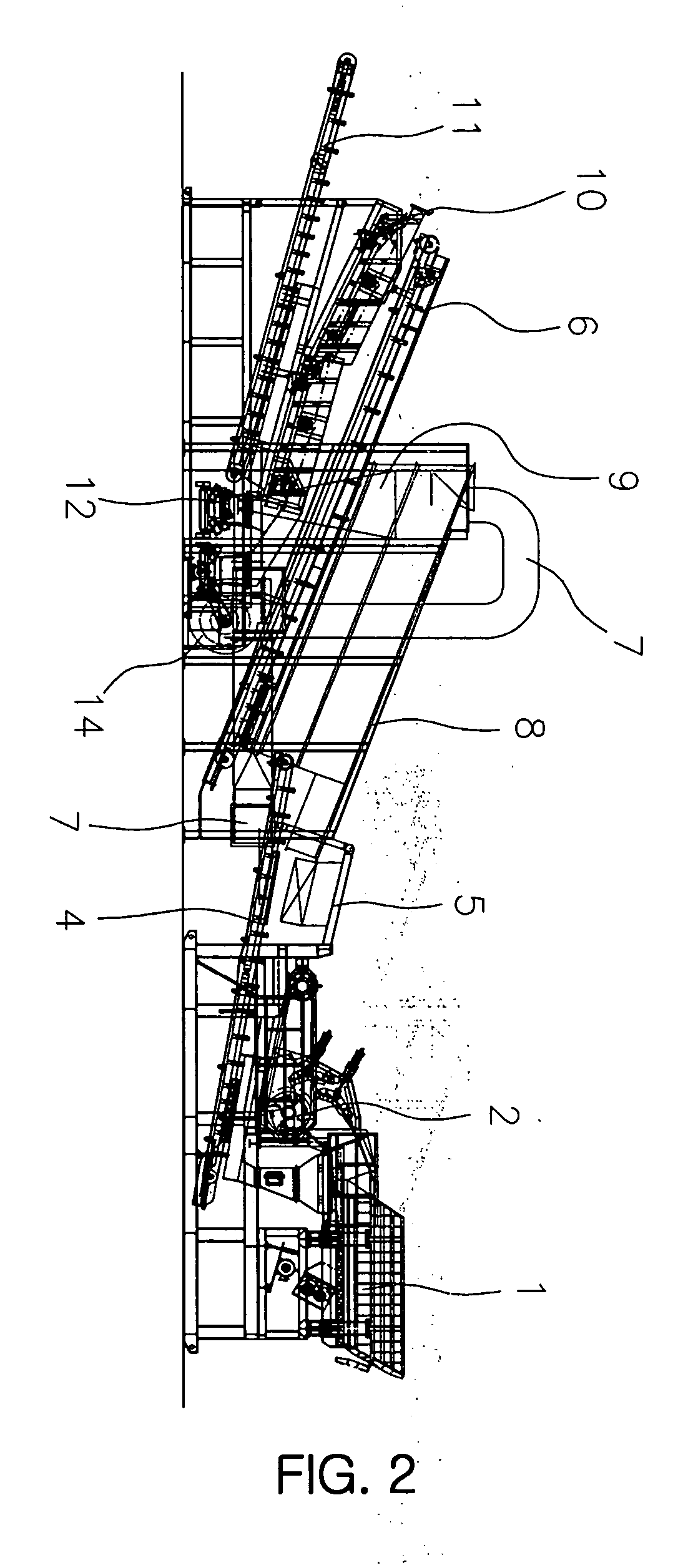

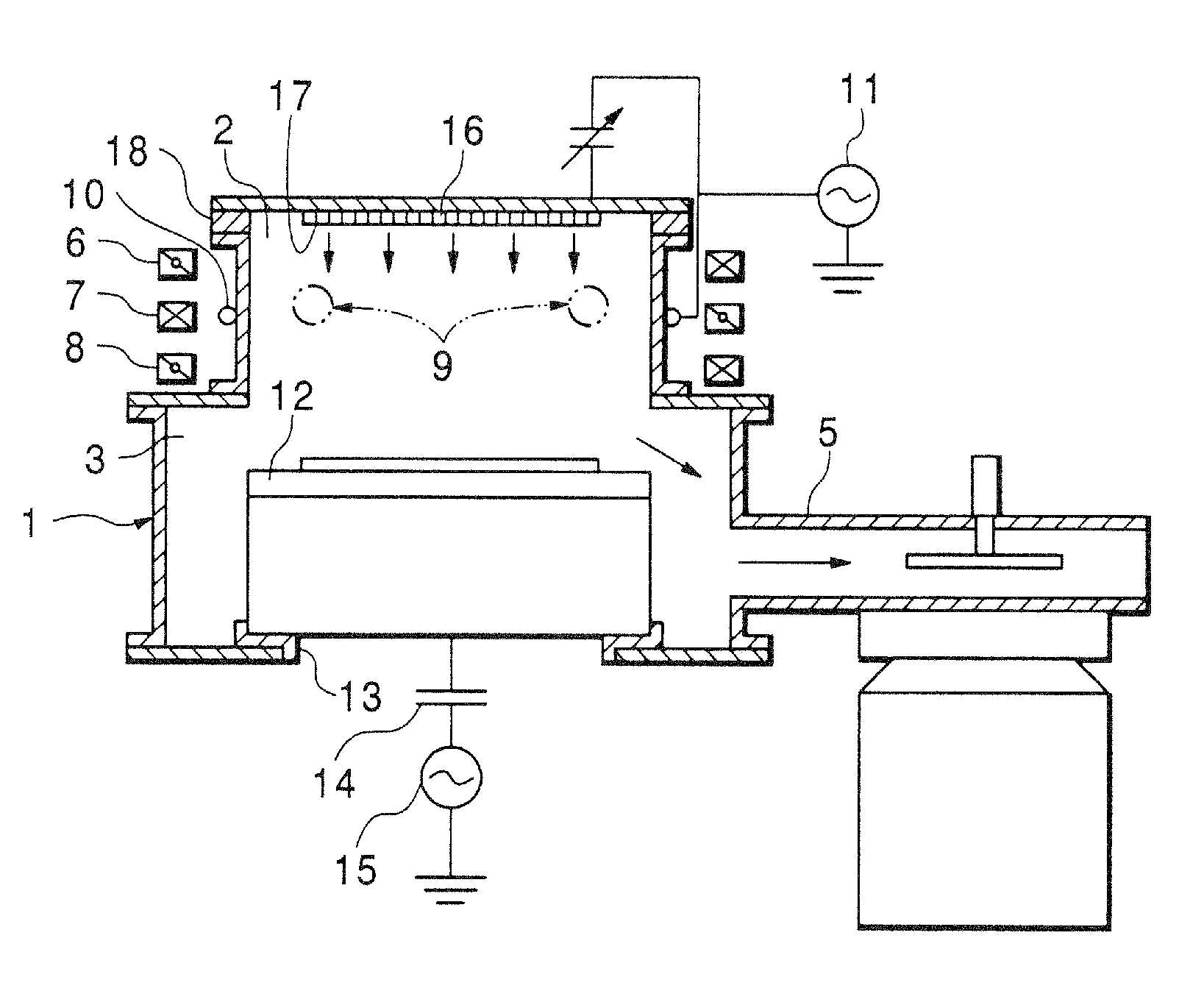

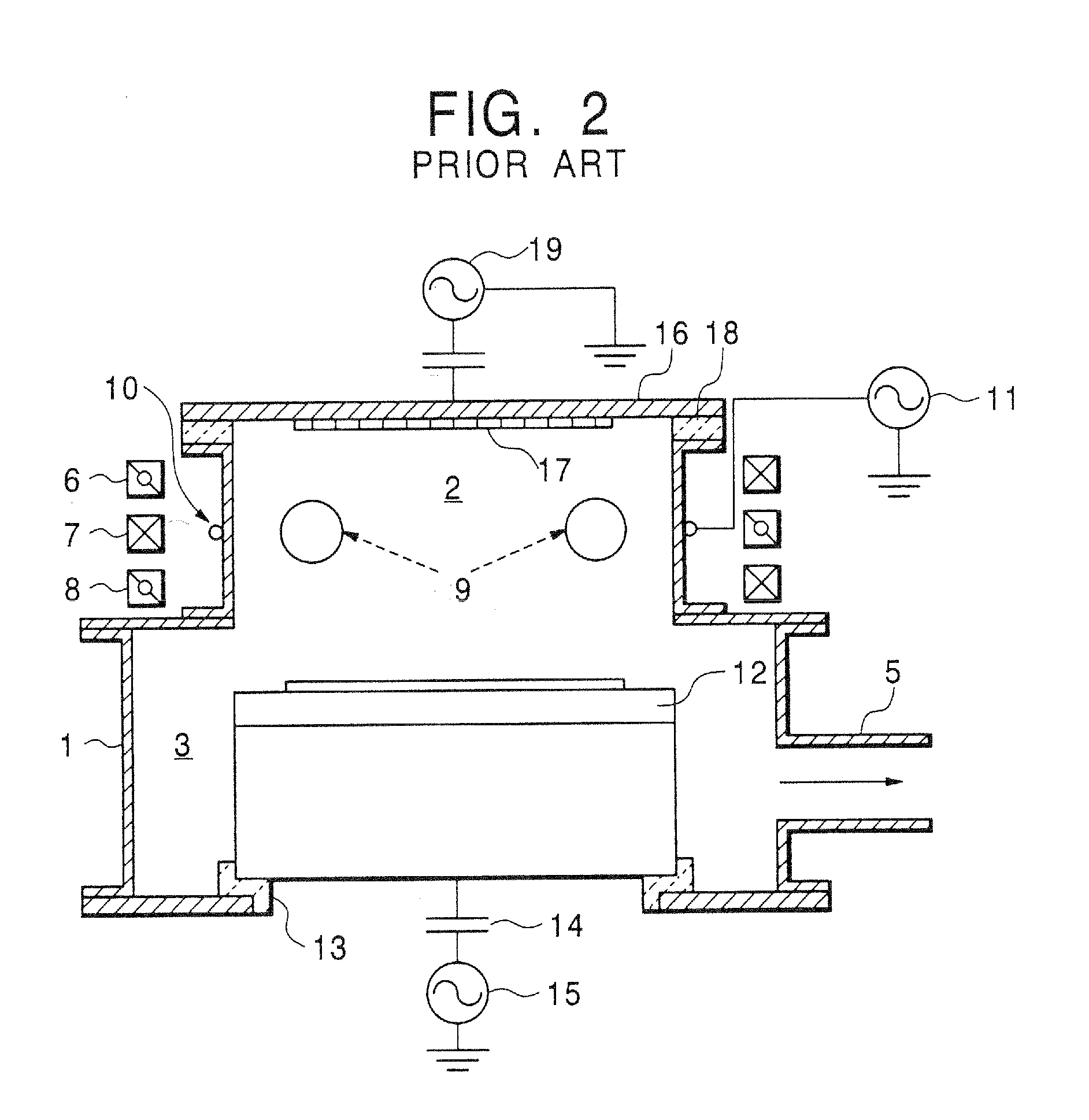

Plasma processing apparatus

InactiveUS20090294063A1Improve resistance of maskSatisfactory etching rateElectric discharge tubesSemiconductor/solid-state device manufacturingFloating electrodeRadio frequency

The present invention is to provide a plasma processing apparatus, whose structure can be simplified, and further, which is capable of forming highly effective plasma and obtaining a satisfactory vertical etching property without involving a problem concerning interference. In the plasma processing apparatus according to the invention, a ground electrode provided at a position opposite to a substrate mounting electrode is configured to be a counter electrode, whose potential is in a floating state, and radio frequency power is branched at an arbitrary position of the radio frequency antenna coil, which generates inductive discharge, into the counter electrode through a capacitor so as to share a part of the radio frequency power used for inductive discharge, thereby generating a self-bias in the counter electrode. In the system, there is provided a mechanism for controlling the radio frequency voltage to be applied to the floating electrode uniformly.

Owner:ULVAC INC

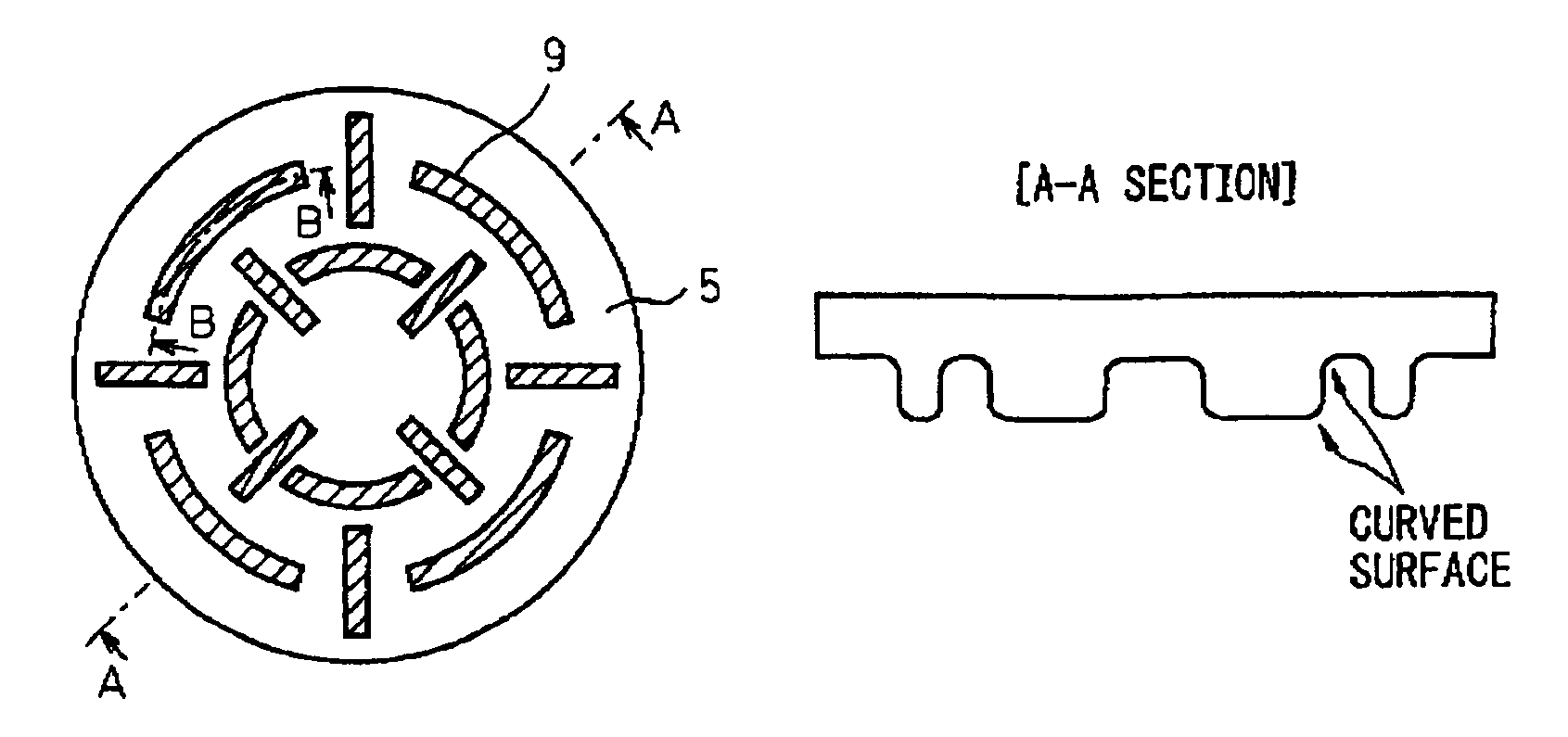

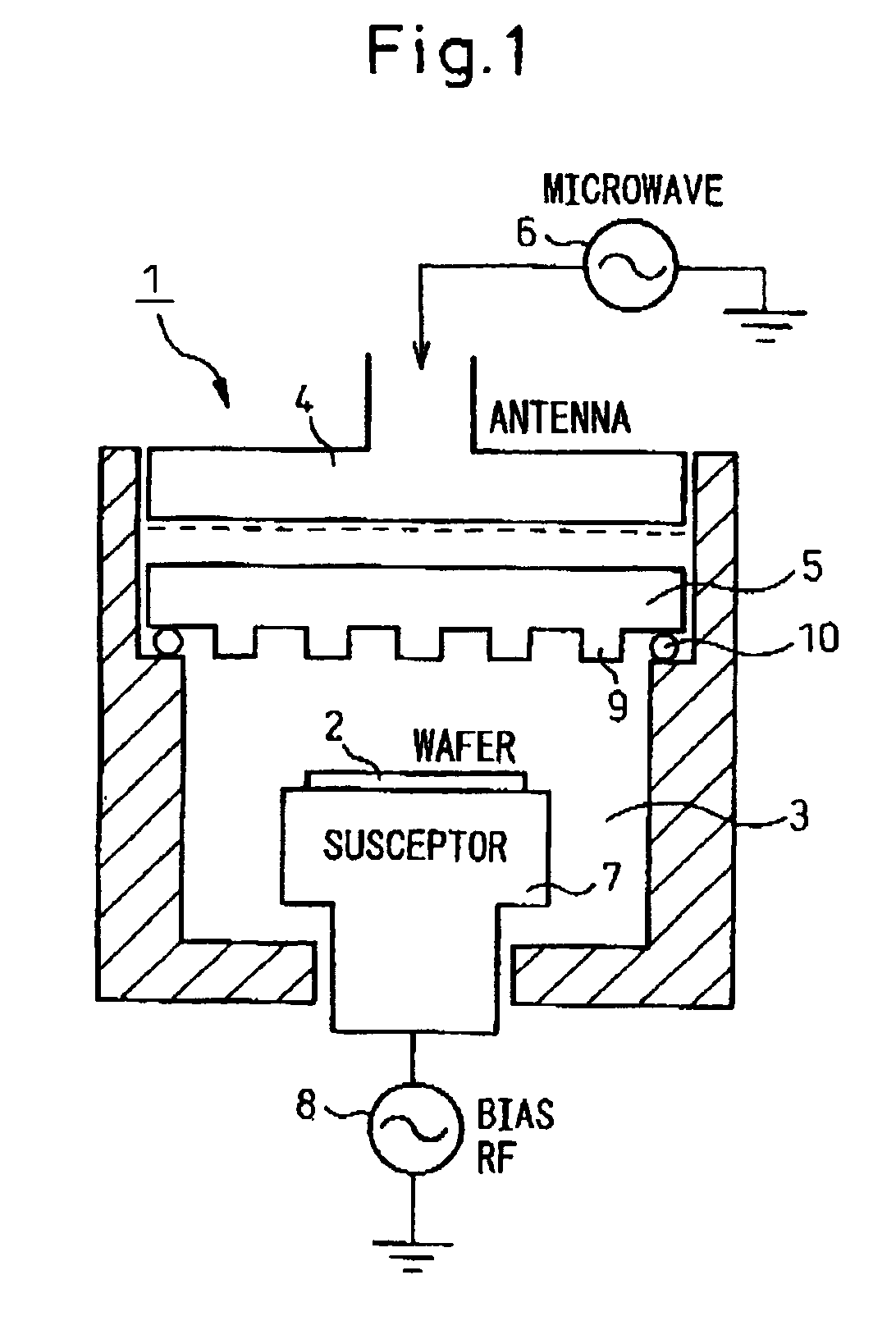

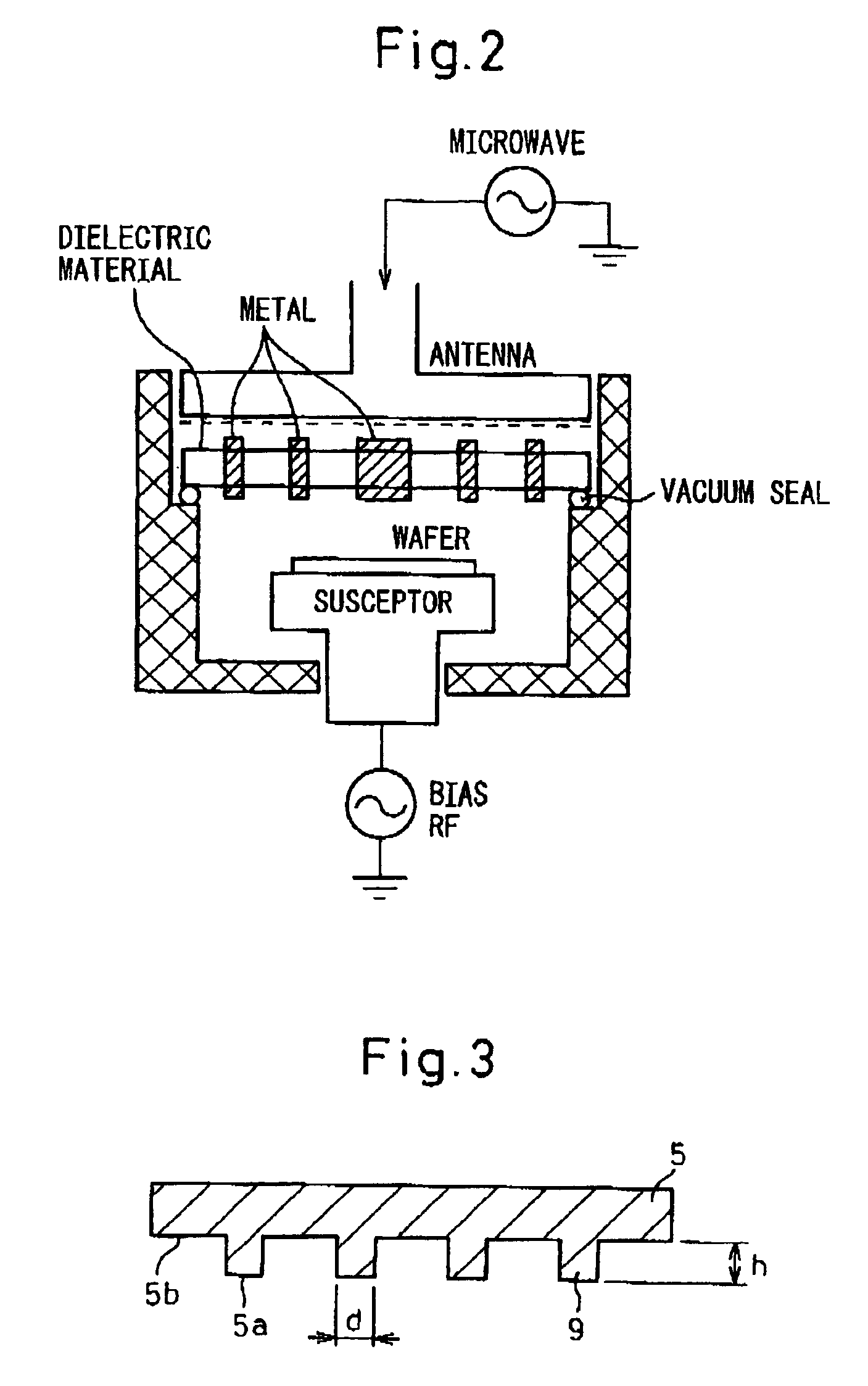

Plasma processing apparatus

InactiveUS6953908B2Inhibit productionSuppression of surface wavesElectric discharge tubesSemiconductor/solid-state device manufacturingDielectricMicrowave

A plasma processing apparatus, comprising: at least, a plasma processing chamber for processing therein an object to be processed; antenna means for guiding microwaves into the plasma processing chamber; and a dielectric member disposed between the antenna means and the plasma processing chamber; wherein a surface of the dielectric member facing the inside of the plasma processing chamber has a projecting shape.

Owner:TOKYO ELECTRON LTD +1

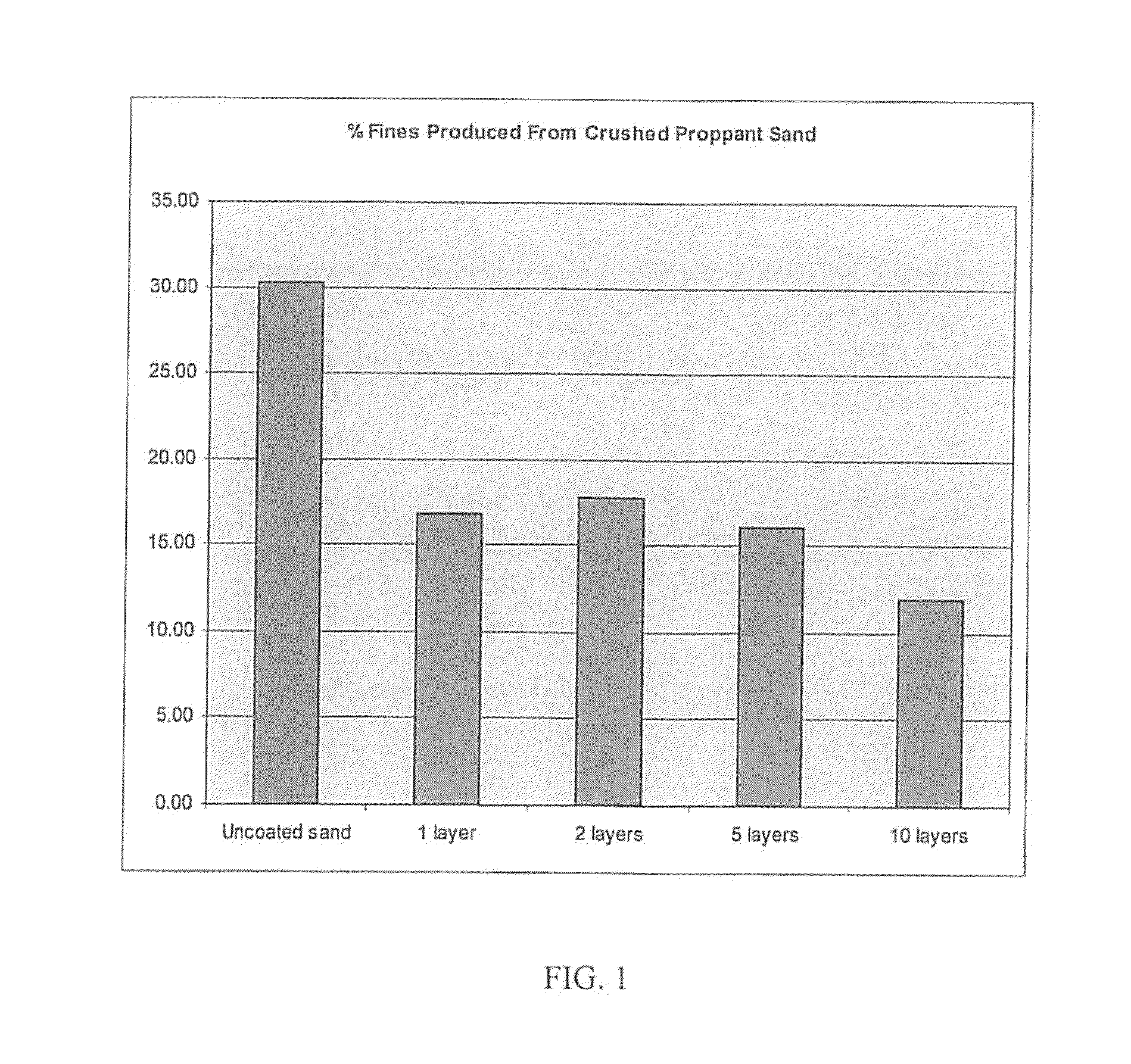

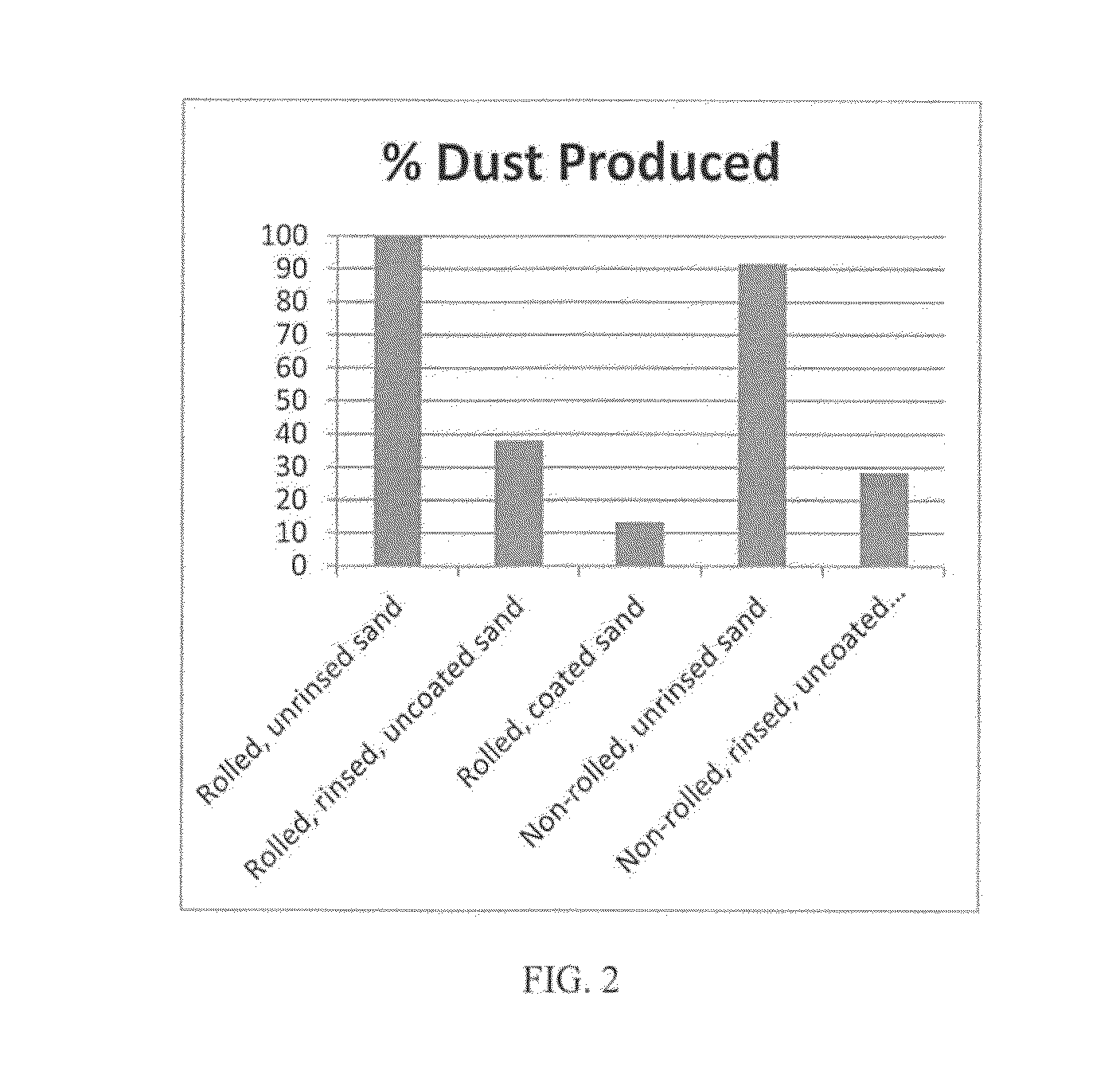

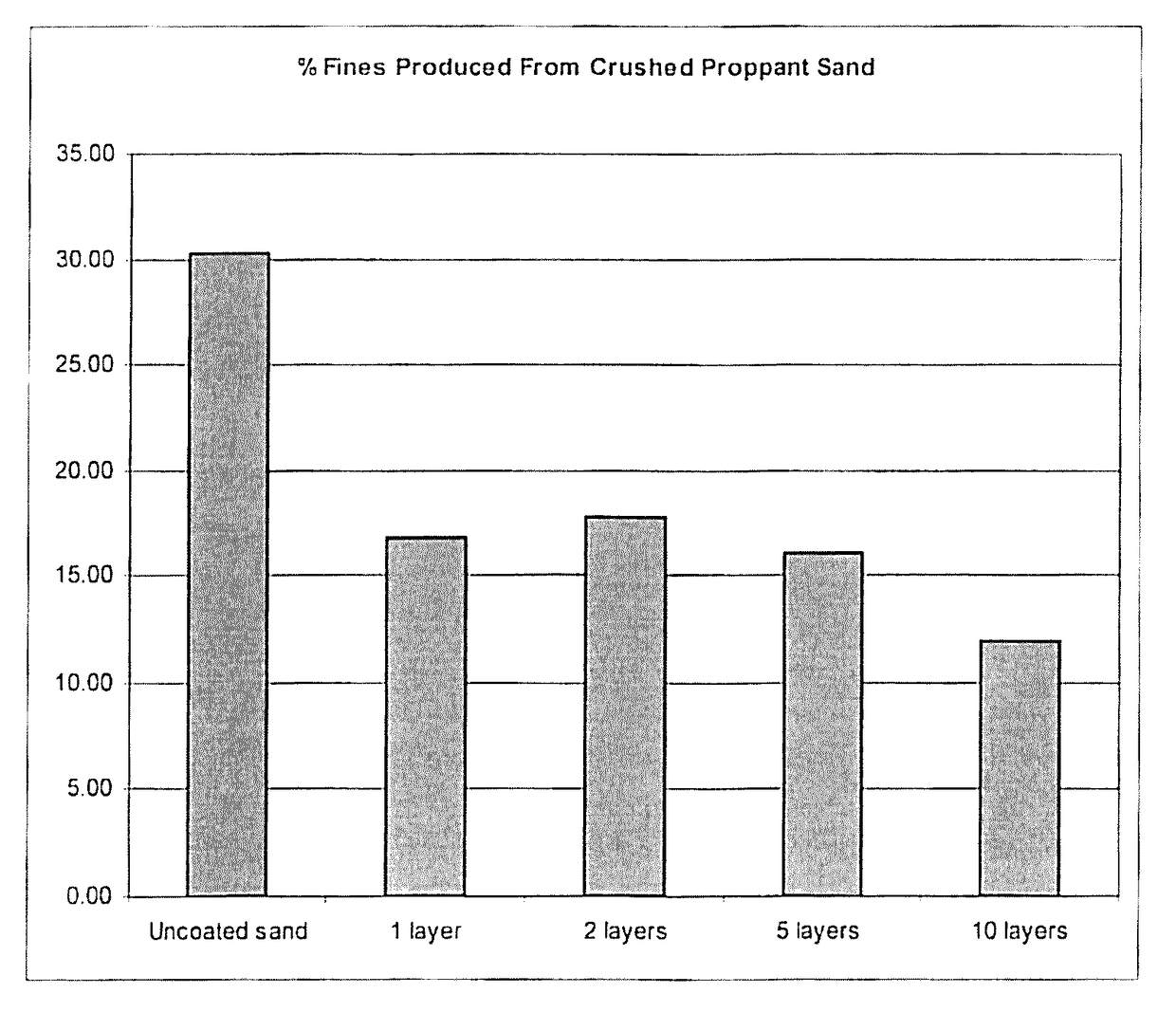

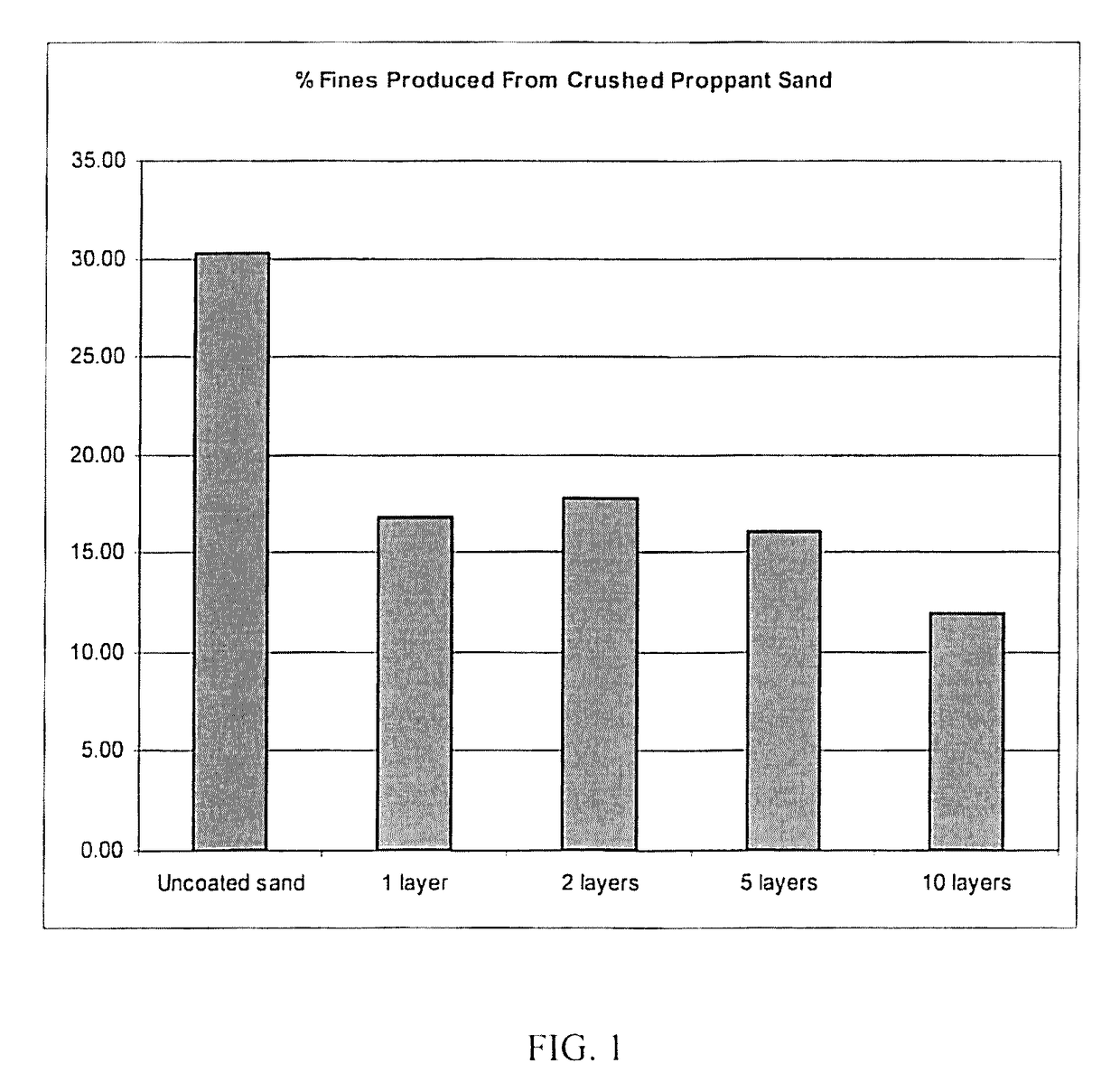

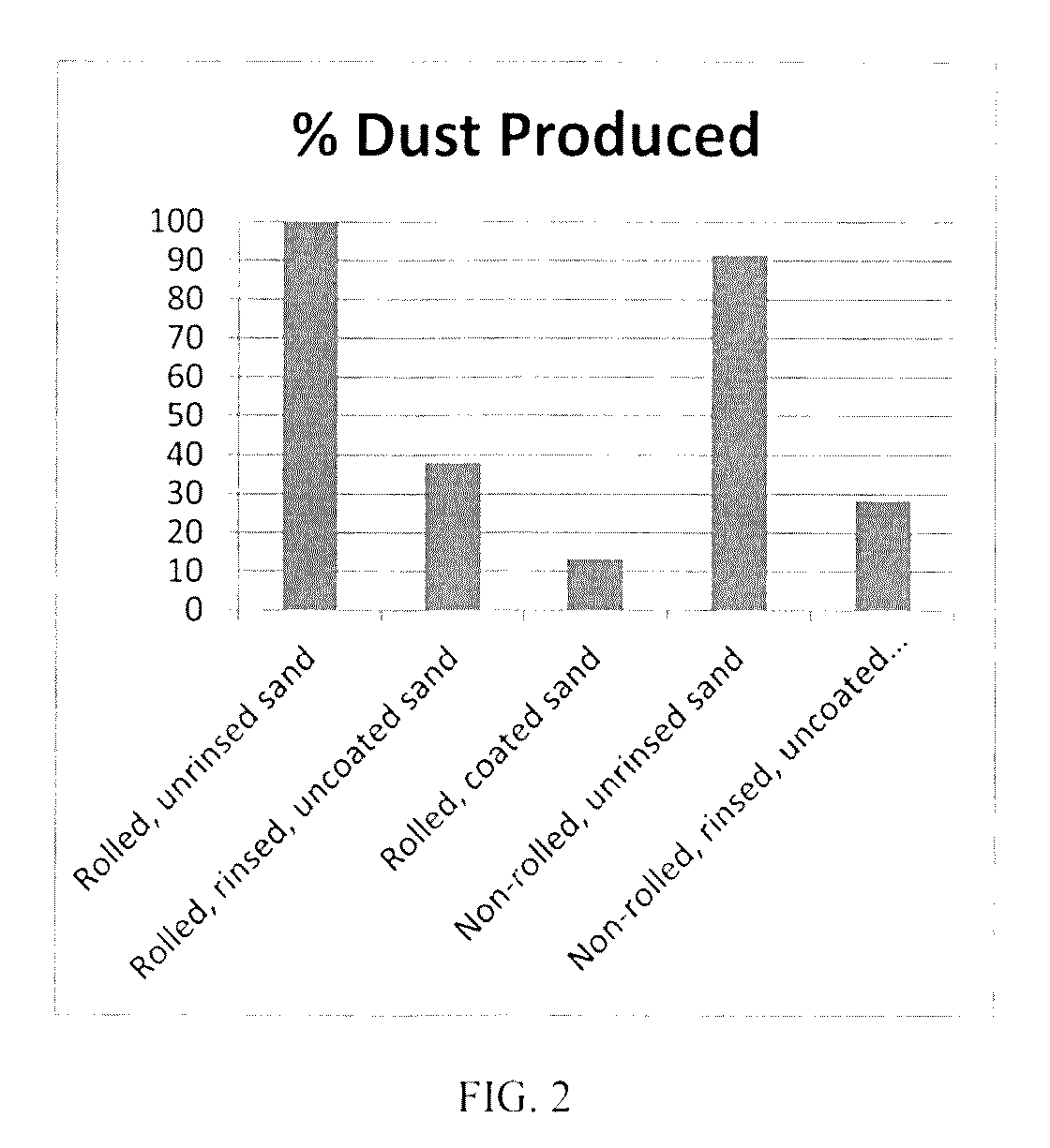

Sand composites and methods of using the same to control dust

ActiveUS20160024360A1Reduce amountReduce the amount requiredMaterial nanotechnologyPigmenting treatmentIonPolymer

A composite is characterized by particulates of sand wherein at least a portion of the surface of the particulates is coated with a polycationic polymer. The presence of the polycationic polymer on the surface of the particulates reduces the amount of dust generated during handling and use of the sand. The polycationic polymer further reduces the amount of dust generated during transport of the sand as well during manufacture, treatment or processing of the sand.

Owner:BAKER HUGHES INC

Carbonaceous porous material and method of manufacturing same

InactiveUS20060125131A1Good molding effectHigh mechanical strengthThin material handlingCeramicwareOrganic matterUltimate tensile strength

A carbonaceous porous material having excellent mechanical strength is obtained by mixing a resin, that can be used as starting material for amorphous carbon, uniformly with carbon powder and an organic substance with a carbon residue rate of 0˜5% and, after molding the mixture in an arbitrary shape, carbonizing the mixture at temperature of 500° C. or higher.

Owner:MITSUBISHI PENCIL CO LTD

Metal oxide film, laminate, metal member and process for producing the same

InactiveUS8206833B2Improve the immunitySuppress generationAnodisationSynthetic resin layered productsChemical solutionMoisture

A metal oxide film suitable for protection of metals, composed mainly of aluminum. A metal oxide film includes a film of an oxide of a metal composed mainly of aluminum, having a thickness of 10 nm or greater, and exhibiting a moisture release rate from the film of 1E18 mol. / cm2 or less. Further, there is provided a process for producing a metal oxide film, wherein a metal composed mainly of aluminum is subjected to anodic oxidation in a chemical solution of 4 to 10 pH value so as to obtain a metal oxide film.

Owner:TOHOKU UNIV +1

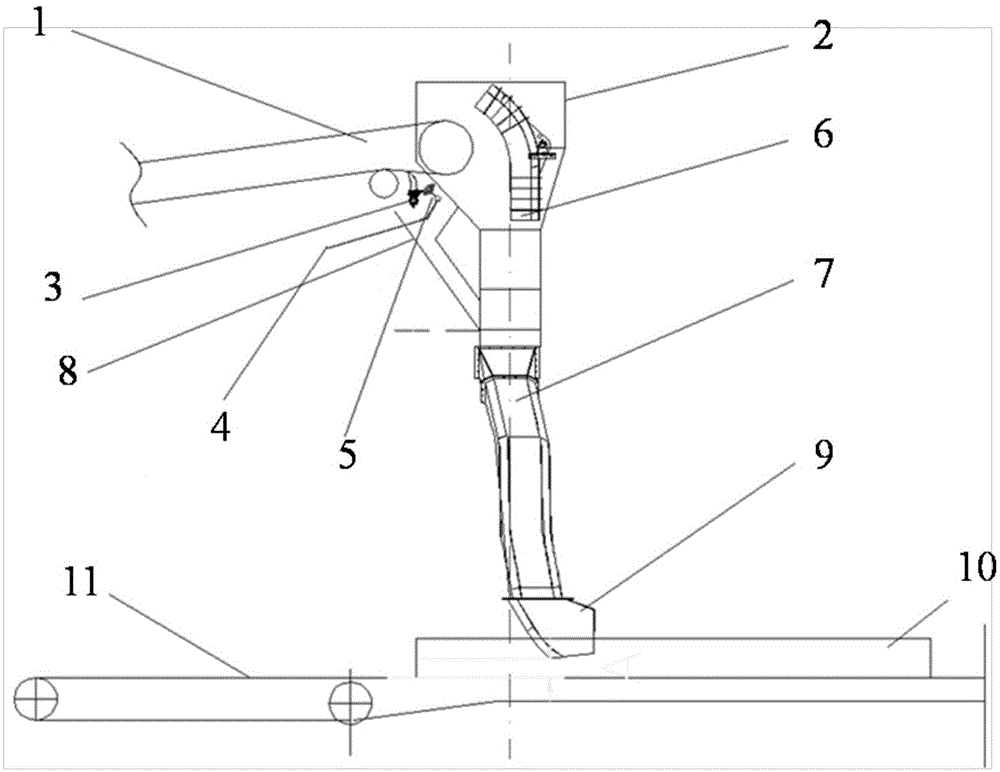

Dust treatment device for belt conveyor

The invention relates to a dust treatment device for a belt conveyor. The dust treatment device comprises a feeding belt, a material collecting hopper, a sweeper, an atomizing pipeline, a spraying nozzle, a material flow adjustment device, a primary sliding groove, a secondary sliding groove, a feeding device, a material guide groove and a material receiving belt, wherein the feeding belt is connected with the material collecting hopper; the sweeper is mounted below the feeding belt; the atomizing pipeline and the spraying nozzle are arranged at the periphery of the sweeper; the material flow adjustment device is arranged in the material collecting hopper; the secondary sliding groove is formed below the sweeper; the lower end of the secondary sliding groove is connected with the primary sliding groove; the primary sliding groove is connected with the feeding device; the material guide groove is formed below the feeding device; the material receiving belt is arranged below the material guide groove. According to the dust treatment device for the belt conveyor, the generation of dust is inhibited from the source, and the dust produced by the sweeper during a sweeping process can also be inhibited.

Owner:INSTALLATION ENG CO LTD OF CCCC FIRST HARBOR ENG

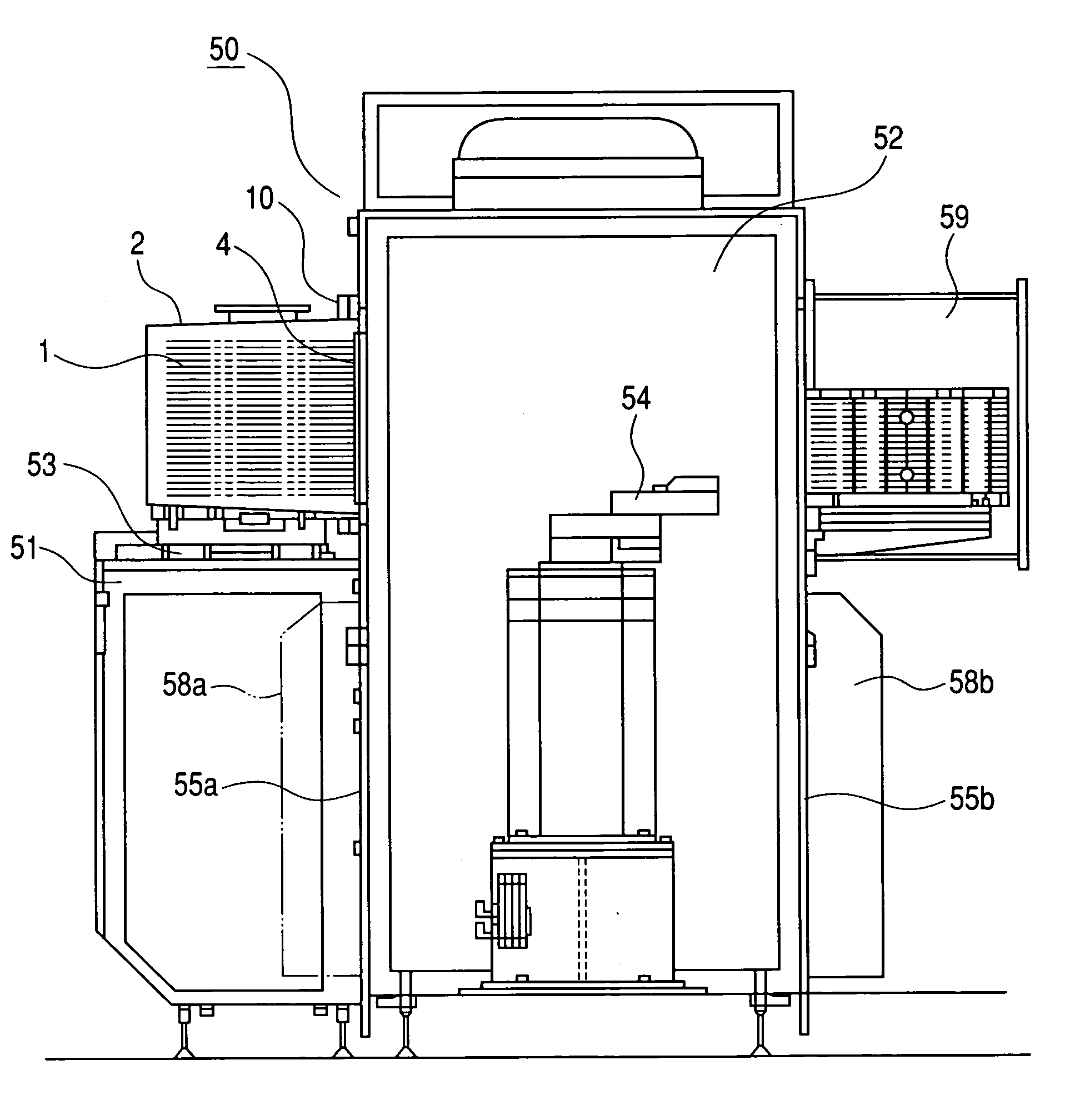

Load port for clean system

InactiveUS20050265812A1Reduce the possibilityEliminate pressure fluctuationsSemiconductor/solid-state device manufacturingArticle unpackingLow speedEngineering

Owner:TDK CORPARATION

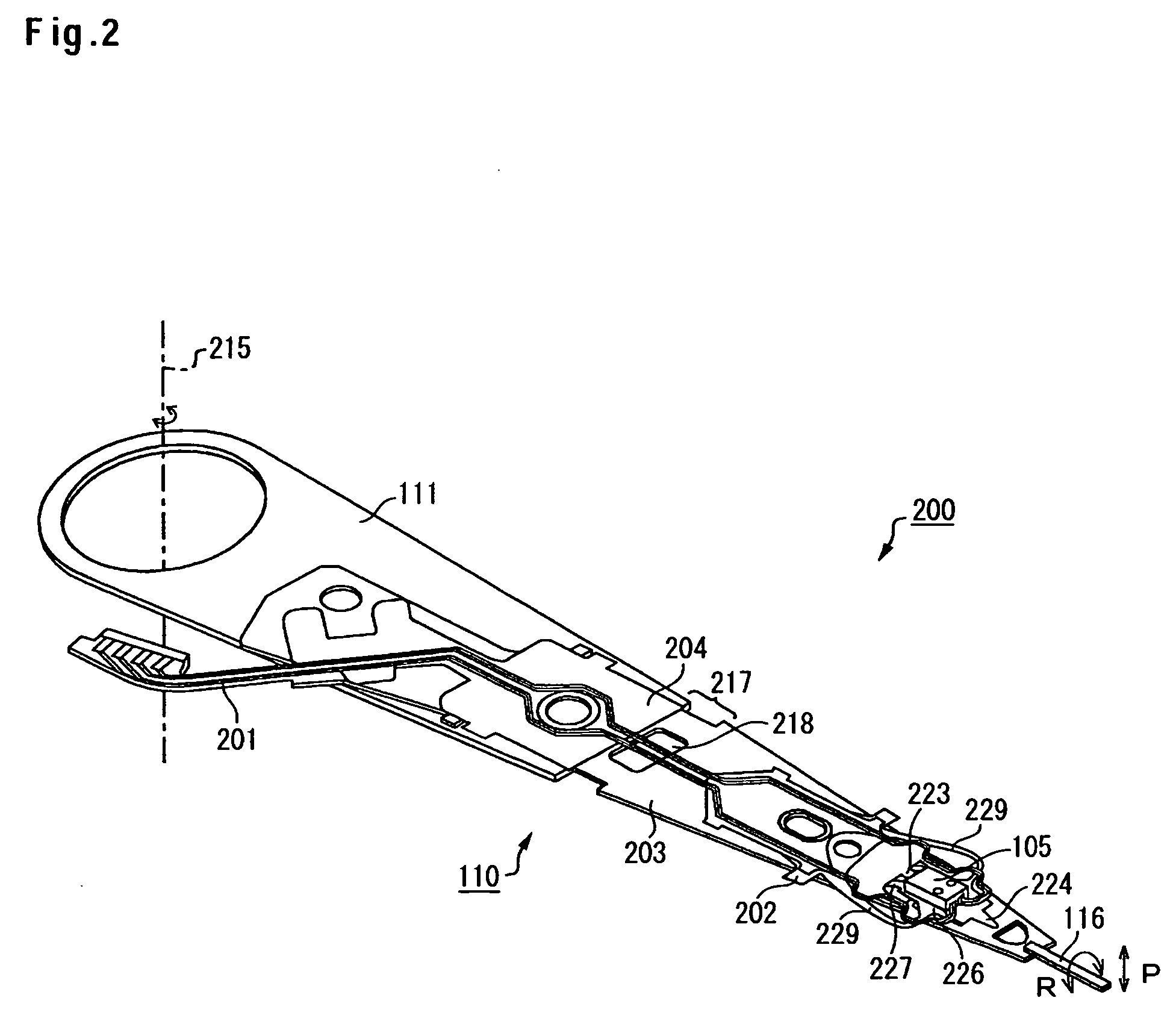

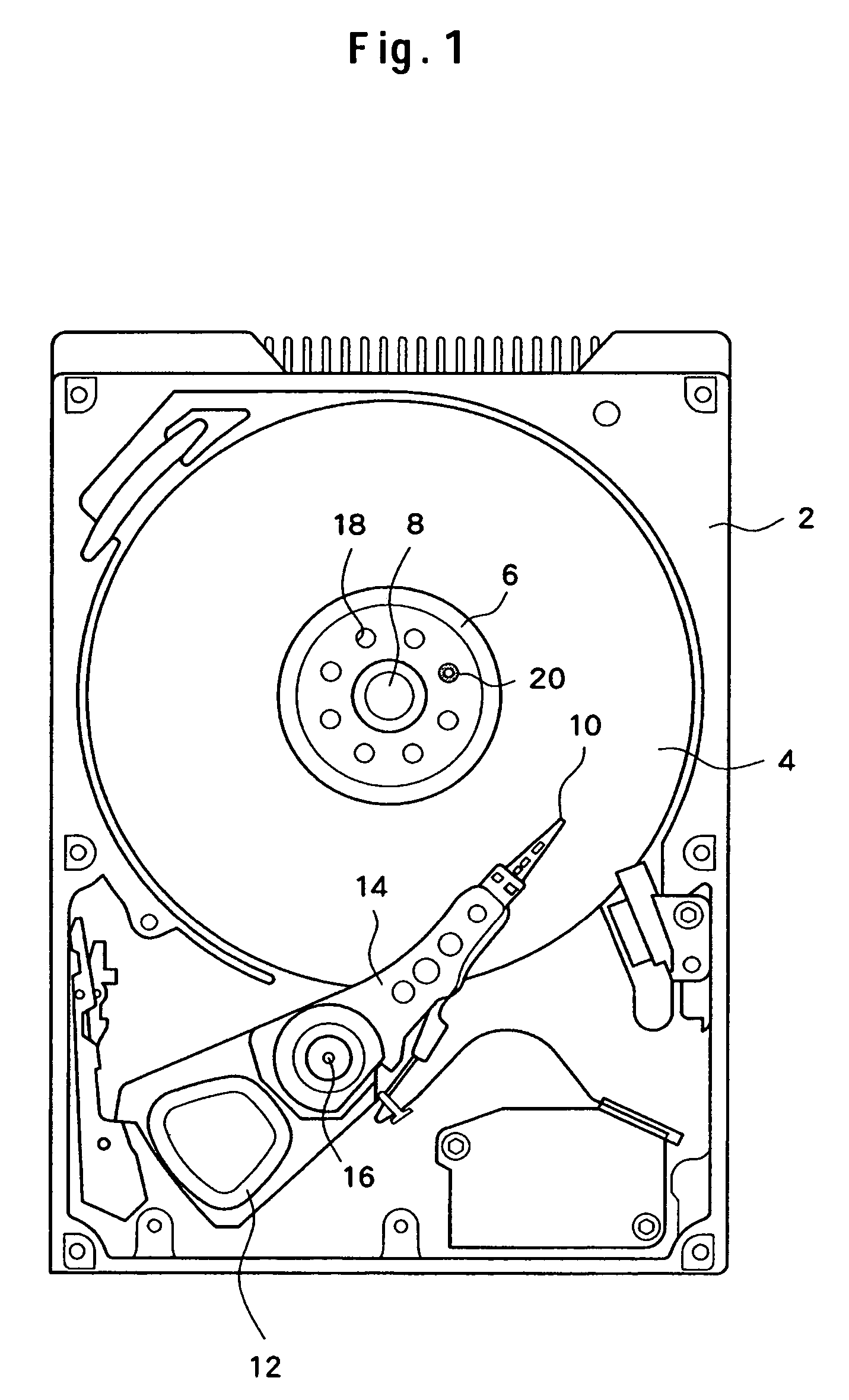

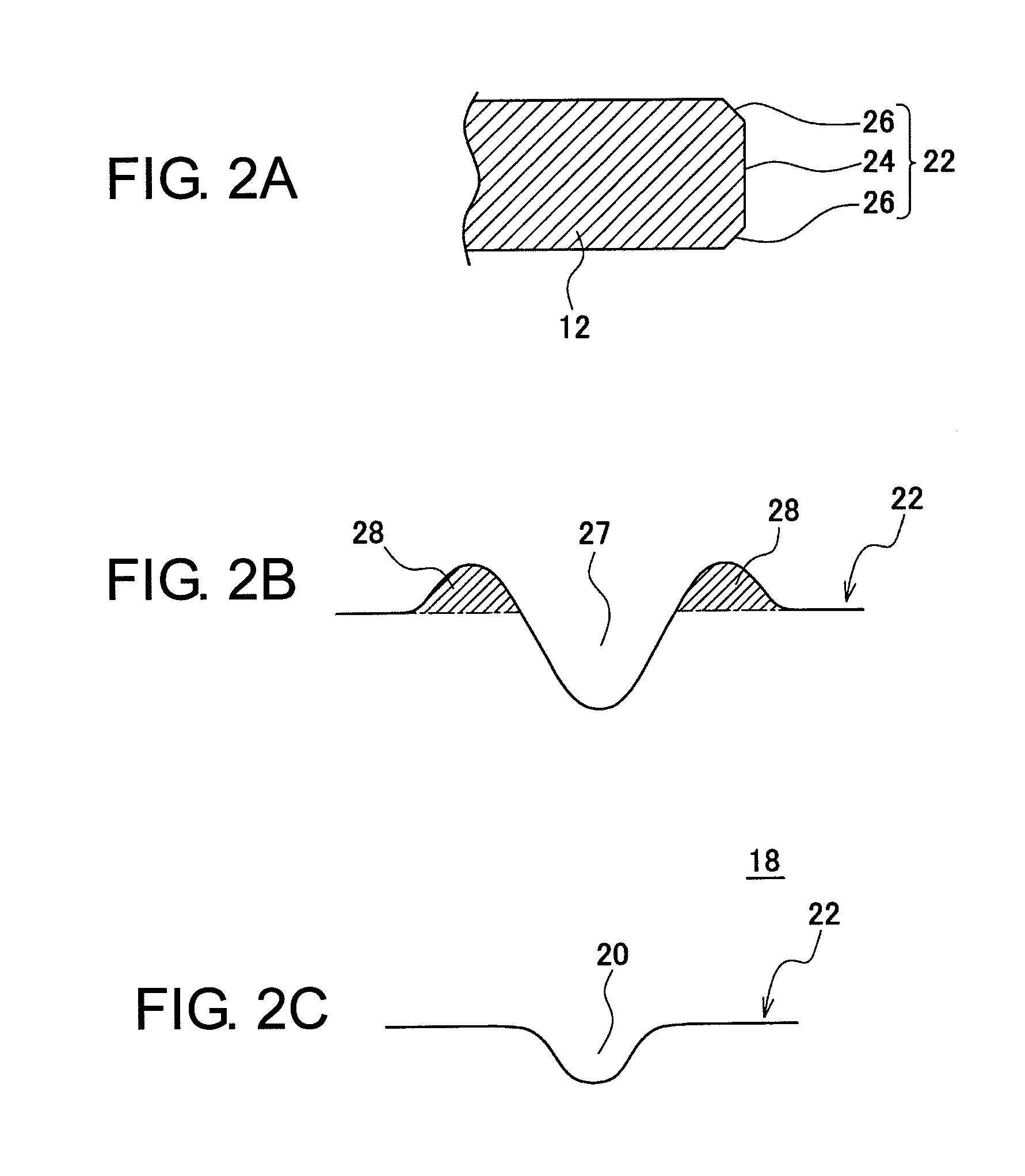

Suspension and limiter mechanism for a data storage device

InactiveUS7583474B2Suppresses generation of dustWithout deteriorating dynamic characteristics of a headRecord information storageMounting/attachment of transducer headHard disc driveEngineering

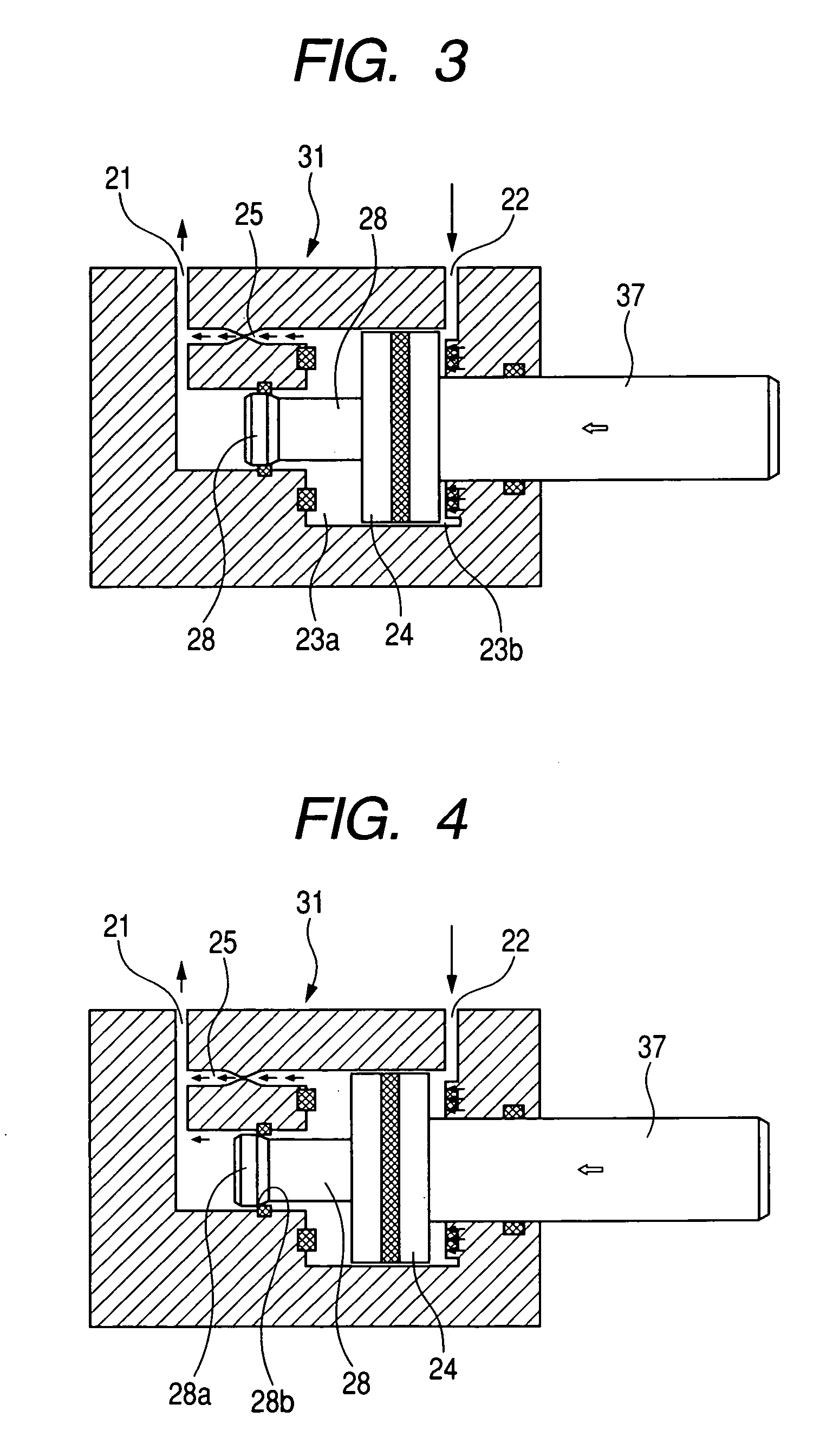

In a suspension used in an actuator of a hard disk drive, a limiter mechanism is to be provided which produces little dust and which can restrict deformation of a gimbals even against a strong shock. According to one embodiment, when a weak shock is applied to the suspension, a limiter tab and a back side of a load beam come into contact with each other to prevent a gimbals from being largely deformed by the shock. Since deformation of the gimbals is restricted by surface contact of both load beam and limiter tab, the generation of dust is suppressed effectively. When a strong shock is applied to the suspension, the limiter tab is deformed and a projecting portion of a restrictive aperture and an end portion of a limiter tab aperture come into contact with each other. The projecting portion retains the limiter tab to restrict a further deformation of the gimbals.

Owner:WESTERN DIGITAL TECH INC

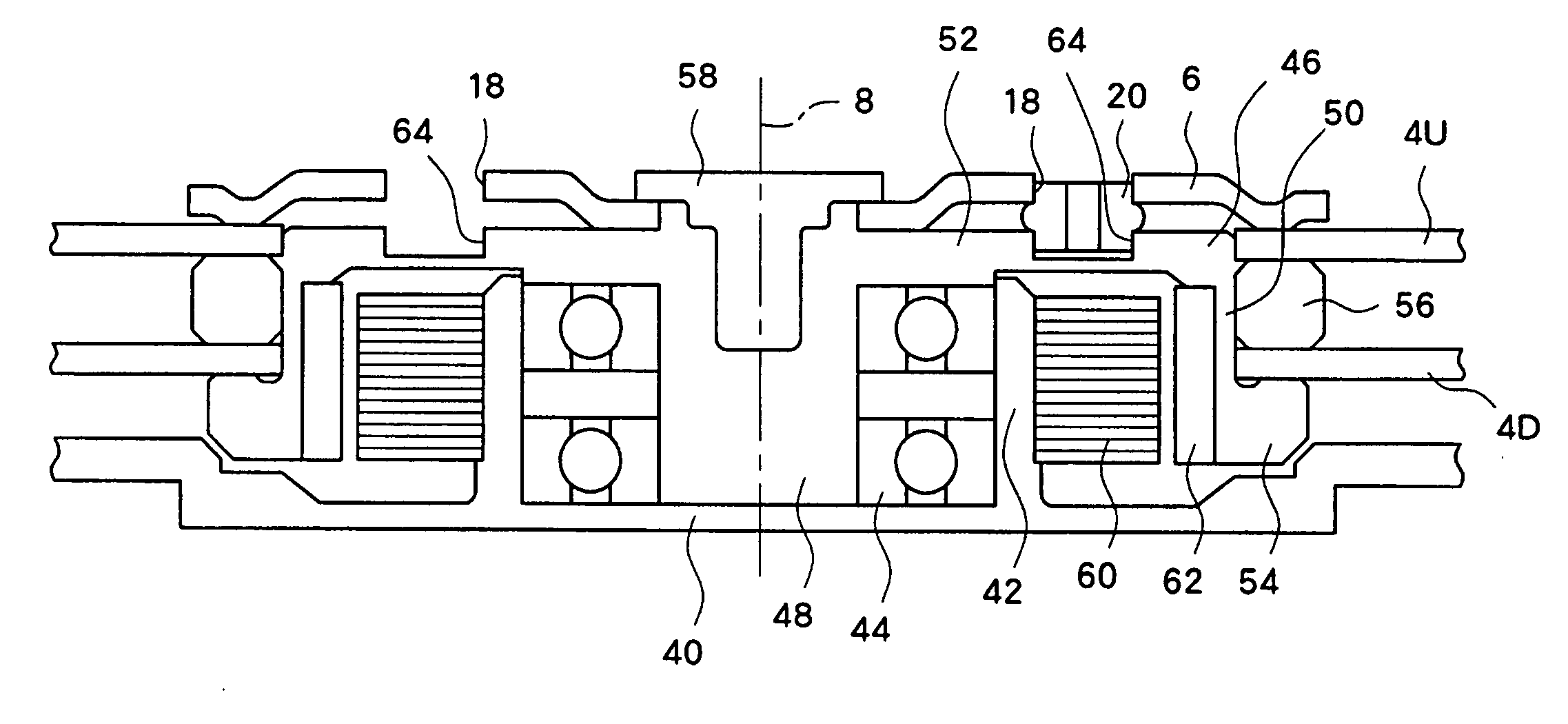

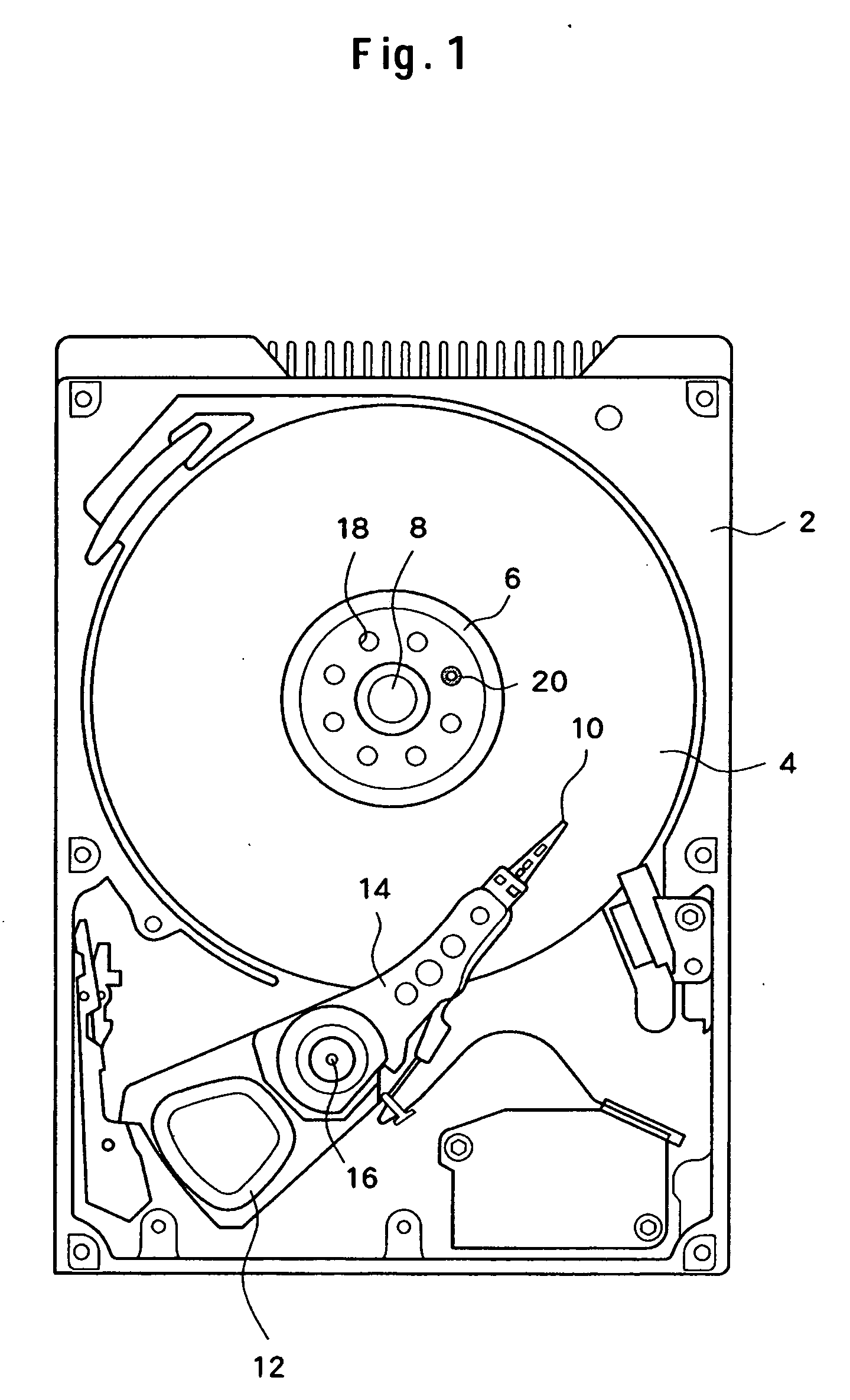

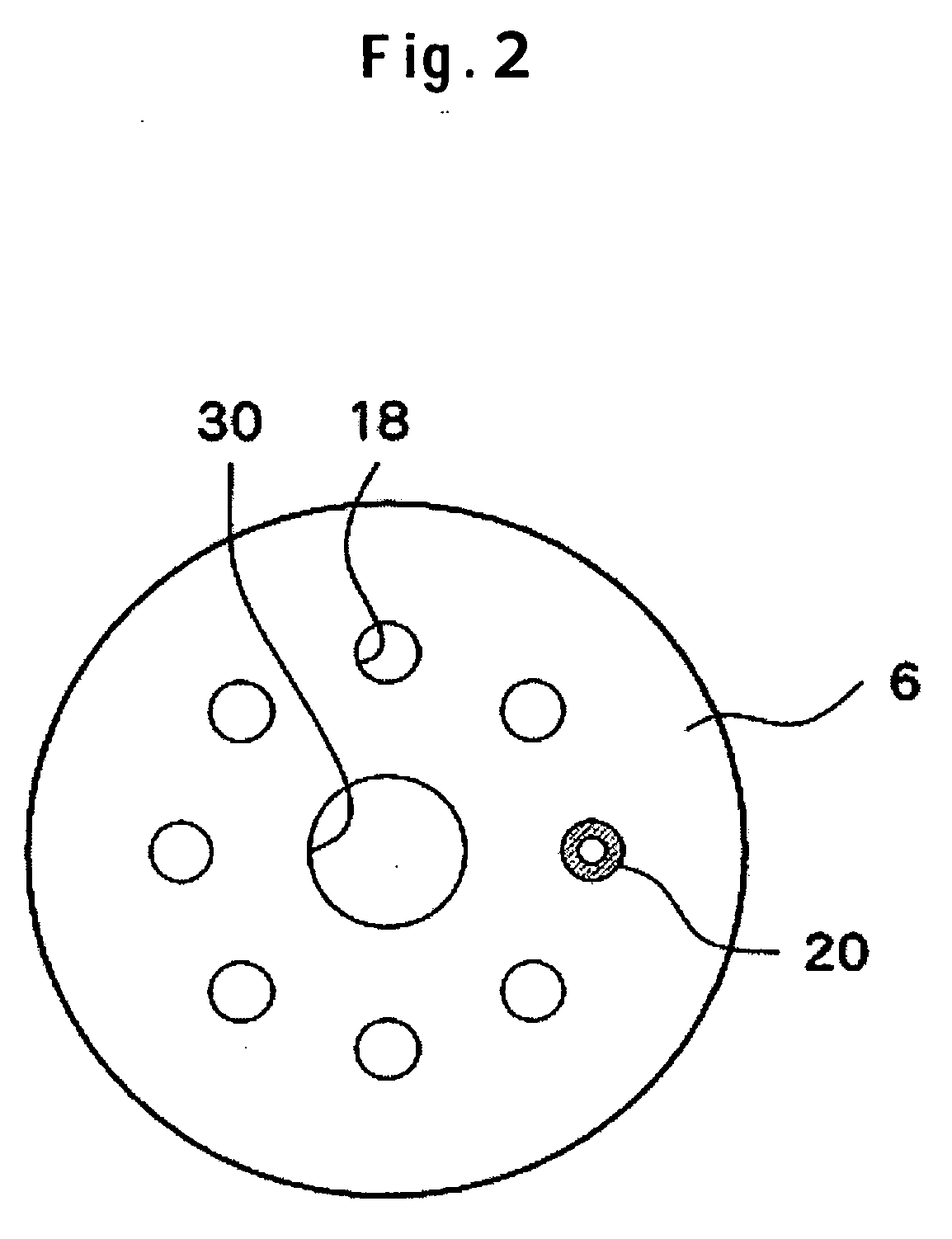

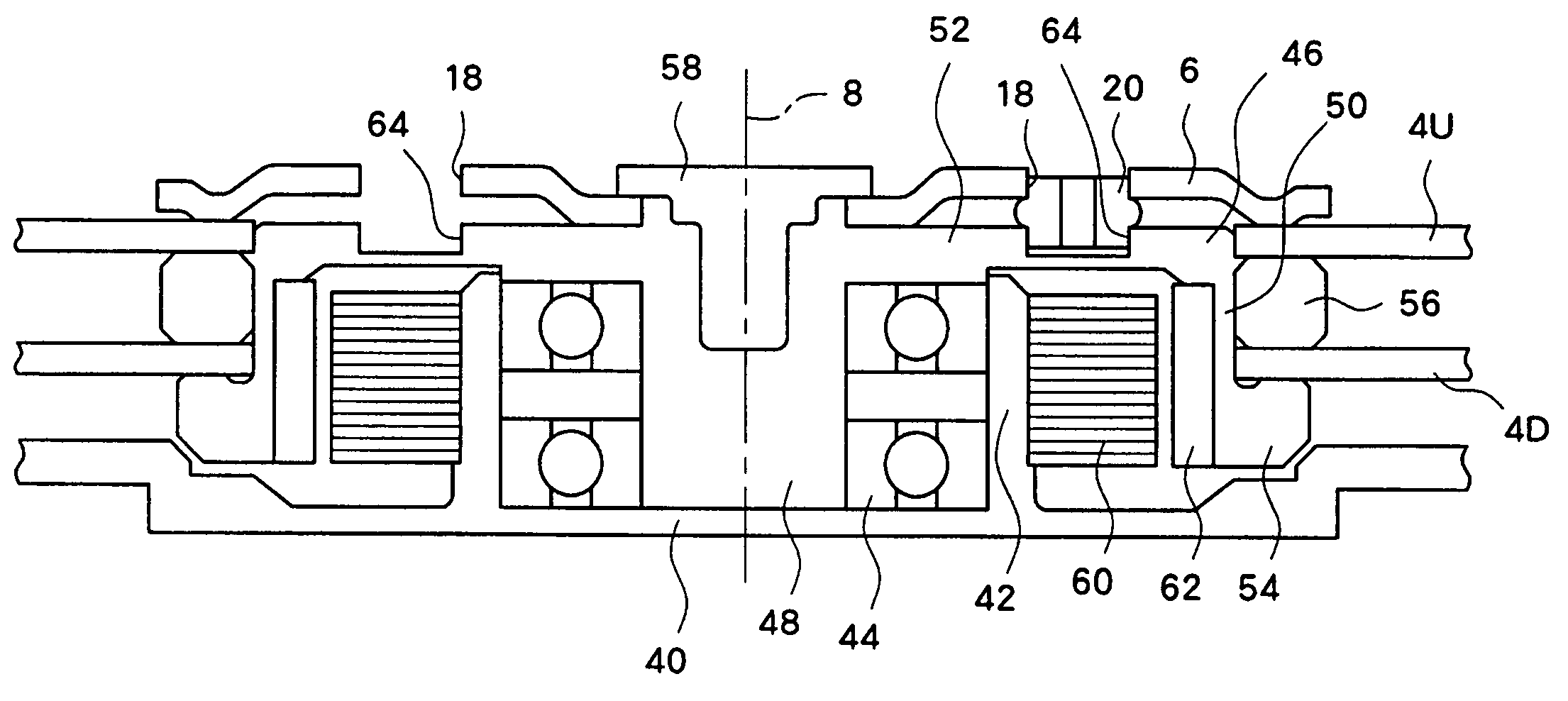

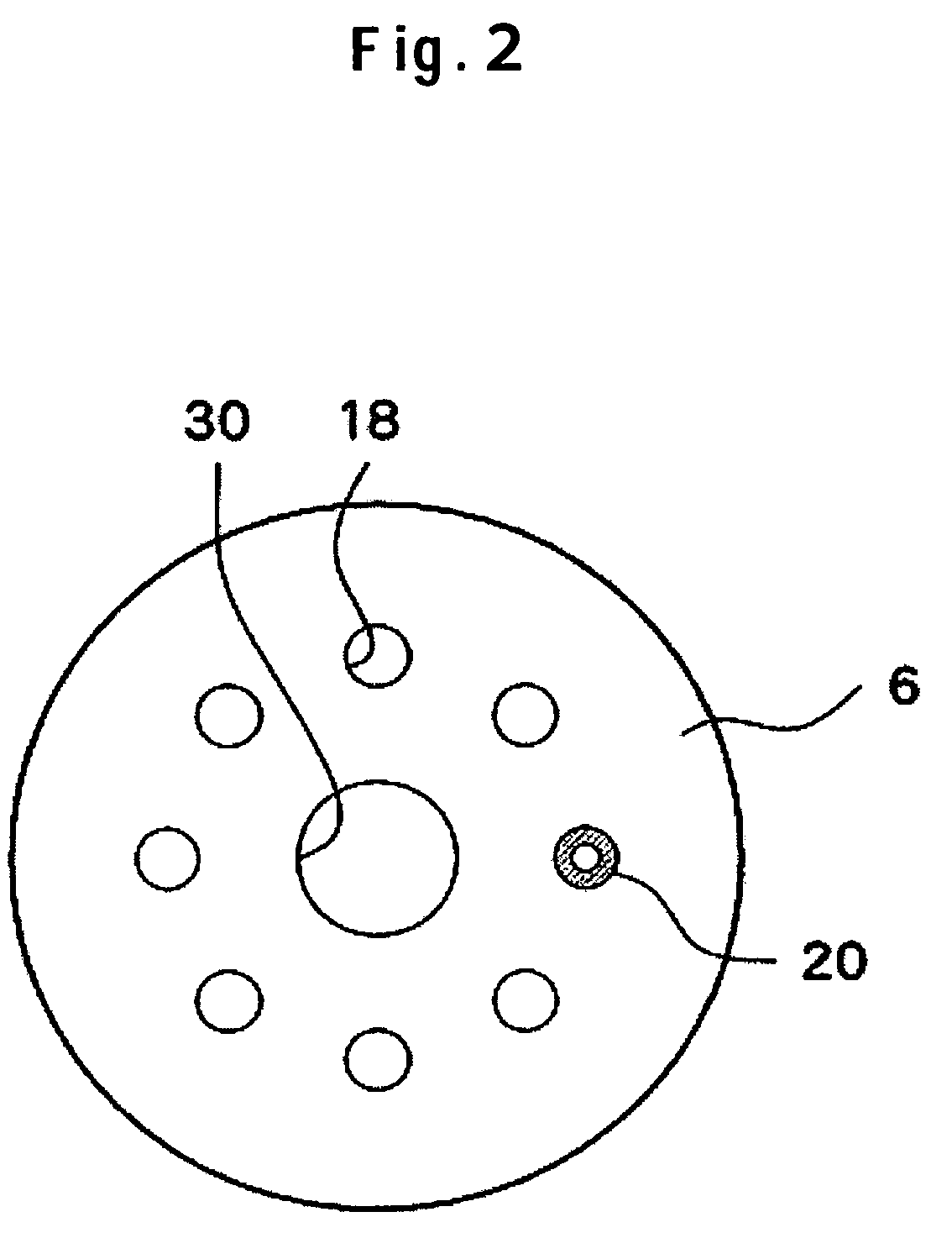

Magnetic disk drive with adjustment of rotational balance

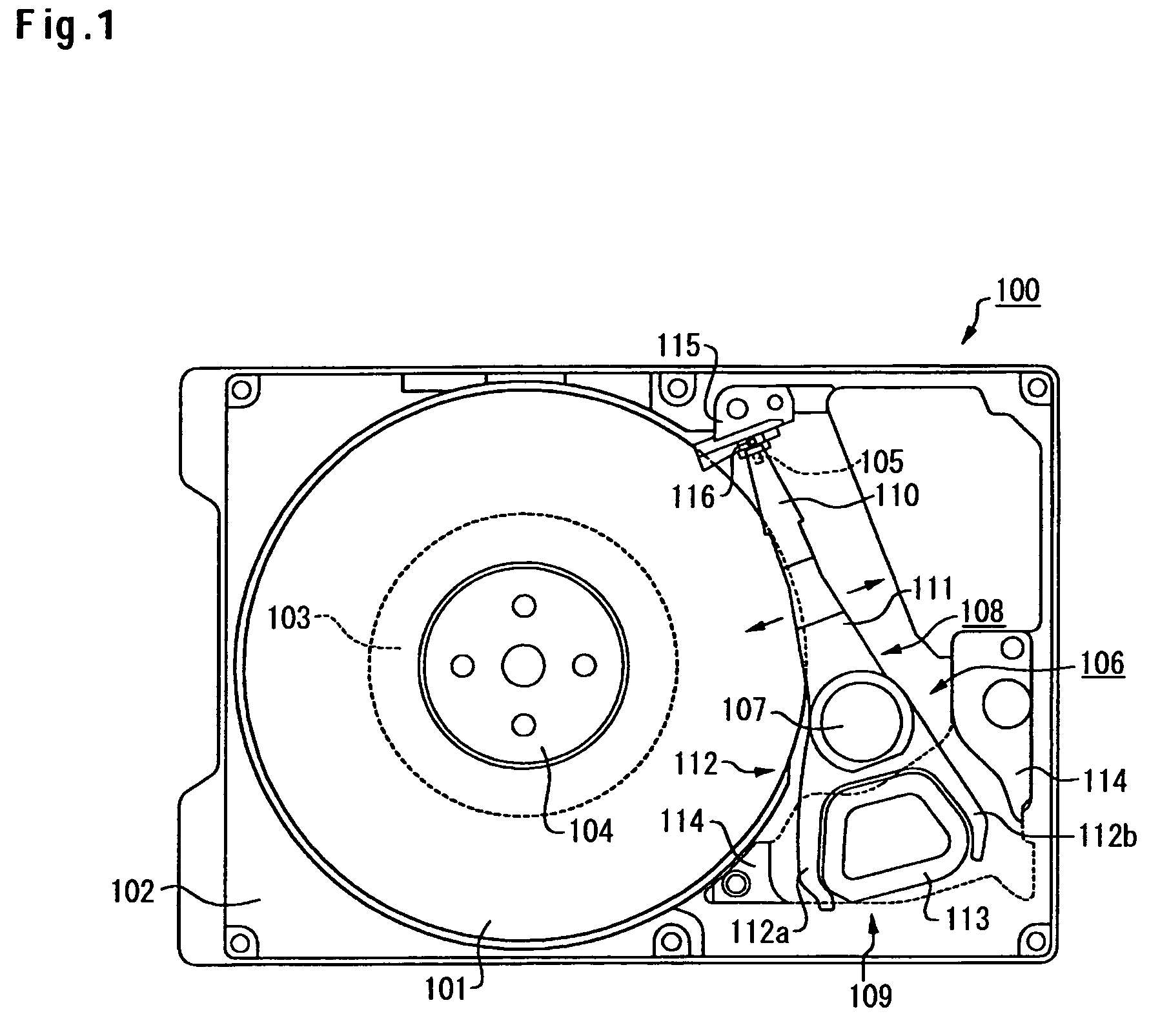

InactiveUS20060119980A1Stable structureSuppresses generation of dustRecord information storageSelf-oscillationElectric machine

Embodiments of the invention provide, in a compact magnetic disk drive, a stable structure capable of reducing self-oscillation occurring from disk spinning, while suppressing generation of dust and dirt. In one embodiment, a magnetic disk is mounted on a hub of a spindle motor. A clamp is further attached to secure the magnetic disk in position. A plurality of opening portions are formed in the clamp around an axis. A counterweight formed of an elastic material is mounted in the opening portion by being press-fitted therein. The counterweight is less likely to generate dust and dirt through friction during insertion and looseness. A gap is provided between the clamp and the hub at locations near the opening portions. The counterweight has a protruded portion on a side surface of a circular column portion. The protruded portion slides into the gap between the clamp and the hub, counteracting a tendency of the counterweight to drop out of position.

Owner:WESTERN DIGITAL TECH INC

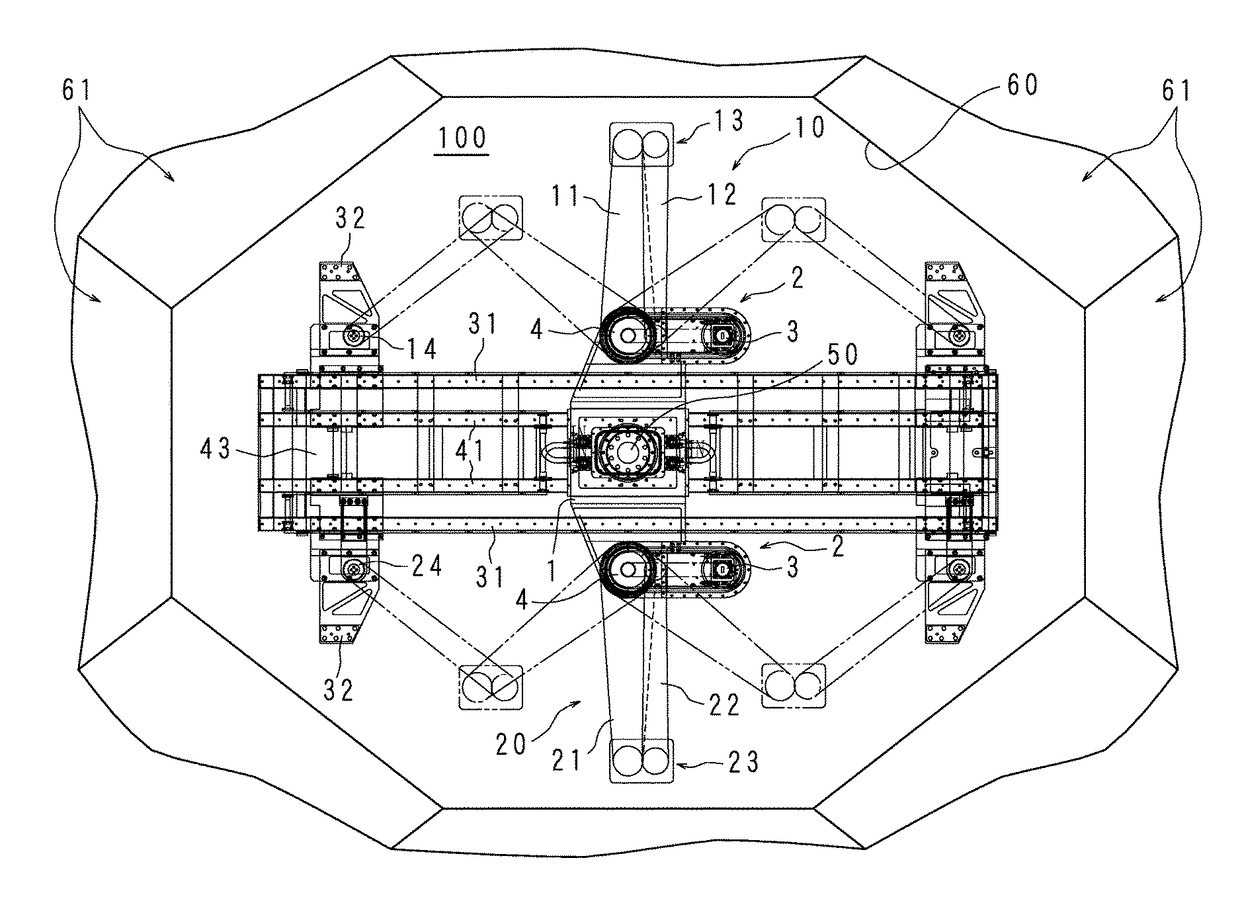

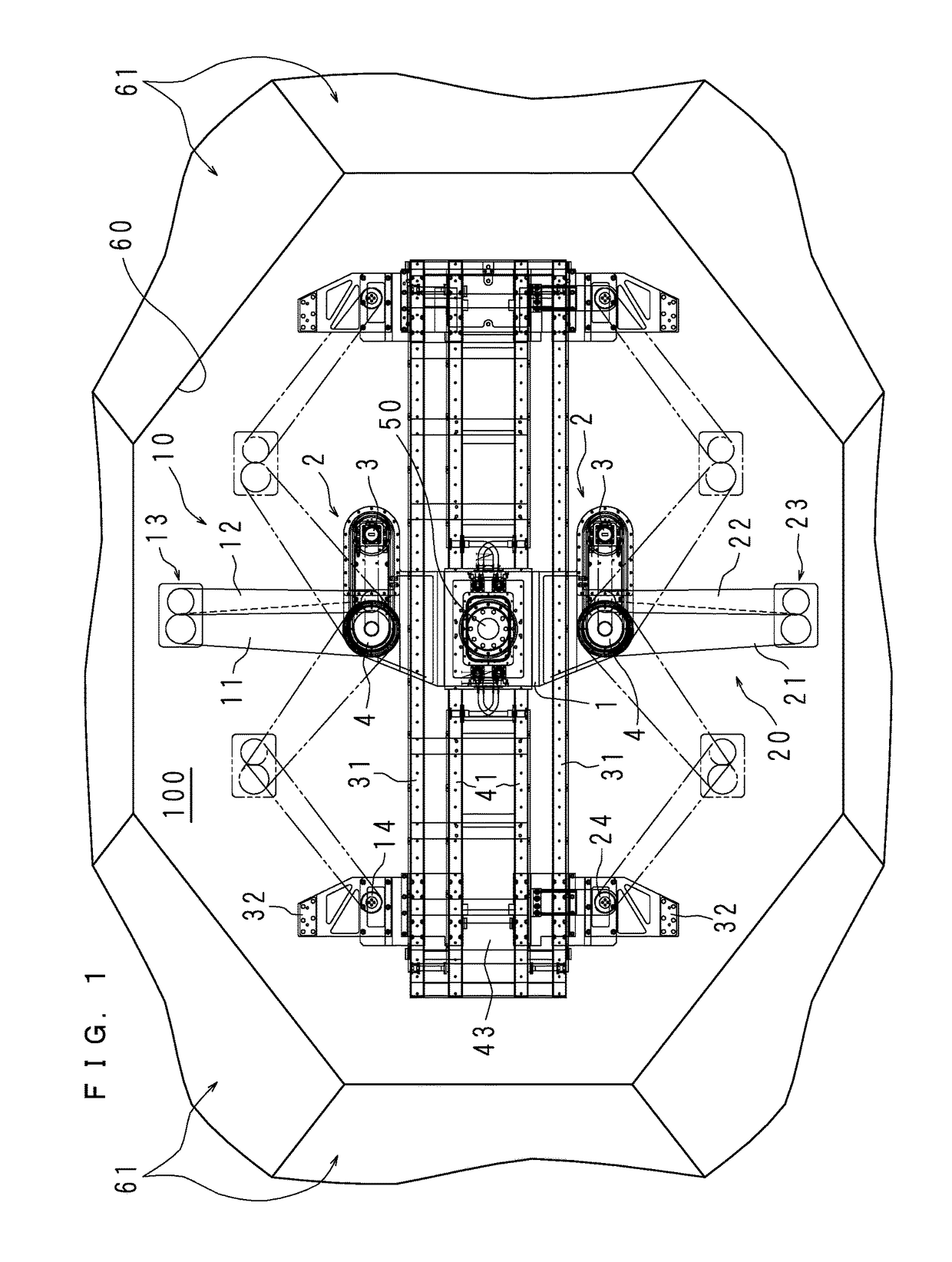

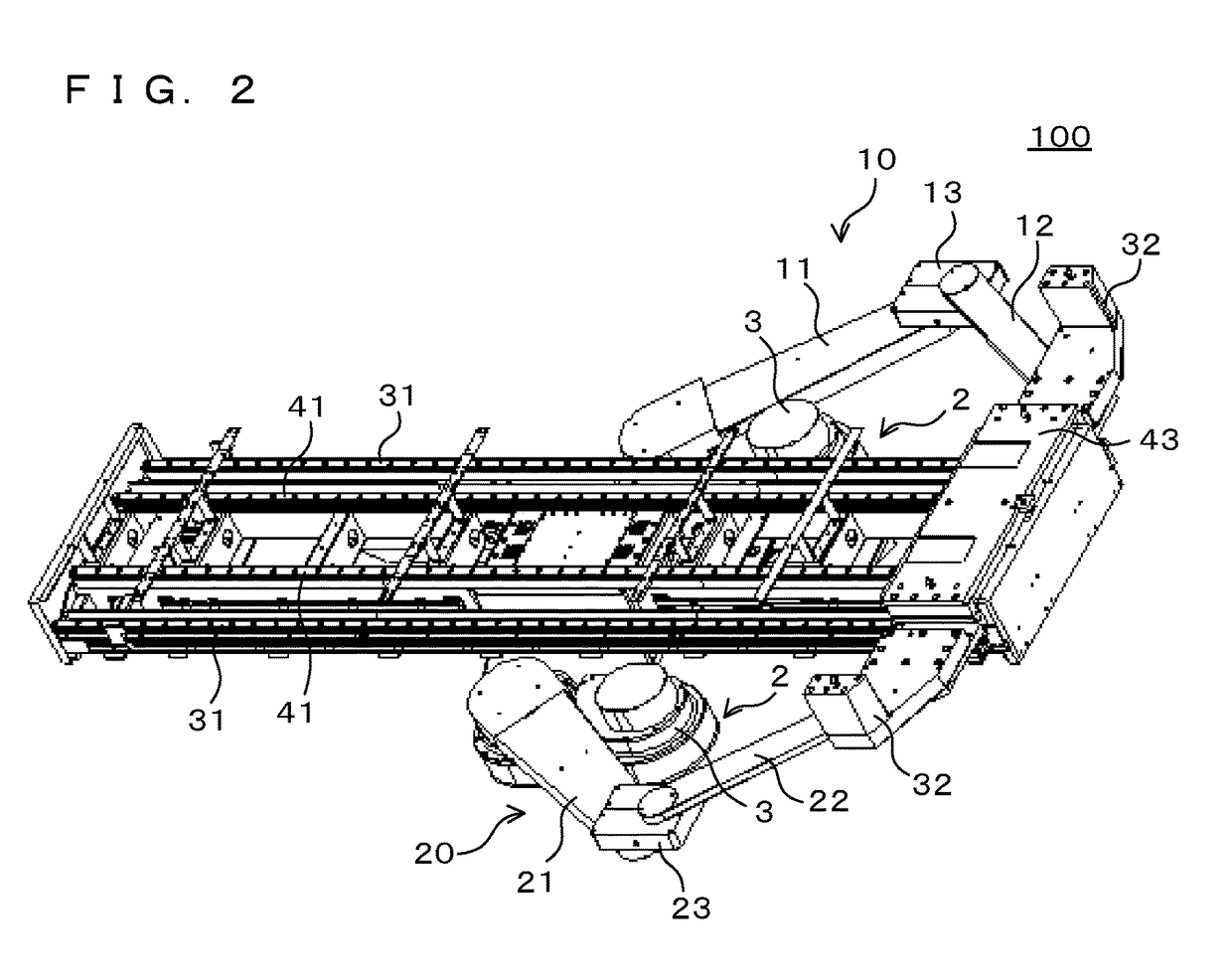

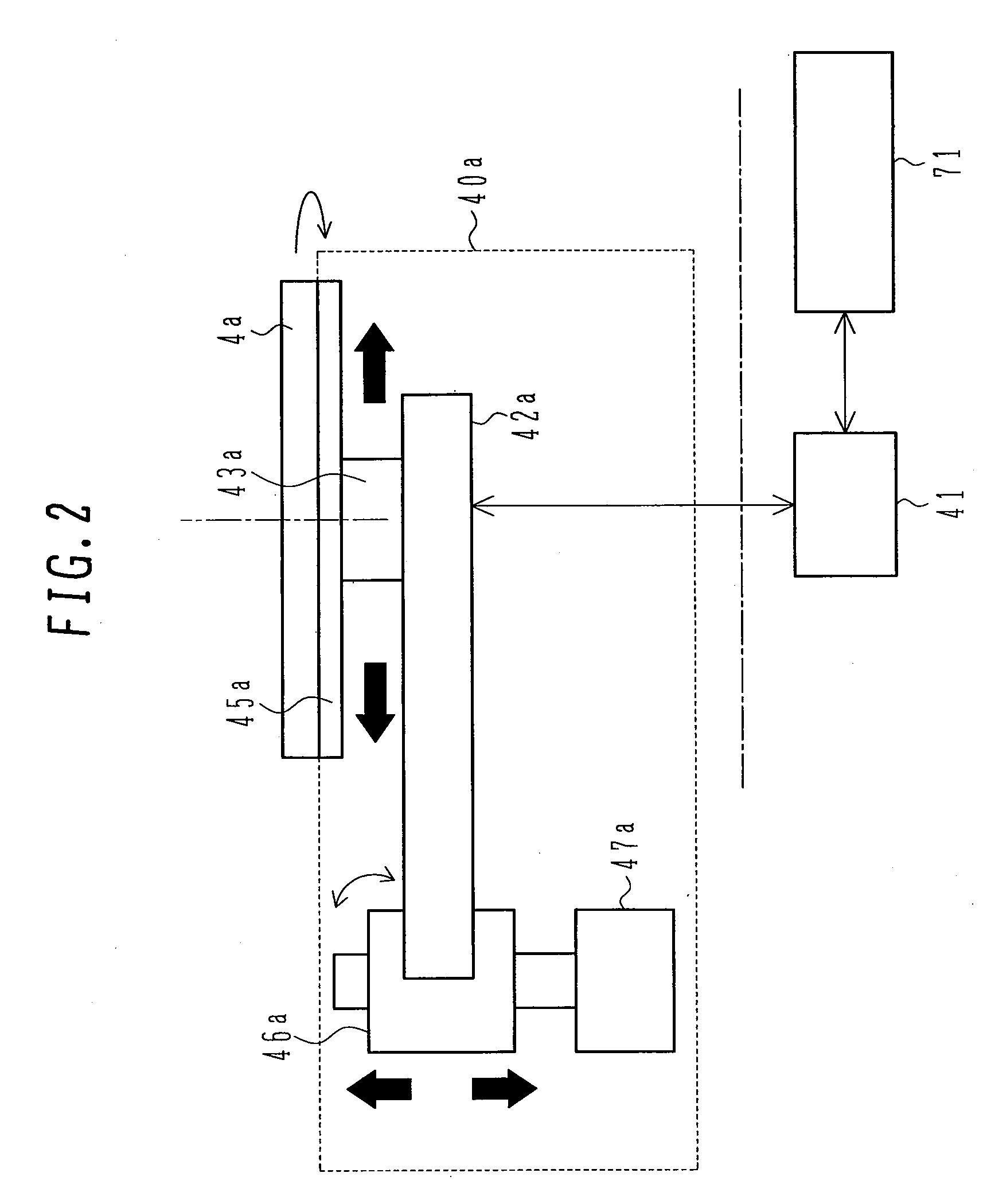

Transfer apparatus

InactiveUS20170088367A1Suppresses generation of dustSimple structureConveyorsToothed gearingsEngineeringMechanical engineering

Owner:DAIHEN CORP

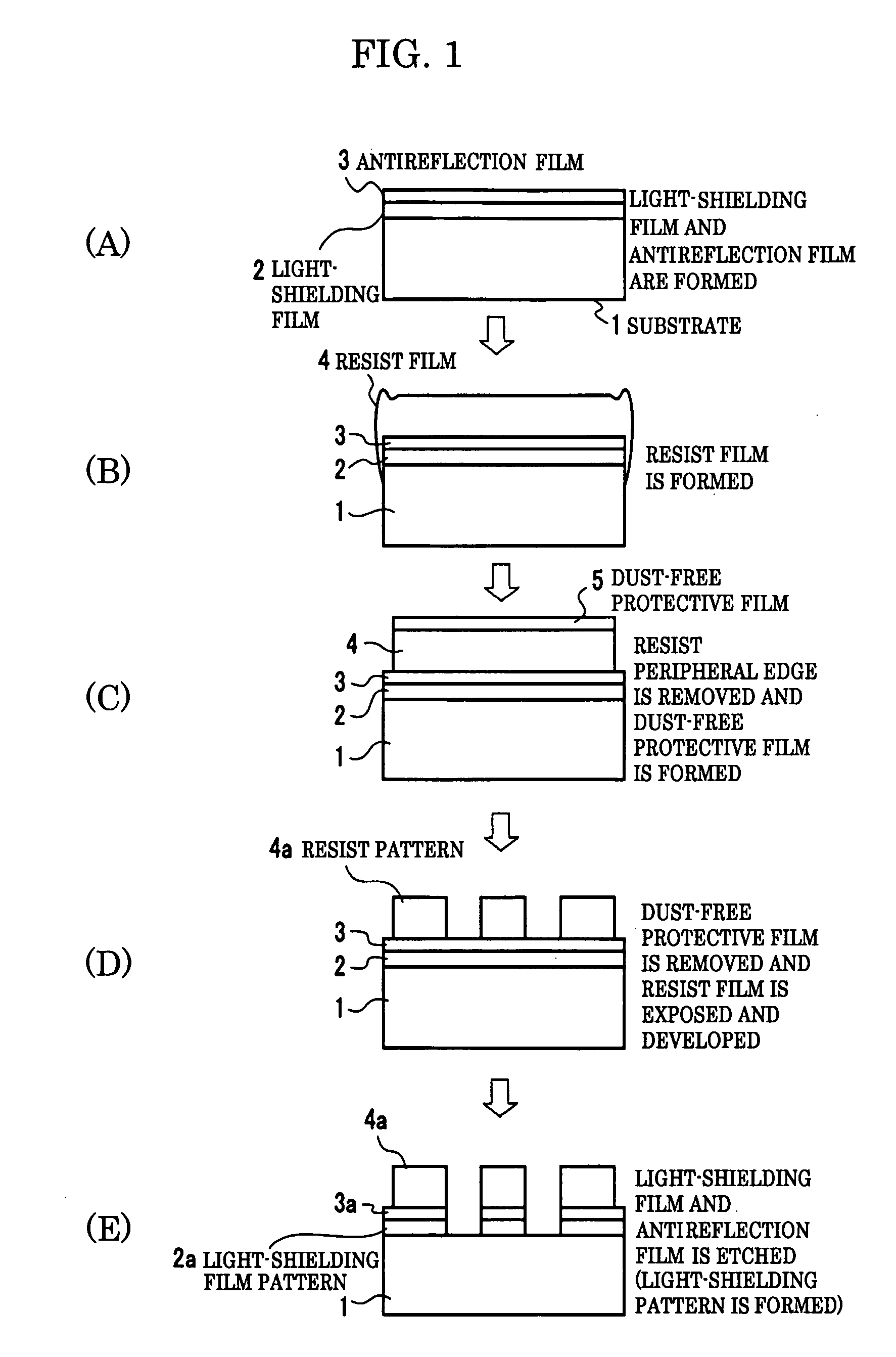

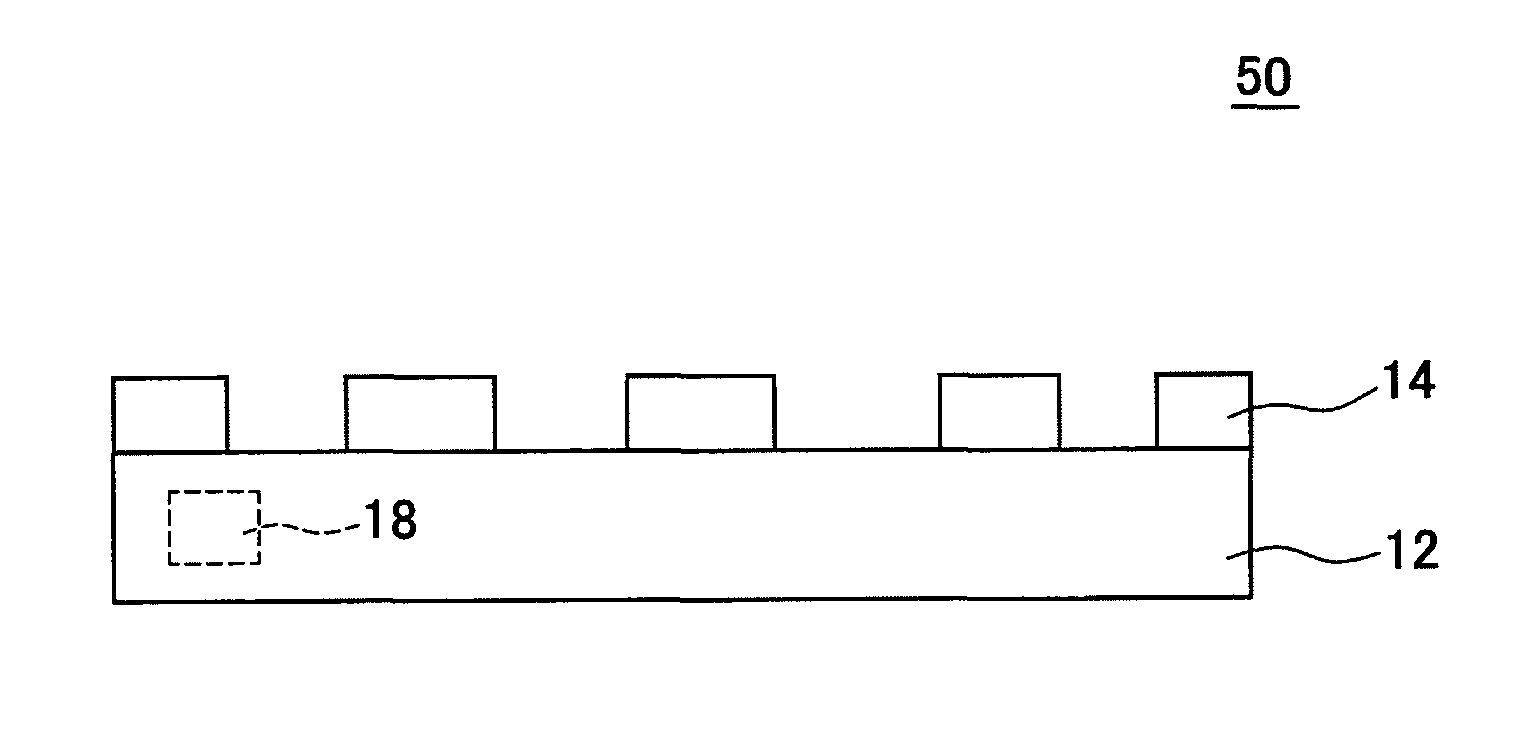

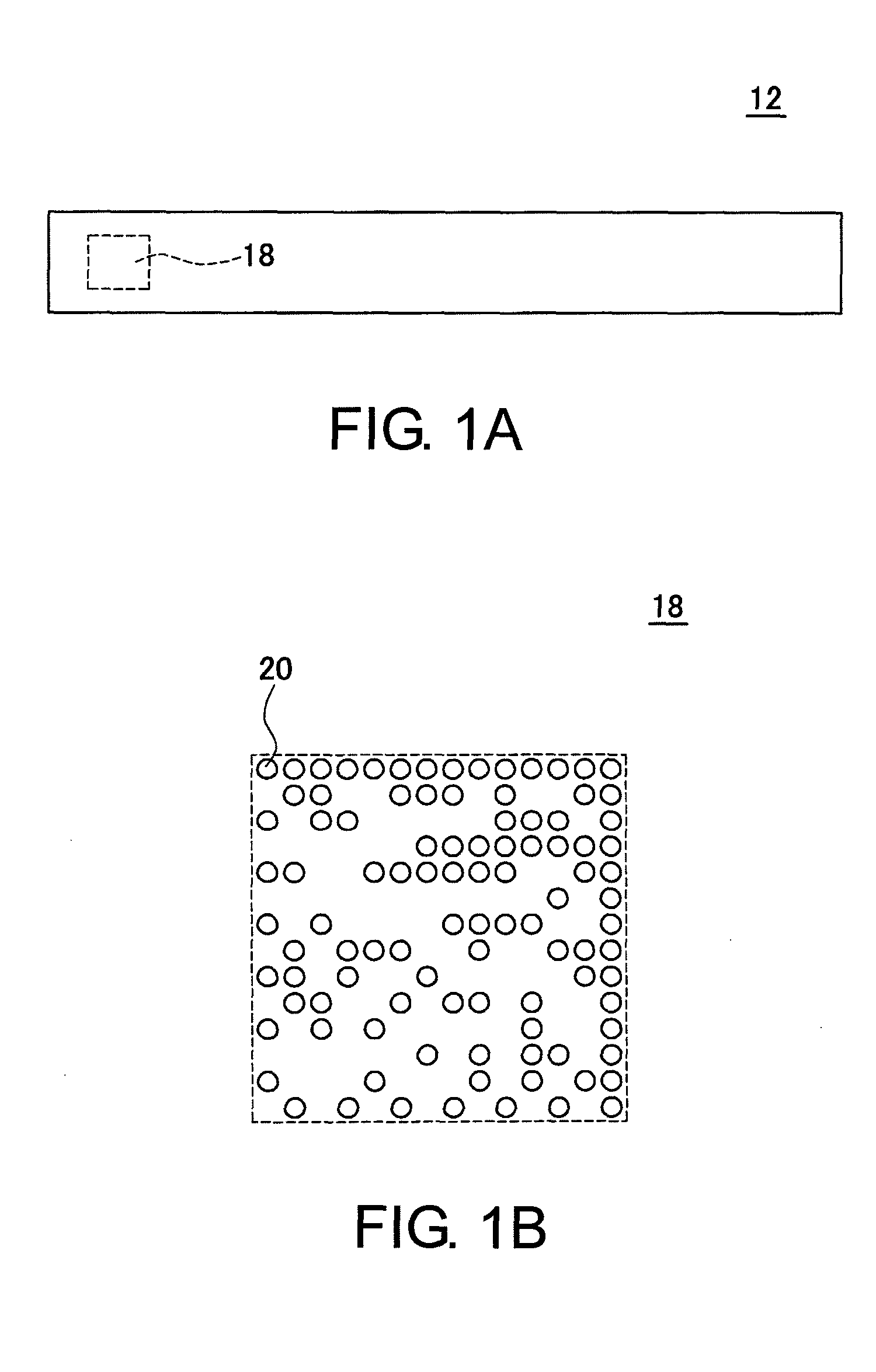

Mask blanks production method and mask production method

ActiveUS20060121359A1Avoid pollutionSuppresses generation of dustPhotomechanical apparatusSemiconductor/solid-state device manufacturingForeign matterEngineering

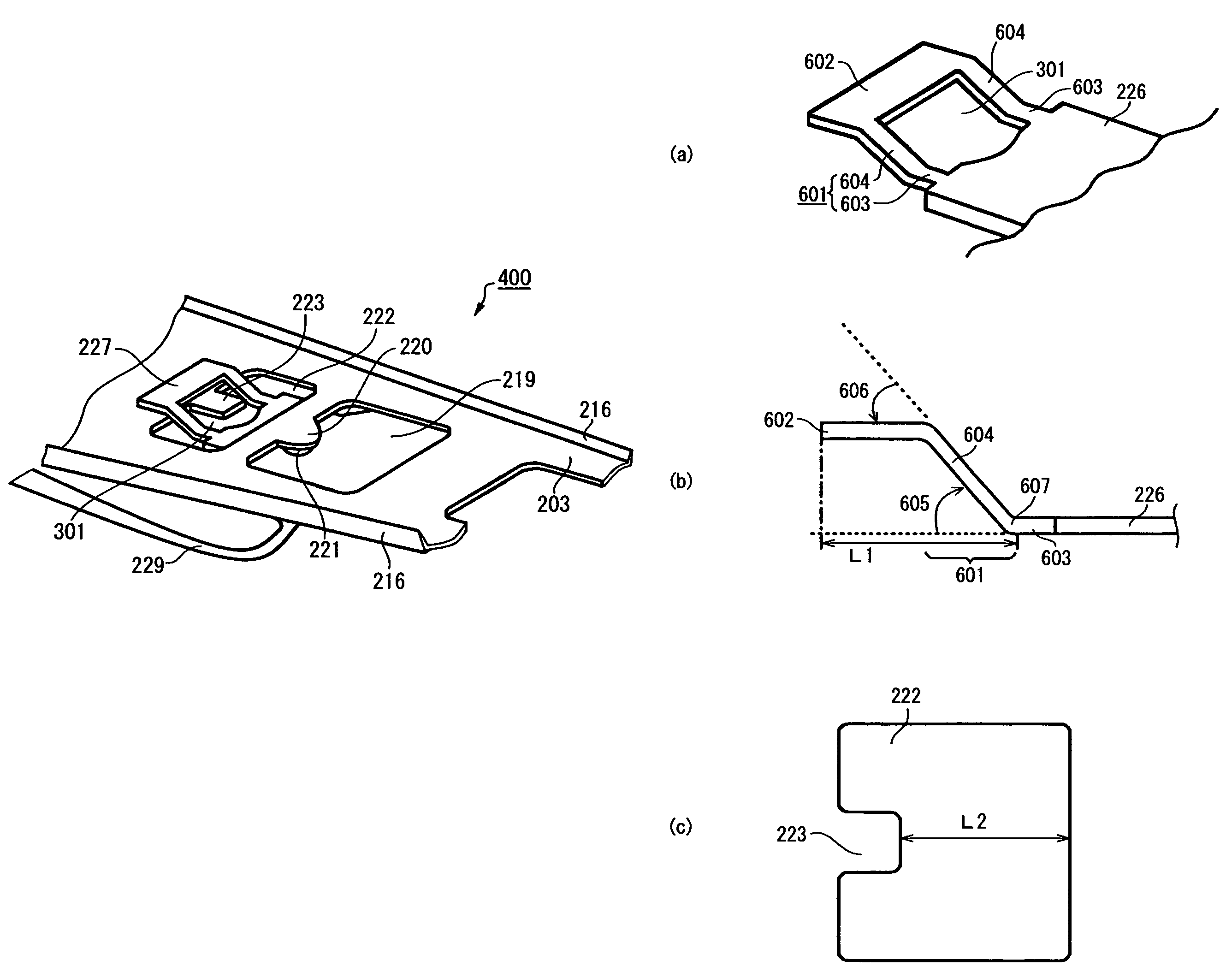

To prevent foreign matters from adhering to a substrate, etc., thereby causing inconveniences during storing and transporting a mask blank, or during manufacturing the mask blank and a mask. Thin films 2 and 3 formed in a mask thin film forming step of a mask blank manufacturing steps are covered by a dust-free protective film 5 formed of water-soluble material, thereby preventing foreign matters from adhering to the surface of the mask blank itself and preventing the surface of the mask blank from being damaged in the subsequent step, and when the mask blank is used, the dust-free protective film is removed.

Owner:HOYA CORP

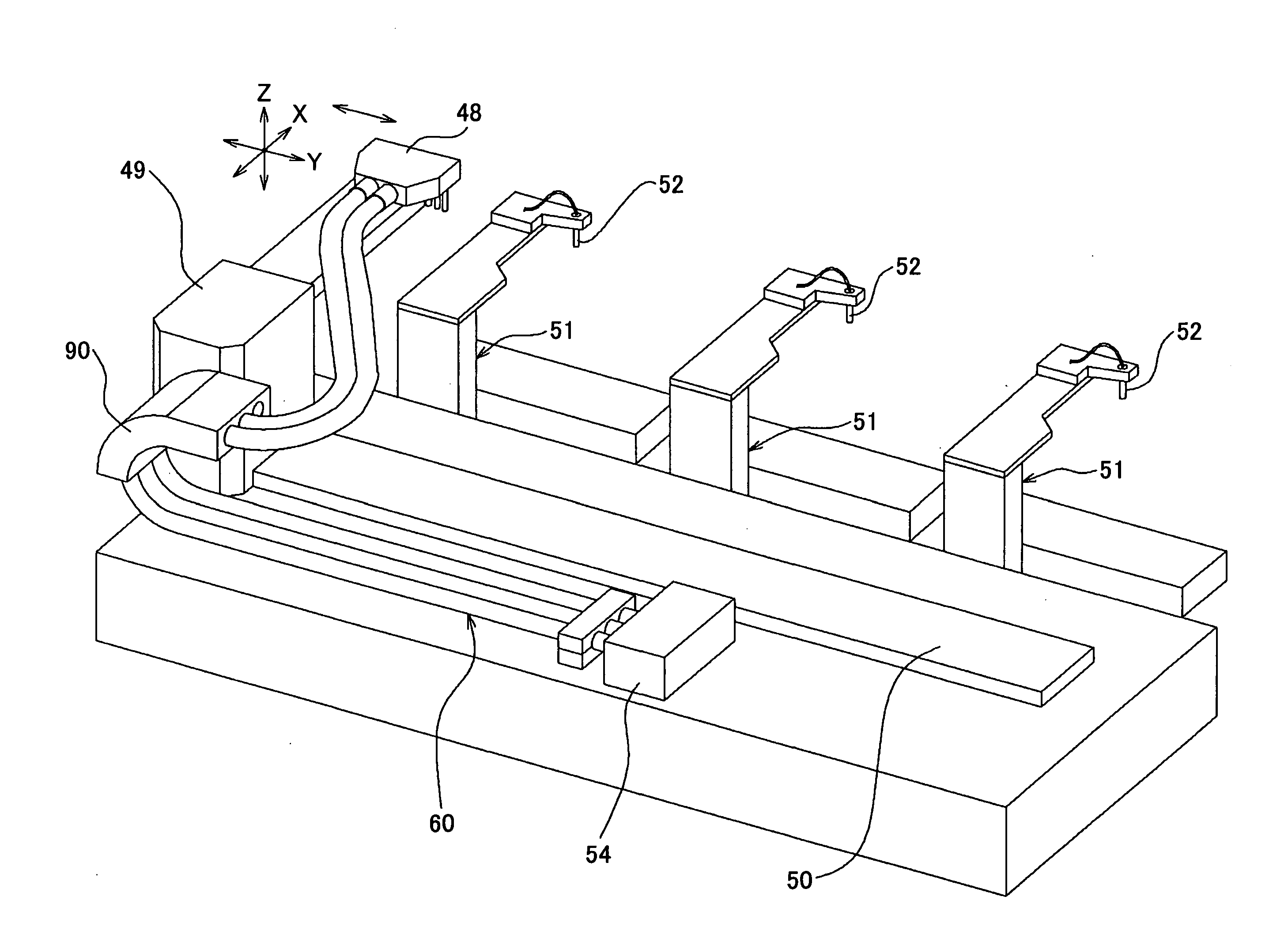

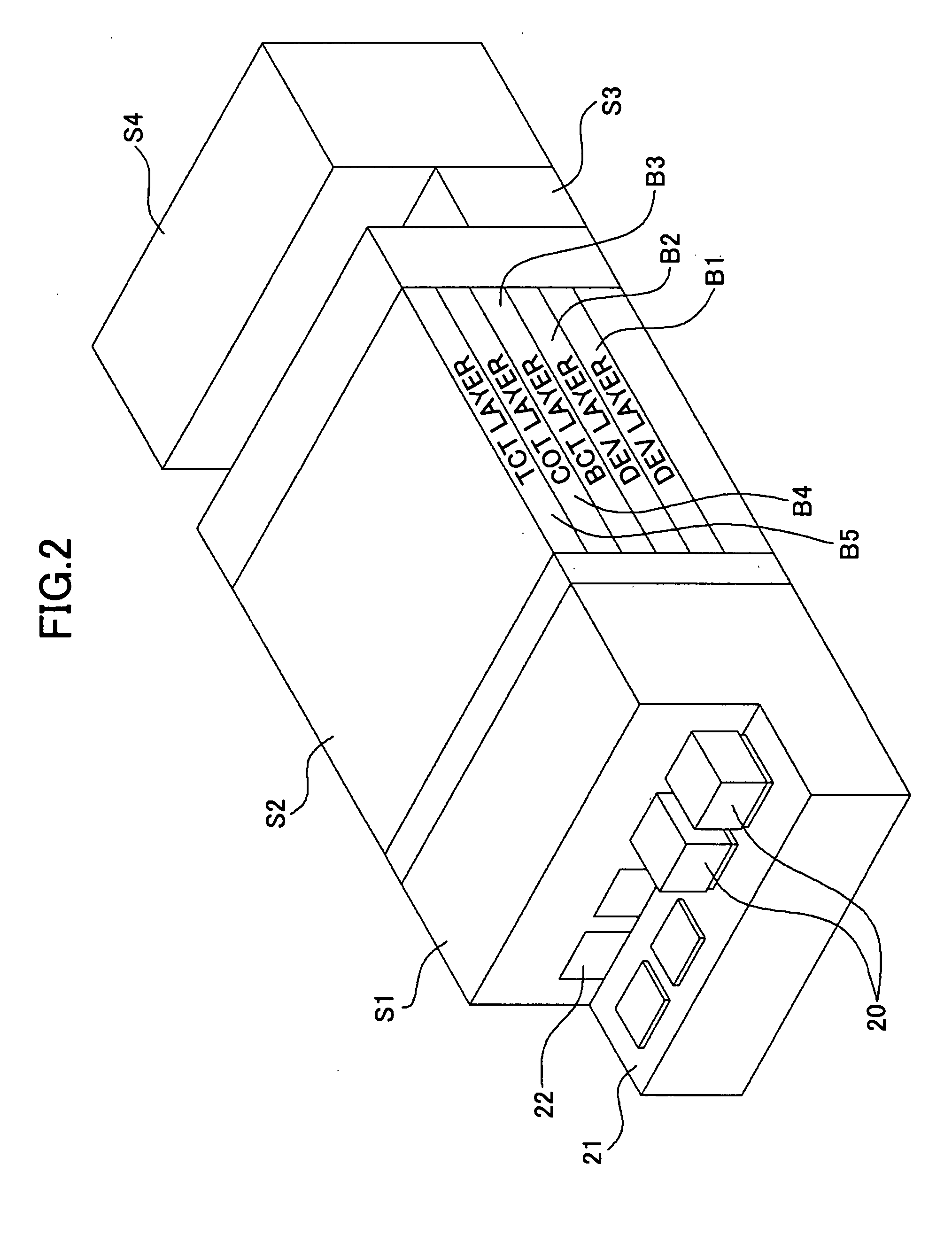

Complex pipe and coating/development processing apparatus equipped with complex pipe

InactiveUS20080289715A1Improve machining accuracyDegree of freedomPipe supportsLiquid surface applicatorsElectricityEngineering

In a complex pipe, a plurality of pipe members containing at least a pipe member for liquid and a pipe member for electricity are fixed in parallel arrangement. One end of the complex pipe is connected to a stationary equipment and the other end is connected to a movable member. The plurality of pipe members are integrally combined by a cover member having flexibility. A liquid supply pipe is inserted with a space in the pipe member for liquid. A fluid for temperature adjustment is supplied to the space between the pipe member for liquid and the liquid supply pipe.

Owner:TOKYO ELECTRON LTD

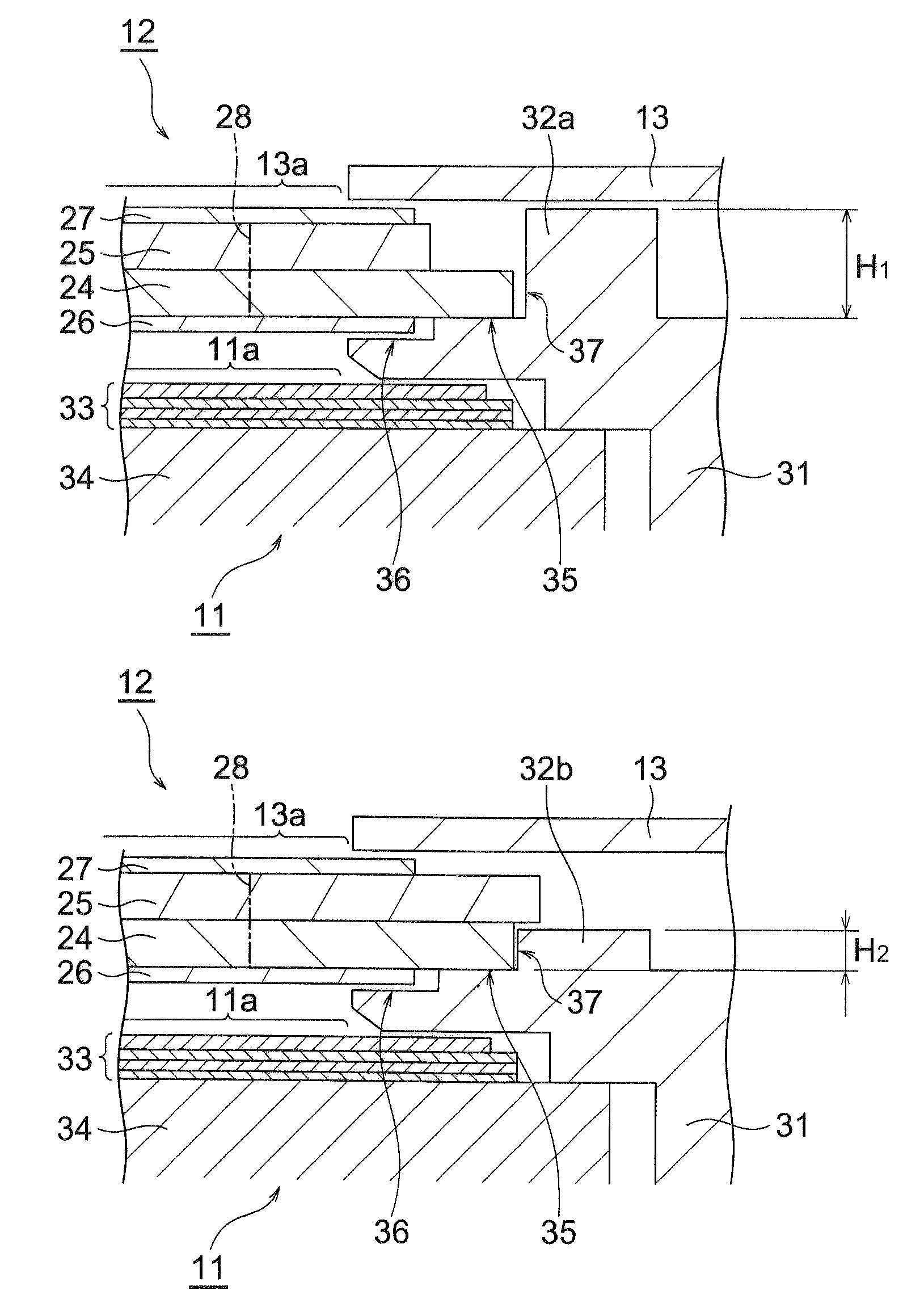

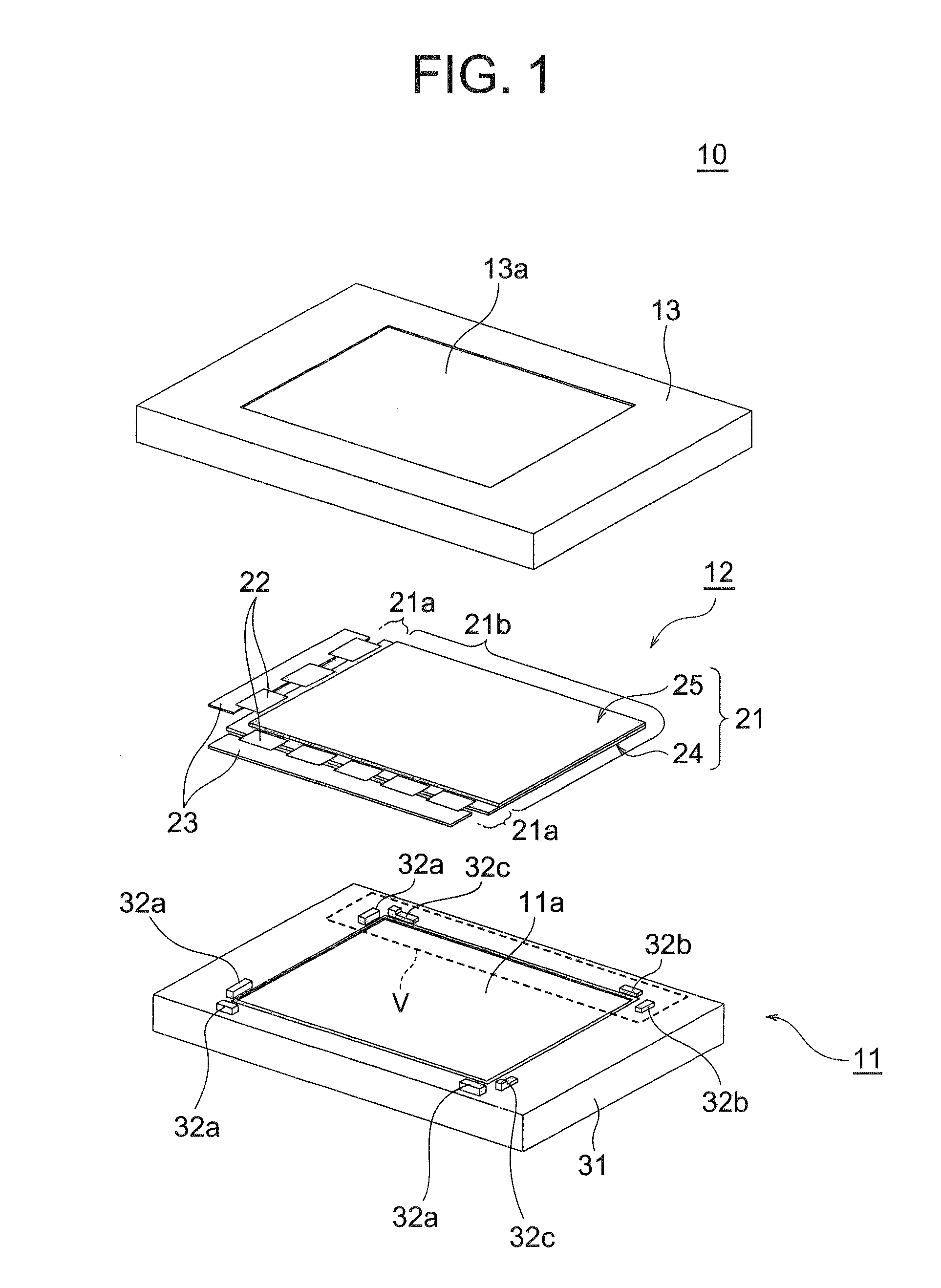

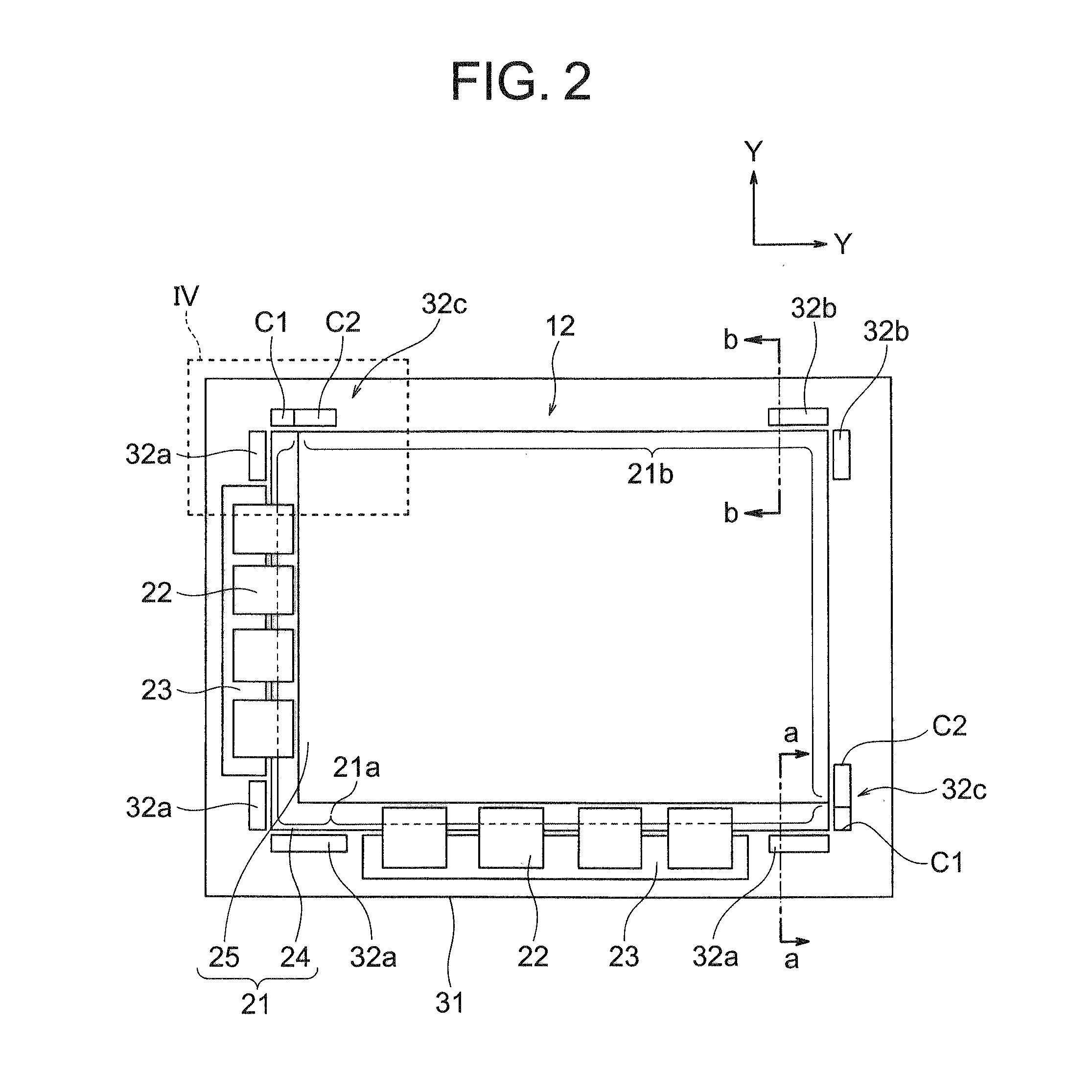

Display device comprising a first positioning wall having a height larger than the height of the bonding surface of the substrates and a second positioning wall having a height smaller than the height of the bonding surface

ActiveUS8111345B2Improve image qualitySuppresses generation of dustTelevision system detailsColor television detailsDisplay deviceEngineering

Owner:NEC LCD TECH CORP

Large-size substrate

ActiveUS8012563B2Suppresses generation of dustLiquid crystal compositionsFlexible-parts wheelsDiagonalLight exposure

A large-size substrate adapted for light exposure is of a plate shape having a diagonal length or diameter of 500-2,000 mm, a thickness of 1-20 mm, and a peripheral surface with a roughness Ra of 0.05-0.4 μm. The number of particles released from the substrate periphery during cleaning is minimized, leading to an improved yield in the cleaning step. The substrate can be manually handled, achieving an improvement in substrate quality without a need for a handling mechanism.

Owner:SHIN ETSU CHEM IND CO LTD

Magnetic disk drive with adjustment of rotational balance

InactiveUS7483239B2Stable structureSuppresses generation of dustRecord information storageSelf-oscillationElectric machine

Embodiments of the invention provide, in a compact magnetic disk drive, a stable structure capable of reducing self-oscillation occurring from disk spinning, while suppressing generation of dust and dirt. In one embodiment, a magnetic disk is mounted on a hub of a spindle motor. A clamp is further attached to secure the magnetic disk in position. A plurality of opening portions are formed in the clamp around an axis. A counterweight formed of an elastic material is mounted in the opening portion by being press-fitted therein. The counterweight is less likely to generate dust and dirt through friction during insertion and looseness. A gap is provided between the clamp and the hub at locations near the opening portions. The counterweight has a protruded portion on a side surface of a circular column portion. The protruded portion slides into the gap between the clamp and the hub, counteracting a tendency of the counterweight to drop out of position.

Owner:WESTERN DIGITAL TECH INC

Mask blank glass substrate, mask blank glass substrate manufacturing method, mask blank manufacturing method, and mask manufacturing method

InactiveUS8048591B2Reduced strengthSuppresses generation of dustOriginals for photomechanical treatmentOptoelectronics

A mask blank glass substrate is for use in manufacturing a mask blank. In the mask blank glass substrate, a marker expressing, by a plurality of pits, information for identifying or managing the mask blank glass substrate is formed on a surface of a region, having no influence on formation of a transfer pattern, of the mask blank glass substrate. Each of the pits forming the marker is a round hole with its edge portion being generally circular and a distance L1 between the edge portions of the adjacent pits is 50 μm or more. The marker is formed, for example, on an end face of the mask blank glass substrate.

Owner:HOYA CORP

Method of suppressing the generation of dust from sand

ActiveUS9637671B2Reduce the amount requiredSuppresses generation of dustMaterial nanotechnologyPigmenting treatmentParticulatesPolymer chemistry

A composite is characterized by particulates of sand wherein at least a portion of the surface of the particulates is coated with a polycationic polymer. The presence of the polycationic polymer on the surface of the particulates reduces the amount of dust generated during handling and use of the sand. The polycationic polymer further reduces the amount of dust generated during transport of the sand as well during manufacture, treatment or processing of the sand.

Owner:BAKER HUGHES INC

Aggregate recycling apparatus having air circulation type foreign substance and fine particle separation means, and method thereof

InactiveUS7387266B2Suppresses generation of dustAvoid it happening againSievingConstruction waste recoveryCycloneAir cycle

Disclosed is an aggregate recycling apparatus having an air circulation type foreign substance and fine particle separation means which directs a blast of air, circulated in a dry state, toward waste having passed through a crushing process immediately after the crushing of the waste and removes fine particles and foreign substances using a cyclone, thereby removing dust generated in the course of separating and screening the waste, and a method thereof. The aggregate recycling apparatus includes a crushing device for crushing waste, an air circulation type fine particle and foreign substance separation device for directing re-circulated air to crushed products received from the crushing device, scattering fine particles and foreign substances and collecting dust in a cyclone, an air conveyor for conveying crushed products deprived of the fine particles and foreign substances, and a double vibration screen for screening the crushed products received from the air conveyor.

Owner:SHINTEK

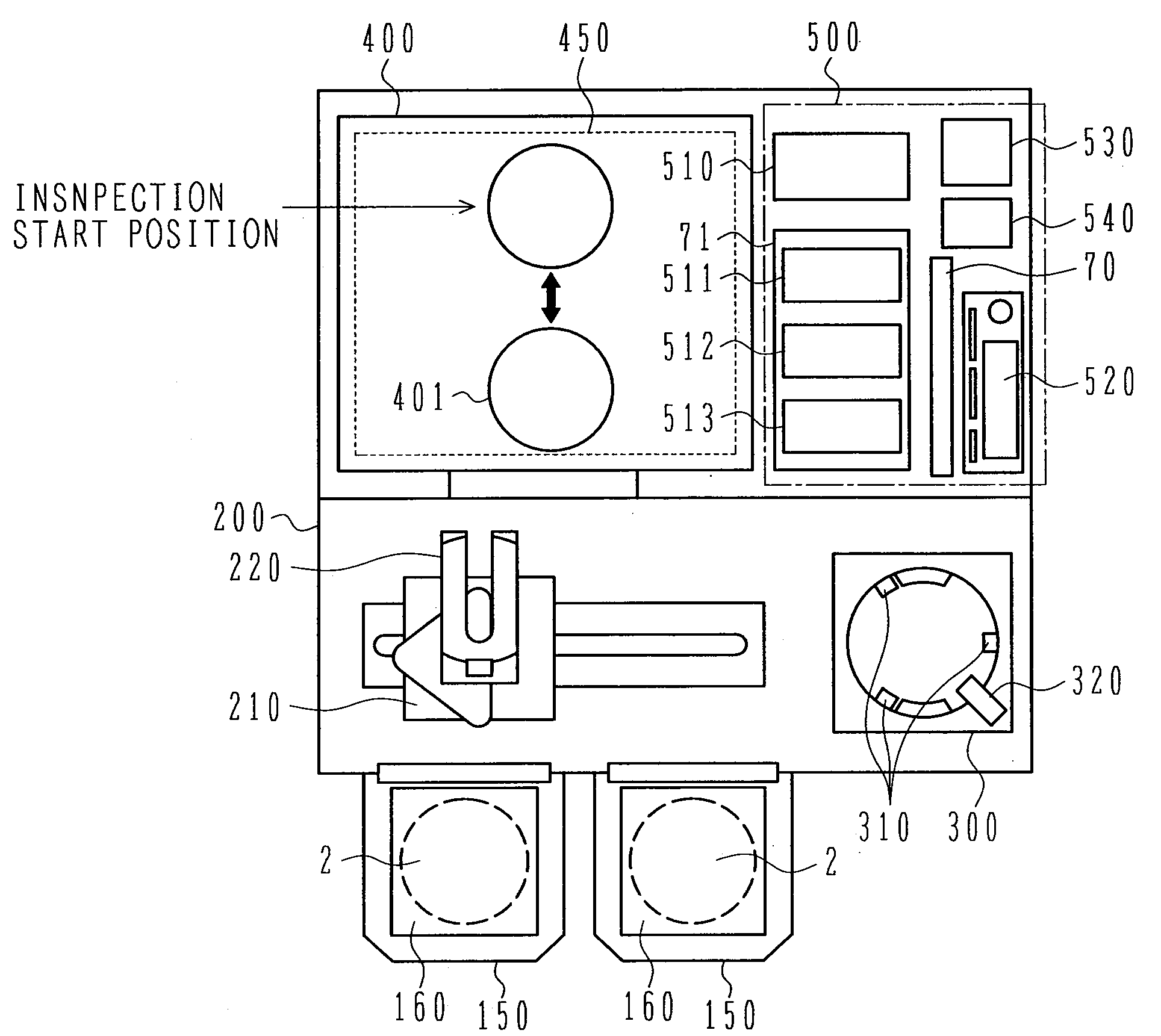

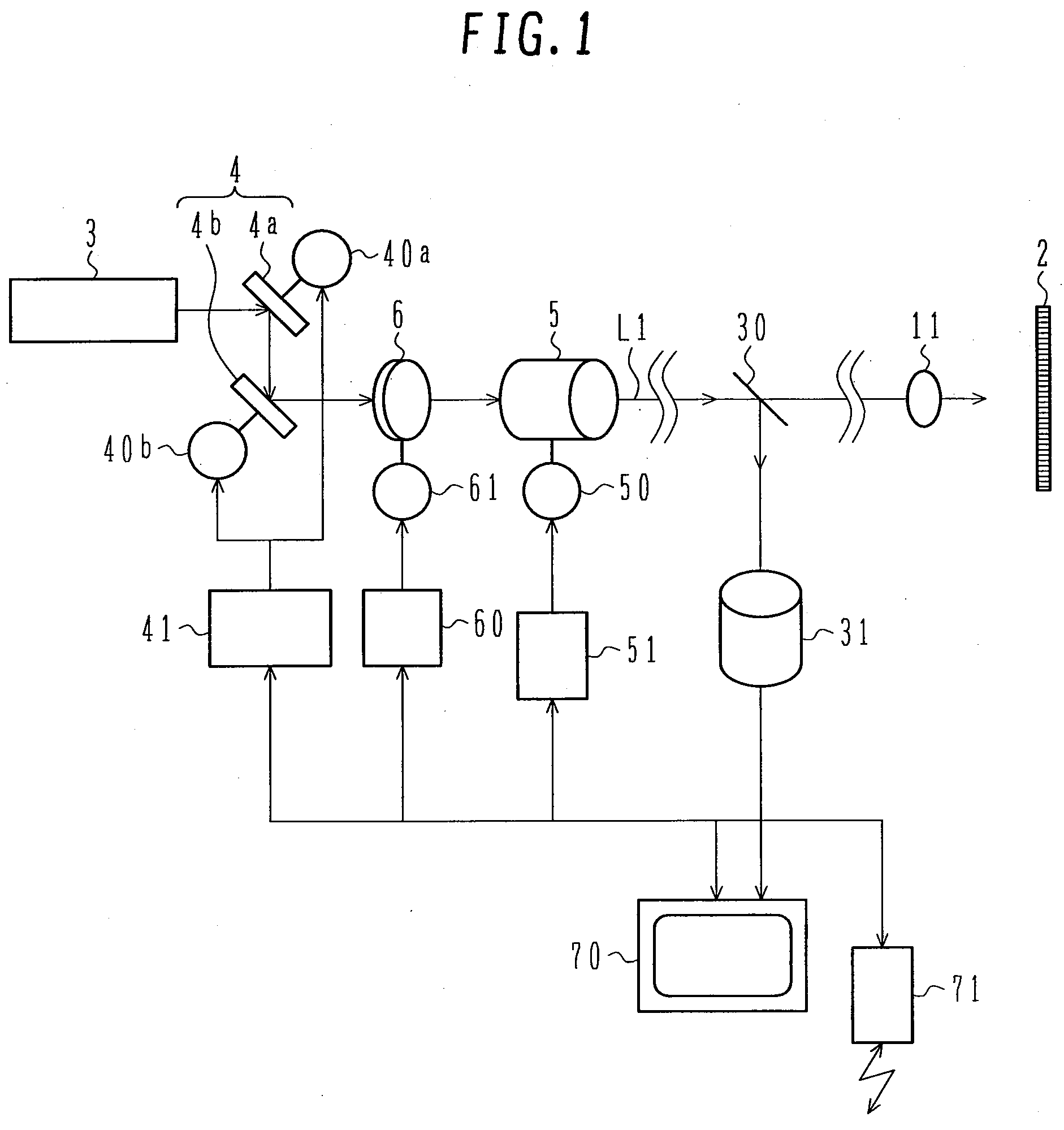

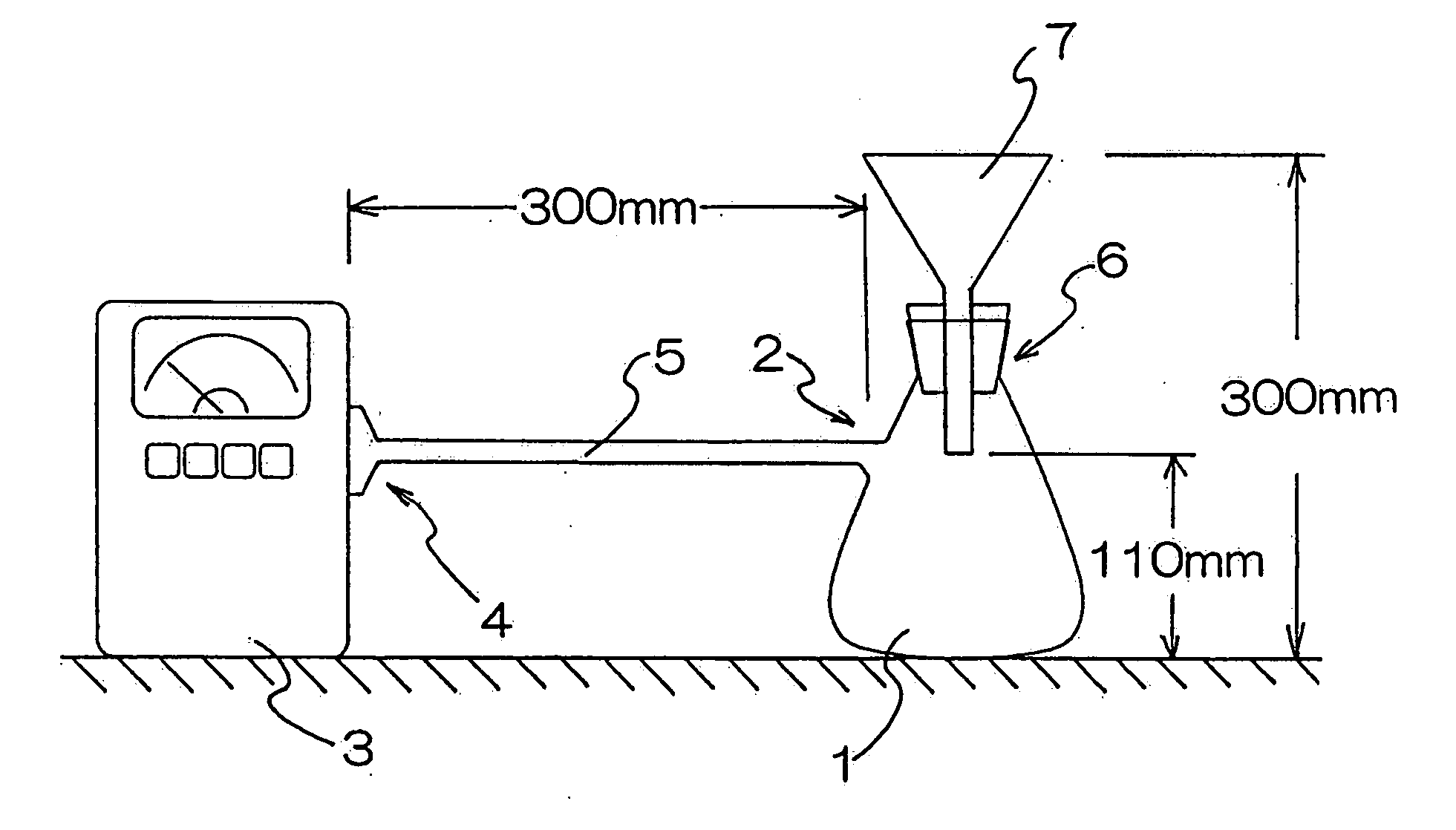

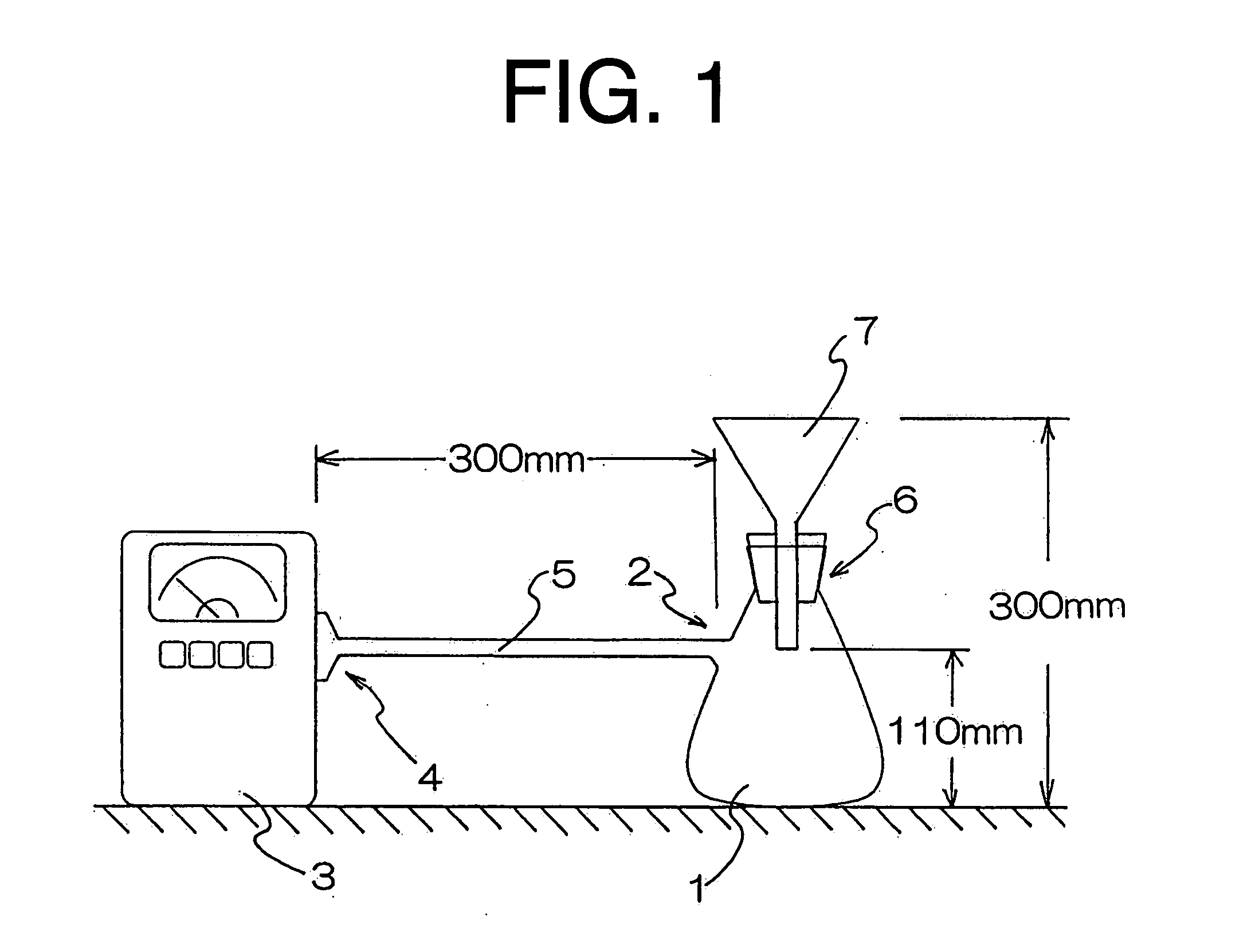

Optical defect inspection apparatus

InactiveUS20100141936A1Extended service lifeReflectance is reducedSemiconductor/solid-state device testing/measurementOptically investigating flaws/contaminationBeam expanderOptical axis

A laser beam oscillated from a laser source is folded in its path by first and second plane mirrors and enters a beam expander. The surface of each plane mirror is deteriorated with illumination by the laser beam and the reflectance is reduced. To avoid a light quantity of the laser beam entering the beam expander from being reduced below a reference value, when the laser beam is illuminated over a certain time, a position on each of the first and second plane mirrors at which the laser beam is illuminated is changed by a structure for rotating and / or translating a reflecting surface of each plane mirror on a plane, which includes the plane mirror, while an optical axis is kept same. Thus, the useful life of each plane mirror can be prolonged without displacing the optical axis.

Owner:HITACHI HIGH-TECH CORP

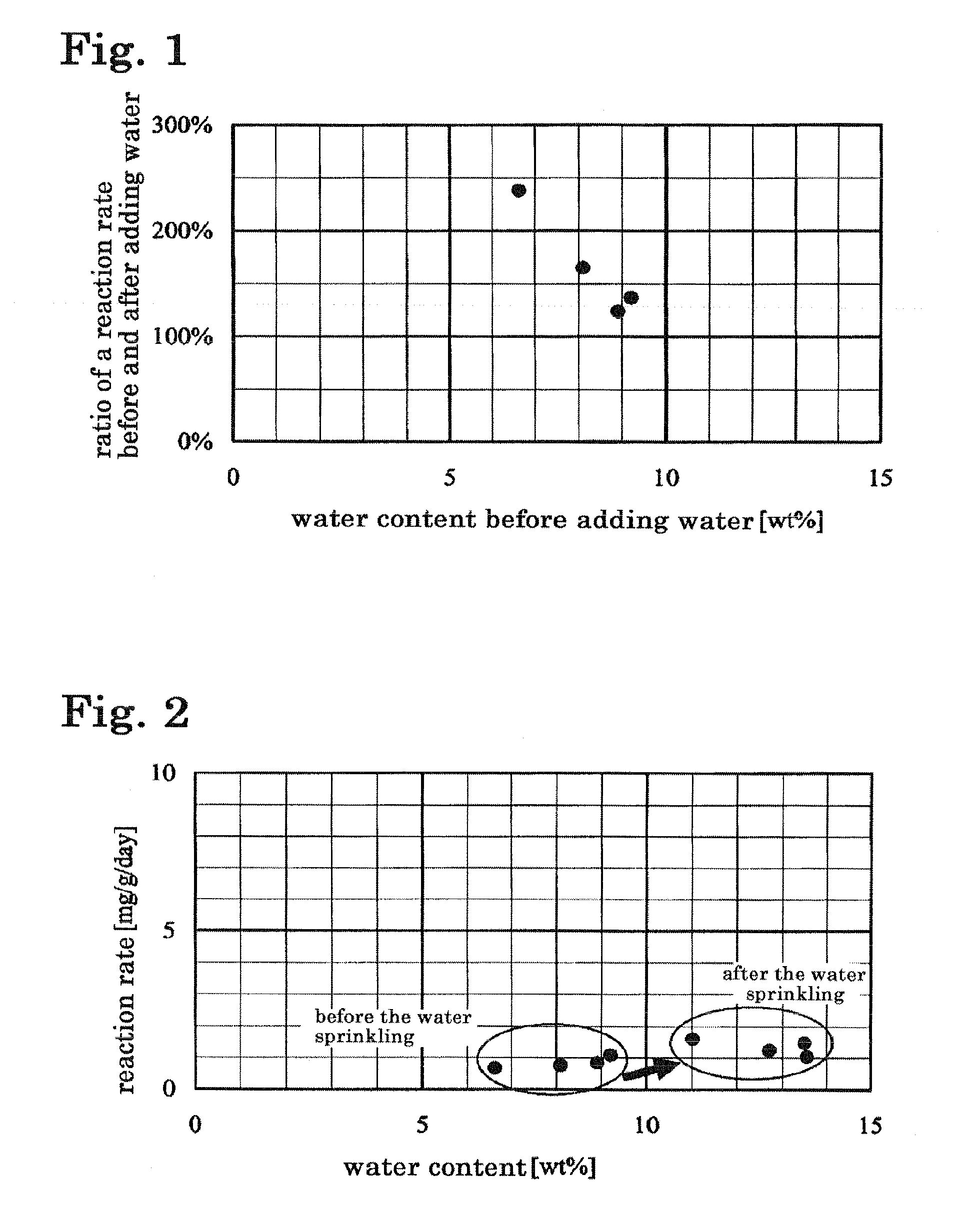

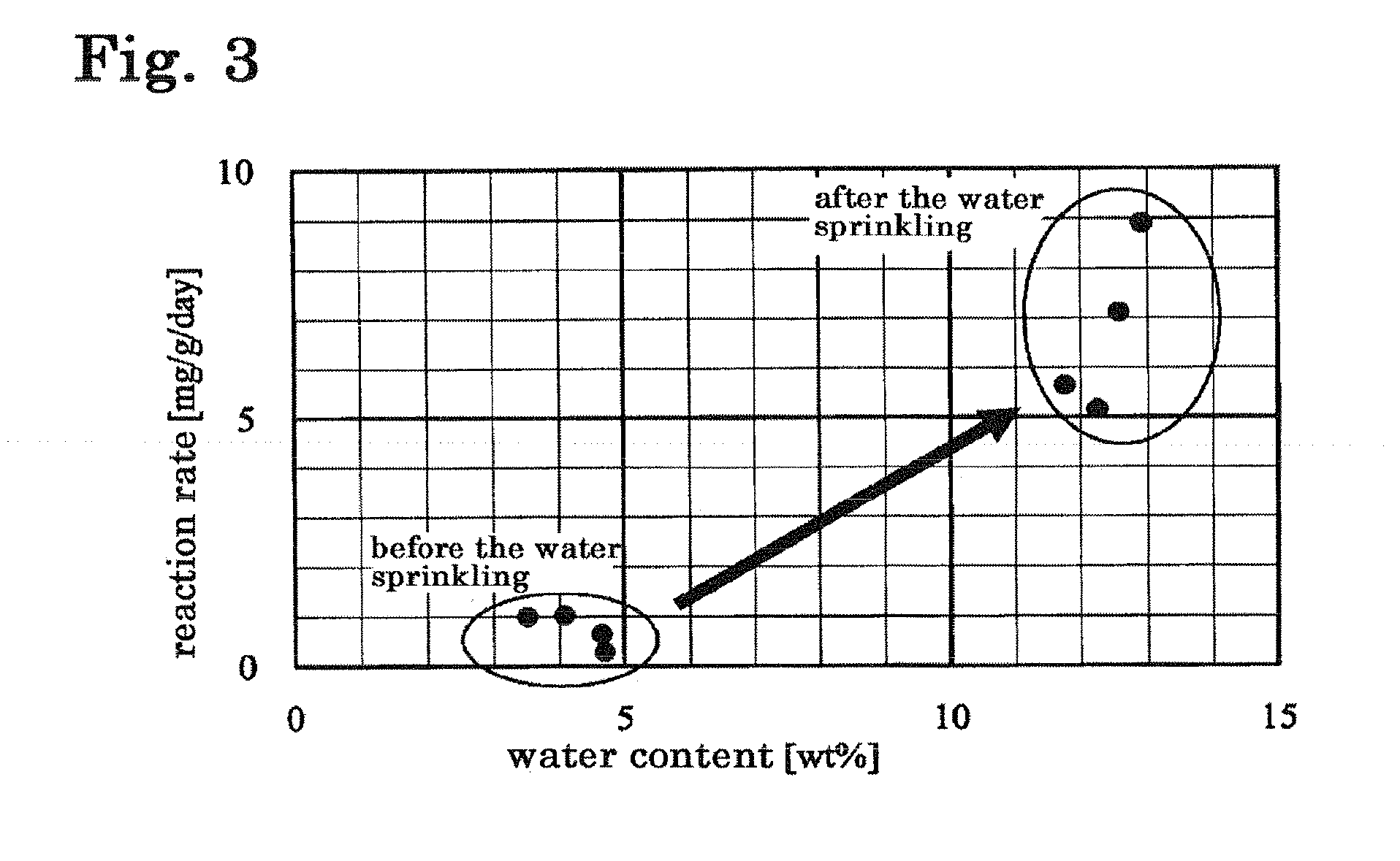

Method for producing modified coal, and modified coal

InactiveUS20160215227A1Suppresses generation of dustSuppress spontaneous ignitionSolid fuelsWater contentCoal

A method for producing modified coal using coal of a low grade comprising:adding water for preventing any dust generation to the dewatered coal; an addition amount of the water is adjusted for a water content rate of the water-added coal to be 6% by mass or more to 16% by mass or less; agglomerating the water-added coal; slowly oxidizing the agglomerated coal; and crushing the oxidized coal.

Owner:KOBE STEEL LTD

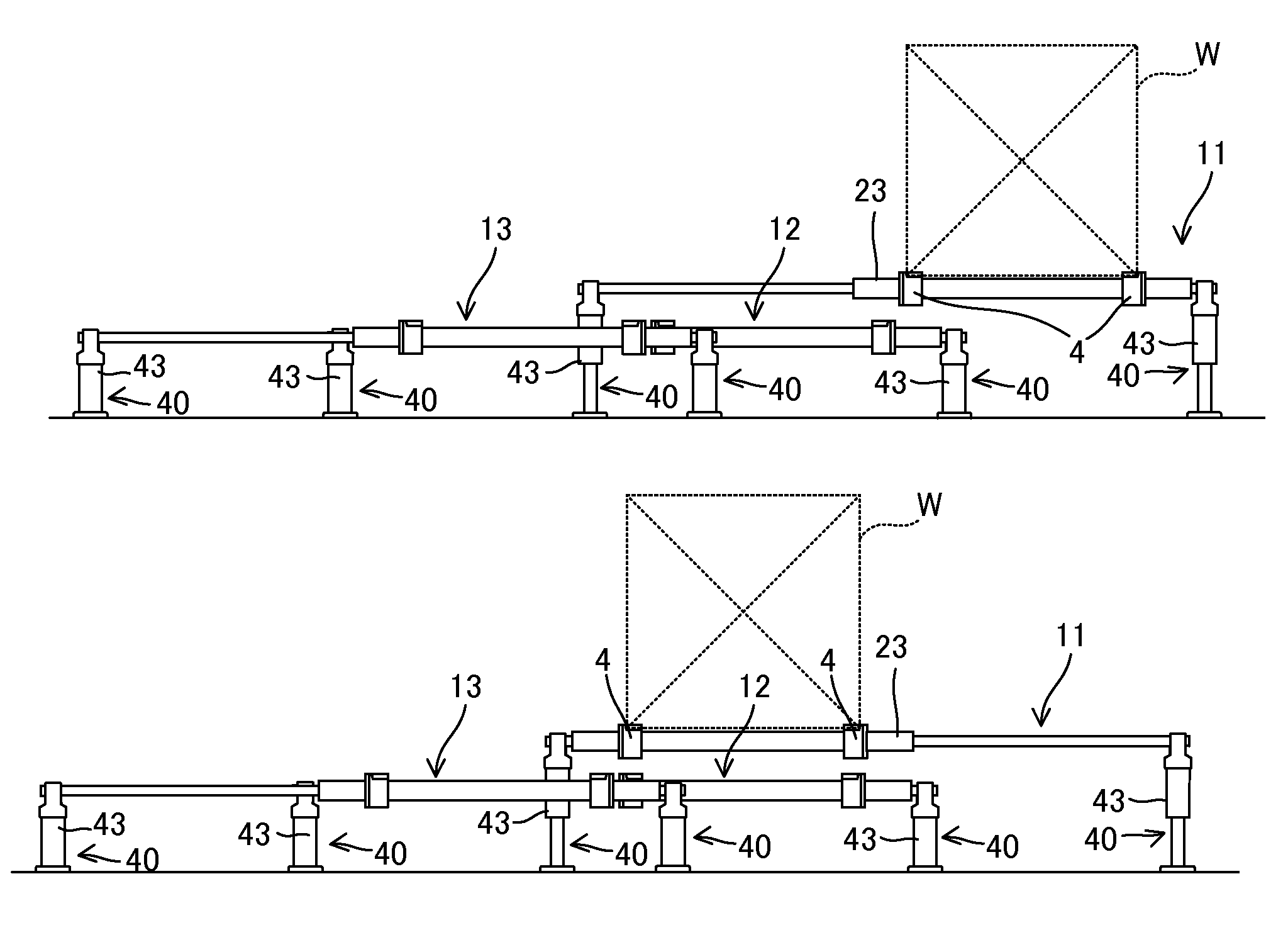

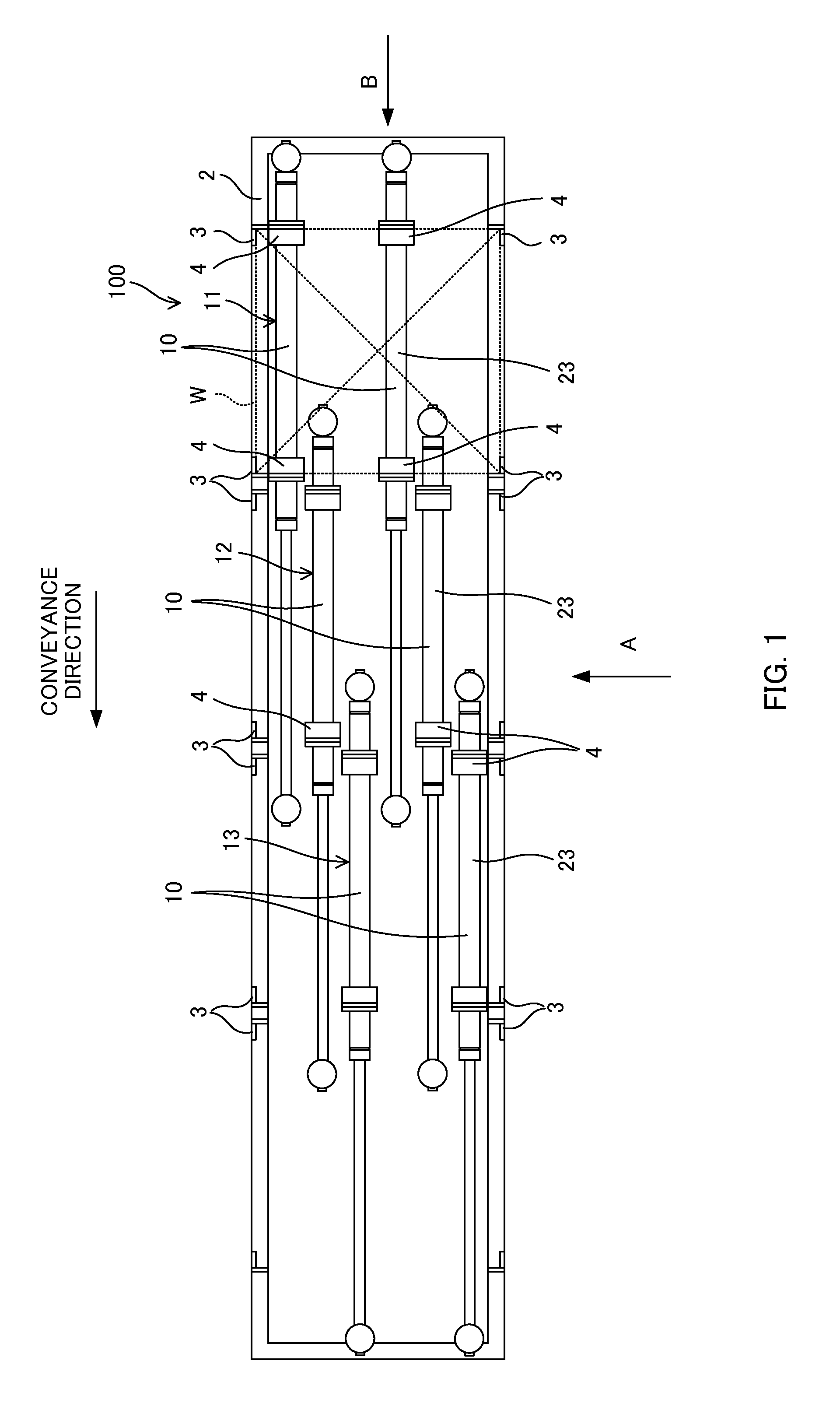

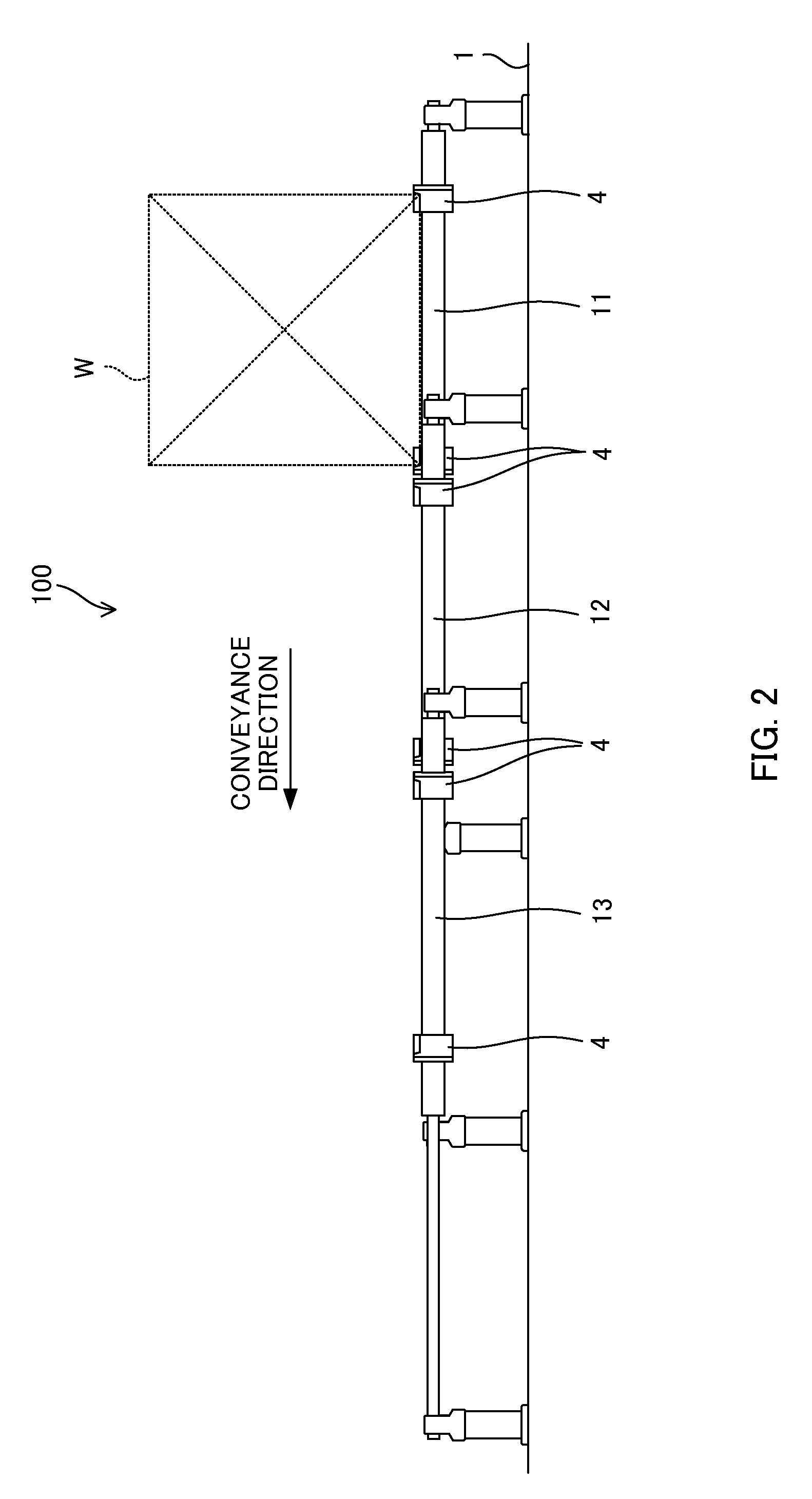

Conveying apparatus

ActiveUS9327908B2Suppresses generation of dustConveyorsFluid-pressure actuatorsInternal pressureHydraulic cylinder

Hydraulic cylinders of a conveying apparatus includes piston rods that extend in parallel, pistons, and cylinder tubes that have an internal pressure chamber partitioned into first and second pressure chambers. A pair of the hydraulic cylinders are arranged in parallel with an interval in a width direction of a conveyance path. The cylinder tube slidingly moves to the first pressure chamber side by supplying a hydraulic pressure to the first pressure chamber and discharging a hydraulic pressure from the second pressure chamber, and the cylinder tubes slidingly move to the second pressure chamber side by supplying a hydraulic pressure to the second pressure chamber and discharging a hydraulic pressure from the first pressure chamber. The workpiece is supported by a pair of the cylinder tubes.

Owner:MIURA COMPANY LIMITED

Method of manufacturing resin molded article, method of manufacturing resin composition, resin molded article, resin composition, resin powder having low dust generation property, and method of reducing dust generation of resin

ActiveUS20150005445A1Suppresses generation of dustImproves fluidity and releasabilityWood working apparatusFlat articlesLiquid paraffinParaffin wax

A method of manufacturing a resin molded article includes a step of preparing a resin powder having low dust generation property by adding a liquid paraffin to a thermosetting resin, and a step of obtaining a resin molded article by heating and kneading the resin powder having low dust generation property, in which the step of preparing the resin powder having low dust generation property includes a step in which the thermosetting resin is melted and the liquid paraffin is added to the melted thermosetting resin to be stirred and mixed.

Owner:SUMITOMO BAKELITE CO LTD

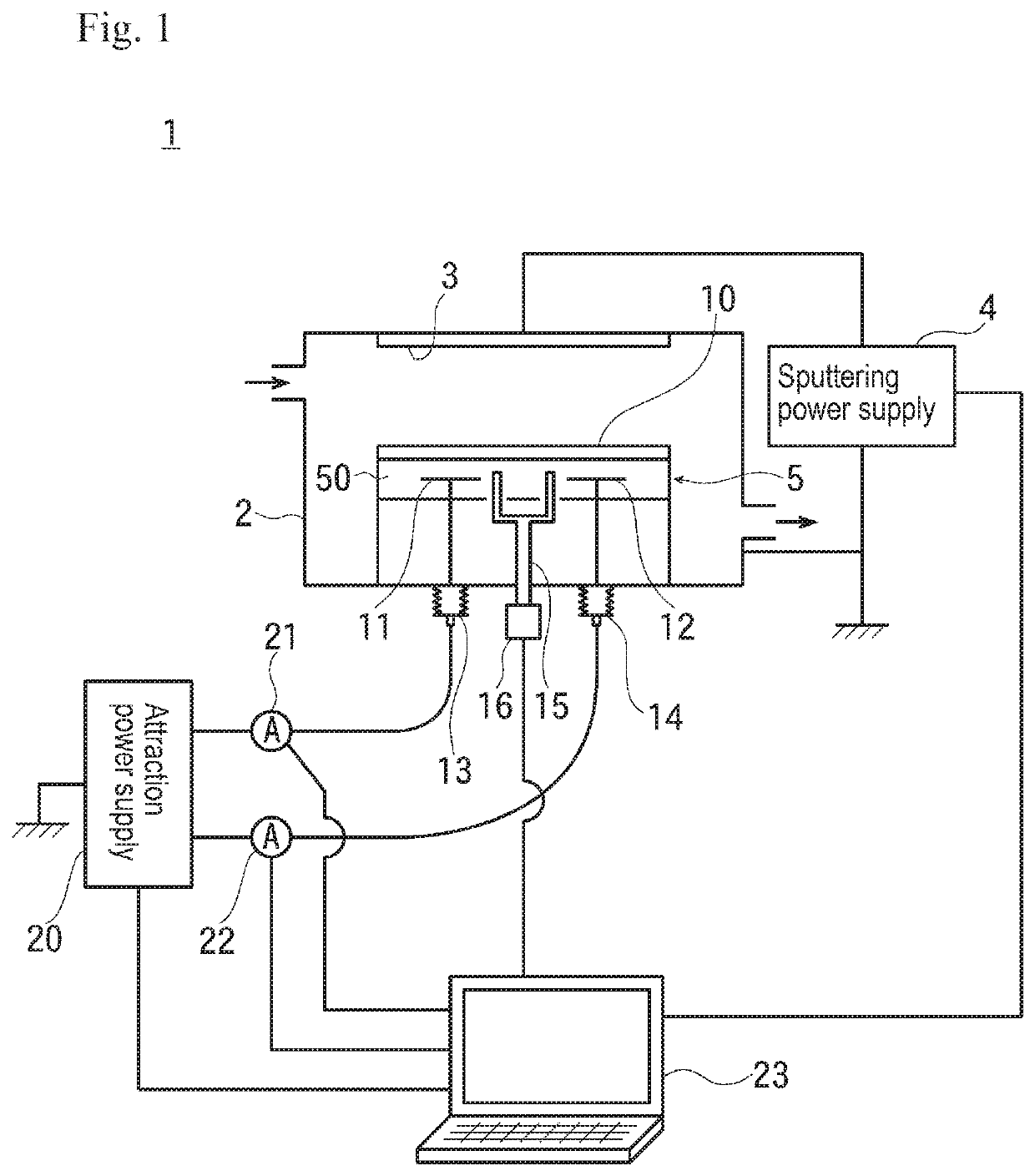

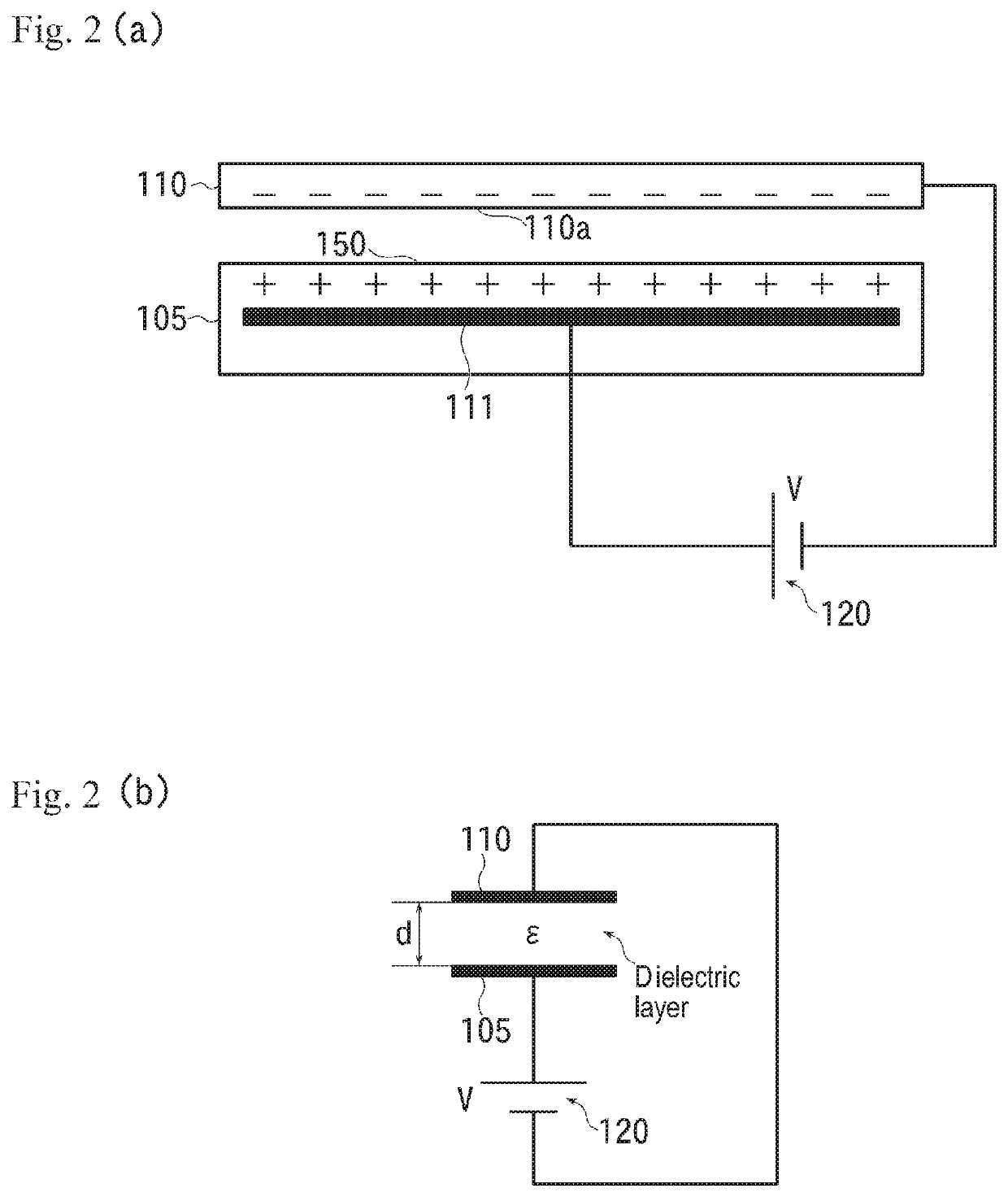

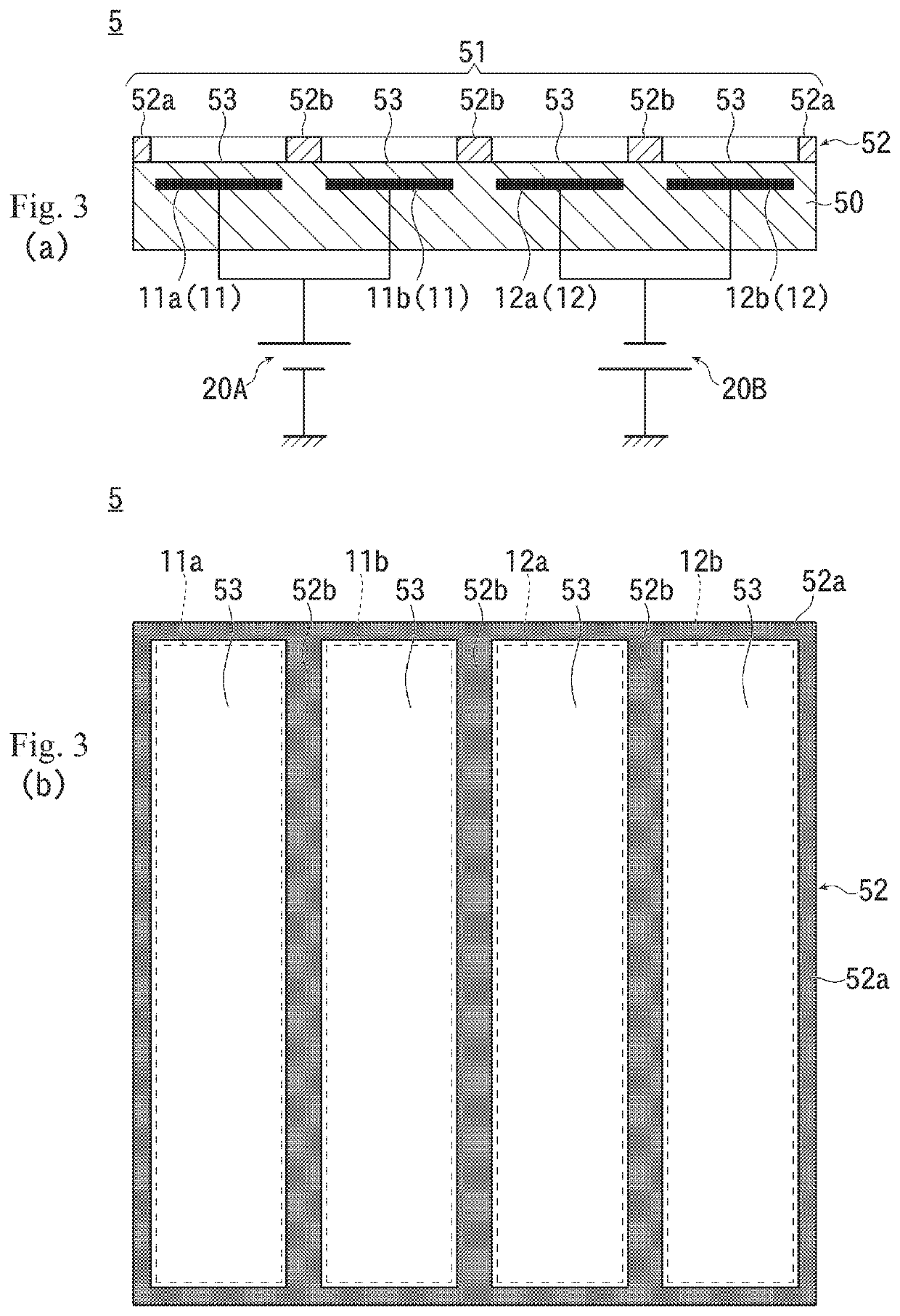

Attraction device, method for producing attraction device, and vacuum processing device

ActiveUS10720858B2Suppresses generation of dustUnified controlElectric discharge tubesSemiconductor/solid-state device manufacturingDielectricEngineering

Providing a technique for suppressing dust generation at the time of attraction and detachment of an object to be attracted, and for enabling control the attraction force of the attraction device to be uniform. The attraction device of the present invention includes a main body part having attraction electrodes within a dielectric; and an attraction part for attracting a substrate, provided on a surface of the main body part at an attraction-side. The attraction part includes a contact support part that is in contact with, and supports the substrate and a non-contact part that is not in contact with the substrate. In the attraction part, the volume resistivity of the material of the contact support part is greater than the volume resistivity of the material of the non-contact part.

Owner:ULVAC INC

Optical defect inspection apparatus

ActiveUS20090147246A1Extended service lifeReflectance is reducedSemiconductor/solid-state device testing/measurementOptically investigating flaws/contaminationBeam expanderOptical axis

A laser beam oscillated from a laser source is folded in its path by first and second plane mirrors and enters a beam expander. The surface of each plane mirror is deteriorated with illumination by the laser beam and the reflectance is reduced. To avoid a light quantity of the laser beam entering the beam expander from being reduced below a reference value, when the laser beam is illuminated over a certain time, a position on each of the first and second plane mirrors at which the laser beam is illuminated is changed by a structure for rotating and / or translating a reflecting surface of each plane mirror on a plane, which includes the plane mirror, while an optical axis is kept same. Thus the useful life of each plane mirror can be prolonged without displacing the optical axis.

Owner:HITACHI HIGH-TECH CORP

Water-Absorbing Resin Composition

ActiveUS20080071004A1Improve the operating environmentImprove adhesion strengthBiocideOther chemical processesInorganic compoundUrine production

A water-absorbing resin composition showing suppressed dusting of an antimicrobial agent and having an antimicrobial activity. A water-absorbing resin composition which contains a water-absorbing resin and an antimicrobial agent comprising an inorganic compound carrying an antimicrobial metal characterized by showing a dusting degree of 100 CPM or less. This water-absorbing resin composition is appropriately usable in sanitary goods such as paper diapers, sanitary pads, incontinence pads, urine-absorbing materials for pet animals, structural materials such as packings, freshness-preserving materials for foods such as drip-absorbers and cooling agents, agricultural / horticultural goods such as water-retention agents for soil and so on.

Owner:SUMITOMO SEIKA CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com