Optical defect inspection apparatus

a defect inspection and optical technology, applied in the direction of optically investigating flaws/contamination, semiconductor/solid-state device testing/measurement, instruments, etc., can solve the problems of deteriorating the reproducibility of the inspection apparatus, difficult to practice the change of the laser illuminated point on the plane mirror to avoid frequent replacement, and the frequency of part replacement can be reduced. , the effect of dispensed alignment of the optical axis of the reflecting mirror

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0048] A first embodiment of the present invention will be first described in detail below with reference to the drawings. A defect inspection apparatus of the first embodiment is intended to suppress variations of conditions, such as a reduction of light quantity (intensity) caused by deterioration of a plane mirror (reflecting mirror), with the provision of a translation mechanism and / or a rotation mechanism, which does not displace an optical axis of the plane mirror, in an optical system.

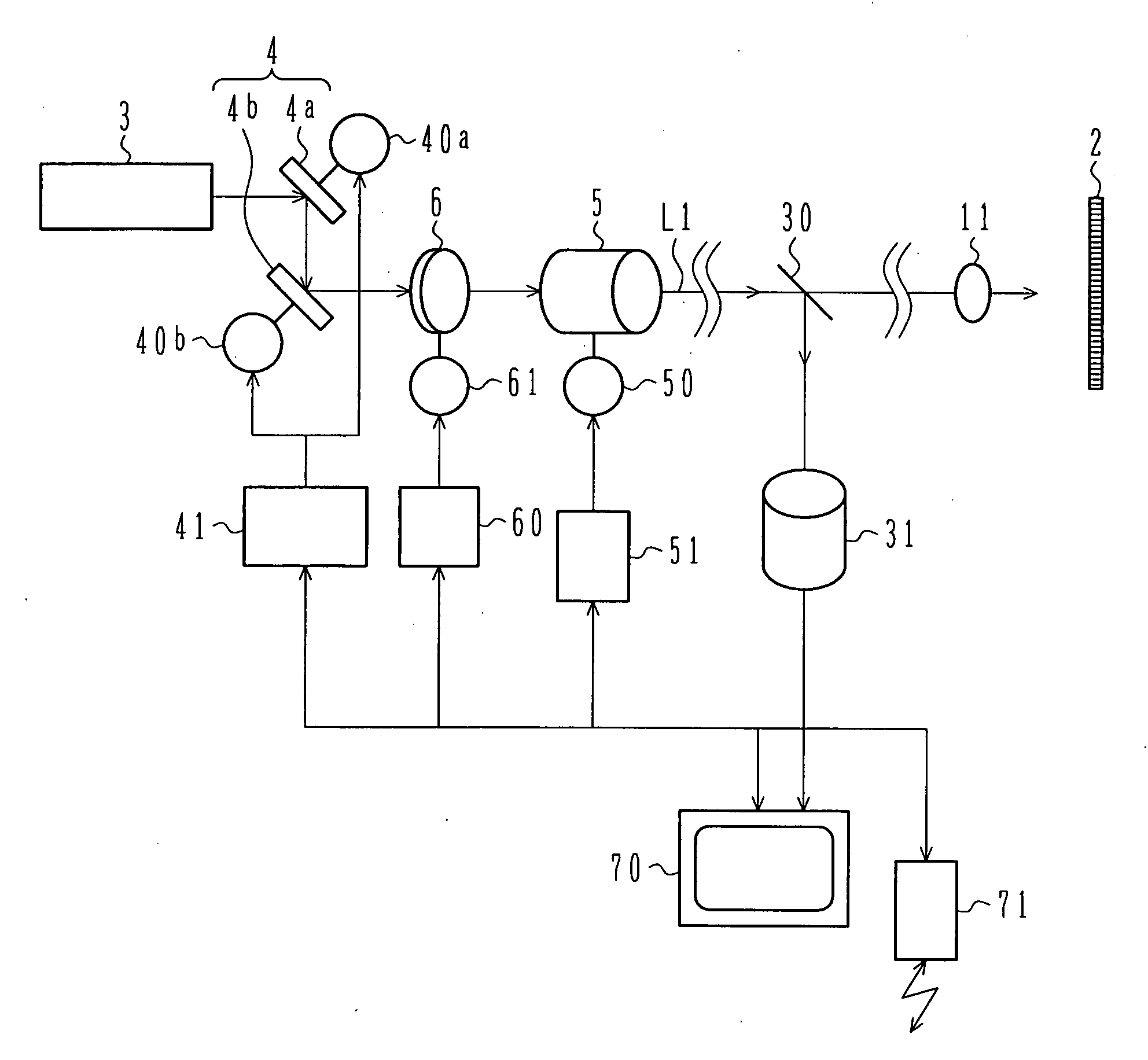

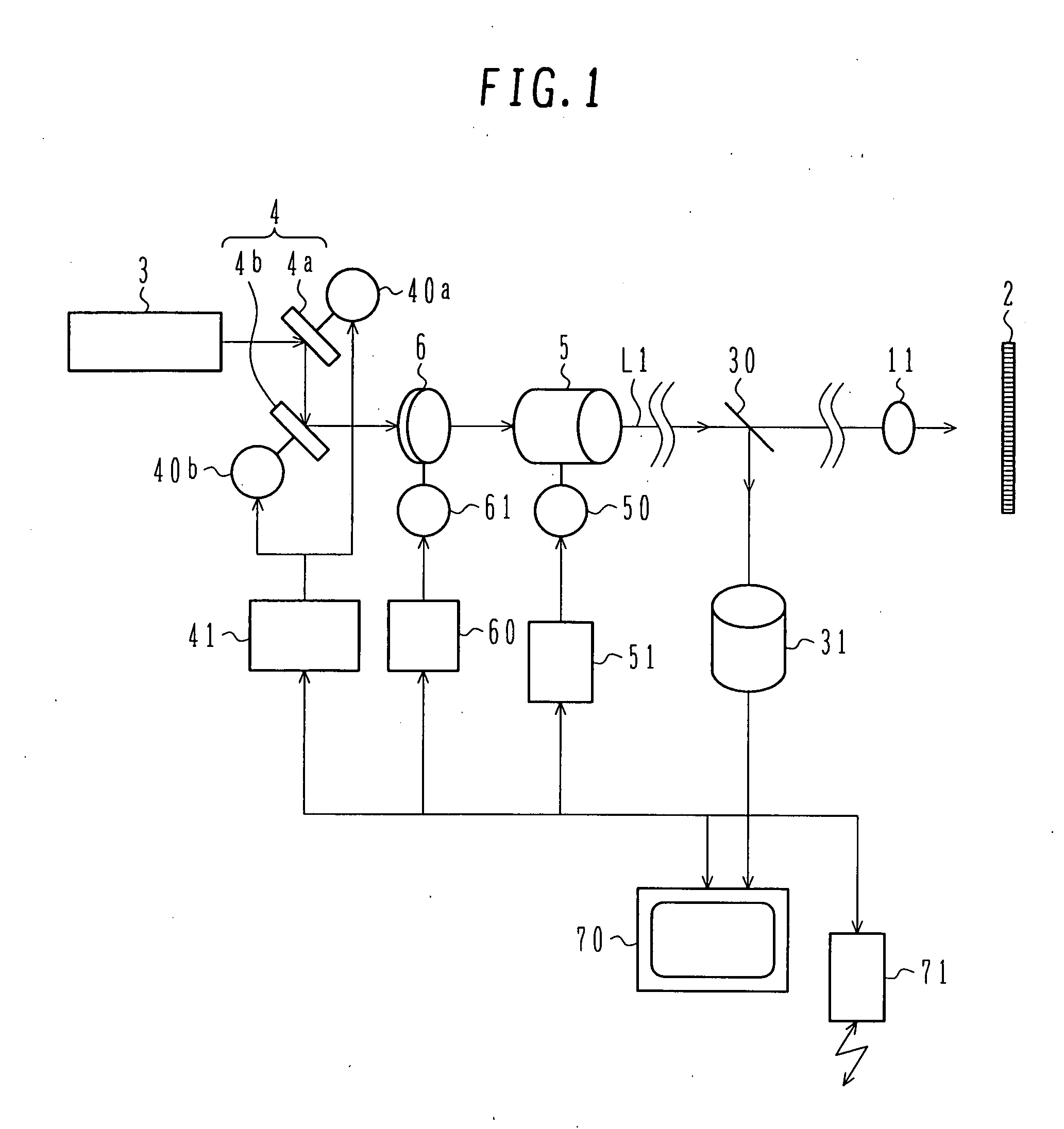

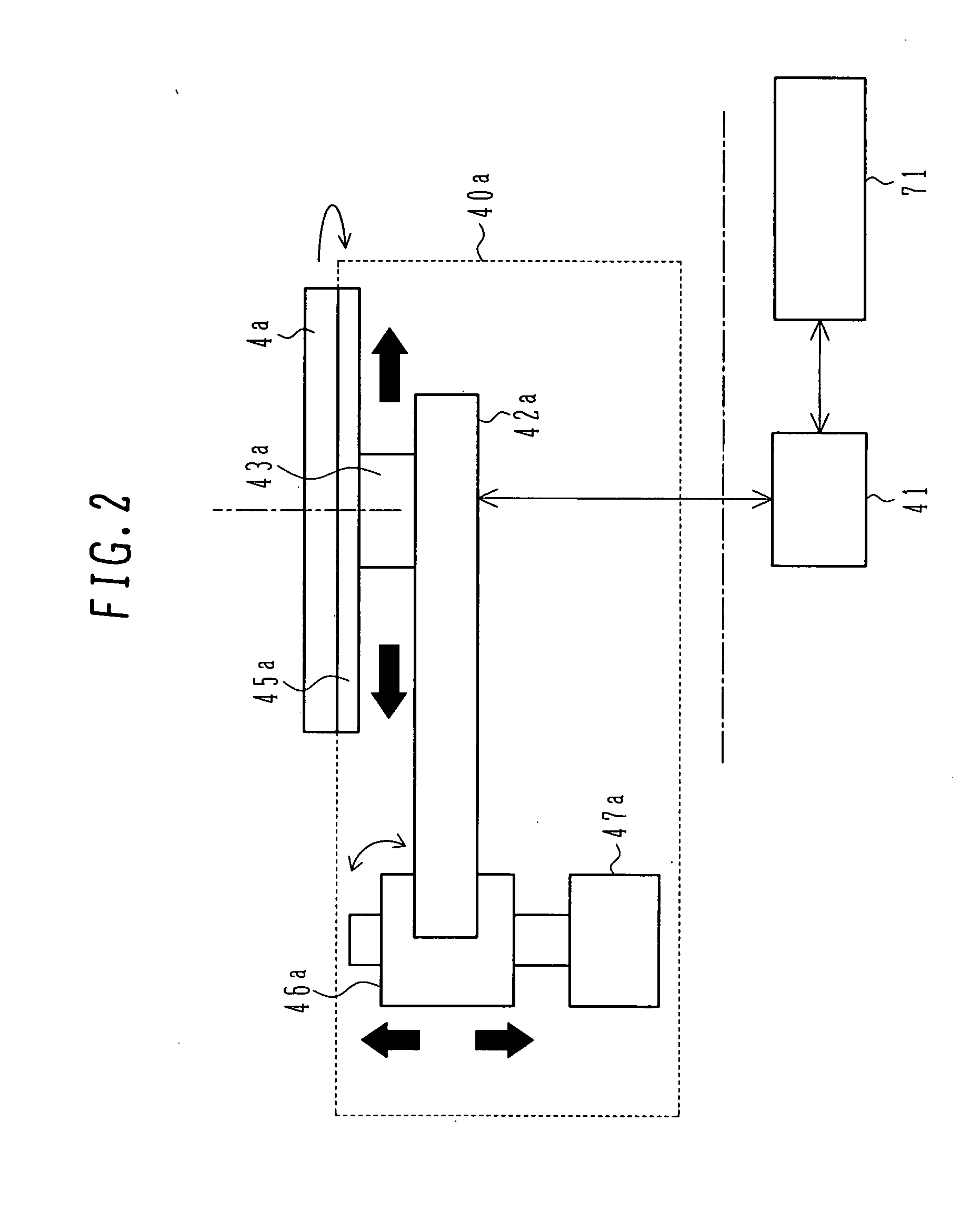

[0049]FIG. 1 schematically shows the construction of an illumination optical system according to the first embodiment of the present invention. The illumination optical system primarily comprises a laser source 3 for emitting an illumination light, e.g., a visible or ultraviolet laser beam, a beam deflection mechanism 4 made up of a plurality of pane mirrors, such as a first plane mirror (reflecting mirror) 4a and a second plane mirror (reflecting mirror) 4b, for deflecting the direction of adv...

second embodiment

[0082] A second embodiment of the present invention will be described in detail below with reference to the drawings. This second embodiment represents the case where the present invention is applied to a surface inspection apparatus. The surface inspection apparatus has the functions of inspecting not only the front surface of an object to be inspected, but also the rear surface thereof. The surface inspection apparatus includes the plane mirror moving mechanisms, the light quantity measuring means, the control means for them, and the diagnosis condition setting means, which are all described above in connection with the first embodiment, but an optical system in the second embodiment differs from that in the first embodiment to some extent.

[0083]FIG. 6 schematically shows the construction of the surface inspection apparatus of the second embodiment. The surface inspection apparatus comprises one or more load ports 150 which also serve to support an inspected object (wafer) 2, a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| optical defect inspection | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com