Valve device

A technology of valve device and cam device, which is applied in the direction of valve device, valve operation/release device, valve lift, etc. It can solve the problems of large opening torque, unbalanced valve body pressure, unsuitable sealing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

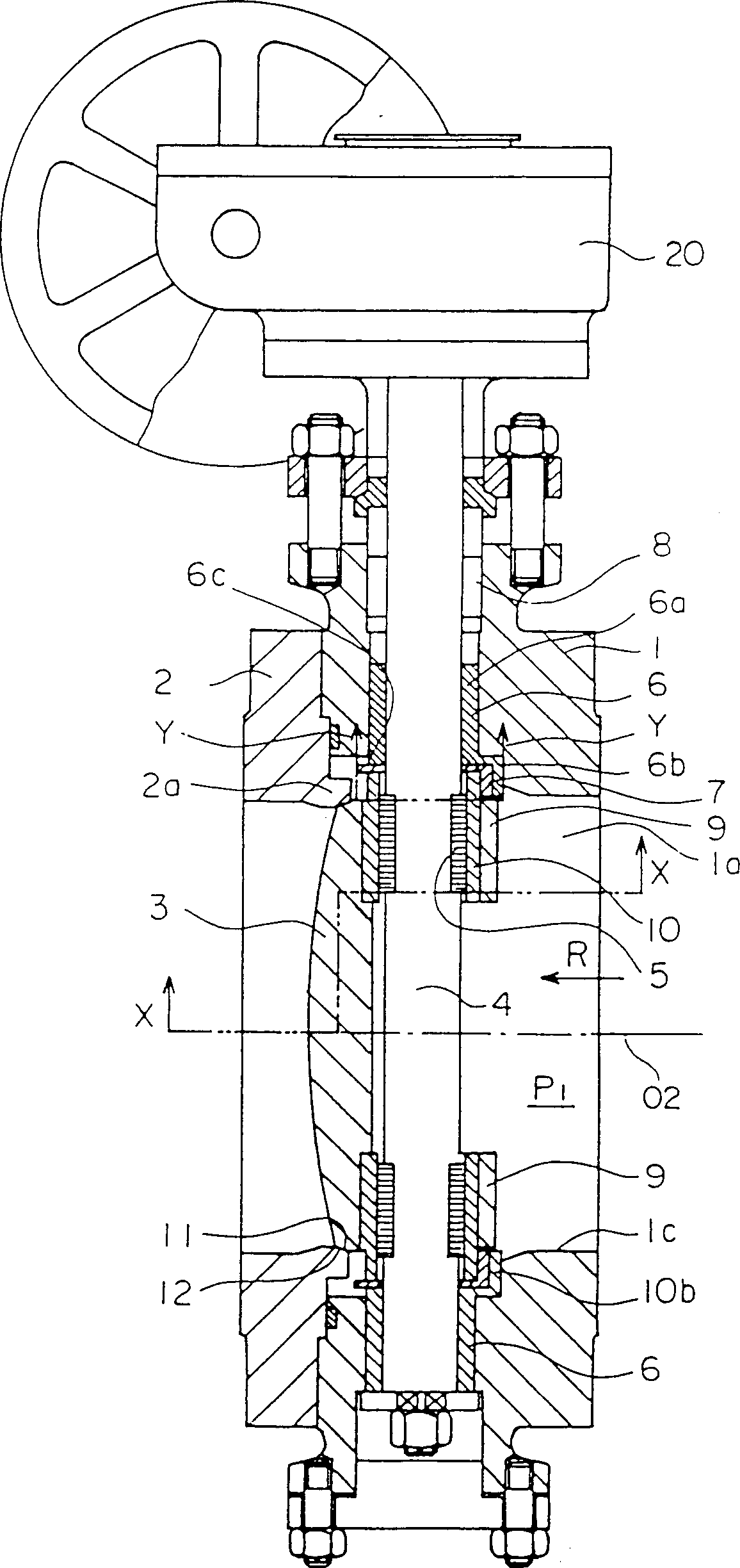

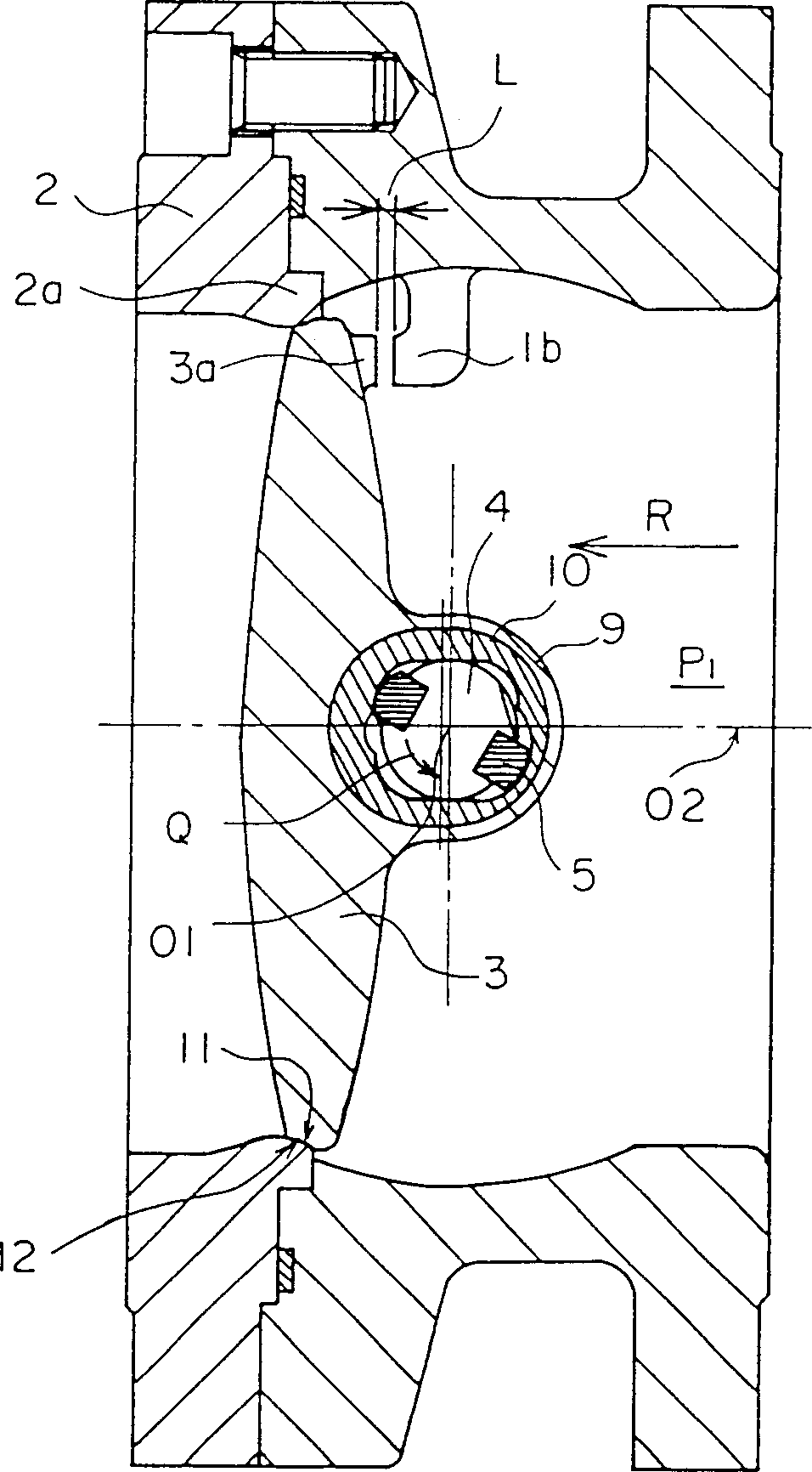

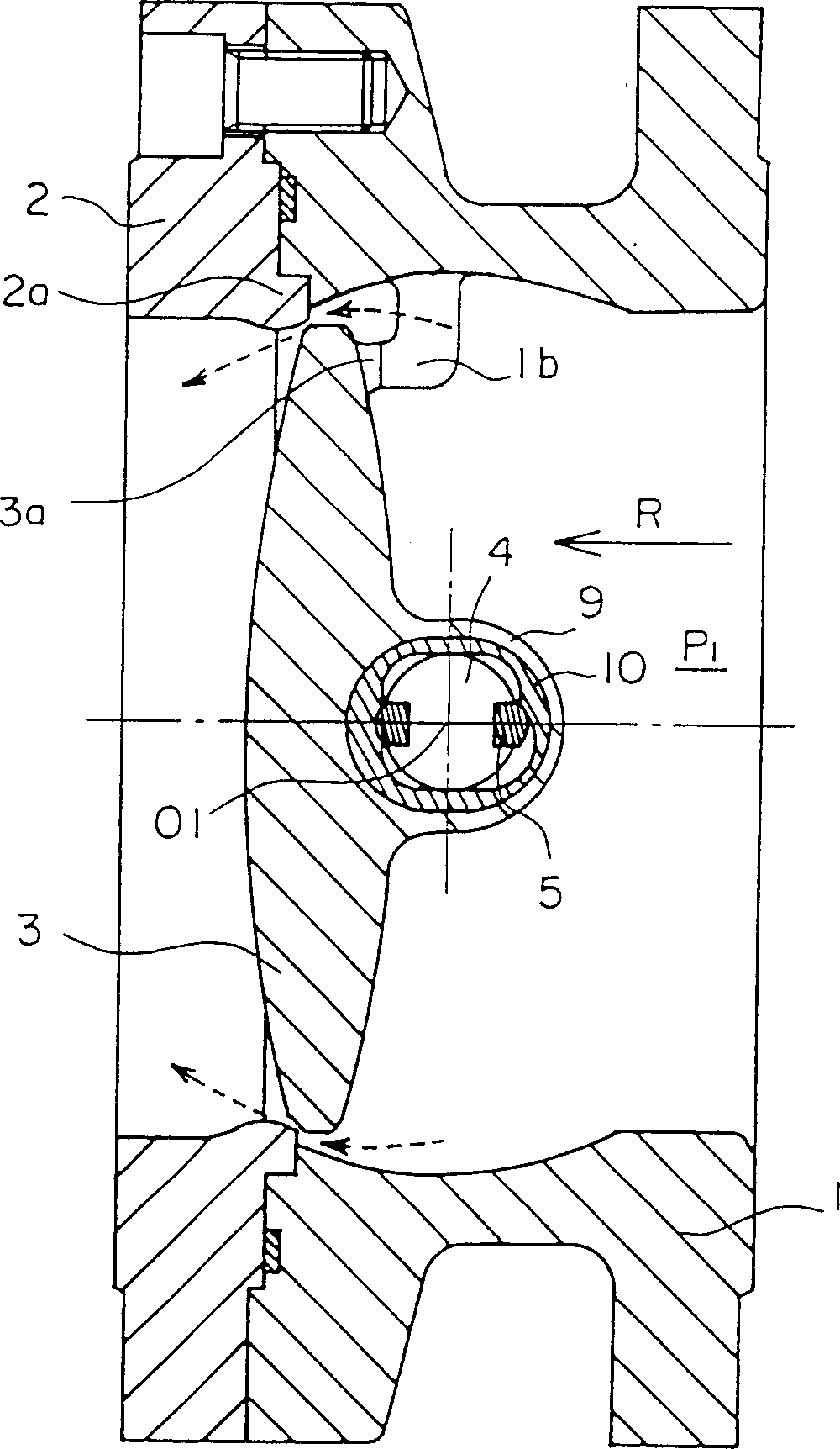

[0026] The preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings, in which the same symbols indicate the same or corresponding parts. In the following description, as far as the direction is concerned, the figure 1 The right side of the paper is the "front side", the left side of the paper is the "back side", and, in figure 1 Among them, the upper side of the central axis 02 is the "upper side" and the lower side is the "lower side". figure 1 The front side of the paper is the "left side", and the back side of the paper is the "right side".

[0027] figure 1 It is a longitudinal sectional view of the valve device of this embodiment in a fully closed state. figure 2 for along figure 1 The cross-sectional view of the x-x line, image 3 and Figure 4 In order to respectively show the state in the middle of opening the valve and the state of full opening and figure 2 Quite a graph. The valve device of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com