Rotary switch operating mechanism

A technology of switch operation and operating mechanism, which is applied in the field of switches, can solve the problems of reducing operating force, reducing stability, reducing contact stability, etc., and achieves the effects of prolonging mechanical life, reducing strength requirements, and reducing operating force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

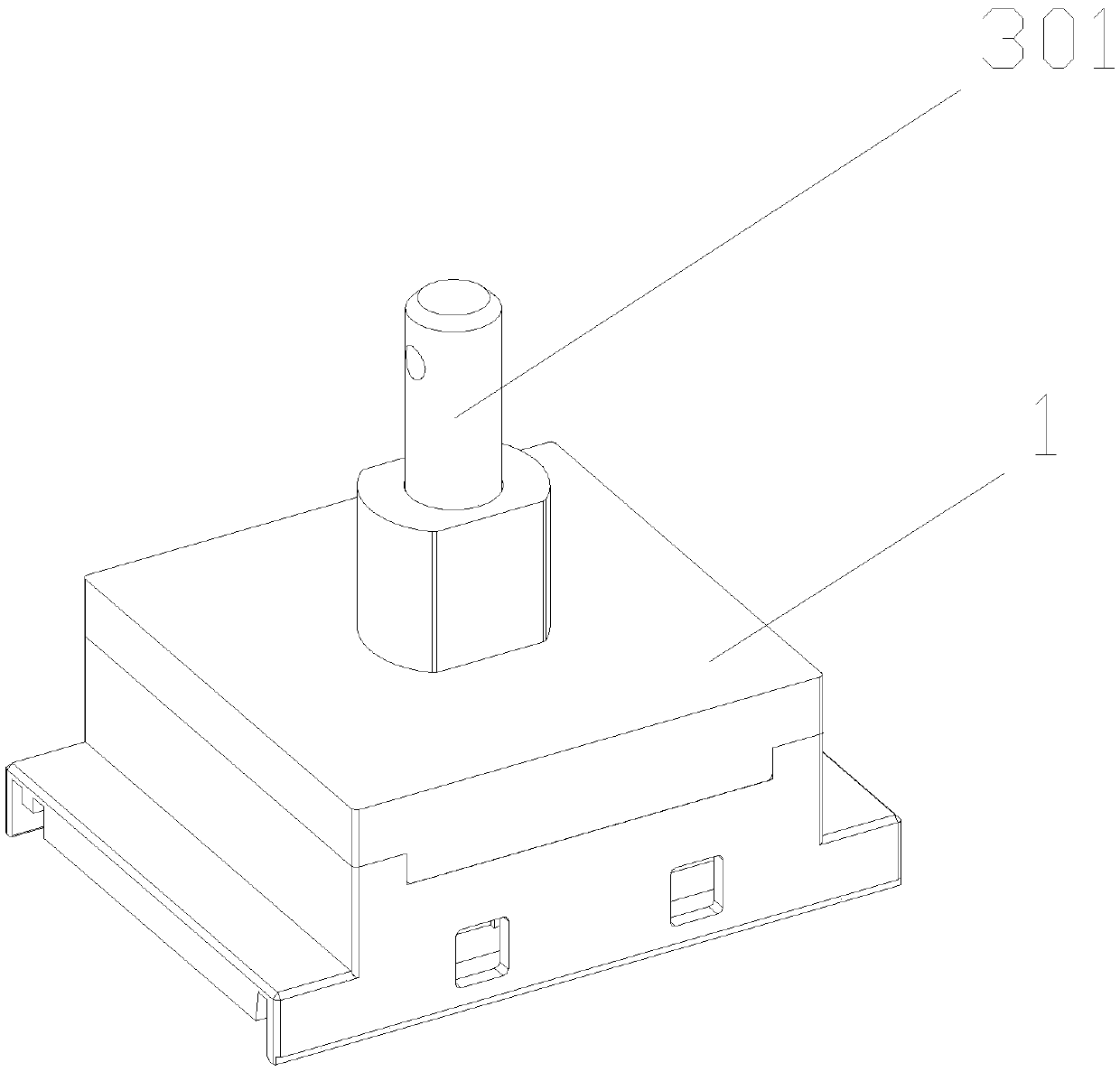

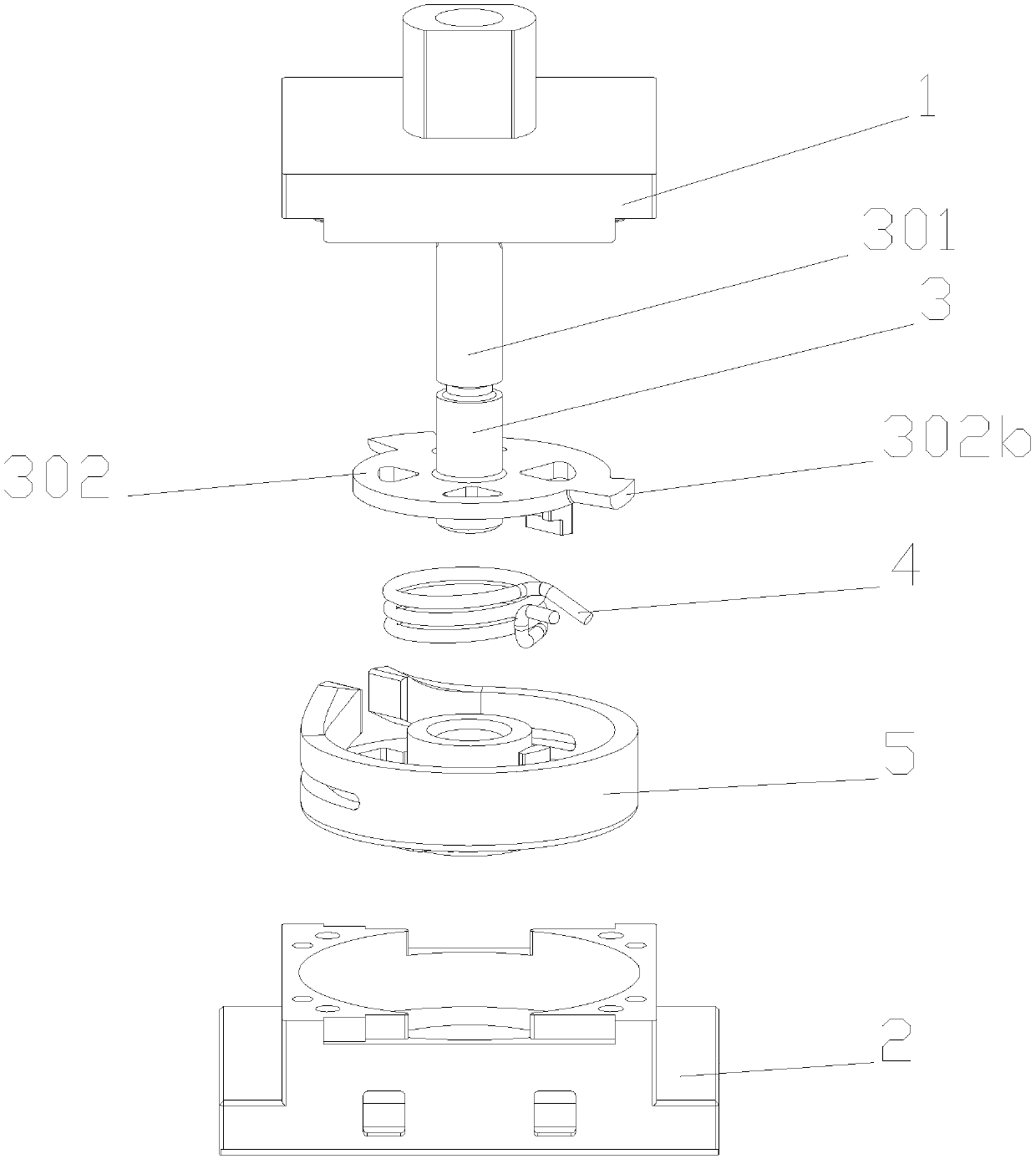

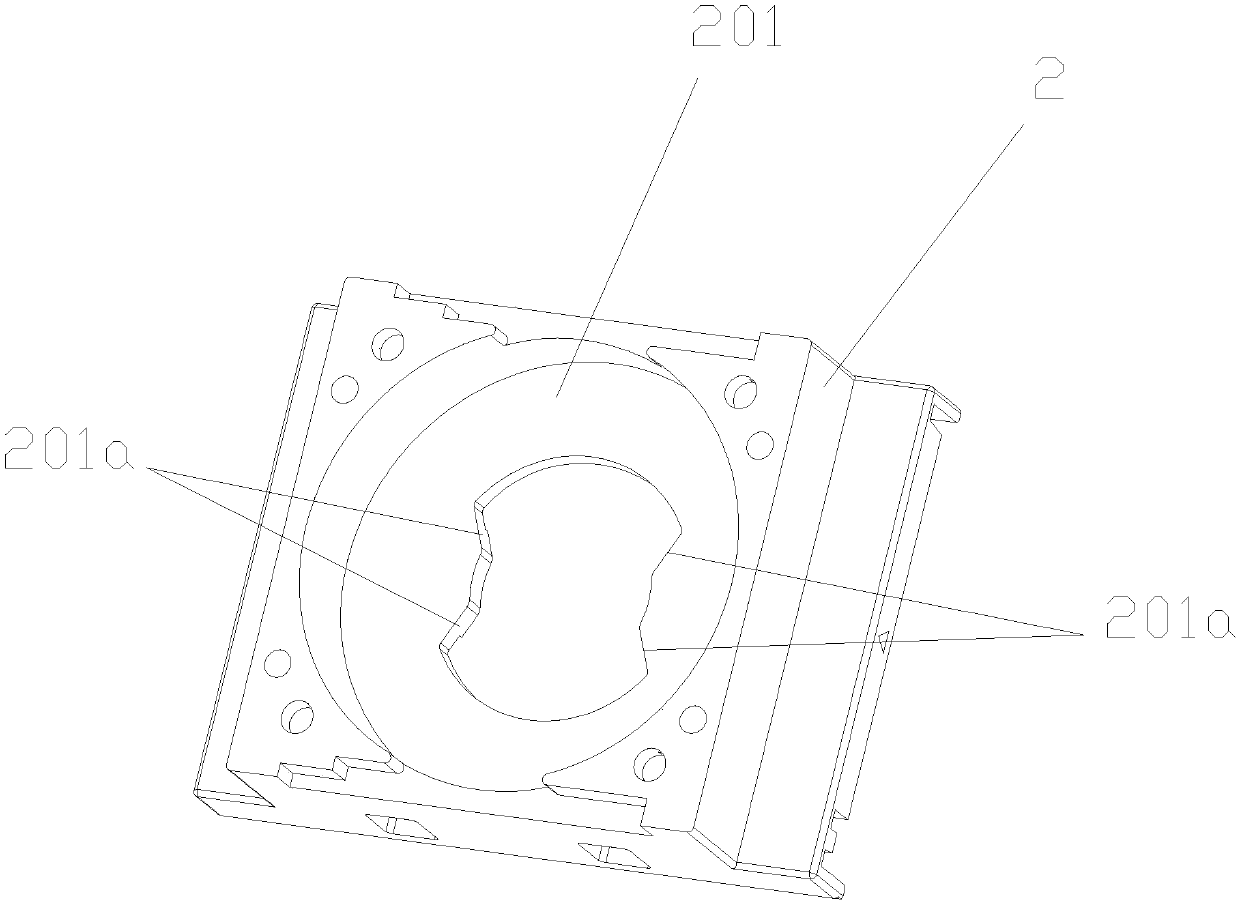

[0034] as attached figure 1 and 2 As shown, a rotary switch operating mechanism designed in this embodiment includes an upper cover 1, an installation base 2, a lever 3, an energy storage element 4 and a rotating shaft 5, and the rotating shaft 5 is installed in the attached image 3 The shaft installation groove 201 of the installation base 2 shown can be rotated in the shaft installation groove 201, the bottom of the rotation shaft 5 is provided with a stop protrusion 505, and the bottom surface of the shaft installation groove 201 of the installation base 2 is provided with a stopper The stopper 201a is installed in the rotating shaft installation groove 201 of the installation base 2 during the rotation process, the stop projection 505 can be limited by the stop stopper 201a to realize the stop of the operating mechanism. The energy storage element 4 is installed in the groove 501 of the inner cavity of the rotating shaft 5, and the end of the energy storage element 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com