Energy-saving automatic control device of cloth-bag dust removal system and control method for blast furnace dust removal

An automatic control device and bag dust removal technology are applied in the field of blast furnace dust removal control and energy saving automatic control device for bag dust removal system, which can solve the problems of iron dust not being effectively recovered, shortened service life of electrical appliances, waste of electric energy, etc. The effect of resisting external interference, reducing heat generation, reducing exhaust gas and soot emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

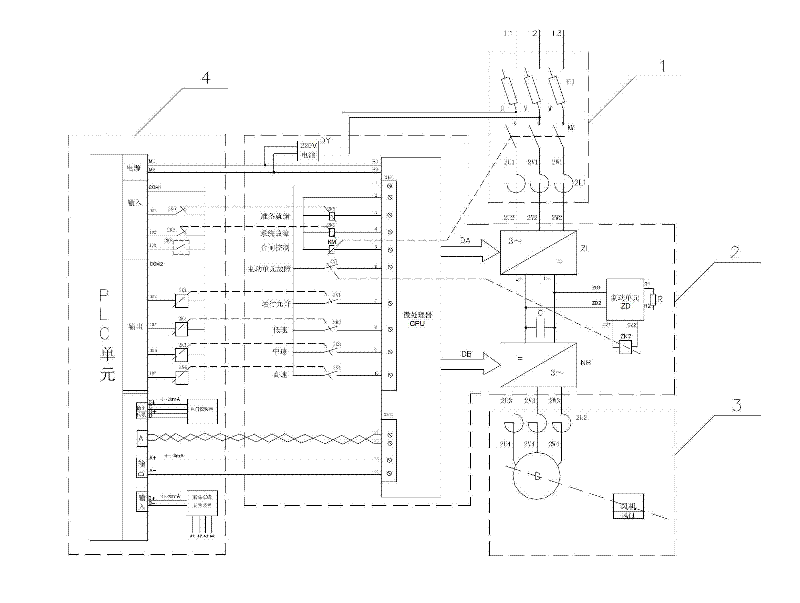

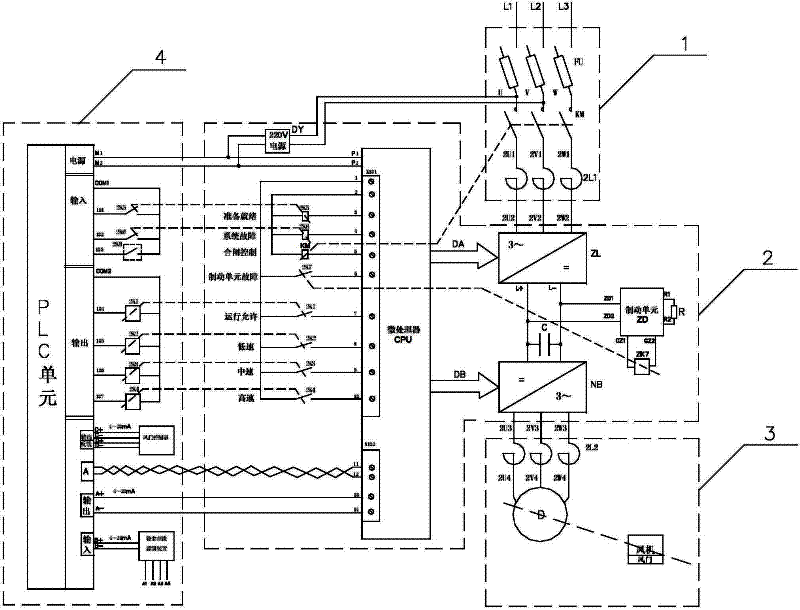

[0026] The present invention will be described in further detail below by taking the blast furnace dedusting system as an example in conjunction with the accompanying drawings.

[0027] like figure 1 As shown, the primary terminals of the fast fuse FU in the input unit 1 are respectively connected to the incoming three-phase power supply L1, L2, L3, and the secondary terminals are respectively connected to the primary terminals U, V, W of the main contactor KM , the secondary terminals of the main contactor KM are respectively connected to the primary terminals 2U1, 2V1, 2W1 of the reactor 2L1, and the secondary terminals of the reactor 2L1 are respectively connected to the main circuit incoming terminals 2U2 and 2V2 of the variable frequency drive unit 2 , 2W2 are connected.

[0028]In the variable frequency drive unit 2, the incoming lines 2U2, 2V2, 2W2 are rectified by the rectifier module ZL and energy stored and filtered by the capacitor C, and then connected to the inpu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com