Automatic control device for rotation of blast furnace chute

An automatic control device and chute technology, applied in the control of electromechanical transmission, motor generator control, electronic commutation motor control, etc., can solve problems such as hidden dangers of personal safety of mechanical equipment, inability to meet control requirements, and unsatisfactory control accuracy. , to achieve the effect of reducing interference and impact of mechanical equipment, reducing exhaust gas and soot emissions, saving electricity and coke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

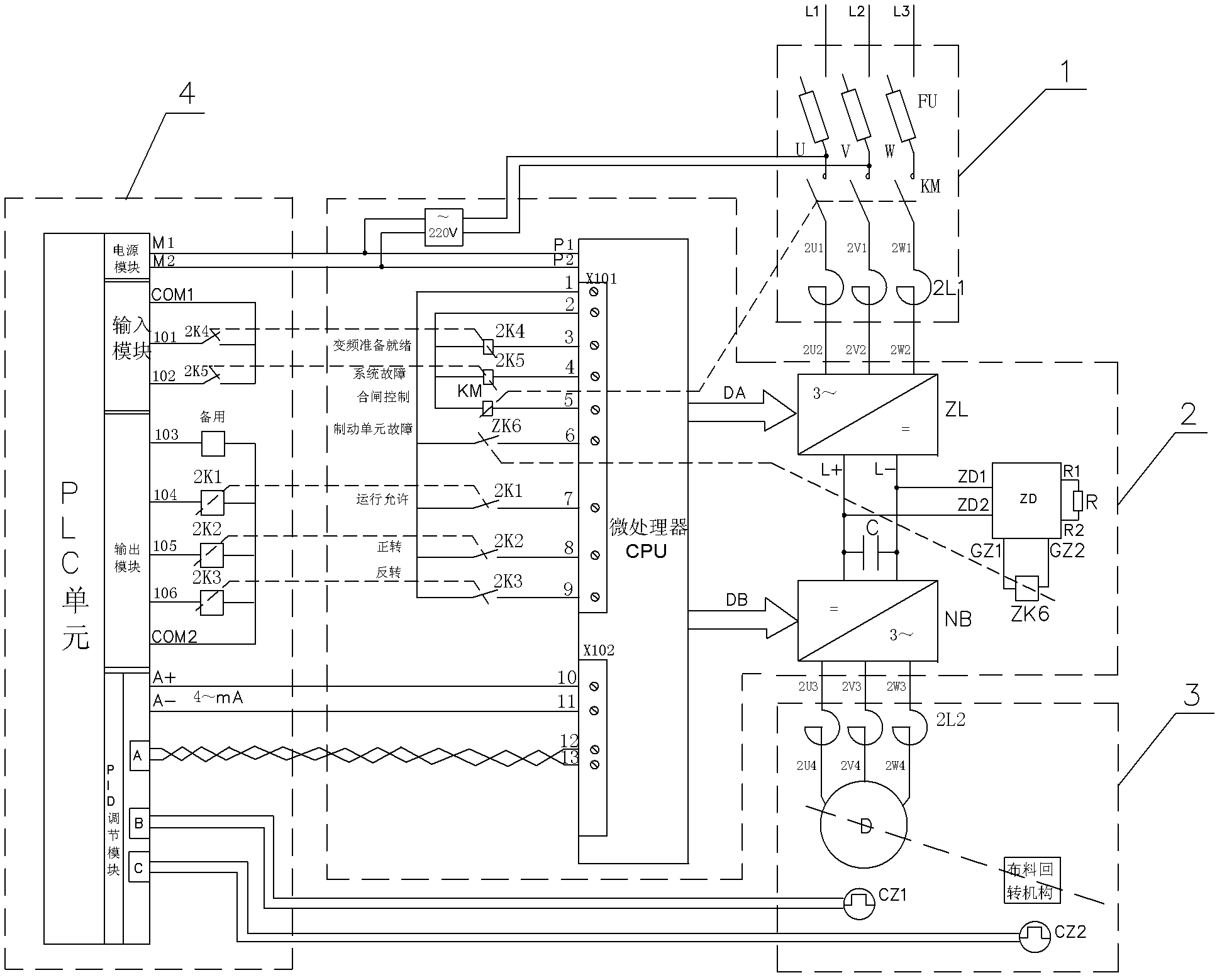

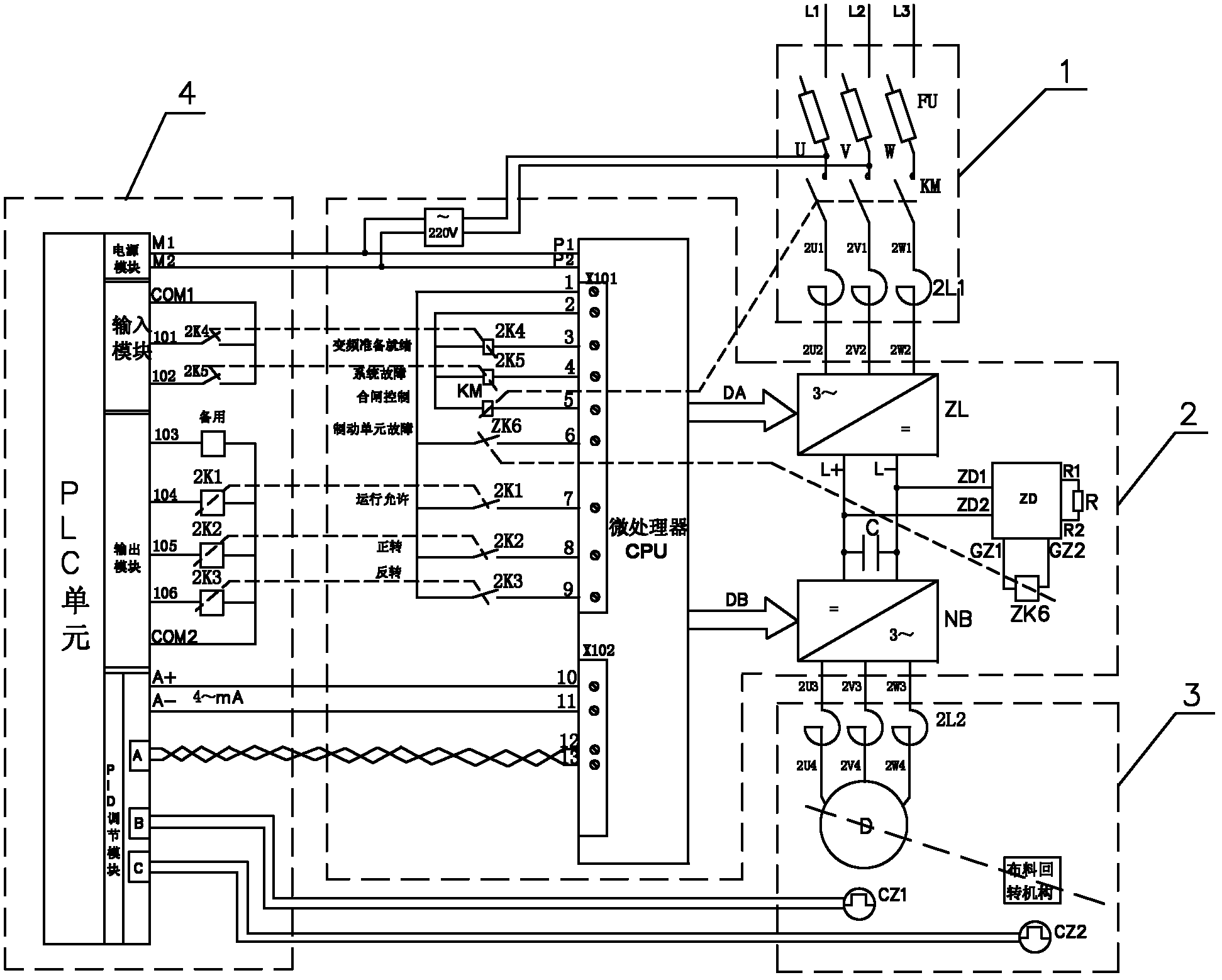

[0018] See figure 1 , is a structural schematic diagram of an embodiment of an automatic control device for blast furnace chute rotation in the present invention, including an input unit 1, a frequency conversion drive unit 2, an execution unit 3 and a PLC control unit 4, and the input unit 1 is connected to the frequency conversion drive unit 2 and the execution unit 3 in sequence , the PLC control unit 4 is connected with the variable frequency drive unit 2, and the input unit 1 includes a fast fuse FU with a short-circuit fast-fuse function, a contactor KM with an automatic control and power cut-off function, and a reactor-2L1 with a filter and compensation function , the three-phase power supply L1, L2, L3 are sequentially connected with the fast fuse FU, the contactor KM and the reactor-2L1;

[0019] The variable frequency drive unit 2 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com