Bipolar secondary cell and method for producing the same

一种二次电池、双极型电极的技术,应用在二次电池、二次电池制造、双极电极等方向,能够解决电池不利、电池输出密度和能量密度劣化、电池能量输出降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

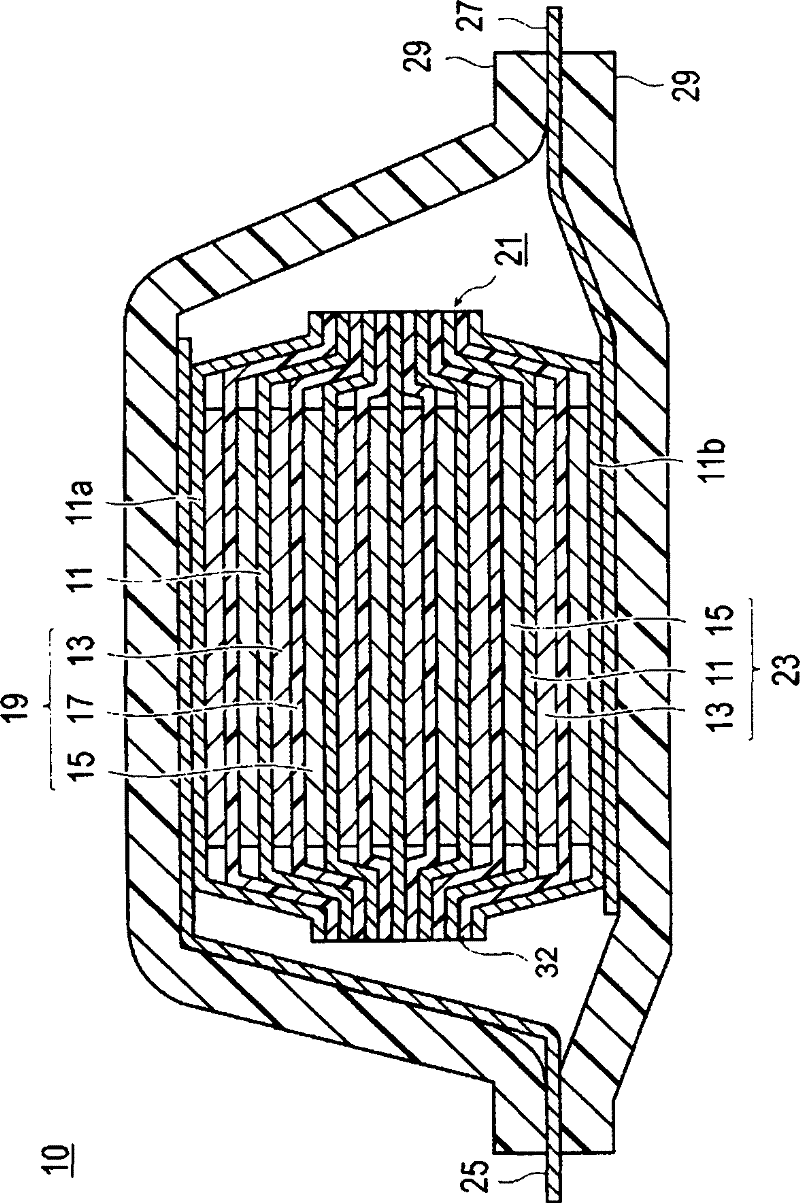

Embodiment 1

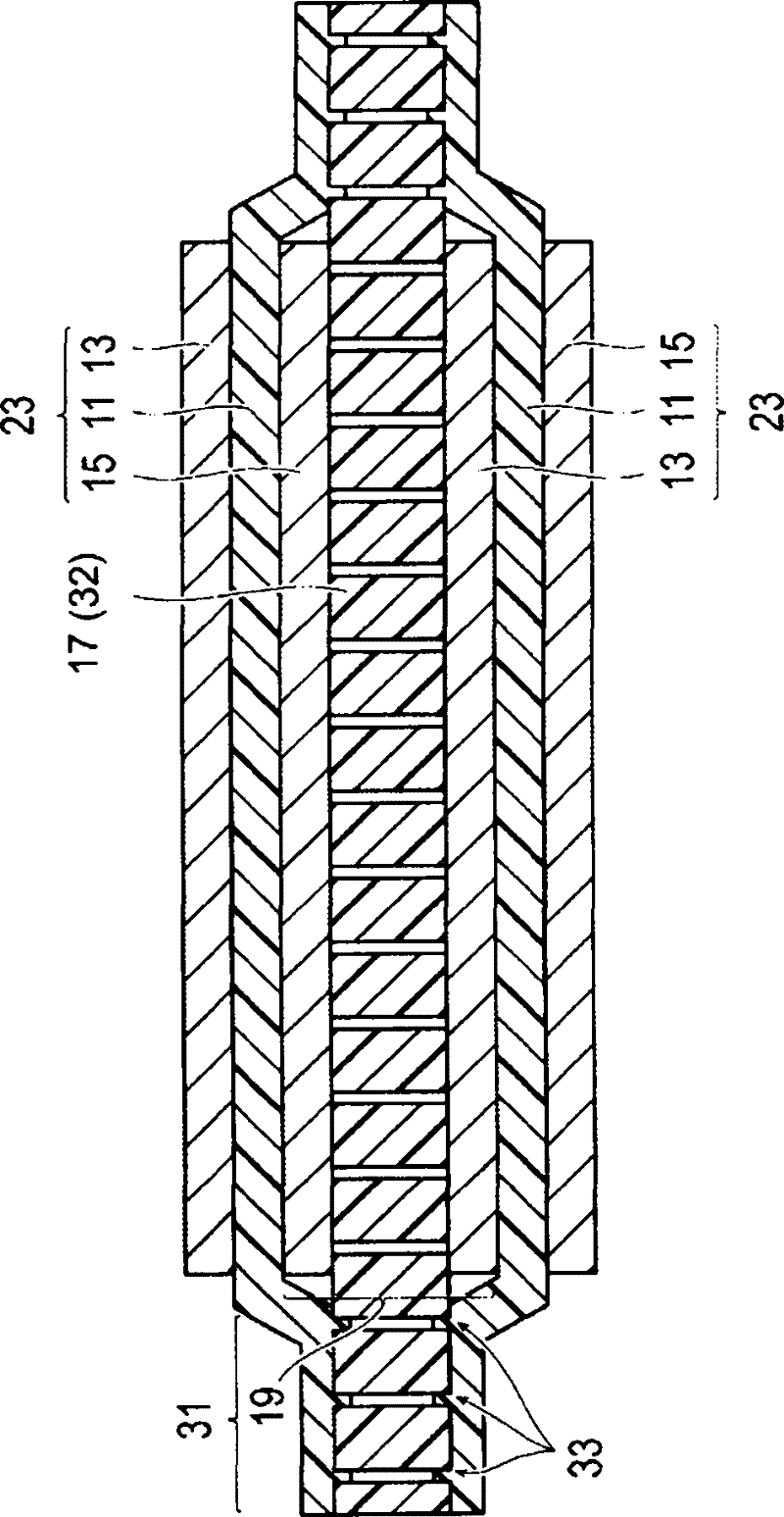

[0098] The positive electrode active material slurry was prepared by mixing: 85% by mass of LiMn as the positive electrode active material 2 o 4 , 5% by mass of acetylene black as a conductive additive, 10% by mass of polyvinylidene fluoride (PVdF) as a binder, and an appropriate amount of N-methyl-2-pyrrolidone (NMP) as a slurry viscosity adjustment solvent . Negative electrode active material slurry was prepared by mixing: 85% by mass of Li as the negative electrode active material 4 Ti 5 o 12 , 5% by mass of acetylene black as a conductive additive, 10% by mass of polyvinylidene fluoride (PVdF) as a binder and an appropriate amount of N-methyl-2-pyrrolidone (NMP) as a slurry viscosity adjustment solvent ). In addition, a conductive resin layer (thickness: 30 μm, volume resistivity in the thickness direction: 1×10 -2 The current collector is provided in the form of Ω·cm). A positive electrode active material layer is formed on one side of the current collector by appl...

Embodiment 2

[0100] A bipolar electrode was produced in the same manner as in Example 1 except that polypropylene was used as the base material of the current collector.

Embodiment 3

[0102] A bipolar electrode was produced in the same manner as in Example 1 except that polyimide was used as the base material of the collector.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com