Building support for construction

A support plate and support rod technology, which is applied in the fields of architecture, building structure, and on-site preparation of building components, can solve problems such as construction safety affecting building quality, problems with building construction quality, and tilting of the top support surface, etc. Achieve the effect of low cost, long service life and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

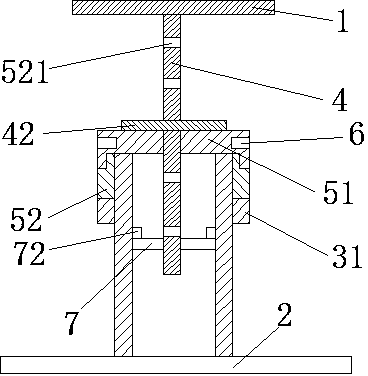

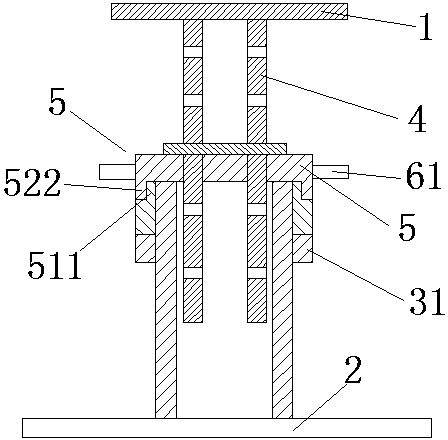

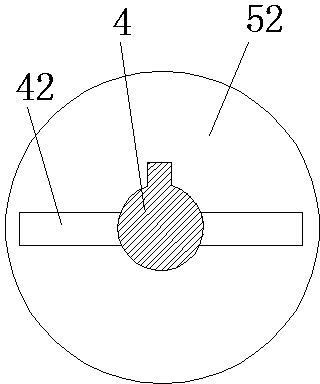

[0036] A building bracket for construction, comprising an upper support plate 1 and a lower support plate 2, a guide cylinder 3 is vertically arranged on the lower support plate 2, a support rod 4 is vertically arranged on the lower surface of the upper support plate 1, and a guide cylinder 3 is sleeved on the upper end A support sleeve 5 that can move up and down along the guide cylinder 3. The support sleeve 5 includes a cylinder body 51 sleeved on the guide cylinder 3 and a cylinder cover 52 that is buckled on the top of the cylinder body 51 and is adapted to the support rod 4. The support rod 4 passes through the through hole from top to bottom, and is inserted into the guide cylinder 3 described in the through hole 521. A limiting part is arranged between the cylinder body 51 and the cylinder cover 52 to prevent the cylinder cover from translating on the horizontal plane. The limiting component includes The inner protruding ring 511 on the top of the barrel body 51 and the...

Embodiment 2

[0040] The difference from the above implementation is that the bottom end of the barrel 51 is provided with an adjusting ring 31 having an internal thread adapted to the external thread.

Embodiment 3

[0042] The difference from the above implementation is that the through hole 521 is a square hole, and the support rod is a square rod, and there is no need to set a limit bar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com