Noble-metal iron-carbon-filler sewage reactor

A sewage reactor, iron-carbon filler technology, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. and other problems, to achieve the effect of improving sewage removal efficiency, reducing chroma, and high COD and COD removal rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

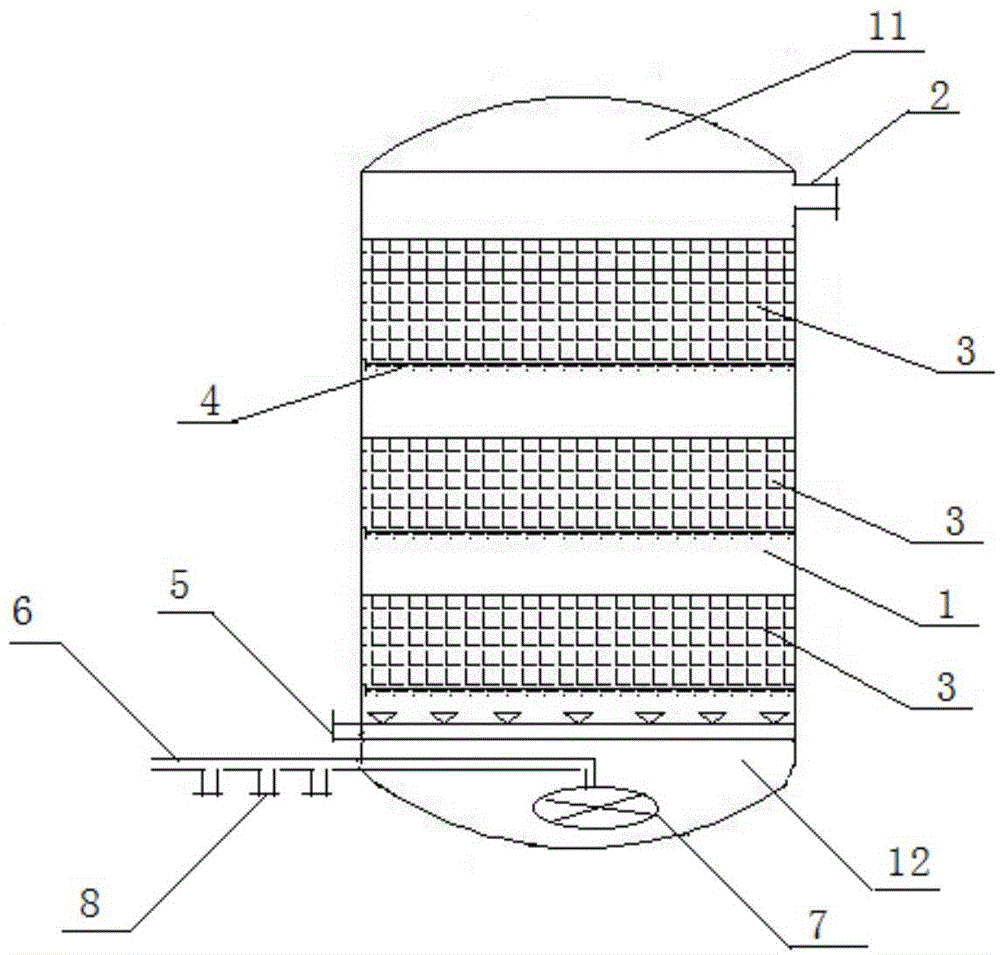

[0027] like figure 1 As shown, a precious metal iron-carbon filled sewage reactor includes a tank body 1 , an upper head 11 and a lower head 12 . The upper part of the tank body 1 is provided with a water outlet 2 near the upper head 11, and the lower part of the tank body 1 is provided with a water inlet pipe 6 and an air distribution pipe system 5 near the lower head 12. Medicine device 8, the end of water inlet pipe 6 is provided with water inlet distributor 7.

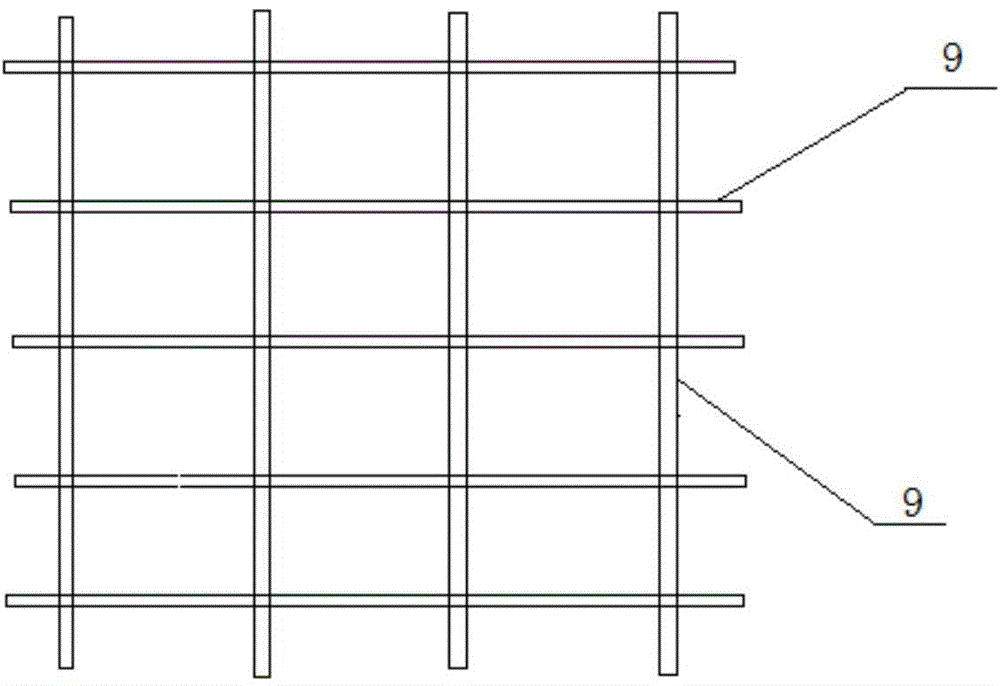

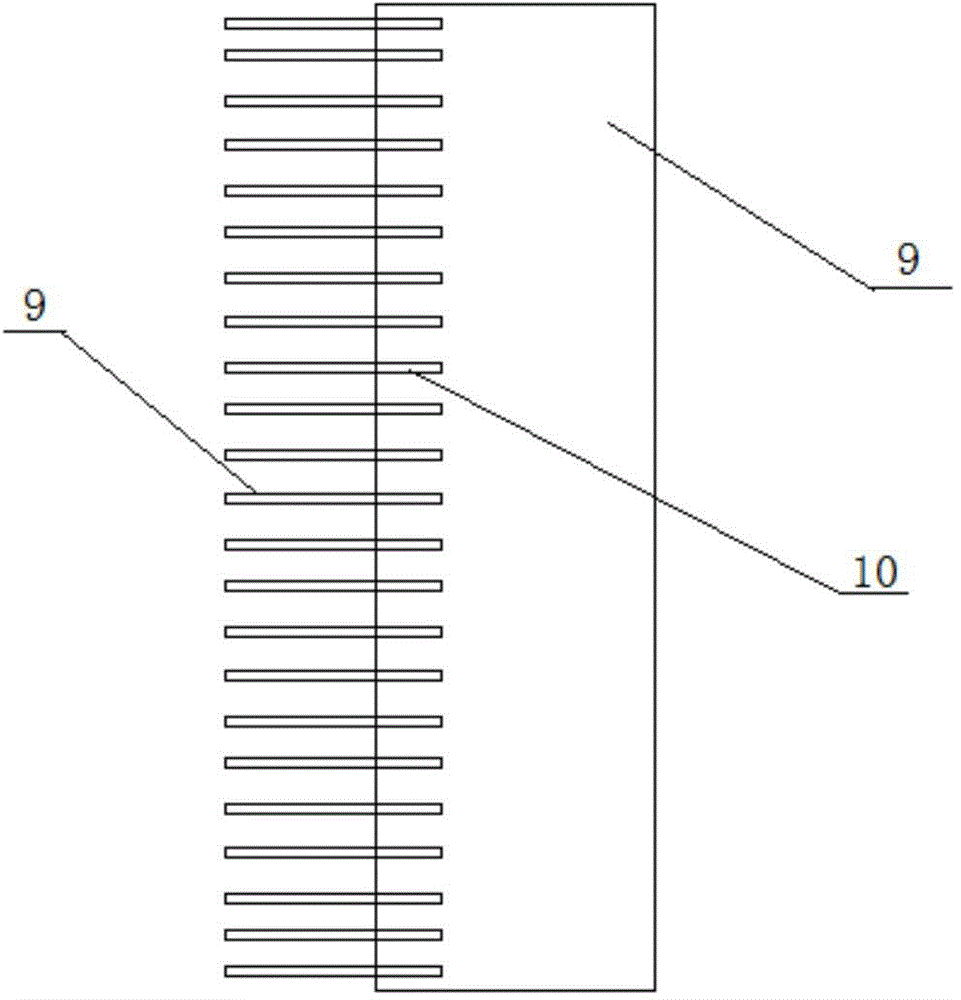

[0028] The tank body 1 is provided with a stainless steel porous filter plate 4, and the stainless steel porous filter plate 4 is provided with an insert type precious metal iron-carbon filler 3. Insert type noble metal iron-carbon filler 3 is composed of several special steel plate units 9 connected to each other through slots 10 to form a grid with a side length of 1.5 cm. The slot 10 is arranged on one side of the special steel plate unit 9, and the groove width of the slot 10 is the same as the thickness of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com