Insulating tube bus-bar connecting device and connecting method thereof

A busbar connection and connection method technology, applied in the direction of connection insulation, connection contact material, shape memory material connection, etc., can solve the problems of reducing the safety and reliability of electrical equipment, low installation efficiency, large power loss, etc., to reduce eddy current and The effect of tip discharge, reduction of installation work intensity, safe and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

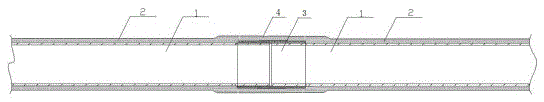

[0025] Such as figure 1 , this embodiment discloses a connection device for insulating pipe busbars, which includes two insulating pipe busbars of the same specification, the outer layer of the insulating pipe busbar core material 1 is covered with an insulating pipe busbar insulating layer 2, and the two ends of the insulating pipe busbar core material 1 According to the diameter of the core material, there are 2 to 20 cm exposed ends. The inner diameter of the pipe bus joint 3 is smaller than the outer diameter of the insulating pipe bus core material 1, and the inner diameter of the pipe bus joint is the same as the outer diameter of the insulating pipe bus core material. The difference is 1 / 100~1 / 2000 of the outer diameter of the core material of the insulating tube bus bar. After heating and expanding the tube bus bar joint, insert the end of the insulating tube bus bar into the heated tube bus bar joint, and then cool it. After the interference fit is completed, an insul...

Embodiment 2

[0027] This embodiment discloses a connection method of the pipe bus connection device described in Embodiment 1, which includes the following steps,

[0028] (1) Clean the two ends of the insulating pipe busbar and the inner and outer surfaces of the pipe busbar joints, polish the burrs, and perform tinning treatment;

[0029] (2) Heat and heat-preserve the pipe bus joints at a certain temperature, and adjust and control the heating and heat preservation temperature and time according to the size of the interference and the expansion of the pipe bus joints;

[0030] (3) When the inner diameter of the pipe busbar joint expands to an inner diameter greater than the outer diameter of the pipe busbar under the action of heating and heat preservation, stop heating and heat preservation, clamp and fix the middle part of the pipe busbar joint with a tool clamp, and quickly insert the insulating pipe busbar connection part into the into the pipe bus connector;

[0031] (4) Cool the ...

Embodiment 3

[0034] The insulating tube bus conductor is selected as Φ100 / 90 copper tube with an outer diameter of 100mm and an inner diameter of 90mm; the intermediate joint is a Φ110 / 99.8 copper tube with an outer diameter of 110mm and an inner diameter of 99.8mm. The inner and outer surfaces of the joints are tin-plated, and the thickness of the tin-plated layer is 2-10 μm. The coefficient of thermal expansion of pure copper is 17.7×10 -6 / °C; put the metal copper tube of the intermediate joint into the heating device, and the temperature rises to 300 °C, then the inner diameter of the metal copper tube of the intermediate joint is: 99.8+ (99.8×17.7×10 -6 / °C×300°C)=100.33 (mm), 100.33mm is 0.33mm larger than the outer diameter of the insulating pipe busbar conductor of 100mm, and the end of the insulating pipe busbar conductor is conveniently inserted into the inner surface of the metal copper pipe of the intermediate joint. After cooling, the interference amount is : (100-99.8)÷2=0.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com