Separator and fuel cell using that separator

A fuel cell and separator technology, which is applied in the direction of fuel cells, fuel cell additives, fuel cell grouping, etc., can solve the problems of narrow gas supply path, blockage of flow path, hindering the diffusion of supplied gas, etc., and achieve sufficient gas diffusion and suppression The effect of an increase in collector resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

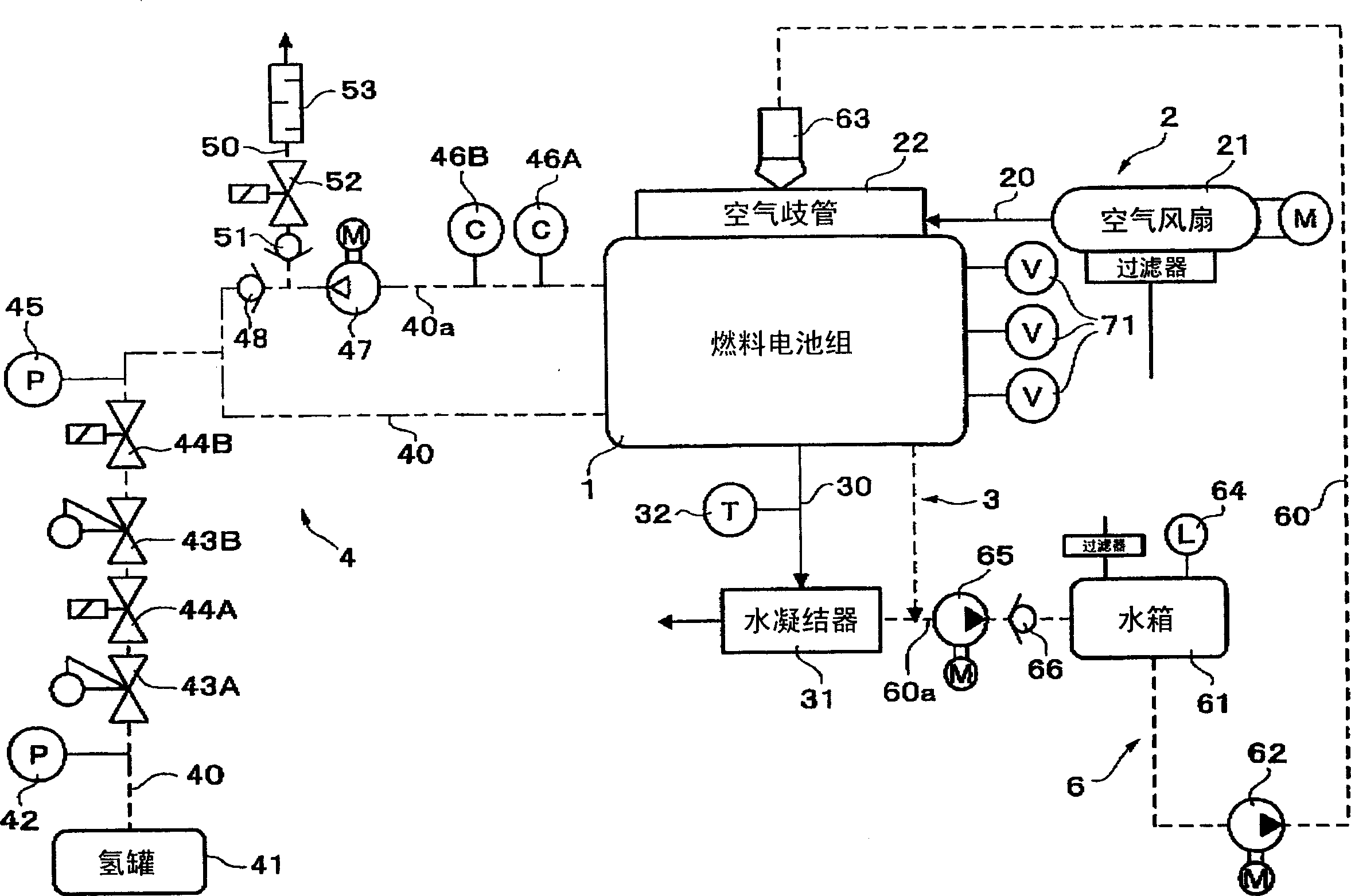

[0033] Embodiments of the present invention will be described below with reference to the accompanying drawings. figure 1 This is the structure of a fuel cell system for a vehicle using the fuel cell stack 1 of the present invention. The fuel cell system includes an air supply system (indicated by a solid line in the figure) 2 including an air fan 21 as an air supply mechanism with a fuel cell stack 1 as a main body, and an air supply system including a water condenser 31 as an air supply mechanism. A fuel cell main body consisting of a discharge system 3; a fuel supply system (indicated by a dashed line in the figure) 4 including a hydrogen tank 41 as a hydrogen supply mechanism; a water supply system (indicated by a dotted line in the figure) for moistening and cooling the reaction part )6.

[0034] An air fan 21 disposed in the main body of the fuel cell is connected to an air manifold 22 through an air supply passage 20, and the air manifold 22 is connected to a case (not...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com