A process for treating sewage in a piece-type precious metal iron-carbon filled sewage reactor

A sewage reactor and iron-carbon filler technology, which is applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of easy passivation hardening, loss of function, long time, etc. , to achieve the effect of reducing chroma and COD, improving biodegradability, and uniform contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

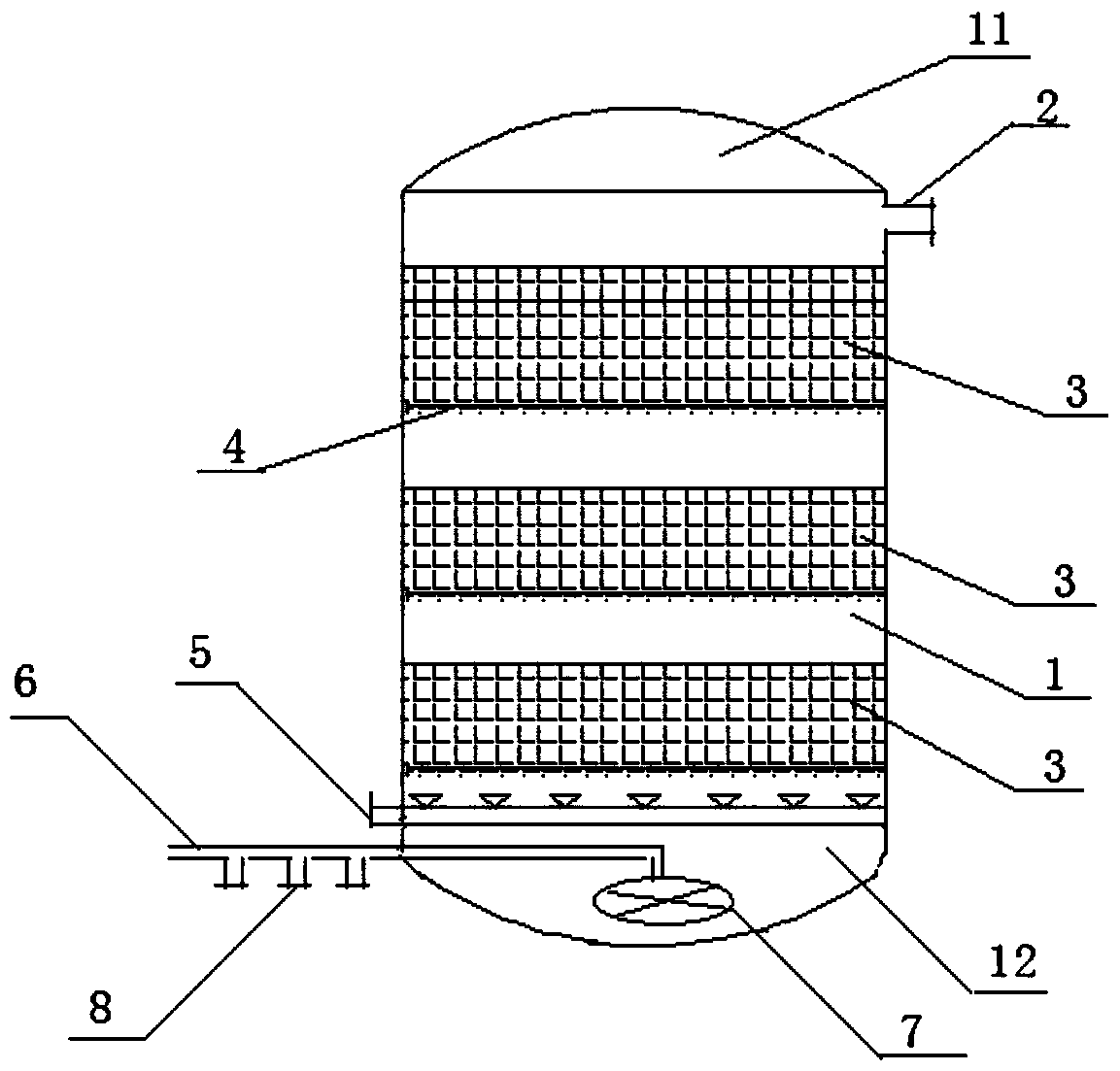

[0031] like figure 1 Shown is a kind of plug-in type precious metal iron-carbon filled sewage reactor used in the process of the present invention, including a tank body 1 , an upper head 11 and a lower head 12 . The upper part of the tank body 1 is provided with a water outlet 2 near the upper head 11, and the lower part of the tank body 1 is provided with a water inlet pipe 6 and an air distribution pipe system 5 near the lower head 12. Medicine device 8, the end of water inlet pipe 6 is provided with water inlet distributor 7.

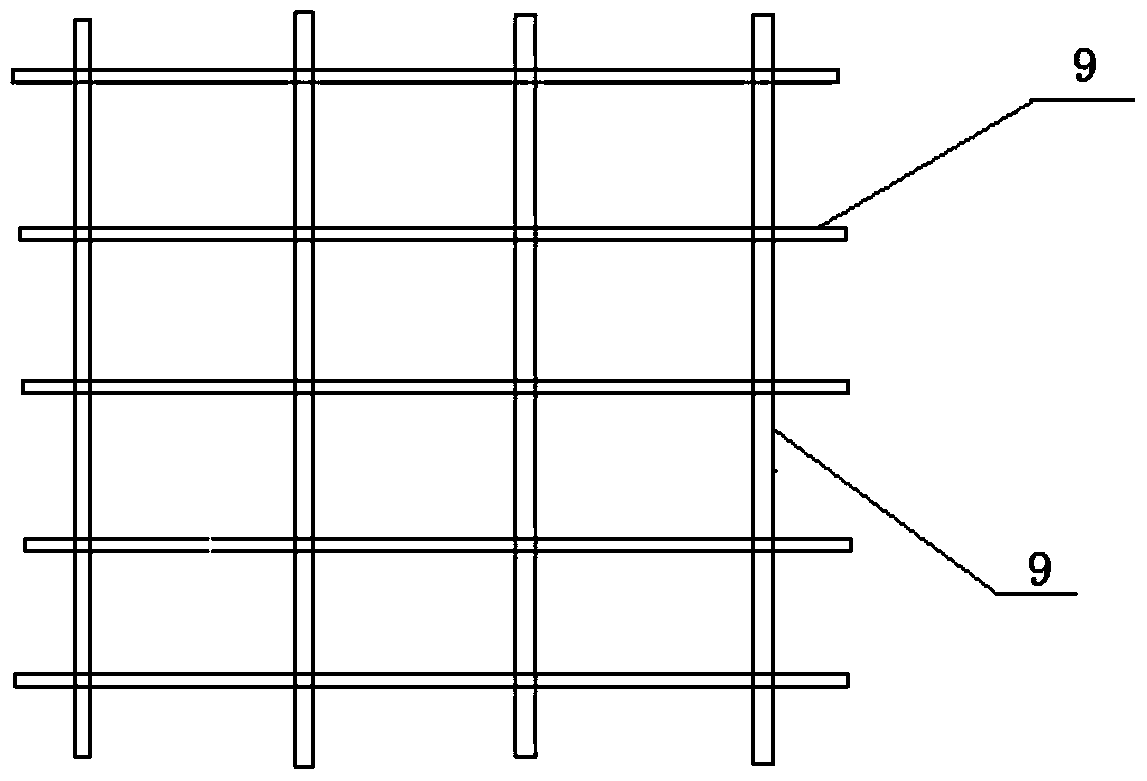

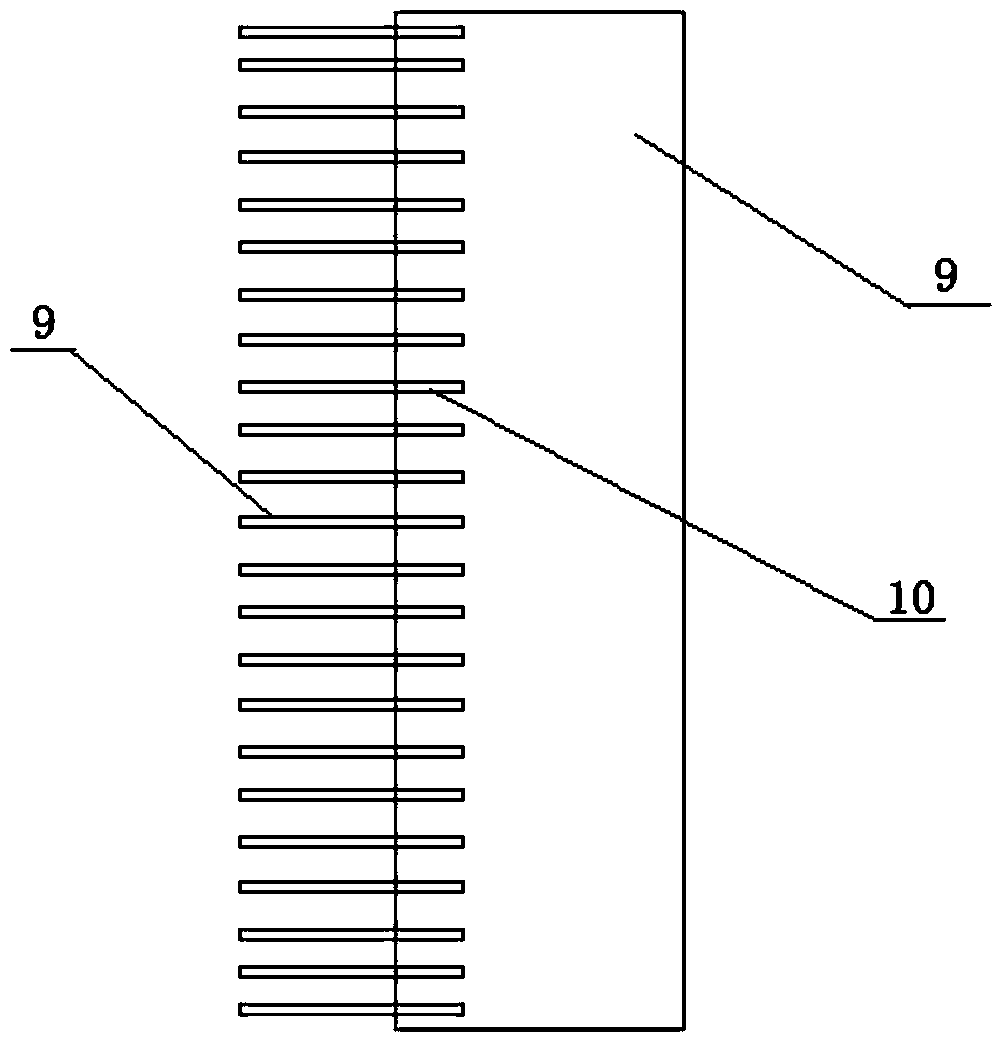

[0032] The tank body 1 is provided with a stainless steel porous filter plate 4, and the stainless steel porous filter plate 4 is provided with an insert type precious metal iron-carbon filler 3. Insert type noble metal iron-carbon filler 3 is composed of several special steel plate units 9 connected to each other through slots 10 to form a grid with a side length of 1.5 cm. The slot 10 is arranged on one side of the special steel plate unit 9, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com