Preparation method of polyaniline /attapulgite/zero valent iron composite material

A technology of composite materials and polyaniline, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc., can solve the problems of easy agglomeration and passivation of iron powder particles, and achieve low-cost and easy-to-obtain , Improve the utilization rate, and the treatment effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation method of polyaniline / attapulgite / zero-valent iron composite material, its step is:

[0019] (1) Add attapulgite to 0.1-0.5mol / L acid solution, stir and disperse for 0.5h;

[0020] (2) Add aniline with 5%-35% of the mass of attapulgite, and stir for 0.5h;

[0021] (3) Add ammonium persulfate with 15-25% of the mass of attapulgite as an initiator, stir and let stand for 0.5h;

[0022] (4) Add iron powder with 25-100% mass of attapulgite, stir and disperse for 0.5h;

[0023] (5) Suction filtration to neutrality, drying at 60°C, and grinding to obtain a composite material.

[0024] The mass percentages of attapulgite, iron powder and aniline are: attapulgite 25-50%, iron powder 25-50%, aniline 5-11%.

[0025] above The attapulgite used is pure soil; the attapulgite is prepared into a 0.01-0.03% suspension solution; the particle size of the iron powder is 200-350 mesh; the acid used is hydrochloric acid, or nitric acid, or sulfuric acid, or the above-me...

Embodiment 1

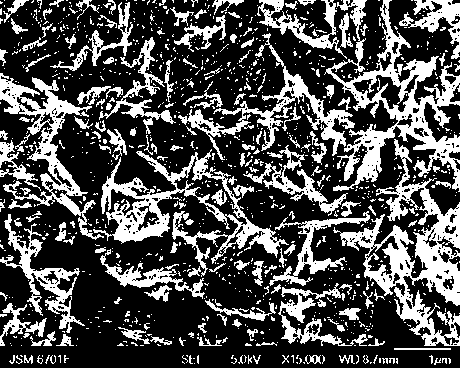

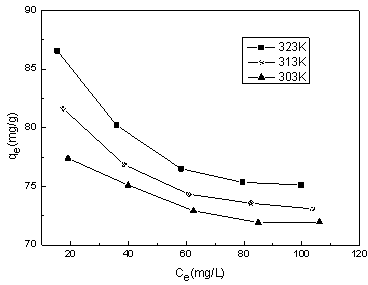

[0028] Example 1: The preparation temperature is 0°C, weigh 2.0g attapulgite, add 0.5mol / L nitric acid 77mL and stir for 0.5h, add 0.6mL aniline and stir for 0.5h, add 2.0g ammonium persulfate, stir and let stand for 0.5h . Add 2.0 g of 350 mesh iron powder. Stir for 0.5 hr, filter until neutral, dry at 60°C, and grind to obtain dark green Fe / PANI / ATP composite material. Such as figure 2 As shown, when the composite material is at pH=3, the adsorption capacity of Cr(Ⅵ) reaches 75.13mg / g. Such as figure 1 Shown is the scanning electron microscope picture of the product that makes.

Embodiment 2

[0029] Example 2: The preparation temperature is 0°C, weigh 2.0g attapulgite, add 0.5mol / L nitric acid 77mL and stir for 0.5h, add 0.5mL aniline and stir for 0.5h, add 2.0g ammonium persulfate, stir and let stand for 0.5h . Add 2.0 g of 320 mesh iron powder. Stir for 0.5 hr, filter until neutral, dry at 60°C, and grind to obtain dark green Fe / PANI / ATP composite material. Such as figure 2 As shown, when the composite material is at pH=3, the adsorption capacity of Cr(Ⅵ) reaches 71.37mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com