Terminal shell and preparing method thereof

A technology for terminal shells and shells, which is applied in portable shells, electrical equipment shells/cabinets/drawers, anodizing, etc., and can solve problems such as complex processing, unsatisfactory conduction effects, and high processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

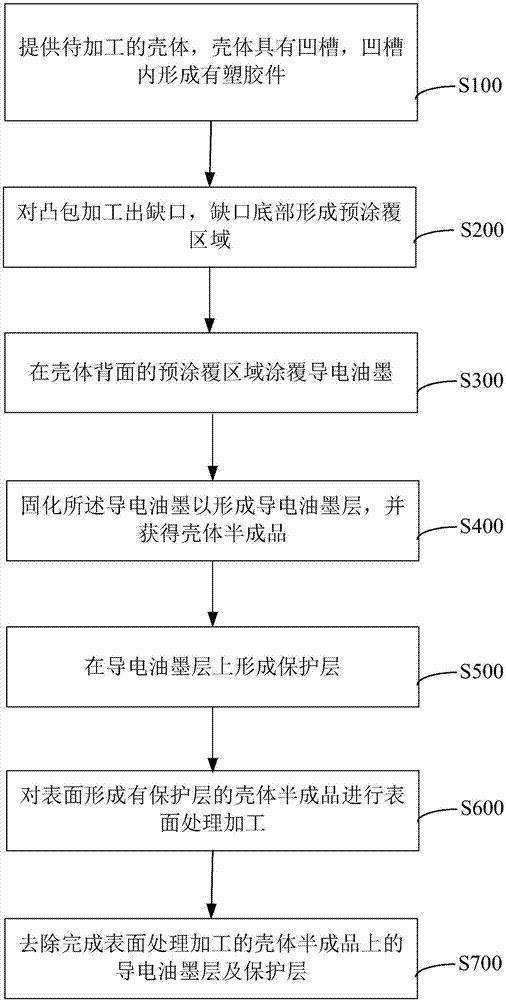

[0029] see Figure 1 to Figure 3 , according to a method for preparing a terminal housing 10 provided in an embodiment, the steps include:

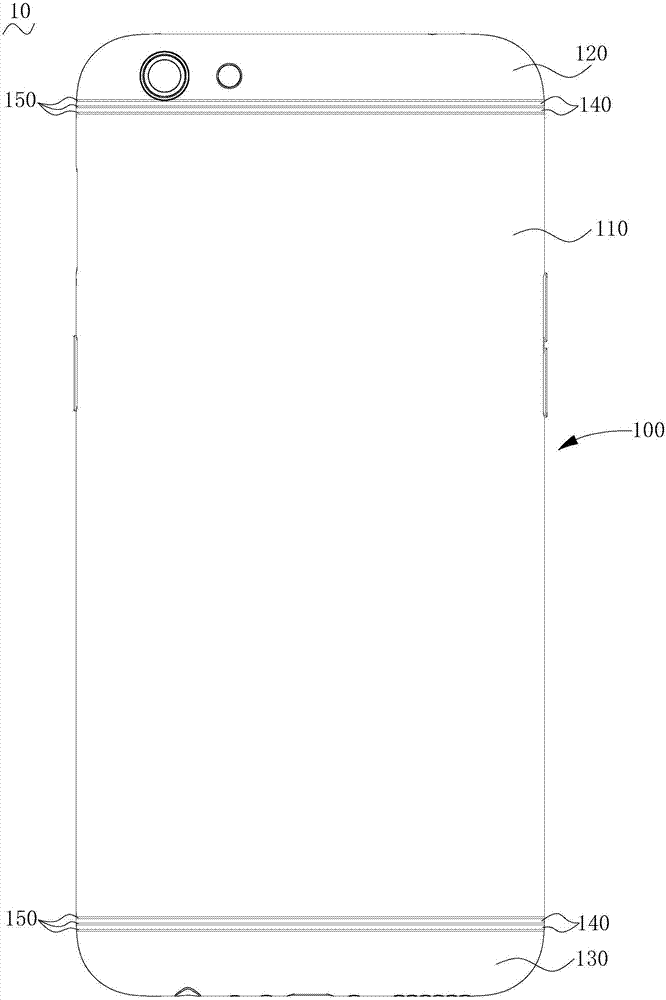

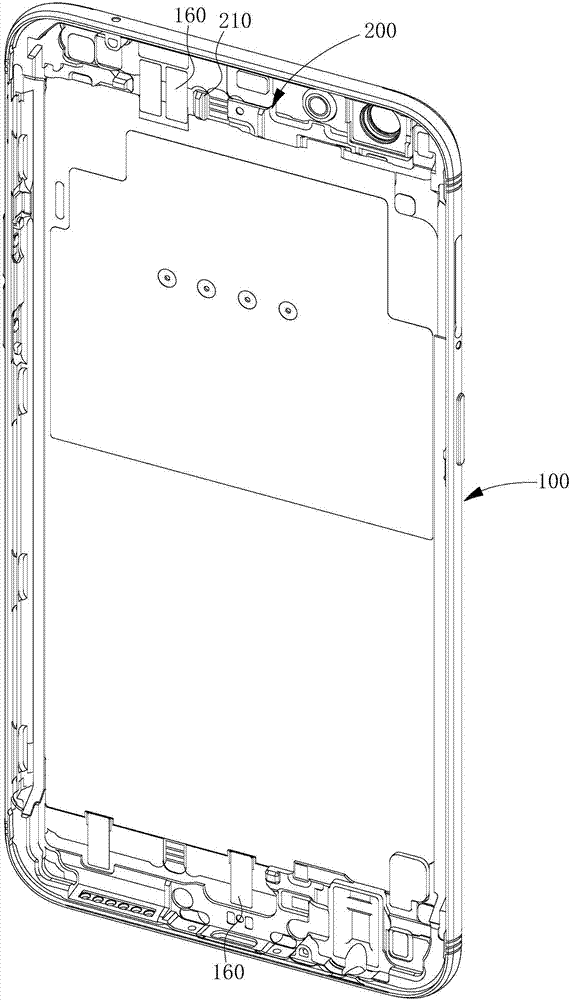

[0030] S100 , providing a casing 100 to be processed, the casing 100 has a groove 150 , and a plastic part 200 is formed in the groove 150 by injection molding. The casing 100 can be classified into two types: one is integrated; the other is insulated by the plastic part 200 , that is, the plastic part 200 separates the casing 100 to form multiple parts spaced apart from each other. After injection molding, the plastic part 200 fills the groove 150 , and the back of the casing and the plastic part 200 together form the convex hull 210 , and the convex hull 210 corresponds to the area of the groove 150 .

[0031] S200, coating conductive ink on the plastic part, and the housings on both sides adjacent to the plastic part are electrically connected by the conductive ink. For the structure with convex hull on the back of the housing, a n...

Embodiment 1

[0043]The convex hulls 210 at the upper and lower ends of the back of the housing are respectively processed into notches, so that the bottom of the notch is on the same plane as the back of the housing, and after the conductive ink is coated in the two pre-coated areas 160 on the back of the housing, the The casing is baked in a baking oven, the baking temperature is set to 60° C., and the baking time is set to 5 minutes. After baking, the casing is taken out of the baking oven to obtain a semi-finished casing.

[0044] Brush the UV protective glue twice on the conductive ink layer of the semi-finished shell. After the first brushing, use ultraviolet radiation to cure the first layer of UV protective glue, then brush the second layer of UV protective glue, and then use ultraviolet radiation to cure the second layer of UV protective glue. Secondary UV protective glue curing. Brush the UV protective glue twice on the conductive ink layer of the semi-finished shell. After the su...

Embodiment 2

[0046] The convex hulls 210 at the upper and lower ends of the back of the housing are respectively processed into notches, so that the bottom of the notch is on the same plane as the back of the housing, and after the conductive ink is coated in the two pre-coated areas 160 on the back of the housing, the The casing is baked in a baking oven, the baking temperature is set to 50° C., and the baking time is set to 15 minutes. After baking, the casing is taken out of the baking oven to obtain a semi-finished casing. Similarly, brush the UV protective glue twice on the conductive ink layer of the semi-finished shell, and use ultrasonic waves to remove the conductive ink layer and the protective layer after the surface treatment of the semi-finished shell to obtain the finished shell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com