Automatic position correcting system for material carrying belt of vacuum belt type drying machine

A vacuum belt drying and conveyor belt technology, which is applied in the direction of drying solid materials, drying, lighting and heating equipment, etc., can solve the problems of deviation correction function failure, drive shaft slipping, poor accuracy, etc., and achieve continuous working status Improvement, Avoid damage to the conveyor belt and improve work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

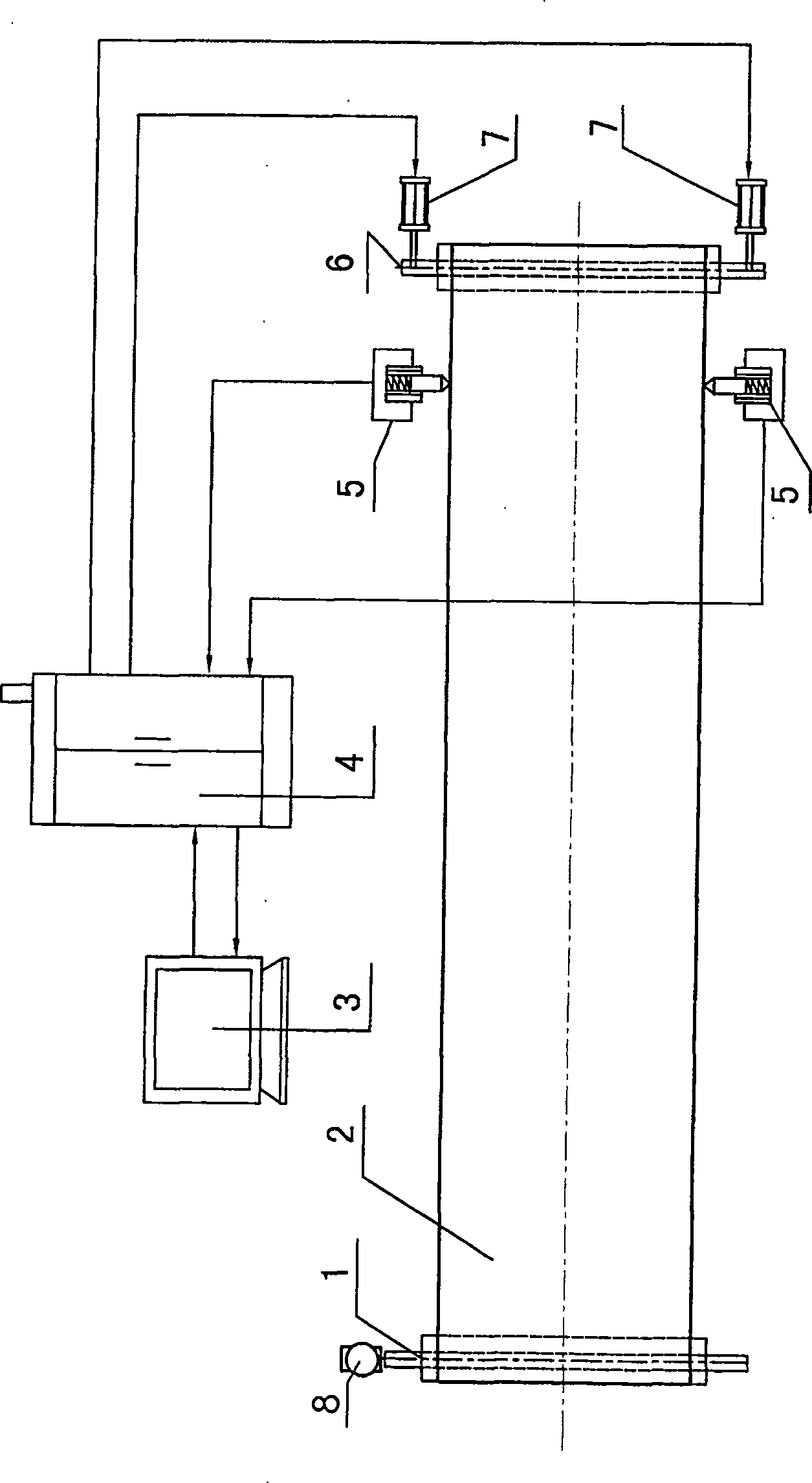

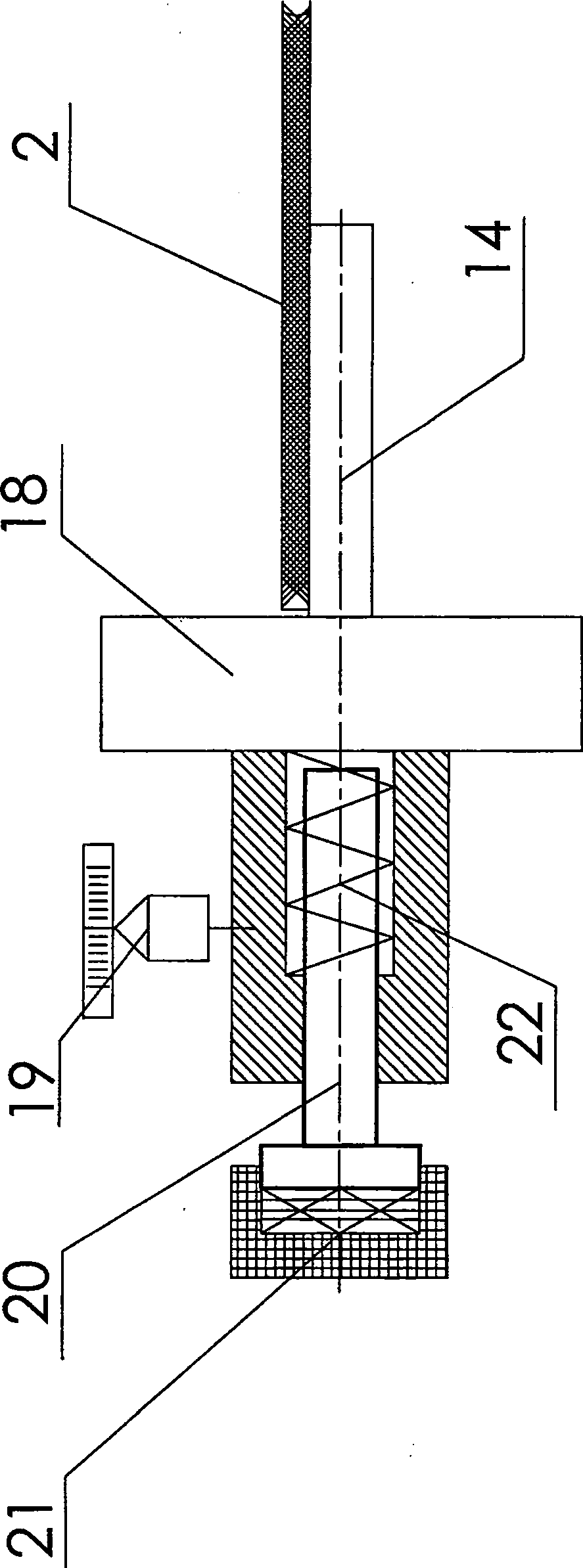

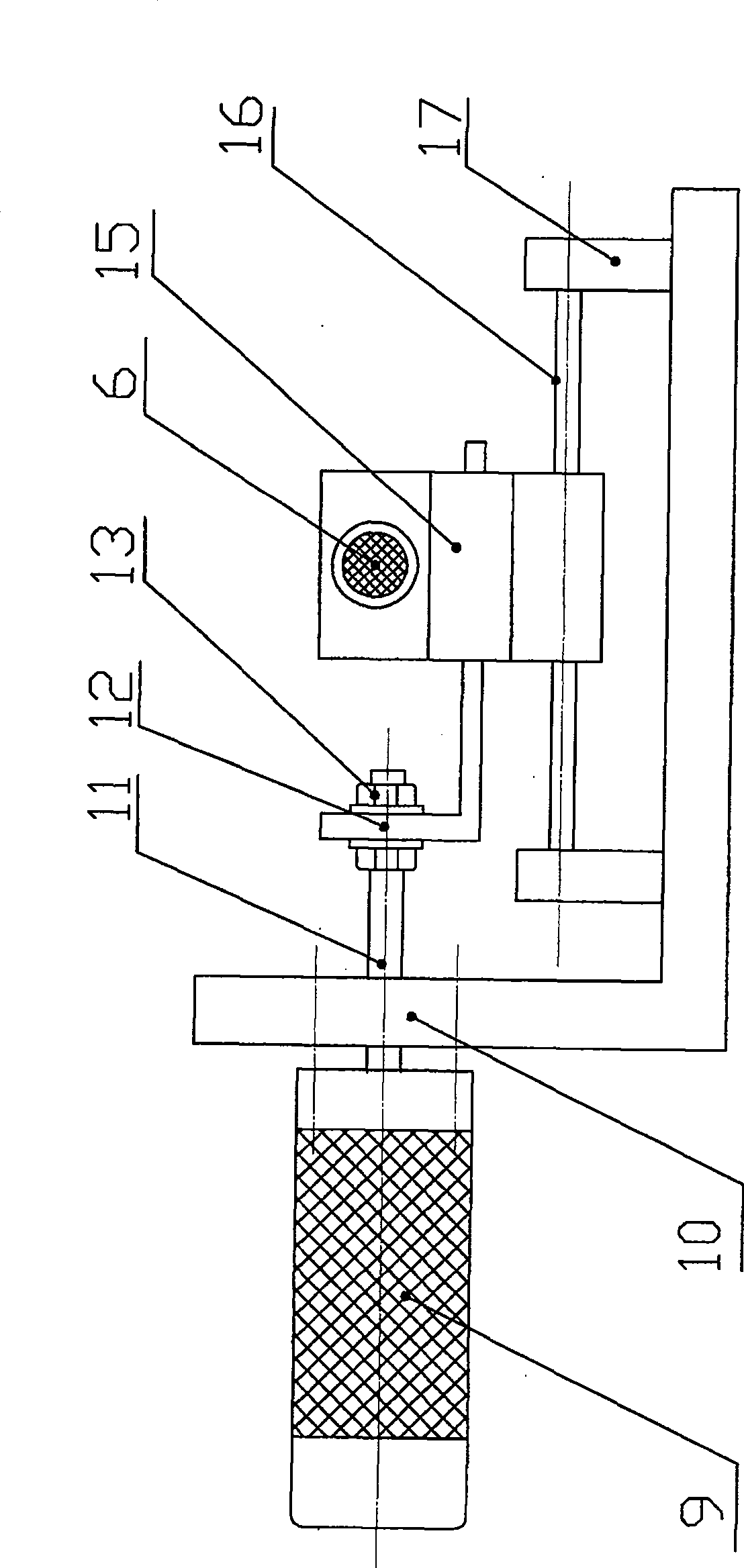

[0012] Such as figure 1 , figure 2 , image 3 In the shown embodiment, the automatic in-position deviation correction system for the loading conveyor belt of the vacuum belt dryer of the present invention includes a deviation correction information collector, a deviation correction cylinder and a computer control system. The deviation correction information collector 5 is arranged on both sides of the loading conveyor belt 2, and is composed of a contactor 18, a displacement detector 19, a sensor 21 and a sensor probe 20. The contactor 18 is kept in contact with the loading conveyor belt 2 by a contactor limit spring 22. belt edge contact. In order to keep the contactor 18 in good contact with the belt edge of the loading conveyor belt 2, the present embodiment sets the contactor guide shaft 14 on the contactor 18, and the contactor guide shaft 14 is placed under the loading conveyor belt 2, so that The contactor maintains good contact with the belt edge of the loaded conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com