Method of forming a porous nickel coating, and related articles and compositions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

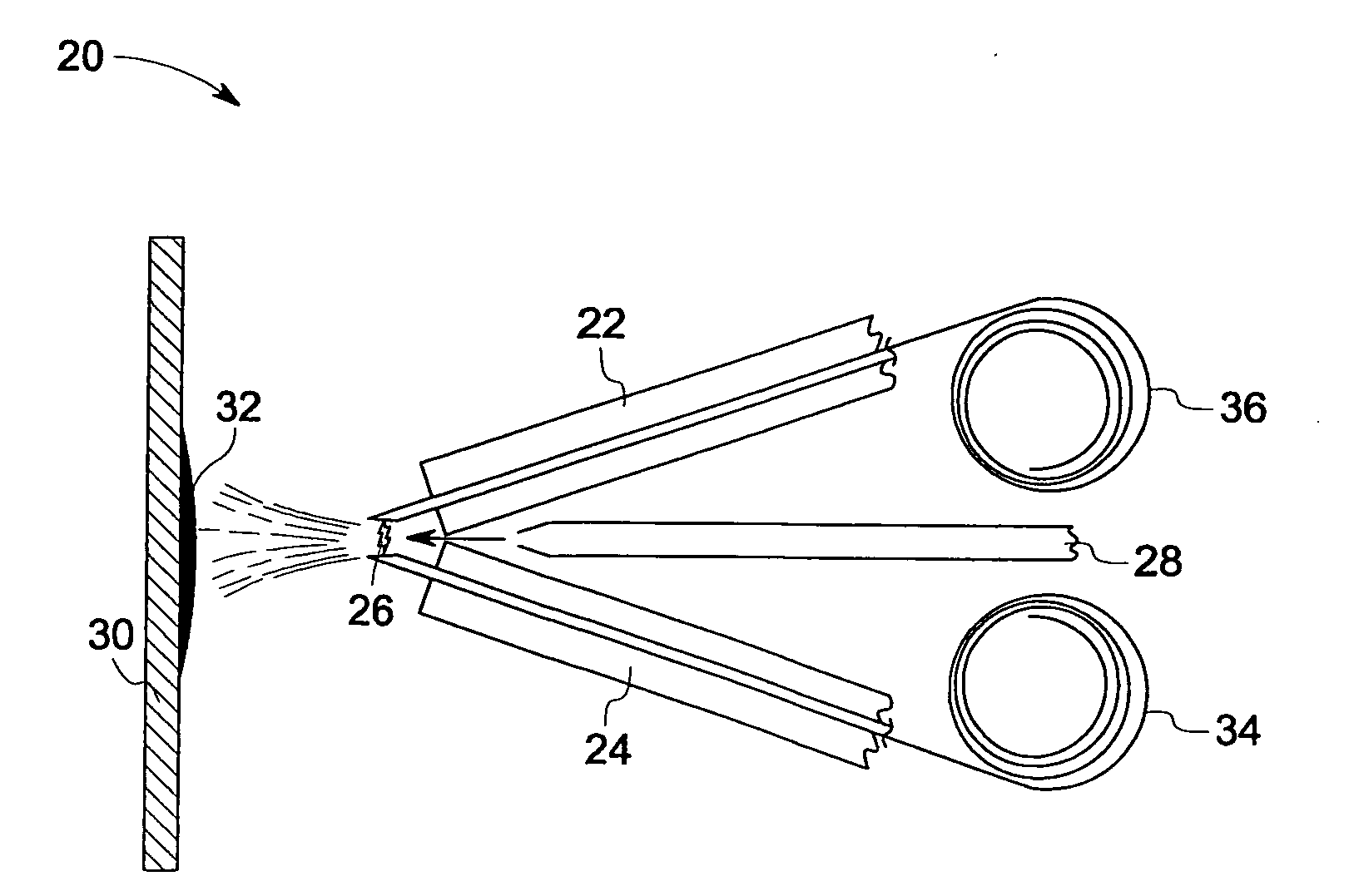

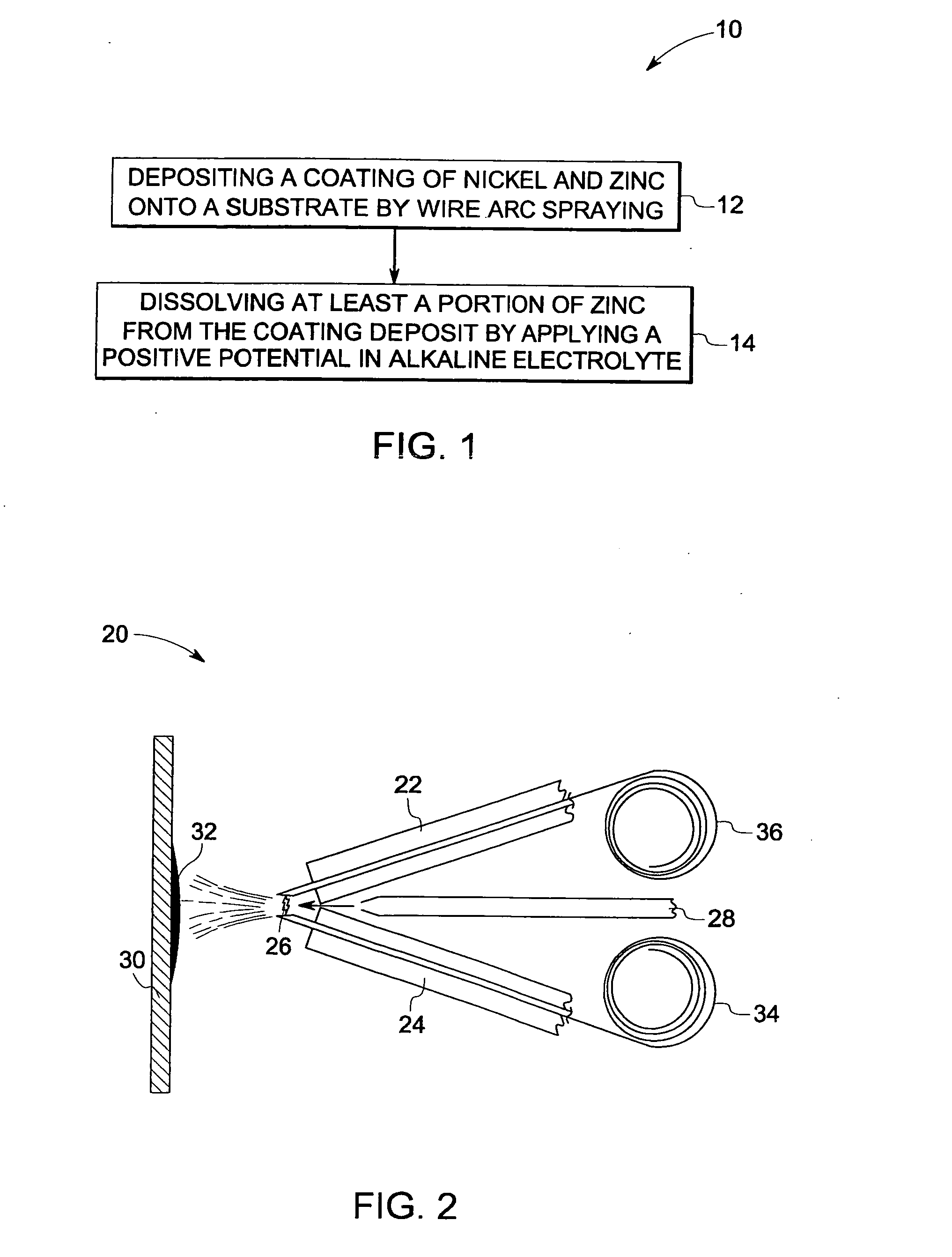

[0053]Sample Preparation: Porous Ni-Based Coatings by Twin Arc Spray Process

[0054]A wire arc coating of Ni based alloys on Microcell cathodes cut from stainless steel 304 sheet with thickness of about 1.6 millimeters was formed, using a SmartArc-350PP Electric Arc Spray System manufactured by Sulzer Metco. Zinc was co-sprayed with Ni and Ni-based alloys by feeding two wires made of these materials into the spray system. For comparison, a set of samples was prepared by co-spraying nickel along with aluminum. The coating thickness was about 114 microns to about 228 microns after 3 passes.

[0055]Zinc Leaching:

[0056]To determine optimal conditions for leaching, different procedures were tested: hot leaching included leaching at 80° C., and cold leaching included leaching at 25° C. Leaching outside the cell included leaching overnight in a beaker with 30% KOH, while cold in-cell leaching included leaching overnight at 25° C. in an assembled cell, and hot in-cell leaching, included leachin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com