Bundled biomass feeding device

A feeding device and biomass technology, applied in the direction of fuel supply, bulk/powder supply/distribution, combustion methods, etc., can solve the problems of inconvenient transportation, time-consuming and laborious burning of biomass fuel, and high investment, and achieve reduction The effects of personal insecurity, reduced manpower consumption, and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

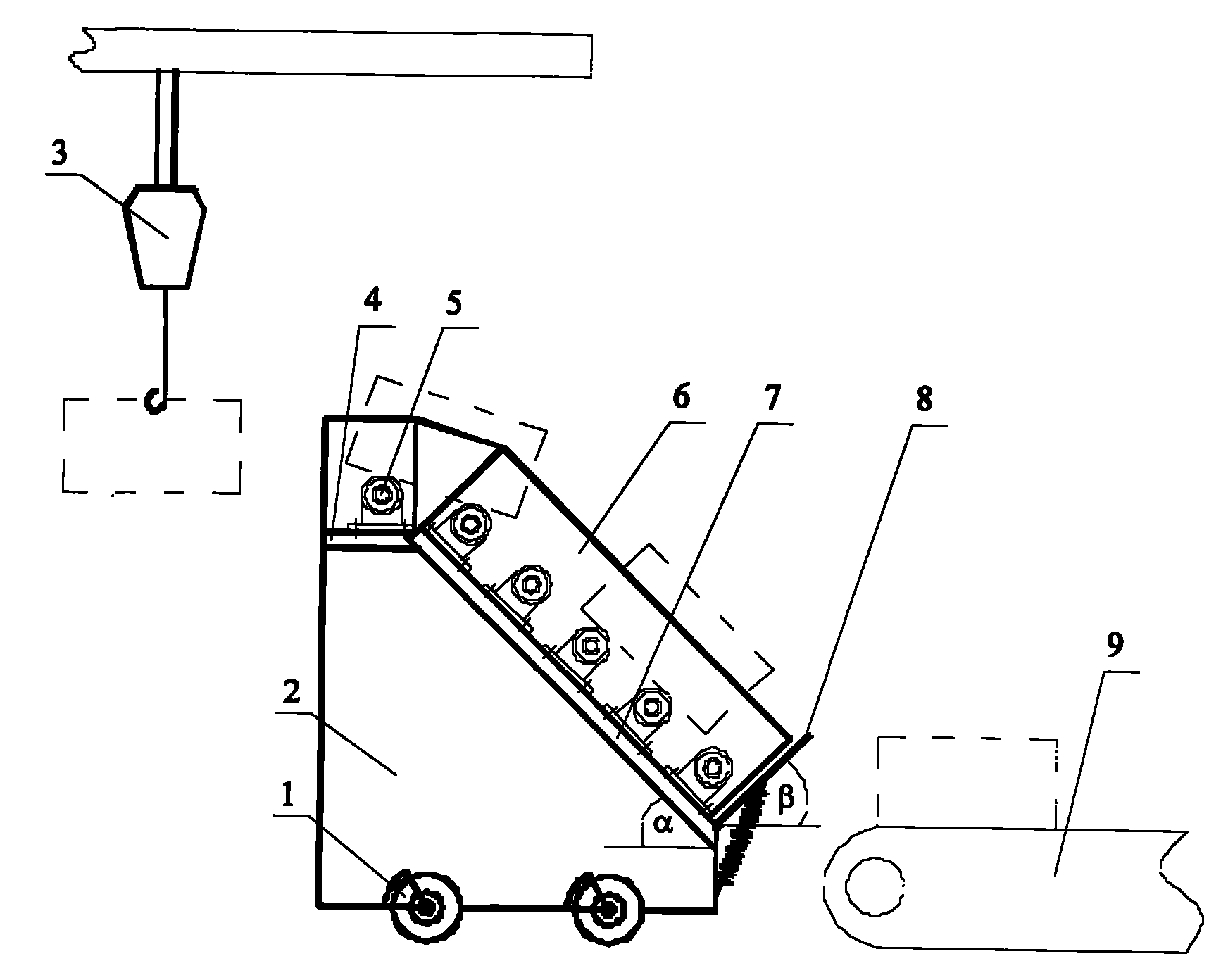

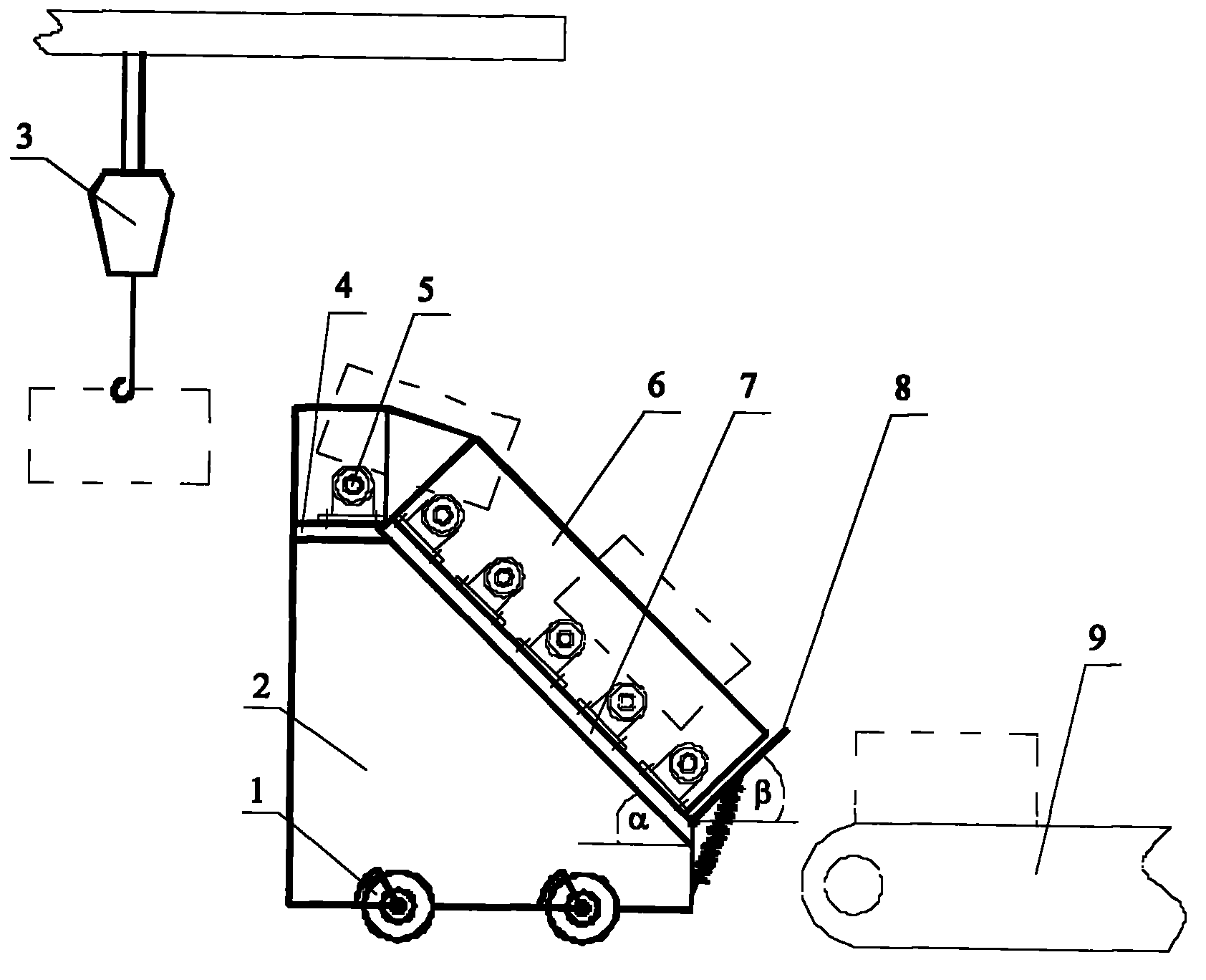

[0011] The invention includes a crane, a mobile platform, a roller, a guard plate, an overlapping partition, and the like.

[0012] Such as figure 1 The crane 3 shown is arranged above the mobile platform 2; the bundled biomass fuel is placed on the crane 3 by manual or mechanical power, and the crane 3 runs along the slideway to the mobile platform 2 fixed at an appropriate position in front of the furnace Above and steadily put bundle shape biomass fuel on the mobile platform 2. The mobile platform 2 has a trapezoidal structure, and rollers 5 are arranged on the horizontal surface 4 of the platform to facilitate the movement of the bundled biomass fuel. The inclined section of the trapezoidal structure of the upper mobile platform 2 is a self-sliding slope 7, and the angle α between the self-sliding slope 7 and the horizontal direction is greater than 45° and less than 90°, and the self-sliding slope 7 is also provided with rollers 5 . Bundle-shaped biomass fuel will slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com