Patents

Literature

371results about "Combustion-air/flue-gas circulation for stoves" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

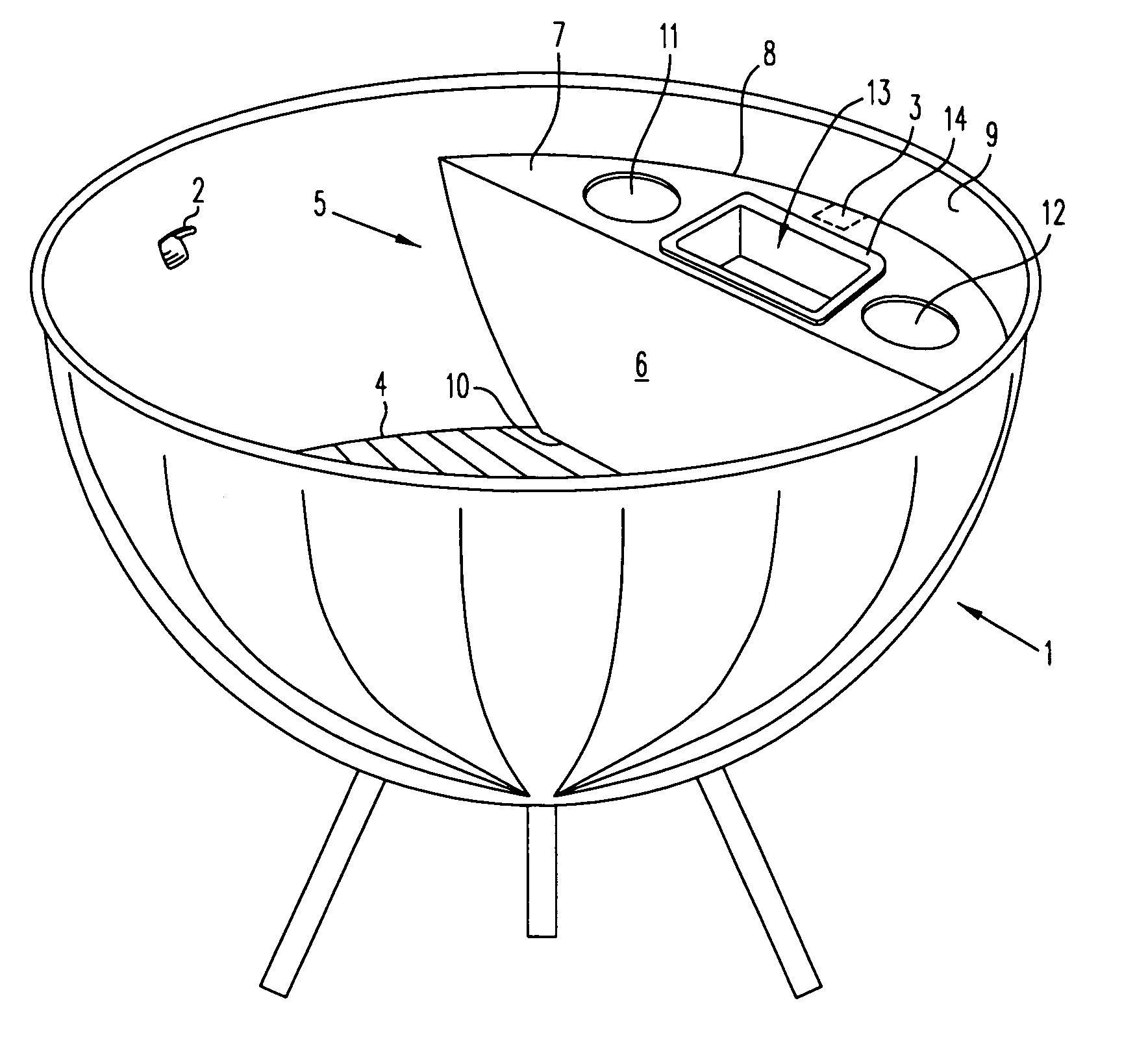

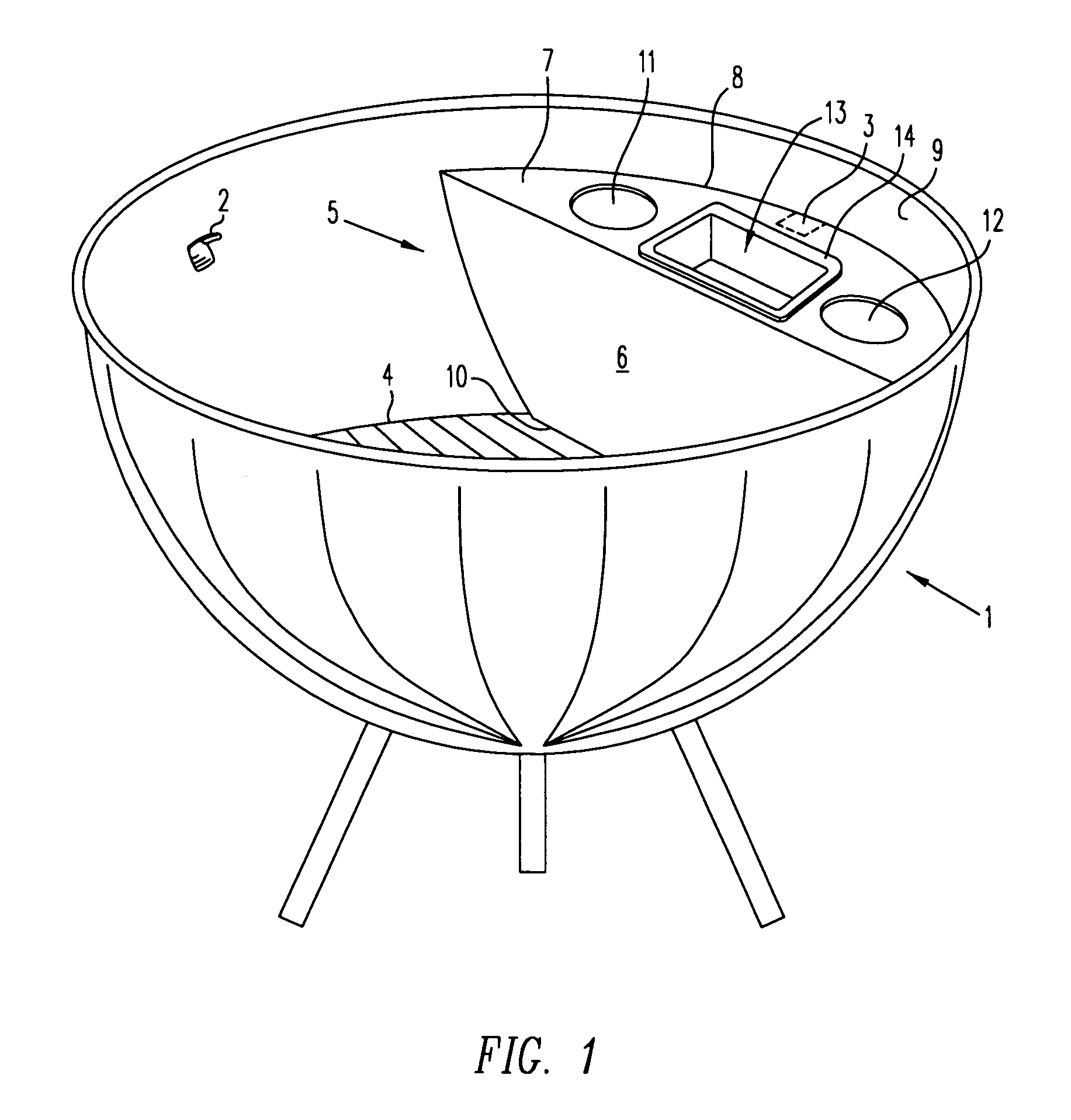

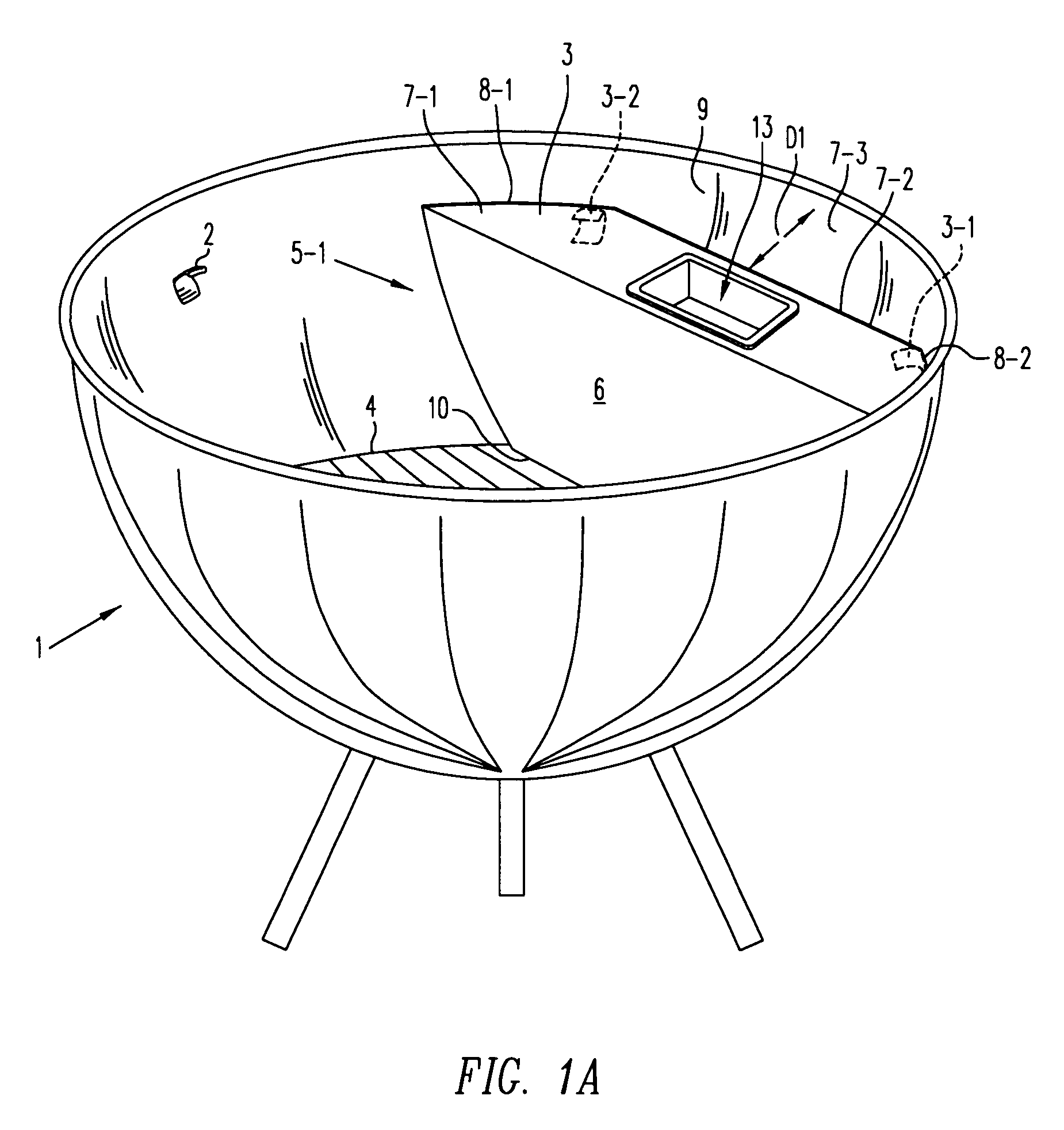

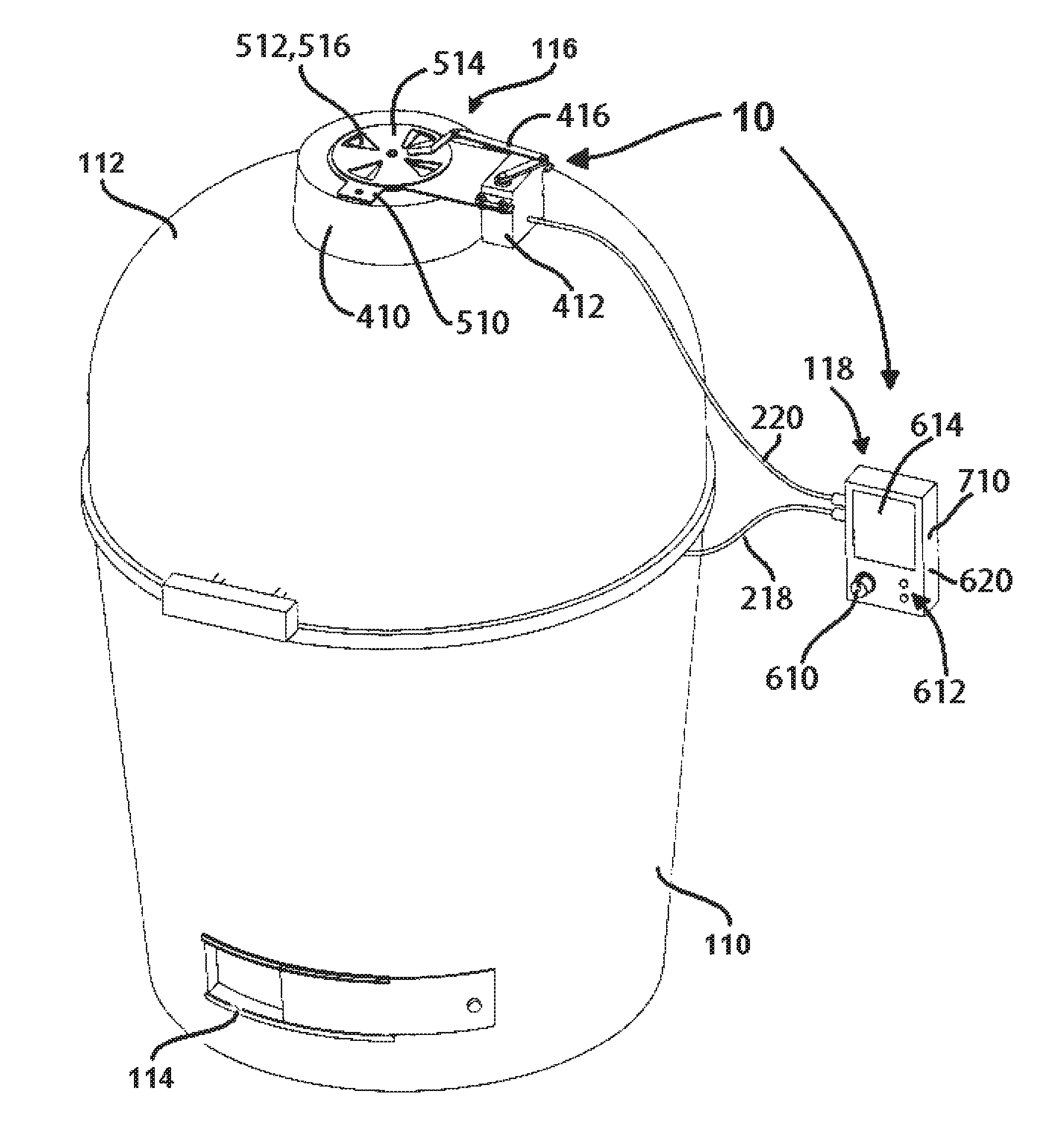

Automated Temperature Control System for Solid-Fueled Grills or Ovens

ActiveUS20130061765A1Precise temperature controlEliminate needTemperature control without auxillary powerLighting and heating apparatusTemperature controlRemote control

An automated temperature control system for a barbecue grill or other structure comprises an automated damper assembly coupled to a vent of said grill, which damper assembly opens and closes selectively to adjust the flow passage area of the grill's vent. The system further comprises an operating area temperature probe for communicating the temperature of the operating area of the grill to the automated damper assembly, such that the automated damper assembly may maintain a user-specified target operating temperature by way of affecting combustion rates within the grill. A remote control may also be provided to allow the user to input a desired temperature for the system to obtain and / or to change temperature information for the grill or other structure.

Owner:IOT CONTROLS LLC

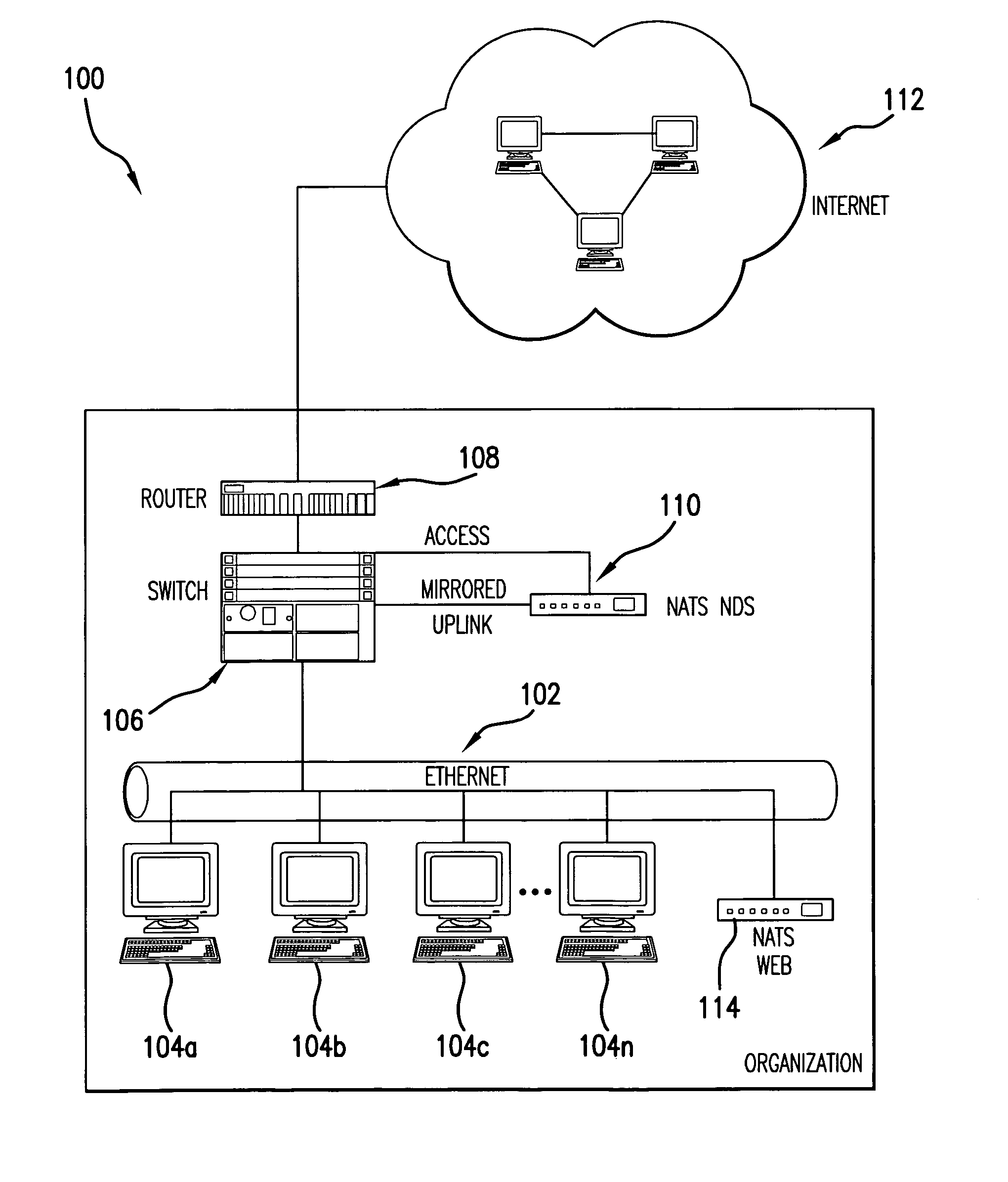

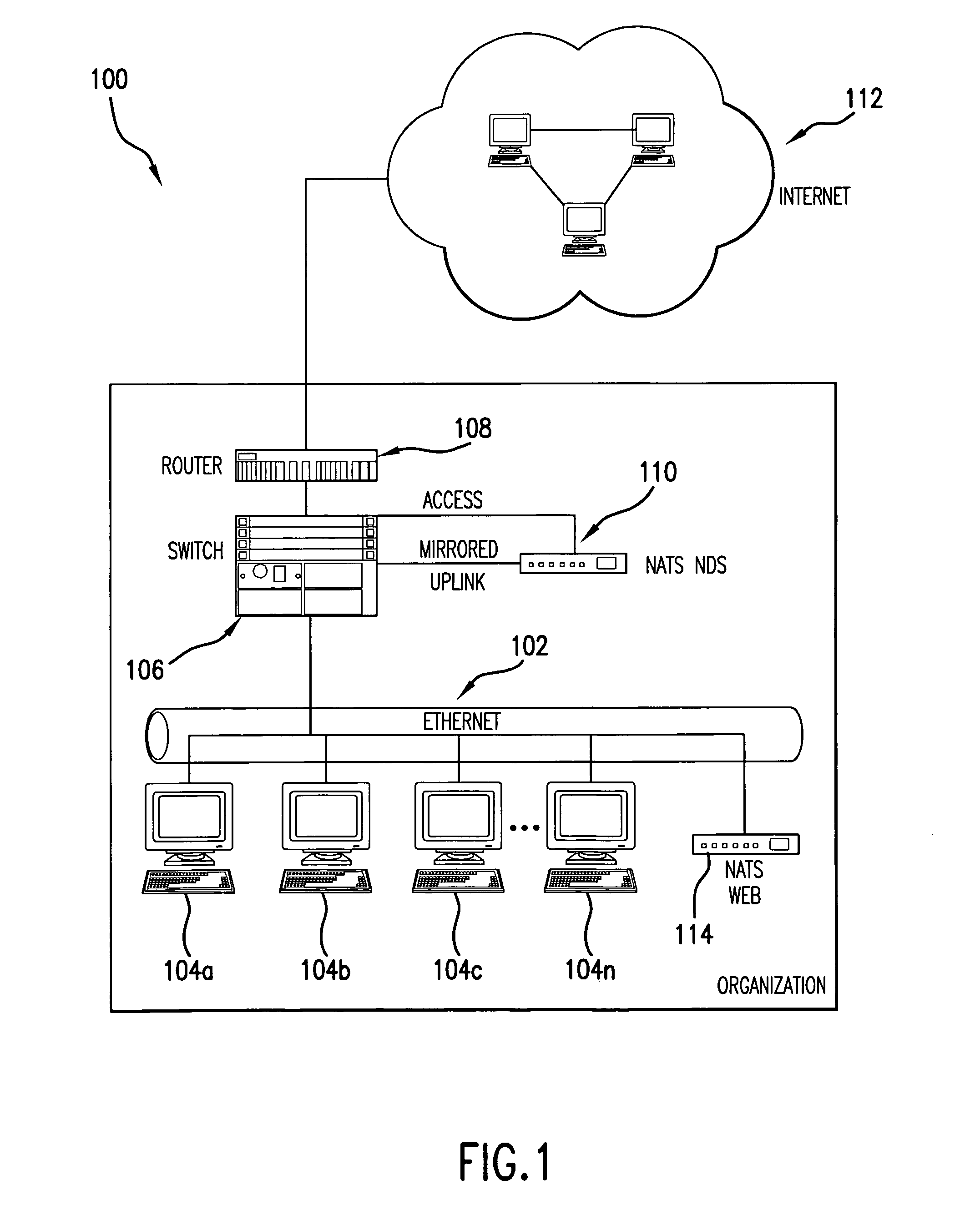

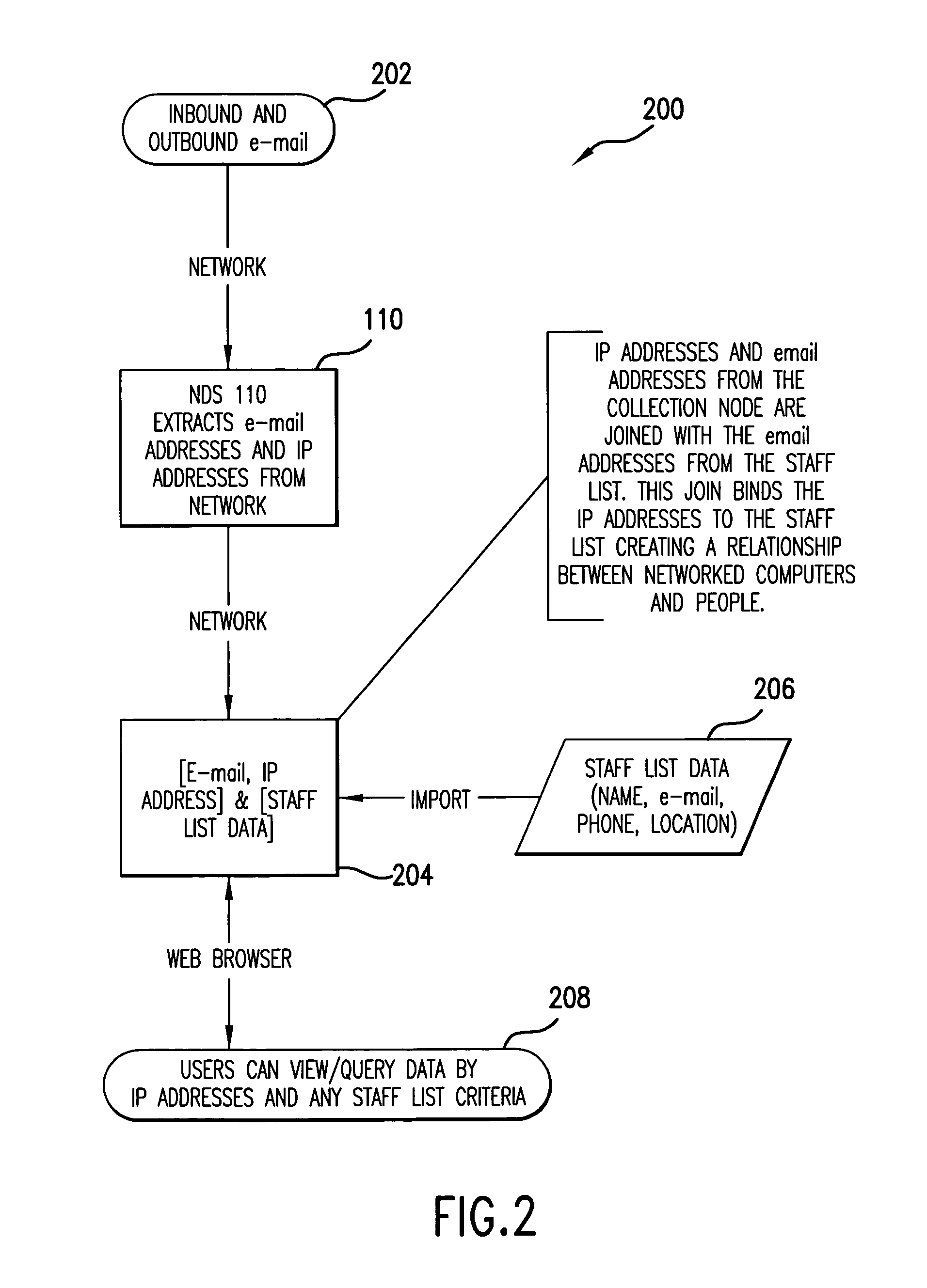

Asset tracker for identifying user of current internet protocol addresses within an organization's communications network

InactiveUS7133916B2Short response timeError is identifiedMetering/charging/biilling arrangementsDigital data processing detailsData packEngineering

Owner:ETELEMETRY

Translucent or opaque colored glass-ceramic article providing a cooking surface and its use

InactiveUS20050252503A1Minimizing contentEasy resistanceCooking-vessel materialsStoves/ranges foundationsChemical reactionAdditive ingredient

The translucent or opaque colored glass-ceramic article provides a cooking surface and has an adjustable light transmission in a visible range under 15%, as measured for a 4 mm sample thickness; a flaw-free upper surface with an impact resistance of greater than 18 cm breaking height, as tested with a 200 g steel ball in a falling ball test; a temperature difference resistance of greater than 500° C.; a high crystallinity with keatite mixed crystals as principal crystal phase in an interior of the glass-ceramic article and with a residual glass phase fraction of less than 8% by weight; a glassy upper surface layer of from 0.5 to 2.5 μm thick, which is substantially free of high quartz mixed crystals and which inhibits chemical reactions, and a content of enriched ingredients in the residual glass phase in the interior of the glass-ceramic and in the glassy surface layer of ΣNa2O+K2O+CaO+SrO+BaO+F+refining agents of from 0.2 to 1.6% by weight.

Owner:SCHOTT AG

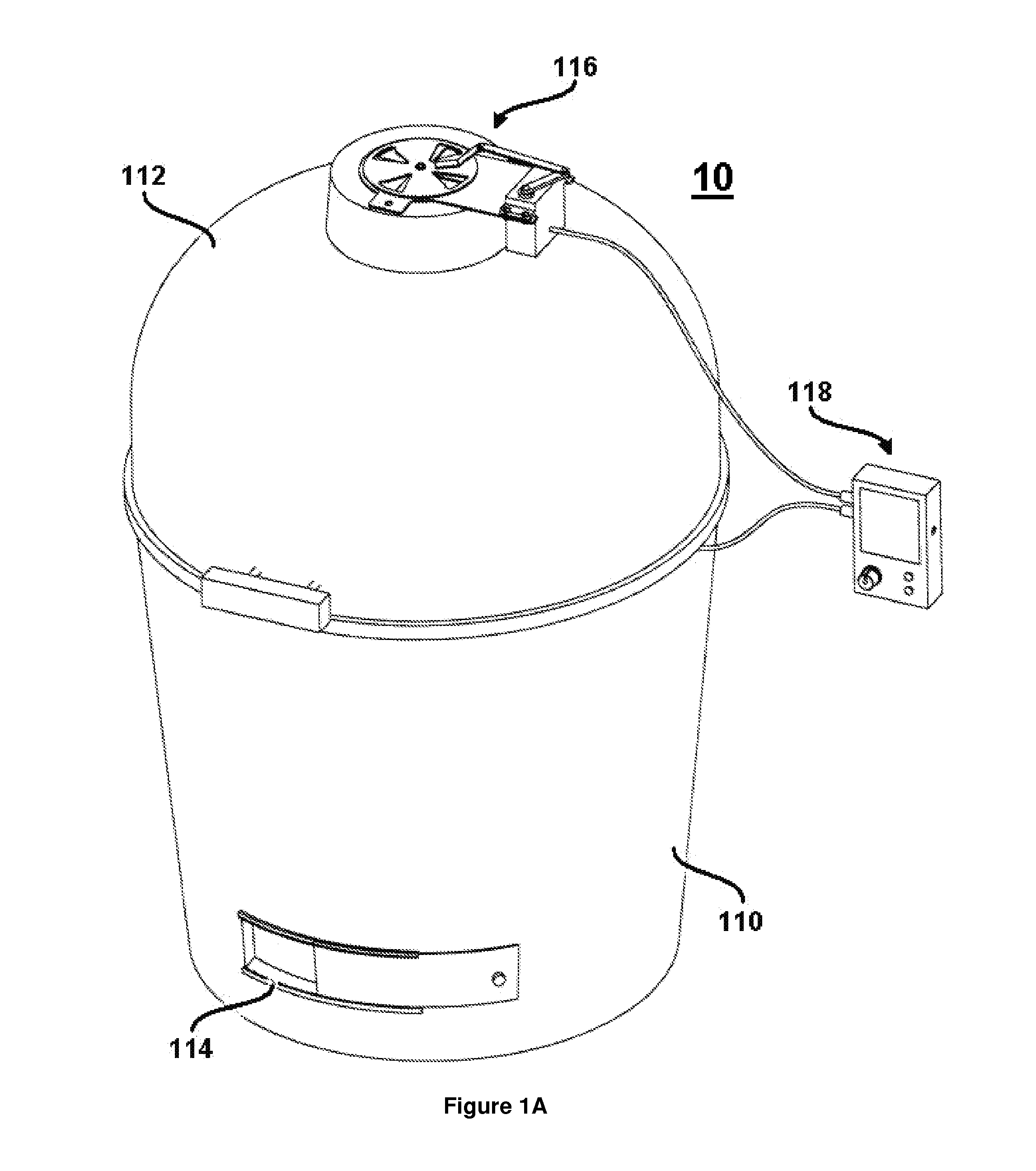

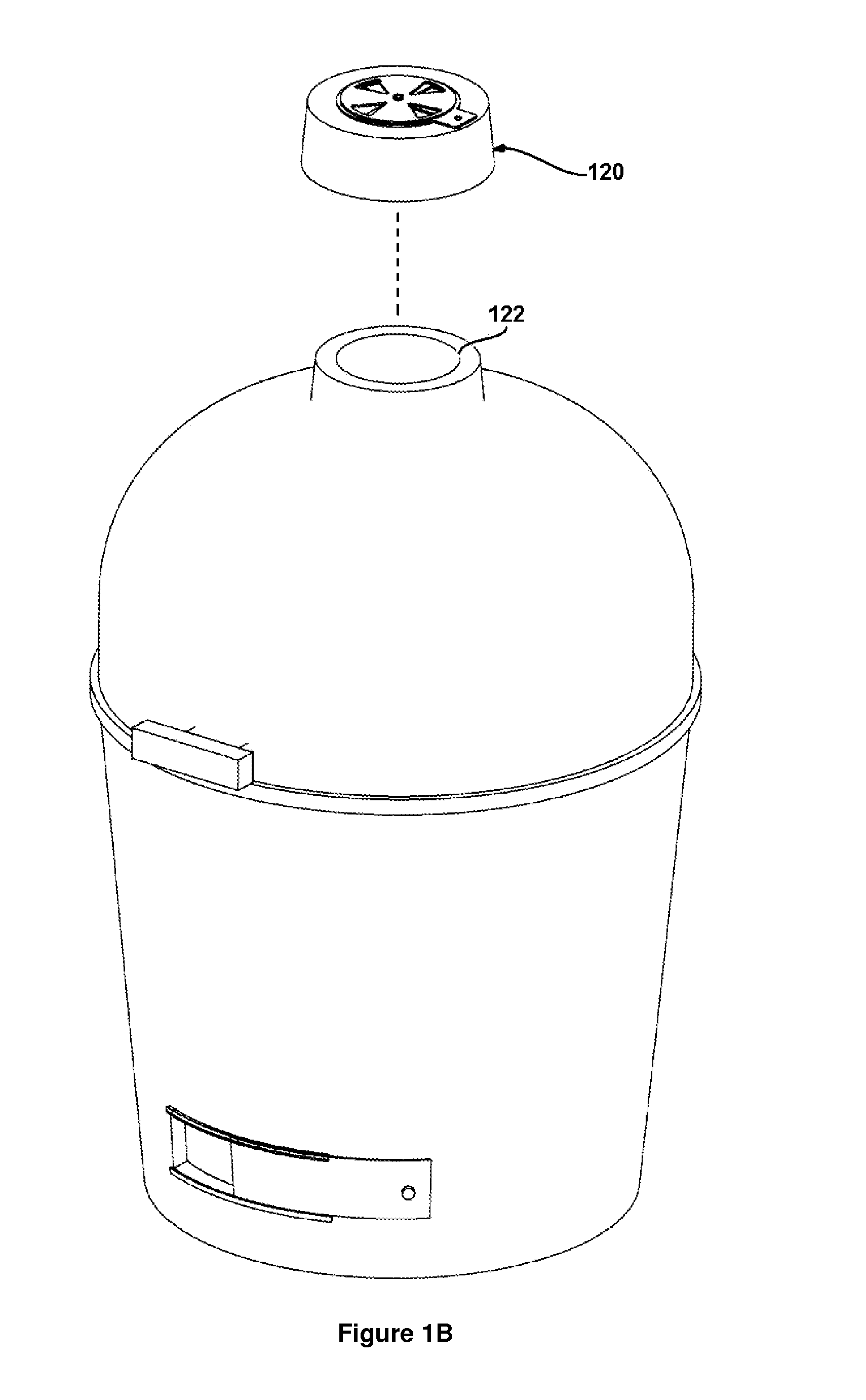

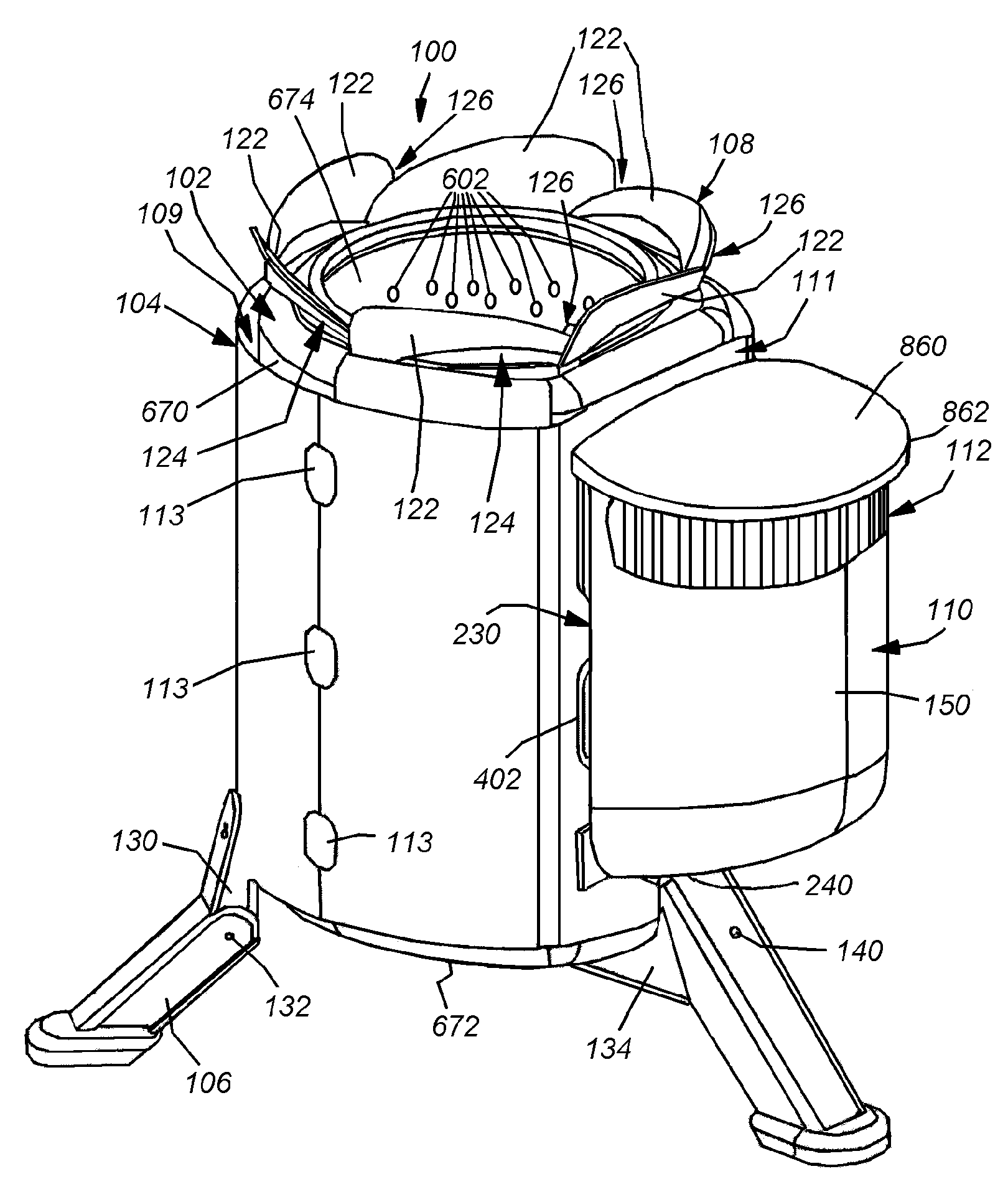

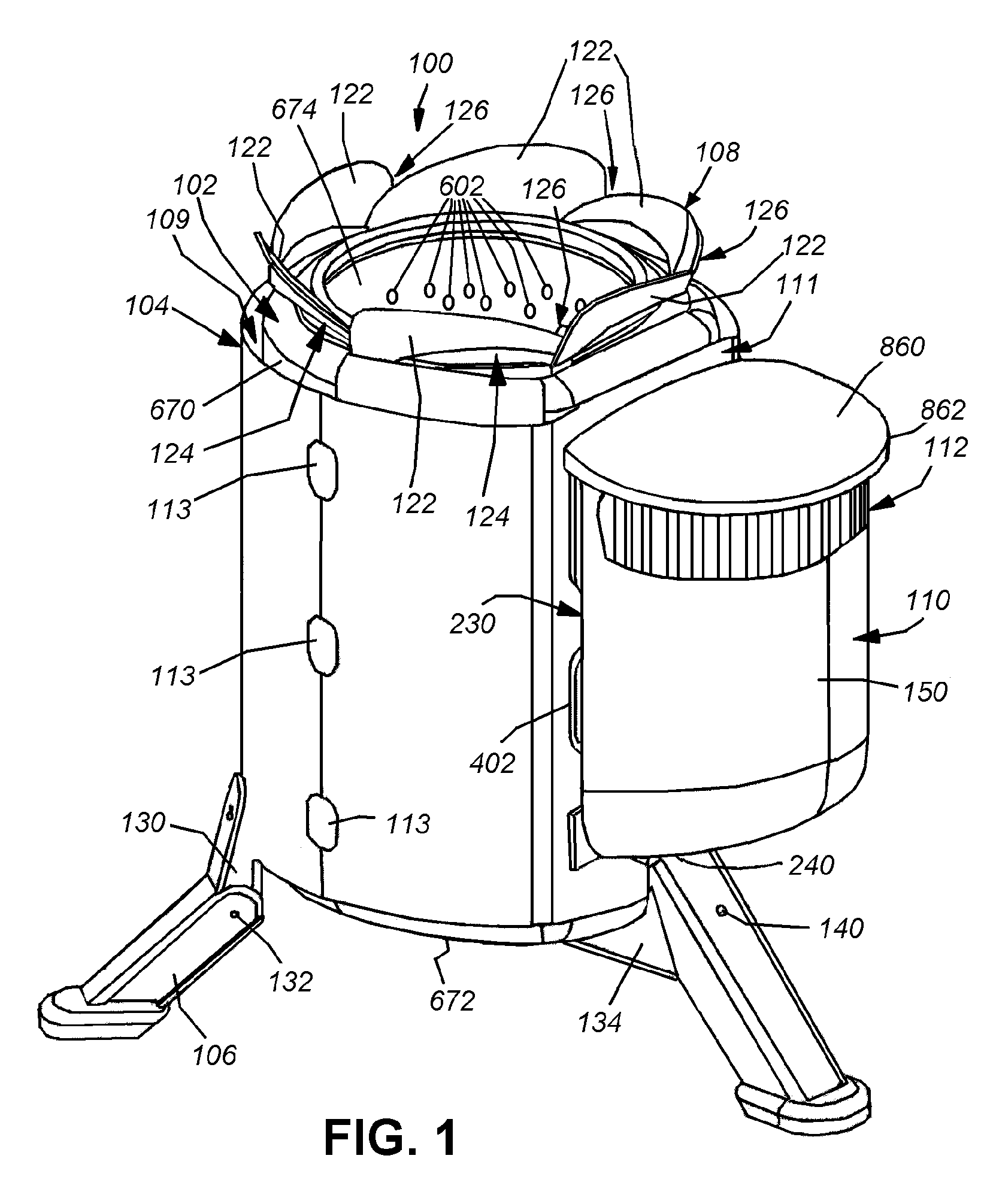

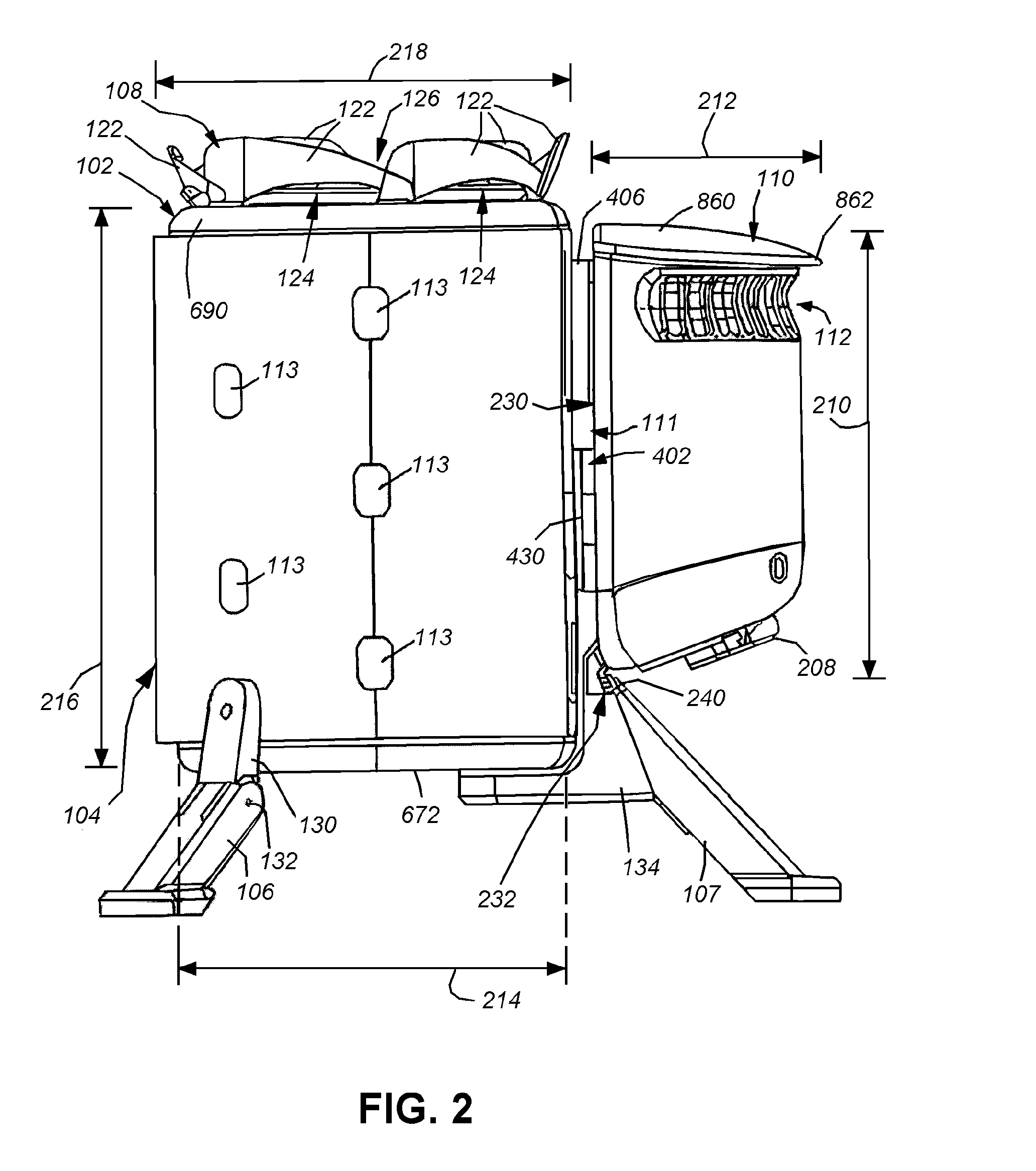

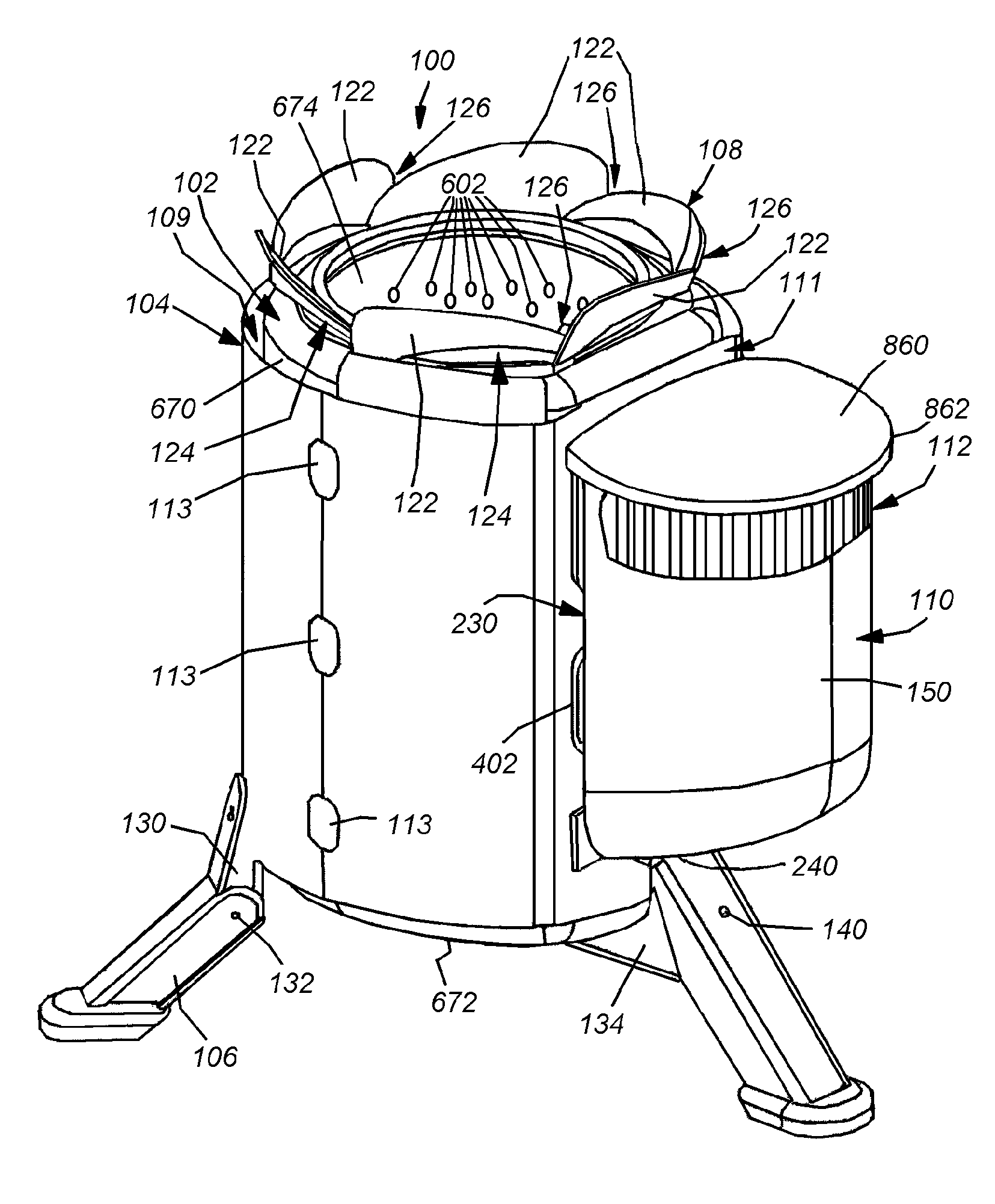

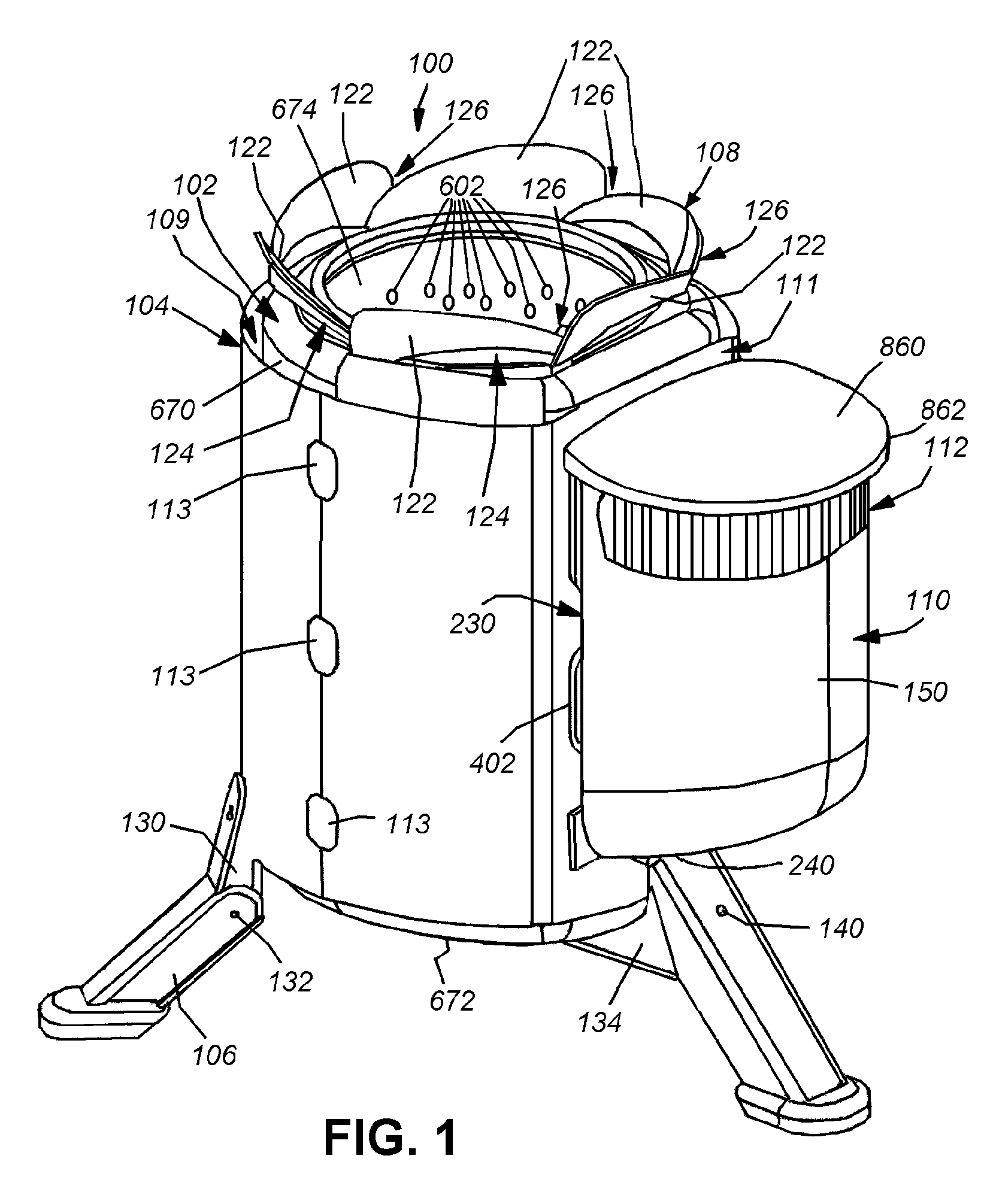

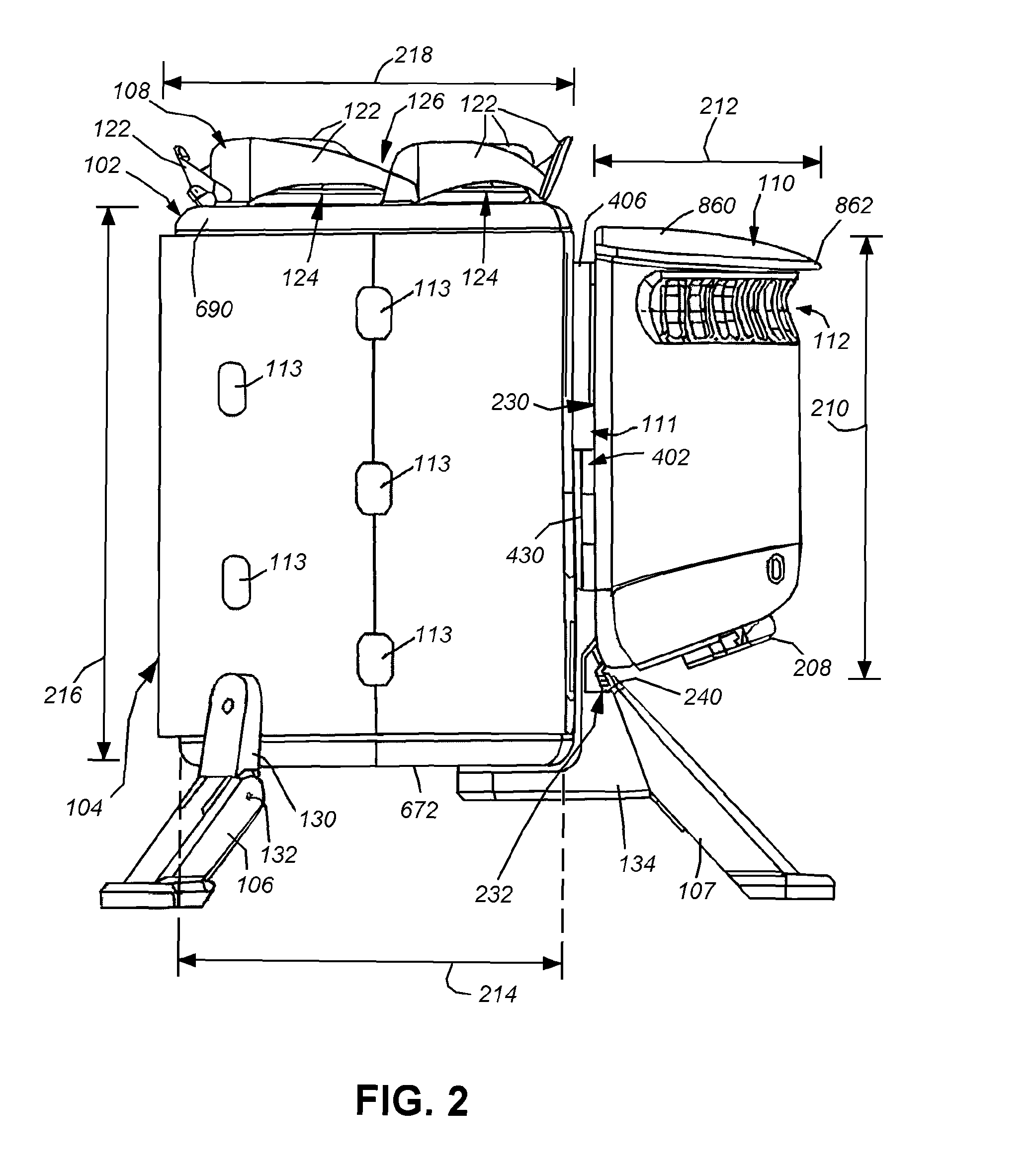

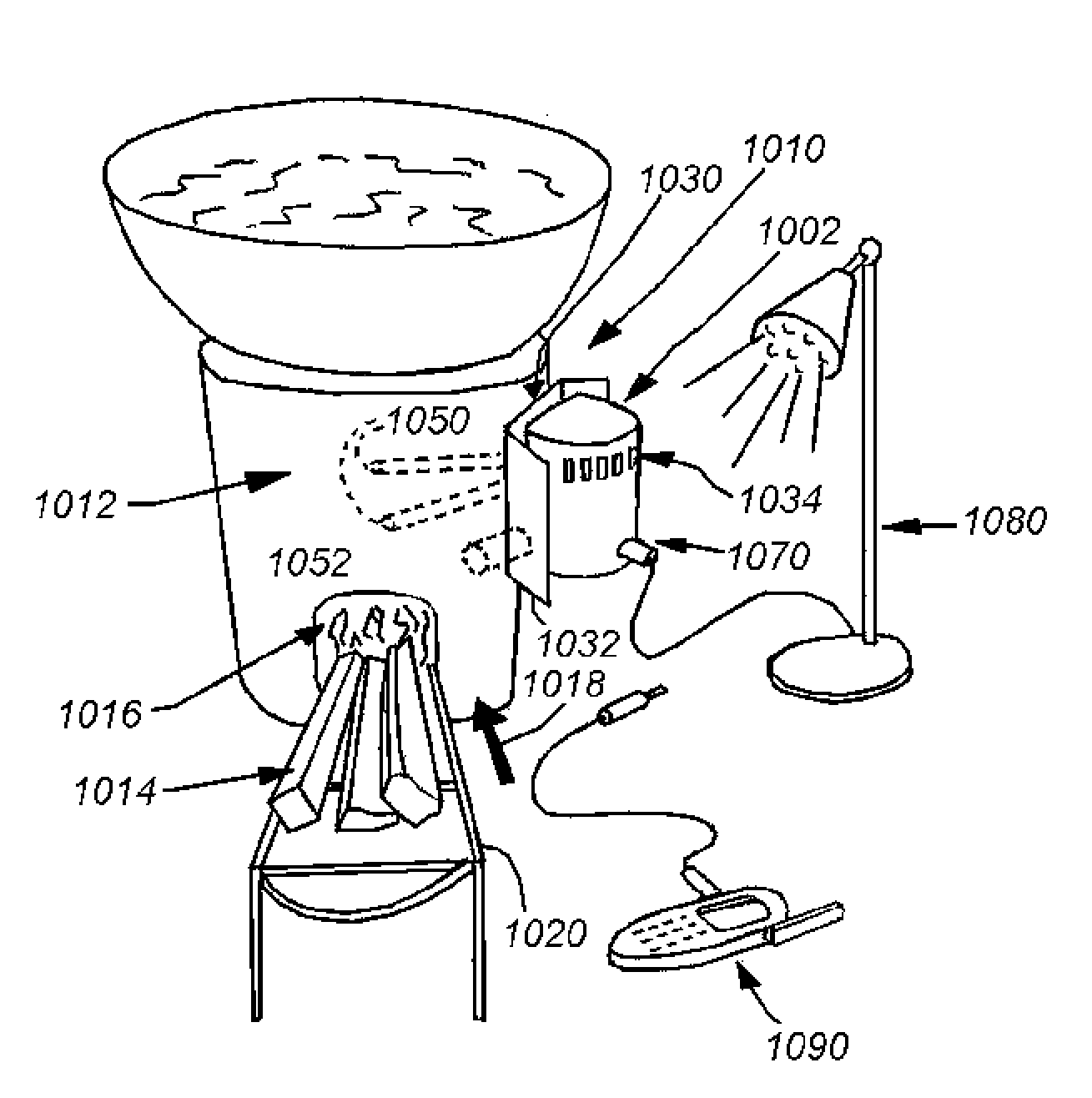

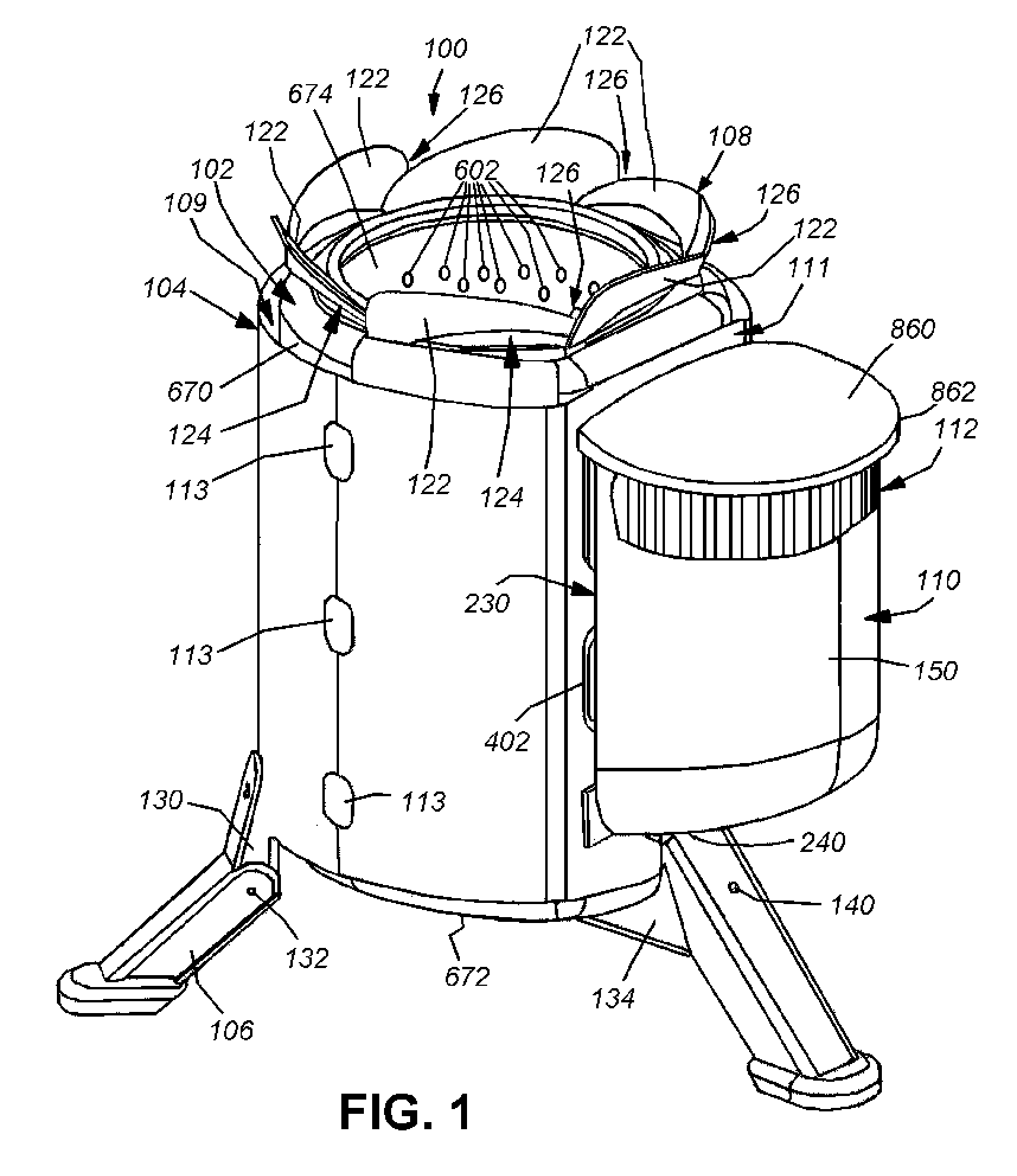

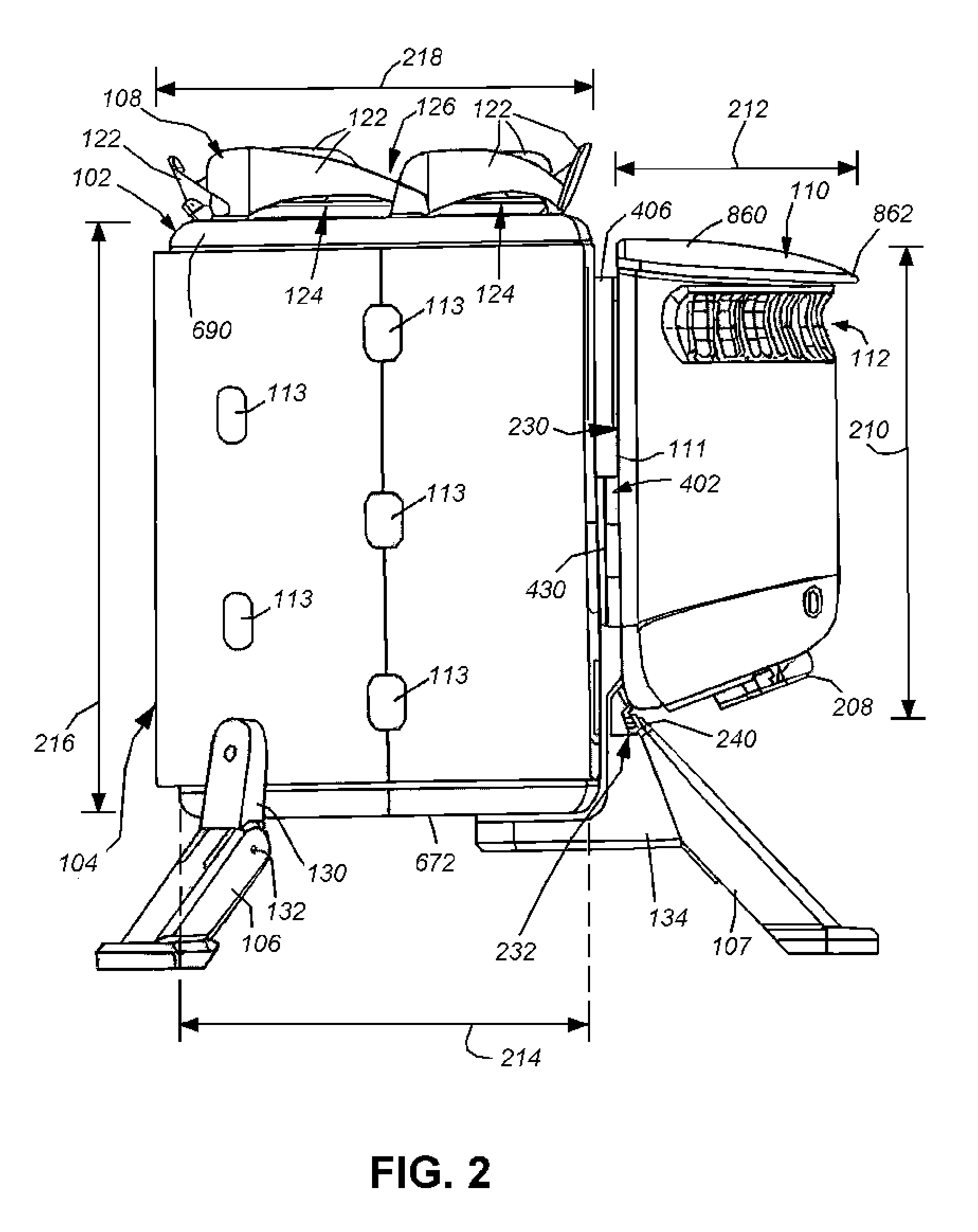

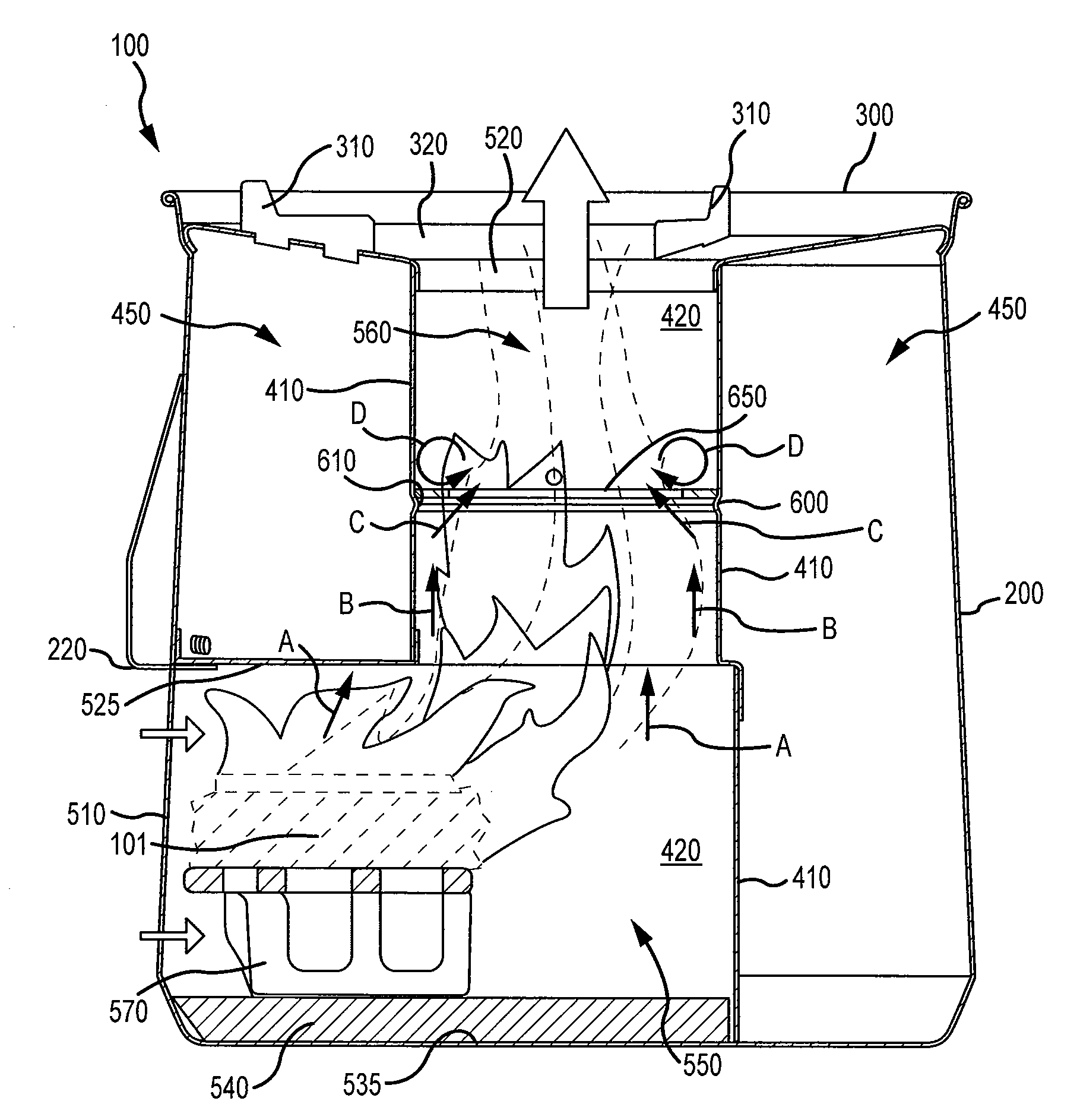

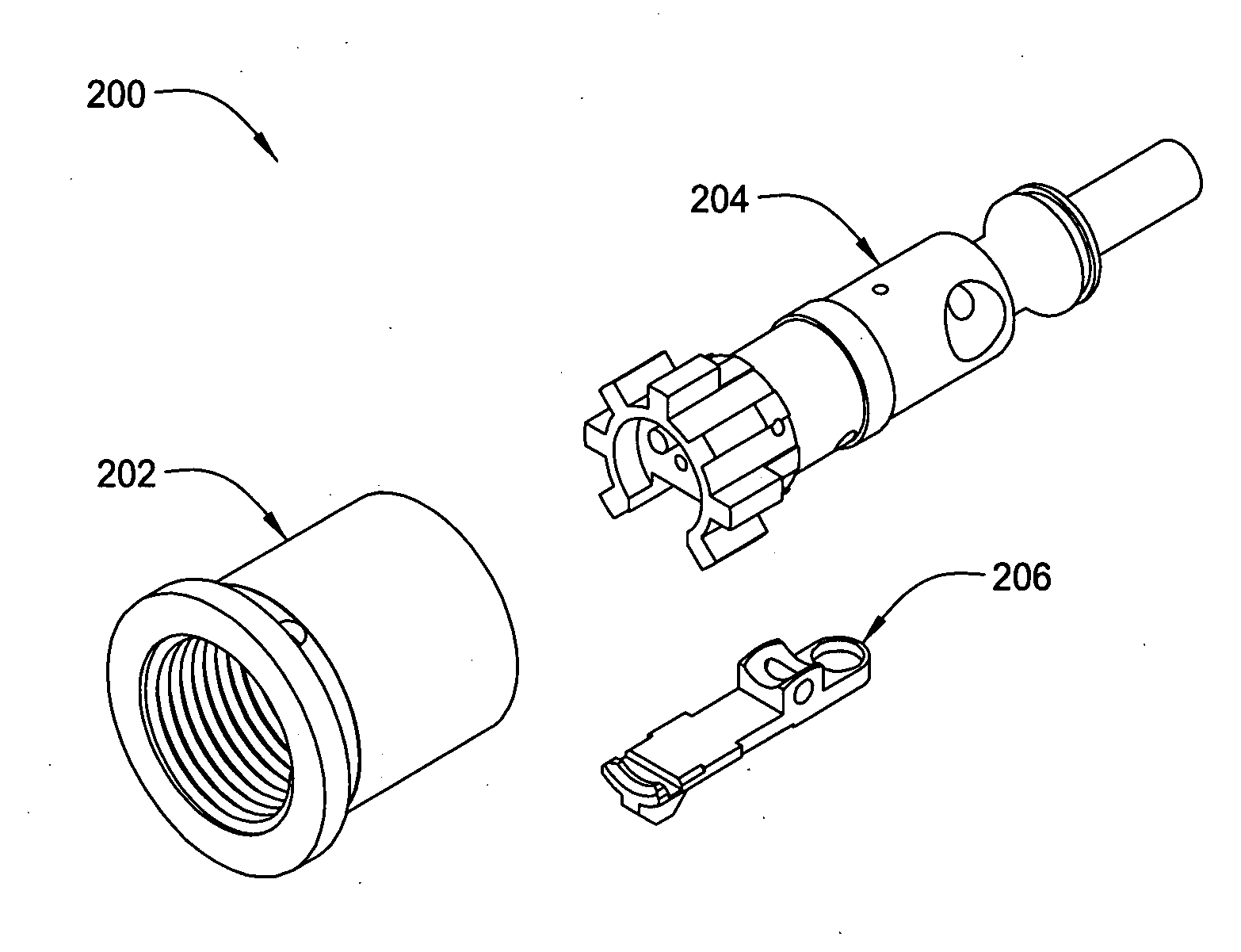

Portable combustion device utilizing thermoelectrical generation

ActiveUS20100083946A1Reduces kindling periodEfficient combustionIncandescent ignitionThermoelectric device with peltier/seeback effectCelluloseCombustion chamber

This invention provides a portable combustion device that provides a cleaner combustion, reduces the kindling period, and provides a more efficient overall combustion through the use of a fan that directs a predetermined volume of airflow over the combustible fuel—typically wood or similar cellulose-based biological solids. The combustion device has a combustion chamber into which the fuel source is placed for combustion. Mounted to the side of the combustion chamber is a housing that encloses the TEG, which generates an electrical output based on a difference in temperature on opposing sides. Mounted onto the TEG housing and protruding into the combustion chamber through a small passageway is a heat-conducting probe and heat-conducting probe base unit. The opposing side of the TEG is also in contact with a heat sink to remove heat from the TEG device through interaction with ambient air that passes over the vanes from a port located along the side of the TEG housing. A motor and fan near the heat sink to draw air away the heat sink and aid in the cooling of the heat sink, and force air onto the combusting fuel through a plurality of peripheral ports that connect with an air space located between the inner and outer walls of the combustion chamber.

Owner:BIOLITE INC

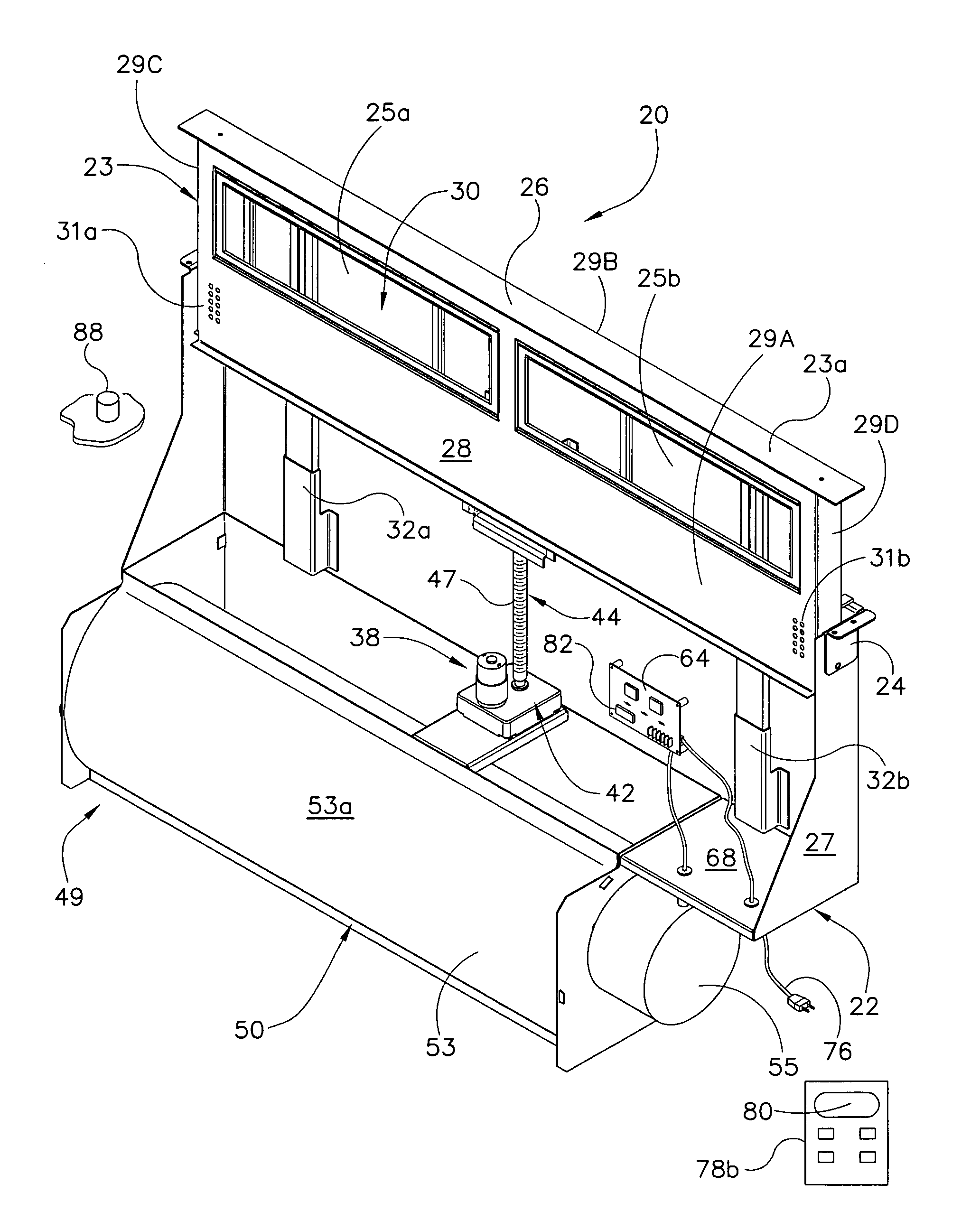

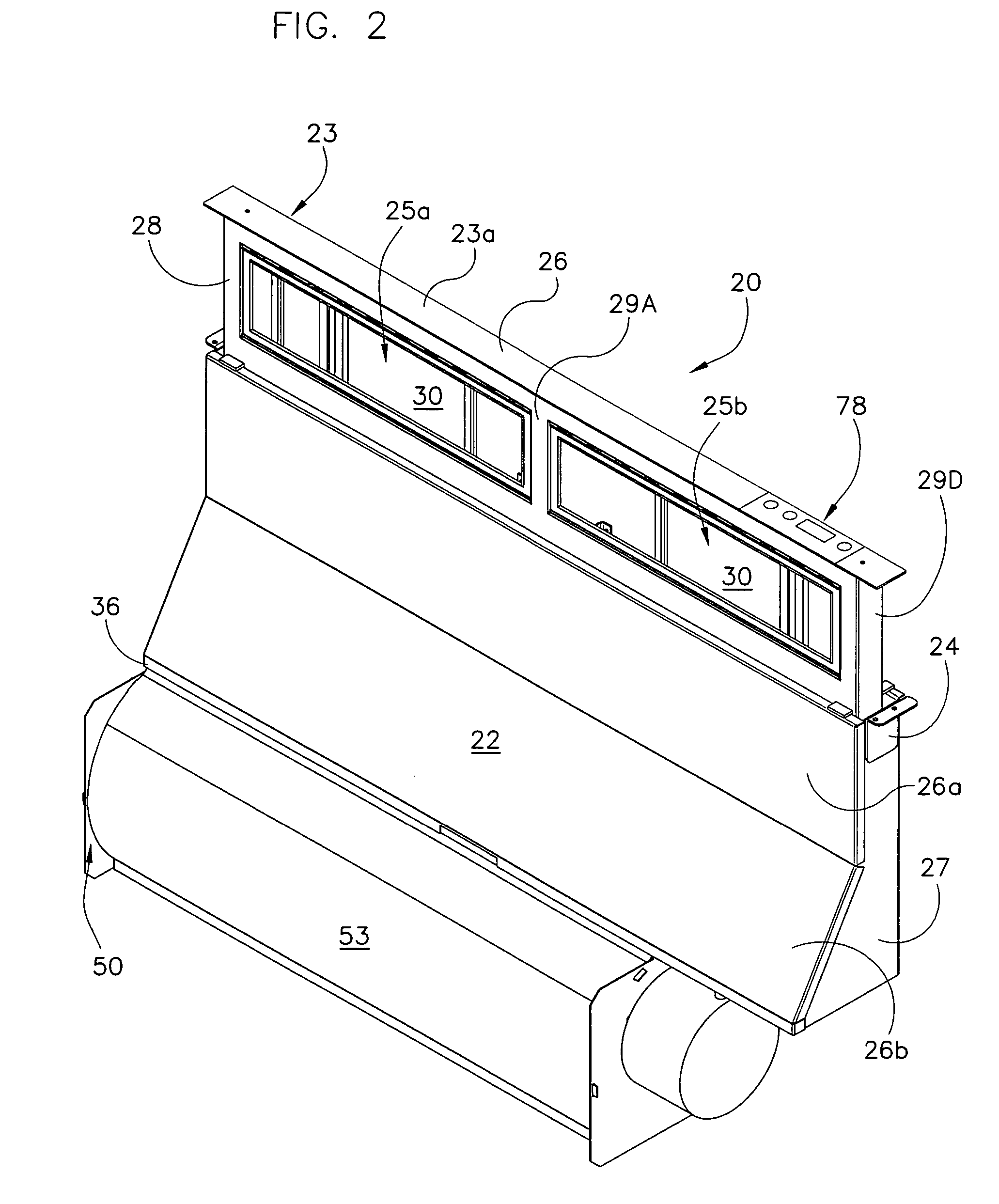

Adjustable downdraft ventilator

InactiveUS7836877B2Improve sealingSmall sizeStoves/ranges foundationsSolar heat devicesElectronic controllerEngineering

An indoor or outdoor downdraft ventilator moves via an electronic controller through preferably a touch keypad. This provides precise control and an efficient way of removal of gases / fumes off a cook top. The electronically controlled telescoping downdraft creates a nearly infinite and selectable range of heights above a cook top from which to properly collect and draw in, filter, re-circulate, or expel exhaust. The downdraft incorporates a lighting system to illuminate the work surface and sensors to detect temperature, filter change requirements, speed, stop points, power, resistance, voltage, and program med operations.

Owner:HAIER US APPLIANCE SOLUTIONS INC D B A GE APPLIANCES

Portable combustion device utilizing thermoelectrical generation

ActiveUS8297271B2Shorten the overall cycleIncrease heatTobacco treatmentThermoelectric device with peltier/seeback effectCelluloseCombustion chamber

This invention provides a portable combustion device that provides a cleaner combustion, reduces the kindling period, and provides a more efficient overall combustion through the use of a fan that directs a predetermined volume of airflow over the combustible fuel—typically wood or similar cellulose-based biological solids. The combustion device has a combustion chamber into which the fuel source is placed for combustion. Mounted to the side of the combustion chamber is a housing that encloses the TEG, which generates an electrical output based on a difference in temperature on opposing sides. Mounted onto the TEG housing and protruding into the combustion chamber through a small passageway is a heat-conducting probe and heat-conducting probe base unit. The opposing side of the TEG is also in contact with a heat sink to remove heat from the TEG device through interaction with ambient air that passes over the vanes from a port located along the side of the TEG housing. A motor and fan near the heat sink to draw air away the heat sink and aid in the cooling of the heat sink, and force air onto the combusting fuel through a plurality of peripheral ports that connect with an air space located between the inner and outer walls of the combustion chamber.

Owner:BIOLITE INC

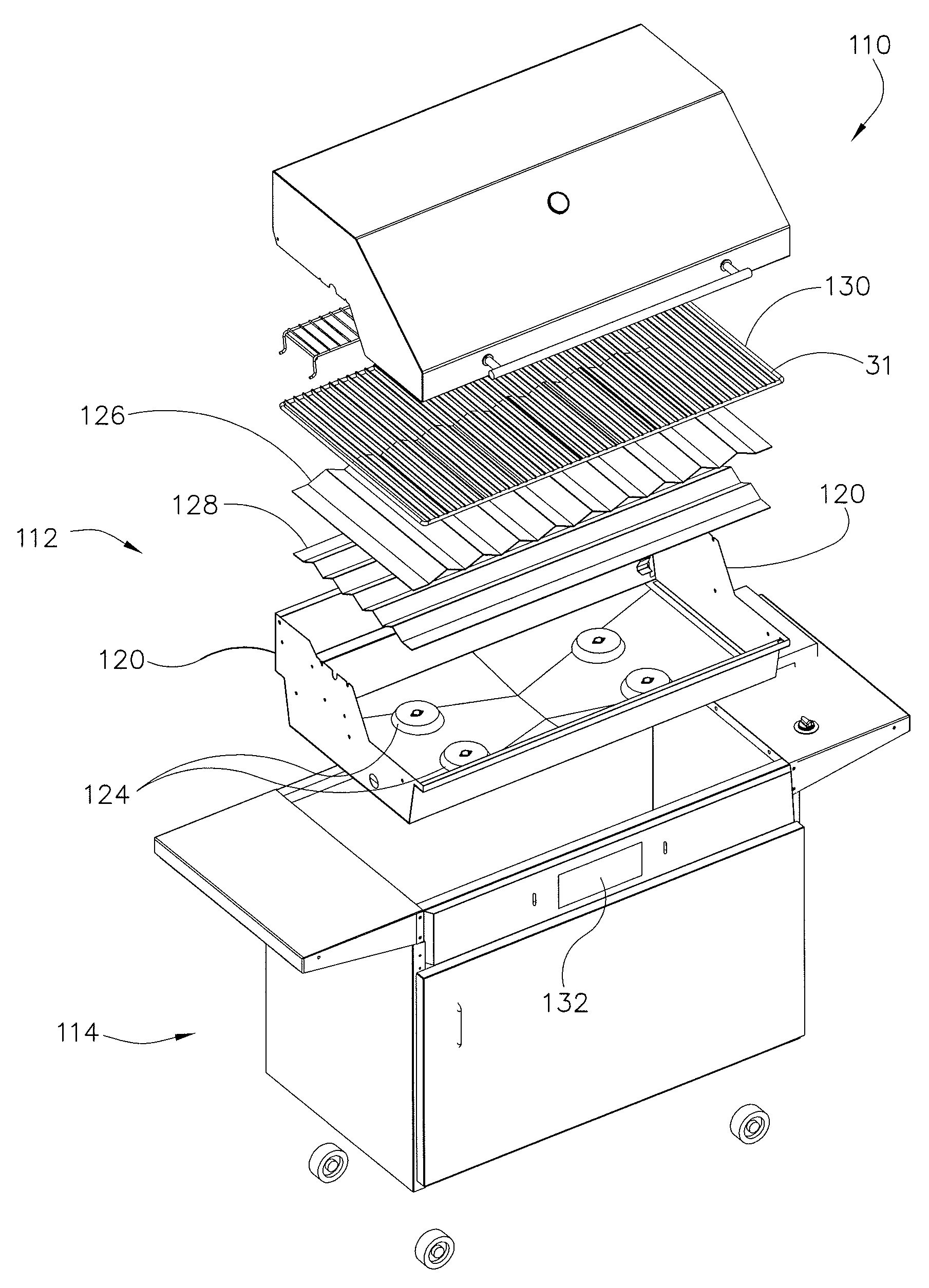

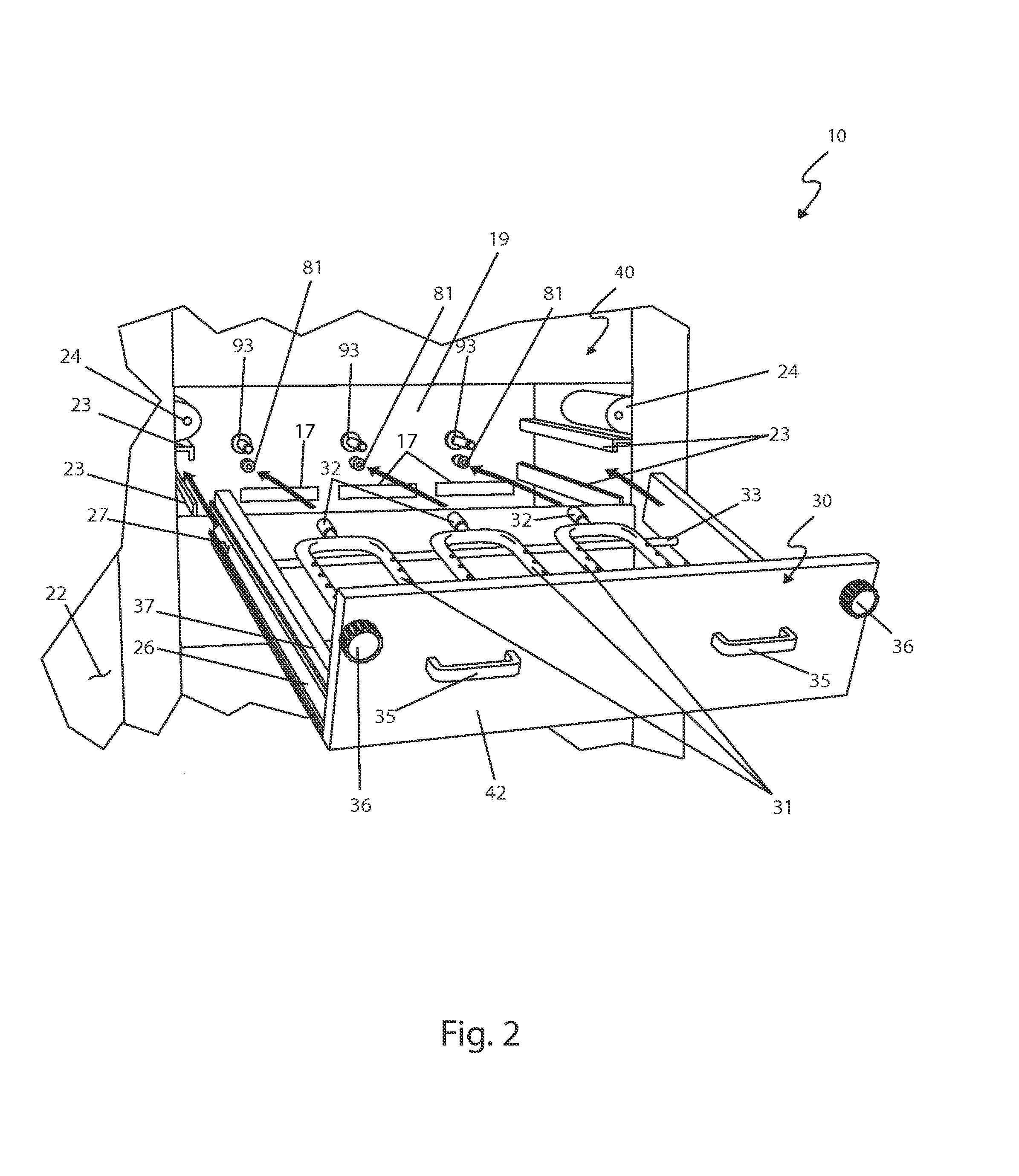

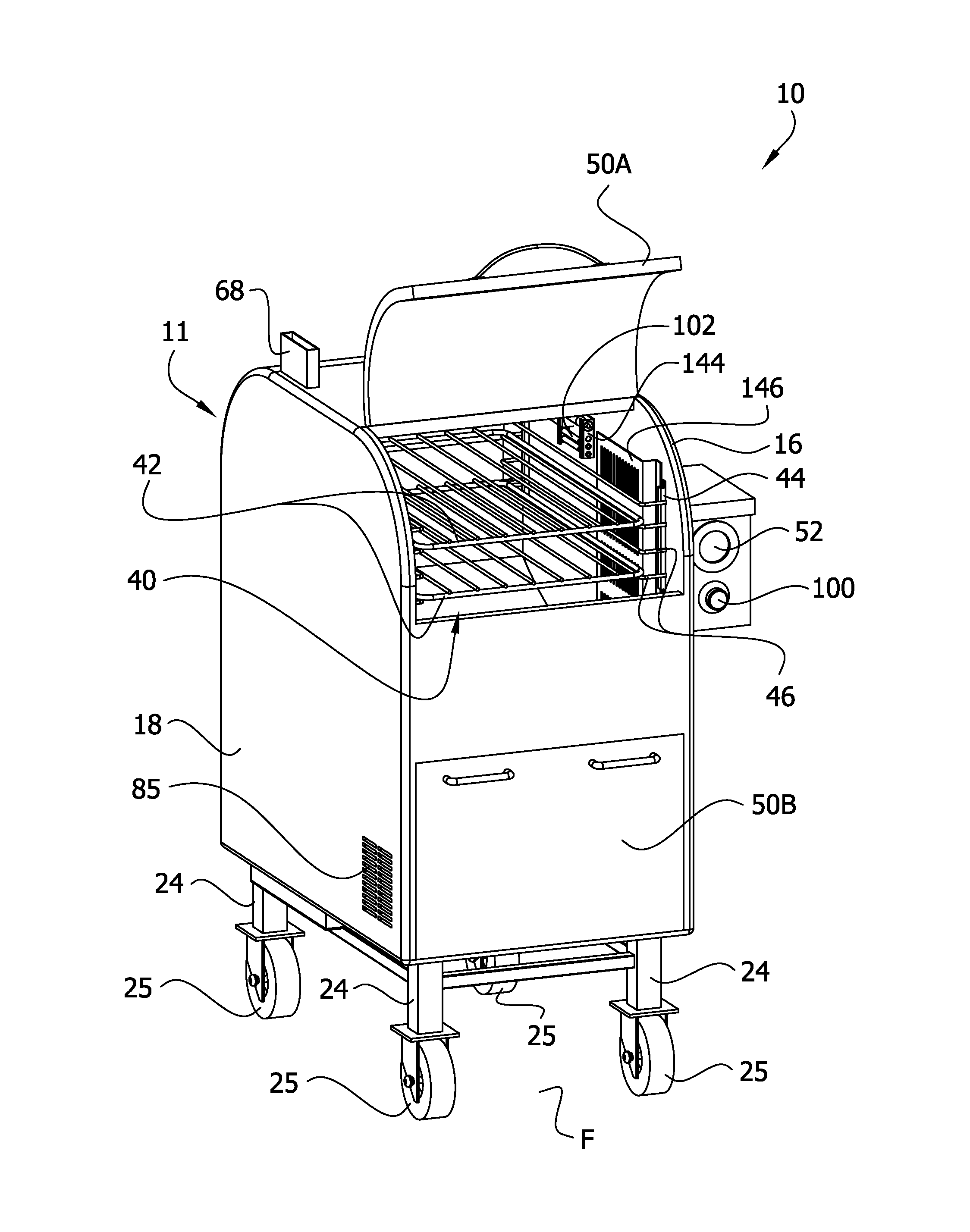

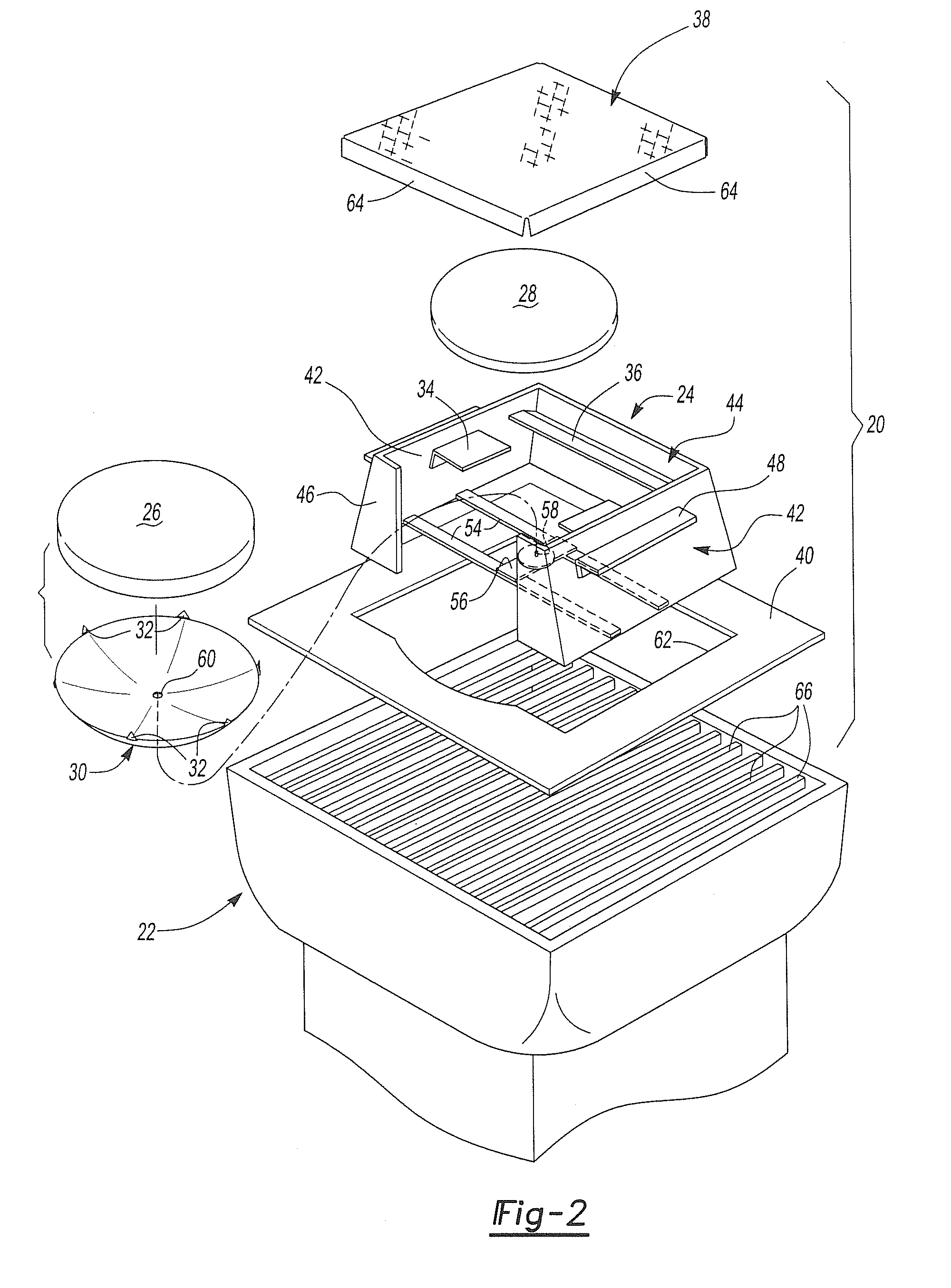

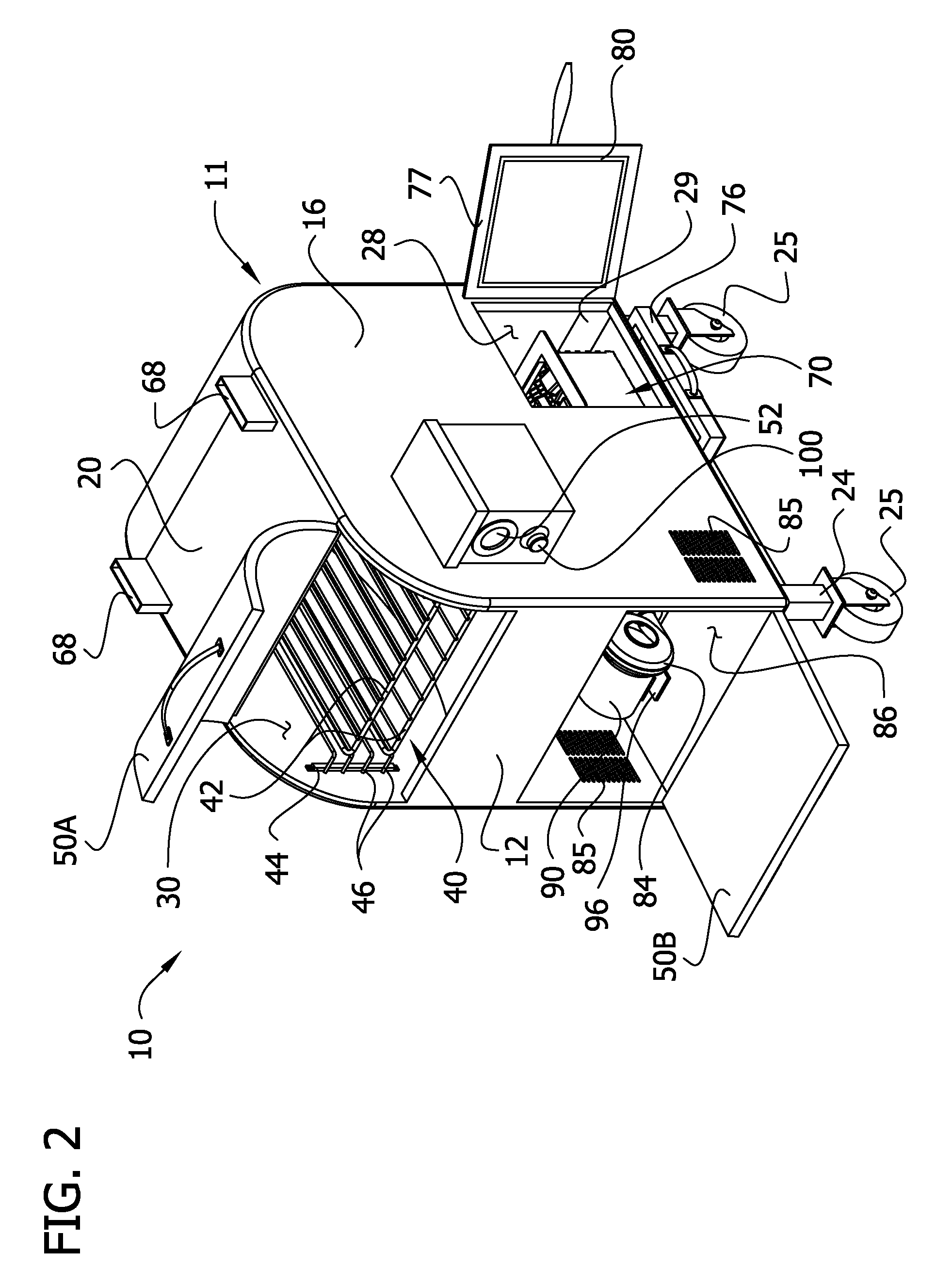

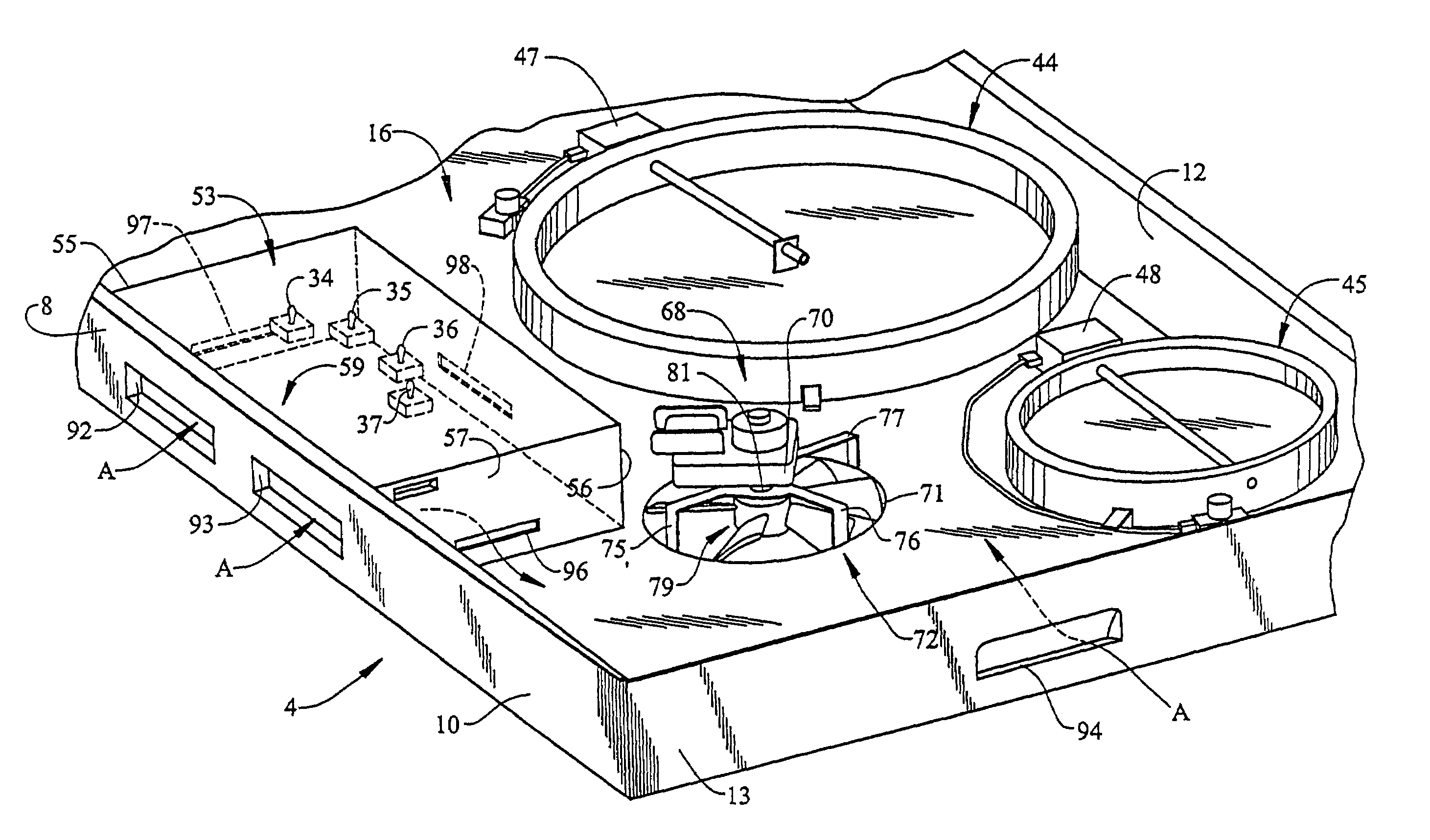

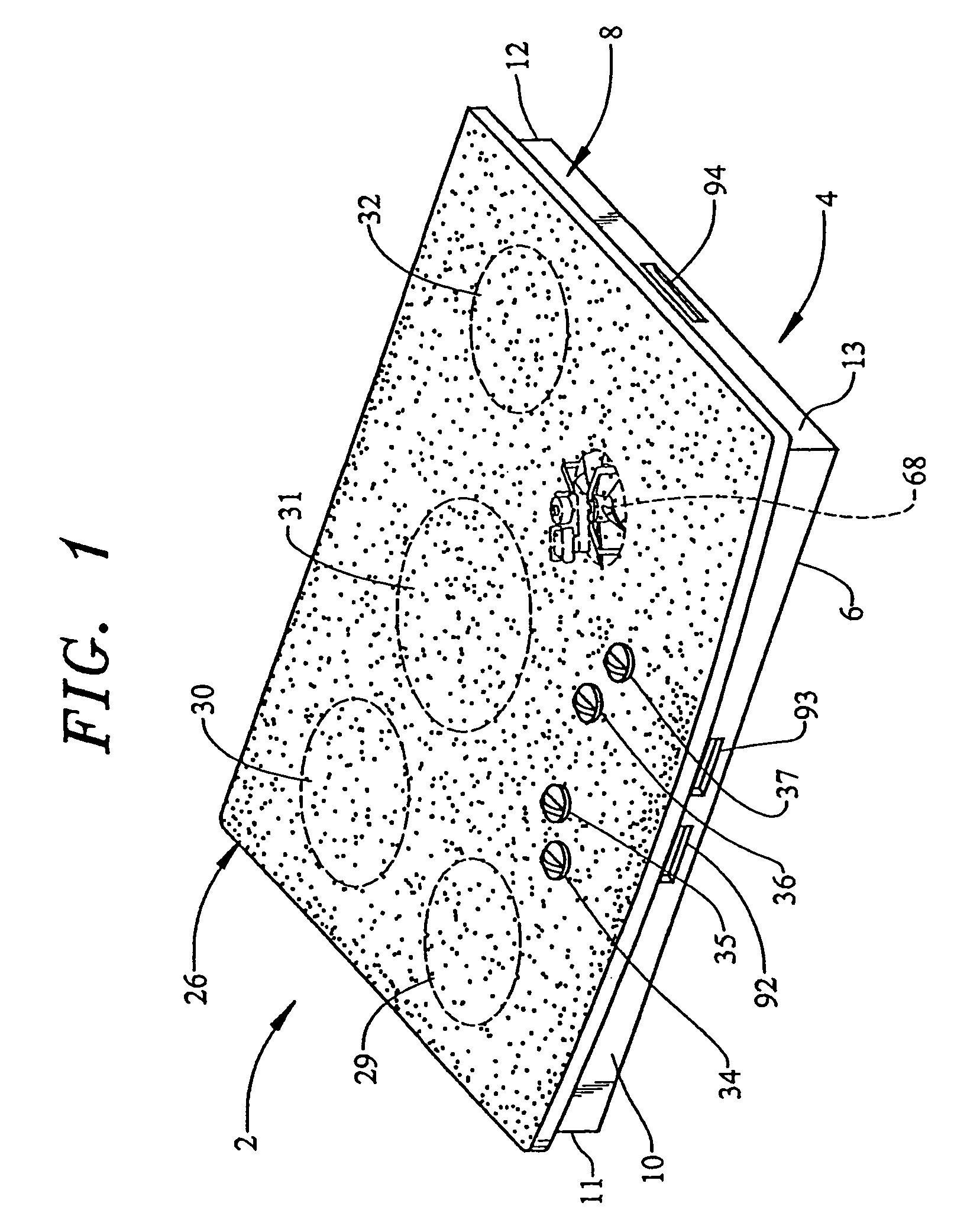

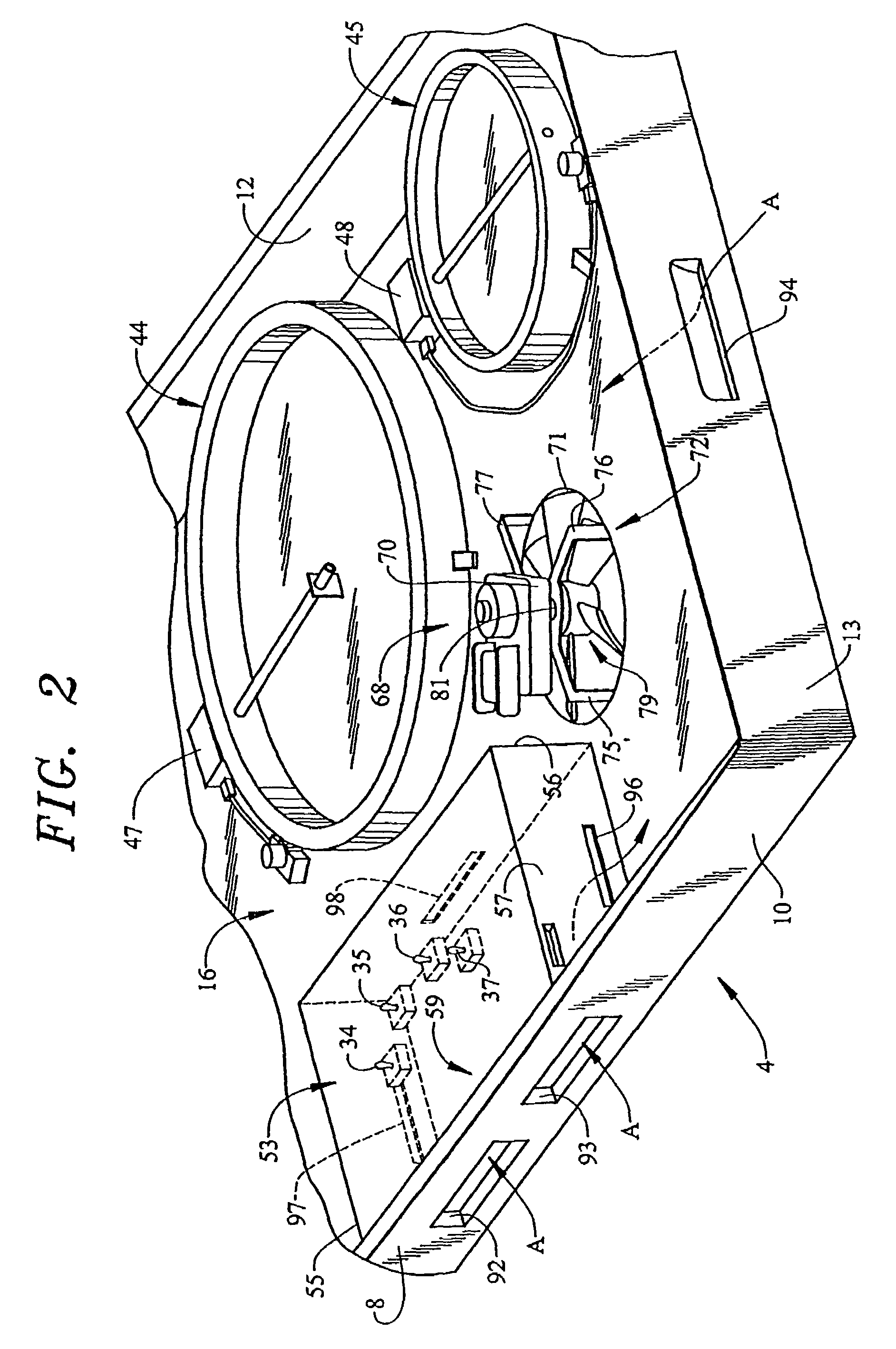

Modular portable grill

InactiveUS7798139B2Easy to controlImprove protectionStoves/ranges foundationsCombustion-air/flue-gas circulation for stovesTemperature controlCombustor

A modular portable gas grill including an energy management system for even temperature control, enhanced flavor devices, and electronic, electro-mechanical, or mechanical controls is provided. The grill includes a touch control system including sliders or knobs providing efficient, precise and accurate control. Heat and flame deflecting shields provide an improved air draft, heat, and flavoring system and can be removed for cleaning. Modular design construction and a quick-connect gas manifold permit the addition of additional components at a later date such as a rotisserie, and a smoke chute for flavoring. Burner shields protect the burner and flame from greases and liquids. The grill also features the ability to easily convert between propane and natural gas fuel and an electronic reigniting system providing individualized control to the burners. The grill also features a dual fuel mode giving a user the ability to use propane or natural gas along with charcoal or other solid fuel.

Owner:HAIER US APPLIANCE SOLUTIONS INC D B A GE APPLIANCES

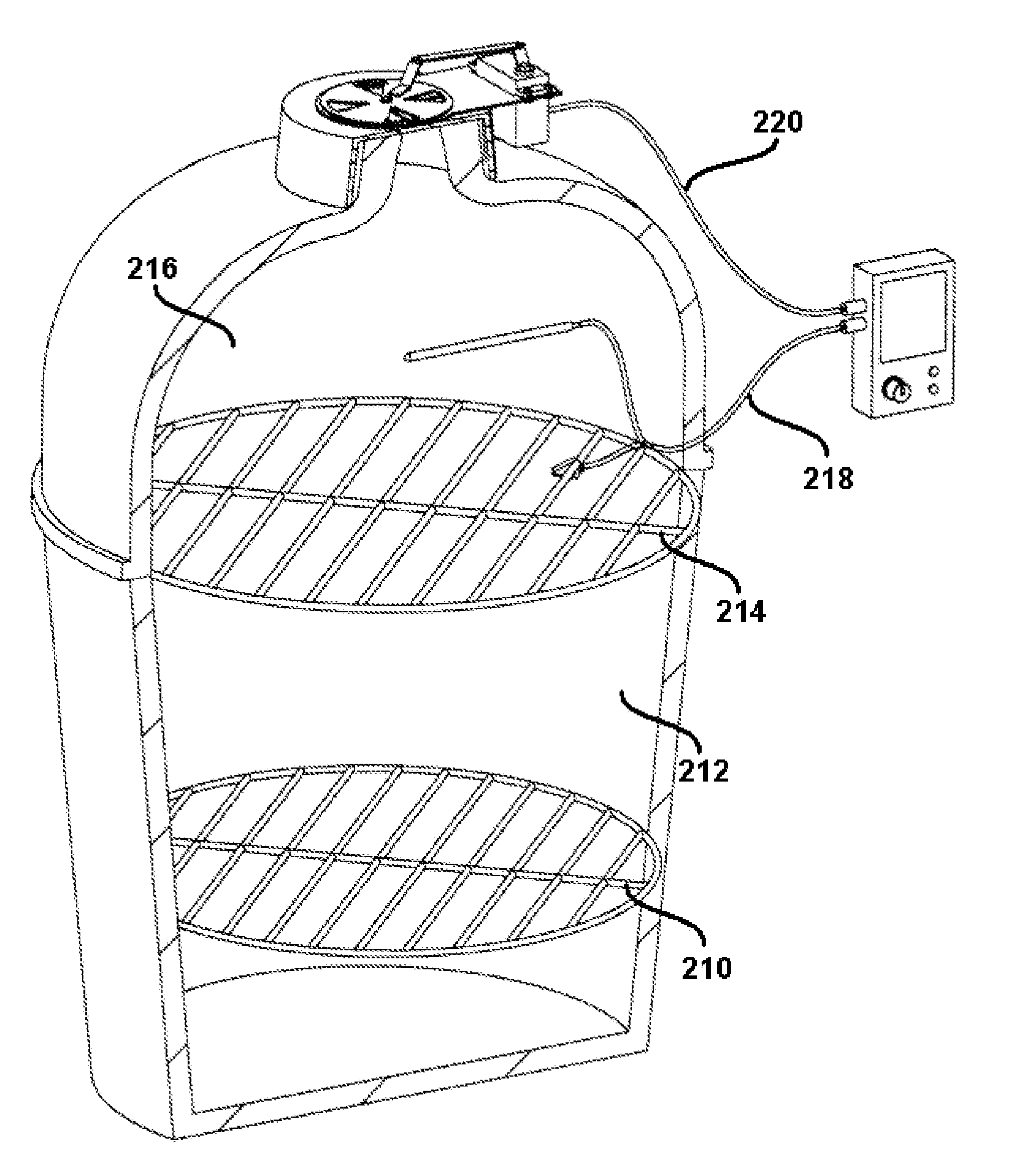

Portable combustion device utilizing thermoelectrical generation

ActiveUS20130112187A1Reduces kindling periodEfficient combustionTobacco treatmentThermoelectric device with peltier/seeback effectCelluloseCombustion chamber

This invention provides a portable combustion device that provides a cleaner combustion, reduces the kindling period, and provides a more efficient overall combustion through the use of a fan that directs a predetermined volume of airflow over the combustible fuel—typically wood or similar cellulose-based biological solids. The combustion device has a combustion chamber with a fuel source. A housing encloses the TEG on the side of the device that generates an electrical output based on a temperature differential between opposing TEG sides. A heat-conducting probe is mounted to the TEG and protrudes into the combustion chamber. The opposing TEG side contacts a heat sink that interacts with ambient air. A fan draws heated air away the heat sink, and forces the air onto the combusting fuel through a plurality of peripheral ports that connect with an air space located between inner and outer walls of the combustion chamber.

Owner:BIOLITE INC

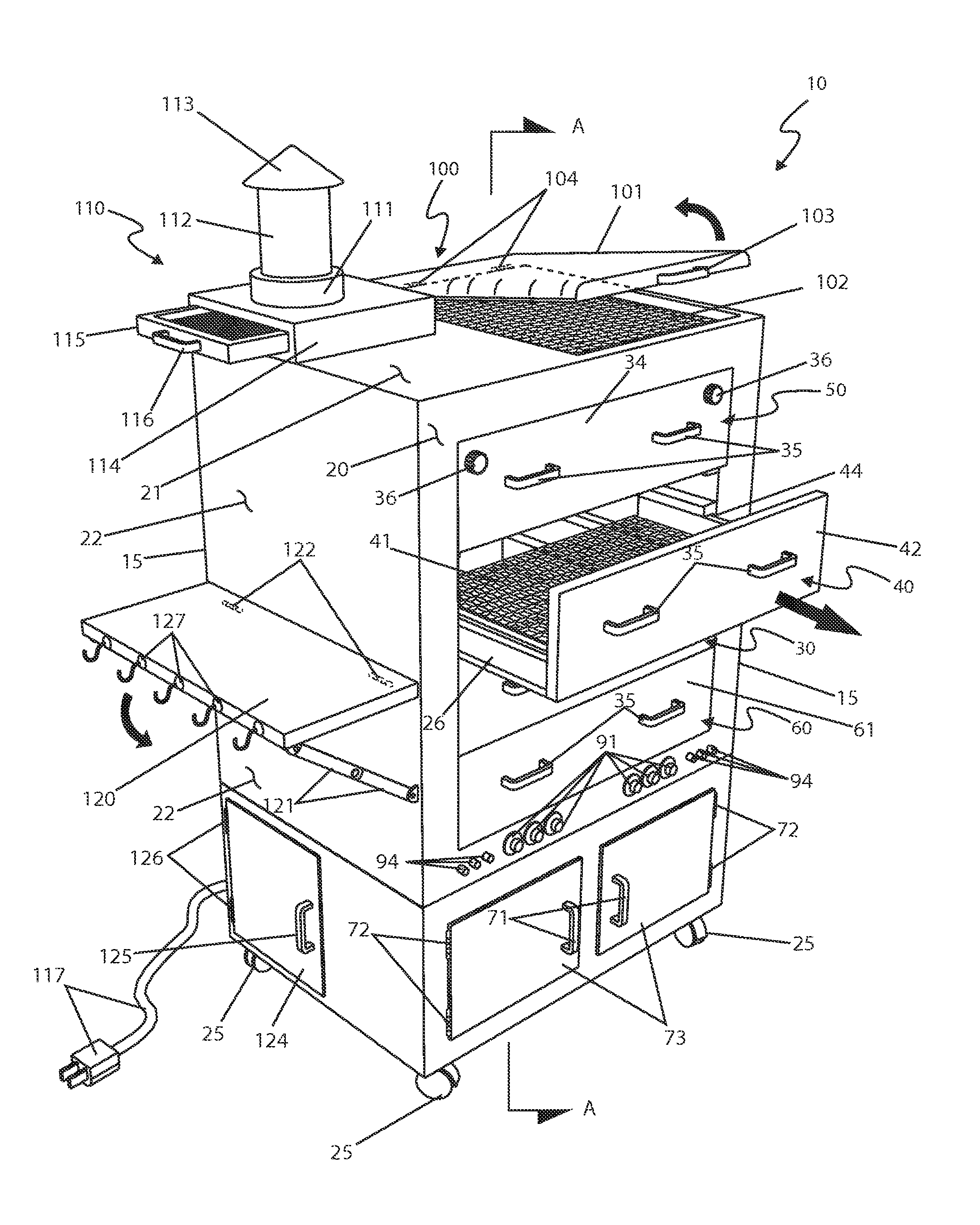

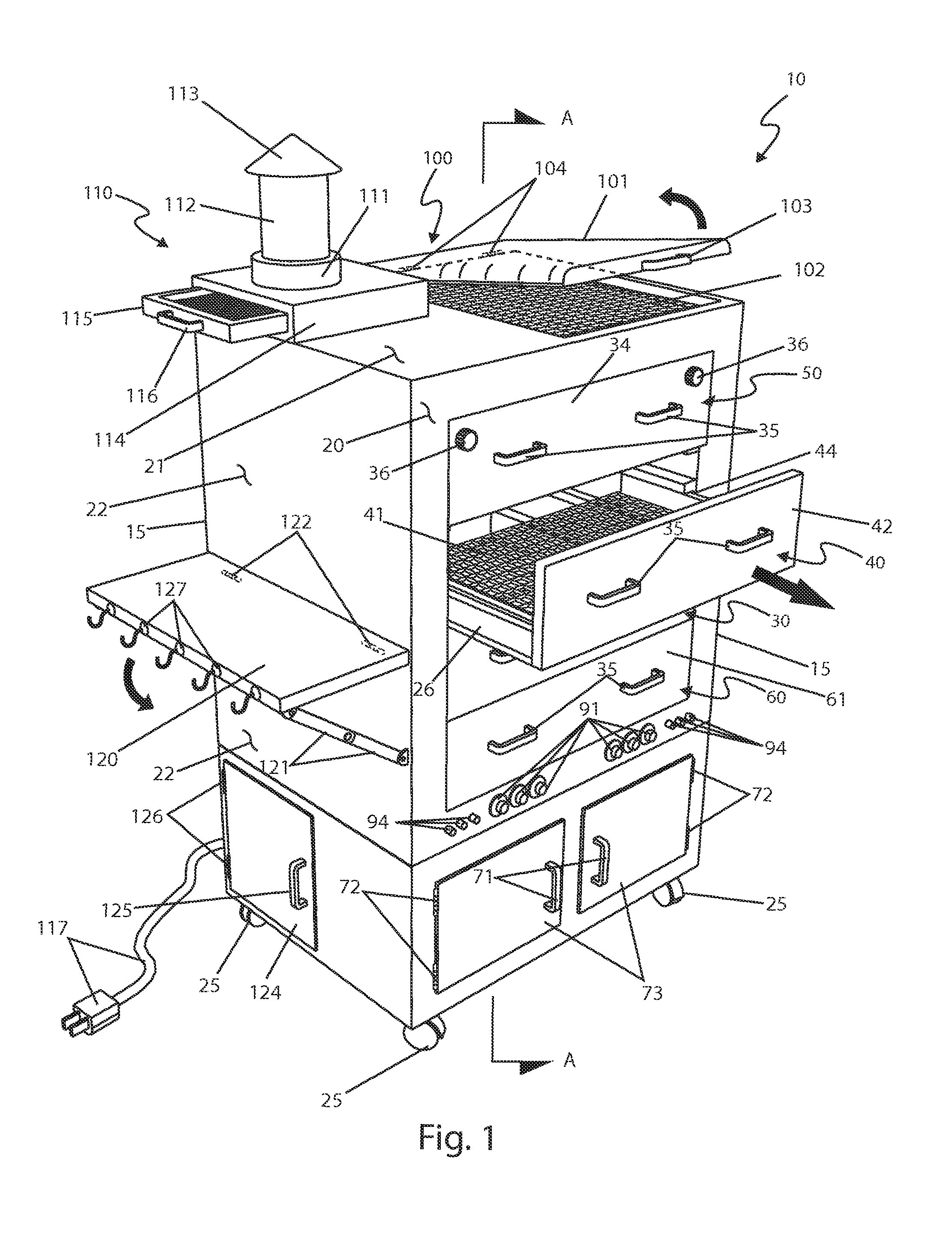

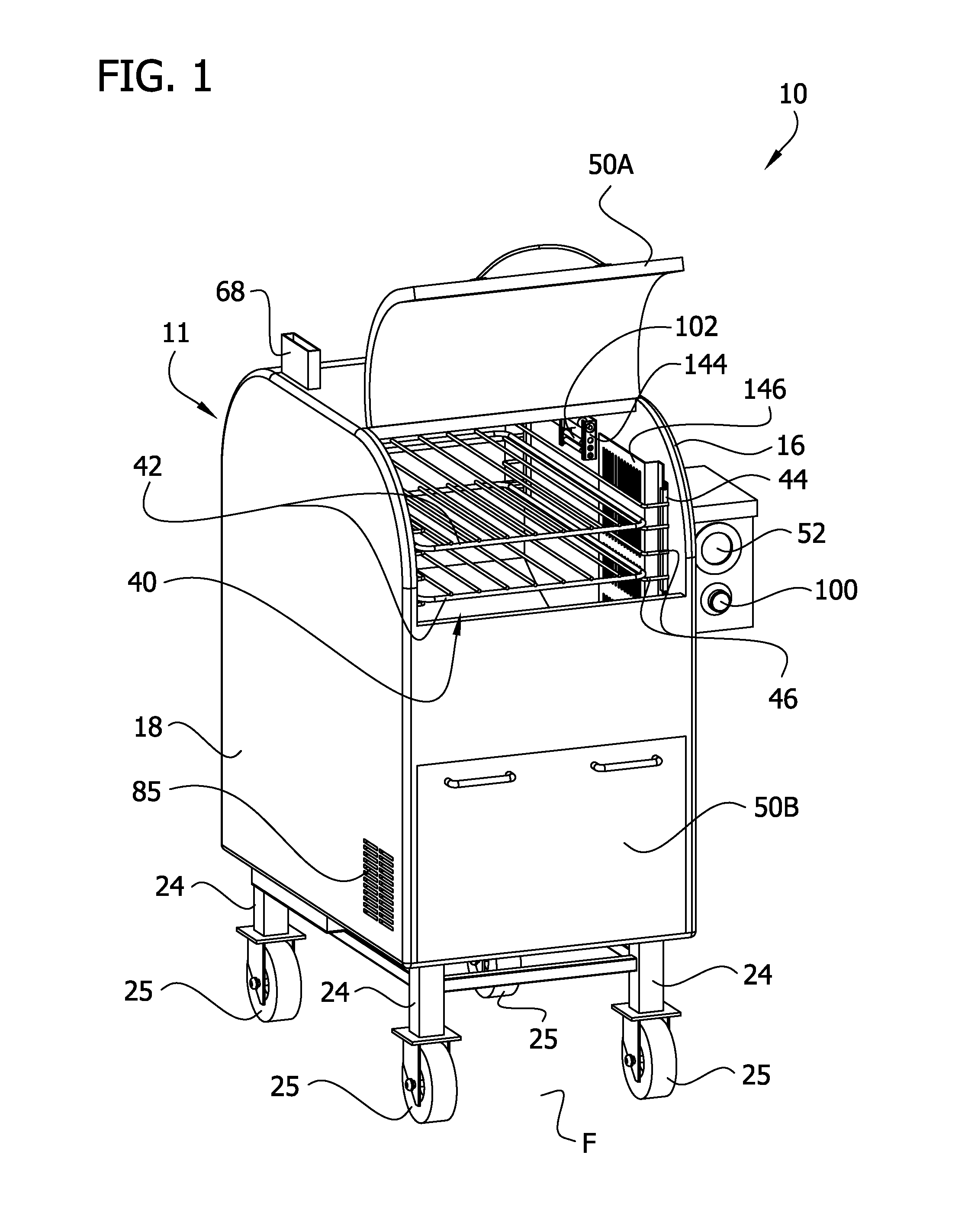

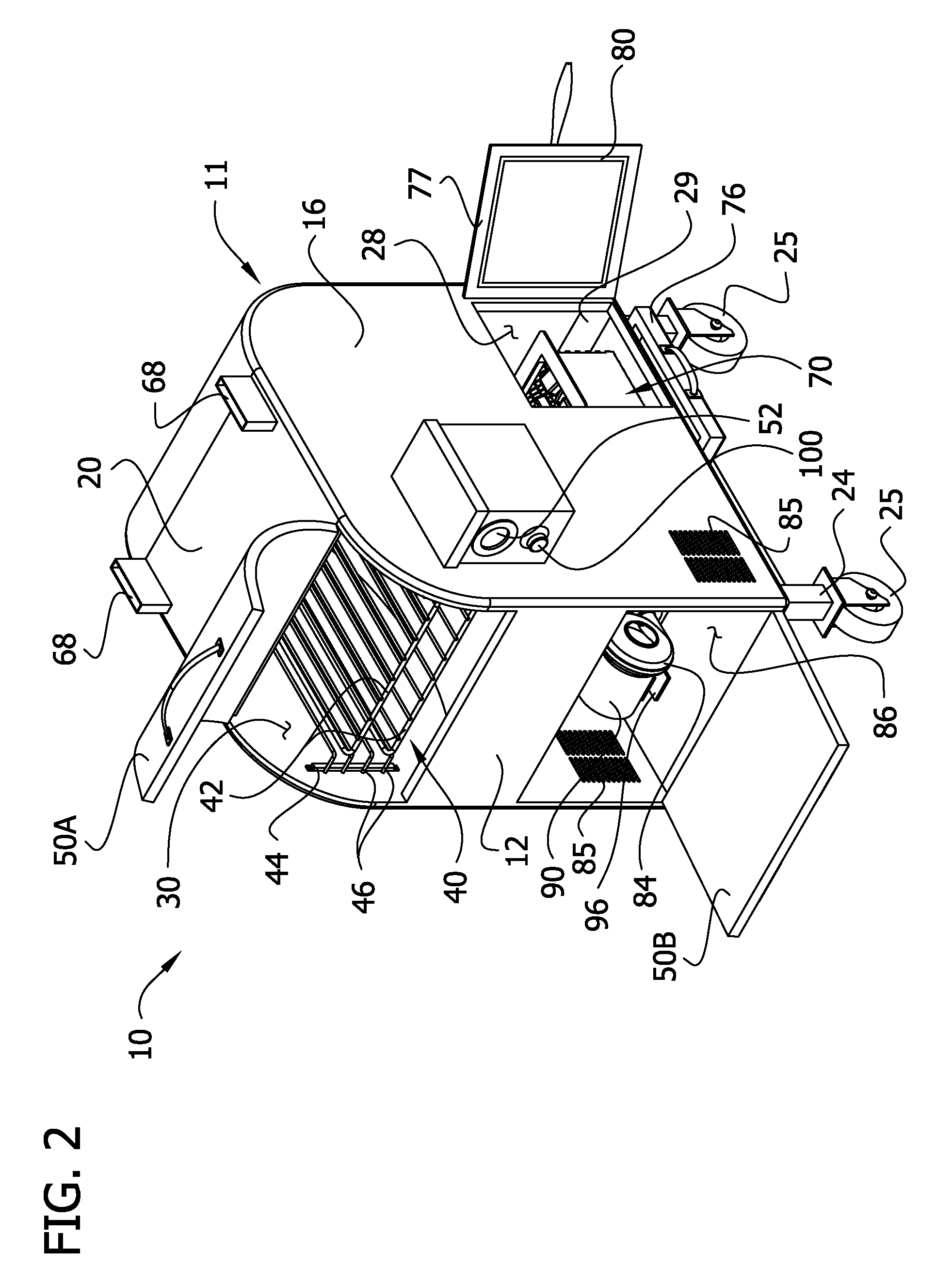

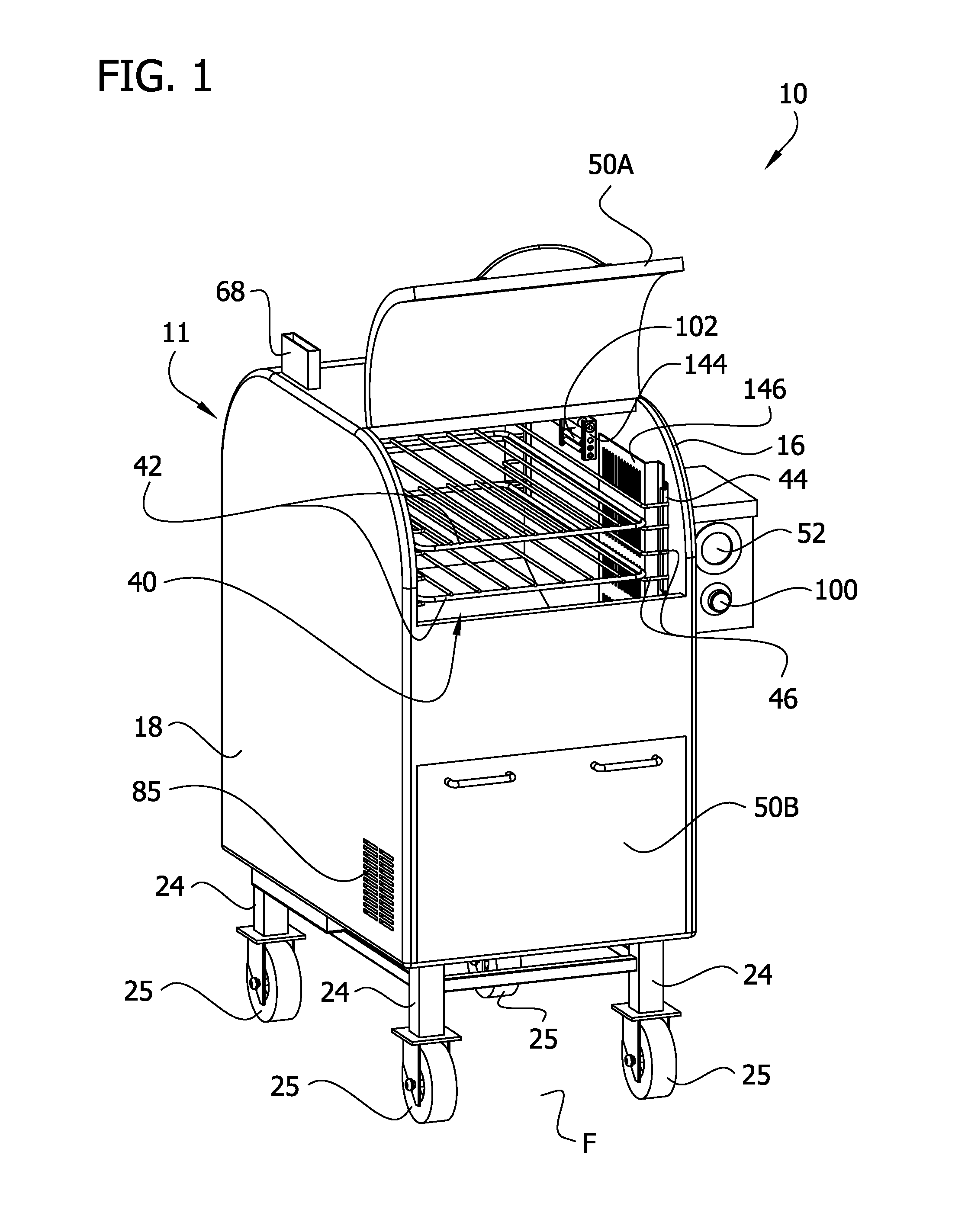

Residential flame broiler

InactiveUS8490614B1Avoid enteringEffective top and bottom cooking meanStoves/ranges foundationsLighting and heating apparatusCombustorBroiler chick

The invention discloses a gas grill with multiple enhancements to allow for easy grilling of foods, subsequent clean-up, and replacement of parts. In lieu of a top-opening lid, the apparatus provides a plurality of removable and insertable drawers, comprising a plurality of burner units, a plurality of grill trays, and a drip tray located in a vertical configuration therein a base unit. All drawers are interchangeable as desired. A storage compartment is located on the bottom directly below the drip tray and an exhaust assembly is located on the top for directing smoke away from the apparatus. The invention is adaptable to propane or natural gas. Additional drawers and burner assemblies are provided and may be used for charcoal or wood burning, bun or food warming, and water steaming. All drawers are easily removable on slides with a safety catch system for easy care and cleaning.

Owner:GREGORY MICHAEL S

Cooker to smoker adapter

ActiveUS7832330B1Reduce heatConveniently addedAir-treating devicesMilk treatmentNuclear engineeringCooker

A cooker to smoker adapter is provided, and in one embodiment the cooker to smoker adapter includes first and second walls constructed to cooperate with a wall of a cooker to provide a fuel containment zone for receipt of fuel to be used in a smoking process. In another embodiment, one of the walls includes at least one aperture to readily permit the addition of fuel to the fuel containment zone. In yet another embodiment, a second aperture is provided in one of the walls, this aperture being adapted to receive a reservoir for a liquid. In a further embodiment, a liquid holding reservoir is provided integral with one of the walls. In another embodiment, stand-alone structures are provided to define a fuel containment zone to permit the burning of fuel while avoiding direct radiant transmission of heat from the fuel containment zone to a food which is being smoked. In one embodiment, the stand-alone structure is adapted to receive a reservoir for water. In a further one of the stand-alone embodiments, a cap is provided on the cooker to smoker adapter structure. In the stand-alone cooker to smoker adapters an aperture is included in the walls to permit the addition of fuel into a fuel containment zone. In the free-standing cooker to smoker adapters, a chute may also be provided to facilitate the addition of fuel into the fuel containment zone.

Owner:AFC BUSINESS VENTURES

Combination smoker and barbecue pit

InactiveUS6874496B2Equally distributedEasy to disassembleStoves/ranges foundationsMeat/fish preservationEngineeringBee smoker

A new and improved combination smoker and barbecue pit having a housing with an open top, a grill resting on said housing, and a hood. A firebox is placed within said housing and is used for holding fuel which, when burned, creates heat and smoke. During the smoking process, the firebox is positioned below a shield which deflects and directs smoke into a pair of chambers within the housing which in turn channel smoke into elongated collection members evenly spaced below the grill. When smoke fills the collection members, is spills out the open-ended bottom of the collection members and drifts toward the grill in an even distribution. The firebox can also rest on the collection members where it is directly beneath the grill for barbecuing.

Owner:WAITS GREGORY A +1

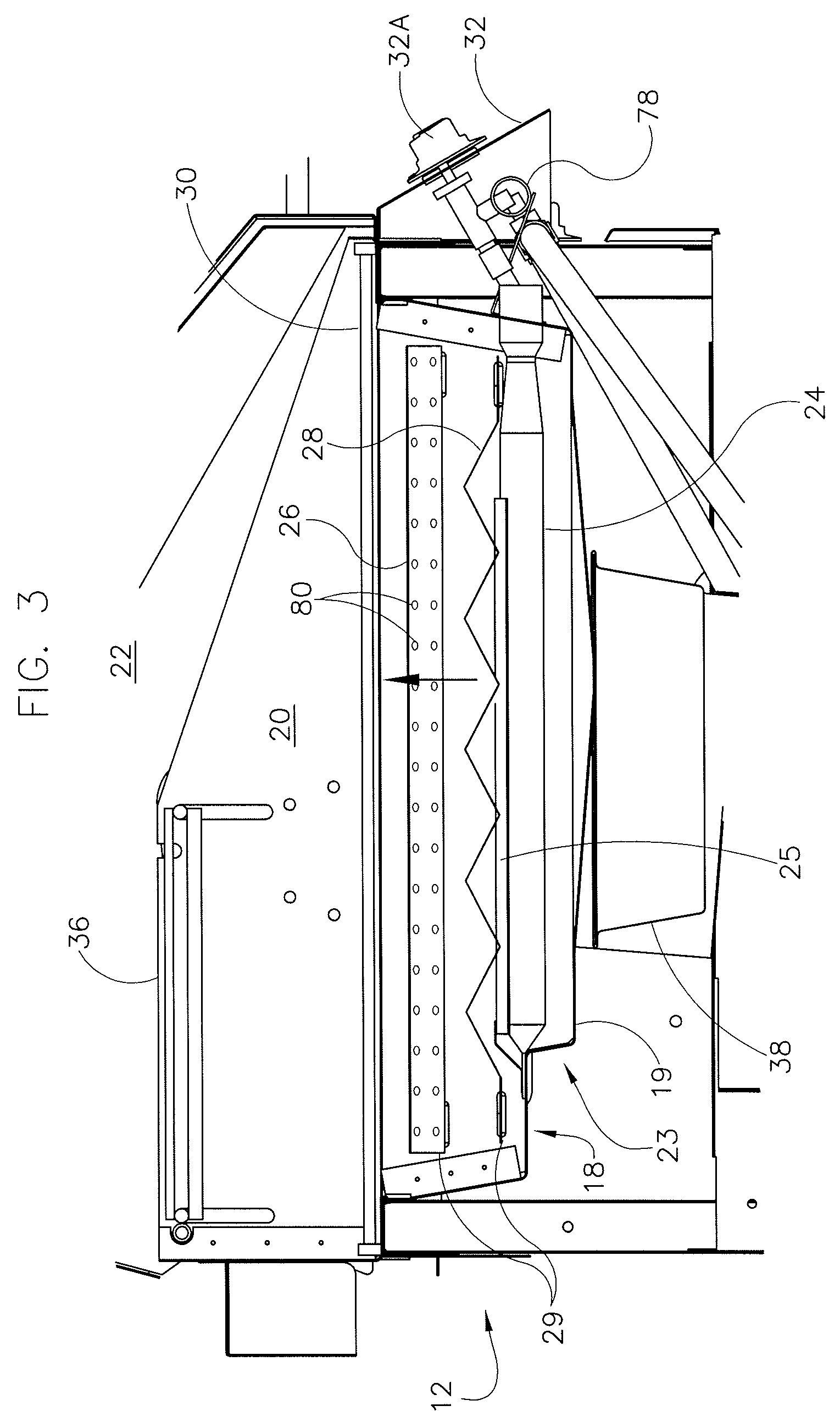

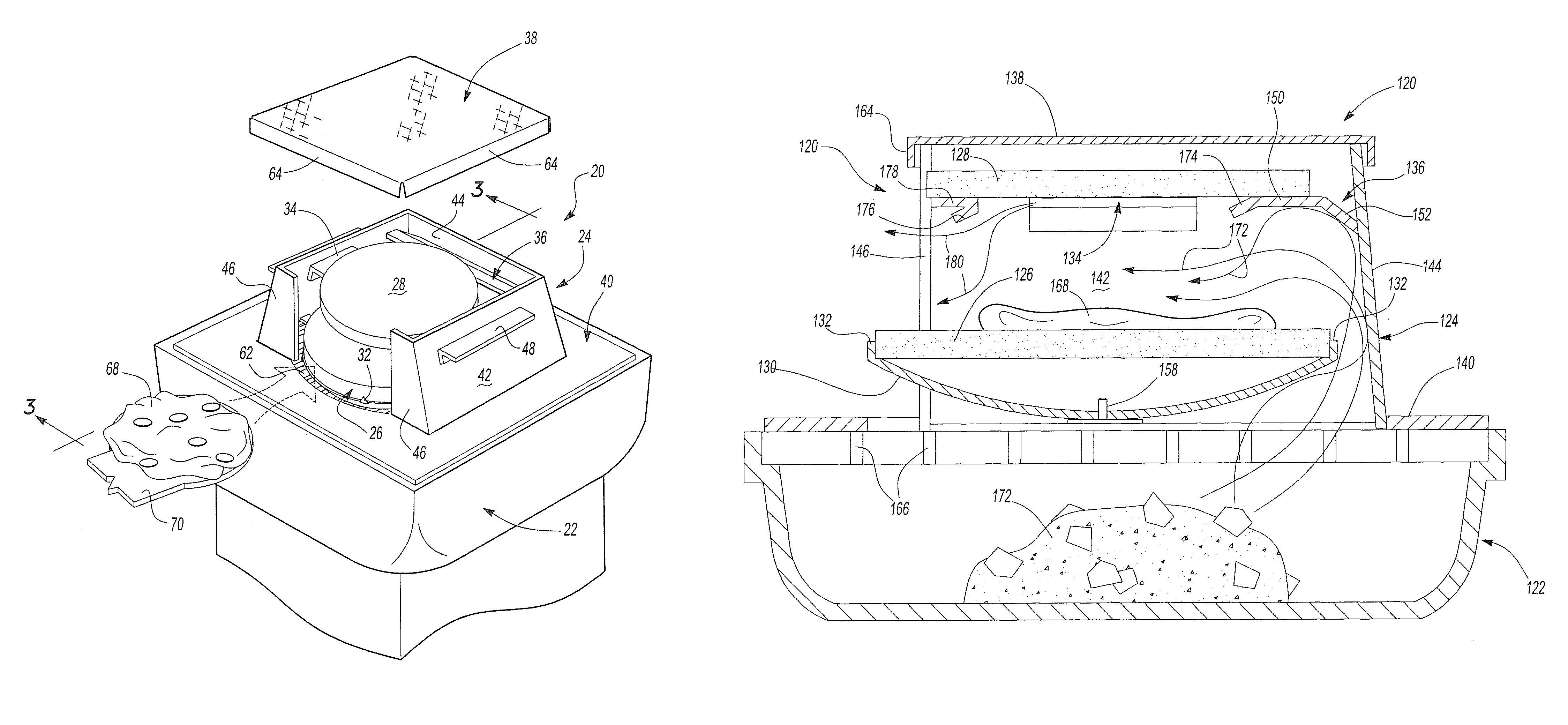

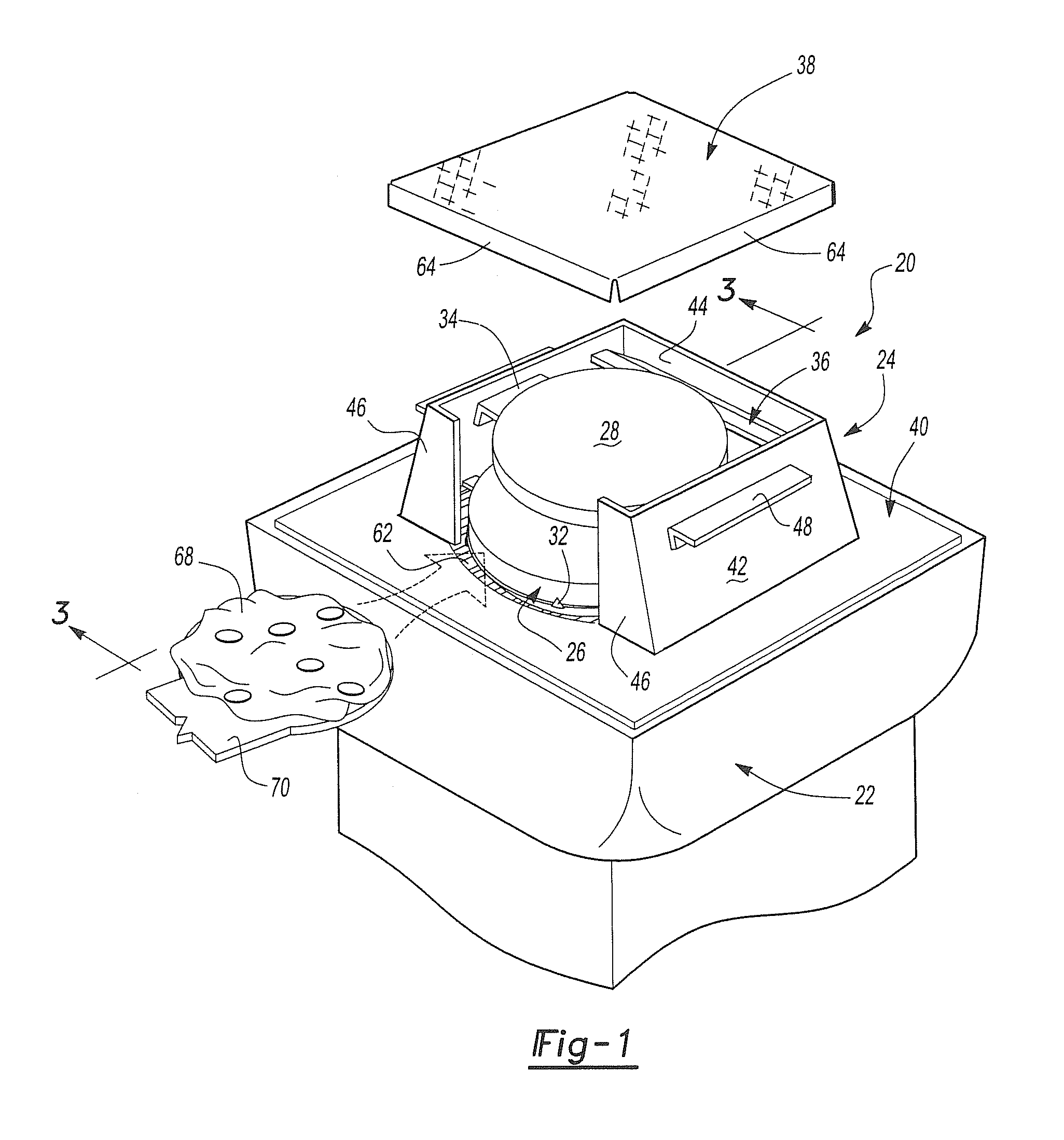

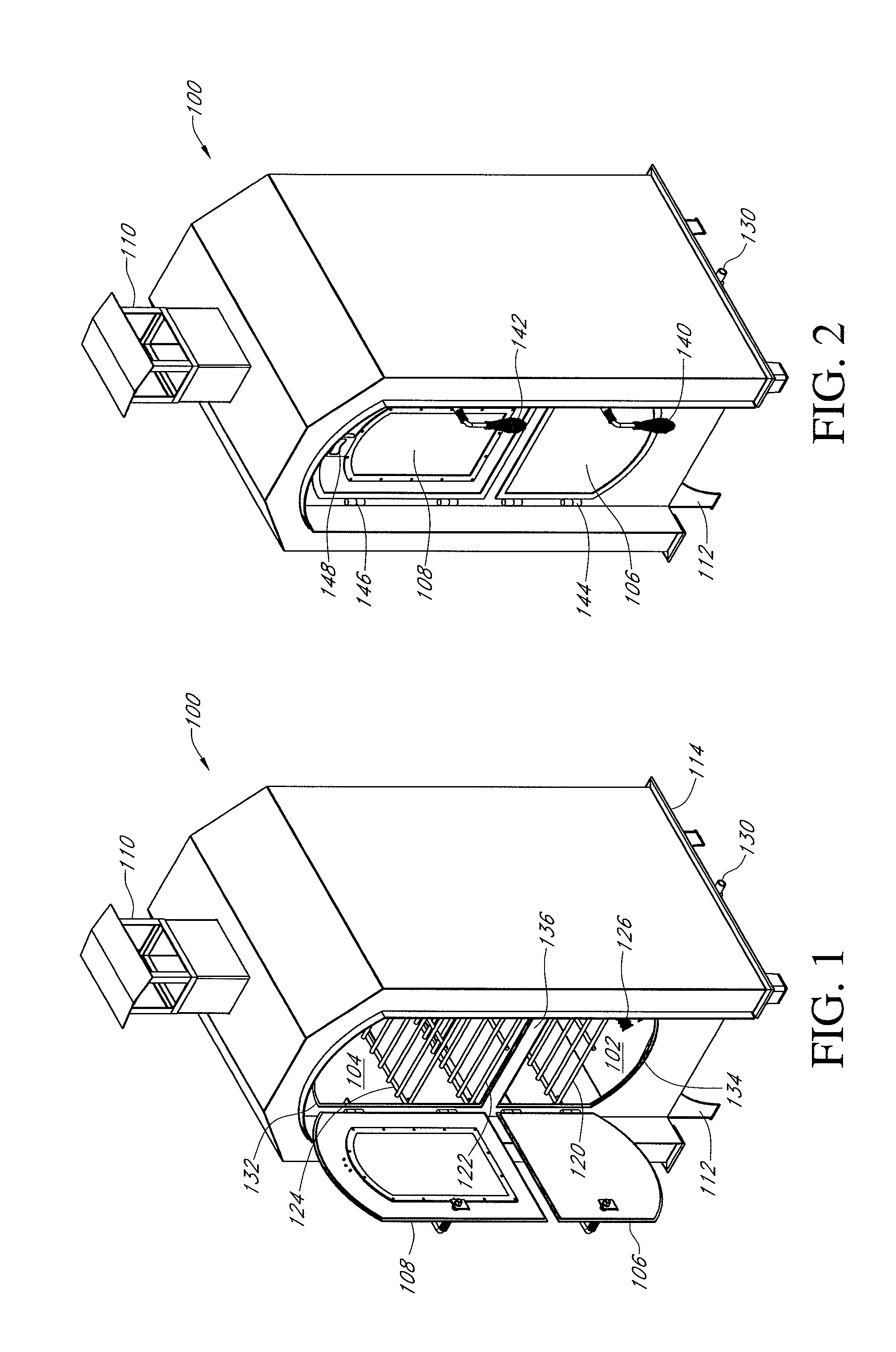

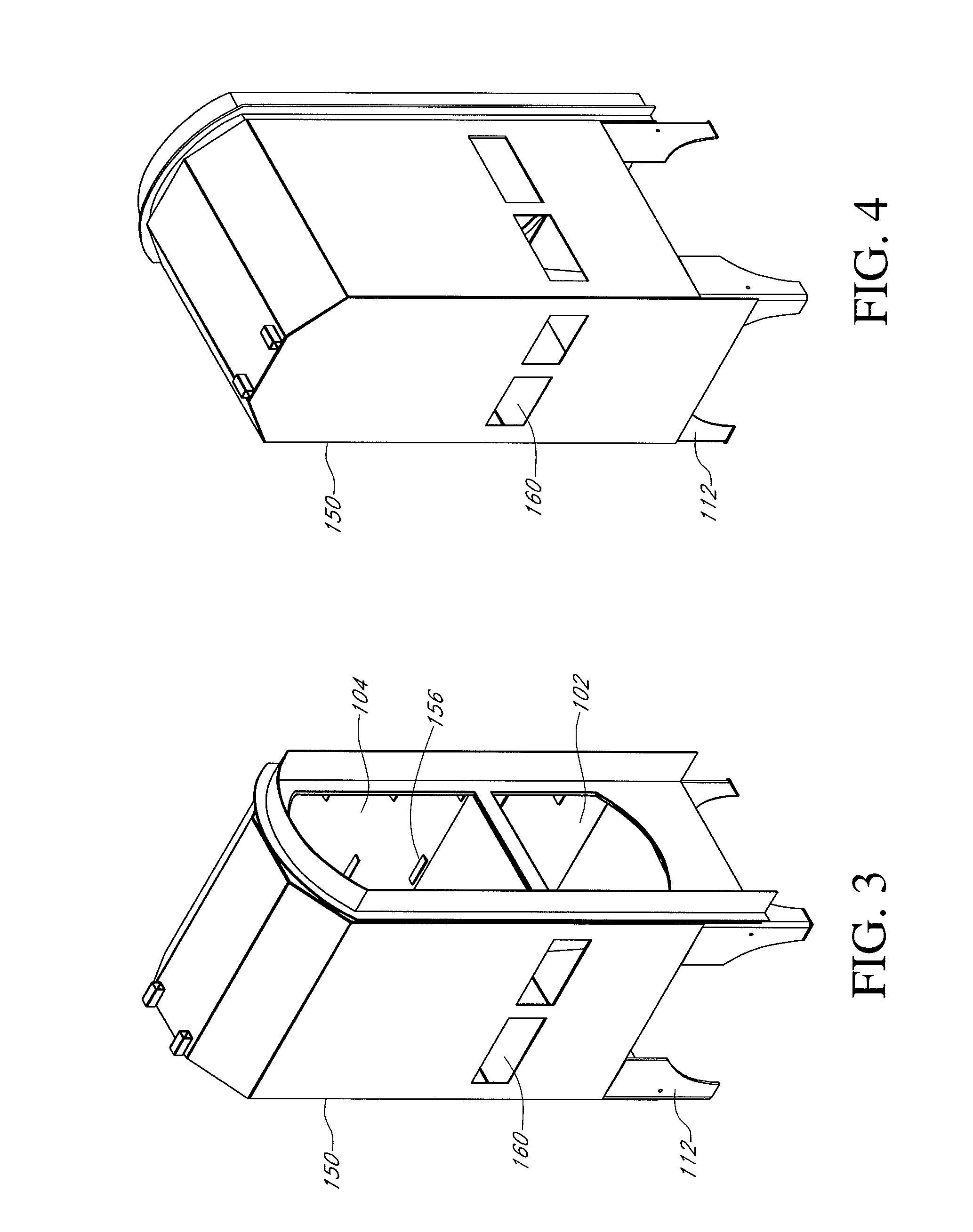

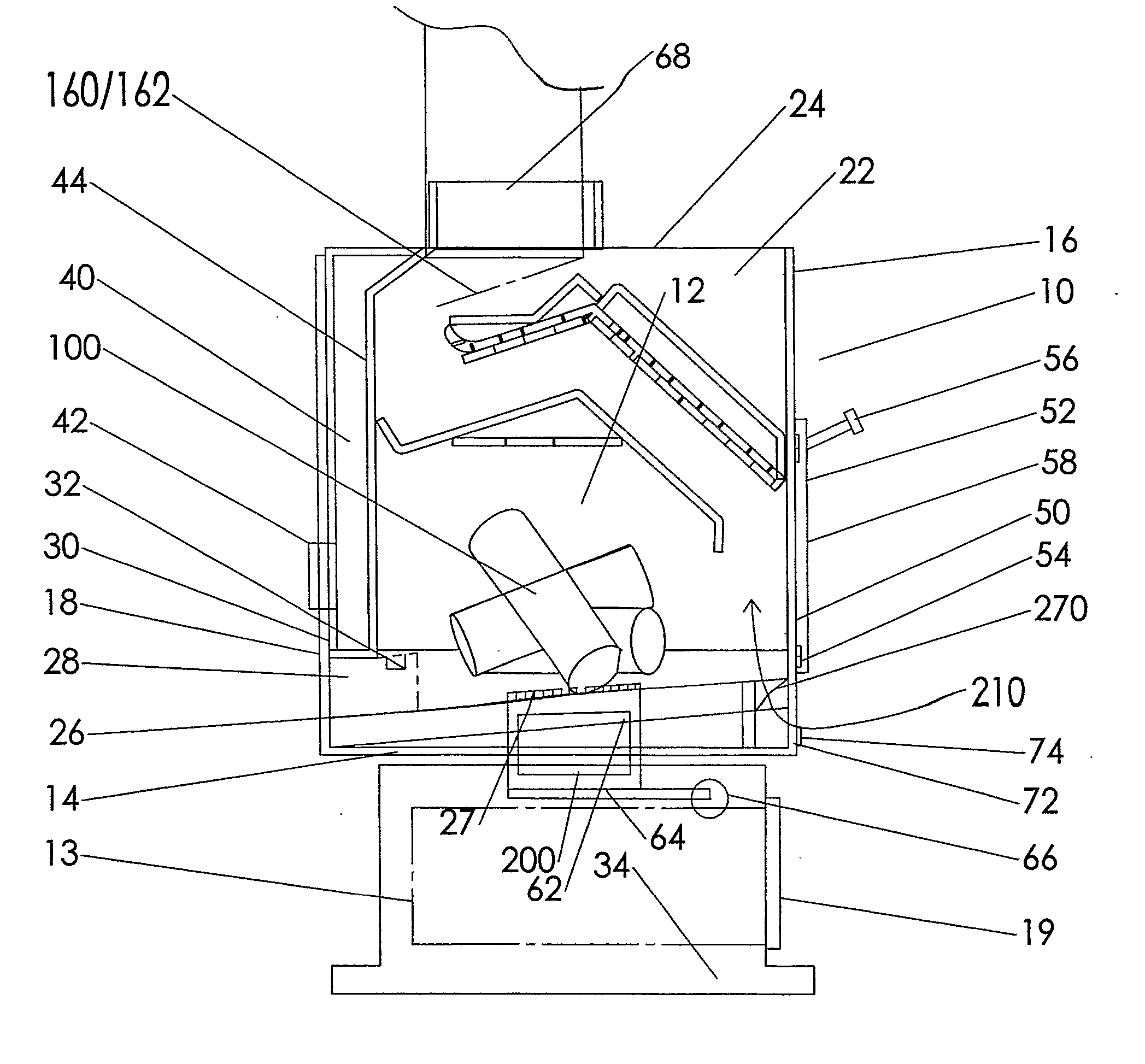

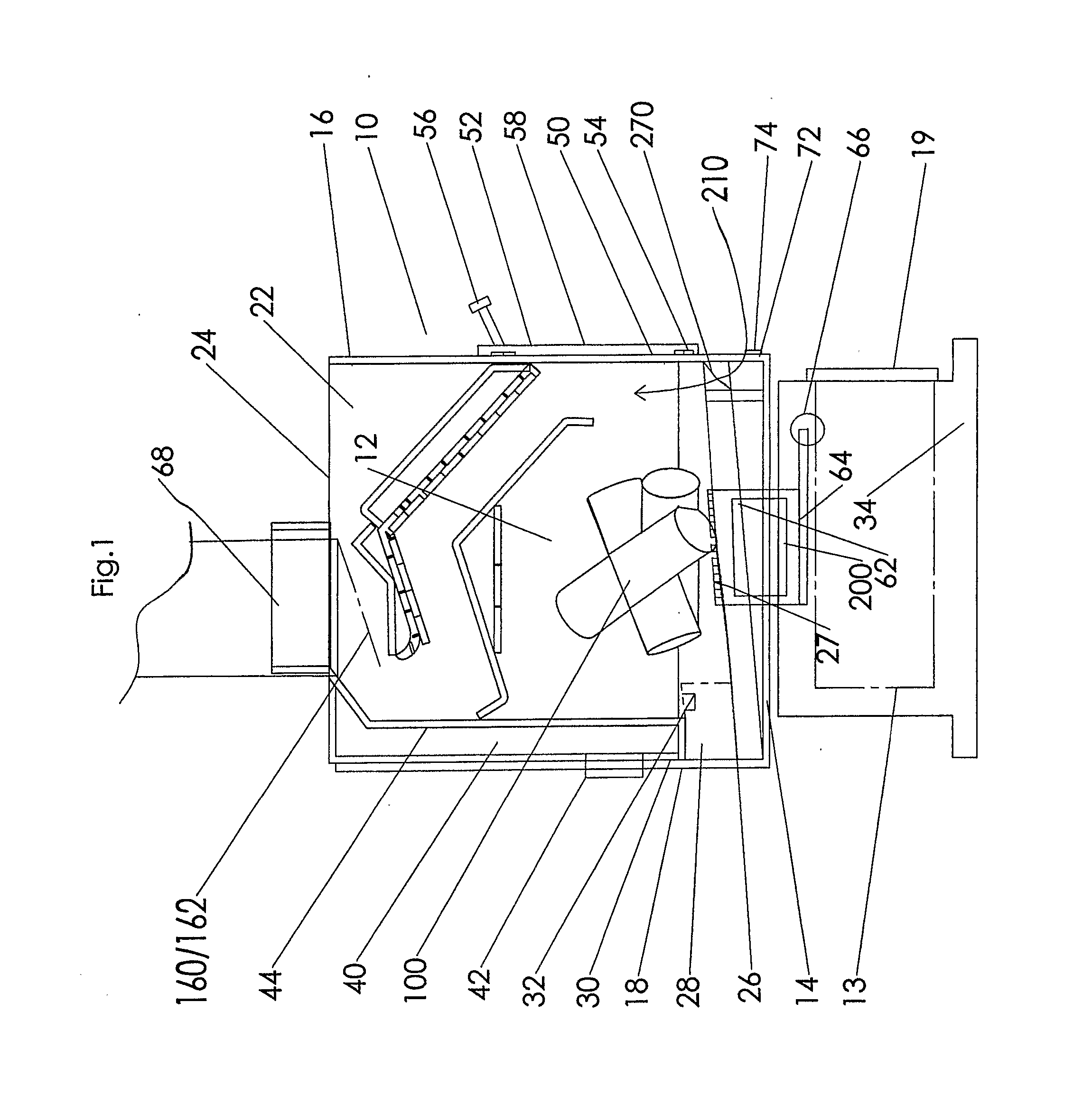

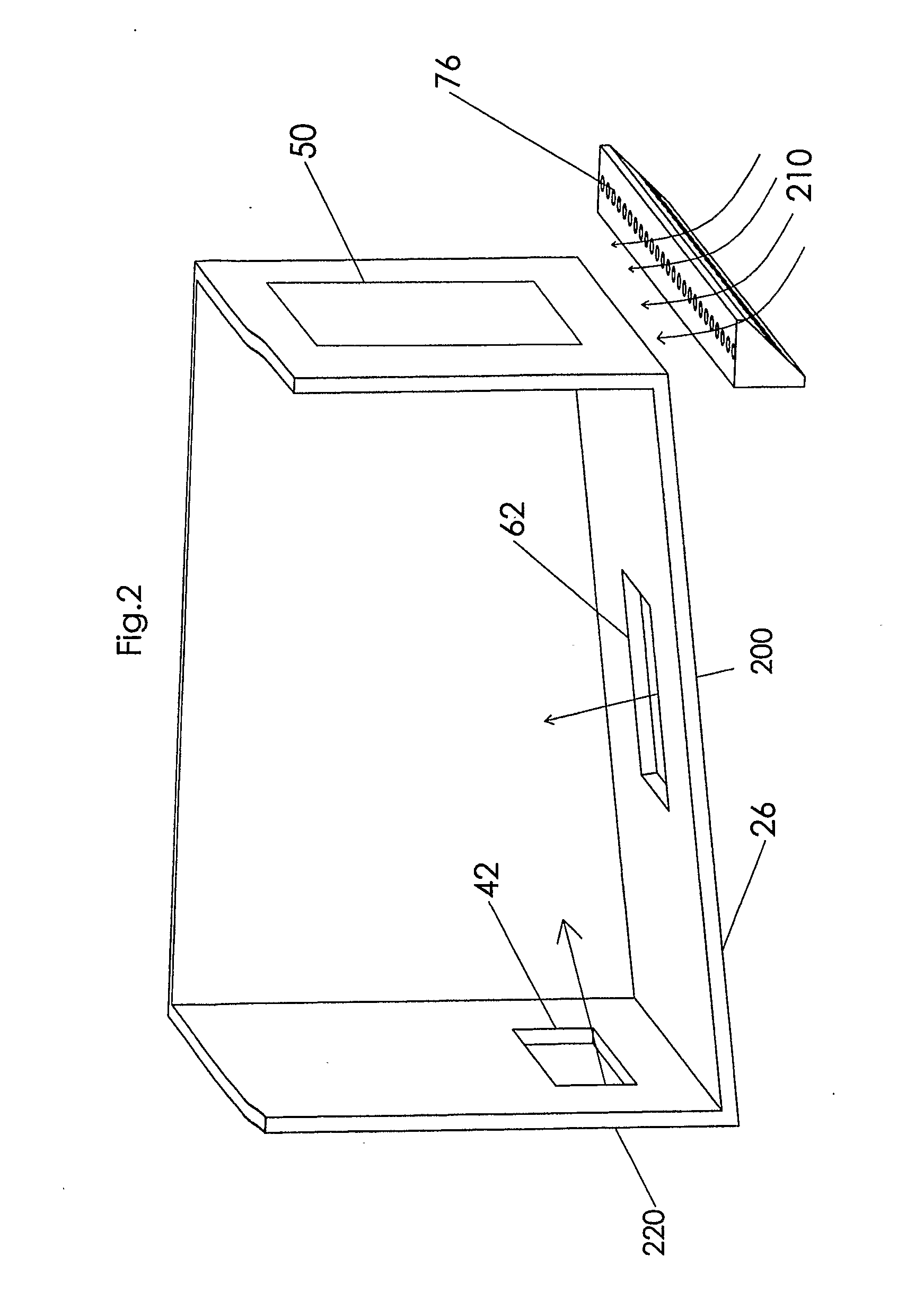

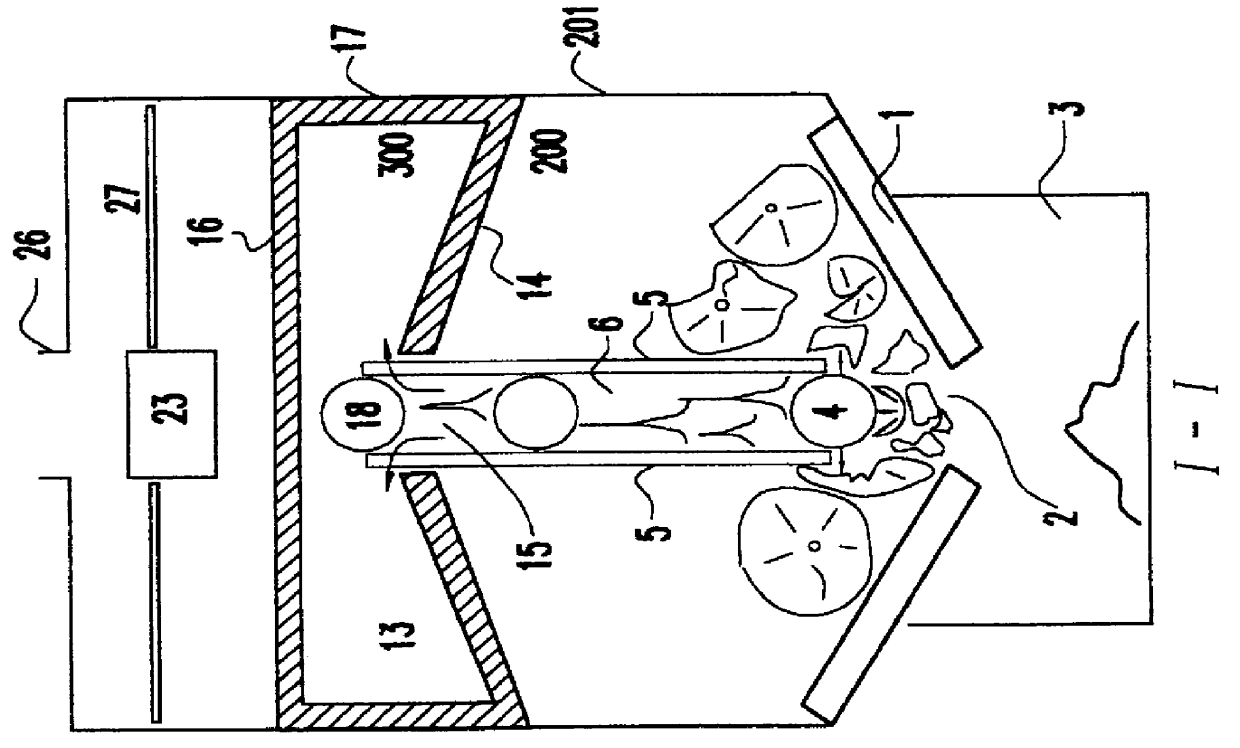

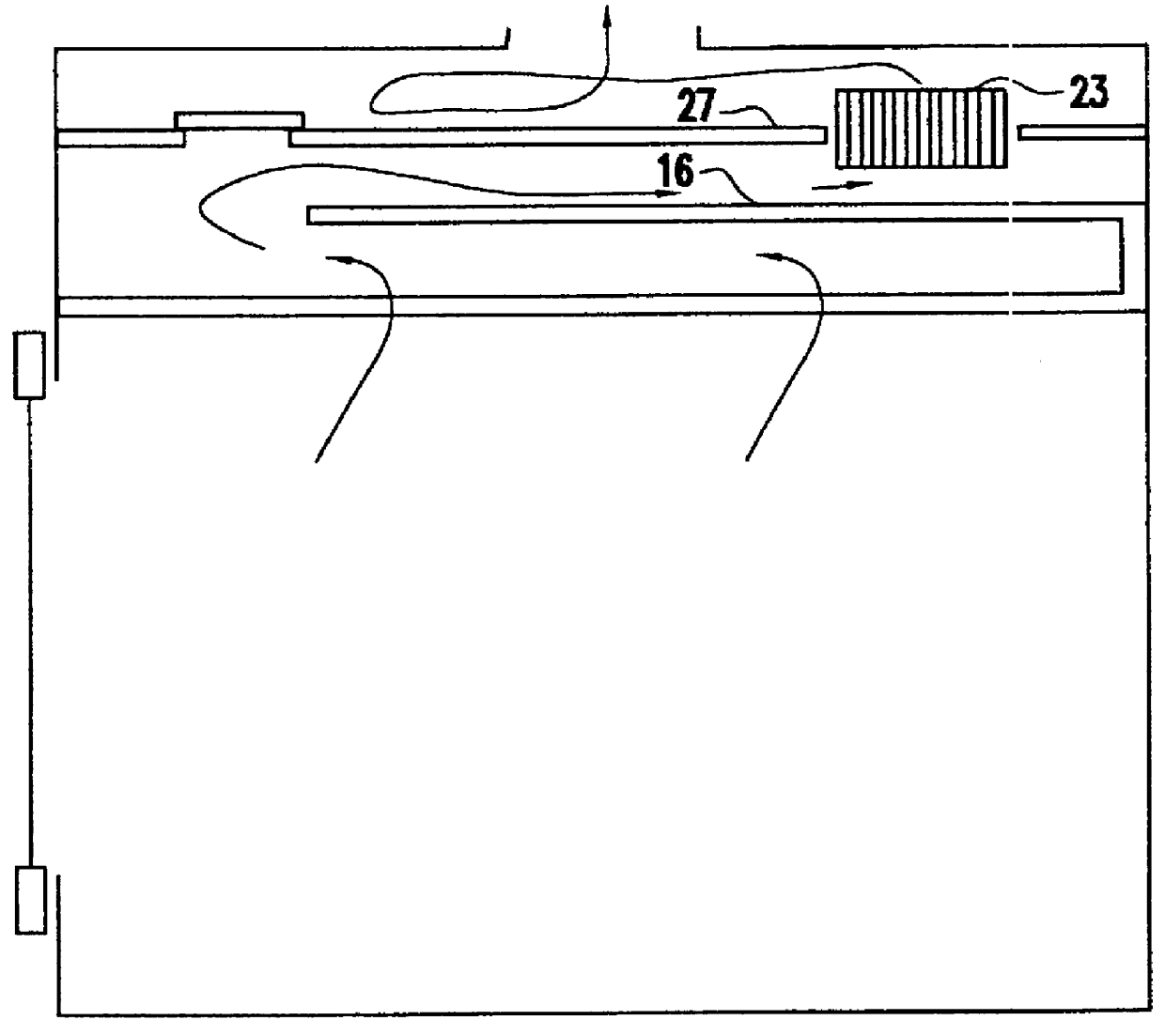

Convection Oven

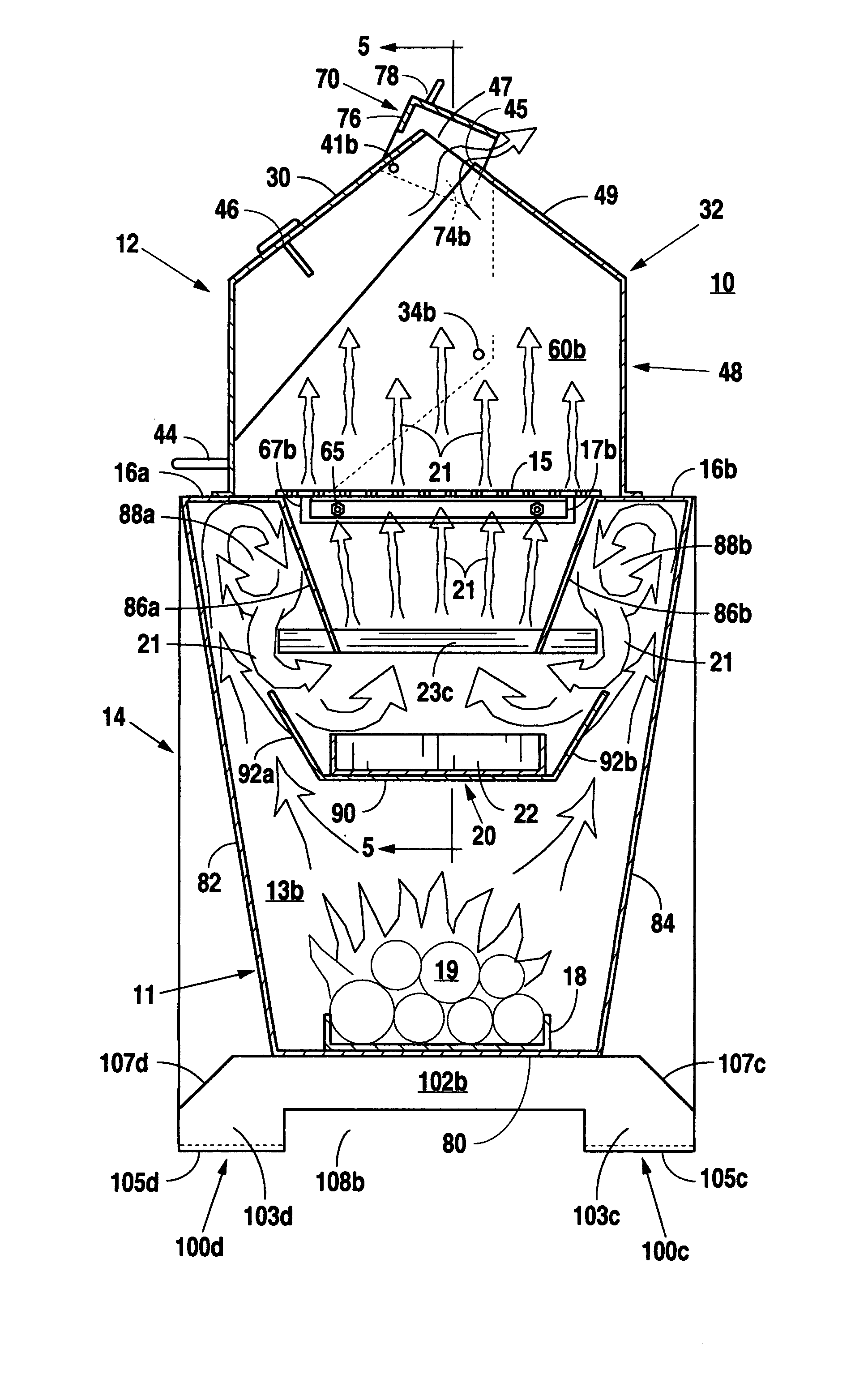

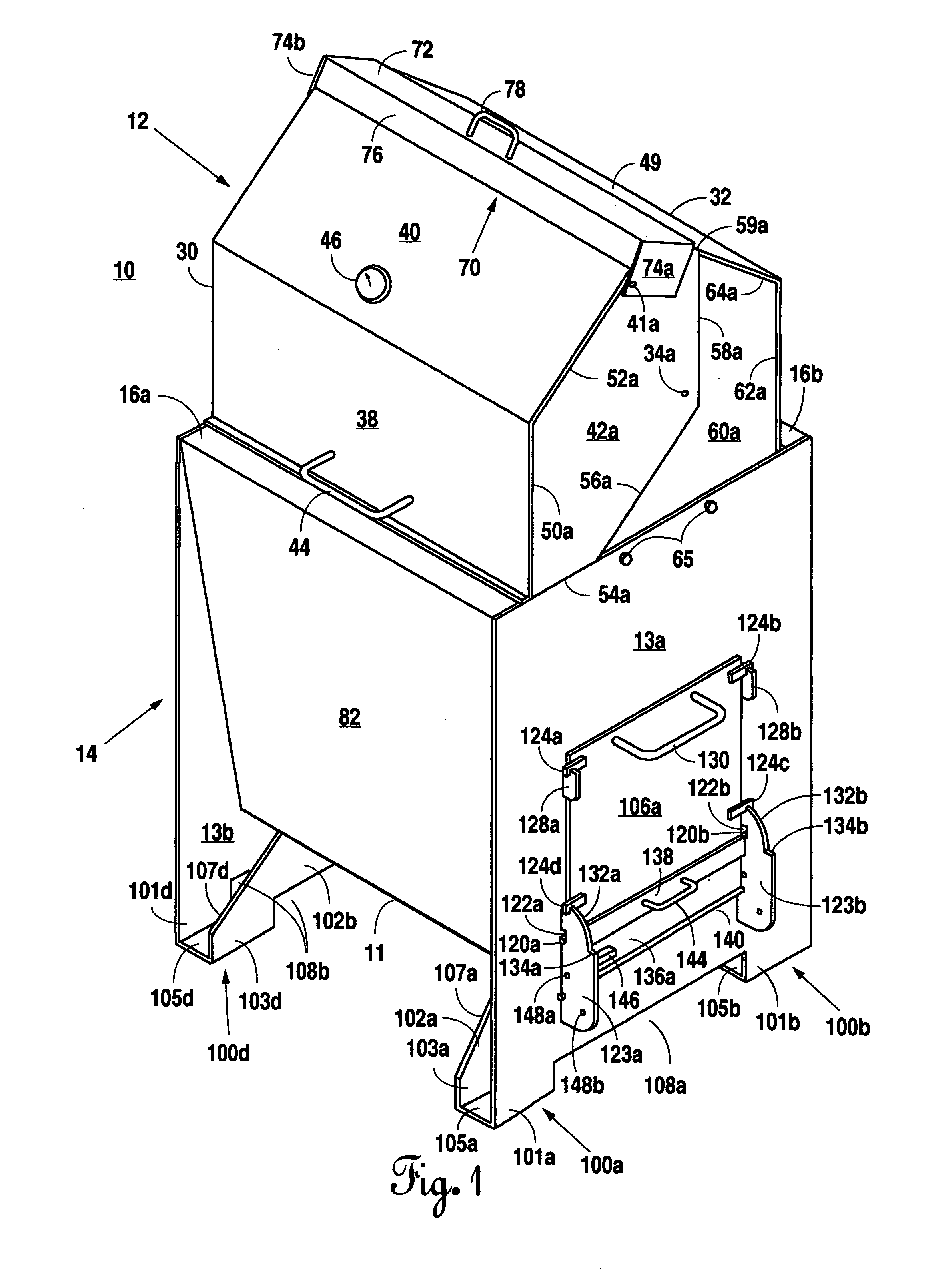

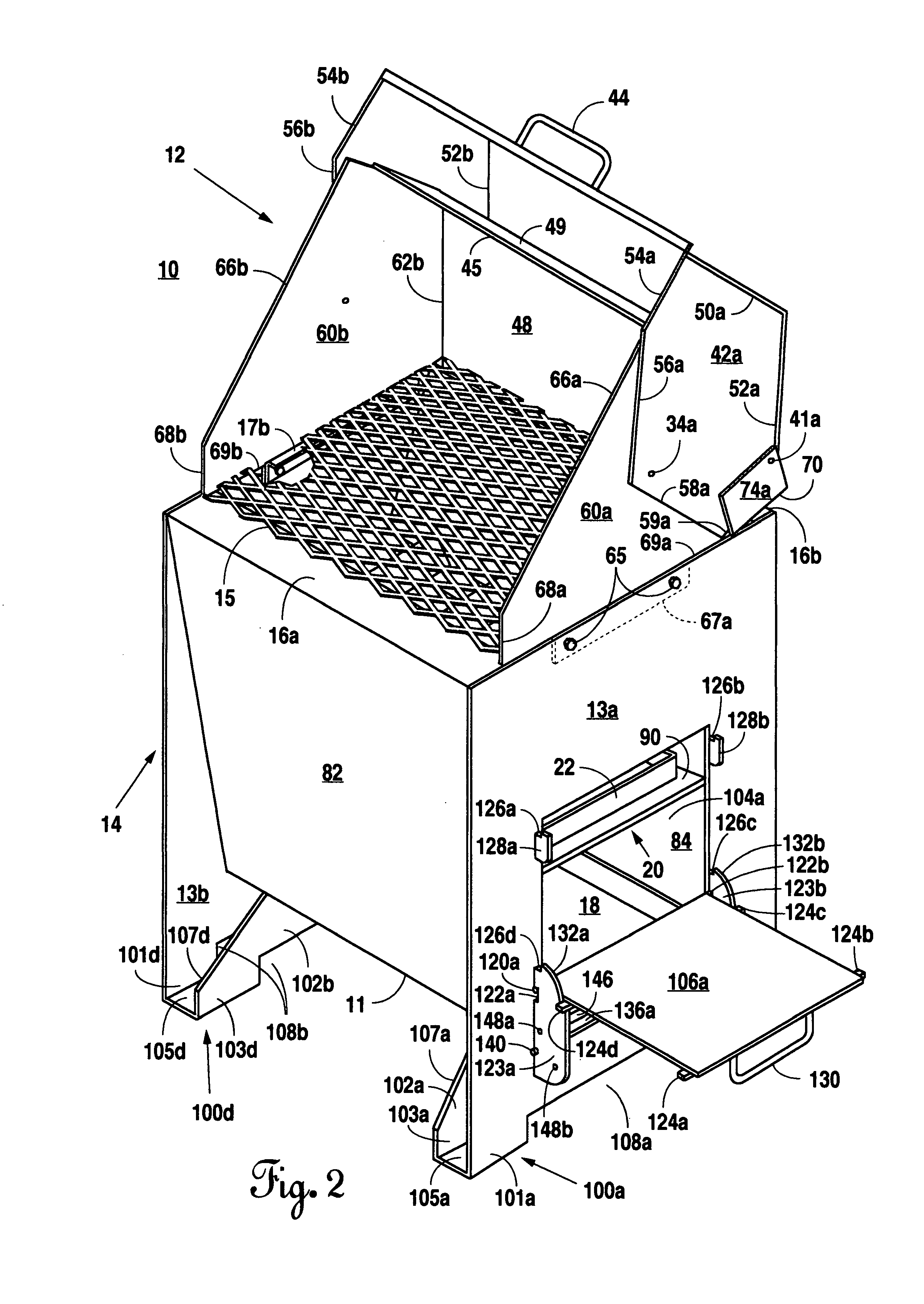

ActiveUS20110275023A1Climate change adaptationCombustion-air/flue-gas circulation for stovesCombustorCombustion chamber

An oven for cooking foods includes a housing having a fire chamber and a cooking chamber disposed generally above the fire chamber. A vessel is receivable in the fire chamber and is adapted to hold combustible material therein to generate heat and smoke for cooking food in the cooking chamber. A blower is mounted on the housing. The blower is selectively operable to move air. A tube is attached to an outlet of the blower and extends into the fire chamber such that when the vessel is received in the fire chamber the tube extends to a position adjacent the vessel so that air from the blower is blown directly into the vessel without first passing a heating element. The oven does not require supplemental heat from a burner or similar heating element.

Owner:DAVID B KNIGHT & ASSOCS

High temperature bake oven and method

ActiveUS8578927B2Short timeHeating can be extremeStoves/ranges foundationsStoves/ranges shelves or racksEngineeringHigh heat

A method of baking bread in a high temperature bake oven, comprising initiating a heating element in a lower portion of the bake oven, locating the bread on a first pizza stone located above the heating element, directing circulating heated air in the oven with a baffle around the first pizza stone to between the first pizza stone and a second pizza stone located above the first pizza stone, and directing the circulating heated air in the oven rapidly from between the first and second pizza stones out of the oven through an opening in the front of the oven.

Owner:NORTH ATLANTIC IMPORTS

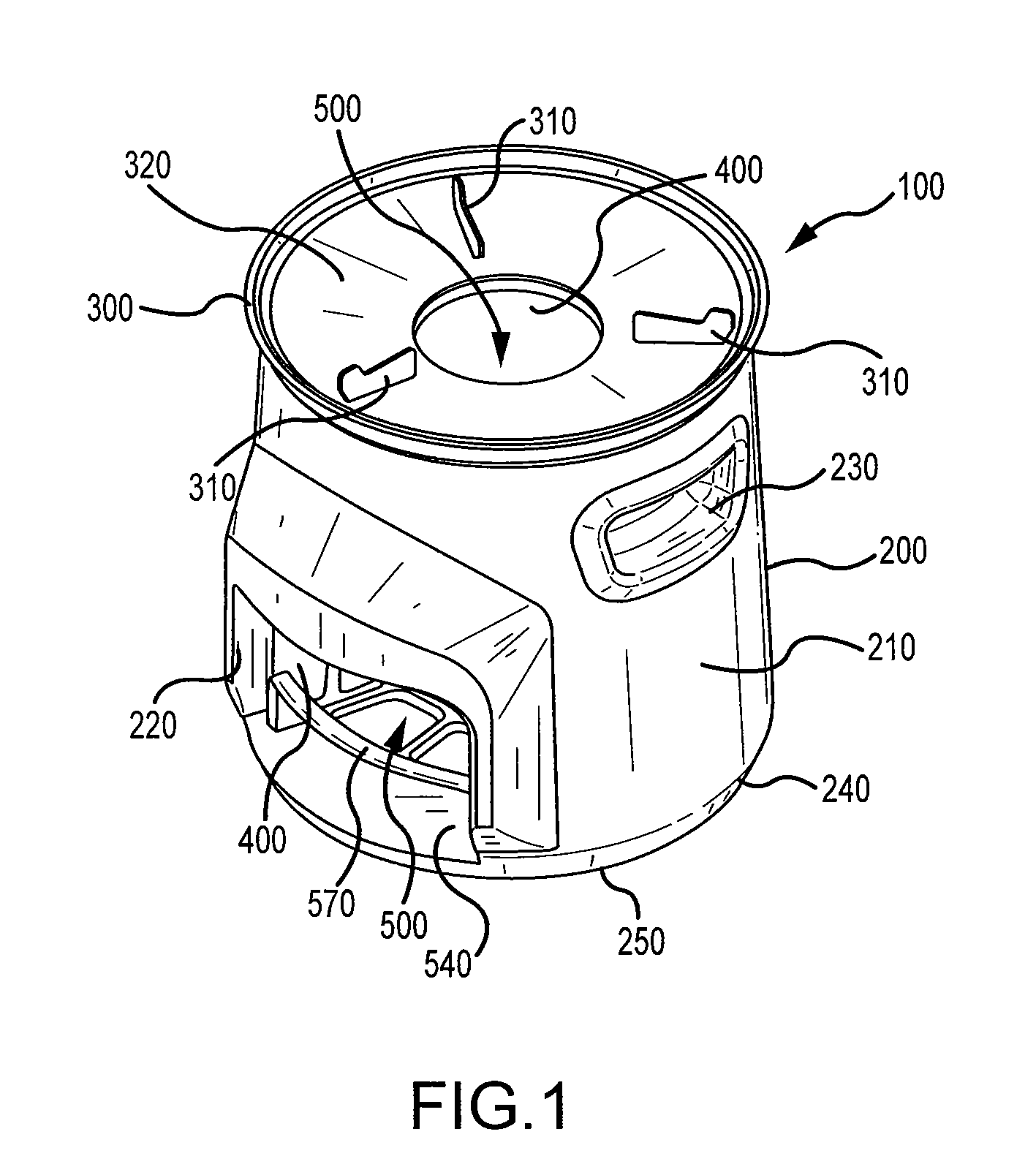

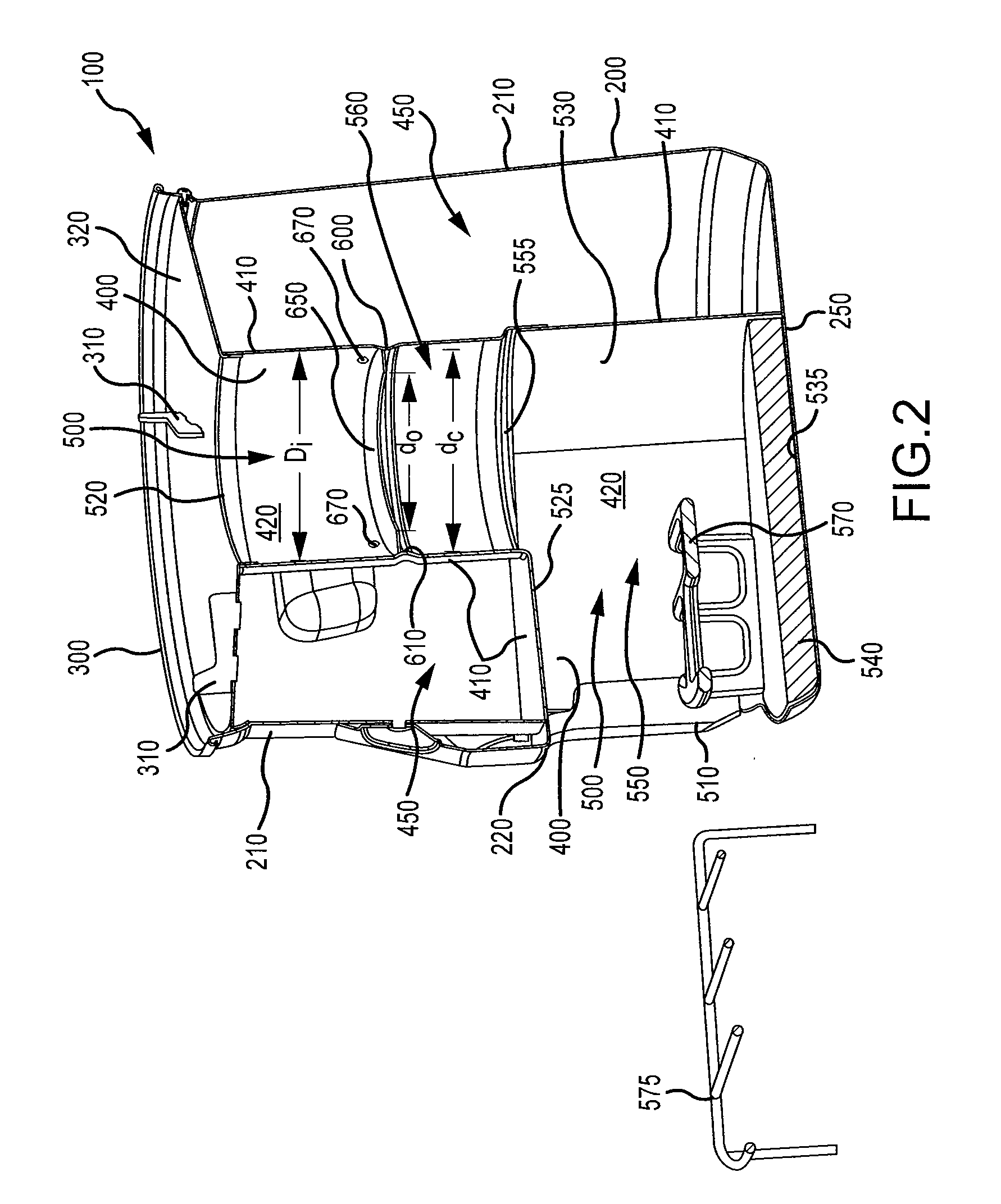

Cook stove assembly

InactiveUS20100258104A1Increase productionReduce productionLighting and heating apparatusCombustion-air/flue-gas circulation for stovesCombustion chamberDirect combustion

A combustion chamber, having an upper part and a lower part, may include an annular constriction, in combination with the combustion chamber, to aid in directing partially combusted gases such as carbon monoxide away from the periphery of the combustion chamber back toward its center, and into the flame front. The annular constriction may also impede the flow of partially combusted gases located at the periphery, thus increasing the time these gases spend within the combustion chamber and increasing the likelihood that any products of incomplete combustion will undergo combustion. The combustion chamber may further comprise a dual burner cooktop for directing combustion gases and exhaust to multiple cooking vessels. In further embodiments, the combustion chamber may be made of, lined, or clad with a metal alloy comprising iron, chromium, and aluminum.

Owner:COLORADO STATE UNIVERSITY +1

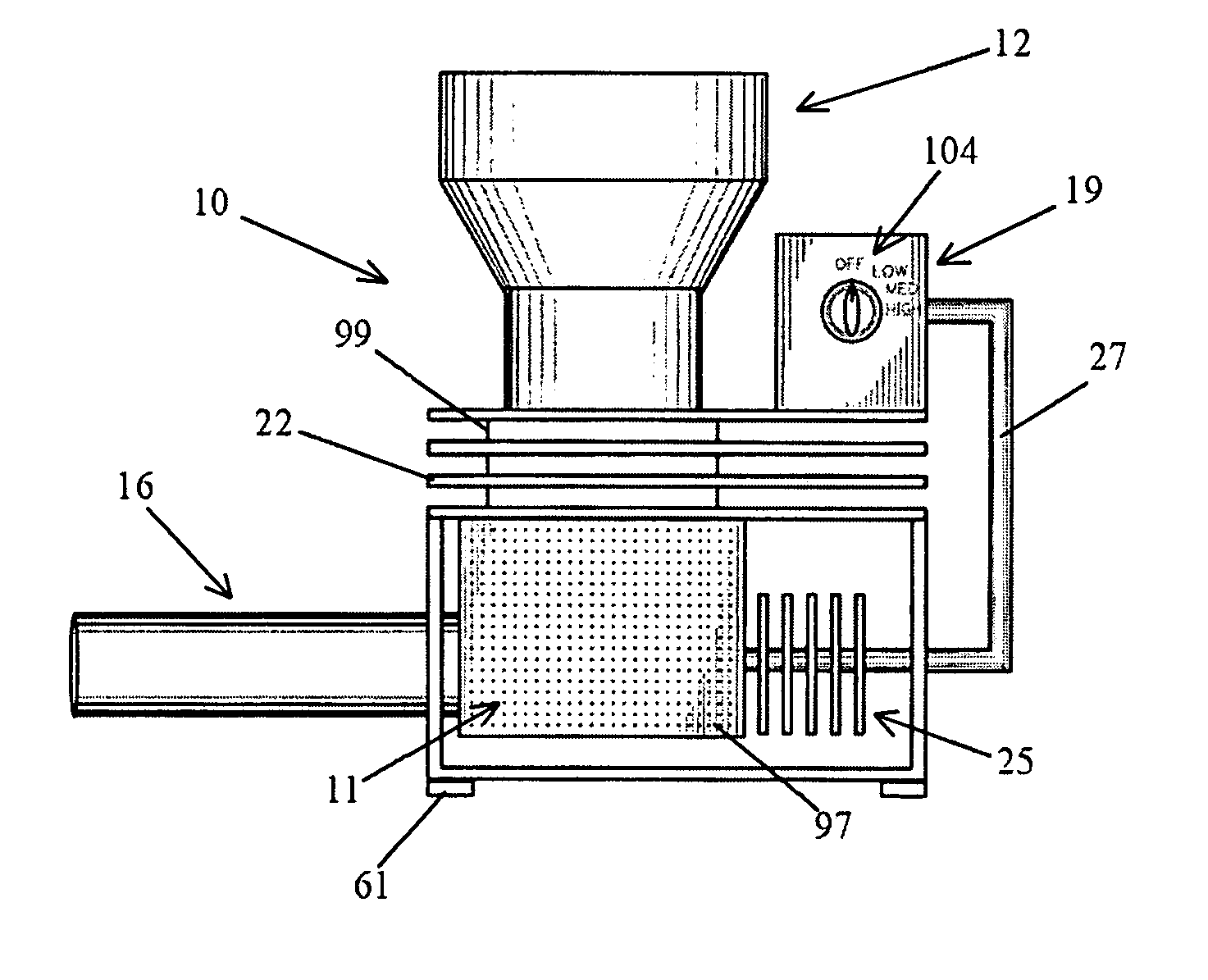

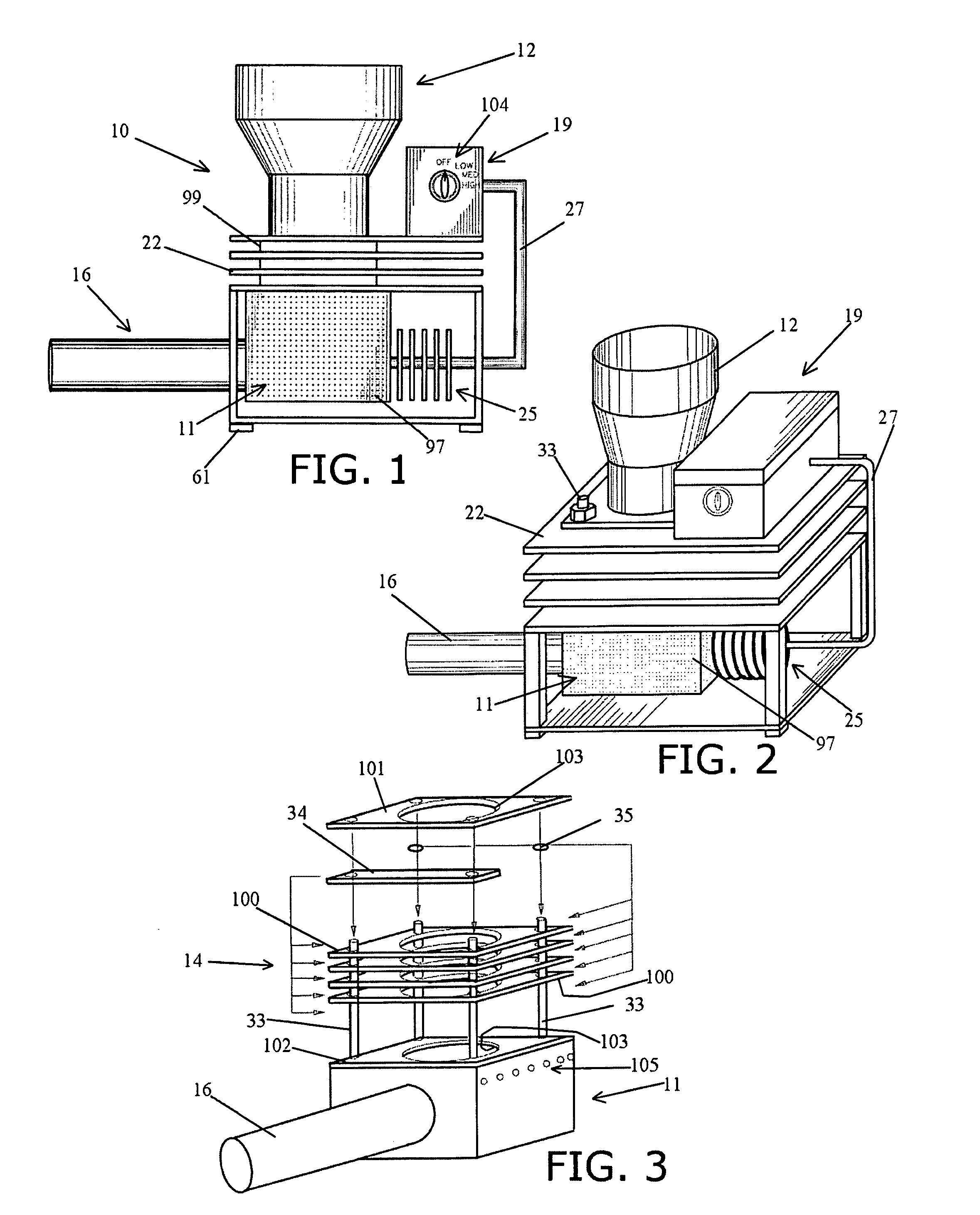

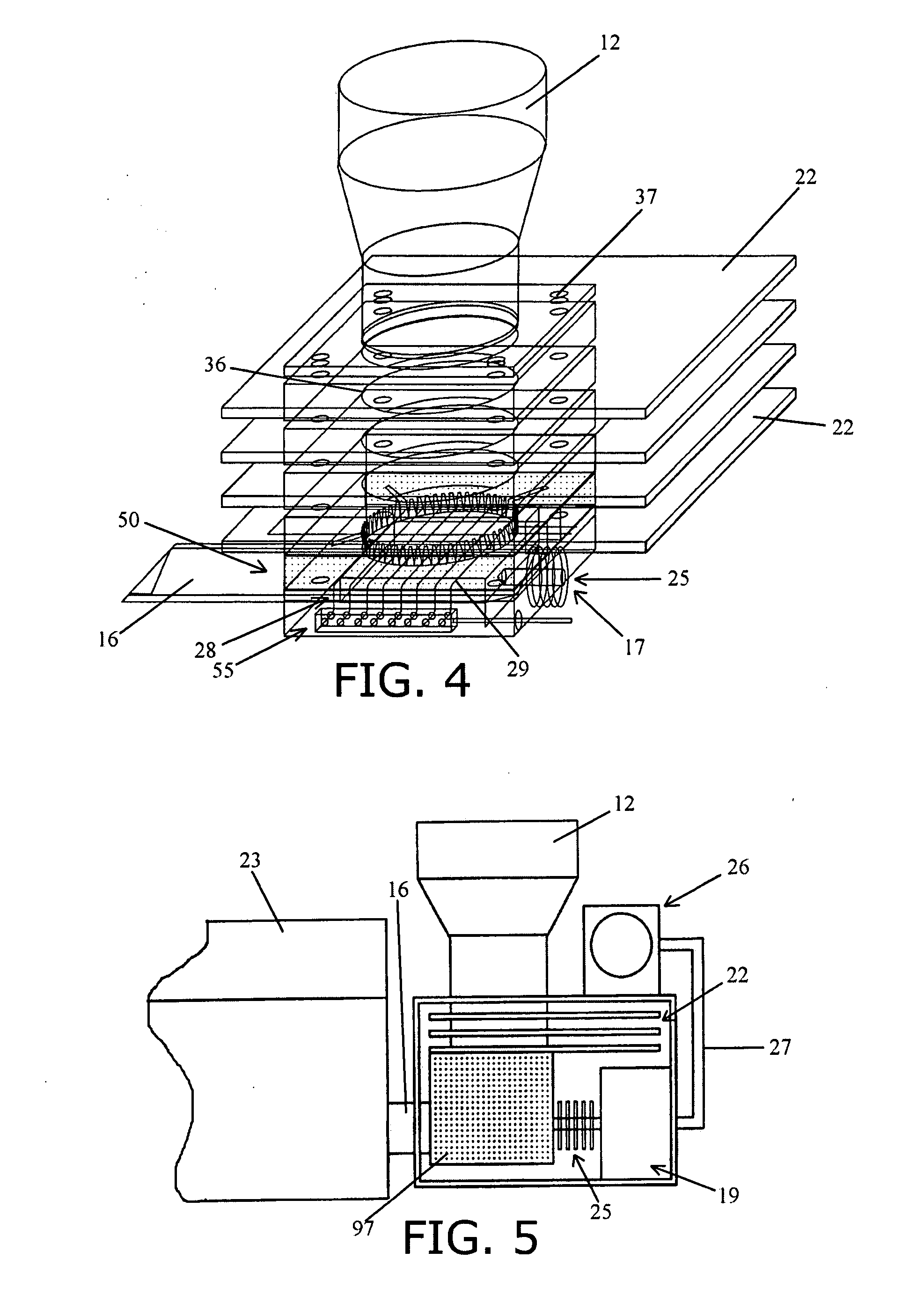

Pellet burning heating assembly

ActiveUS20080060632A1Low costShort cooking timeStoves/ranges with convection heatingCombustion-air/flue-gas circulation for stovesAtmospheric airWood gas

A portable pellet fired heating element for mounting to a grill or stove and comprising a gravity fed pellet holder, a unitary tubular structure having a burner, an air intake and an exhaust chute. Fuel may be supplied to the pellet holder by various supply means such as a conveyer, ramp, scooped, held in bulk in a hopper, and like pellet supply structures and methods. Fuel is fed to the air-cooled insulated burner area onto a decomposer grate, which defines the primary combustion area and which is partially open to the atmosphere for air intake. An adjustable high-pressure flow of gas or vapor is introduced to the primary exhaust chute below the decomposer grate to create a low pressure flow above the grate and which upon ignition, cause flames to be pulled into the pellet mass on the grate. In operation, air from the primary air intake maintains hot charcoal in the primary combustion area, and the secondary combustion area provides a steady flow of wood gas that mixes with a predetermined or adjustable amount of air supplied by the secondary air intake to maintain the flame. The super heated gasses and any ash are provided to the grill or stove by means of the exhaust chute. For cleaning purposes, an electrical / mechanical device may be provided to move the decomposer grate or to provide a sudden burst of high gas pressure.

Owner:GRILLSON

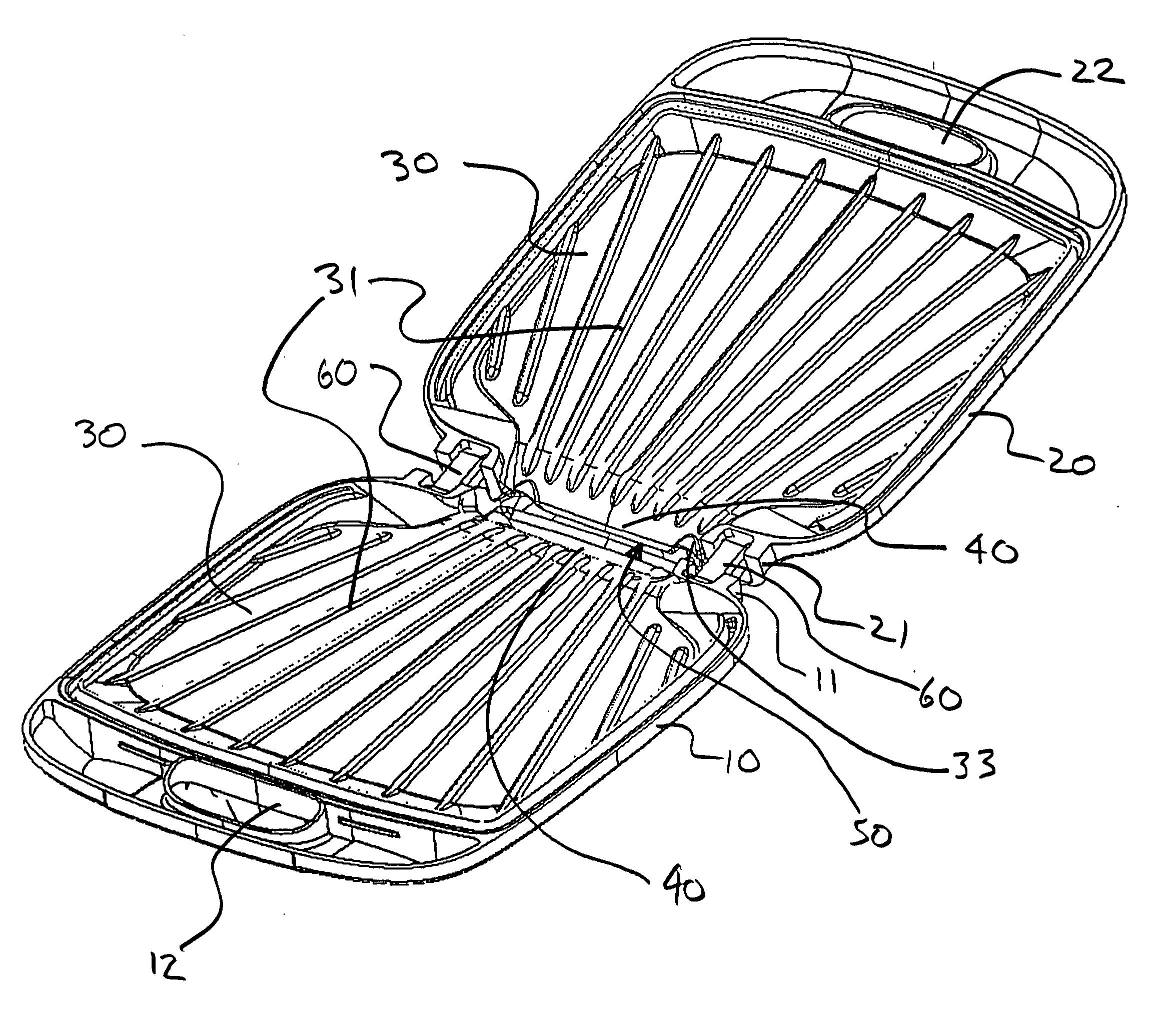

Portable cooking appliance

InactiveUS20040216730A1Stoves/ranges foundationsLighting and heating apparatusEngineeringHeating element

An article of manufacture for cooking of food in a manner that may remove a portion of the fat contained in said food, comprising a plurality of housing parts, hingeably attached, with removable cooking surfaces to distribute heat generated by heating elements, housing geometry that allows positioning the invention to cook in a sloped, fat draining mode, a level mode, or a combination level and draining mode, or closed mode, and geometry that allows efficient storage in the vertical orientation.

Owner:SAWHNEY RAVI K +3

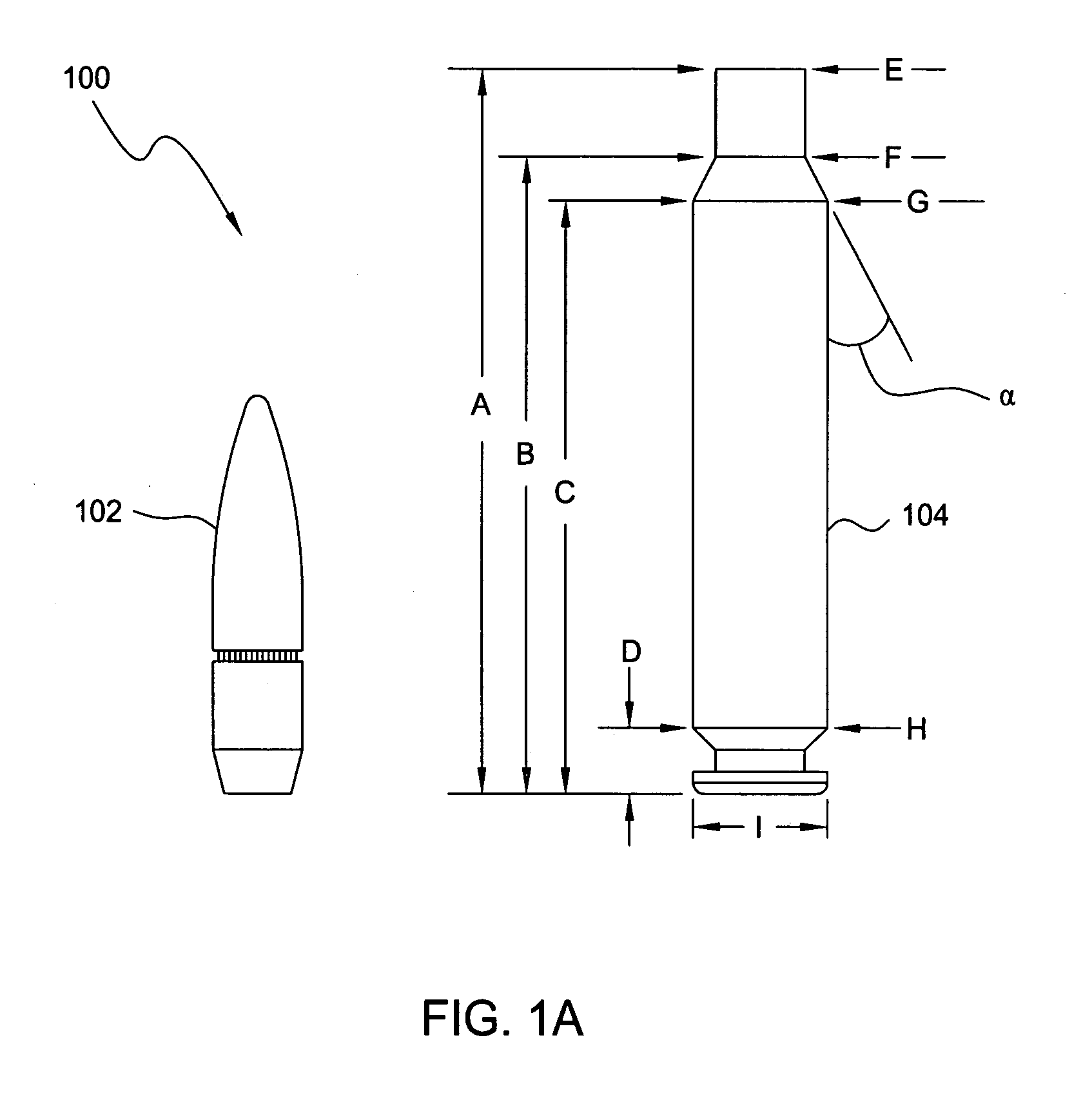

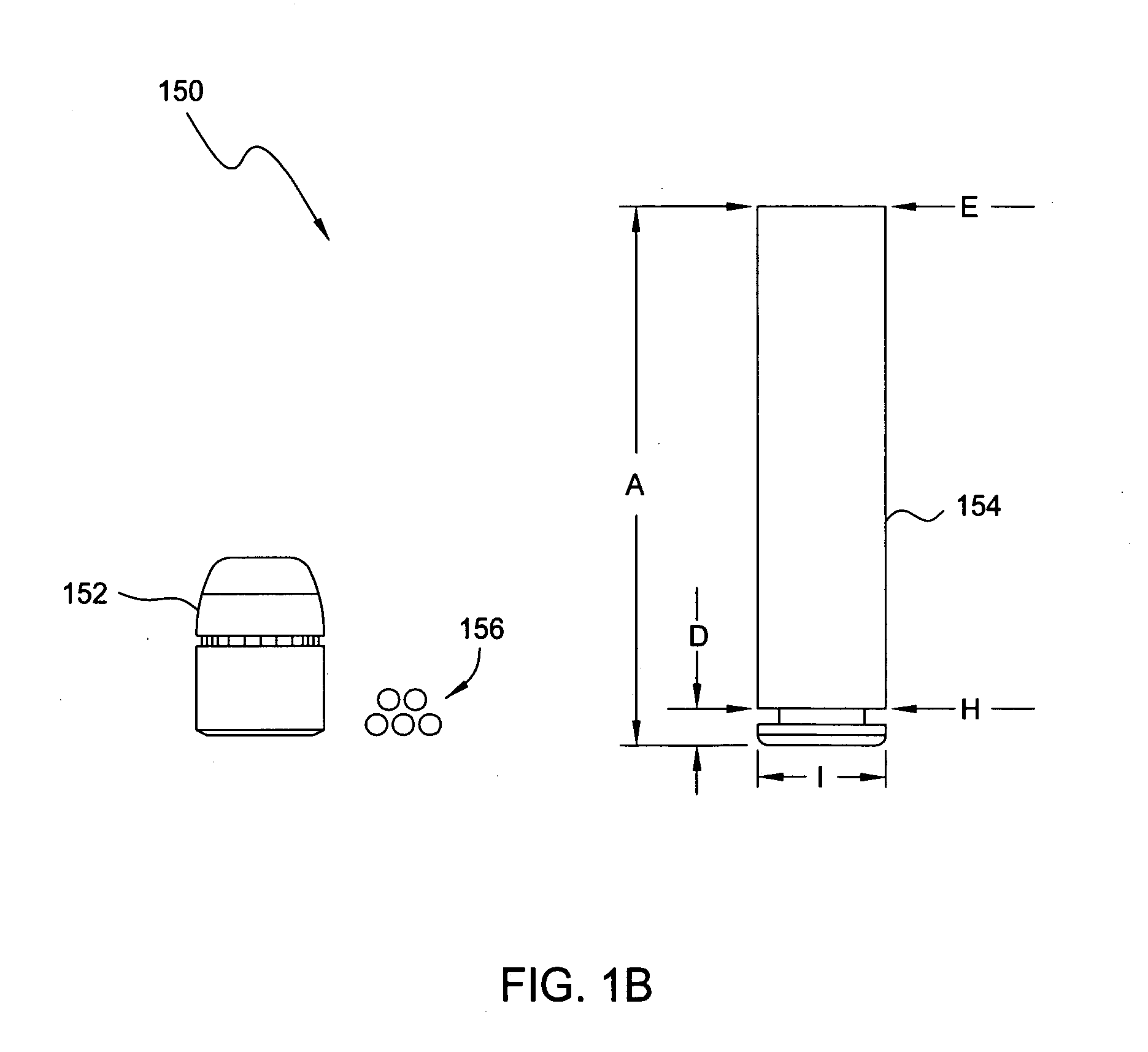

Cartridges and modifications for m16/ar15 rifle

Embodiments of the present invention relate generally to cartridges and modifications for an M16 / AR15 rifle. In one embodiment, a modified M16 / AR15 rifle or carbine includes a bolt having a maximum outside diameter greater than that of a standard M16 / AR15 bolt; and a bolt extractor pivoted to the bolt. The bolt and the bolt extractor are operable to: transport a cartridge from a magazine to a barrel, and eject a spent cartridge from the barrel. The rifle or carbine further includes a barrel extension configured to receive the bolt; a standard M16 / AR15 upper receiver coupled to the barrel extension; a standard M16 / AR15 lower receiver coupled to the upper receiver.

Owner:KRAMER LAWRENCE S

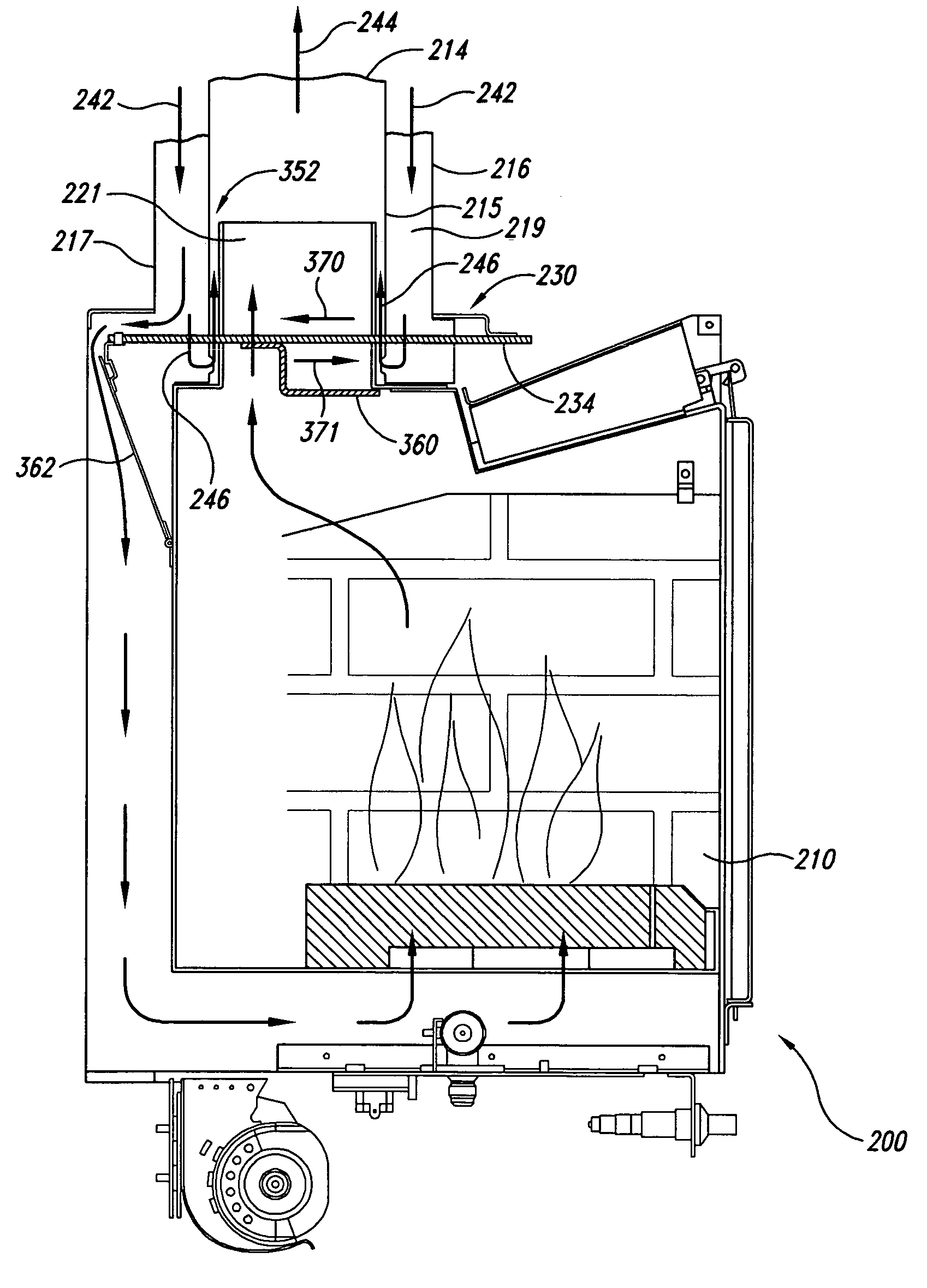

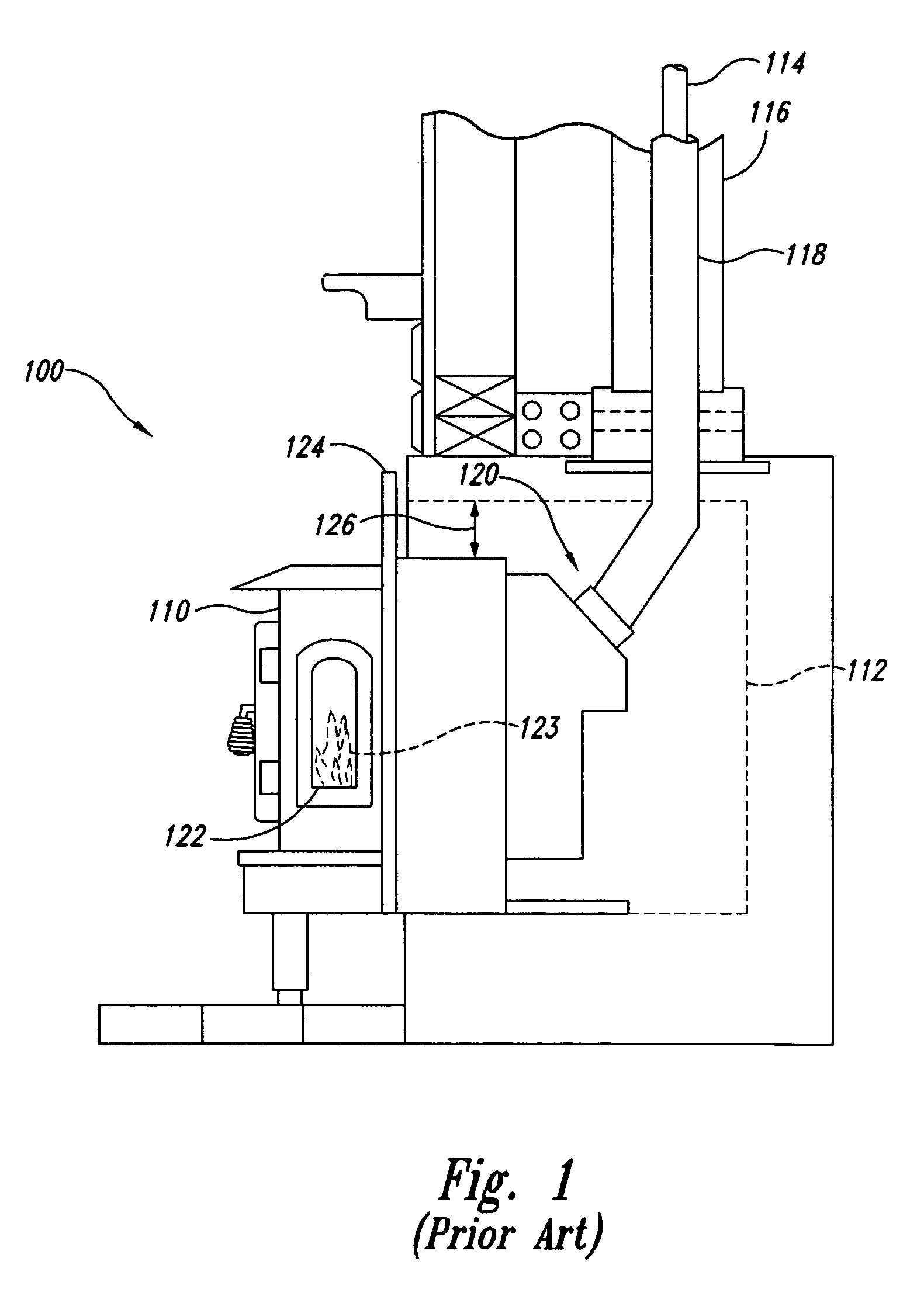

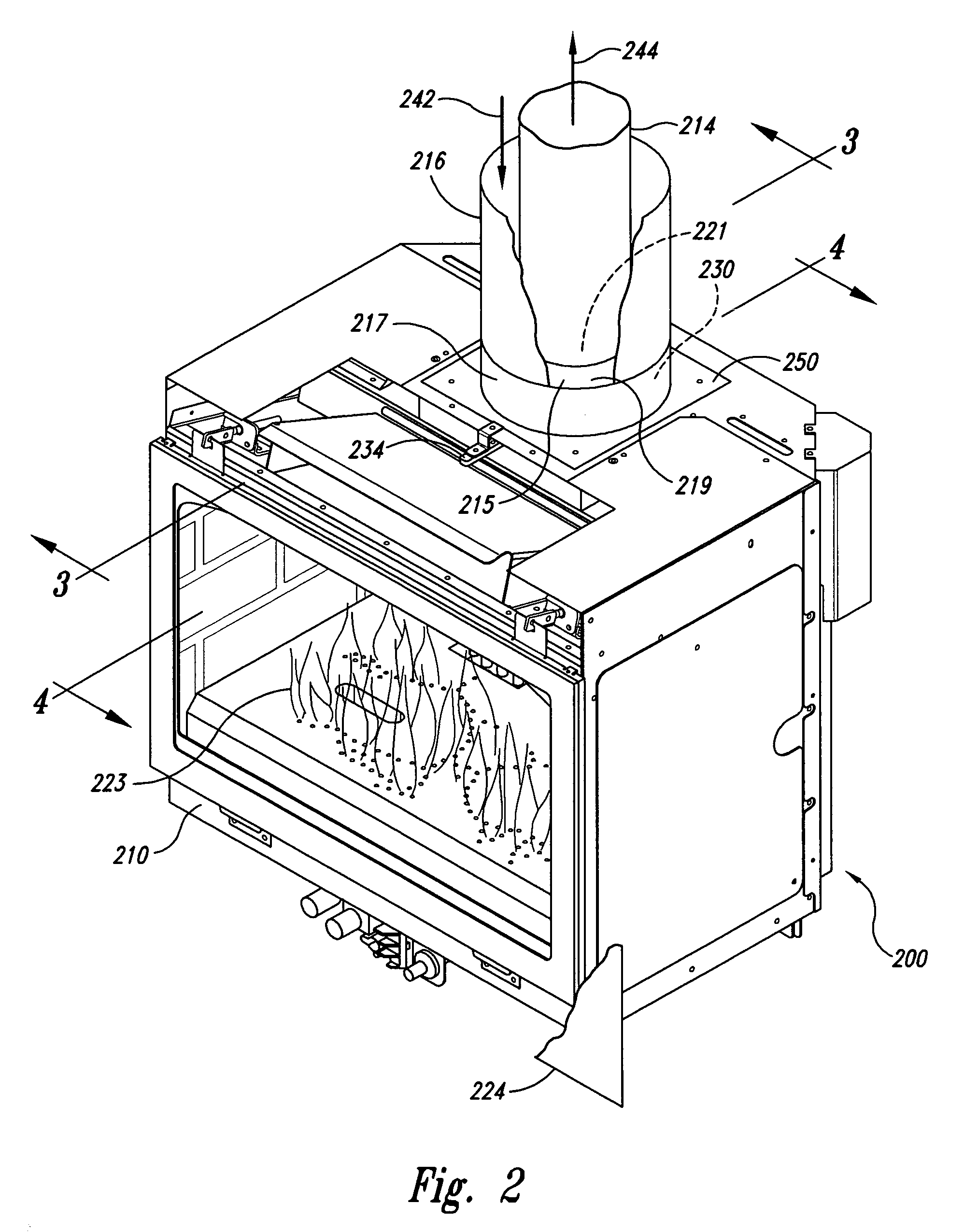

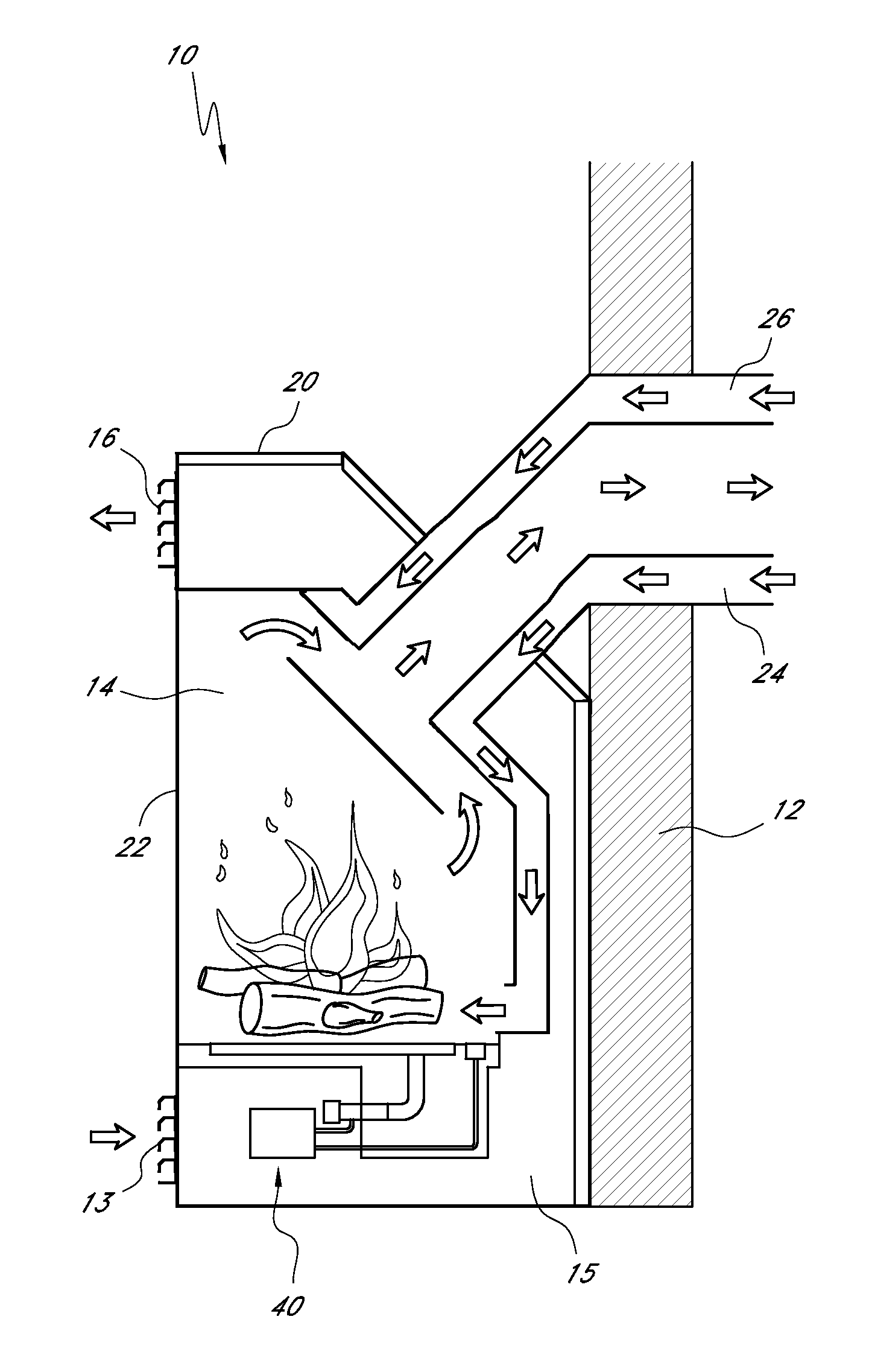

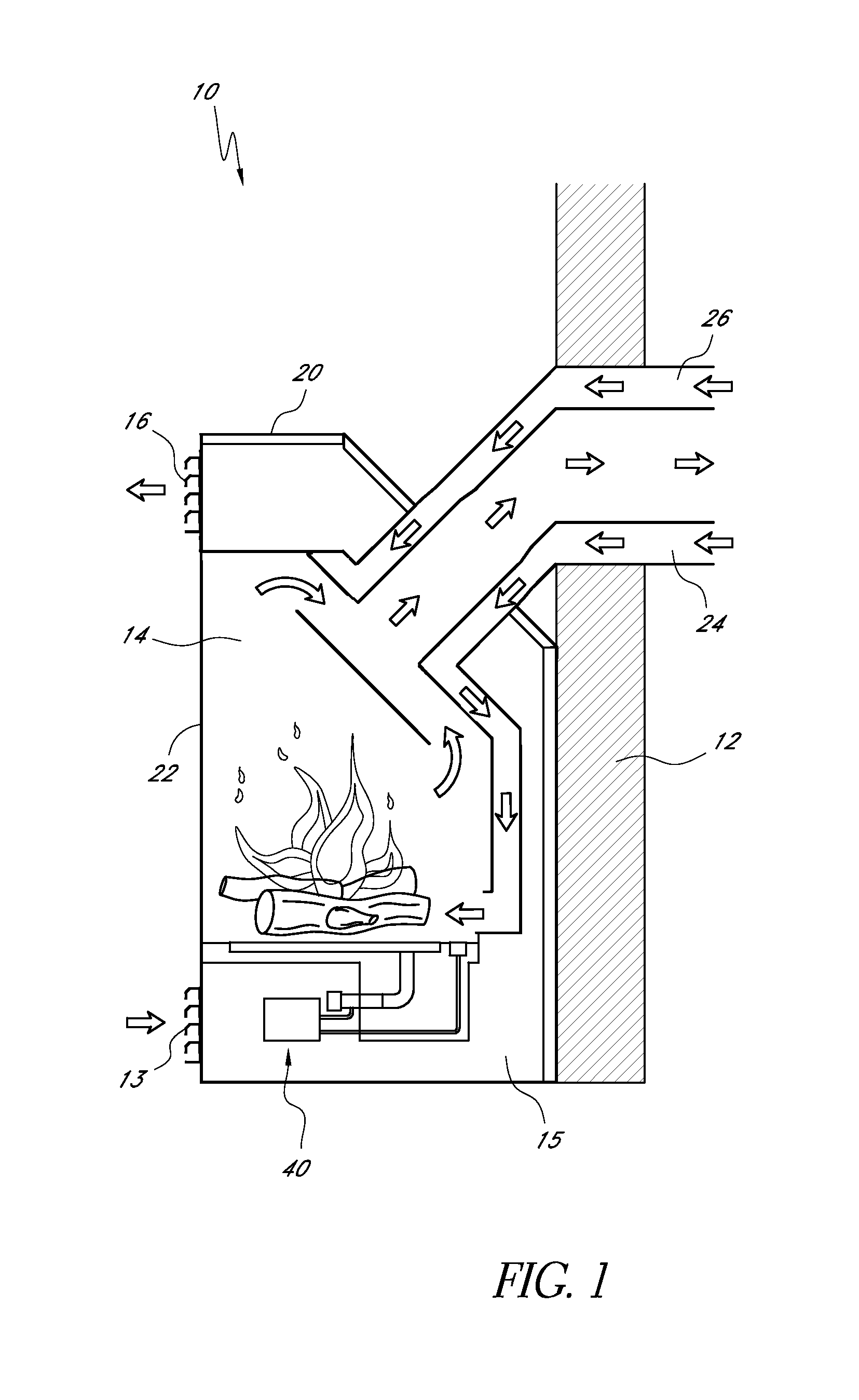

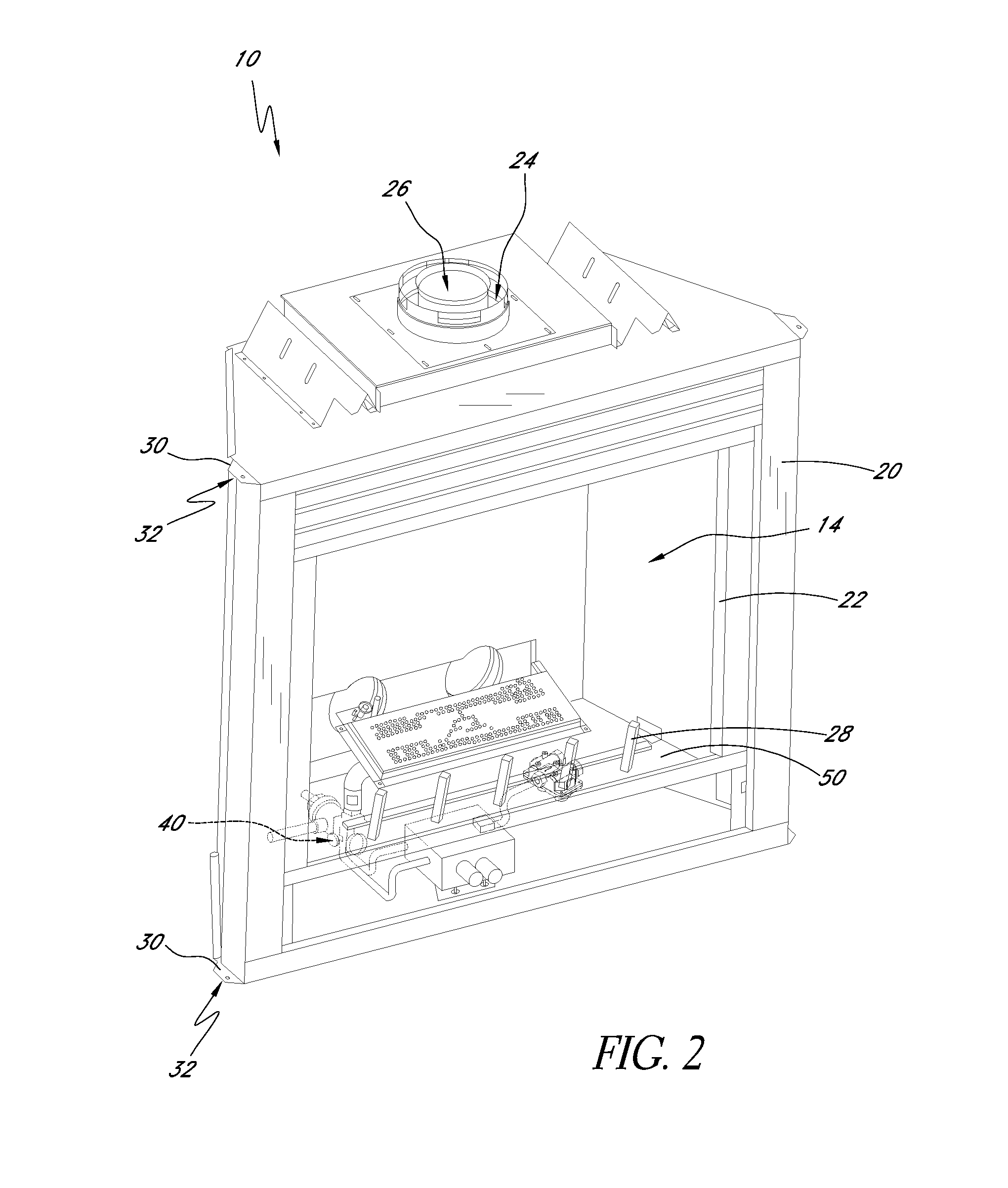

Apparatuses and methods for balancing combustion air and exhaust gas for use with a direct-vent heater appliance

InactiveUS7066170B1High trafficControl flowCombustion-air/flue-gas circulation for stovesCooking fumes removalCombustion chamberExhaust valve

A combustion air and exhaust gas balancing system for use with a direct-vent heater appliance. The balancing system includes a combustion air valve in fluid communication with a combustion air duct and an exhaust gas valve in fluid communication with an exhaust gas duct. The combustion air valve is operatively coupled to the exhaust gas valve with an actuator. The combustion air and exhaust gas valves are shaped and sized so that a single operation of the actuator simultaneously adjusts the flow of combustion air into the firebox and the flow of exhaust gas out of the firebox and provide selected flame characteristics in the firebox. In one aspect of this embodiment, a movement of the actuator in a first direction simultaneously increases the flow of combustion air and exhaust gas, and a movement of the actuator shaft in a second direction simultaneously restricts the flow of combustion air and exhaust gas. The actuator shaft is securable after final adjustment of the combustion air and exhaust gas flows to maintain the selected adjustment. In another embodiment, the exhaust gas duct includes a dilution air inlet aperture that permits combustion air to pass from the combustion air duct into the exhaust gas duct without first passing through the firebox.

Owner:TRAVIS IND

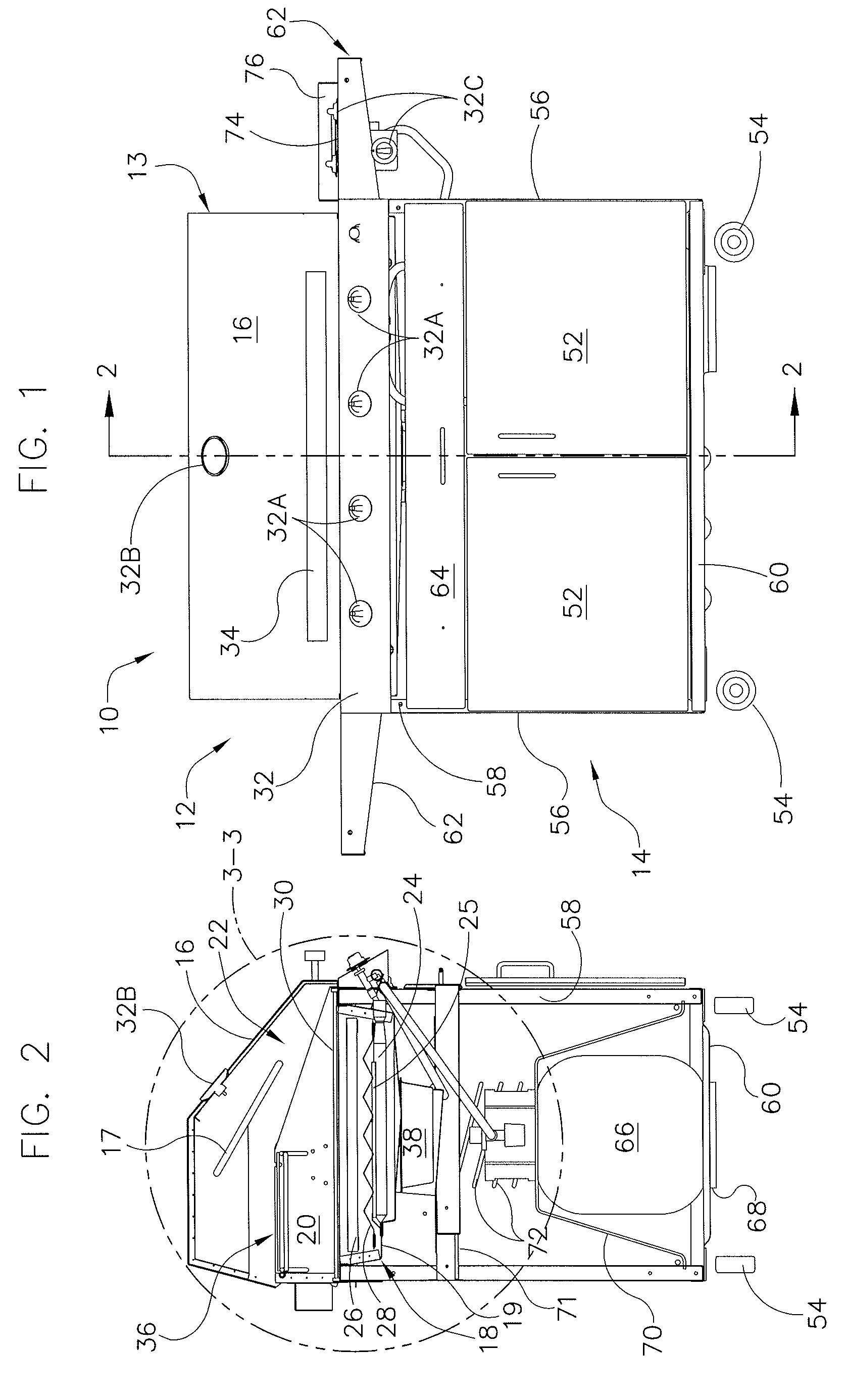

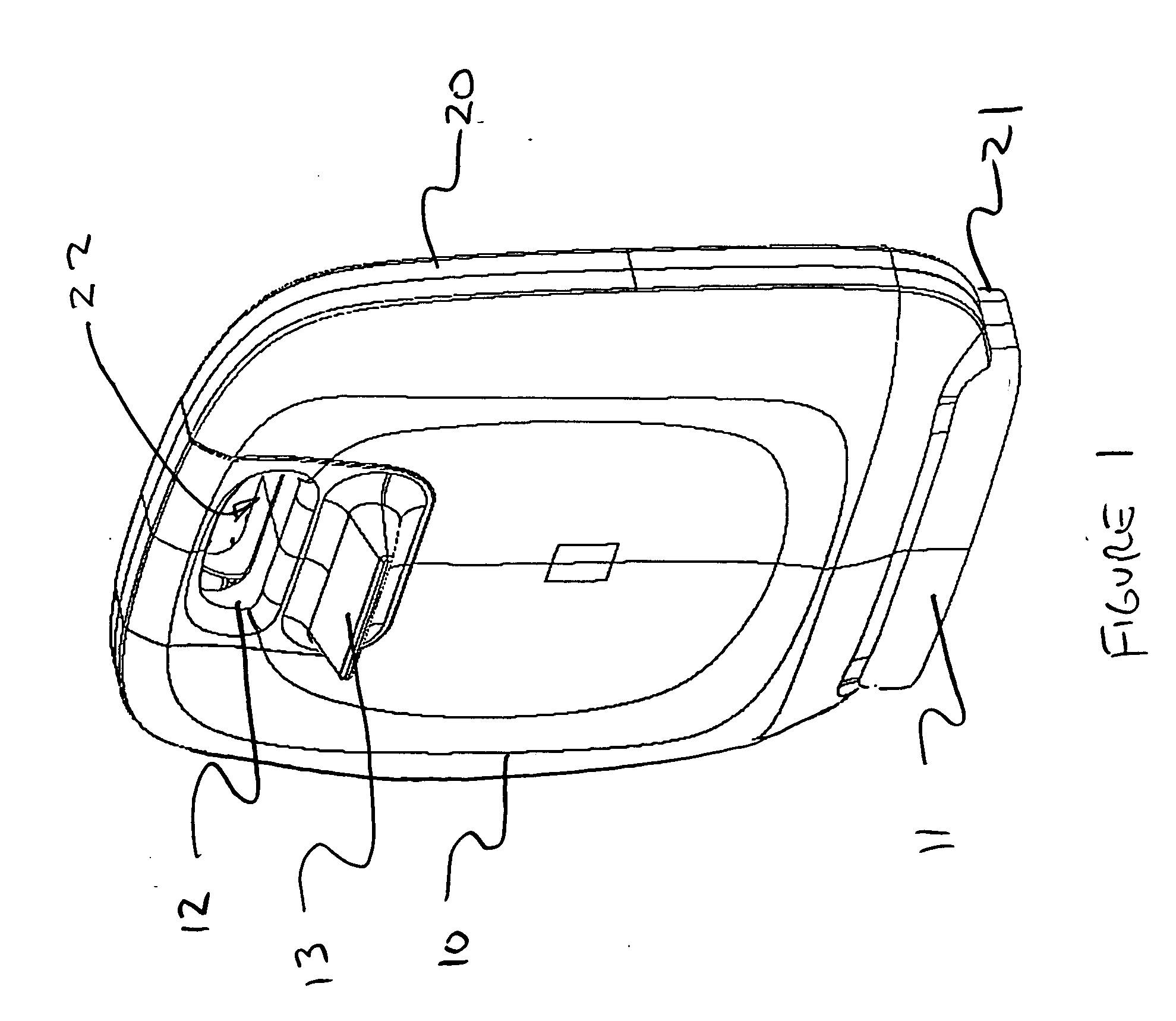

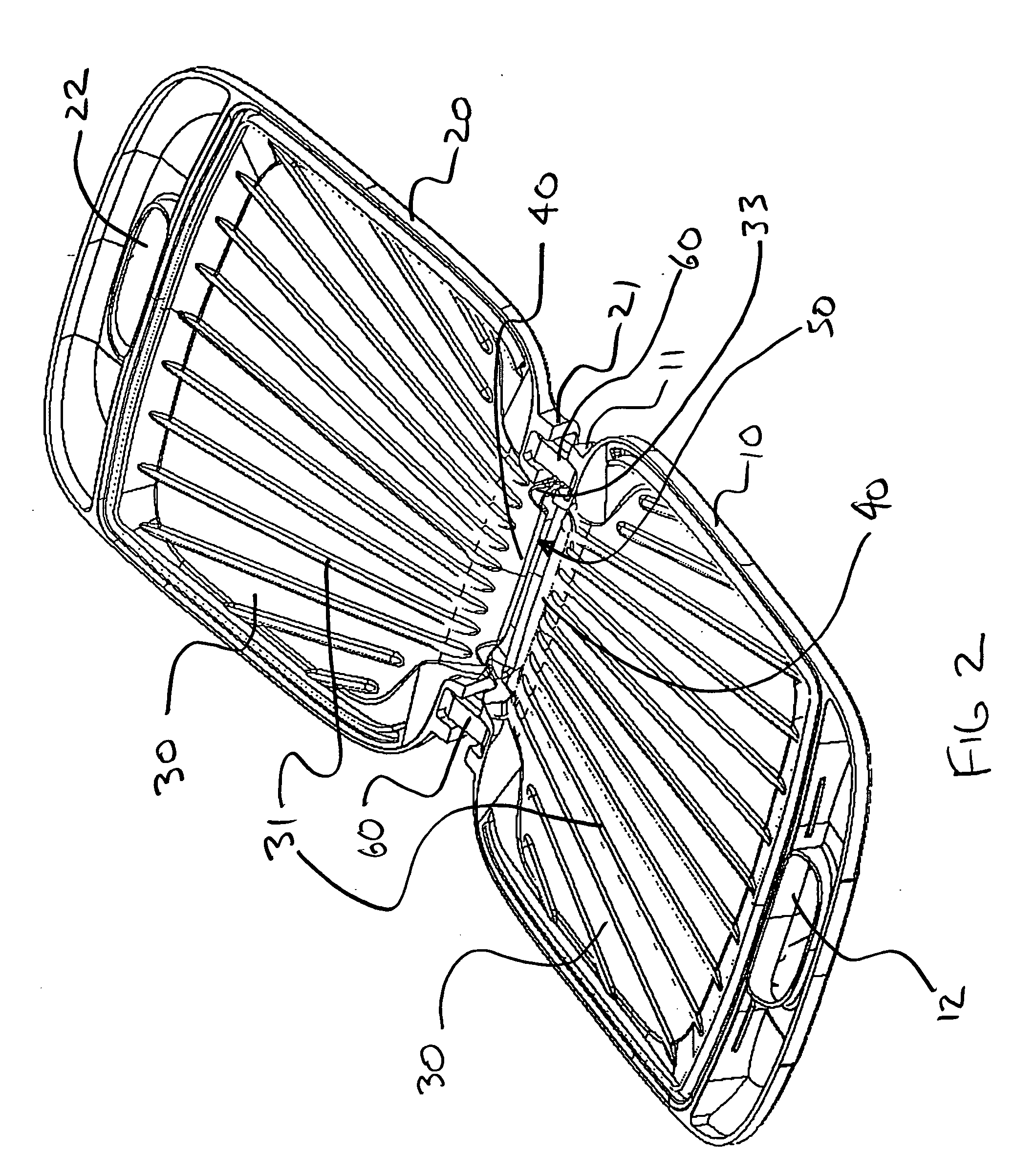

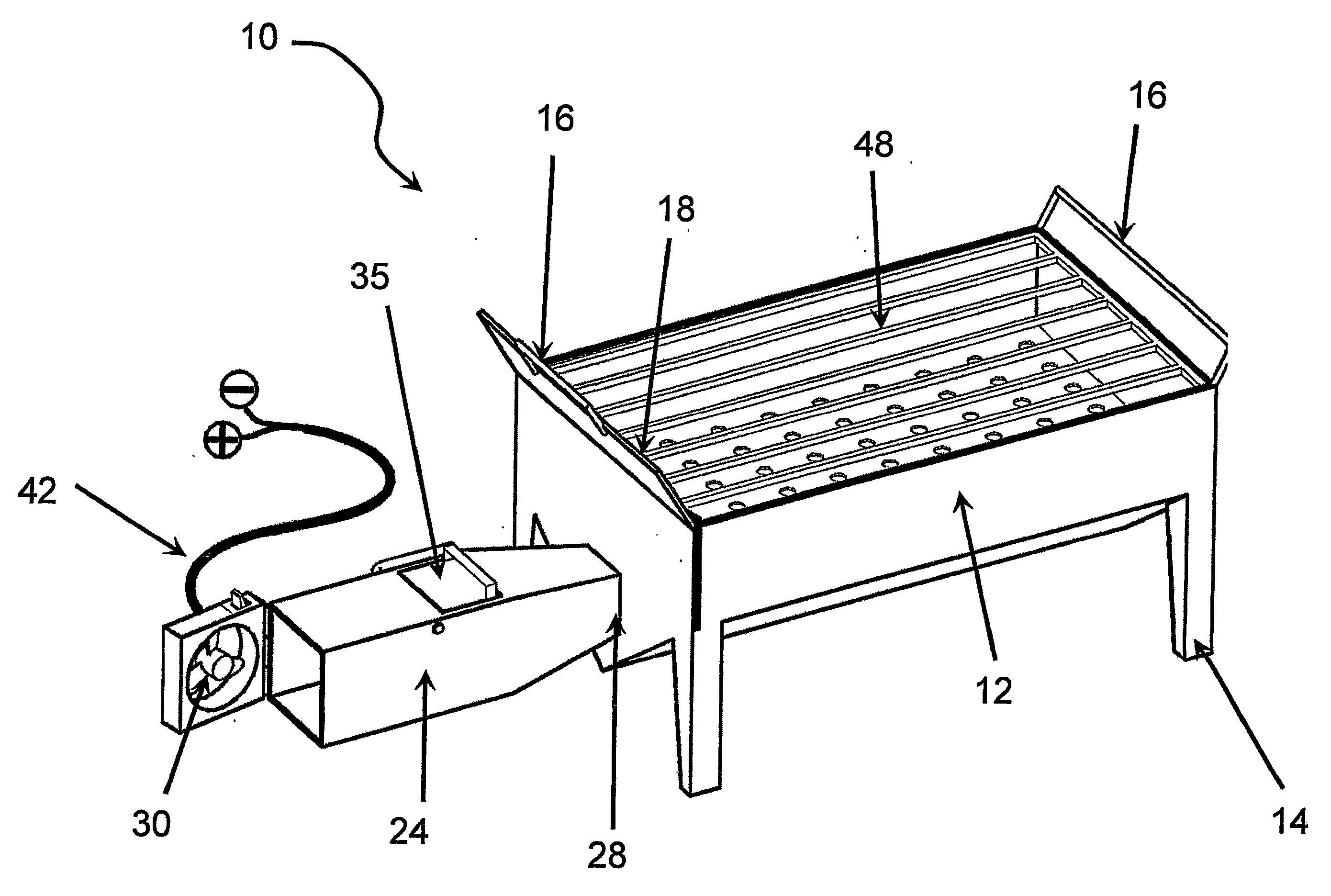

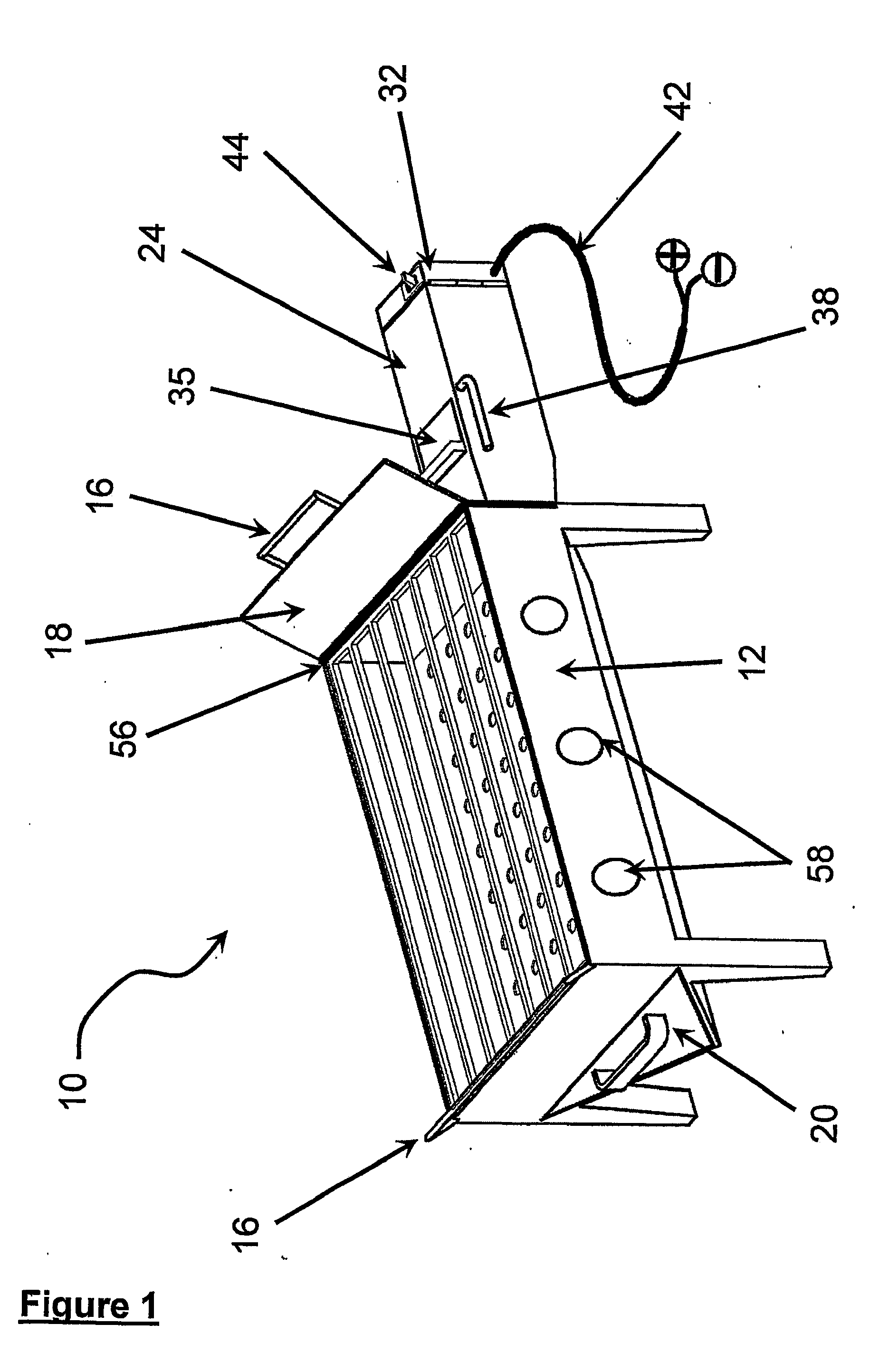

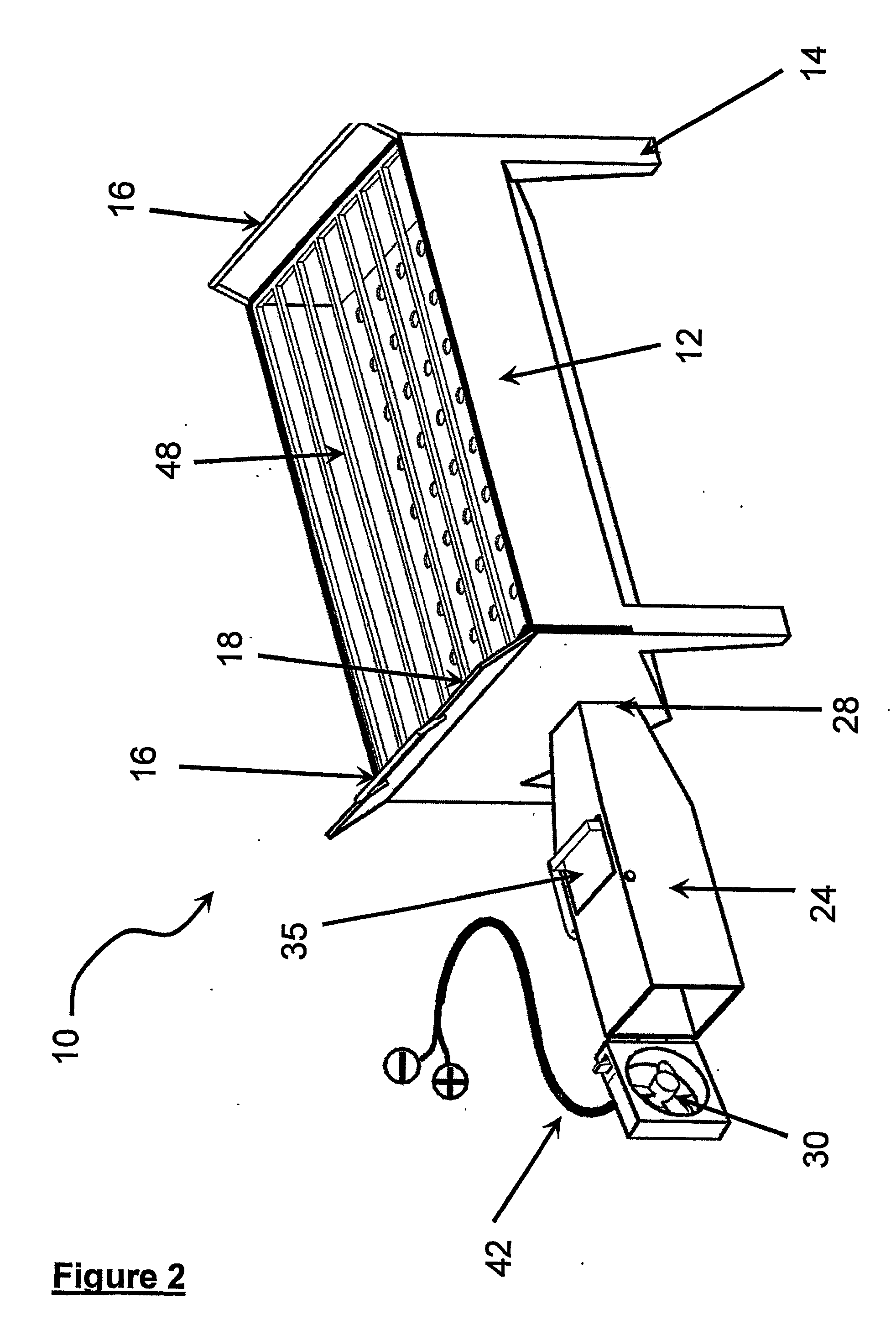

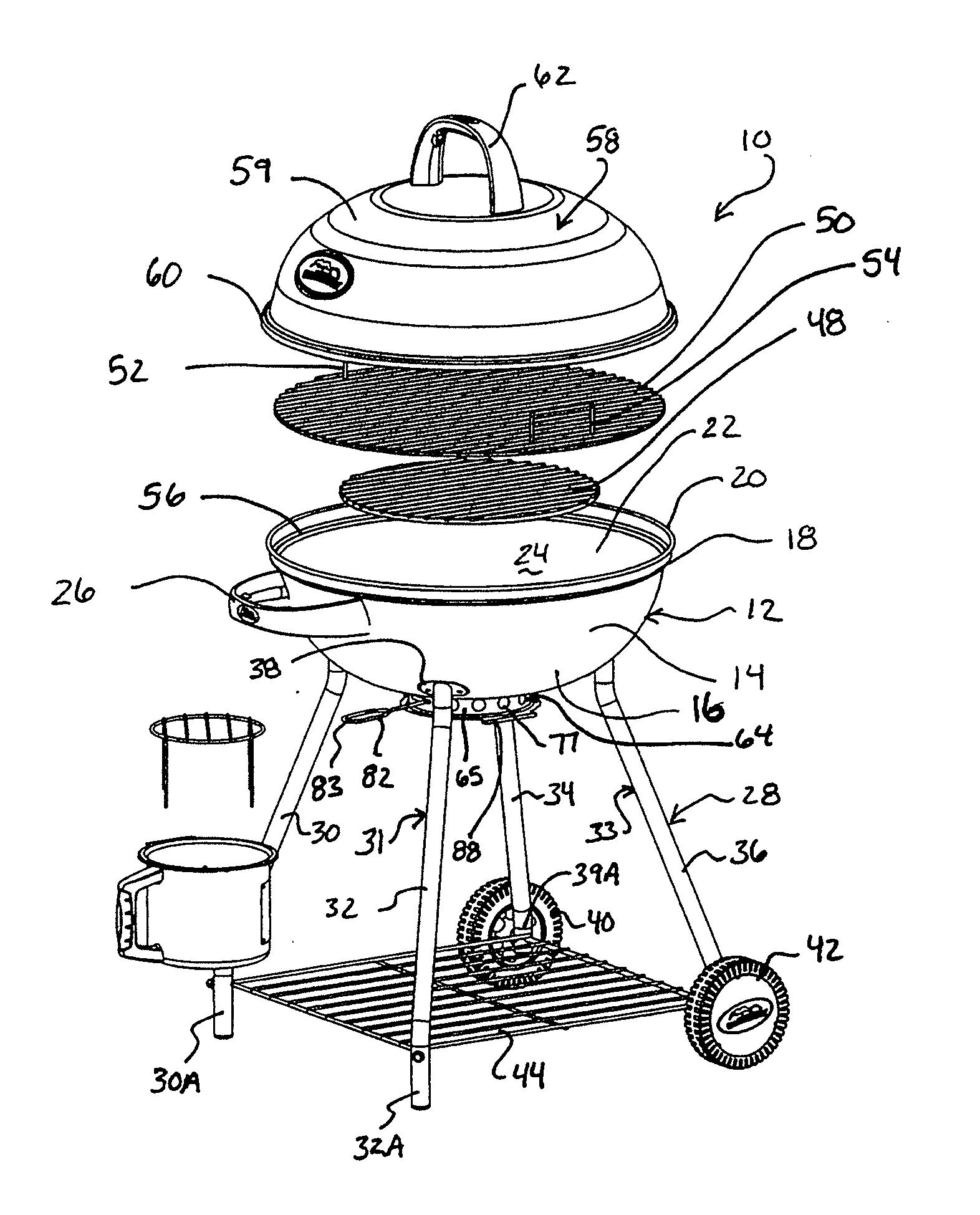

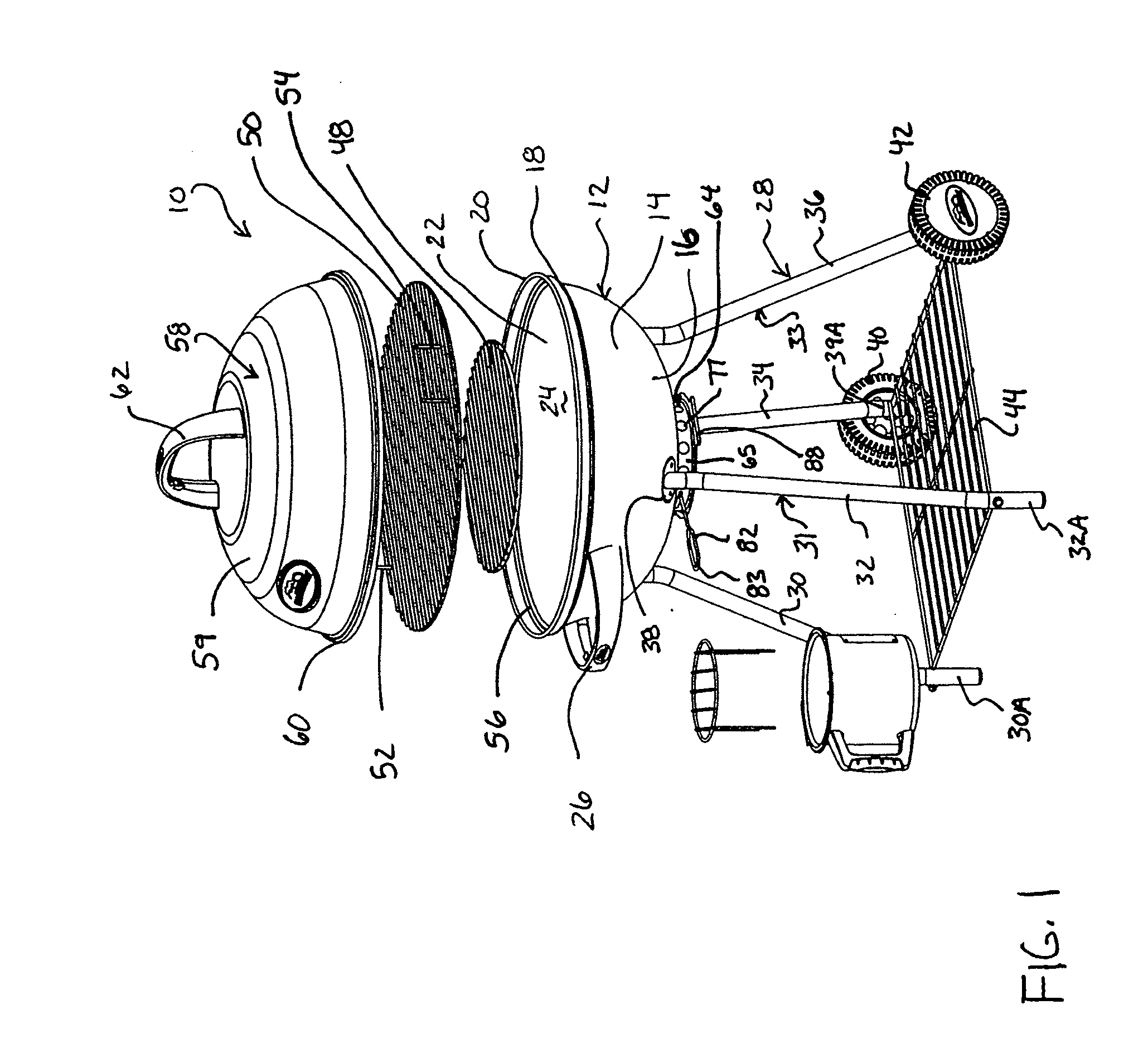

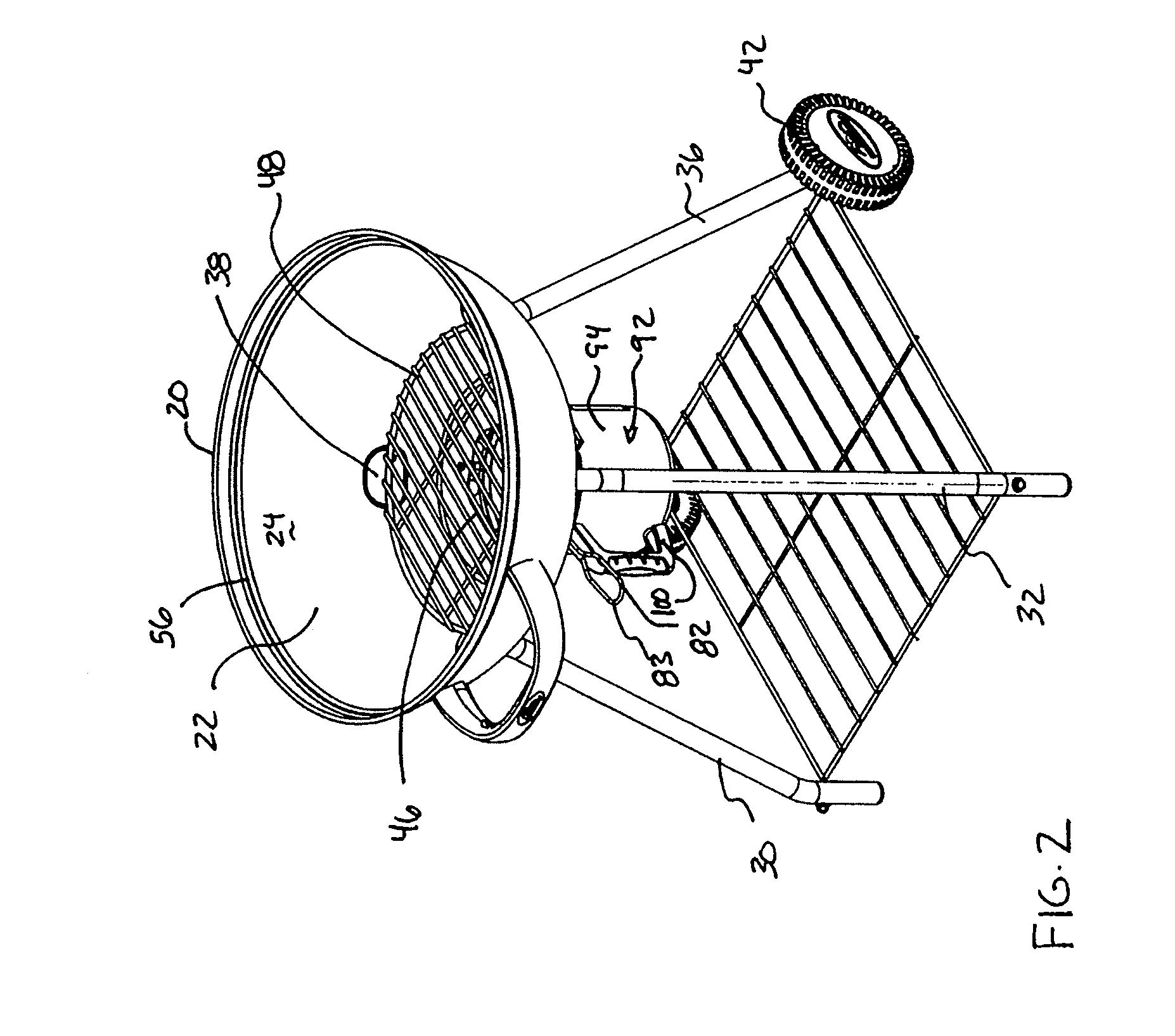

Portable Charcoal Grill With Incorporated Fan

InactiveUS20080168977A1Fast ignitionFast heatingTobacco treatmentLighting and heating apparatusEngineeringAirflow

A charcoal grill (10) providing a rapid ignition and heating of the charcoal, by means of an electric fan (30) that is coupled to the body (12) of the grill. The fan decreases the overall time required to heat the charcoal to proper cooking temperature by increasing the flow of air provided to the charcoal. The increased airflow created by the incorporated fan accelerates the firing-up and heating of the charcoal by channeling air across and through the charcoal. The decreased time required to heat the charcoal to a temperature suitable for cooking, further more ensures more efficient use of the charcoal.

Owner:DAUD FARID

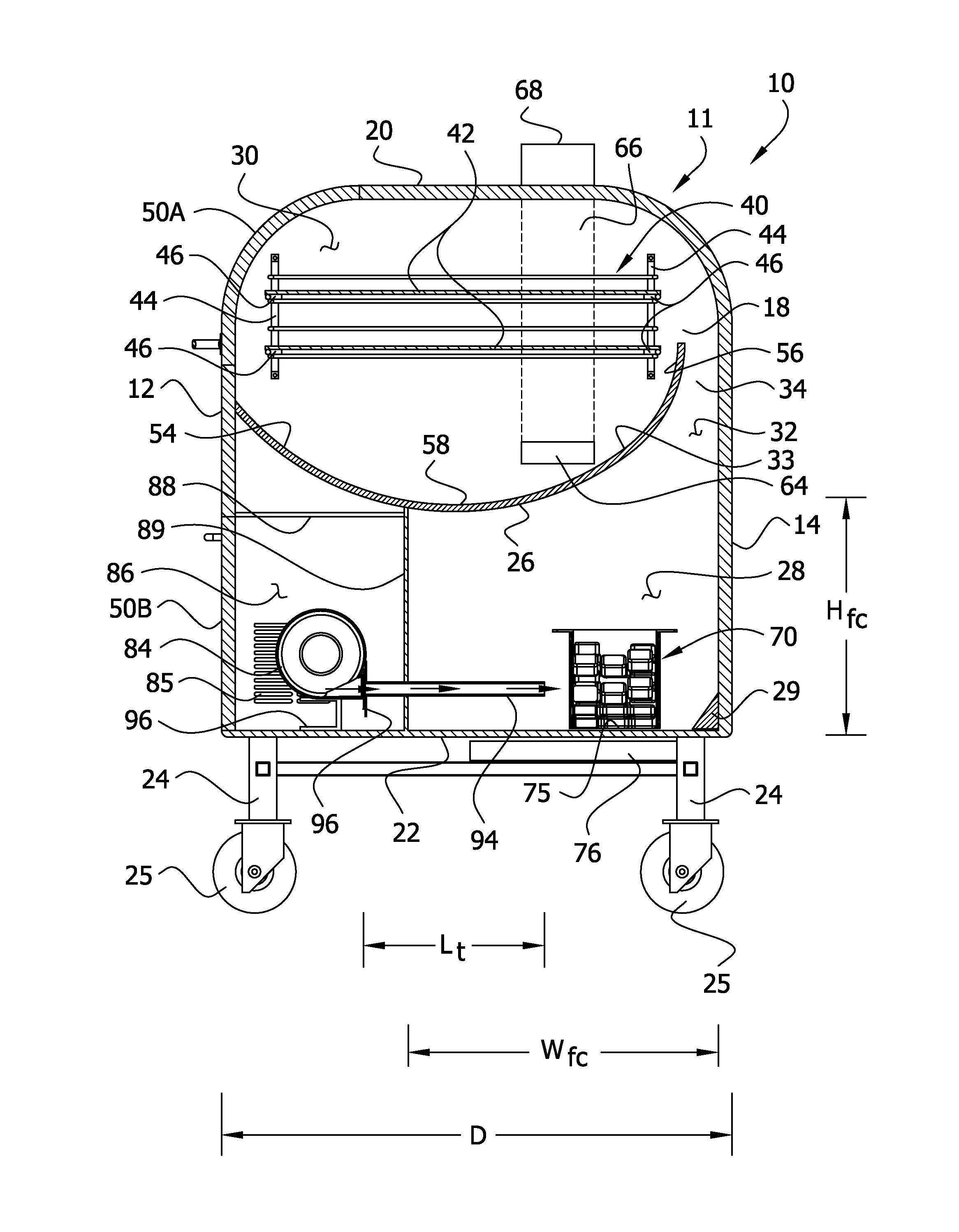

Convection oven

ActiveUS8833360B2Climate change adaptationCombustion-air/flue-gas circulation for stovesCombustion chamberCombustor

An oven for cooking foods includes a housing having a fire chamber and a cooking chamber disposed generally above the fire chamber. A vessel is receivable in the fire chamber and is adapted to hold combustible material therein to generate heat and smoke for cooking food in the cooking chamber. A blower is mounted on the housing. The blower is selectively operable to move air. A tube is attached to an outlet of the blower and extends into the fire chamber such that when the vessel is received in the fire chamber the tube extends to a position adjacent the vessel so that air from the blower is blown directly into the vessel without first passing a heating element. The oven does not require supplemental heat from a burner or similar heating element.

Owner:DAVID B KNIGHT & ASSOCS

Apparatus and method of automatically regulating intake of air into heating unit

InactiveUS6041771ACounteracting forceDischarge cleaningCombustion-air/flue-gas circulation for stovesCheck valvesCombustion chamberGas pressure

This invention relates to a novel apparatus and method for automatically and dynamically regulating the intake of air into the combustion chamber of a heating unit such as a wood burning stove, furnace, or fireplace to ensure even and efficient burning of fuel. More particularly, this invention pertains to a method and apparatus that uses negative gas pressure in the heating unit's flue, and no additional temperature or pressure sensors, to automatically and dynamically control a damper regulating intake of air into the combustion chamber in inverse relation to changes in negative flue gas pressure. This method and apparatus are especially useful in combination with a heating unit having two combustion chambers, one chamber for combustion of solid fuel and a second chamber for further combustion of exhaust gases and other byproducts from combustion in the first chamber. The two-stage combustion in a dual chamber heating unit is an especially dynamic situation where traditional static controls are not very effective.

Owner:HAYES CECIL JOSEPH

Cooking apparatus with a cooking fuel ignition facilitator and method of assembling and using same

InactiveUS20120090593A1Rapid and highly ensured ignition maintenanceEasy to igniteStoves/ranges foundationsCombustion-air/flue-gas circulation for stovesEngineeringTinder

A cooking fuel ignition assembly for an outdoor cooking apparatus as in a barbeque grill. The ignition assembly includes a tinder support combination of an ash can and tinder support stand. An operator inserts the tinder support stand within the ash can such that its lower spacer structure makes contact with the base of the ash can receptacle and the upper tinder platform is in the upper region of the ash can. The operator places tinder T on the upper surface of the tinder platform. The tinder combination with tinder is mounted in suspended fashion below an aperture in the grill base such that upon ignition of the tinder a flame extends up through, for example, an interface slide catch collar assembly and into an ignition relationship with supported cooking fuel above.

Owner:MASTERBUILT MFG LLC

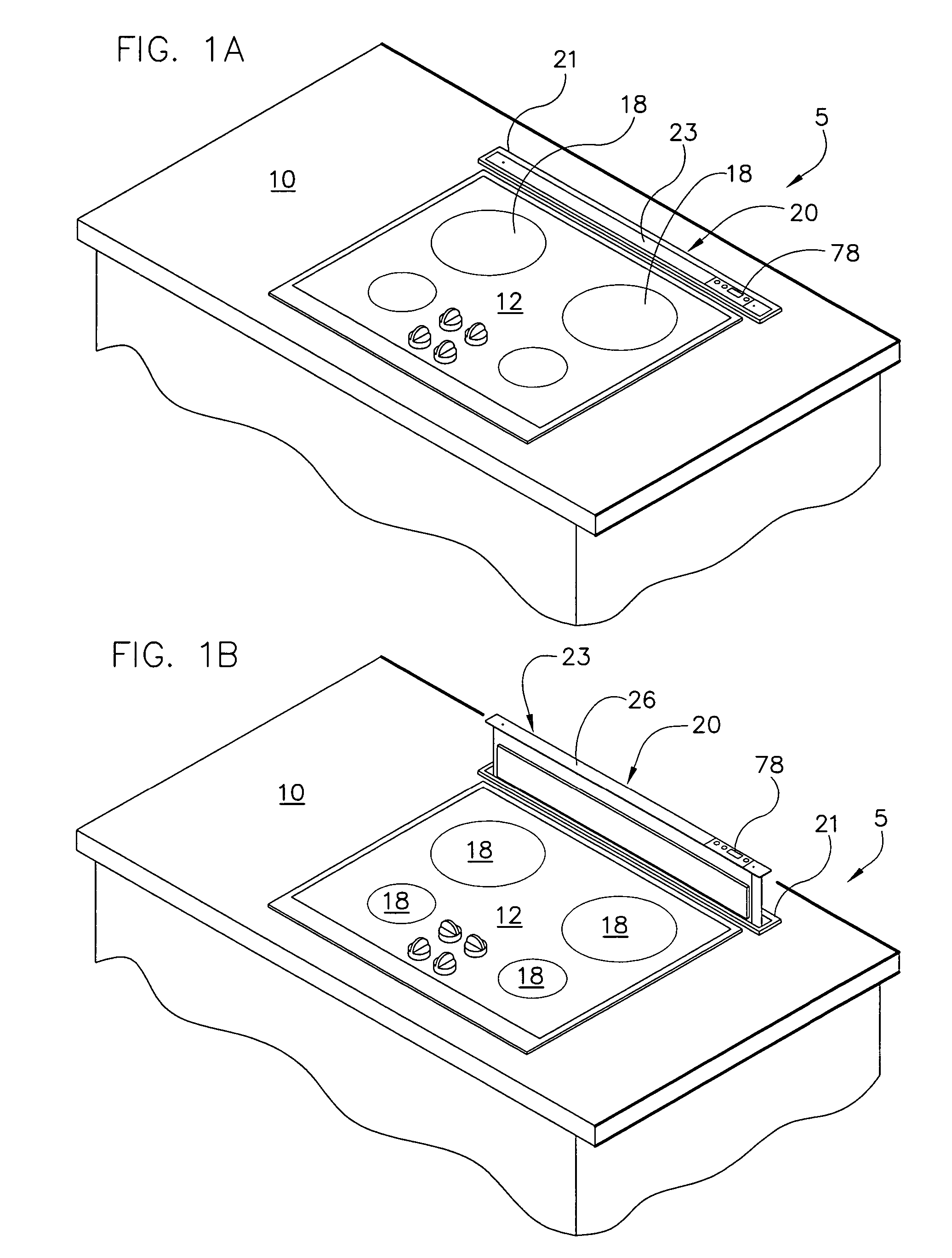

Ventilation system for a cooking appliance

A cooking appliance includes a frame having a bottom wall for supporting heating elements and a peripheral side portion that extends from and about an outer periphery of the bottom wall so as to define a chassis upon which is arranged a cooktop. The peripheral side portion includes a plurality of openings that lead into the chassis. A control box is mounted in the chassis for housing control elements and associated electronics. The control box includes a plurality of side walls, with at least one of the side walls being provided with a vent which opens into the chassis. A fan is mounted within the chassis wherein, when the fan is activated, a cooling airflow is developed, with a first portion being drawn directly into the chassis, while a second portion first enters the control box housing before being directed into the chassis. A cover can be disposed beneath the chassis to guide and disperse the airflow.

Owner:MAYTAG

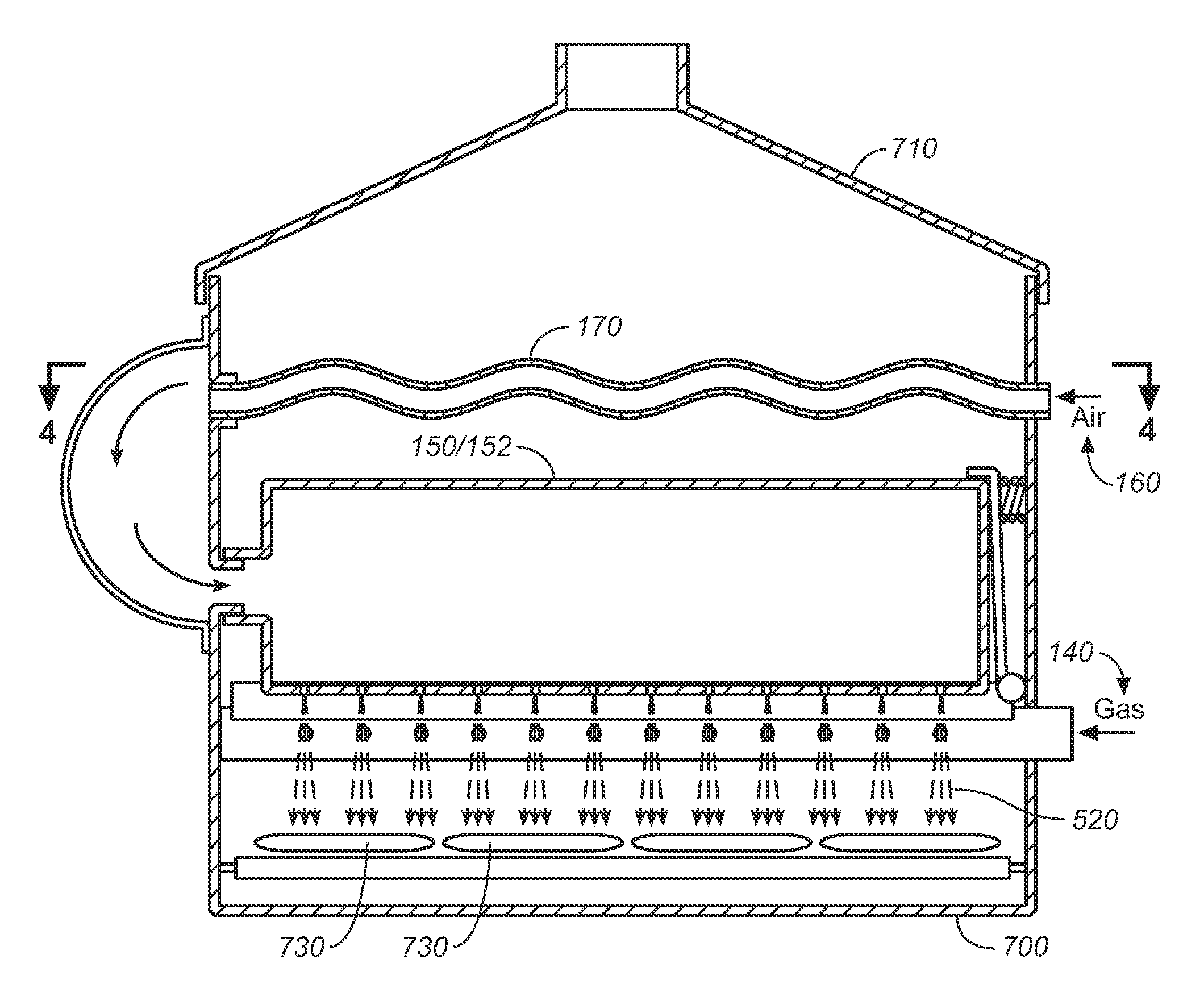

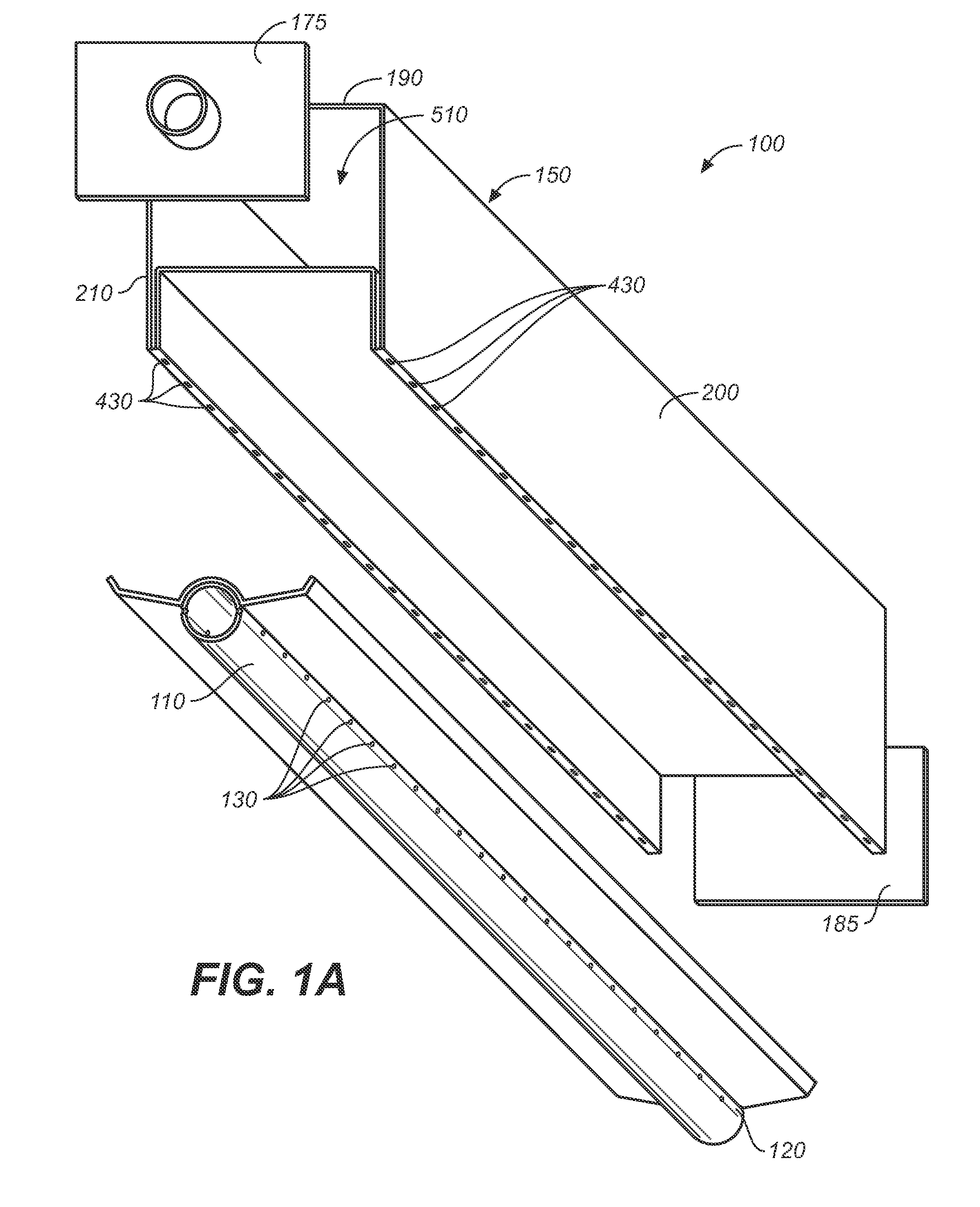

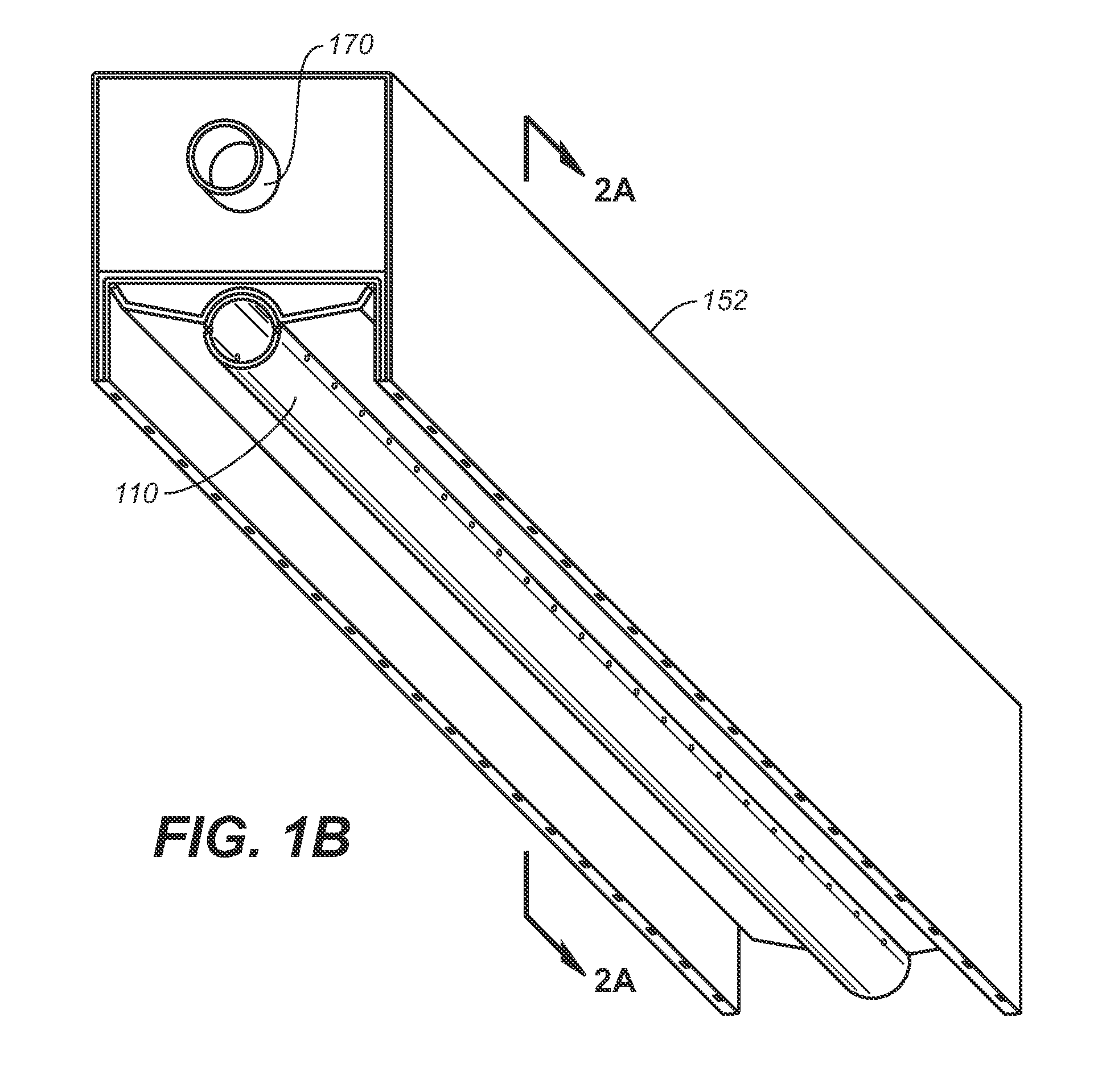

Broiler, conveyor oven, and toaster system with pressurized air guide for heat and flames

ActiveUS20110139140A1Improve energy efficiencyUnexpected energy savingLighting and heating apparatusFood processingCombustorBroiler chick

A cooking apparatus having a waste heat recovery system for incorporation into broilers, ovens, and toasters, the apparatus including a cooking chamber having a cooking platform, at least one air plenum disposed in the upper portion of the cooking chamber and having a plurality of air outlets for producing a focused forced air, a low pressure air source connected to the air plenums, a heating element or burner disposed under each of said air plenums, such that said curtain of focused forced air guides and directs heat from said heating element toward food product being cooked, and heat exchange pipes disposed between at least two of said air plenums. Radiant heat generated from the heating elements or burners rises in the cooking chamber and is retained between the air plenums to maximize heat transfer from the heated air to the heat transfer pipes, and thus to the low pressure air in the low pressure air system. The recycled heat enhances cooking.

Owner:NIECO CORP

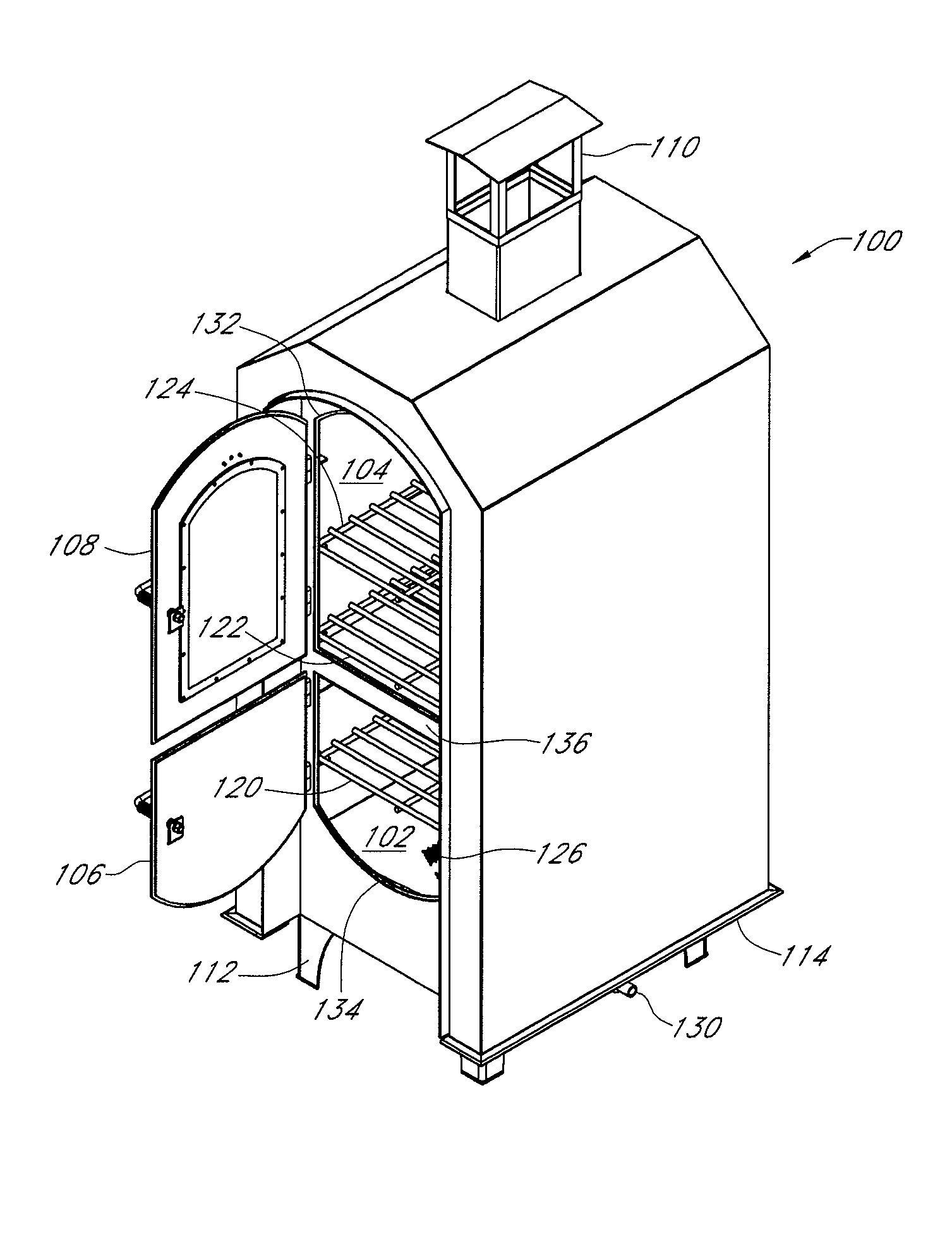

Fireplace oven

ActiveUS8061348B1Stoves/ranges foundationsStoves/ranges shelves or racksCombustion chamberEngineering

A portable outdoor cooking and decorative appliance including a combustion compartment and a separate oven compartment. The appliance can burn a variety of solid, liquid, and / or gaseous fuels. Material combustion products are inhibited from contacting food items inside the oven compartment to avoid contamination and transfer of undesired tastes, smells, and materials. The appliance is constructed to more efficiently transfer heat to the oven compartment to improve cooking speed and capability and reduce fuel needed. The appliance can include transparent doors such that users can view the interior of the appliance during use, without opening the doors.

Owner:RODRIGUEZ MARTIN

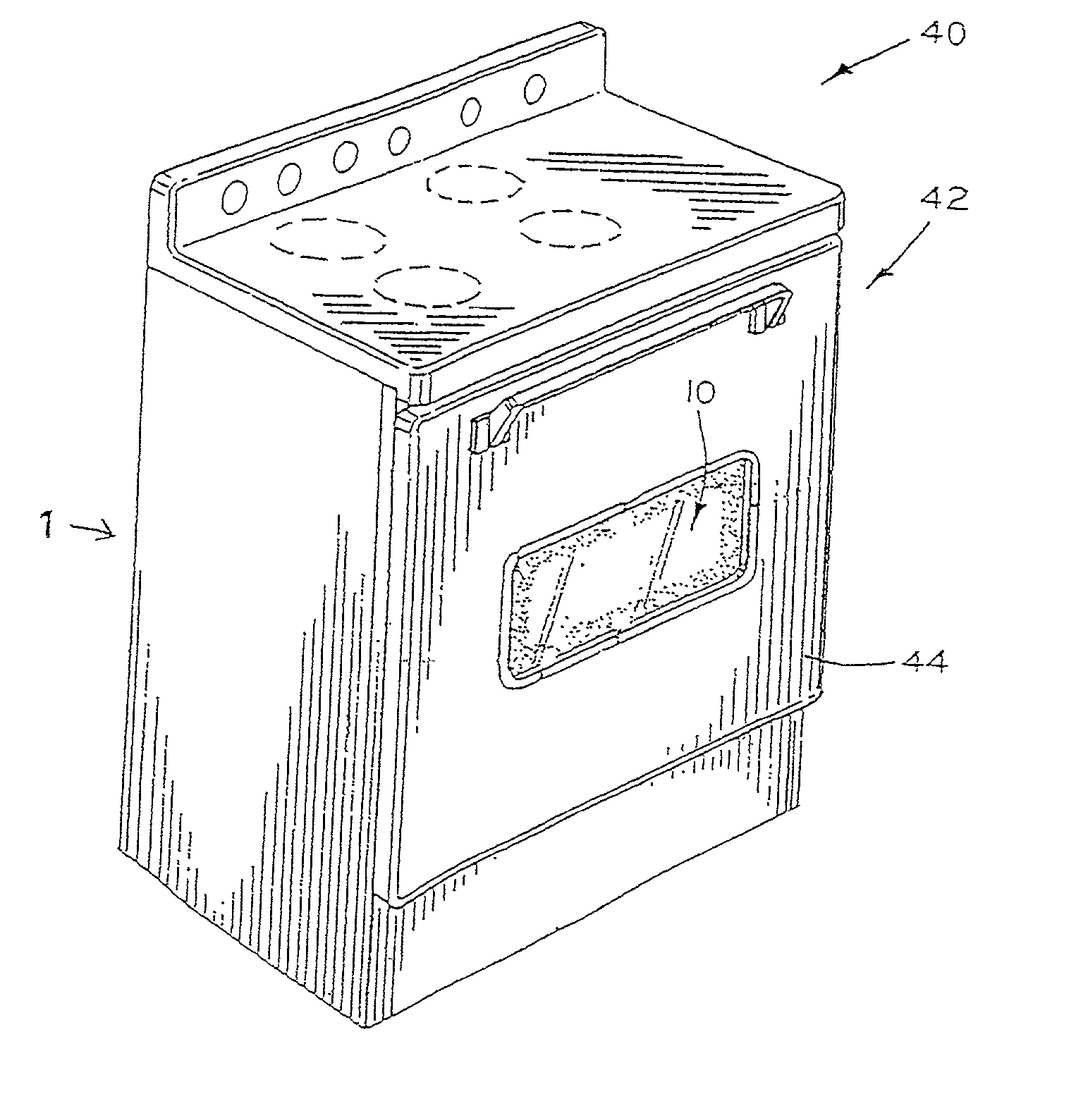

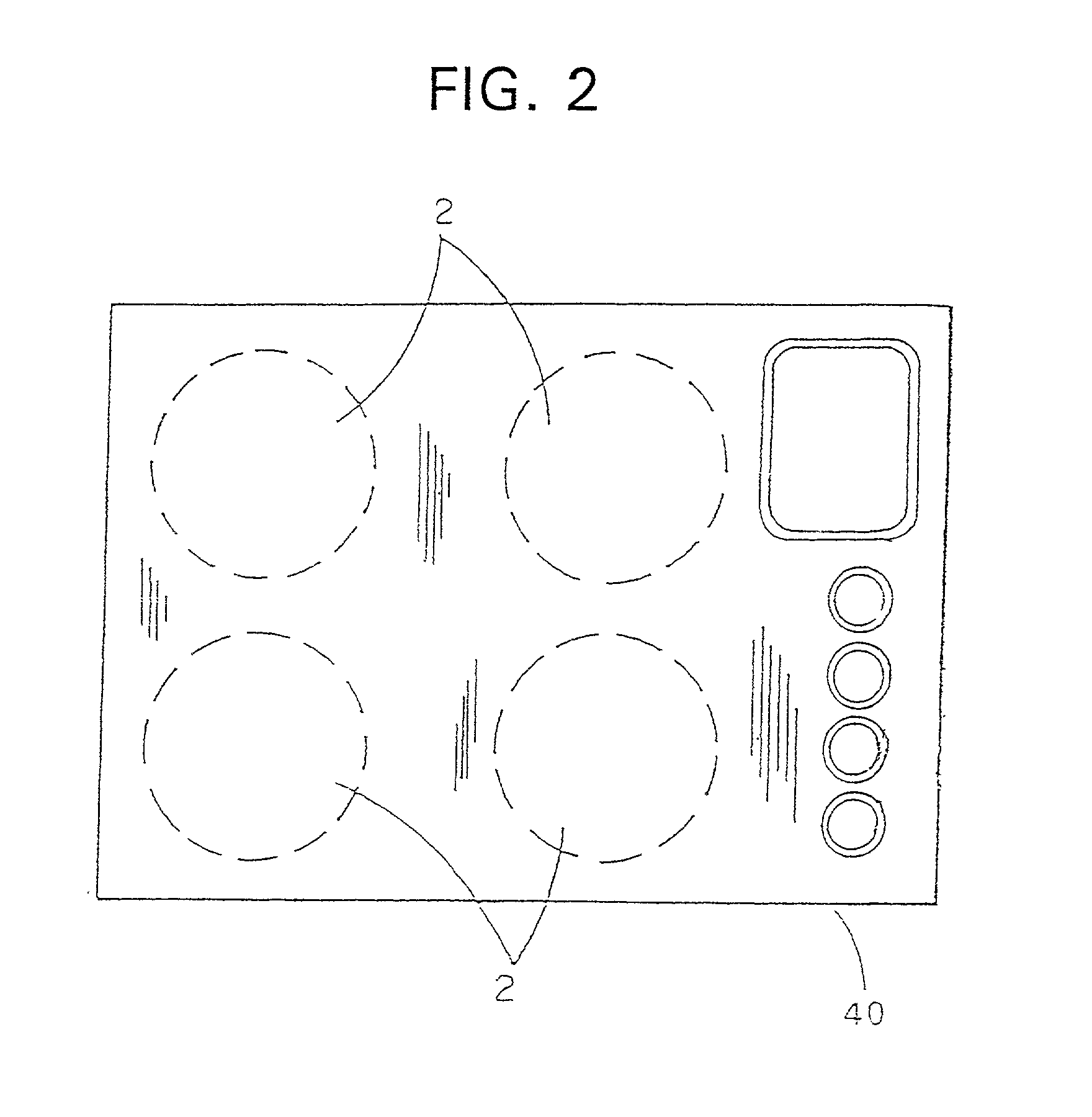

Cooking stove having a smooth-top glass ceramic cooktop, and a smooth-top glass ceramic cooktop with a glass ceramic cooktop cooking surface, method for production of stoves with smooth-top glass ceramic cooktops and smooth-top glass ceramic cooktops

InactiveUS20020026932A1Easy to cleanStoves/ranges foundationsLighting and heating apparatusGlass-ceramicCook stove

There is disclosed a stove, with a smooth-top cooktop, for cooking food, the stove comprising: a stove body; a smooth-top cooktop to cook food thereon; and at least one heat source disposed adjacent to a cooking surface of said cooktop. The cooktop comprises glass ceramic with an upper layer and an inner layer, with the upper layer comprising a different glass ceramic material than the inner layer. The upper layer is configured to minimize surface defects such as fissures, cracks, pits, and pores. The inner layer is configured to provide resistance to impact to the upper layer from cooking utensils being dropped onto the upper layer of the smooth-top cooktop, and at least the inner layer of the glass ceramic being configured to obscure visibility of the at least one heat source, through the upper layer of the glass ceramic.

Owner:SCHOTT AG

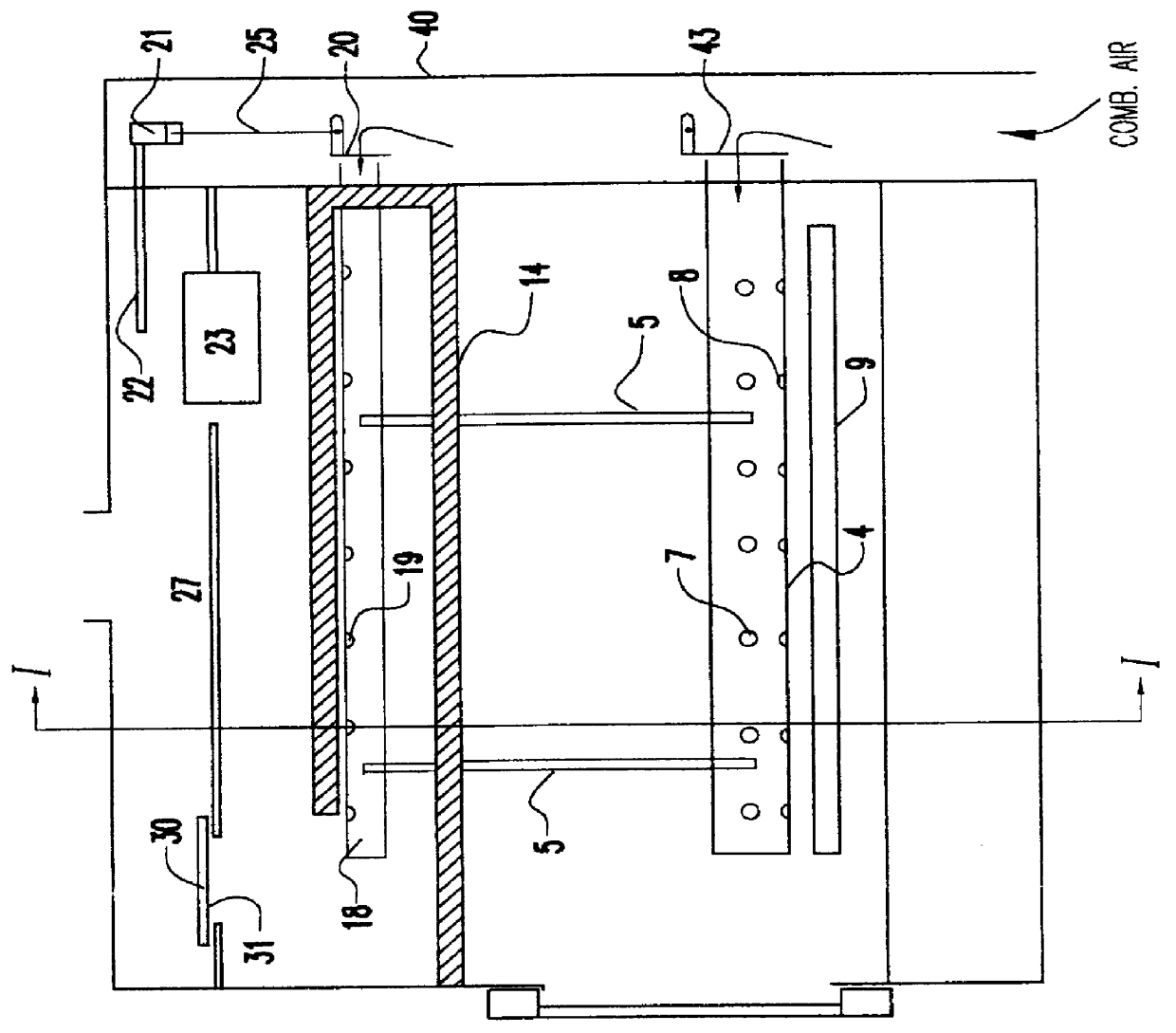

Combustion Apparatus for Solid Fuel

InactiveUS20080041357A1Emission reductionShort structureCombustion-air/flue-gas circulation for stovesIndirect carbon-dioxide mitigationSolid fuelHearth

A combustion apparatus for the burning of solid fuel using a plurality of secondary combustion zones is disclosed. The combustion apparatus includes primary and secondary air inlets, an inclined hearth and a unique second air source which washes up a window in the combustion apparatus creating a floating flame effect and rendering the window self-cleaning. A series of baffles define a secondary combustion pathway which optimizes secondary combustion of exhaust gasses and particulate matter. Coaxial rear and top direct venting apparatus are also disclosed. The combustion apparatus provided combusts a wide range of solid fuel at a high level of efficiency.

Owner:BROWN STEPHEN CHARLES

Combustion system

InactiveUS6067979AAvoid quenchingIncrease gasification rateSolid bar grateCombustion-air/flue-gas circulation for stovesCombustion systemCombustion chamber

A combustion system includes a primary combustion chamber divided into left and right sides by fuel-retaining standards defining a canyon or void extending into a secondary combustion chamber is provided. The floor of the primary combustion chamber and the fuel-retaining standards direct the burning solid fuel toward the lower part of the canyon, while at the same time retaining the non-burning solid fuel on either side of the fuel-retaining standards. The combustion system further includes an air delivery system having a lower air tube supplying high and low velocity air and an upper air tube. The lower air tube is positioned proximate to a firebox floor, while the upper air tube is positioned within the secondary chamber. Automatic air setting mechanisms are provided so that proper air settings can be maintained during various phases of a fire. The combustion system further includes a loading door having openings and a bypass system preventing the loading door from being fully closed unless the bypass is in the completely closed position. The secondary combustion chamber includes at least fuel protecting baffles and a secondary combustion chamber ceiling which extends partially over the entire length of the secondary combustion chamber or includes openings. A catalyst mounting system which minimizes canning and masking and a radiant catalyst heating system are also provided.

Owner:JAASMA DENNIS R

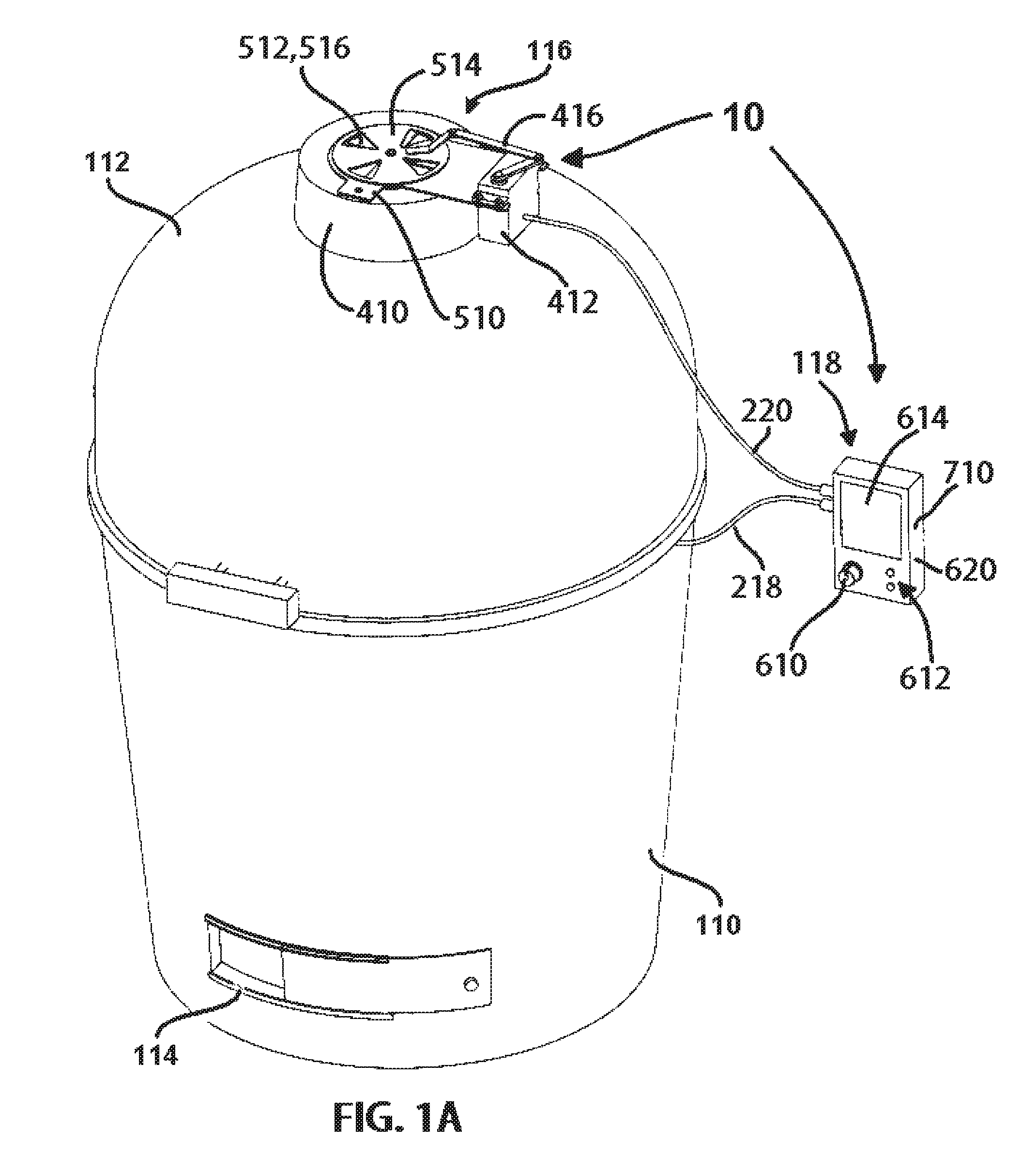

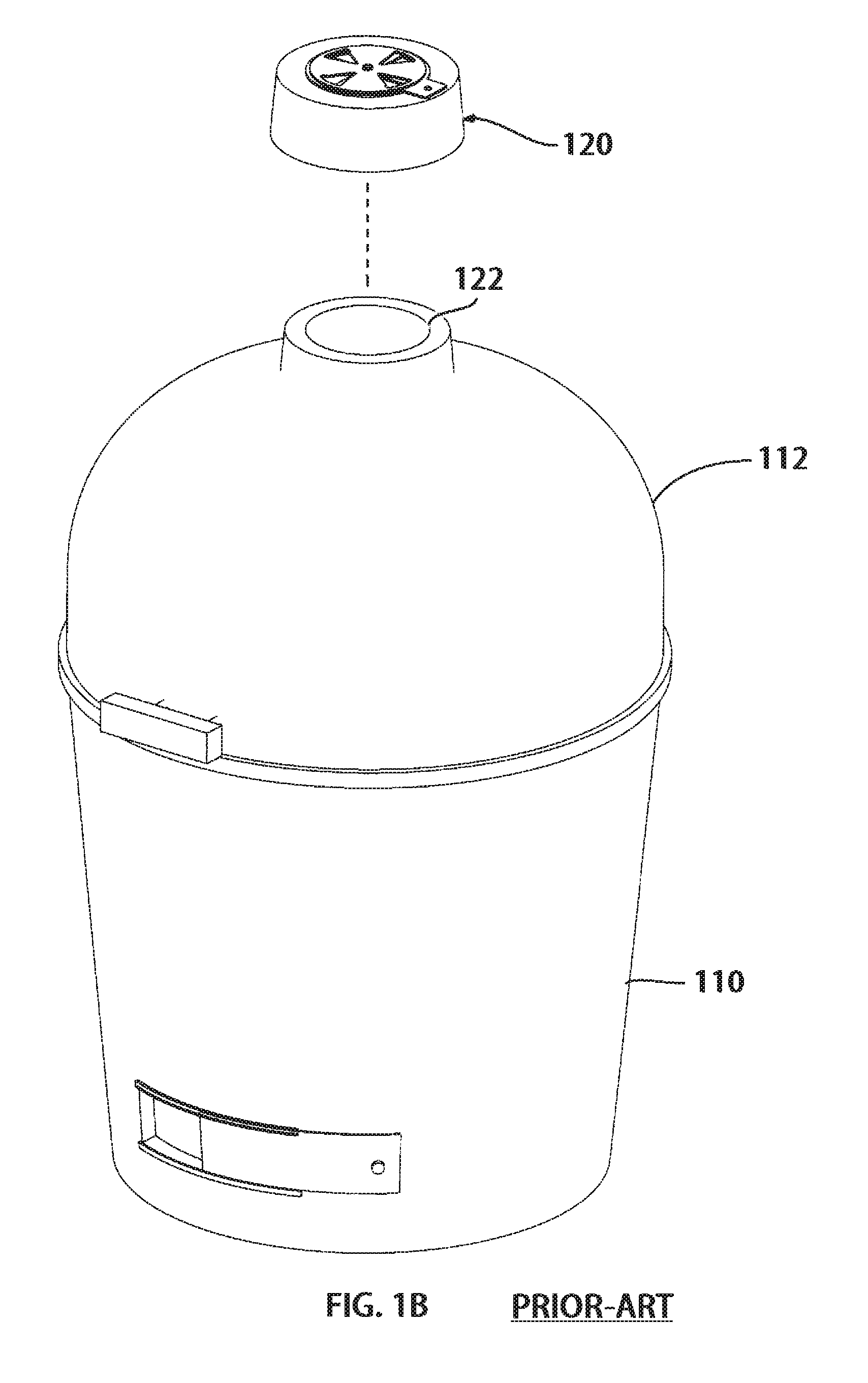

Automated temperature control system for a solid-fueled cooker

ActiveUS9427107B2Eliminate needEasy to operateLighting and heating apparatusTemperature measurement in household appliancesTemperature controlControl system

An automated temperature control system for a barbecue grill or other structure comprises an automated damper assembly coupled to a vent of said grill, which damper assembly opens and closes selectively to adjust the flow passage area of the grill's vent. The system further comprises an operating area temperature probe for communicating the temperature of the operating area of the grill to the automated damper assembly, such that the automated damper assembly may maintain a user-specified target operating temperature by way of affecting combustion rates within the grill. A remote control may also be provided to allow the user to input a desired temperature for the system to obtain and / or to change temperature information for the grill or other structure.

Owner:IOT CONTROLS LLC

Heating apparatus with fan

InactiveUS20120031392A1Reduced temperature external surfaceLiquid heating fuelCombustion-air/flue-gas circulation for stovesInterior spaceCombustion chamber

Owner:DENG DAVID

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com