Patents

Literature

60 results about "Tinder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tinder is easily combustible material used to start a fire. Tinder is a finely divided, open material which will begin to glow under a shower of sparks. Air is gently wafted over the glowing tinder until it bursts into flame. The flaming tinder is used to ignite kindling, which in turn is used to ignite the bulk material, to produce a fire.

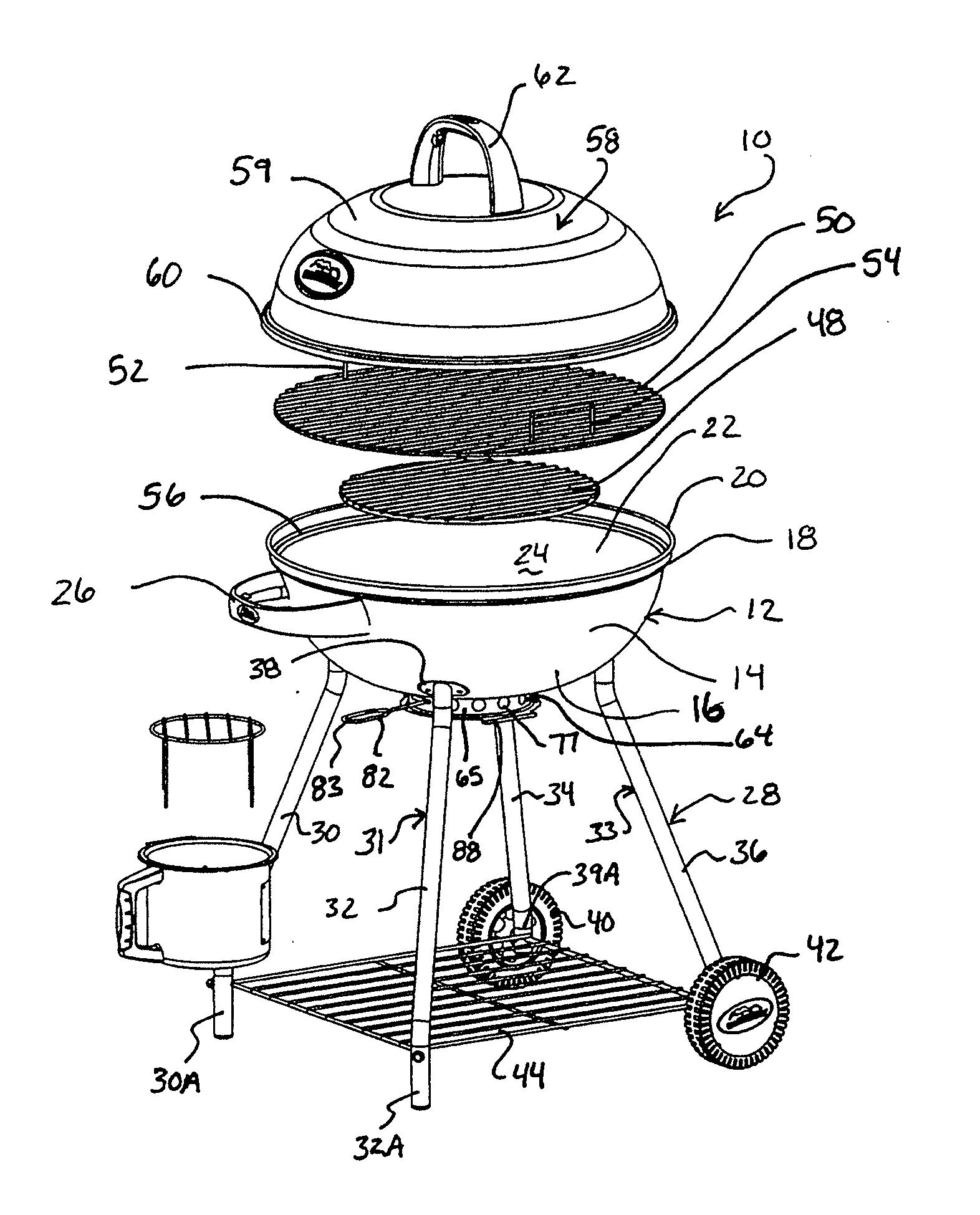

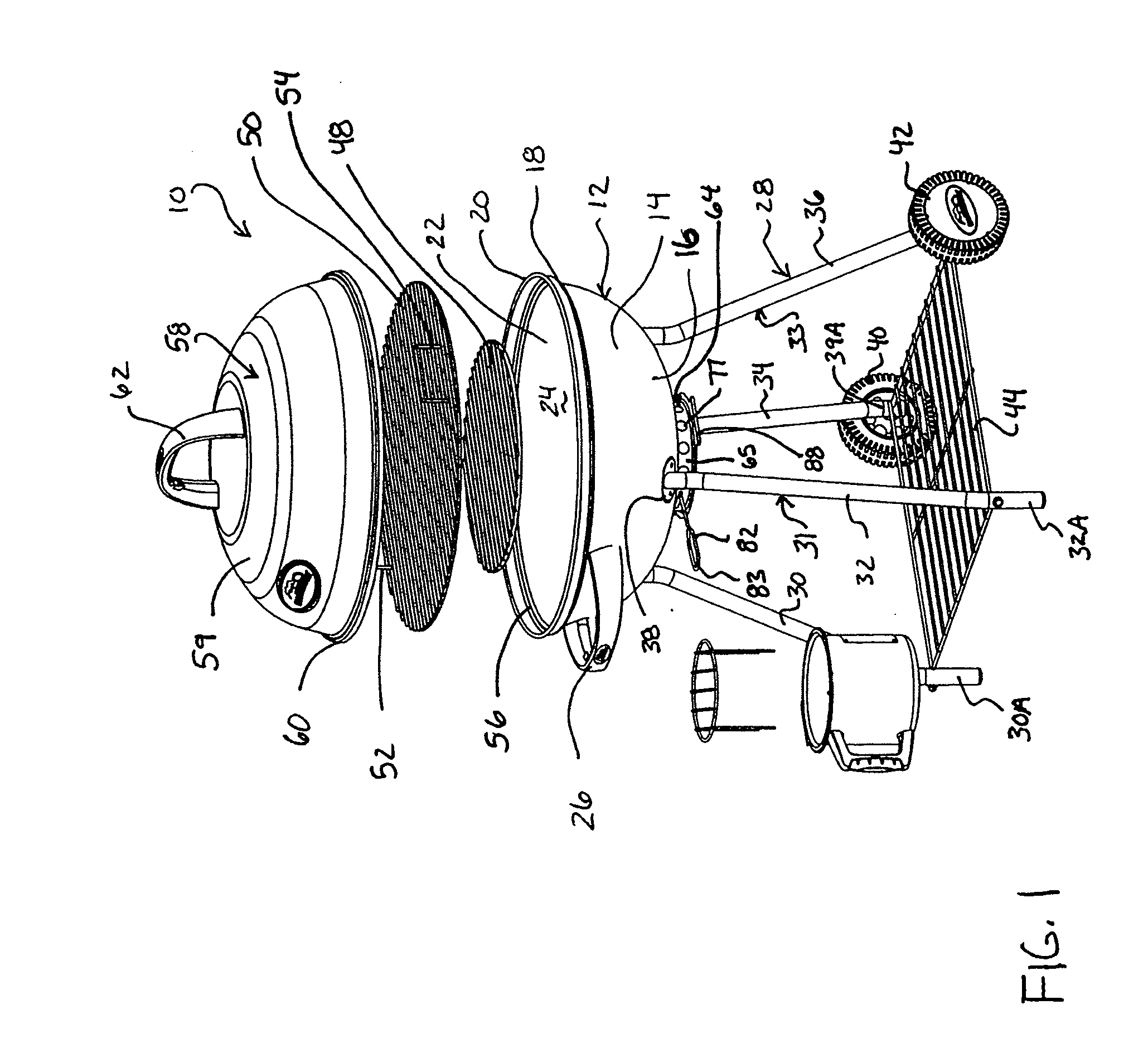

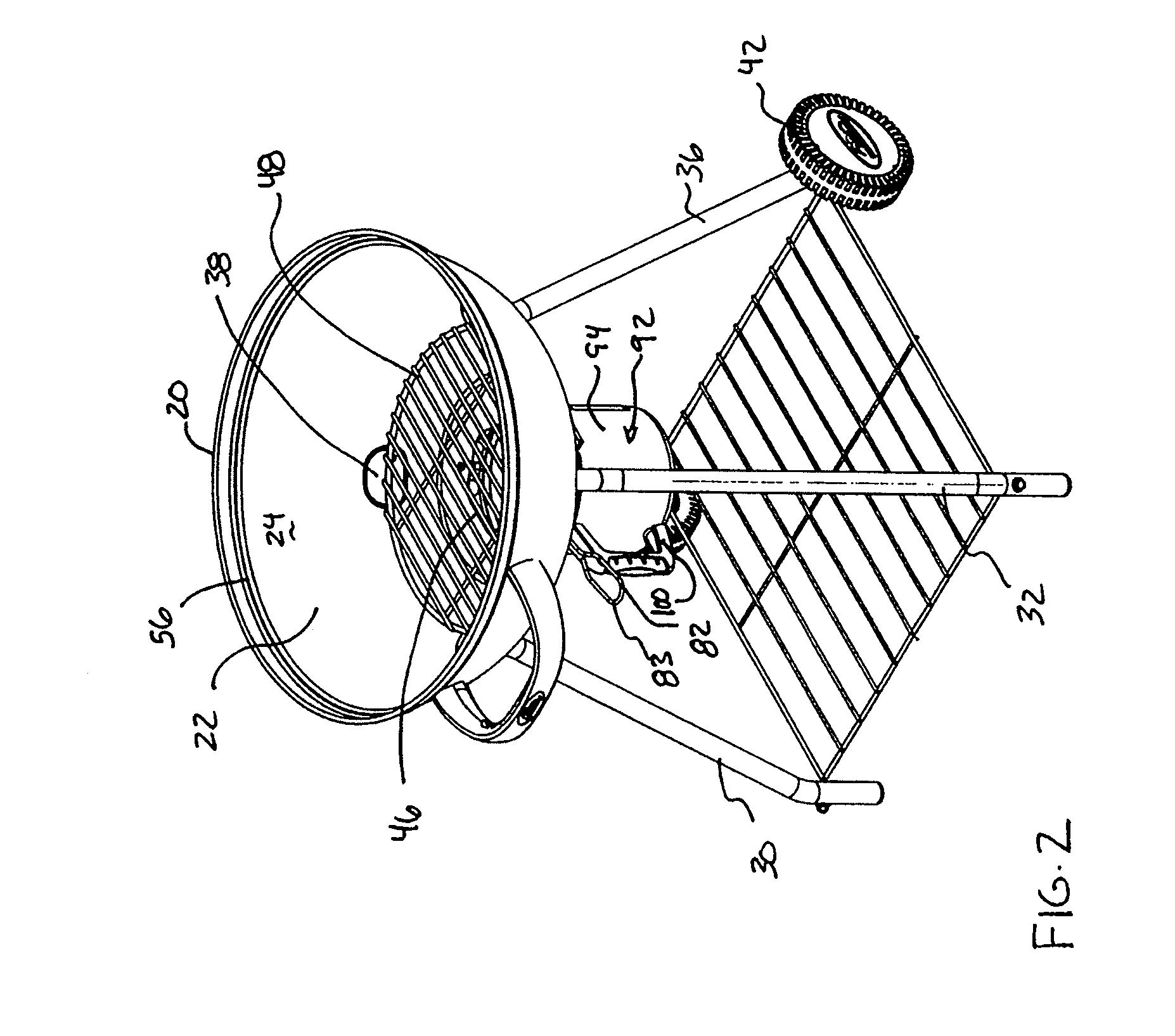

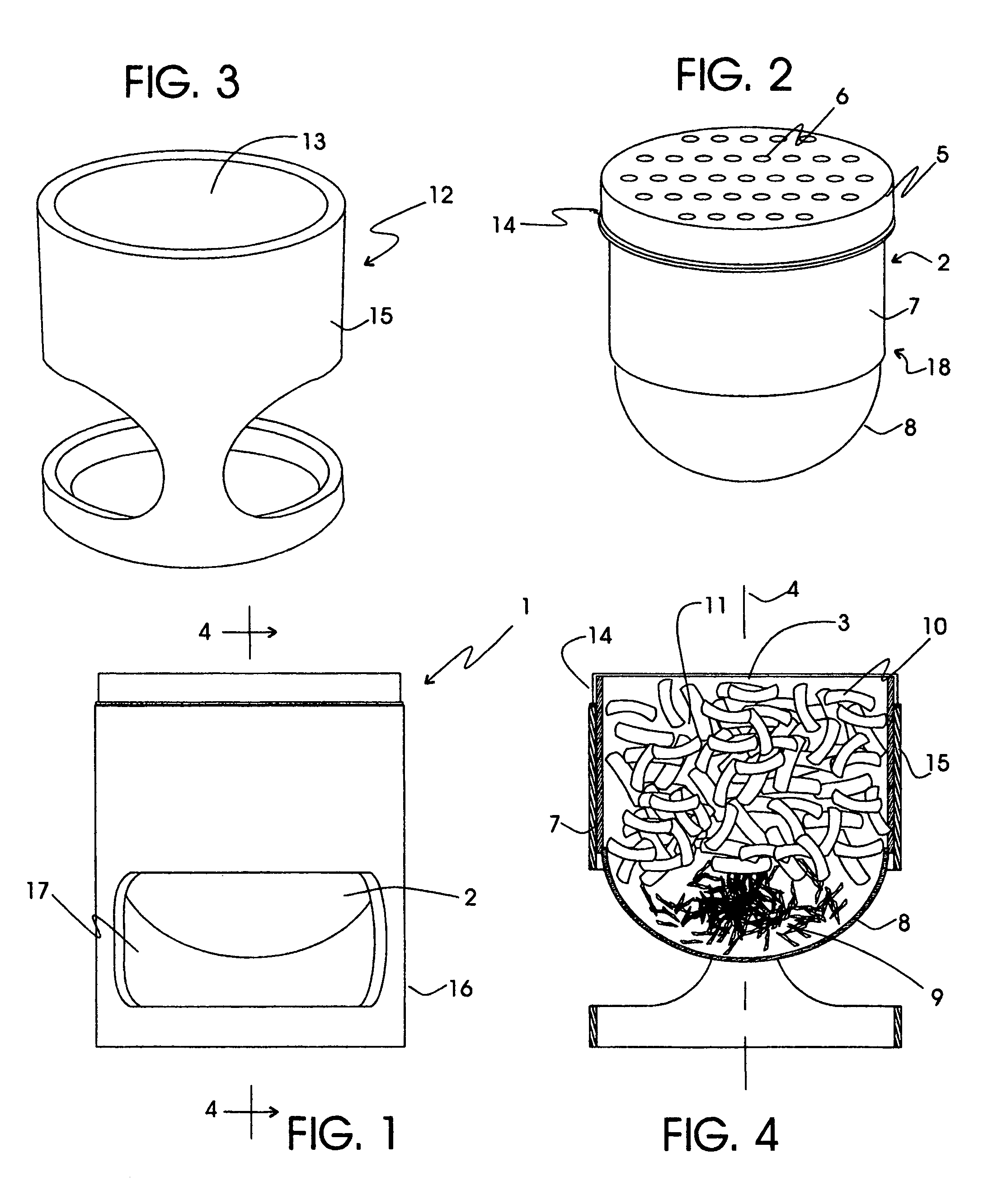

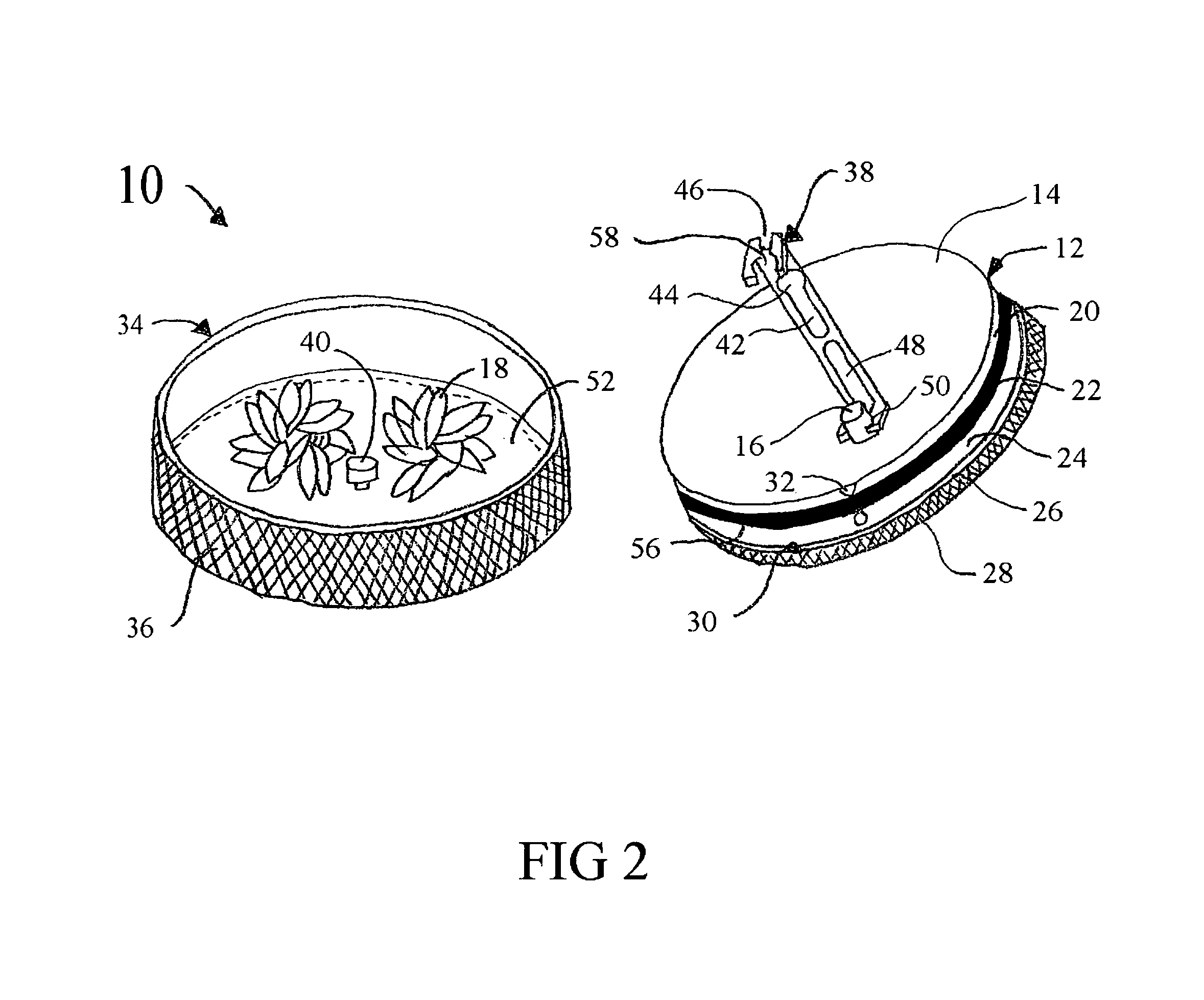

Cooking apparatus with a cooking fuel ignition facilitator and method of assembling and using same

InactiveUS20120090593A1Rapid and highly ensured ignition maintenanceEasy to igniteStoves/ranges foundationsCombustion-air/flue-gas circulation for stovesEngineeringTinder

A cooking fuel ignition assembly for an outdoor cooking apparatus as in a barbeque grill. The ignition assembly includes a tinder support combination of an ash can and tinder support stand. An operator inserts the tinder support stand within the ash can such that its lower spacer structure makes contact with the base of the ash can receptacle and the upper tinder platform is in the upper region of the ash can. The operator places tinder T on the upper surface of the tinder platform. The tinder combination with tinder is mounted in suspended fashion below an aperture in the grill base such that upon ignition of the tinder a flame extends up through, for example, an interface slide catch collar assembly and into an ignition relationship with supported cooking fuel above.

Owner:MASTERBUILT MFG LLC

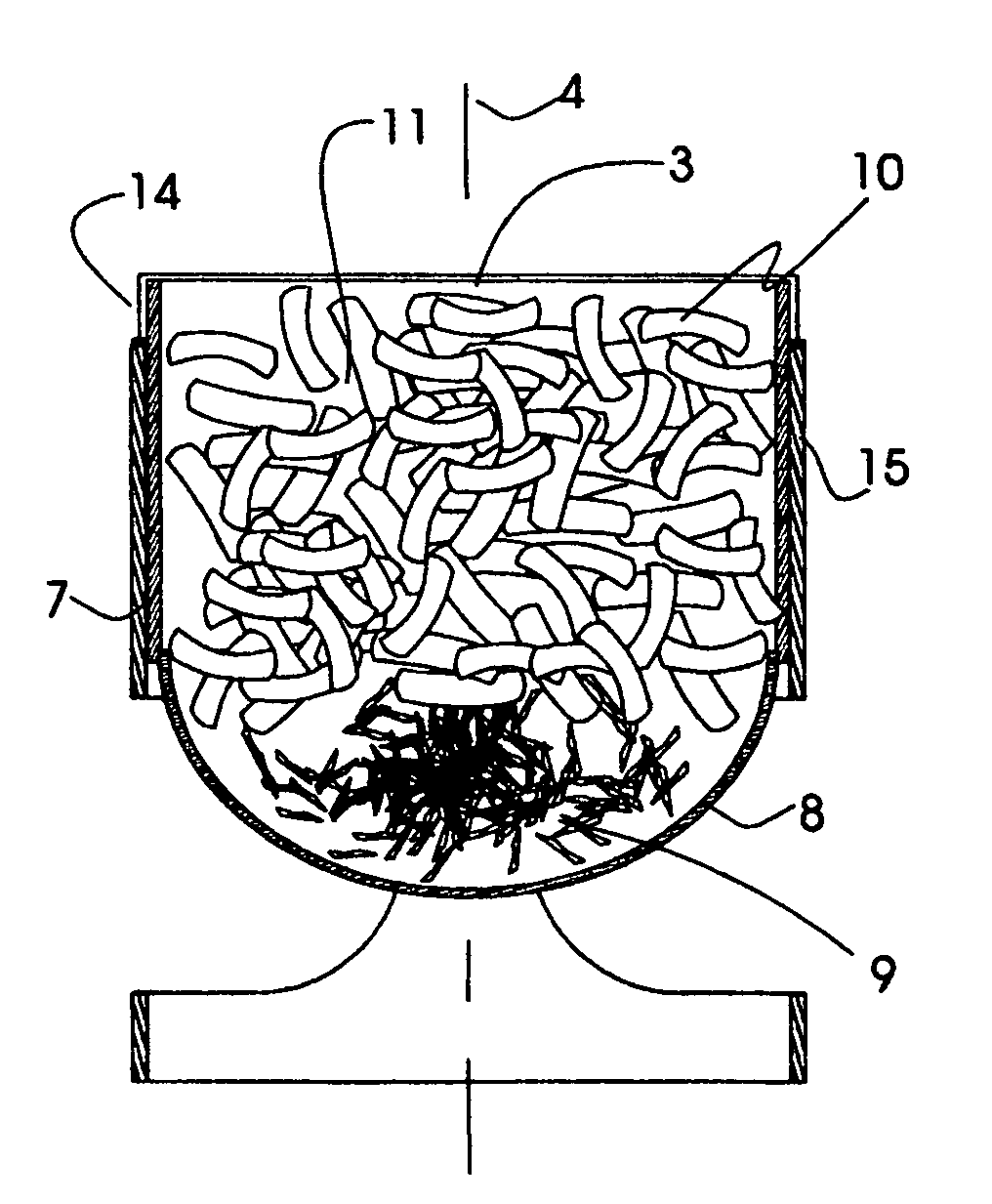

Smoke generator cartridge for food processing

InactiveUS6971305B1Convenient lightingAir-treating devicesMilk treatmentTinderMechanical engineering

An assembly for generating a continuous stream of smoke for food processing such as barbecue cooking includes a reusable cartridge holder for holding upright a disposable smoke generating cartridge. The cartridge includes an outer covering enclosing a chamber. The covering includes a perforated top, a non-perforated upper portion designed to not burn during the process and a readily combustible lower portion. At the bottom of the chamber is a readily combustible tinder material that is easily set afire by the burning lower portion. The balance of the chamber is filled with wood pellets that smolder and emit desirable smoke when ignited by the tinder, the smoke passing upward through the perforated top. The convection currents produce a stream of smoke without the need for a fan. The pellets don't fall through the cartridge after the bottom portion burns away because they swell up and are held in place within the upper portion.

Owner:THOMAS THOMAS A

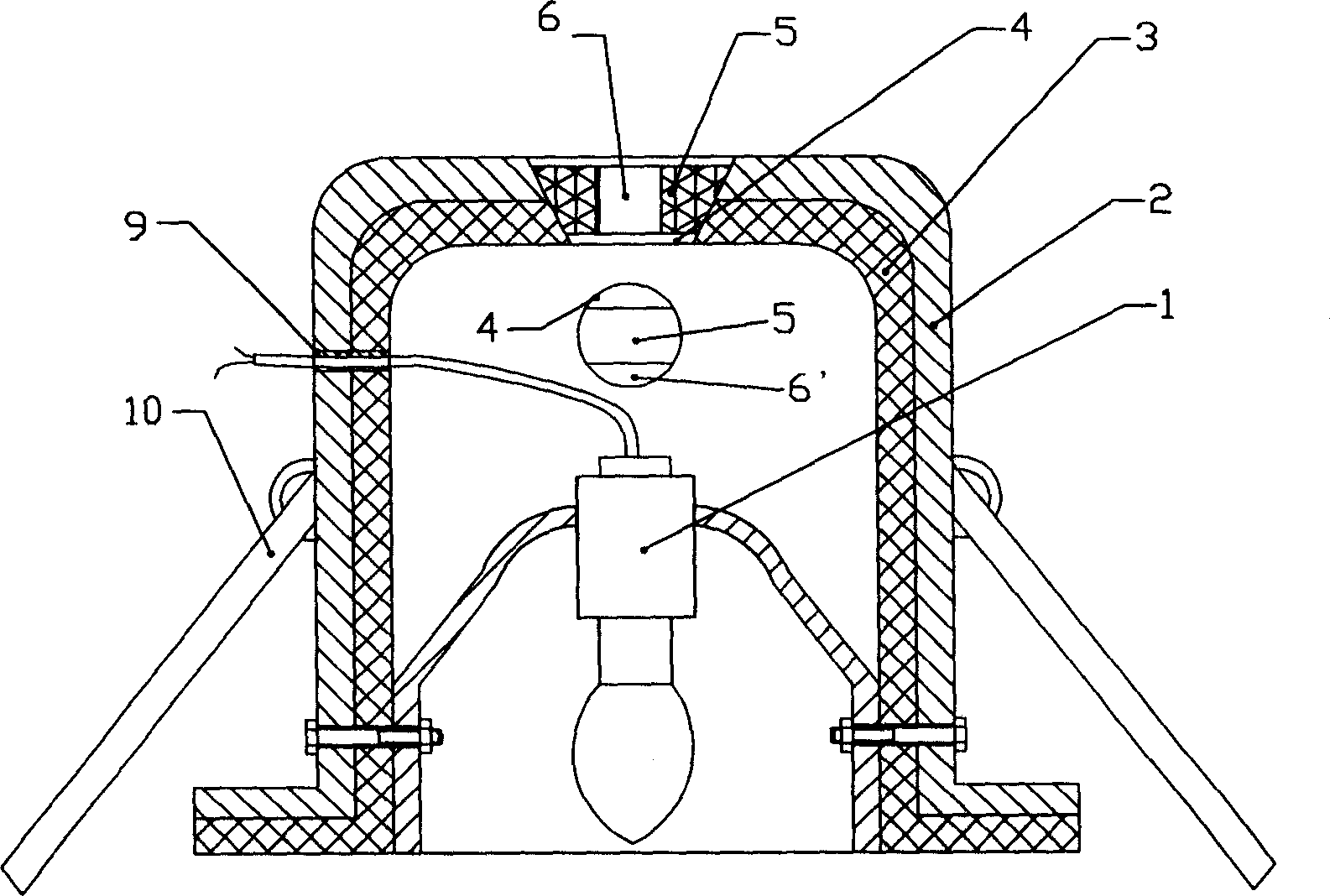

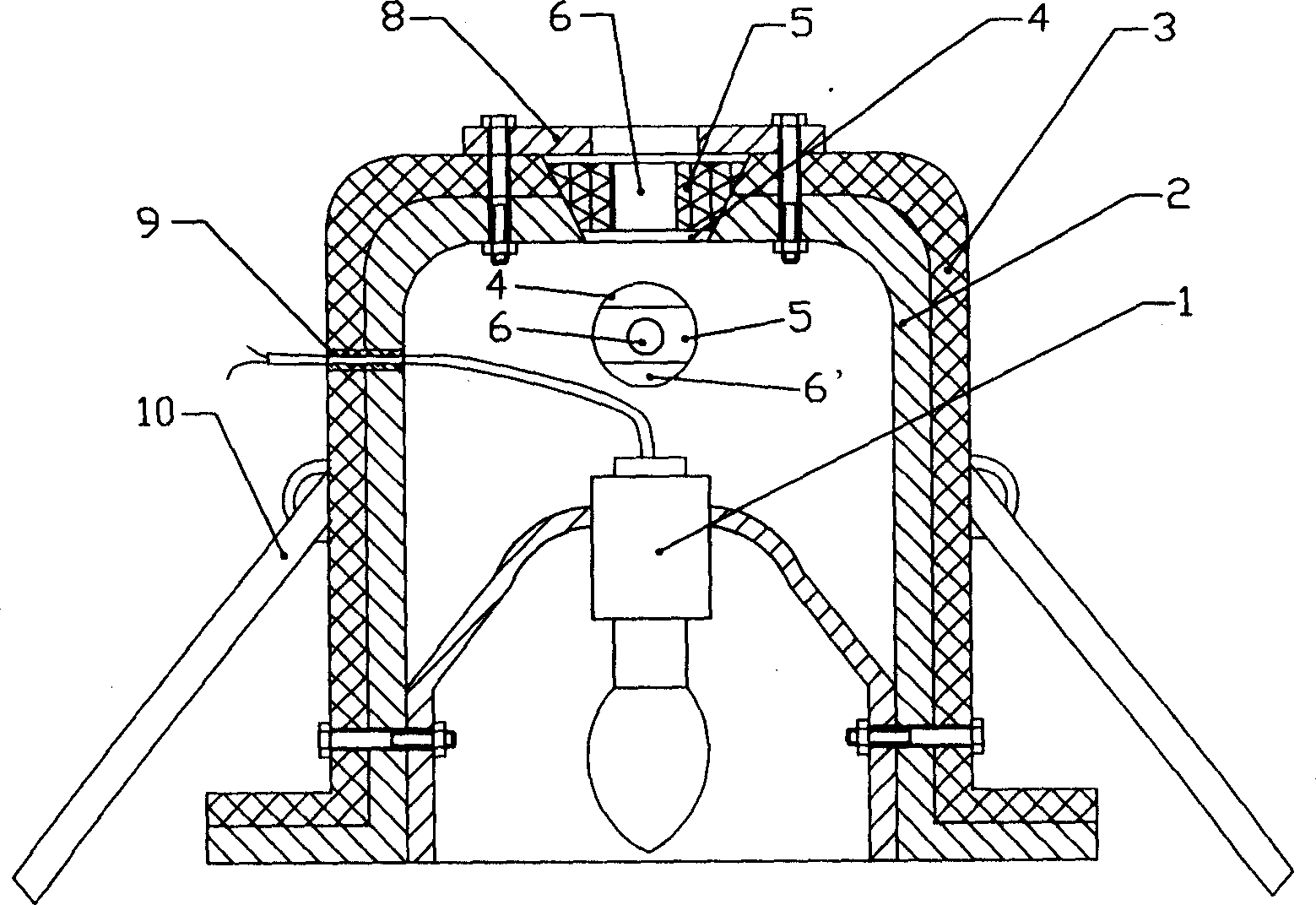

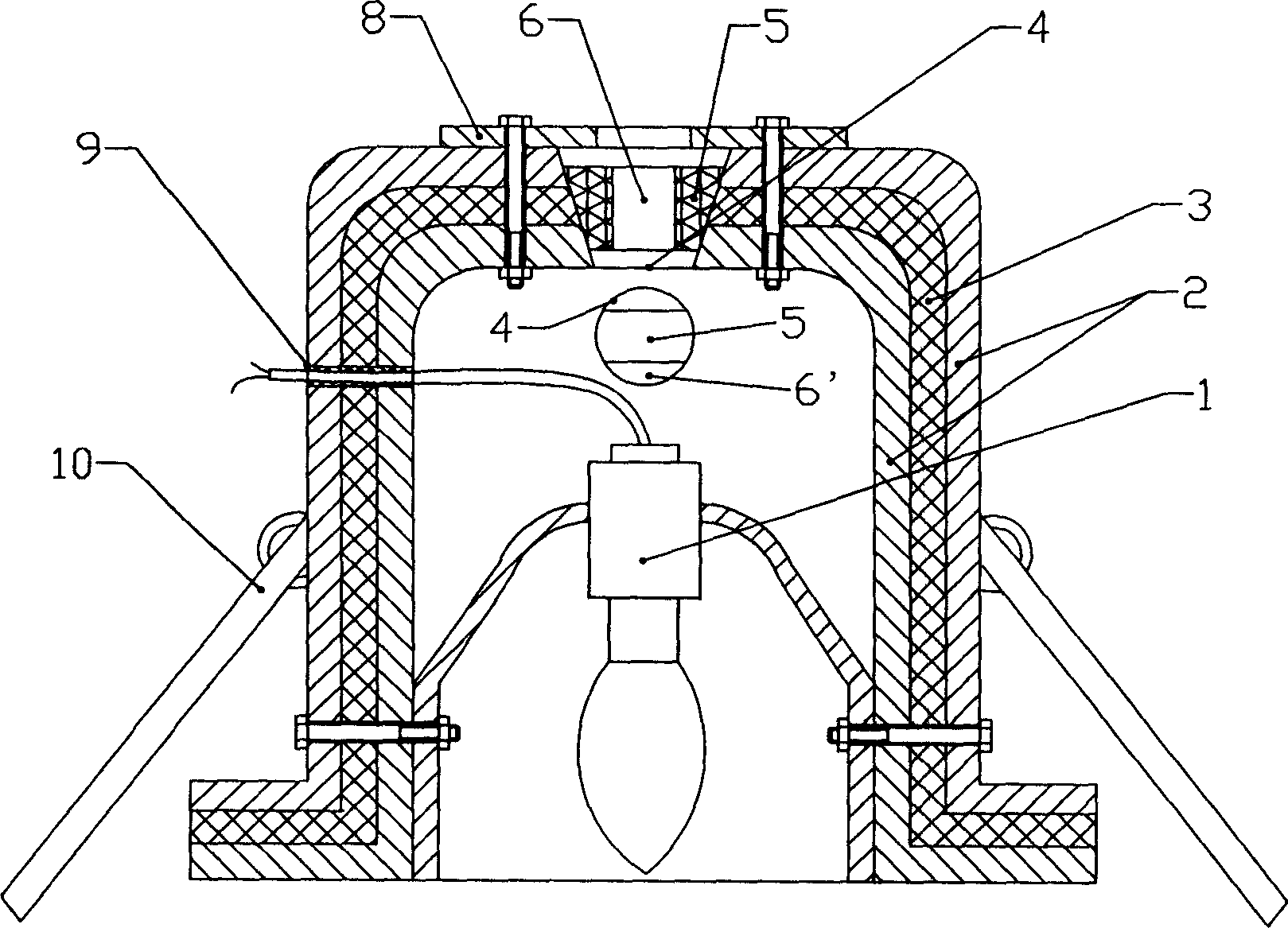

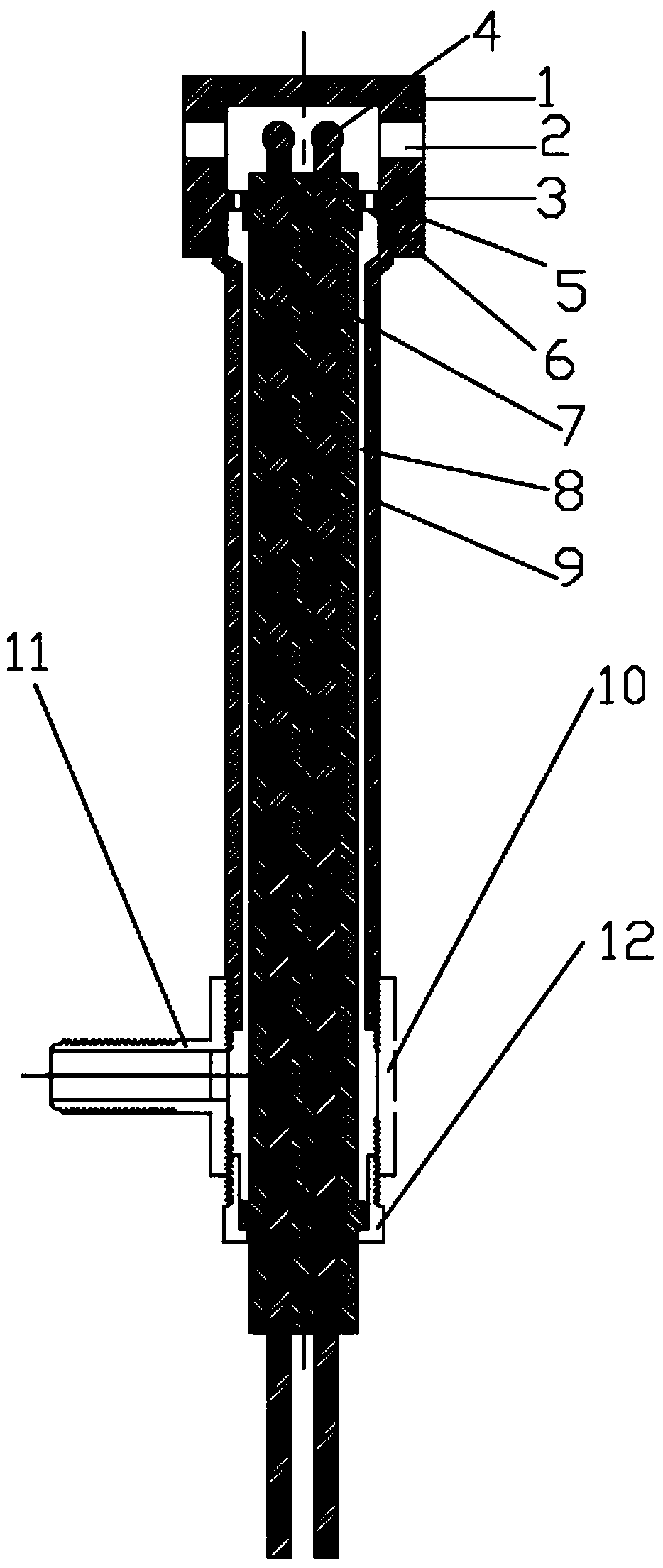

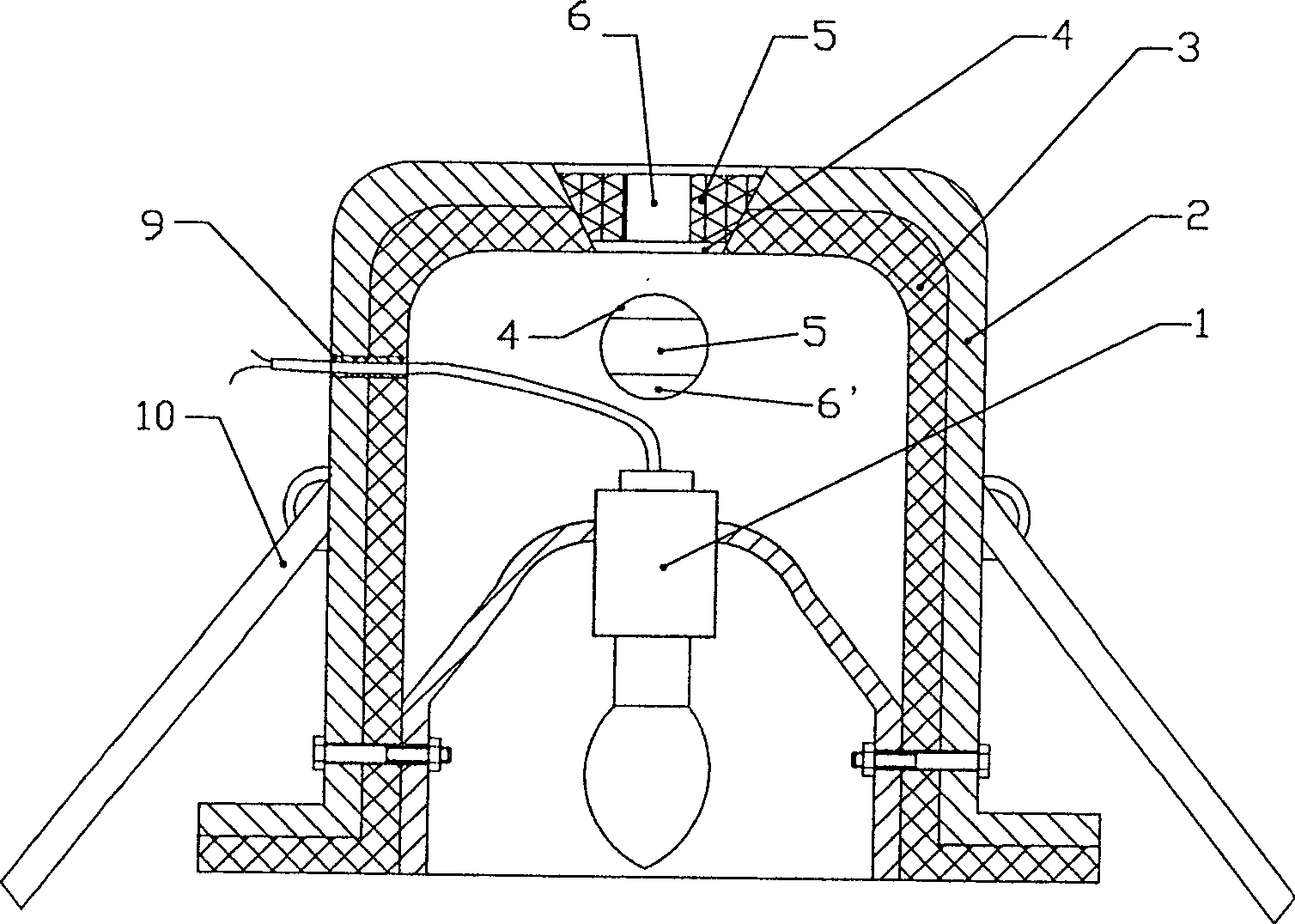

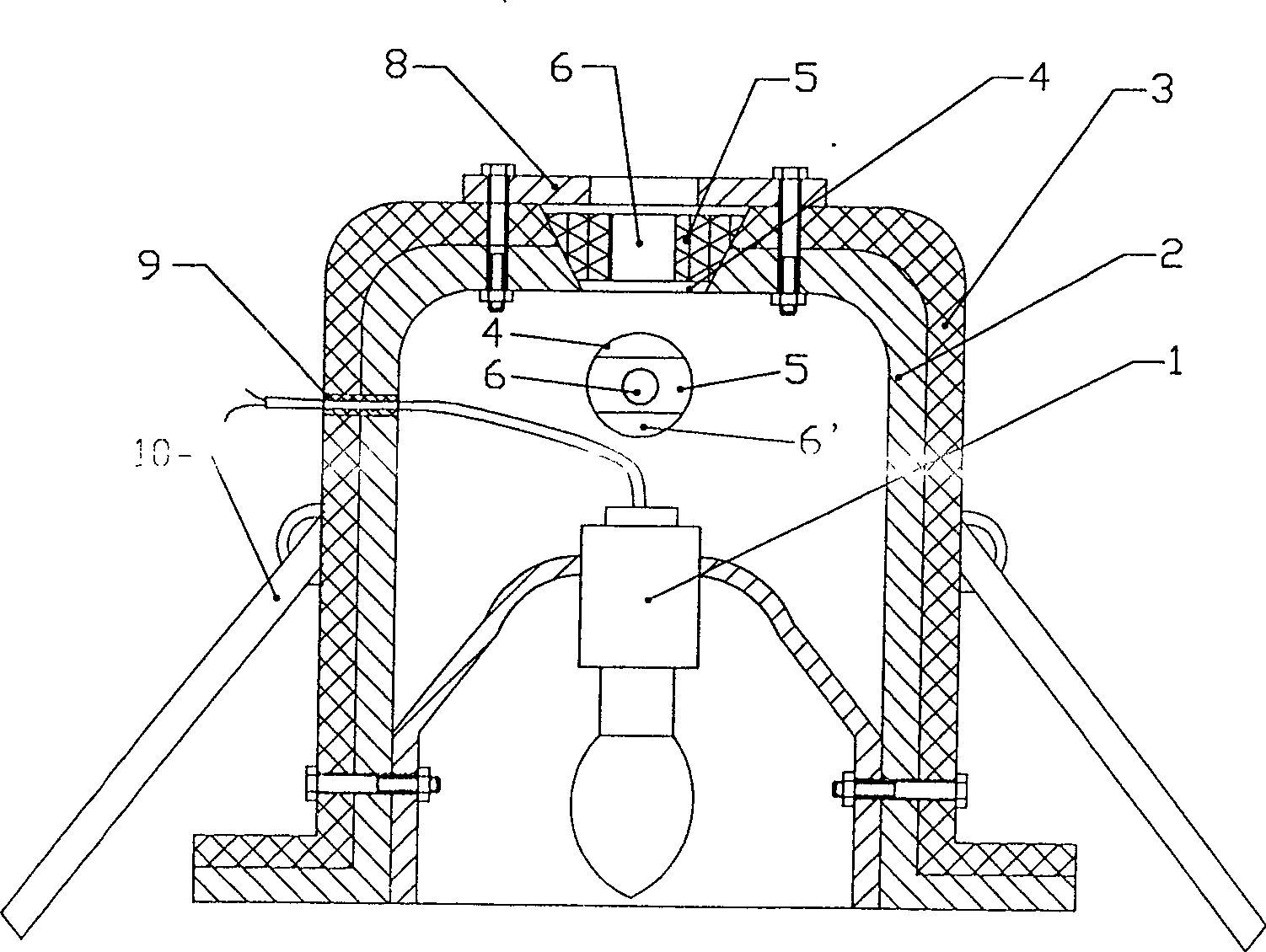

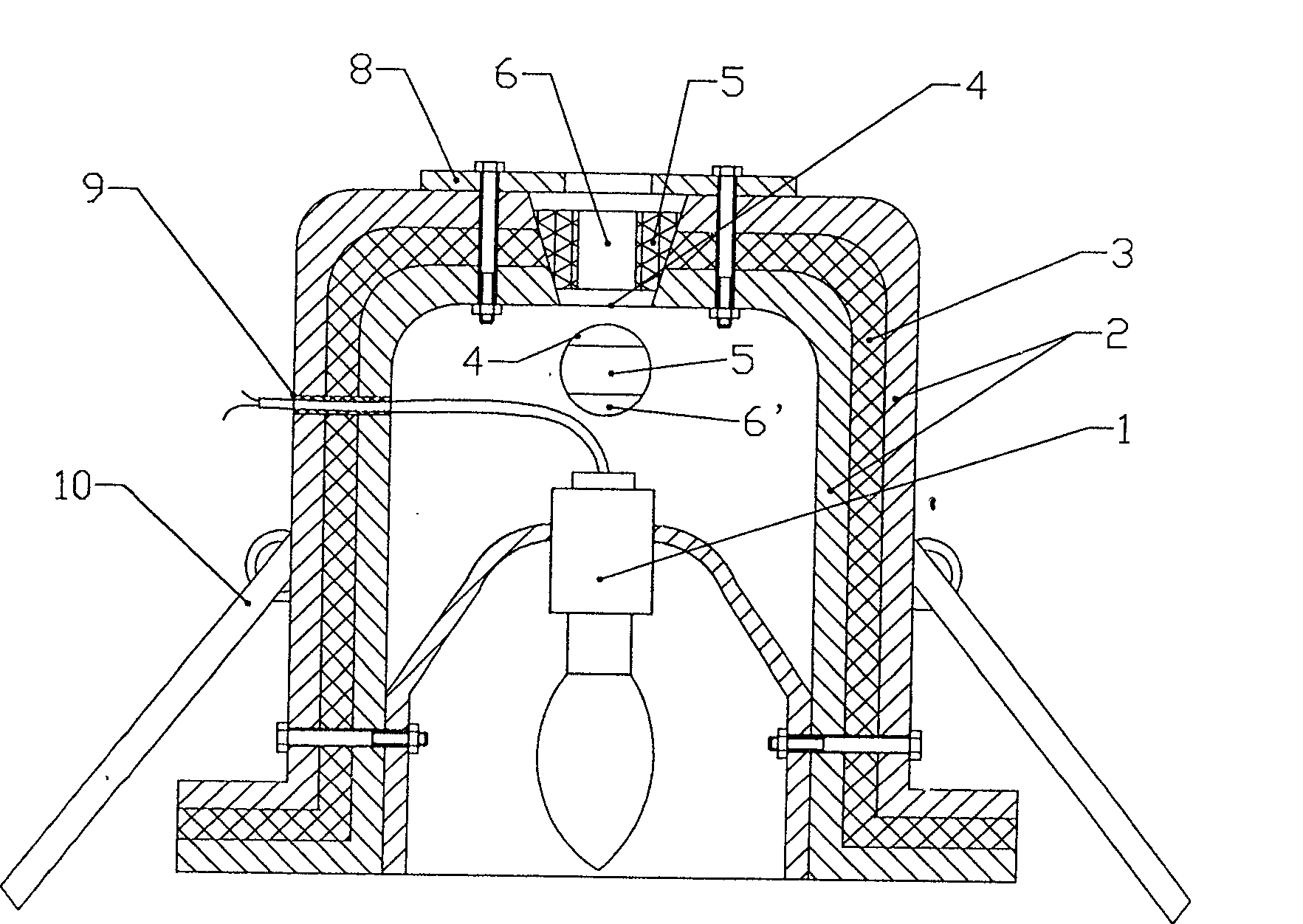

Embedded lamp

The invention discloses an embedded lamp with a lamp body mounted in a fire-proof cover, the fire-proof cover is composed of a metal layer envelopping a fire-proof heat insulation layer or coated with the fire-proof heat insulation layer, the fire-proof cover can prevent fire propagation from the lamp body to circumambience, and the fire-proof heat insulation layer would not make a temperature of an outer surface of the fire-proof cover be excessive high so as to result burning of some tinder around the fire-proof cover, a cover wall of the fire-proof cover is provided with a heat dispersion opening mounted with an expanded type fire-proof sheet, a heat dispersion hole is arranged at a position of the expanded type fire-proof sheet corresponding to the heat dispersion opening and / or the heat dispersion hole is arranged between an edge of the expanded type fire-proof sheet and an edge of the heat dispersion opening, so that the lamp can performing heat dispersion normally at a common condition, when encountering a fire, the heat dispersion opening can be automatically closed by rapid expansion of the expanded type fire-proof sheet, the fire-proof cover completely insulates the lamp from outside tinder, thereby preventing the tinder propagation from the lamp to outside.

Owner:武良举

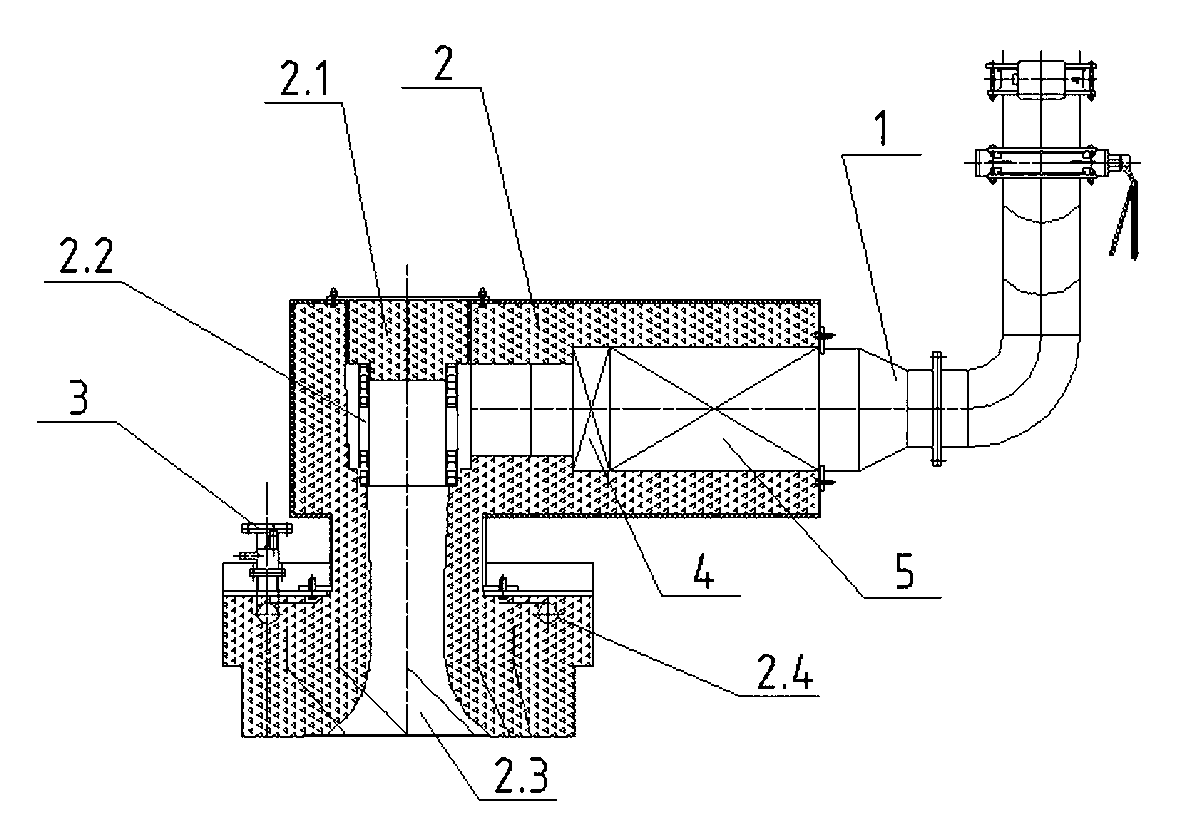

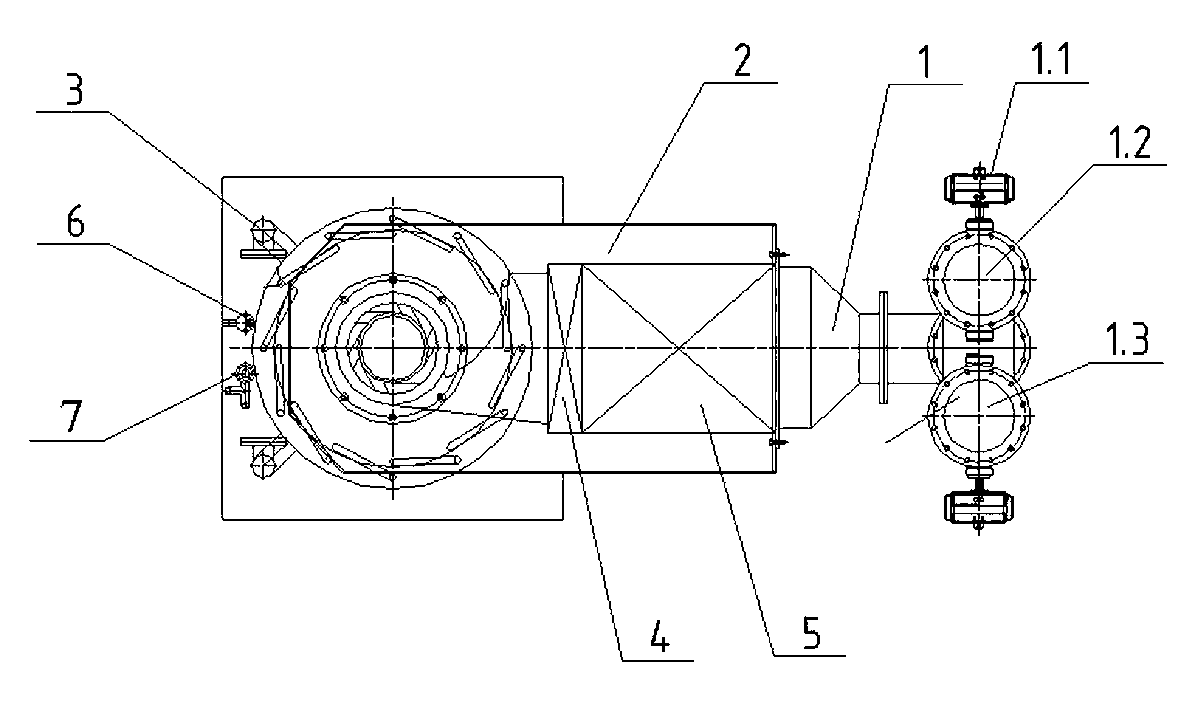

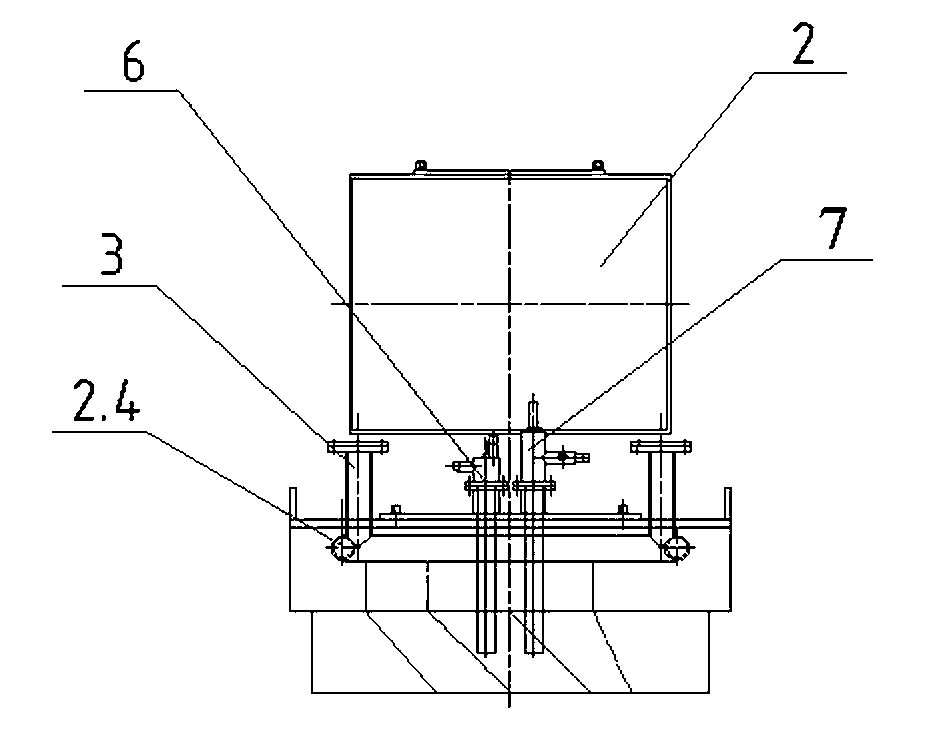

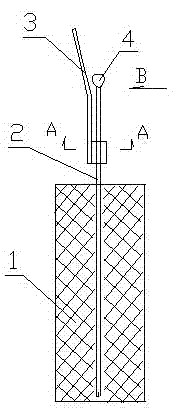

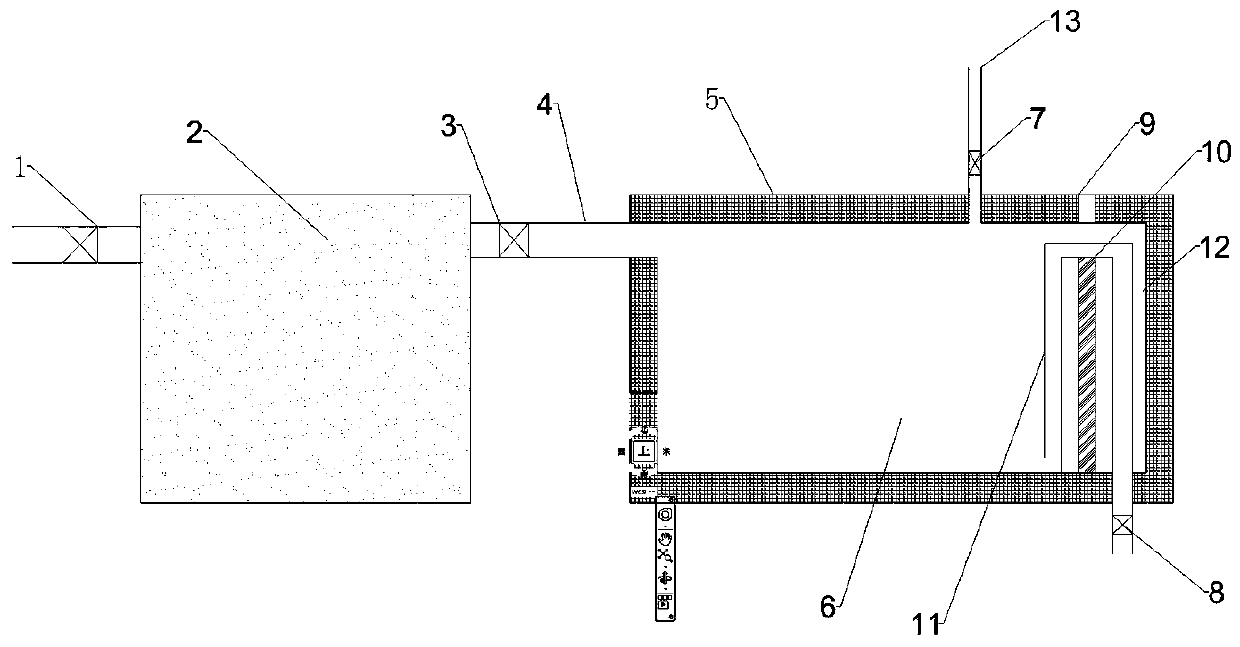

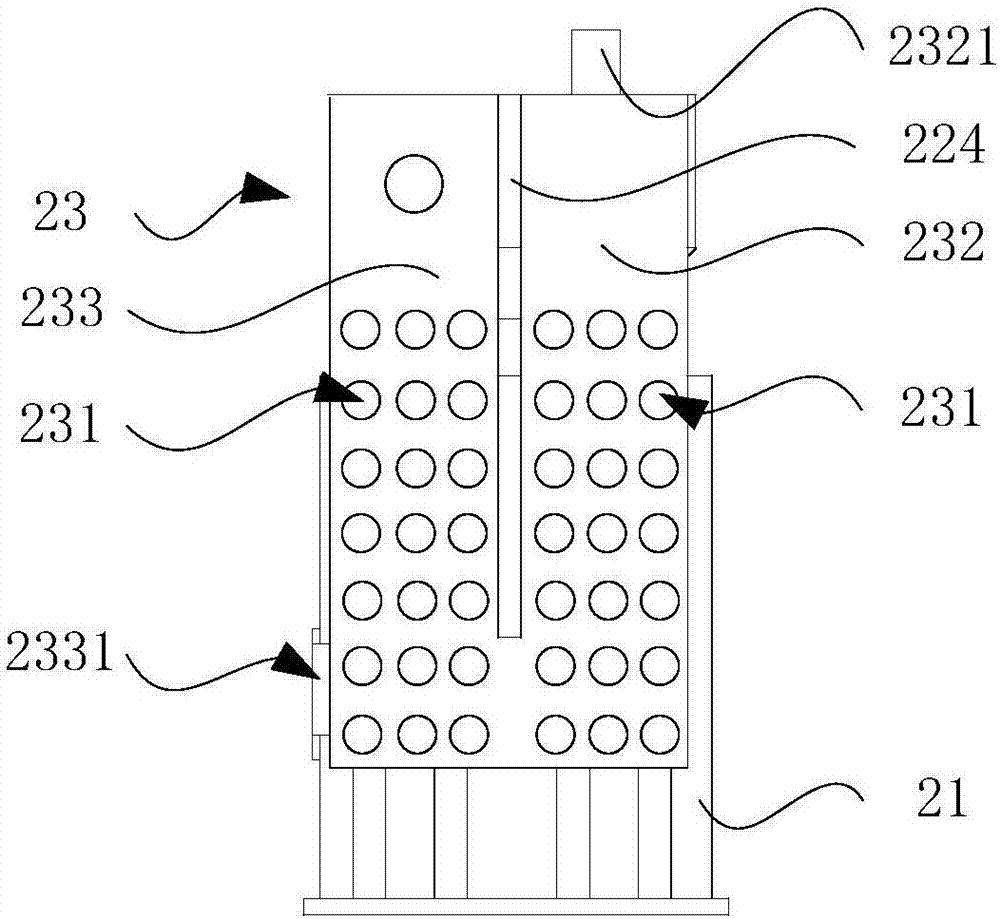

Heat accumulative gas burner

ActiveCN103307600AWell mixedImprove thermal efficiencyGaseous fuel burnerCombustion regulationBrickFlue gas

The invention discloses a heat accumulative gas burner which comprises an air distribution device, a nozzle, a gas controlling assembly, a blocking brick, a heat accumulator, an ignition device and a tinder placing device, wherein the main tube of the air ignition device is connected to the right end surface of the nozzle in a sealing manner, and two breeches tubes at the other end are respectively an air inlet tube and a flue gas outlet tube. A cyclone body is arranged inside the hole at the other end which is axial with the opening of the nozzle, the residual holes are sealed by plugs, and the blocking brick and the heat accumulator are arranged in the hole which is perpendicular to the opening of the nozzle. A ring channel is arranged inside the tube wall at one end of the ring opening of the nozzle, air hole groove openings are formed uniformly in the ring channel, and the gas controlling assembly mounted at one end of the openings penetrate the built-in ring channel, so as to introduce gas in the ring cannel. According to the heat accumulative gas burner provided by the invention, spiral ribs are arranged on the inner wall of the openings and the cyclone body, so as to enable the combustion air and the gas to generate rotational air swirl flow, and be beneficial to mixing and blending. According to the device provided by the invention, the ignition device is used to ignite at the first time, and the tinder placing device ignites later on, the ignition is reliable, and the safety is good.

Owner:JIANGSU TENGTIAN IND FURNACE

Candle with ignition device

The invention discloses a candle with an ignition device. The candle comprises a candle body (1) with a candlewick (2); the ignition device comprises a gunpowder head (4) fixed on the candlewick and a fire pulling sheet (3) which is sleeved on the candlewick and can move on the candlewick, wherein an ignition layer (5) is arranged on the fire pulling sheet; and the fire pulling sheet is pulled outwards, so that ignition layer and the gunpowder head catch on fire by contact friction to ignite the candle. The candle with the ignition device is arranged in a lamp shade (6) formed by combining different shapes and patterns to form various candle lamps. In the candle, an ignition tool is not needed to be arranged and carried specially to generate kindling materials, and the candle can be ignited only by pulling the fire pulling sheet outwards on the ignition device assembled on the candle by using hands anywhere and anytime; and by utilizing the ignition device, the candle can be ignited directly, and the candle also can be ignited after the candle lamps are manufactured, so the candle can be ignited at a time conveniently, quickly, reliably and safely.

Owner:付启波

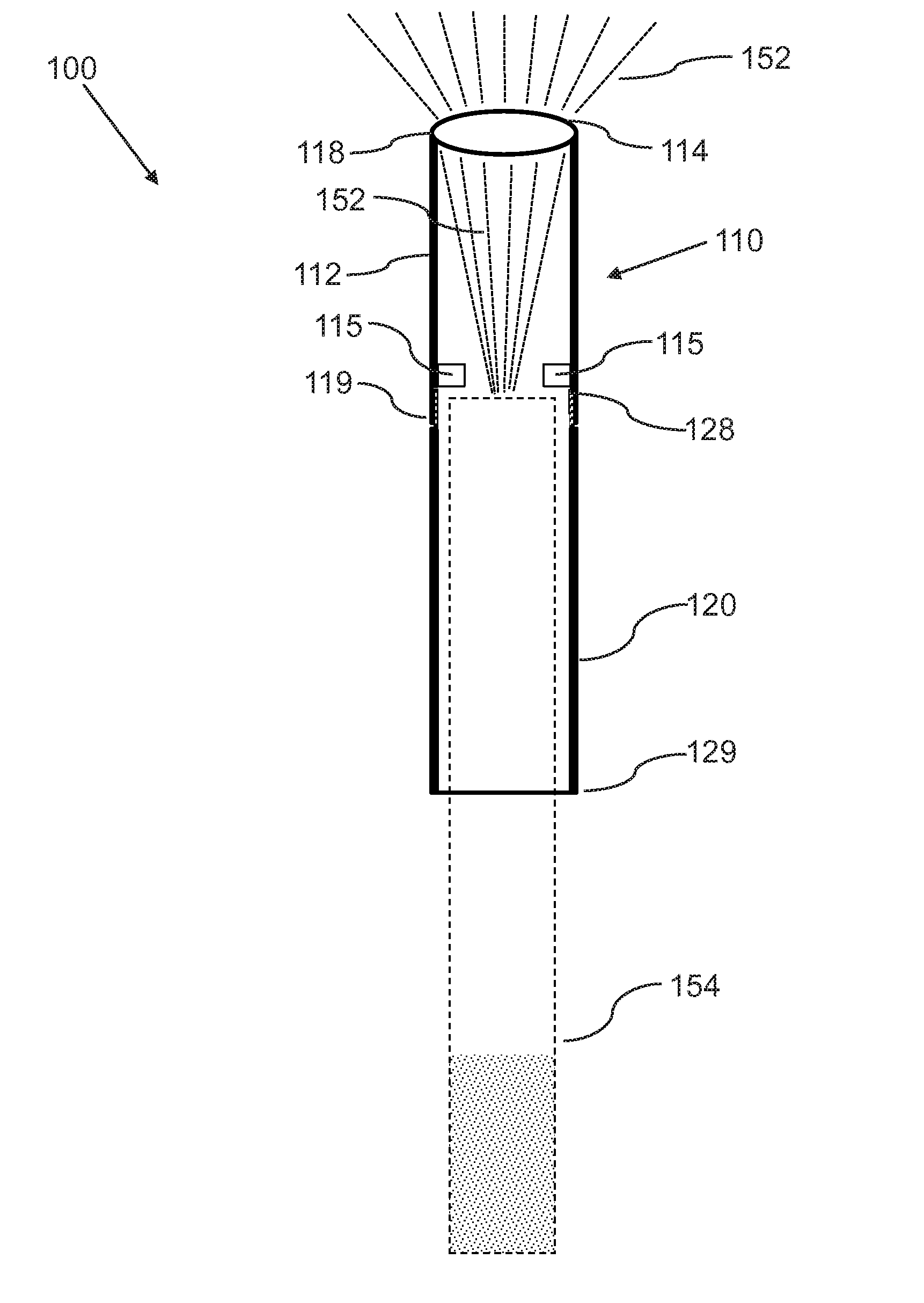

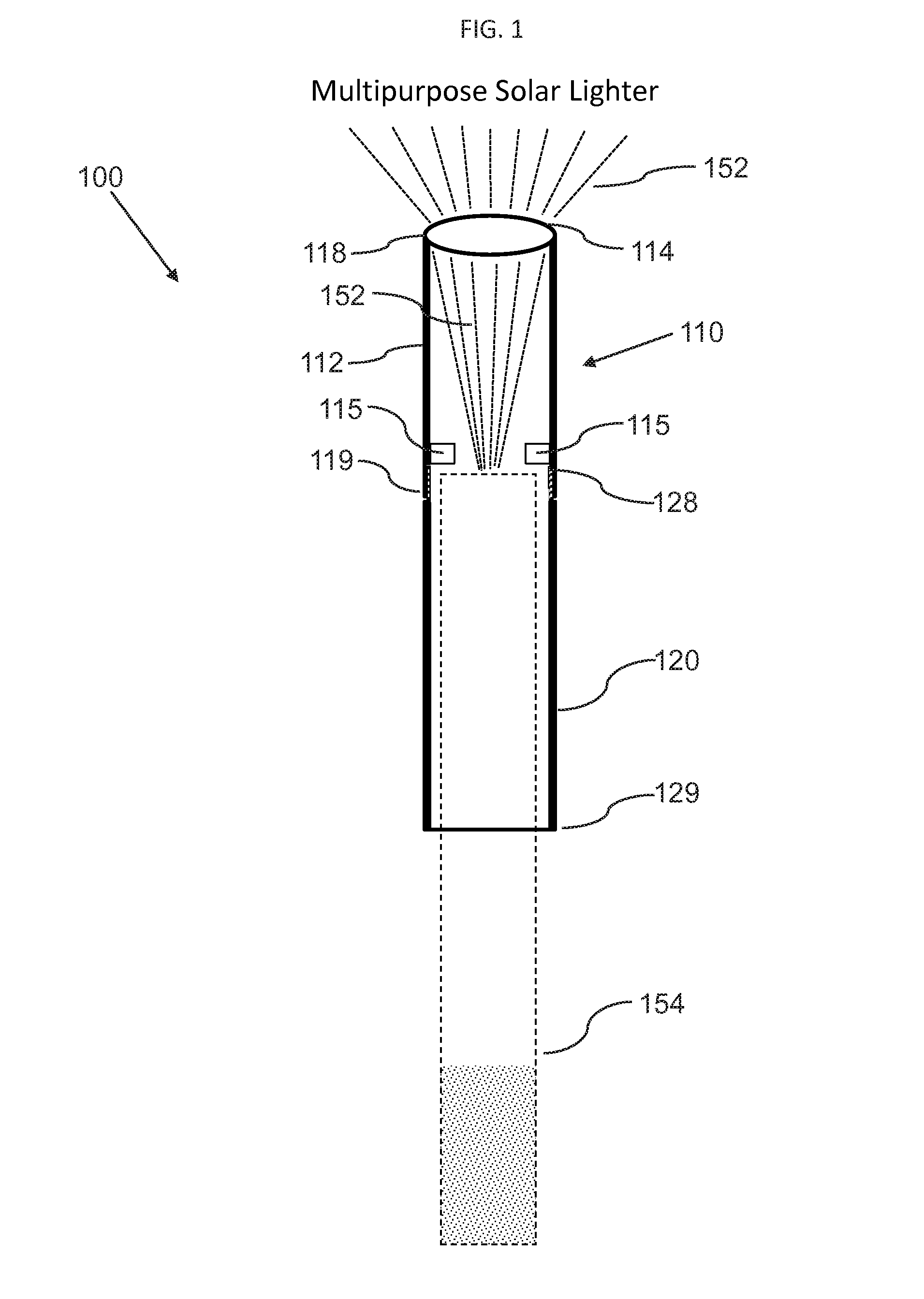

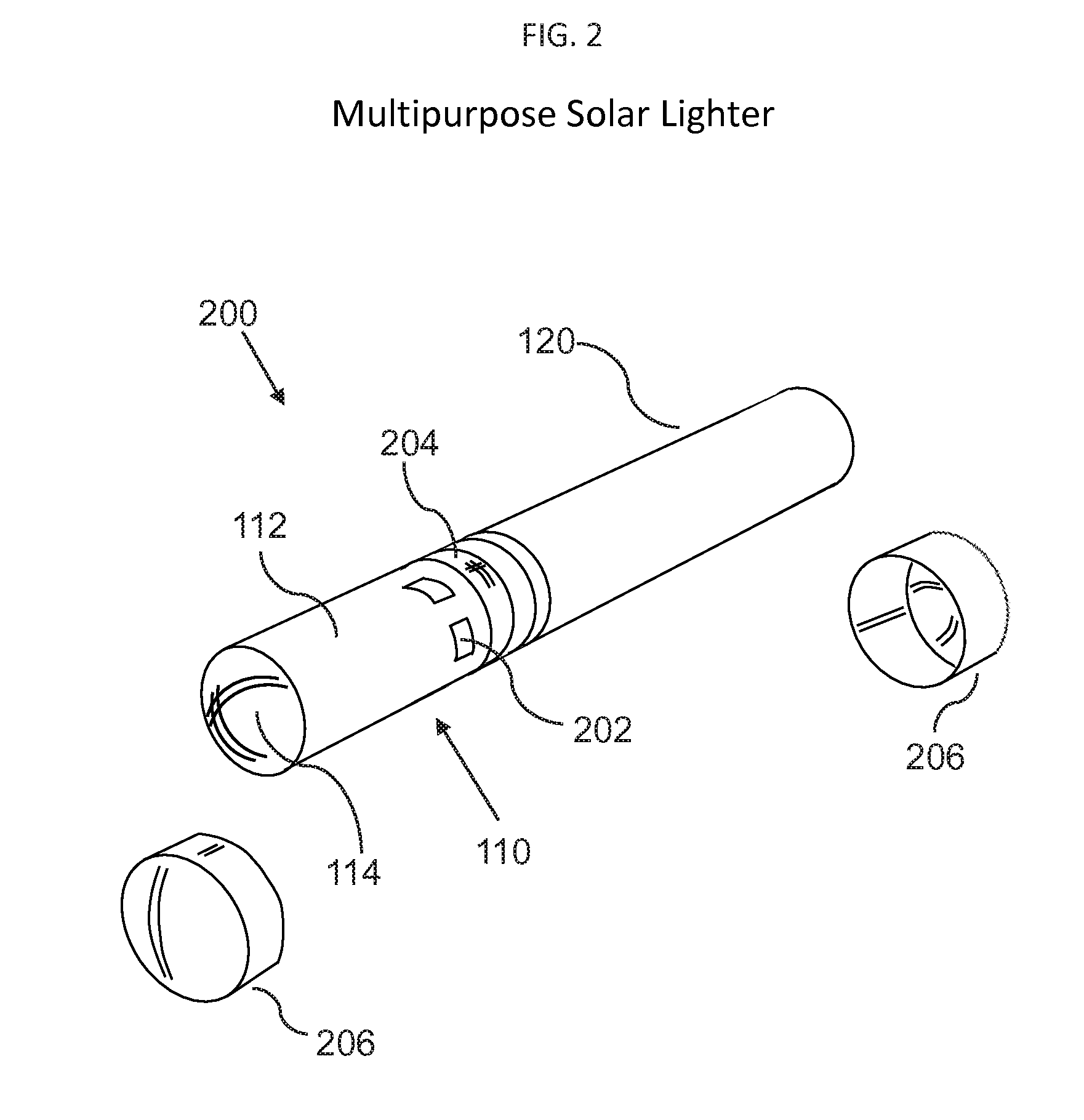

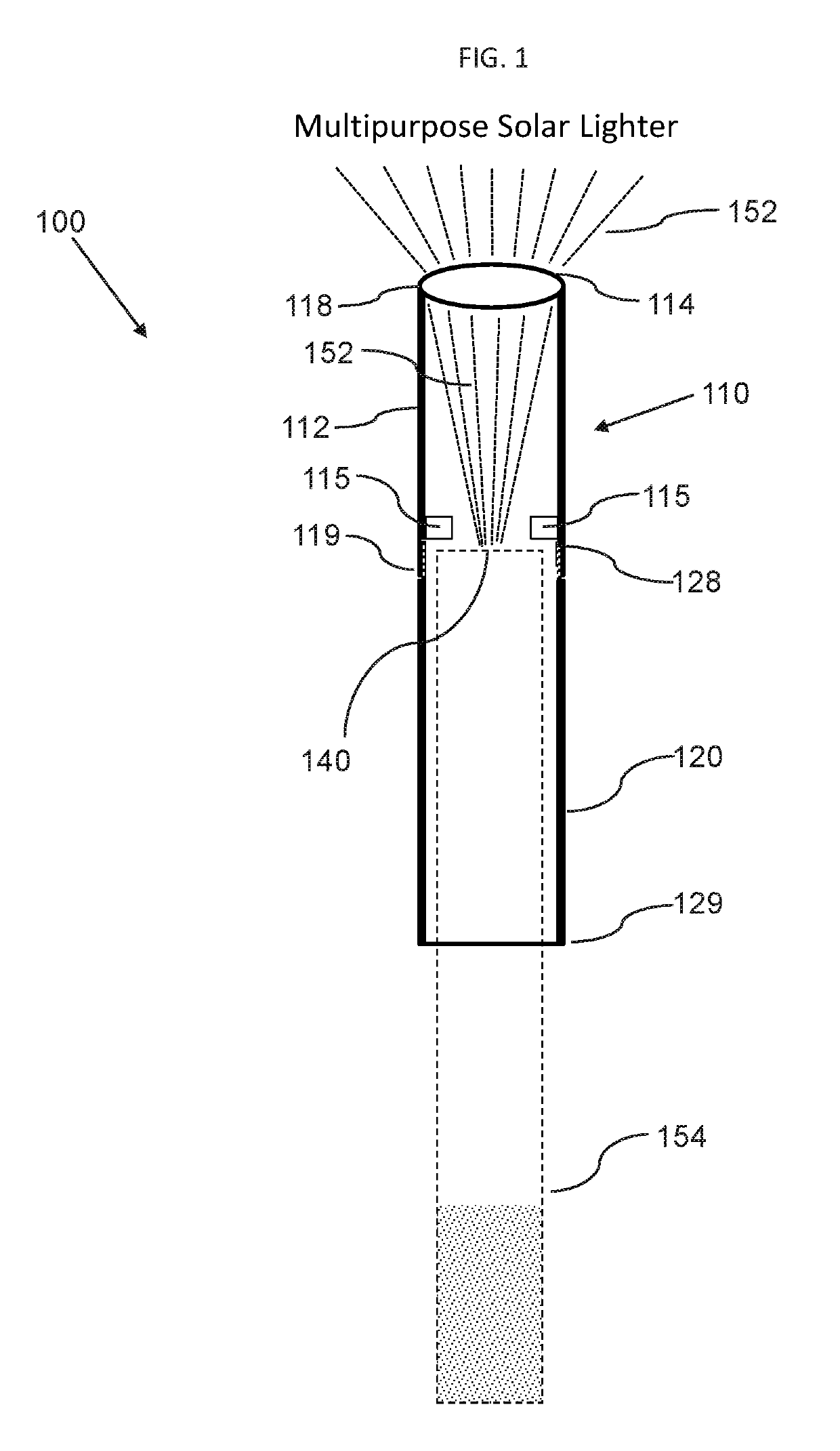

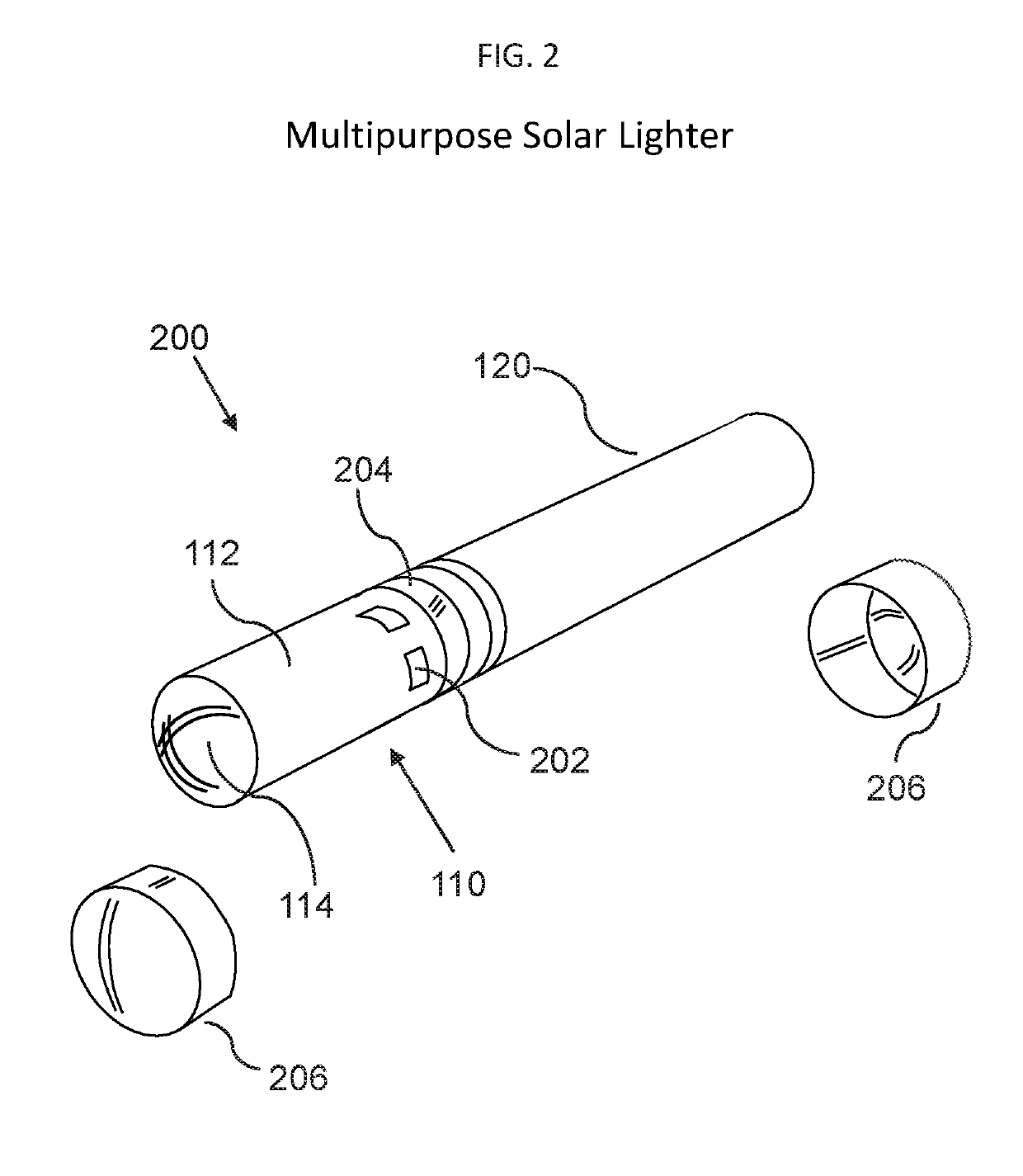

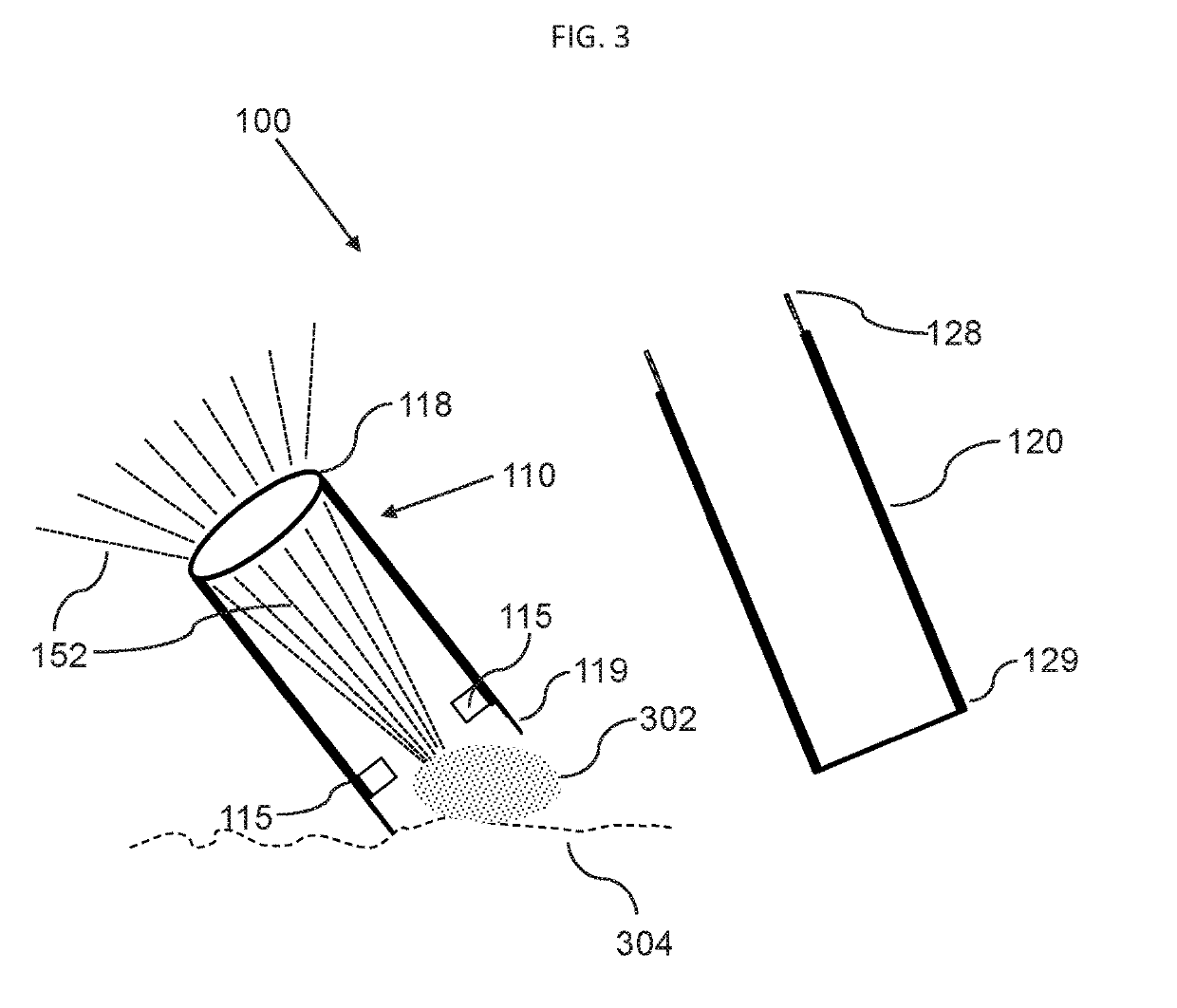

Multipurpose solar lighter

A multipurpose solar lighter for conveniently lighting a cigarette, tinder, or other flammable objects, includes a hollow upper part, which further includes an upper elongated piece, a convex lens, and a stopping tab; and a hollow lower part; such that the upper part connects to the lower part, whereby a cigarette can be inserted into the solar lighter, until it reaches the stopping tab, and is lighted by focused solar light. The upper part can also be used separately to ignite tinder. Furthermore, the solar lighter can include a fire steel surface and a fire striker, and end mounted thumb caps for holding the upper and lower parts, when striking the fire steel surface with the fire striker to produce sparks that can light a fire.

Owner:BOLGER JOSEPH P

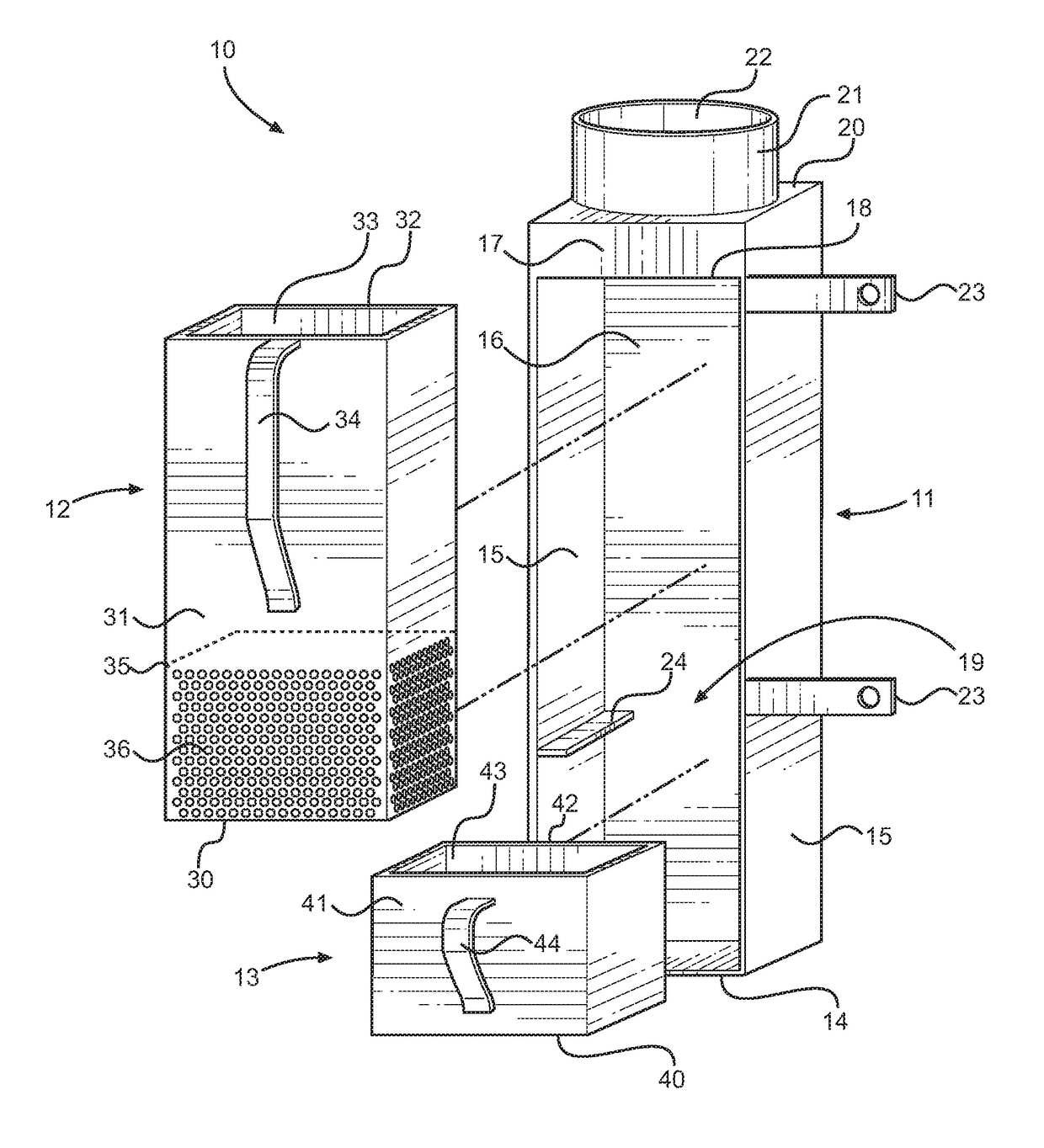

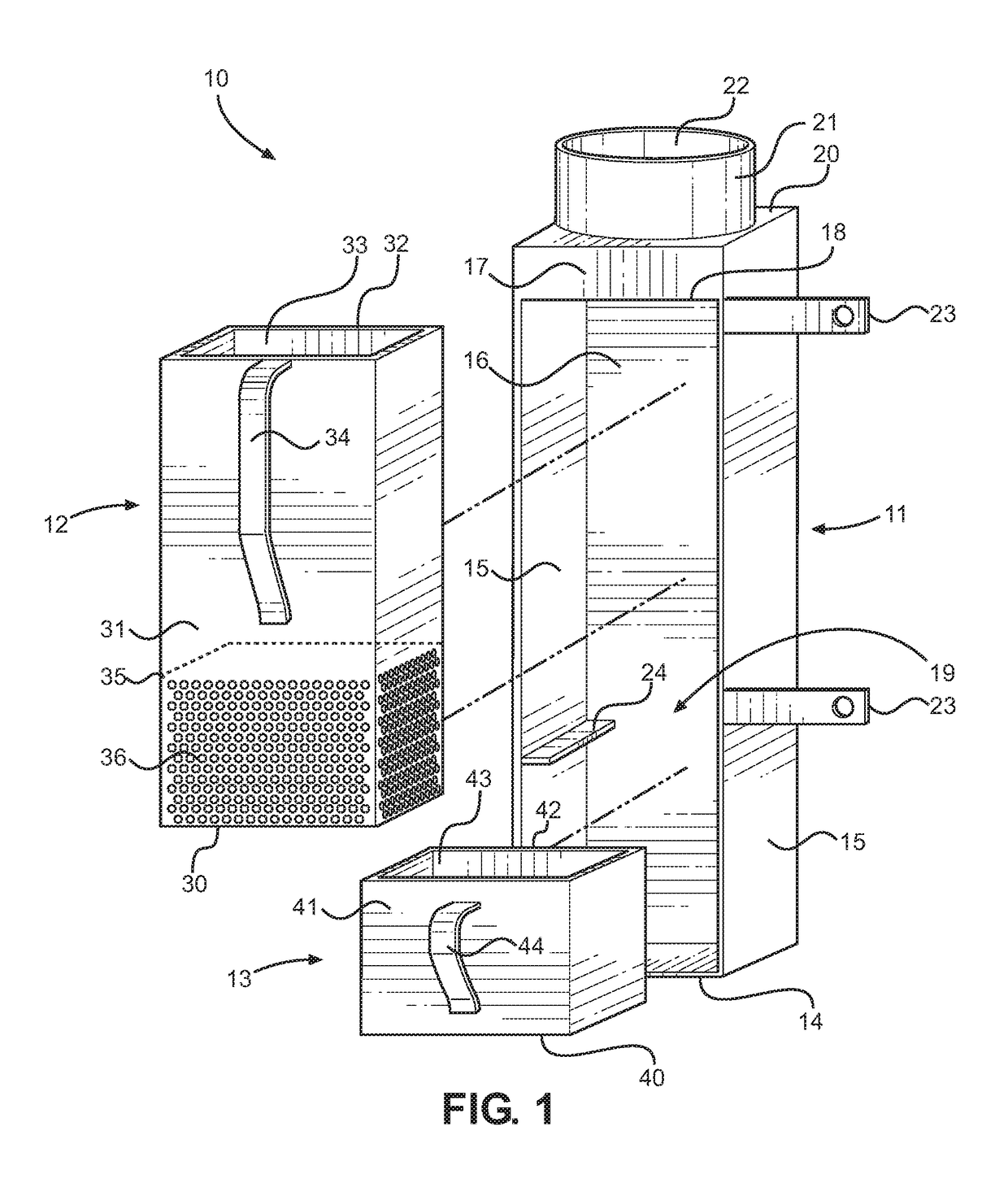

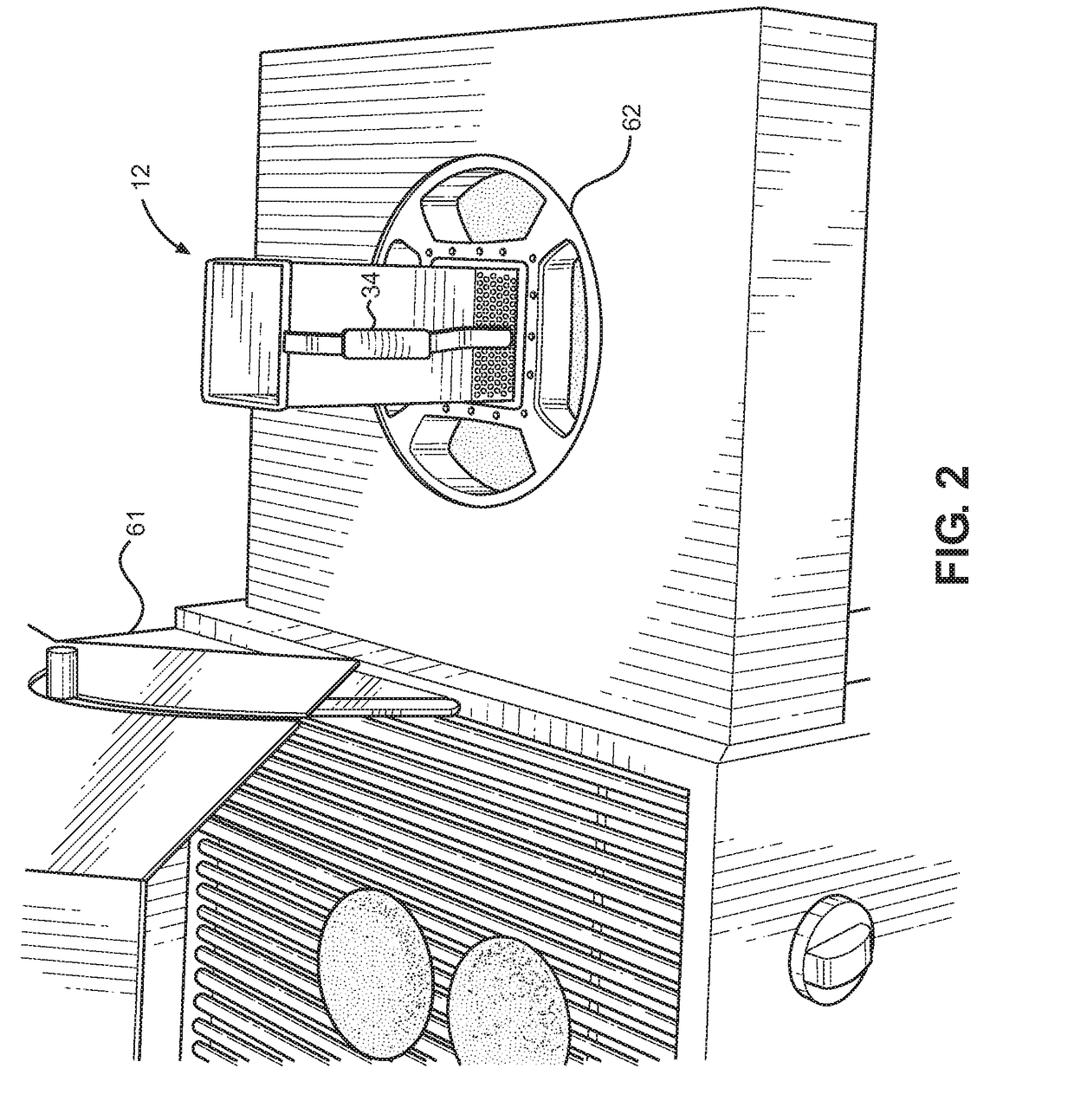

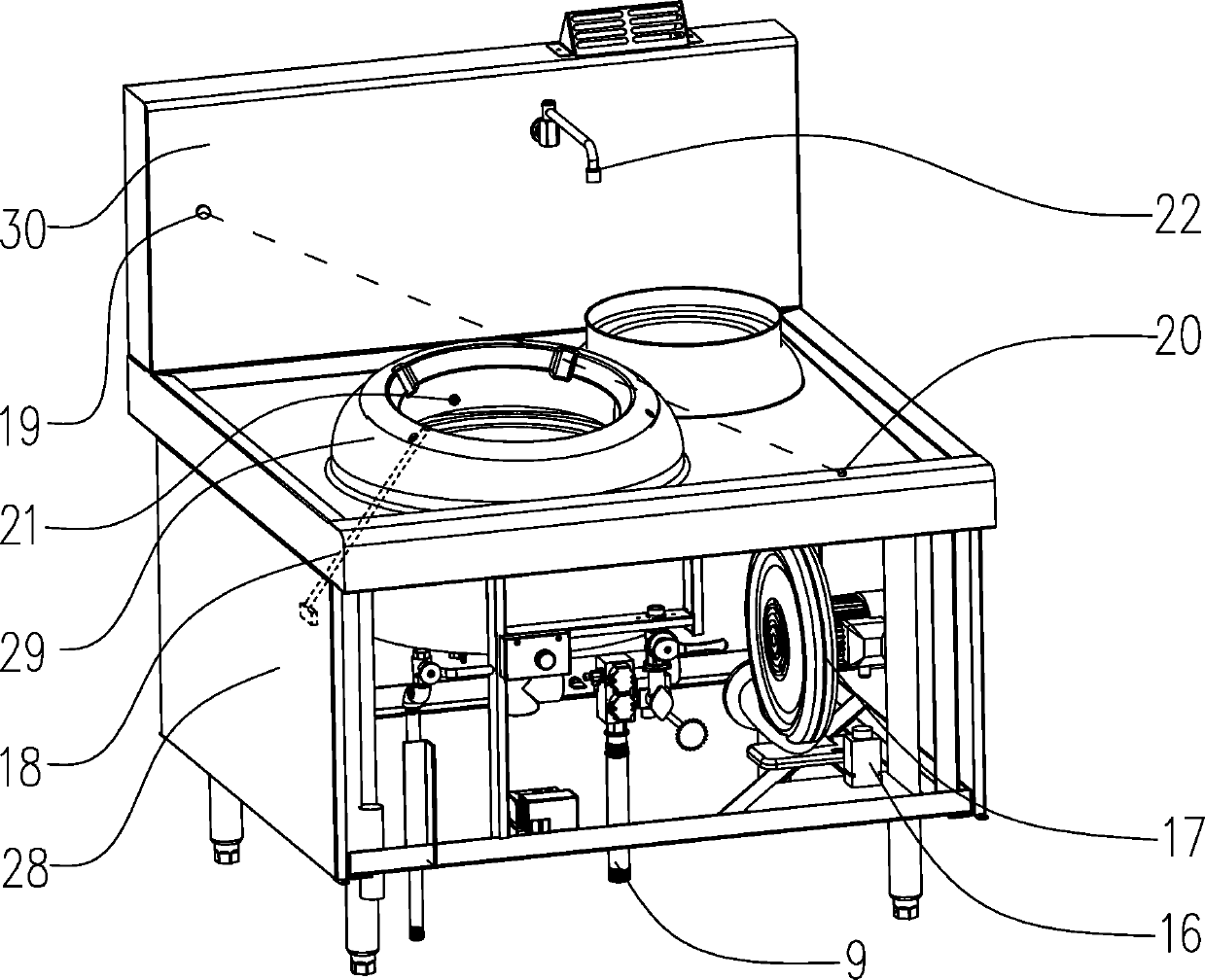

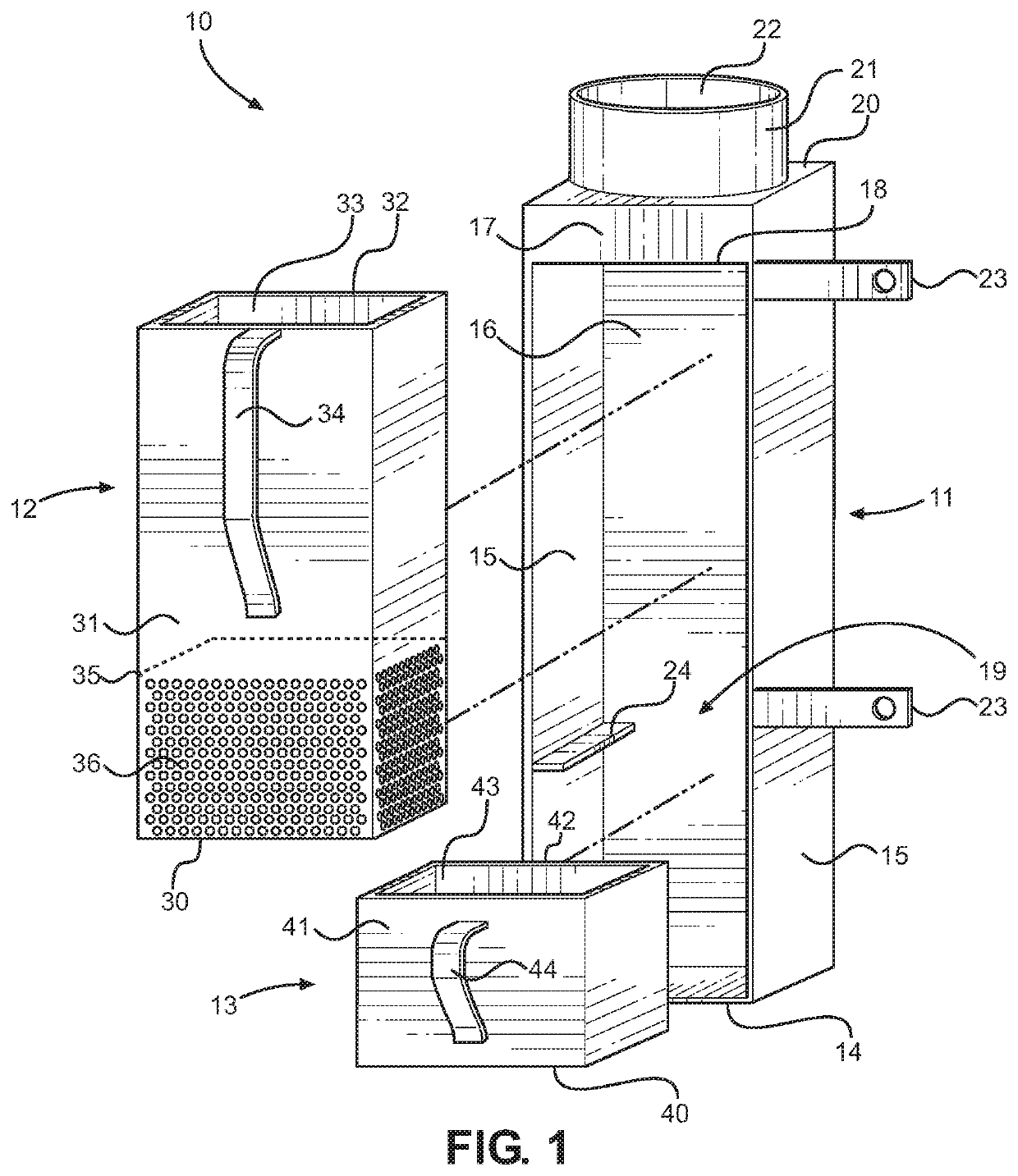

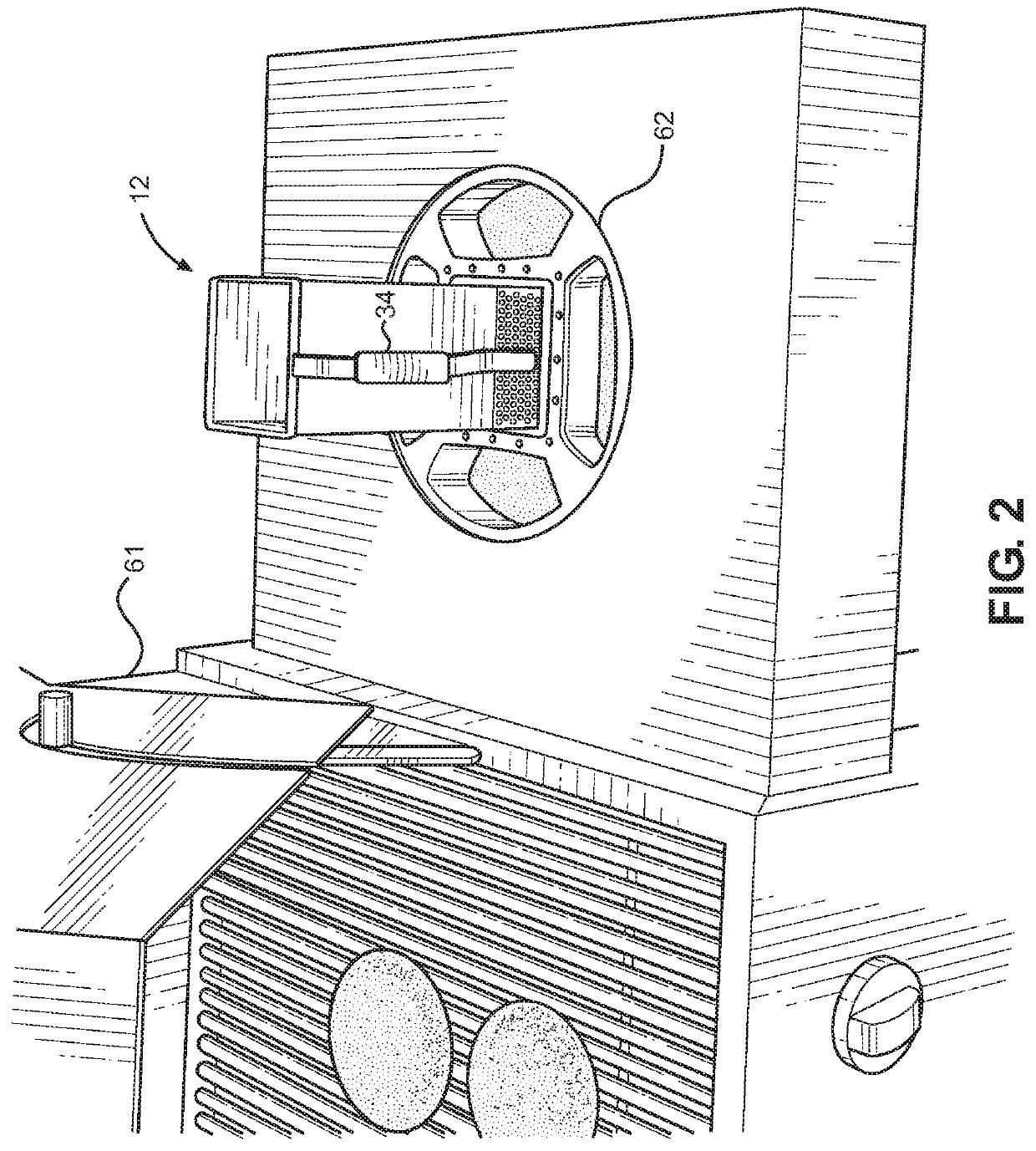

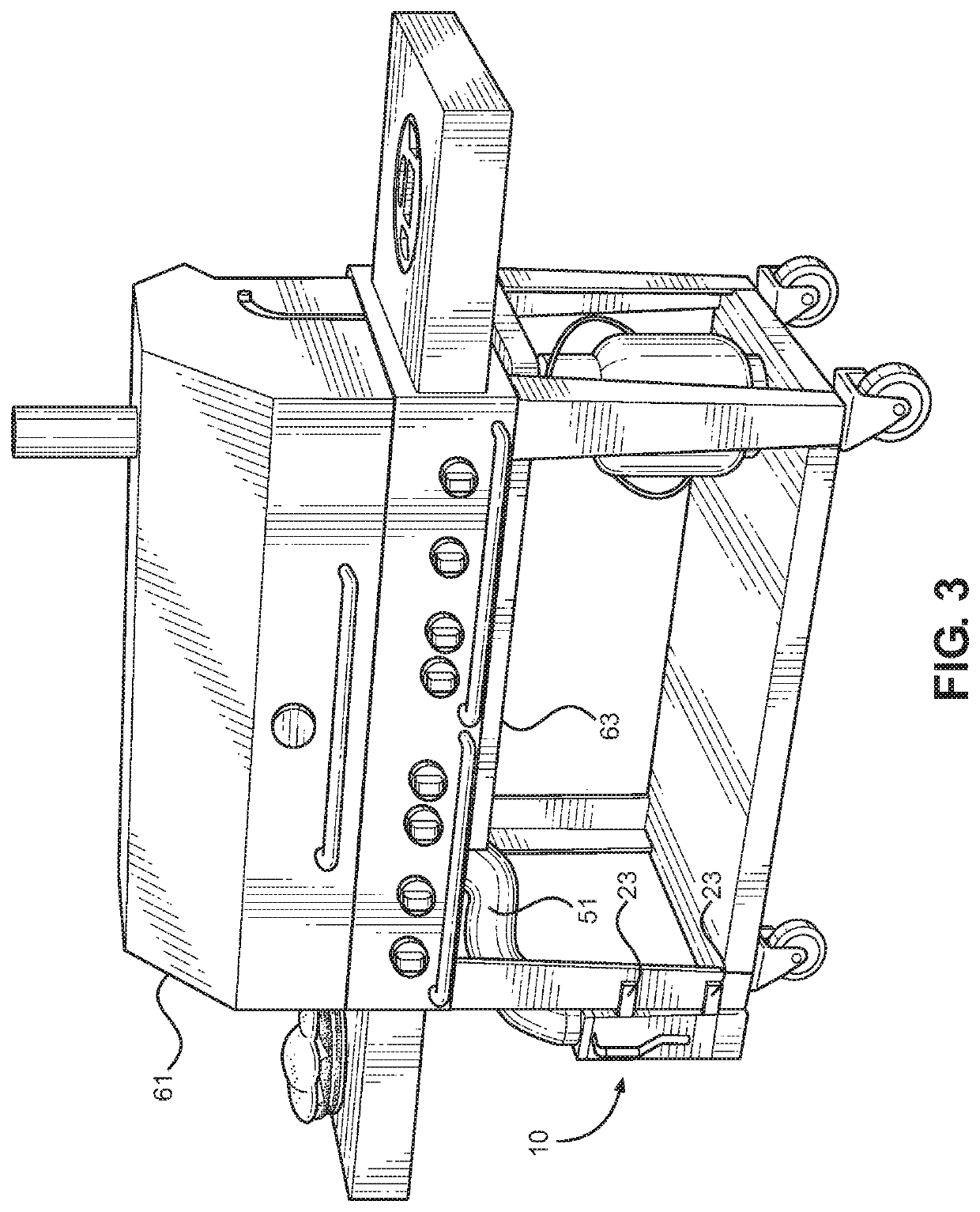

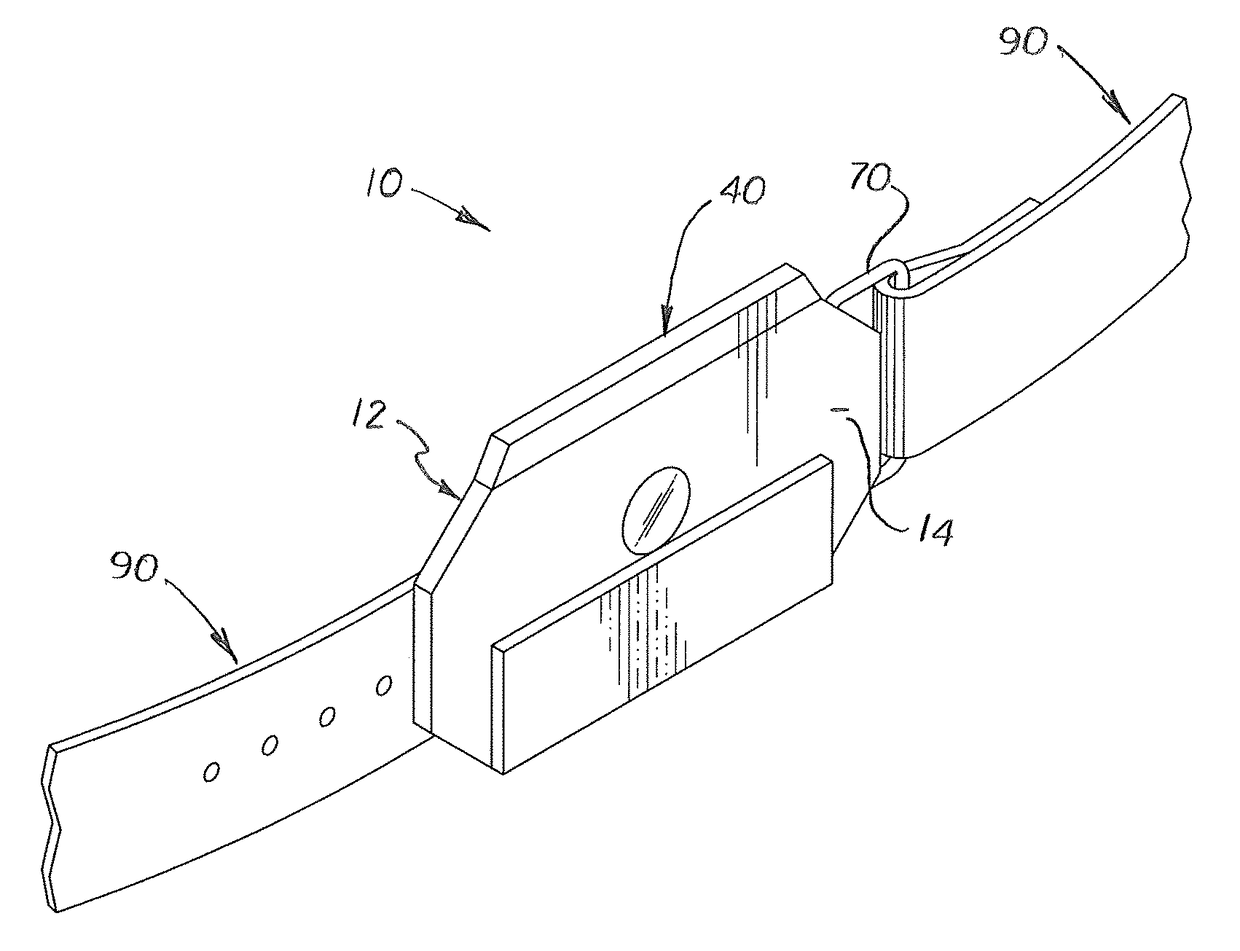

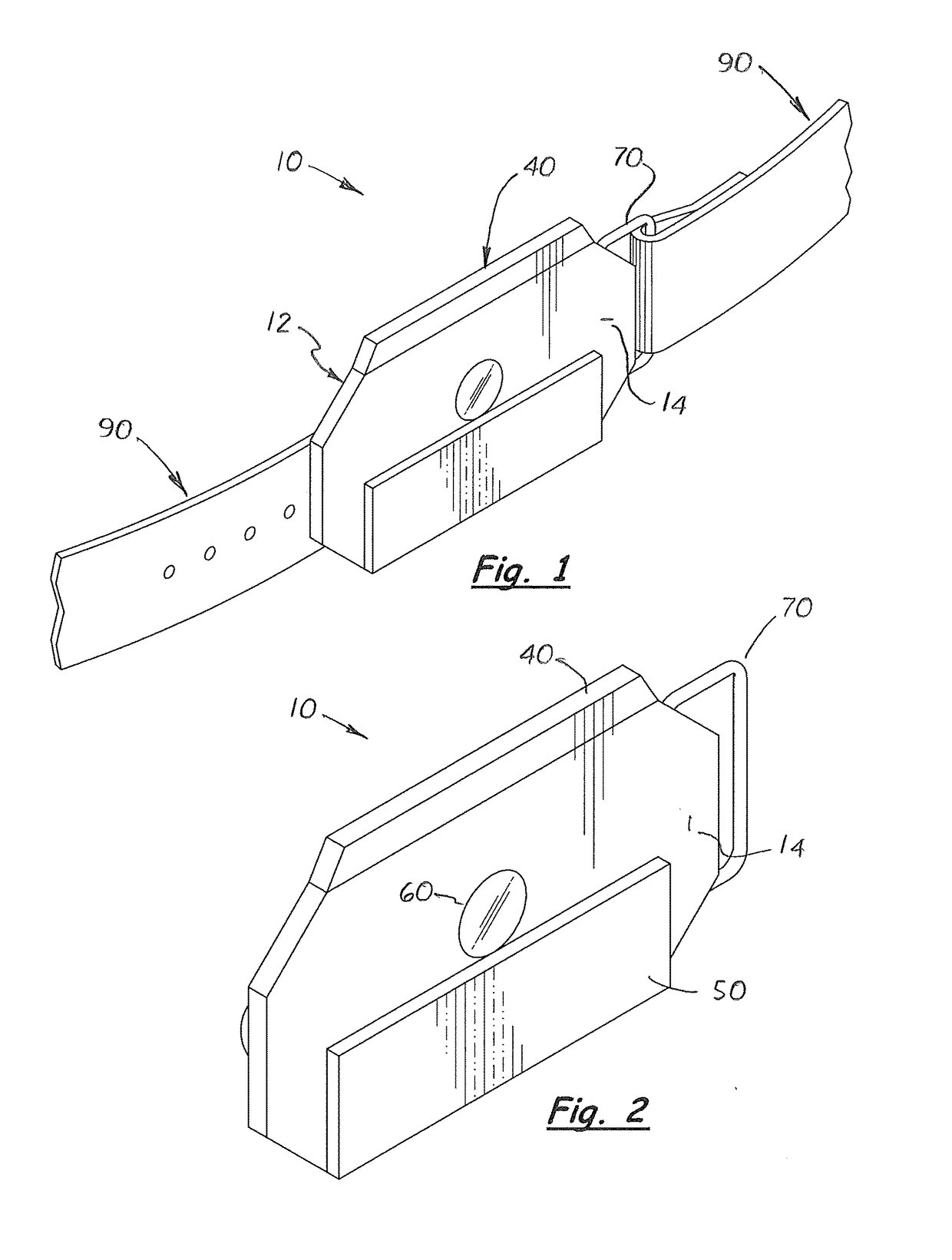

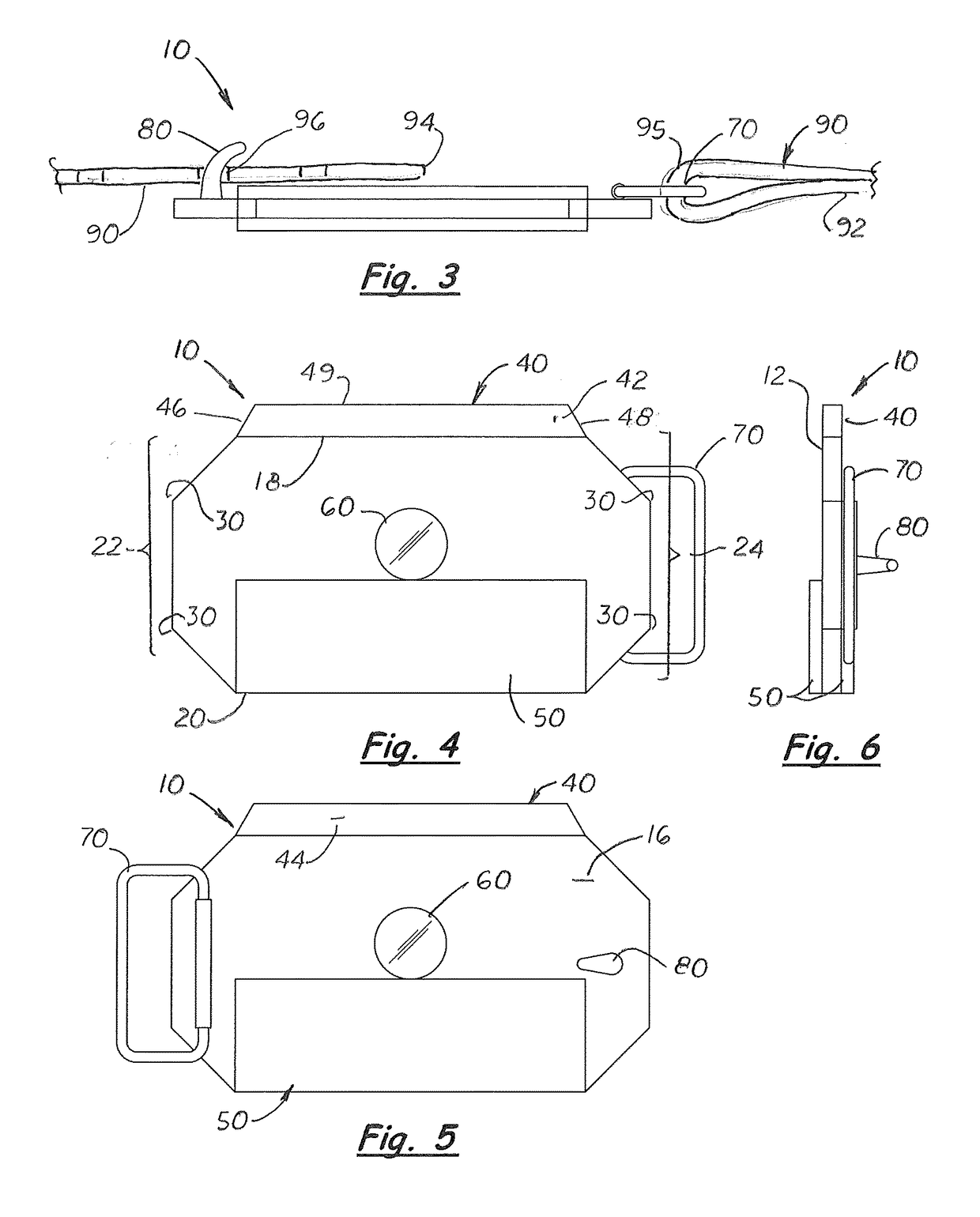

Smoker Attachment For Gas Grill

ActiveUS20170227232A1Easy to transportDesirable flavorDomestic stoves or rangesLighting and heating apparatusEngineeringTinder

A smoker attachment for a gas grill. The smoker attachment includes a housing having a base, a pair of opposing sidewalls, a rear wall, a front face defining an opening, and an interior volume. A tinder box having an interior volume for receiving fuel therein is removably insertable into the housing. An ash catcher having an interior volume for catching ash from the tinder box as the fuel combusts is removably insertable into the housing below the tinder box. A connector is disposed on a top wall of the housing, and a connecting hose attached to the connector is insertable into an interior enclosure of a gas grill. The connecting hose facilitates the transfer of smoke from the tinder box to the interior enclosure of the gas grill. The smoker attachment enables users to convert a conventional gas grill into a smoker.

Owner:HAMMS BBQ TECH LLC

Blast furnace top ignition method

ActiveCN110643761AImprove securityShorten the timeBlast furnace componentsBlast furnace detailsThermodynamicsSlag

The invention relates to a blast furnace top ignition method. The method comprises the operation steps that (a) theoretical slag iron complete discharging time is calculated at the later stage of thelast slag iron discharging before damping down of a blast furnace; (b) a cloth bag glasses valve is closed after the damping down of the blast furnace, a backflow valve is opened after the damping down of the blast furnace, part of gas flow in the furnace is led out along a backflow pipe, and a furnace top ignition manhole is opened after backflow of the part of gas flow; (c) a coal gas kindling material is ignited and then put in an ignition port of an ignition gun, the ignition gun is turned on, and then the coal gas is ignited; and (d) furnace top steam and nitrogen are closed, the ignitiongun is turned on and extended into the furnace, the top of flame of the ignition gun is in contact with the material surface, the coal gas in the furnace automatically combusts when meeting the kindling material of the ignition gun, and the furnace top ignition operation is completed. By normalizing the furnace top ignition operation steps, the safety performance of the furnace top ignition operation of blast furnace operators can be improved, the time consumed by the furnace top ignition operation is shortened, and the danger caused by furnace top ignition in the abnormal damping down stateof the blast furnace is avoided.

Owner:SGIS SONGSHAN CO LTD

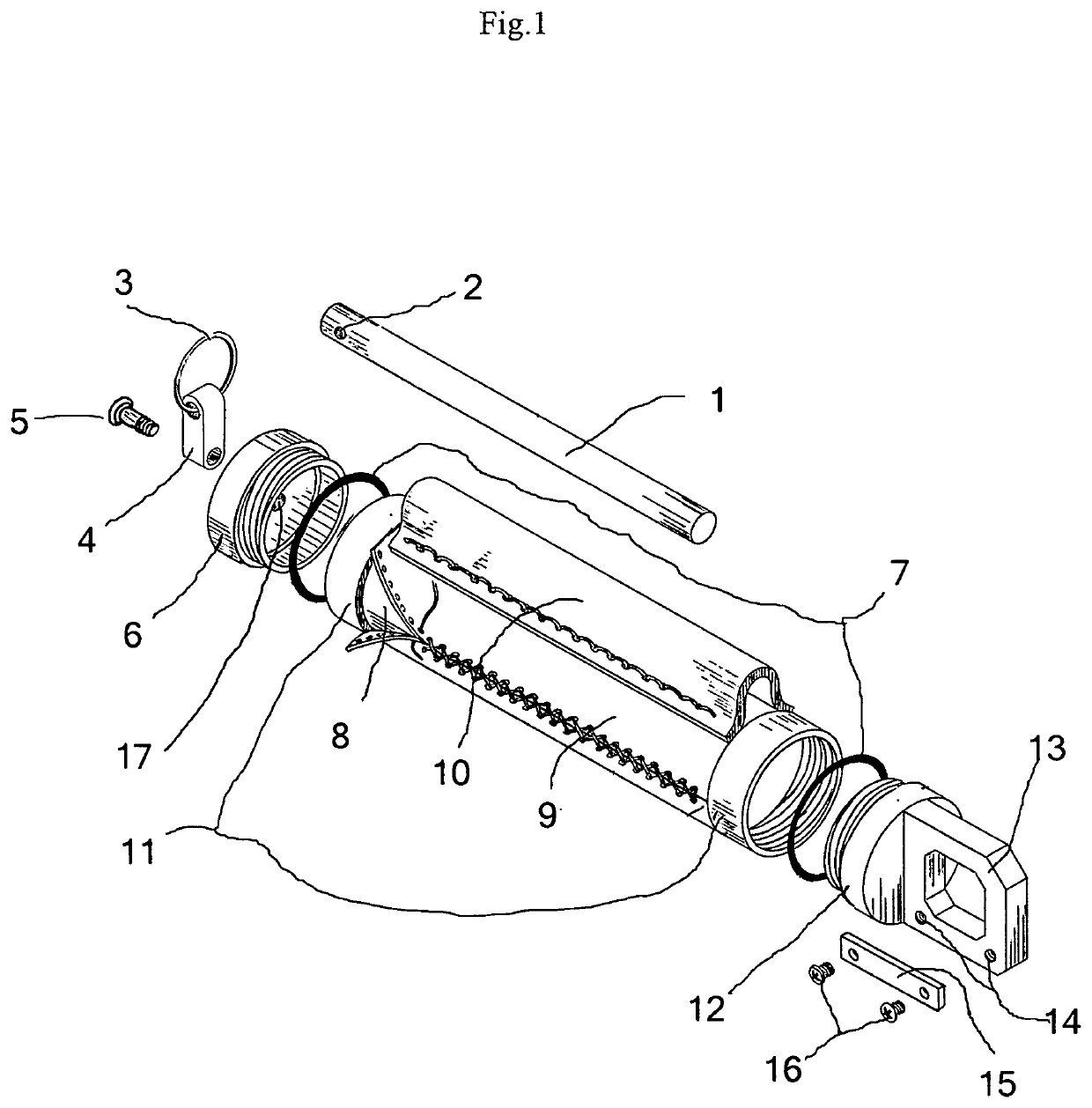

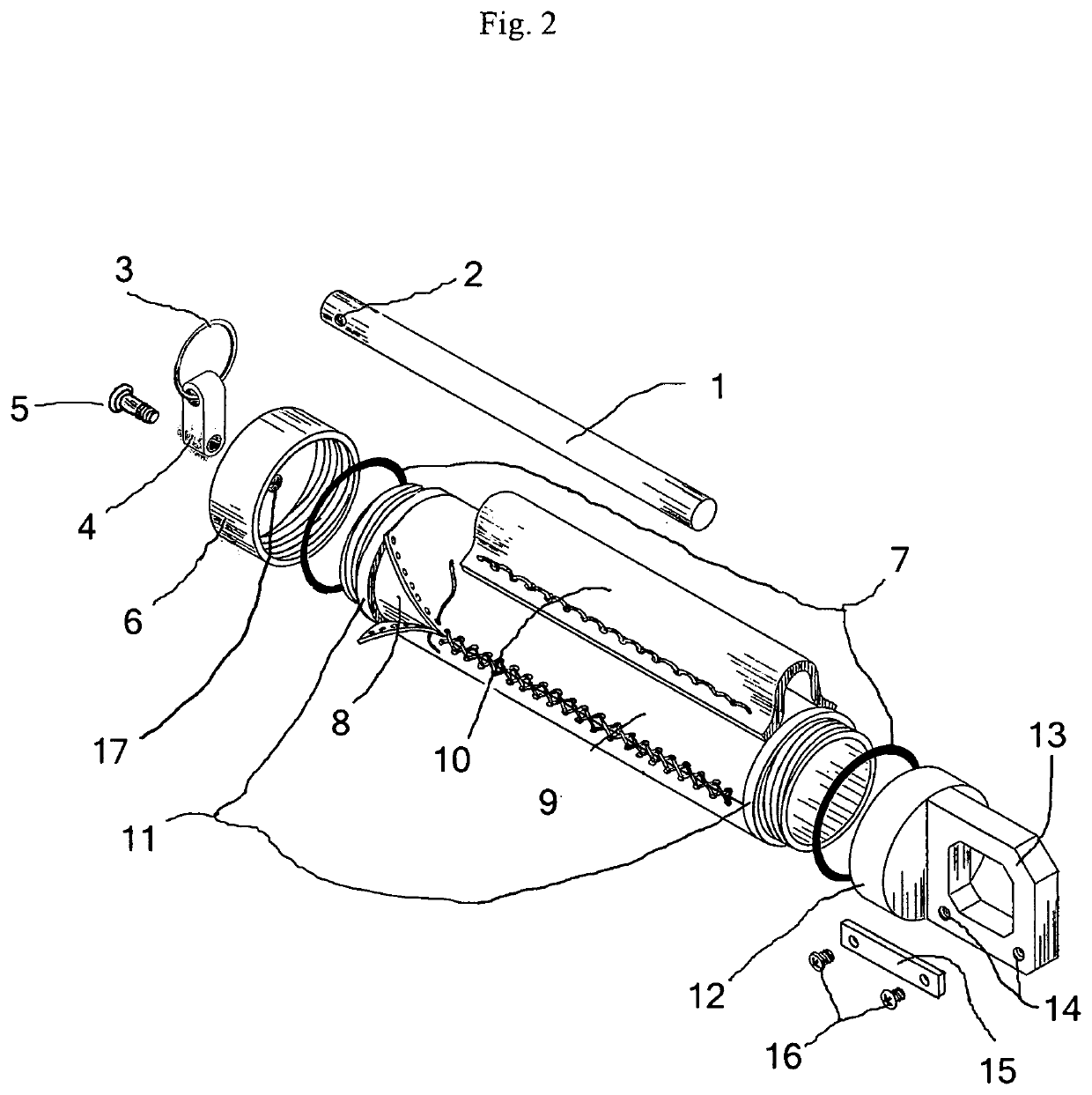

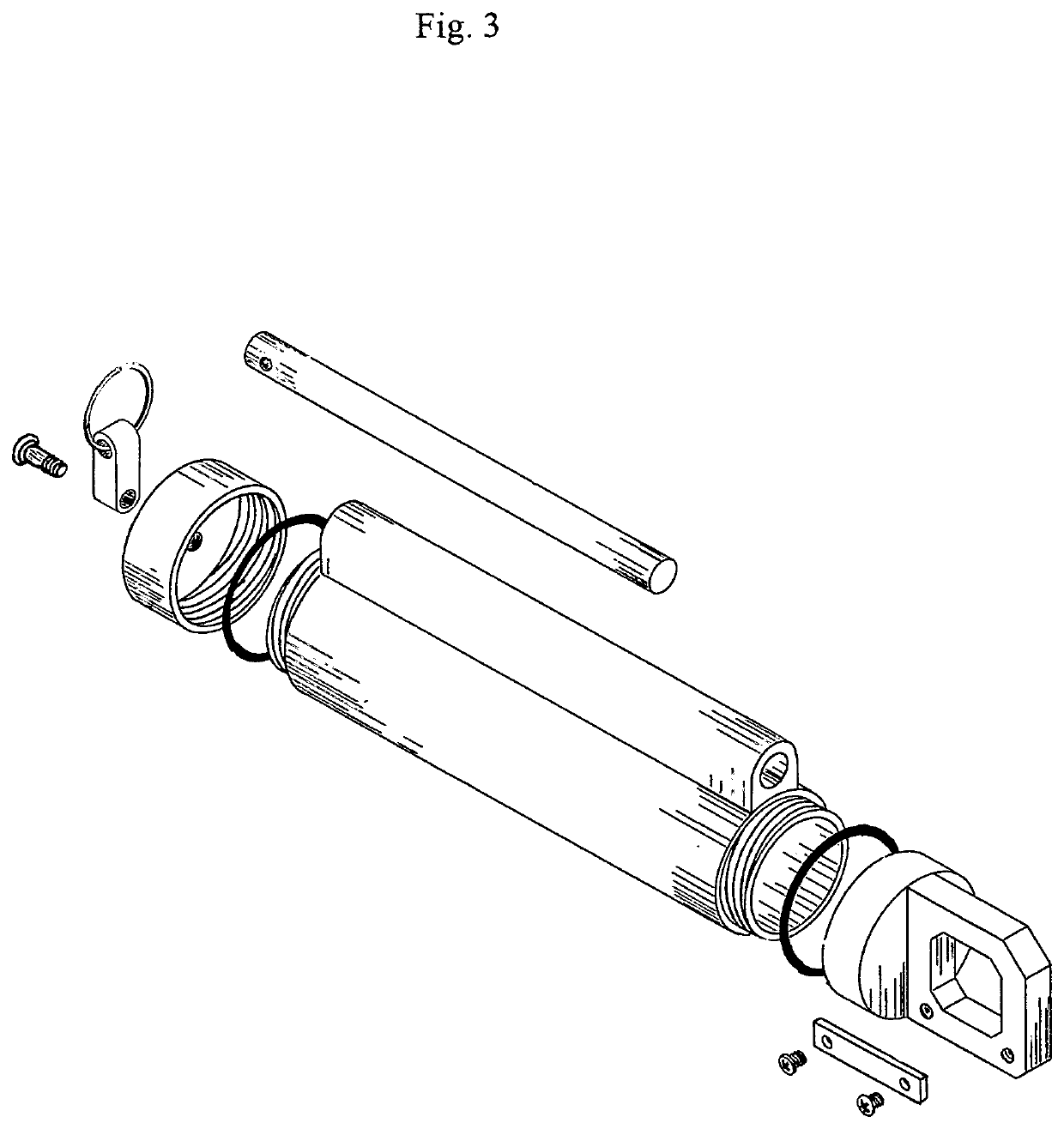

Handheld storage tube having an externally integrated firestarter

ActiveUS10684011B2Maximized internal storage areaEliminate tendencyTravelling carriersPursesHand heldEngineering

Owner:SEITLER JR SAMUEL LEE

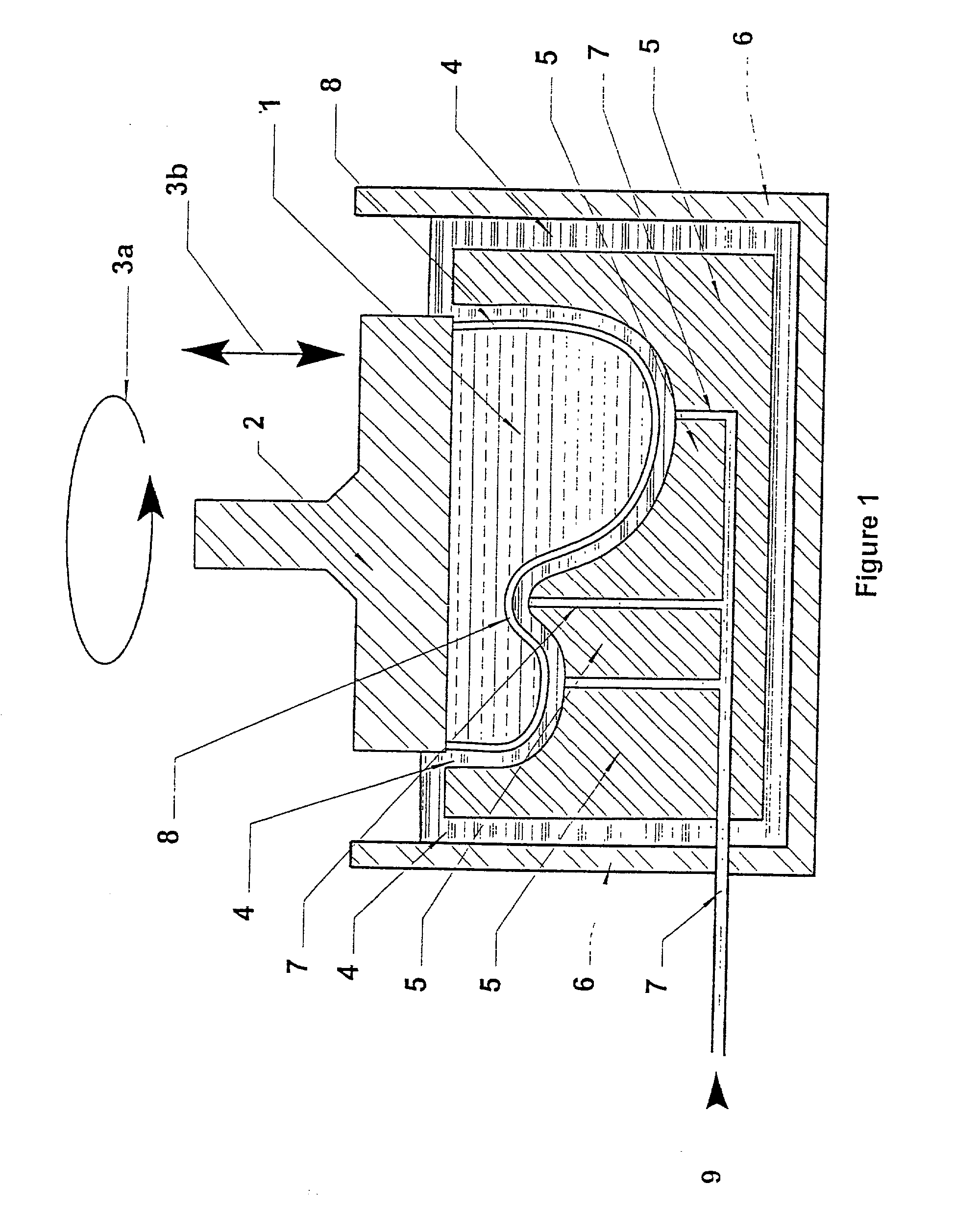

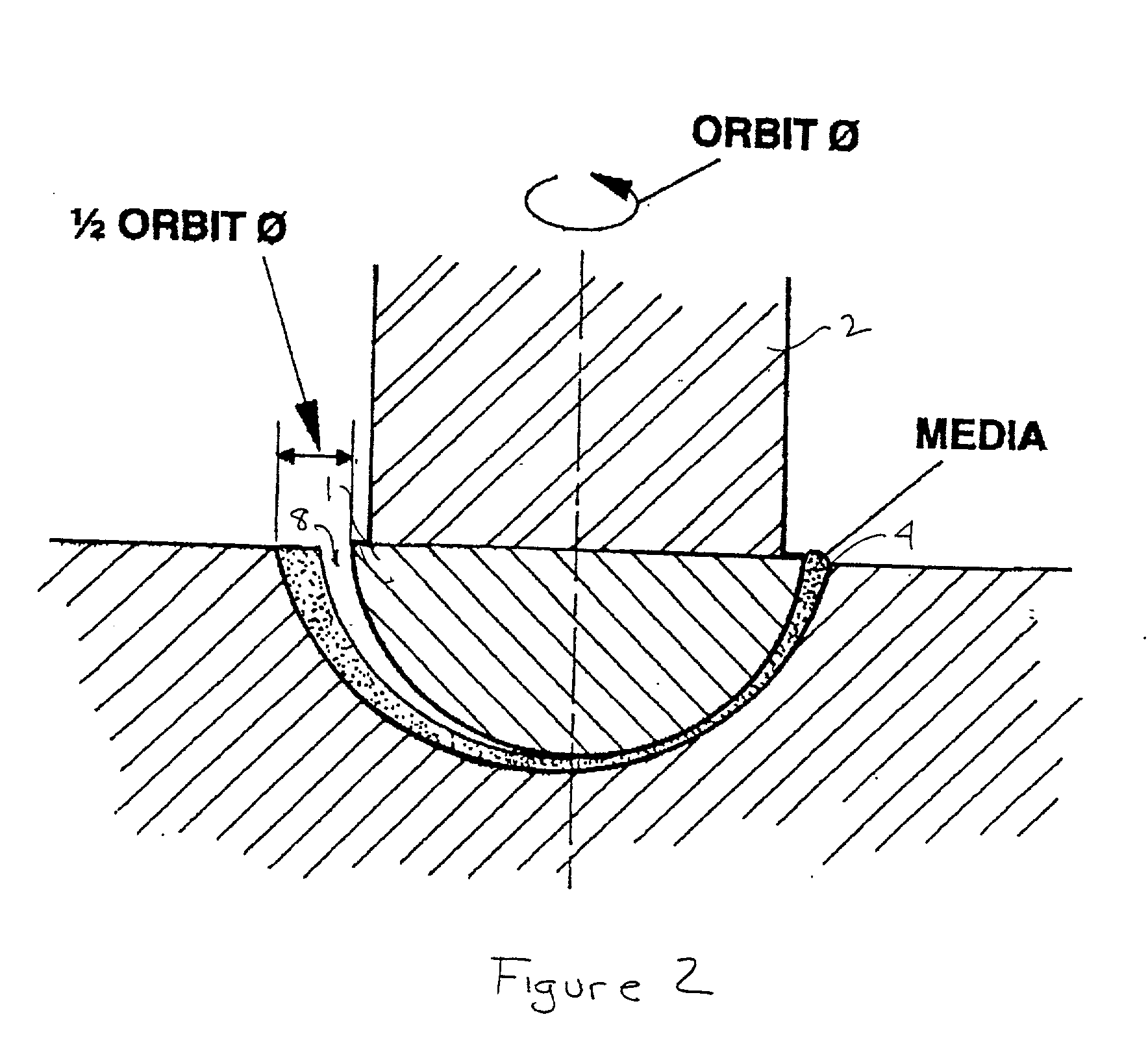

Abrasive polishing apparatus

The present invention is based on the practice of abrasive machining with no sealed working chamber by the employment of a visco-elastic abrasive medium, behaving predominantly as an elastic solid at the applied strain of the orbital working motion, and applying orbital or other relative working motion to produce strain rates which bring the medium into a predominantly elastic deformation and often near, but not to exceed, the compressive stress limit at the strain rate employed. The preferred visco-elastic abrasive medium is a rheopectic poly(boro-siloxane) filled with viscosity increasing stiffening agents and high loadings of the abrasive of choice and relatively minor amounts of plasticizers. The system is operated in an open chamber under applied strain rates such that at least about 50%, particularly about to 99%, and preferably about 80 to 95%, of the deflection of the medium tinder the conditions of operation occurs by elastic deformation and is elastically recovered, and less than 50%, particularly about 1 to 50%, preferably about 5 to 20%, of the deflection of the medium occurs by fluid or plastic flow.

Owner:EXTRUDE HONE CORP

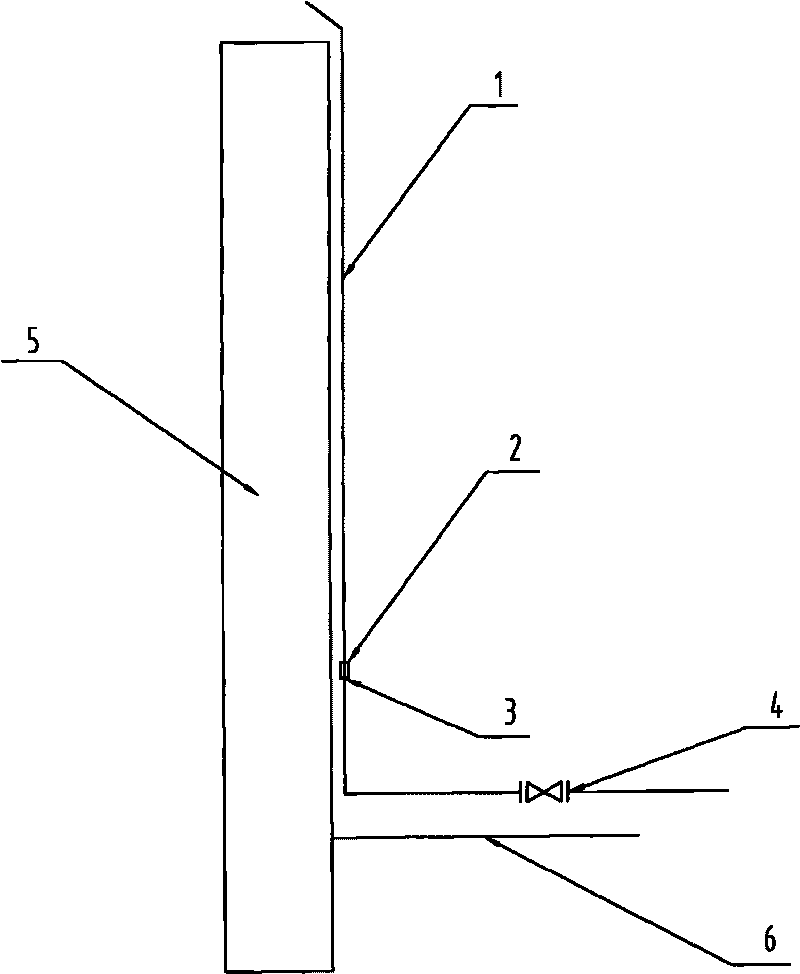

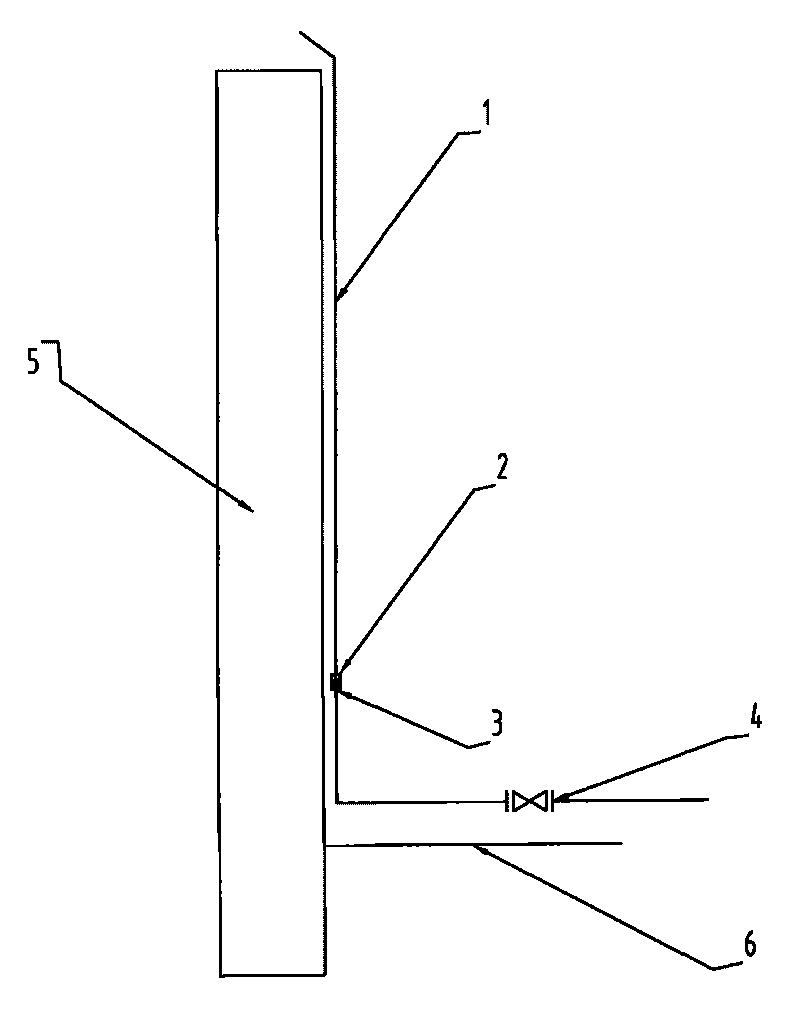

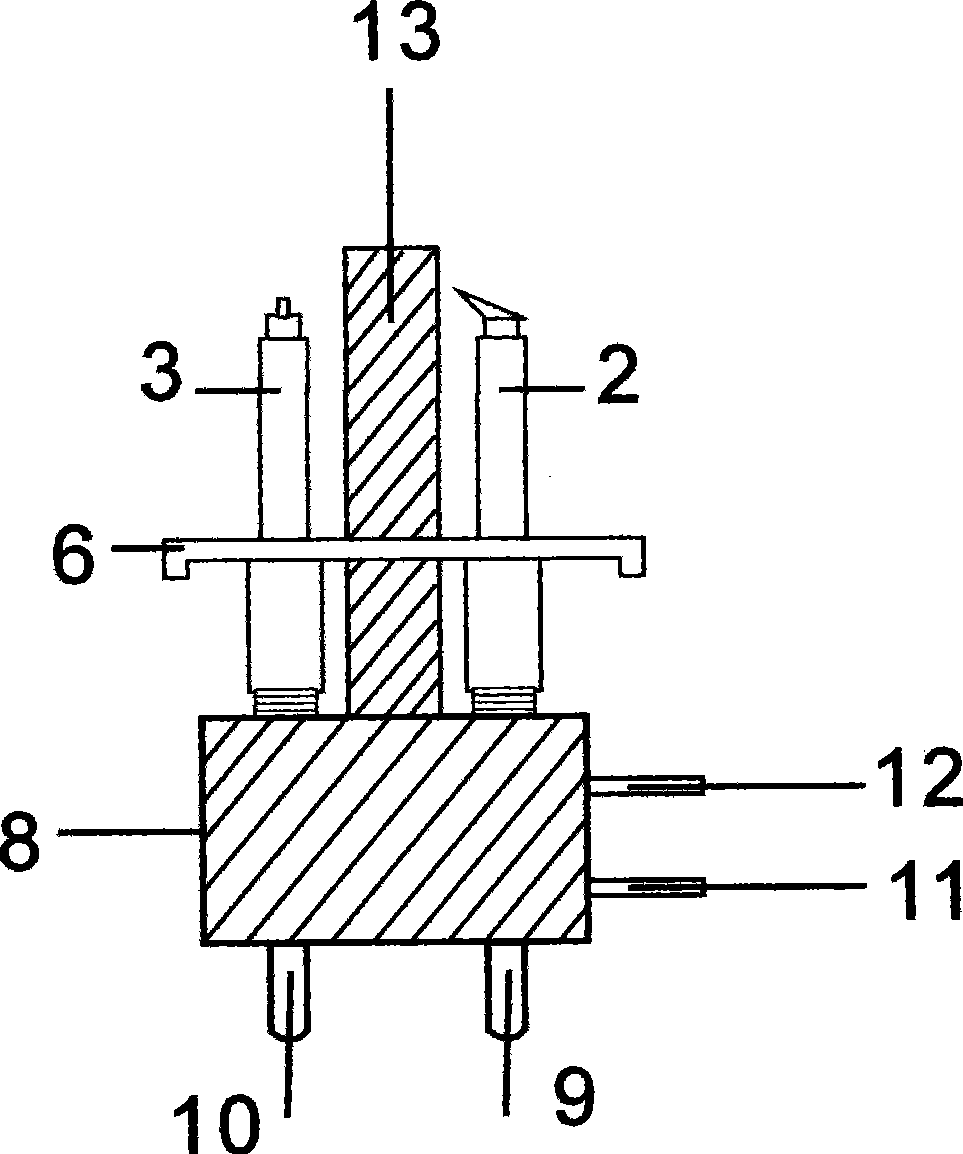

Crude gas ignition method of coke oven diffusing tubes and device thereof

InactiveCN101701714AEmission reductionImprove securityIncinerator apparatusPollutant emissionsCoke oven

The invention belongs to the technical field of coke oven crude gas treatment, in particular a crude gas ignition method of coke oven diffusing tubes and a device thereof. A steel tube is erected on the outer side of each diffusing tube of a coke oven in the same direction, the tops of the steel tubes are bent to the ports of the diffusing tubes, and the horizontal sections of the steel tubes are provided with one valve; an air inlet is arranged on the vertical section of the steel tube and is enclosed by an air door made of a steel board; the front end of the valve on the horizontal section of the steel tubes is filled with coke oven crude gas for heating the coke oven; the valves on the steel tubes are opened, the coke oven crude gas is ignited by a tinder at the air inlet, the burning flame rises to the tops of the steel tubes and spouts to the ports of the crude gas diffusing tubes; crude gas diffusing valves are opened, and then the crude gas is diffused to be ignited for burning. The invention greatly improves the safety of special operation of the crude gas diffusion of the coke oven, reduces the labor intensity, enhances the timeliness, greatly reduces the pollutant emission and has the advantages of simple operation, practicality, convenient maintenance and low investment cost.

Owner:NANJING IRON & STEEL CO LTD

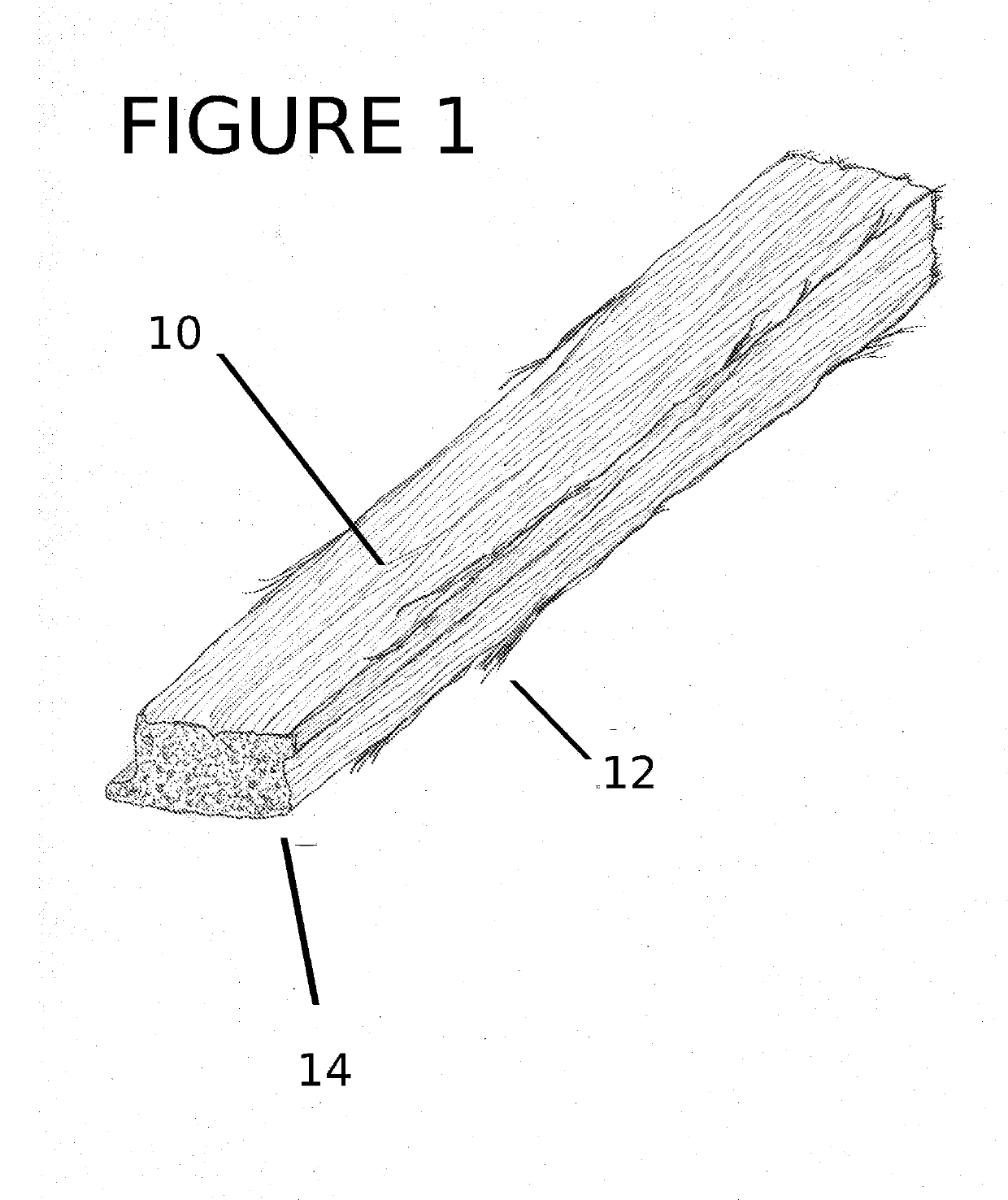

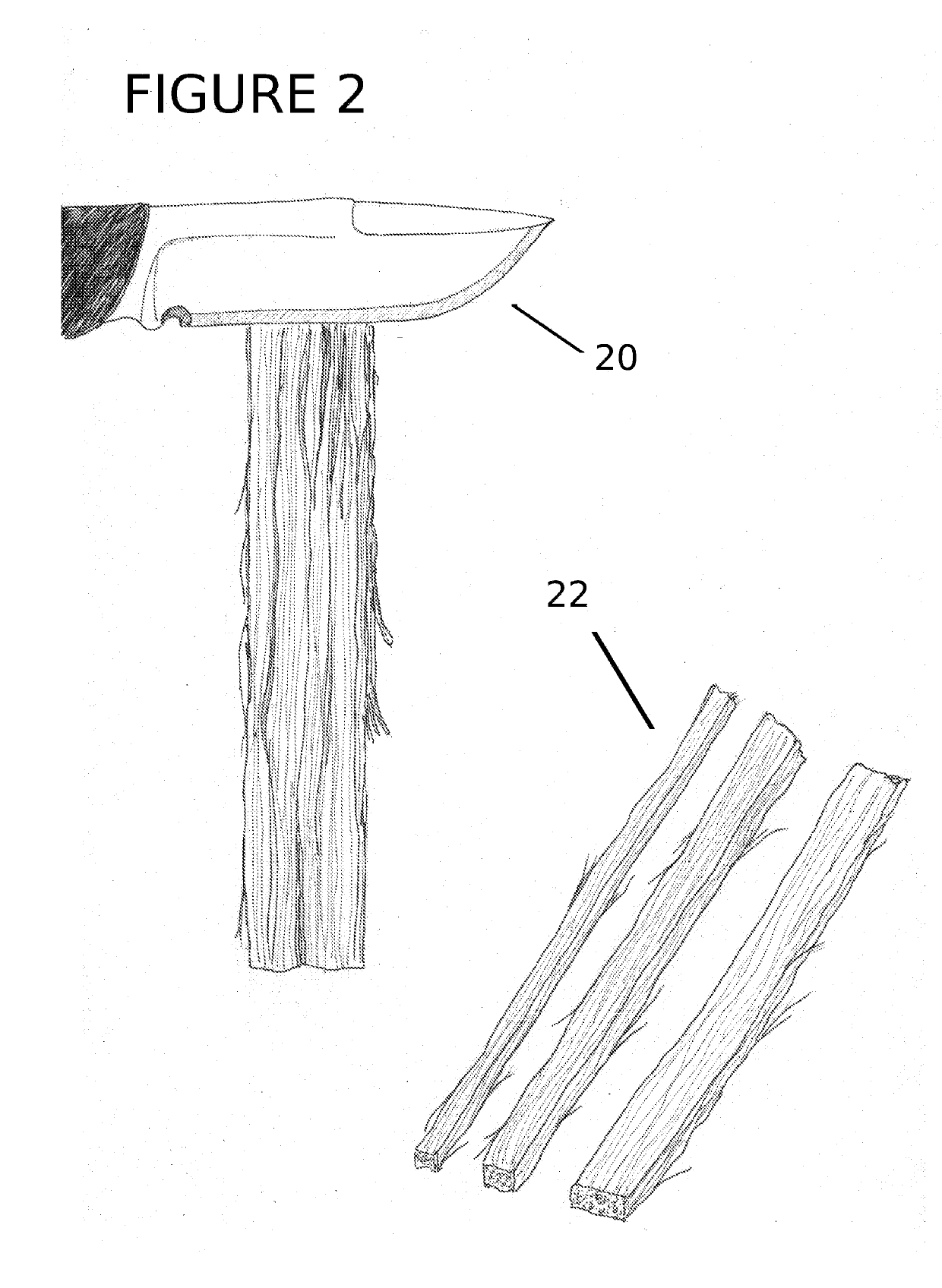

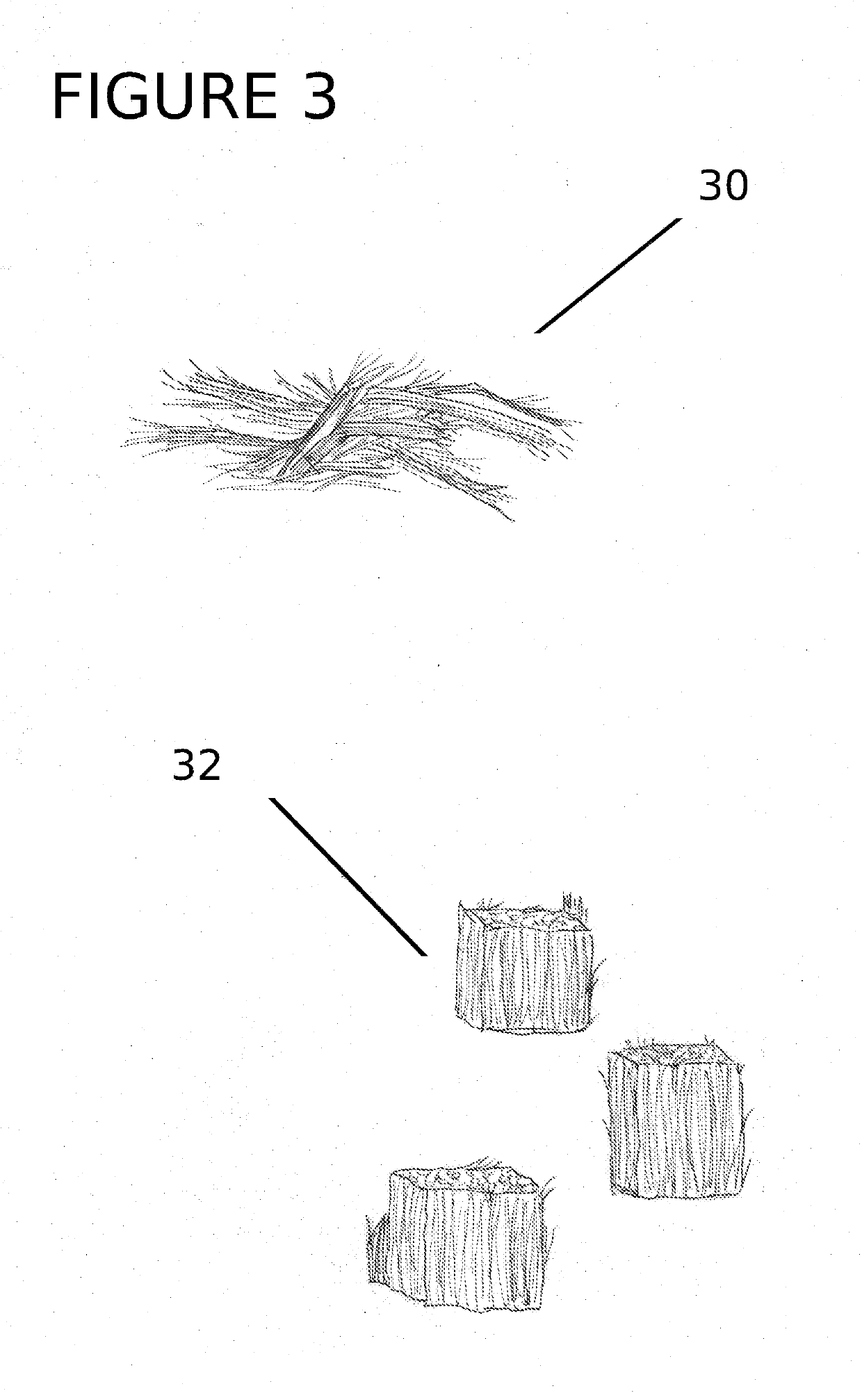

Shredable and splitable wax accelerant impregnated fire tinder

InactiveUS20190127653A1Improve resistance performanceEasy to packBiofuelsSolid fuelsParaffin waxEngineering

A fire starting implement in where the fuel source is an unadulterated piece Red Western Cedar Bark is impregnated with a secondary fuel source that acts as an accelerant. The combination of Red Western Cedar with Paraffin wax or other wax based accelerant creates a fire starter that is easily manipulated by hand or by tool. The final product can be split into smaller pieces or be pulled apart and shredded into finer strands. The fire starting implement created from this combination creates a highly weather resistant and versatile fire starter.

Owner:BRENDER ERIC JAMES

Time released curing system

Curable urea formaldehyde binder compositions are provided which are useful in coated abrasive and wood engineering applications, in a time released fashion. The time released curable binder compositions include a urea formaldehyde resin and an aryl phosphite in varying concentrations. The curable binder compositions of the present invention provide desirable working times and faster curing times tinder ambient or near ambient conditions.

Owner:MOMENTIVE SPECIALTY CHEMICALS

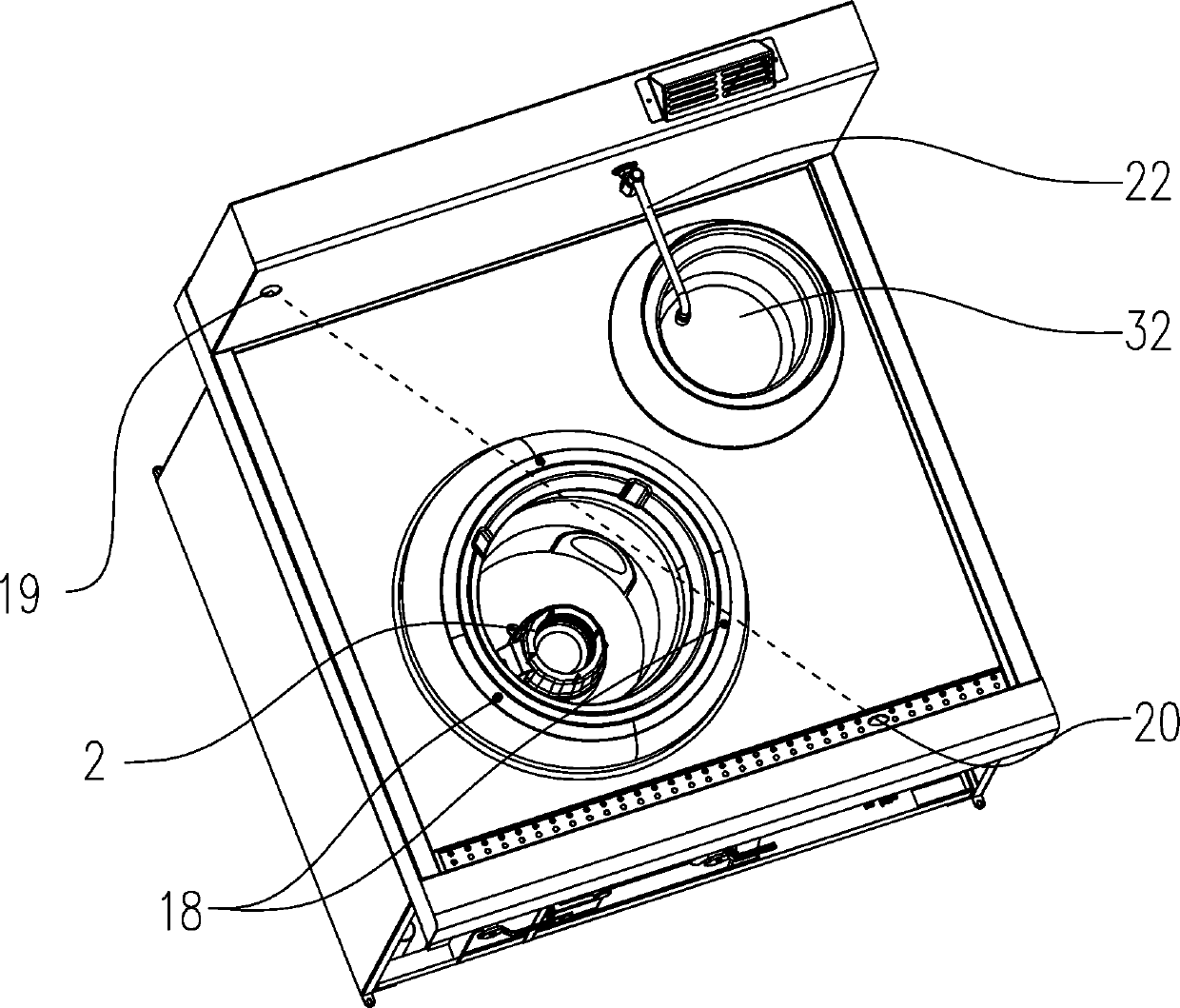

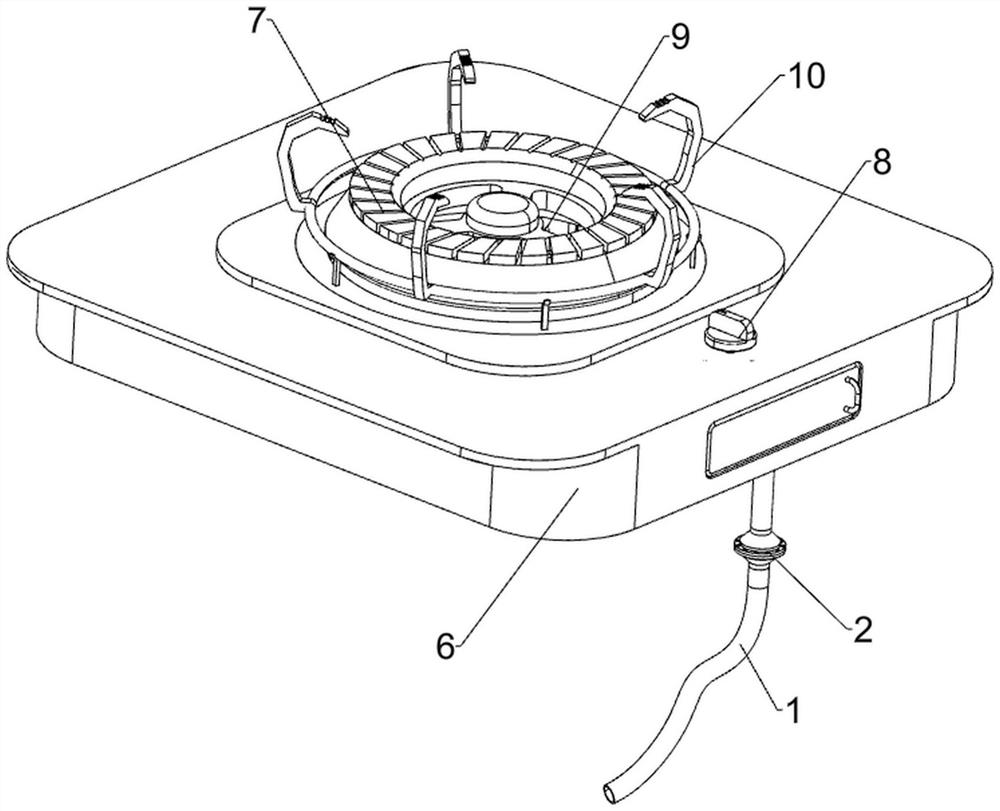

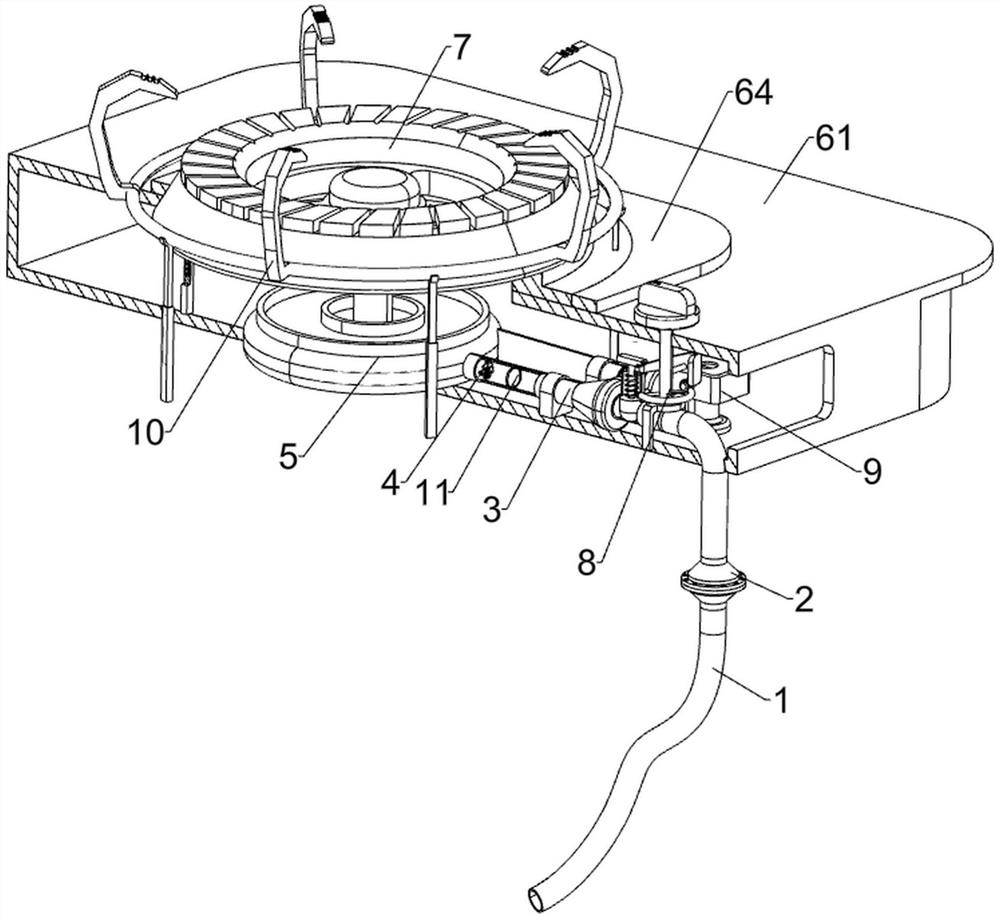

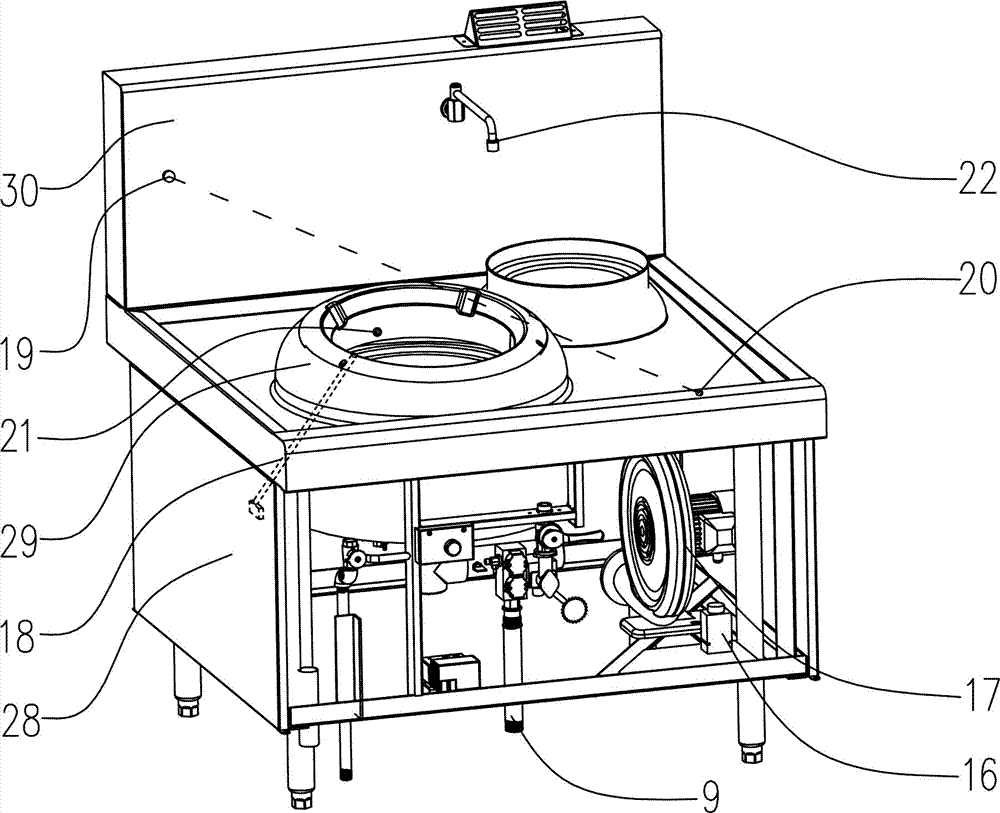

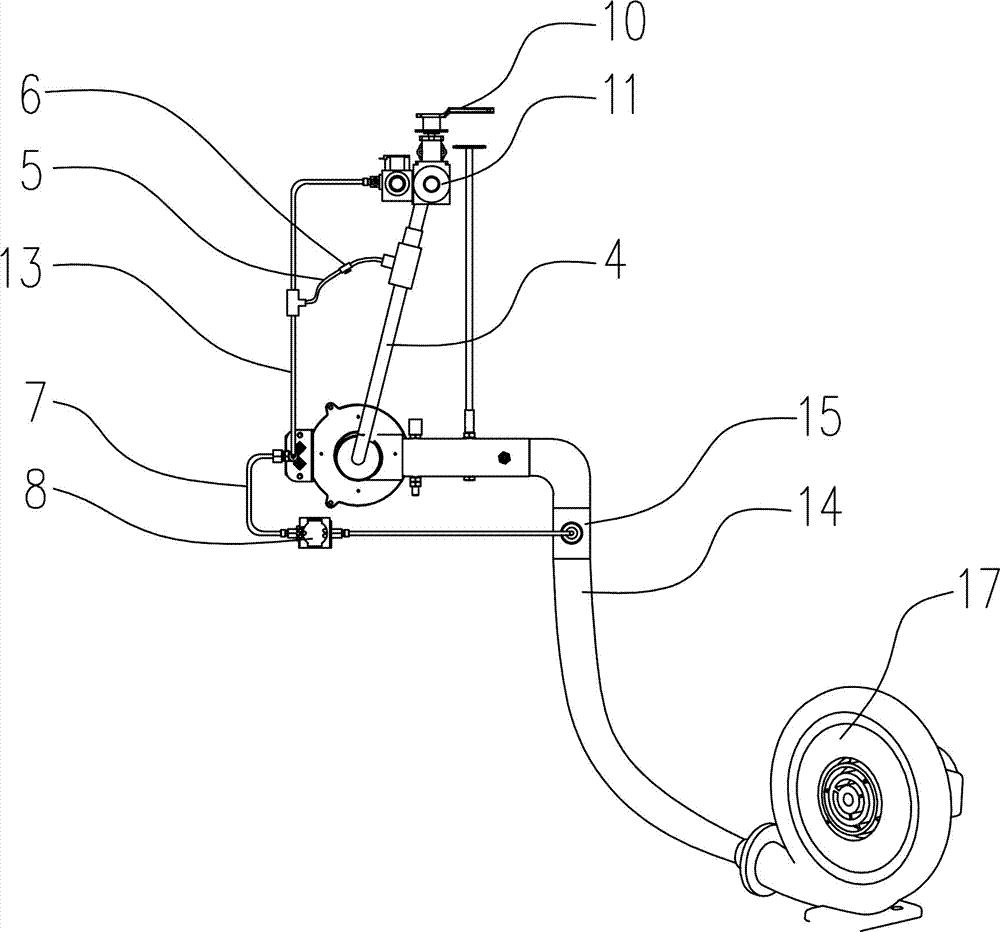

Intelligent fuel gas stove and control method

PendingCN107726377ARealize automatic controlAvoid misuseDomestic stoves or rangesLighting and heating apparatusProcess engineeringTinder

The invention provides an intelligent fuel gas stove and a control method. The intelligent fuel gas stove comprises a stove body. A stove platform is arranged on the top part of the stove body; a furnace end is arranged in the stove platform; a tinder head is arranged on one side of the furnace end; the furnace end is connected with a fuel gas proportioning valve through a fuel gas pipe; the tinder head is connected with the fuel gas proportioning valve through a tinder pipe; a fuel gas tee joint is arranged on the fuel gas pipe and is connected with one end of a tinder balance pipe; the otherend of the tinder balance pipe is connected with the tinder pipe through the tinder pipe tee joint; a tinder fuel gas valve is arranged on the tinder balance pipe; a fan is connected with one end ofan air pipe; the other end of the air pipe is connected with the furnace end; and the fuel gas proportioning valve, the tinder fuel gas valve and the fan are electrically connected with a control device. Through detecting a pot space position, the gas stove is intelligently controlled. Through adopting a scheme that the control device is connected with the fuel gas proportioning valve, the tinderfuel gas valve and the fan, a flame is automatically controlled, and with the tinder balance pipe, the flame of a tinder can be prevented from being influenced by a fuel gas flow of the furnace end.

Owner:HUBEI JINYUAN HOTEL EQUIP SUPPLIES

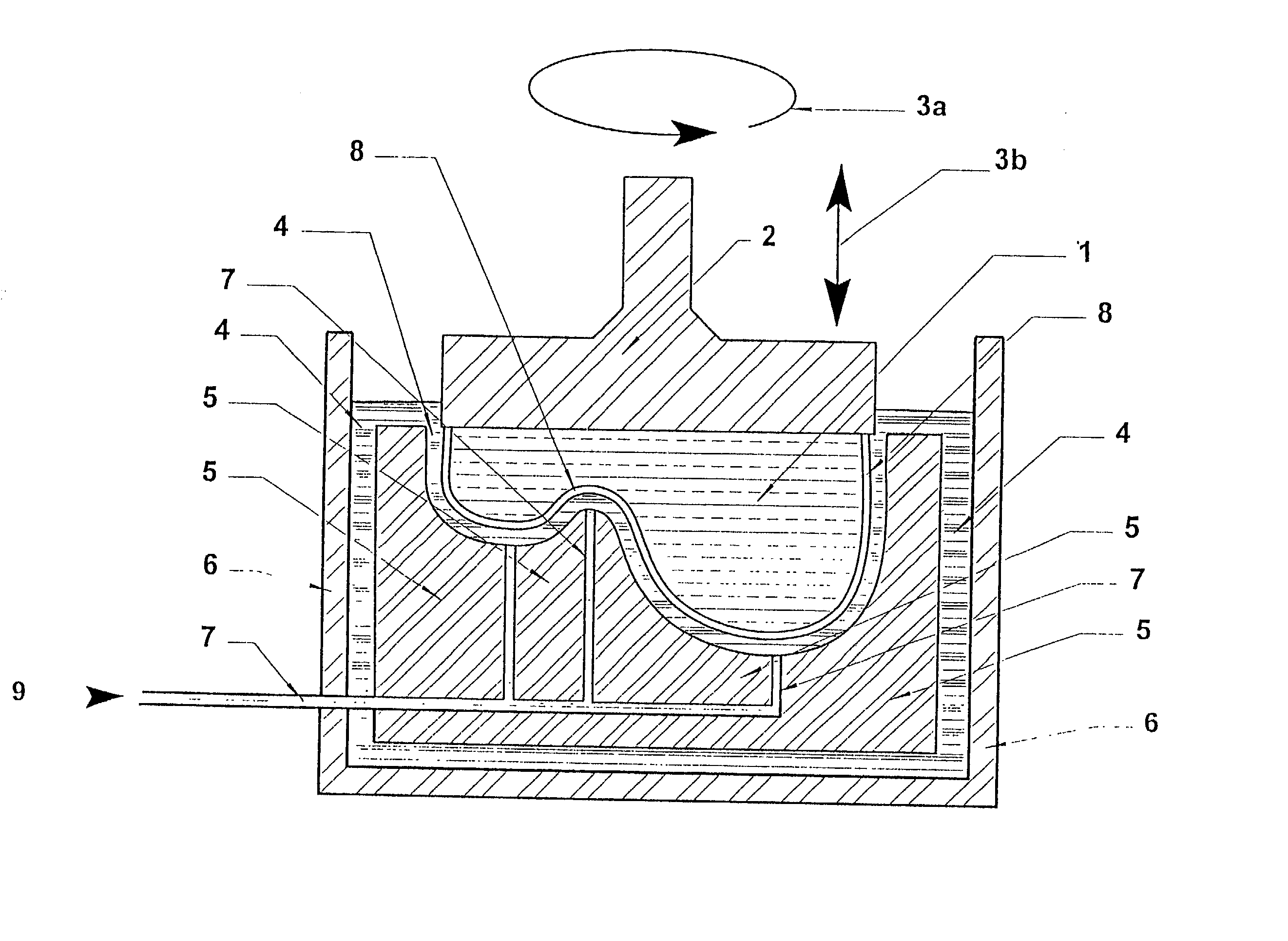

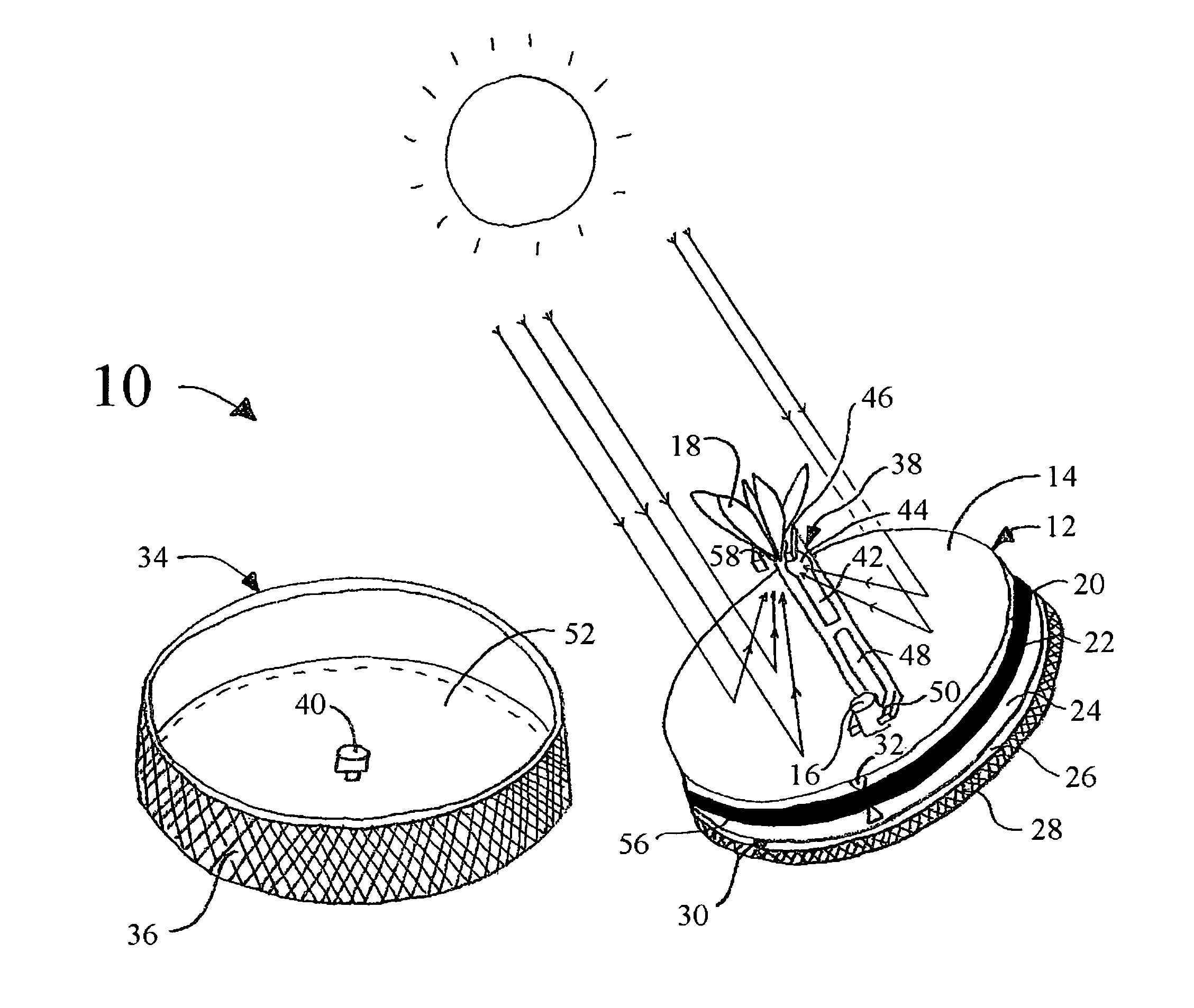

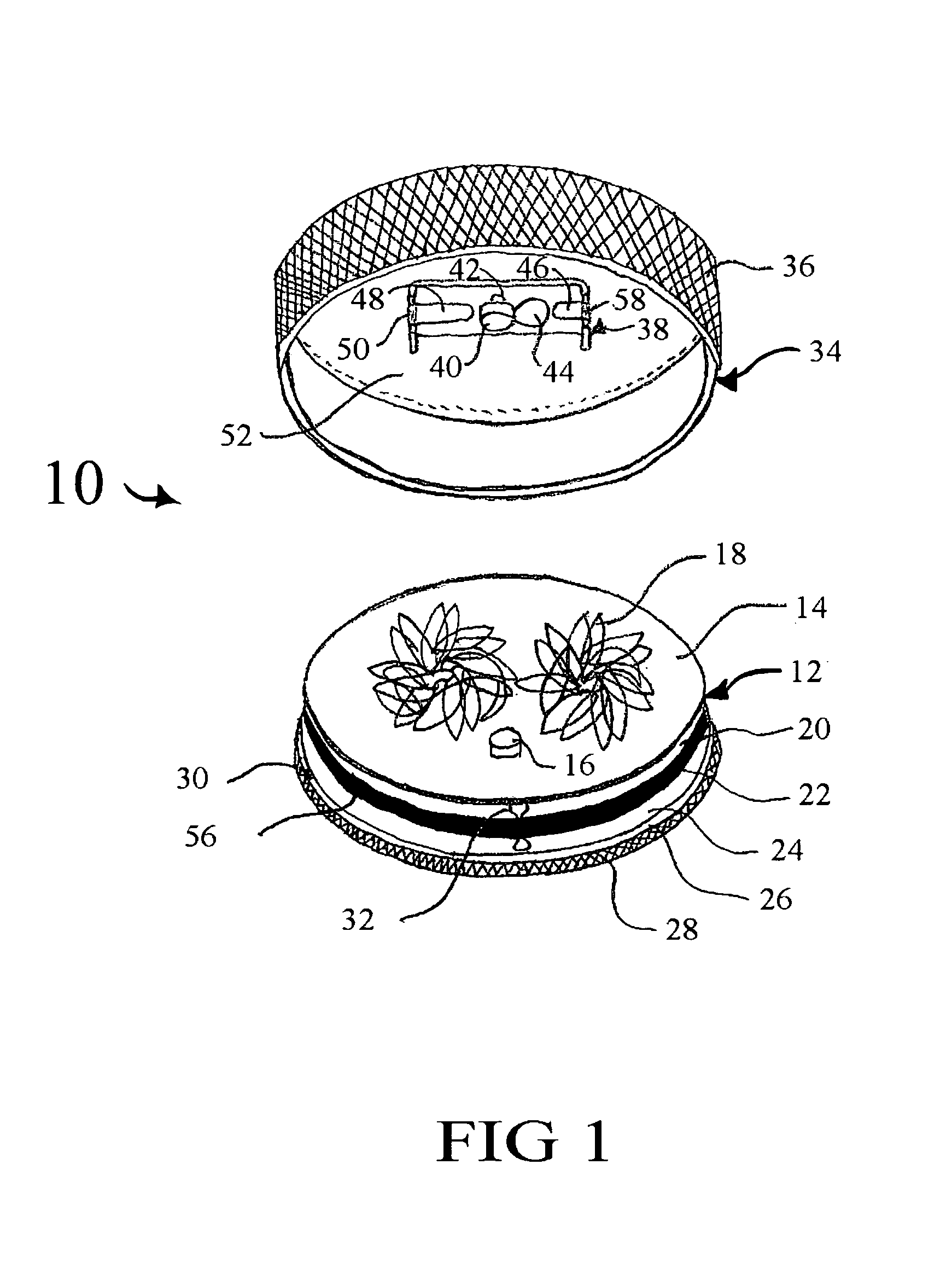

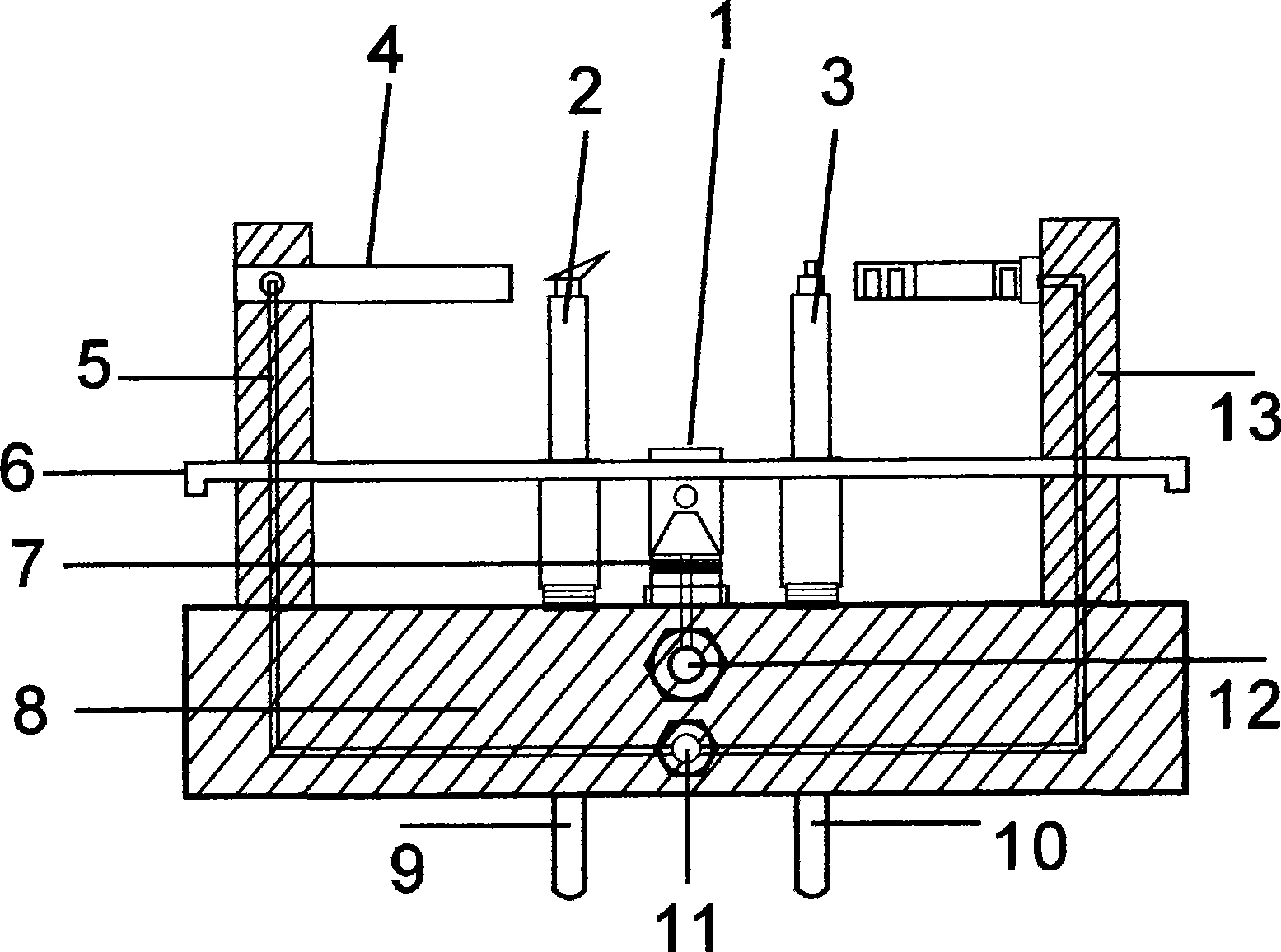

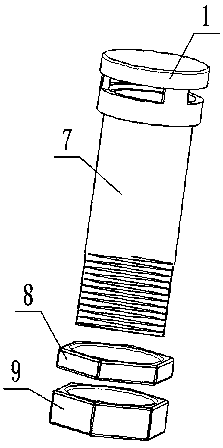

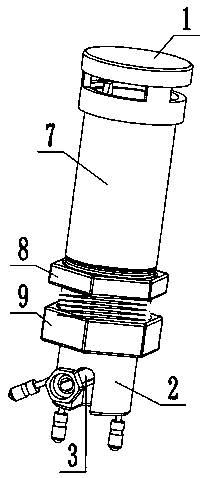

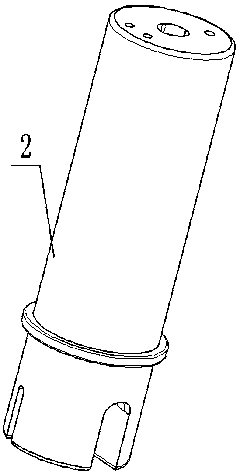

Tinder storage container solar powered fire starter

ActiveUS9404653B1Improve maximum efficiencyRapid positioningSolar heating energySolar heat devicesCouplingEngineering

A tinder storage container solar powered fire starter that includes top and lower housings that when coupled together form a water tight tinder storage cavity of which the inside bottom surface is a machined parabolic reflector that when used in conjunction with a tinder holder arm that securely positions the fire starting tinder at the exact focus of the reflective parabolic surface of the lower housing is able to use solar power to ignite combustible materials. The tinder holder arm is stowed in the top housing during non-use and incorporates a series of light through holes, and flex points, that provide maximum efficiency and quick positioning from stow configuration to fire starting configuration. The inside reflective inside surface of the top housing is a signal mirror, a lanyard hole is provided to prevent loss. An hour glass shaped air escape slot provides easy coupling of the top and bottom housings.

Owner:THE FOUNTAIN HEAD GROUP INC

Auto-ignition energy-saving burner of gas appliance

InactiveCN101520179ABurn fullyAvoid wastingElectric spark ignitersGaseous fuel burnerPhysical healthTime delays

The invention discloses an auto-ignition energy-saving burner of a gas appliance; the double-sided ignition way by an electronic ignition needle is designed at a gas jet of the burner, thereby being capable of solving the defects of difficult ignition, fire-lighter borrowing and time delay during the use of the burner. The burner adopts the double-sided ignition and the method of eruption type space burning, thereby improving the mixing situation of gas and air, leading the gas to be burned completely and reducing the emissions of nitrogen oxides and carbon monoxide during the burning; flames during burning are ice blue pure fire, thereby well protecting environment and the physical health of a user; and the waste of mixed burning in the currently used commercial burner of the gas stove is avoided, thereby greatly saving gas resources.

Owner:汝爱峰

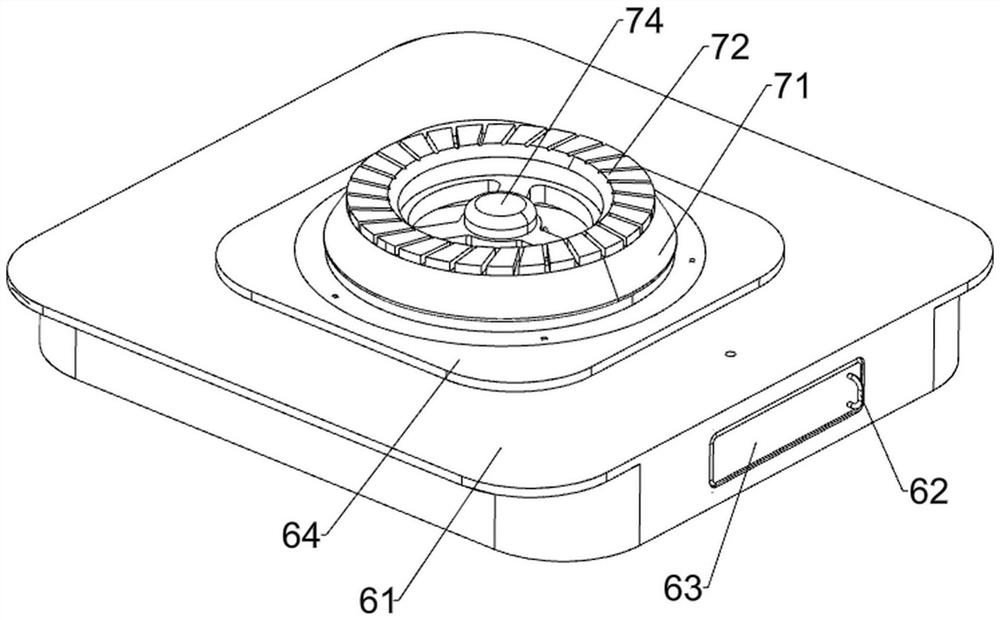

High-leg furnace end with uniform gas mixing function

InactiveCN113339847APrevent backflowReduce distanceDomestic stoves or rangesLighting and heating apparatusFlame arresterThermodynamics

The invention relates to a high-leg furnace end, and particularly relates to a high-leg furnace end with a uniform gas mixing function. The high-leg furnace end with the uniform gas mixing function mainly aims at achieving the effects that an air door is not needed, flame instability is avoided, fuel gas is driven to be stably output, the combustion efficiency is guaranteed, meanwhile, fuel gas backflow is prevented, and safety is guaranteed. The high-leg furnace end with the uniform gas mixing function comprises a gas receiving hose, a flame arrester, a gas conveying pipeline, a turbine, a furnace end, a containing mechanism and a furnace assembly, wherein the containing mechanism is arranged in the high-leg furnace end, the furnace assembly is arranged on the top of the containing mechanism, the furnace end is arranged in the containing mechanism, one side of the furnace end is connected with the gas conveying pipeline, the flame arrester is arranged at the bottom of the gas conveying pipeline, the gas receiving hose is arranged at the bottom of the flame arrester, and the turbine is rotationally arranged between the inner walls of the gas conveying pipeline. By arranging the containing mechanism and the furnace assembly, fuel gas is driven to flow out of the furnace end through the gas conveying pipeline, kindling is driven to make contact with the fuel gas to cause fire, and the basic function is achieved in cooperation with use of the furnace end.

Owner:江西发扬实业有限公司

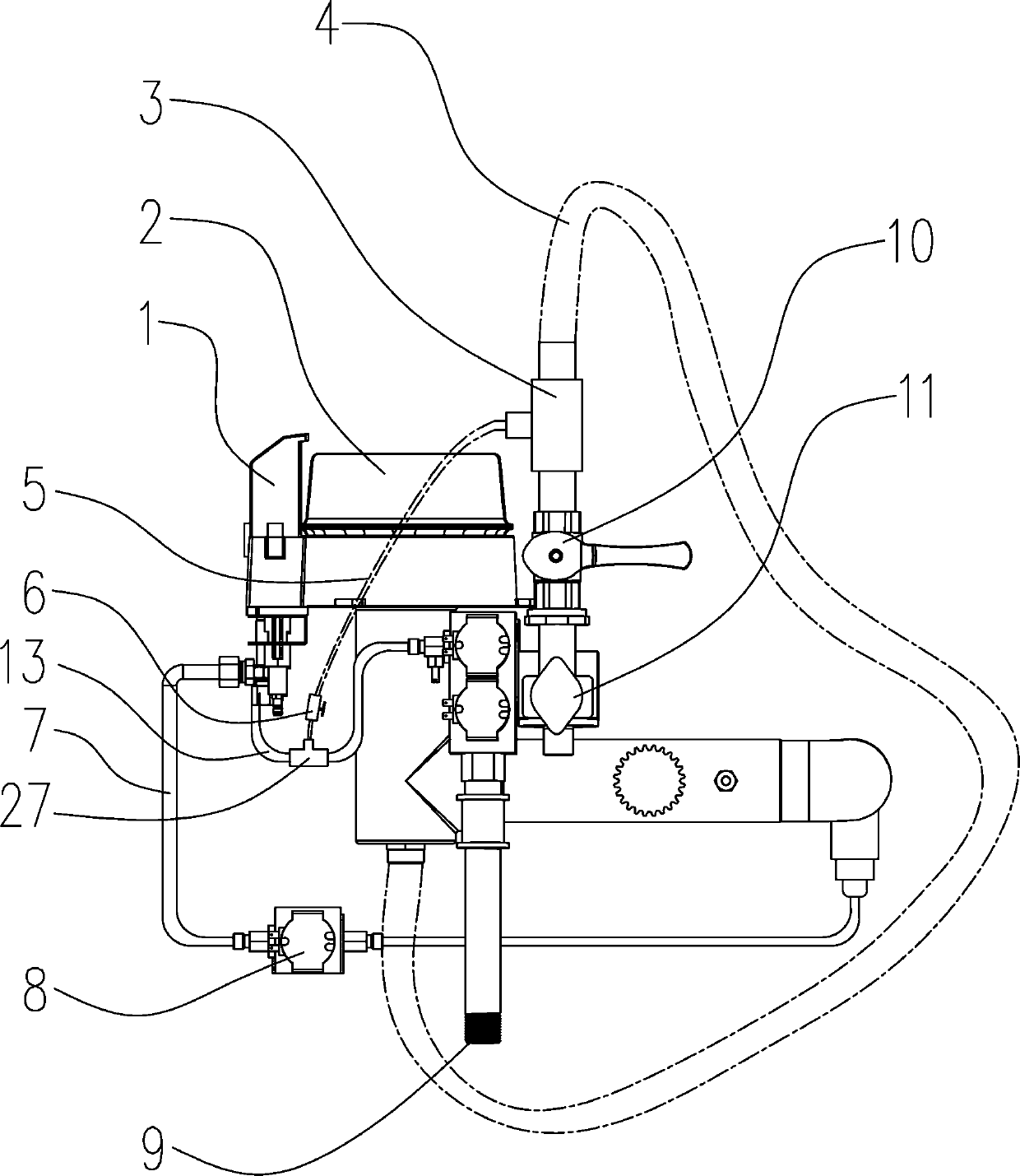

Intelligent gas stove burner

PendingCN107514634ACause shockIntelligent controlDomestic stoves or rangesGaseous fuel burnerEngineeringProportional valve

The invention provides an intelligent gas stove burner. The intelligent gas stove burner comprises a burner; a kindling head is arranged on one side of the burner; the burner is connected with a gas proportional valve through a gas pipe; the kindling head is connected with the gas proportional valve through a kindling pipe; a gas tee joint is arranged on the gas pipe, and is connected with one end of a kindling balance pipe; and the other end of the kindling balance pipe is connected with the kindling pipe through a kindling pipe tee joint. The kindling balance pipe is adopted; after gas is introduced in the burner, the gas of the burner is partially leaded to the kindling head to guarantee no pressure change of the gas; flame of the kindling head has enough length; and when the flame of the burner is extinguished, the burner can be ignited again by the kindling head. The intelligent gas stove burner adopts the scheme of controlling through a main control chip to intelligently control the gas of the burner, the gas of the kindling head and the kindling air supply.

Owner:HUBEI JINYUAN HOTEL EQUIP SUPPLIES

Smoker attachment for gas grill

ActiveUS10641495B2Easy to transportDesirable flavorDomestic stoves or rangesLighting and heating apparatusThermodynamicsEngineering

A smoker attachment for a gas grill. The smoker attachment includes a housing having a base, a pair of opposing sidewalls, a rear wall, a front face defining an opening, and an interior volume. A tinder box having an interior volume for receiving fuel therein is removably insertable into the housing. An ash catcher having an interior volume for catching ash from the tinder box as the fuel combusts is removably insertable into the housing below the tinder box. A connector is disposed on a top wall of the housing, and a connecting hose attached to the connector is insertable into an interior enclosure of a gas grill. The connecting hose facilitates the transfer of smoke from the tinder box to the interior enclosure of the gas grill. The smoker attachment enables users to convert a conventional gas grill into a smoker.

Owner:HAMMS BBQ TECH LLC

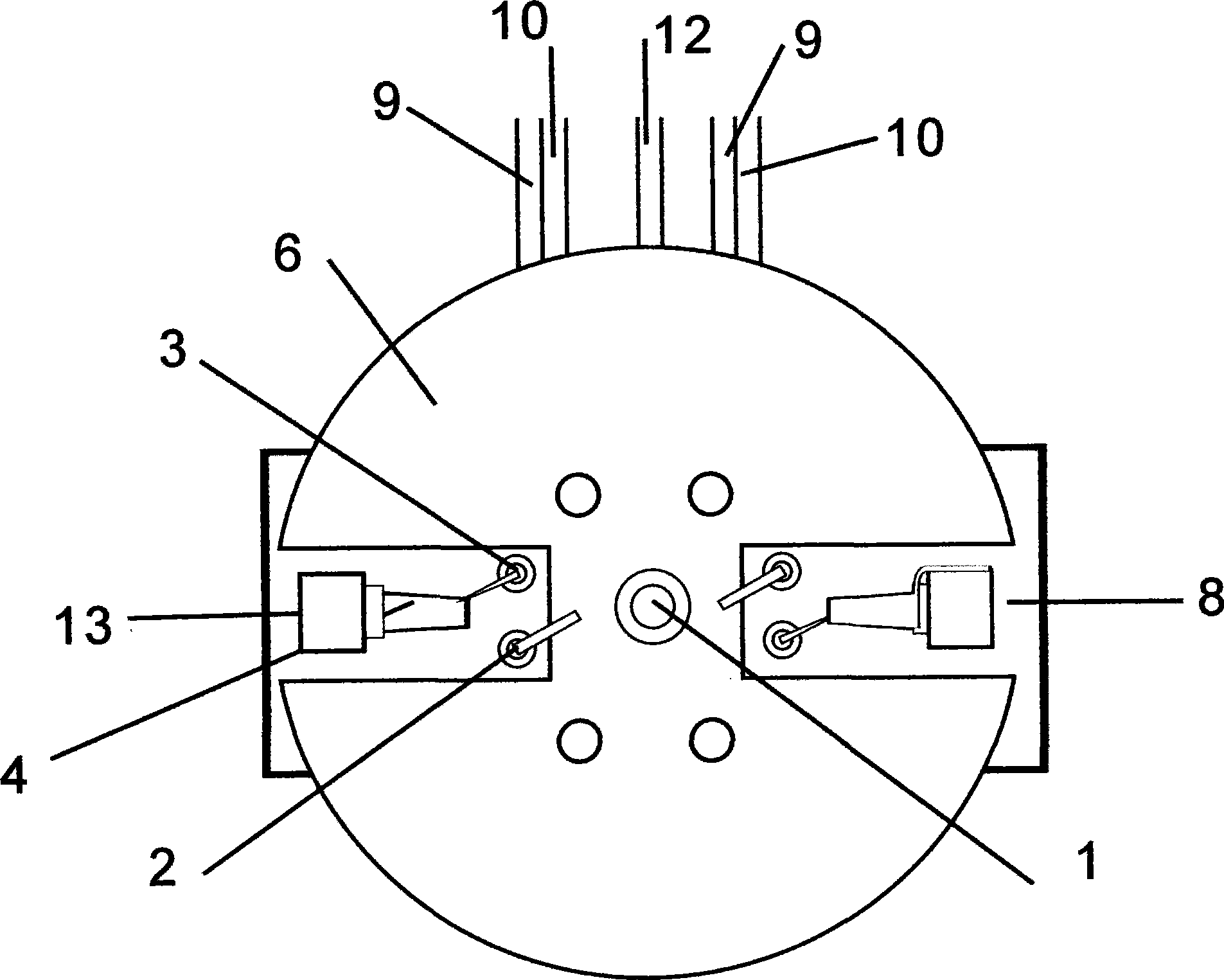

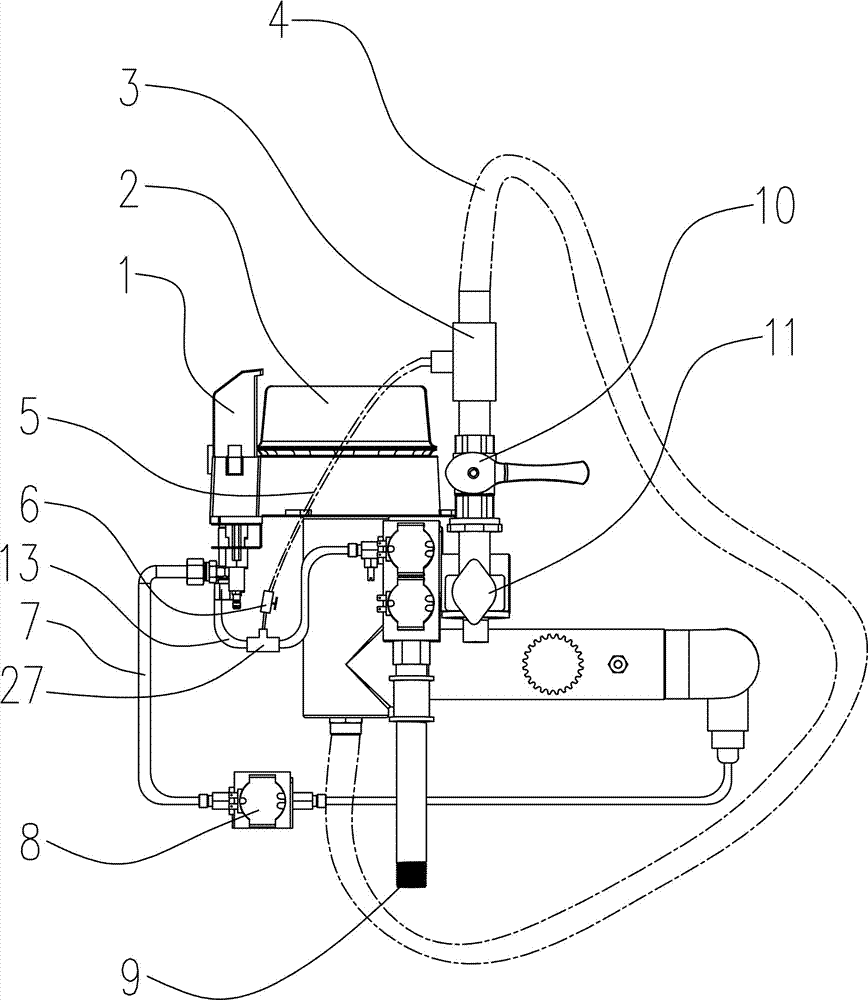

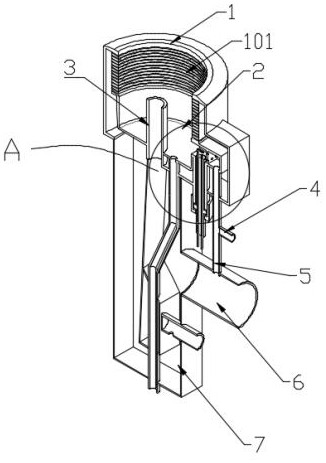

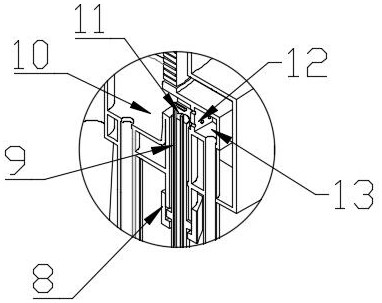

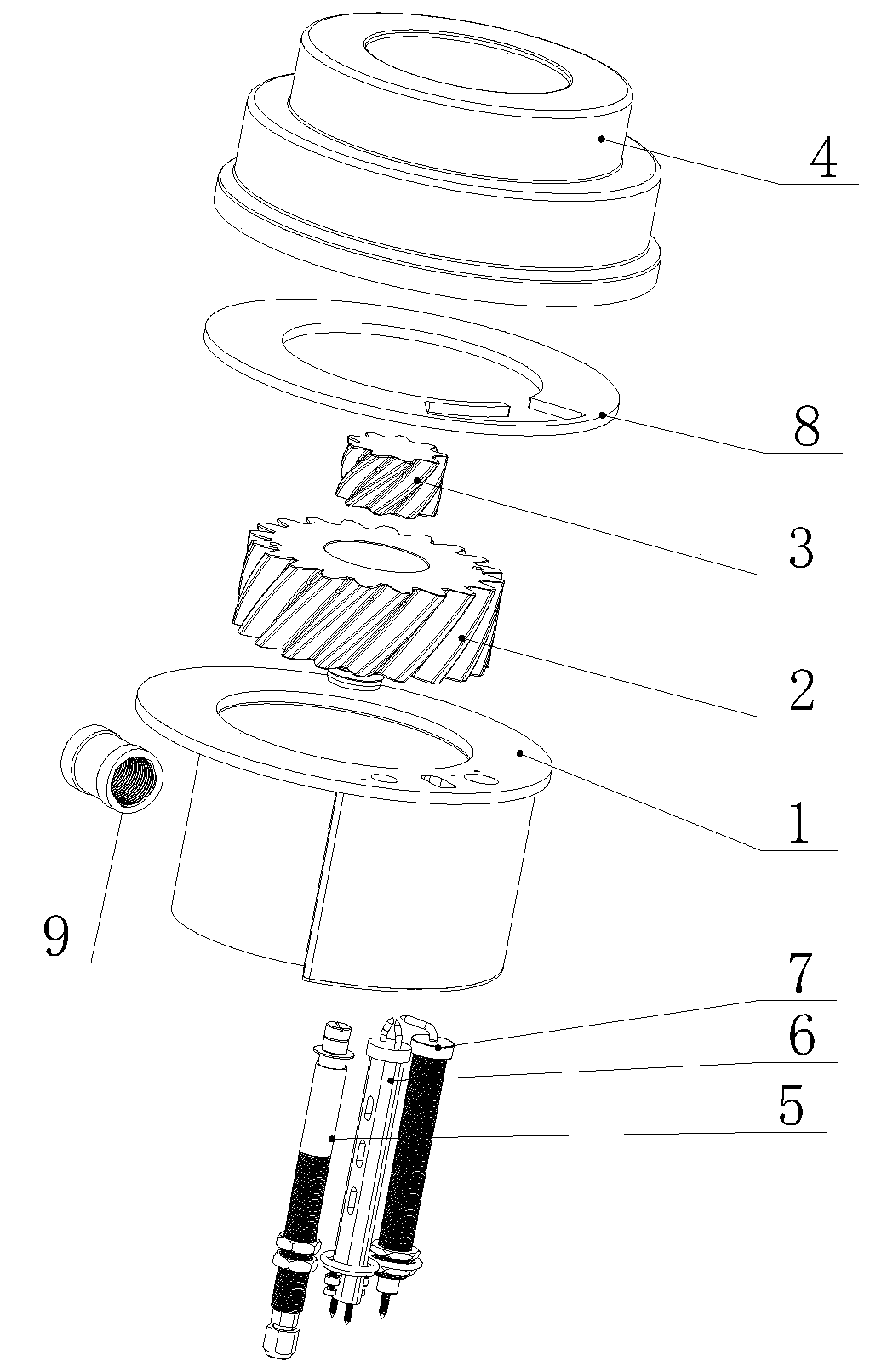

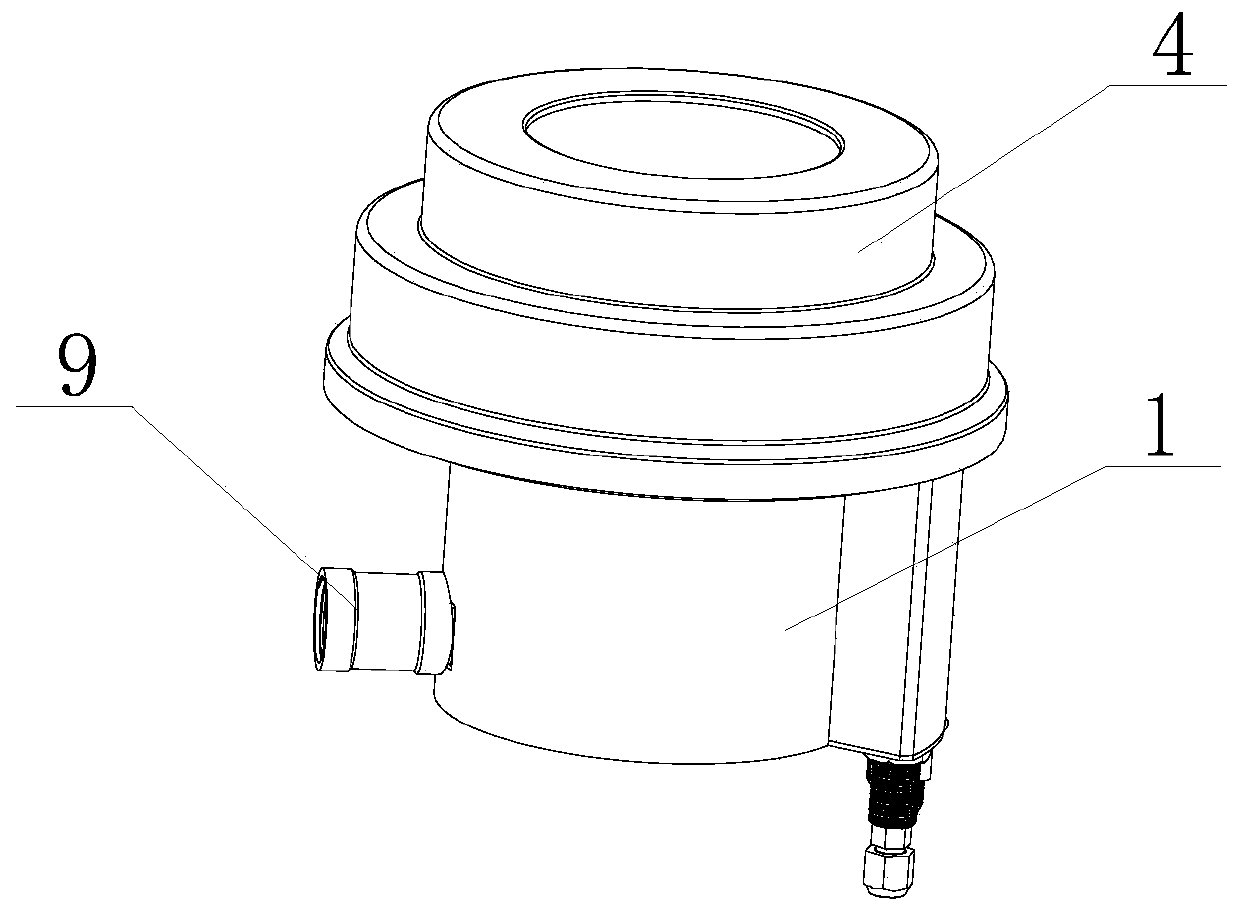

Ignition or kindling device coaxial with furnace end combustion chamber

PendingCN108930961ARealize the role of ignitionAvoid destructionGaseous fuel burnerCombustion chamberEngineering

The invention relates to the technical field of commercial gas stove fittings, in particular to an ignition or kindling device coaxial with a furnace end combustion chamber. The ignition or kindling device comprises a kindling tube, a kindling head, an umbrella cover, an umbrella cover pillar, an ignition needle, a gas transmission tee and locking nuts. By adopting the ignition or kindling deviceprovided by the invention, as the diameter of the umbrella cover is larger than the diameter of the kindling head, oil-water sundries which fall down in the use process of a furnace end can be thoroughly sheltered from falling into the kindling head, damages caused on baffle plate fire holes, an ignition needle and a ceramic can be thoroughly avoided, benefits can be brought to a kindling functionand the use stability of the ignition needle and prolonging of the service life; and meanwhile, the kindling tube is coaxial with the ignition needle, the circumference of a cavity in a mixed gas chamber can be guaranteed to be consistent, so that gas circulation of a premixed gas chamber can be avoided from generating resistance change, the benefit is bought to promotion of the uniformity of thecombustion energy and a flame of the furnace end, the adverse effect of the oil-water sundries to the kindling and the ignition needle can be effectively prevented, and the adverse effect on the uniformities of an air pressure and a flow rate caused when the furnace end organizes gas to combust can be effectively avoided.

Owner:湖北裕晨智能商厨科技有限公司

Ejector matched with high-depth combustion chamber and combustor of ignition structure

PendingCN111853778AOutflow smoothlyFast and smooth mixingElectric spark ignitersGaseous fuel burnerCombustion chamberCombustor

The invention relates to the technical field of commercial kitchen ware and in particular discloses an ejector matched with a high-depth combustion chamber and a combustor of an ignition structure, wherein an air ejection hose is arranged at the bottom of a distributor, an air flow ejected by the air ejection hose can dredge gas in the combustion chamber to flow out of the combustion chamber to reduce the probability of occurrence that the gas vibrates to induce squeal, and air ejected by the air ejection hose supplements air secondarily for combustion reaction of primary fire and mixed gas, so that the air flow of the fixed gas in the main fire can be reduced. A kindling material fire ejecting port is arranged in the inner side surface of an oil-water sundry reserving basin, so that the main fire and the mixed gas can be ignited quickly and stably to reduce the ignition time delay and avoid detonation generated by accumulation of the mixed gas. The ejector has independent tissue air and gas supplying and mixing and combusting functions and an independent kindling material mixed gas distribution chamber. An ignition needle function is not affected by a combustion flame in the distributor fully, so that the ejector has fully independent self-combustion and self-regulation function.

Owner:浙江惠厨节能科技有限公司

Multipurpose solar lighter

Owner:BOLGER JOSEPH P

Survival Belt Buckle

A fire producing survival belt buckle configured to be worn around the user's waist that may make a fire under different environmental conditions. The belt buckle includes a rigid body made of high carbon steel. The body includes a plurality of sharp striking points that when stuck against a flint, chert rock, or quartz produces a spark to ignite dry tinder or other combustible material. On a perimeter edge of the body is a ferrocerium rod that can be used with a steel knife or stone to produce spark. Also on a perimeter edge of the body is a magnesium bar that produces small shavings that can be ignited. Also in the rigid body is a magnifying lens used to ignite tinders by sun rays. The belt buckle is waterproof, easily transported and can be use with a knife, hard stone, other metal pieces, or with similar belt buckles worn by others.

Owner:MILLER RONALD

Online water examining technology for blast furnace cooling wall and water tank applying the same

ActiveCN110643765AAccurately judge water leakageChange the disadvantages of relying on manual experience to judge waterCooling devicesChecking devicesInlet valveEngineering

The invention relates to an online water examining technology for a blast furnace cooling wall. The technology comprises the following steps that a cooling wall water inlet valve is turned down according to the pressure inside a furnace in the blast furnace smelting state, so that the water inlet pressure is smaller than the pressure inside the blast furnace, a cooling wall water outlet pipe is inbutt-joint with a water tank, and water inside the cooling wall is made to flow into the water tank; whether or not a coal gas detector has a coal gas detection value in the process is observed; whenthe water level inside the water tank is increased to an isolation plate, water inside a reservoir is drained out step by step, meanwhile, the cooling wall water outlet pipe is disconnected from thewater tank, and pressure relief is performed inside the water tank; if the coal gas detector displays a coal gas value, a kindling material is introduced, and emitted coal gas is combusted. Water examination can be performed on the cooling wall under the production state, whether or not the cooling wall leaks water can be judged precisely, the defect that existing water examination is judged by means of artificial experience is changed, and the online water examining accuracy of the blast furnace cooling wall is improved.

Owner:SGIS SONGSHAN CO LTD

Blind fire tinder fuel in condition of low temperature and low pressure

InactiveCN101285014ASolve technical problems usedImprove securitySolid fuelsPotassium nitrateCombustion

The invention provides a fire source fuel for the combustion of low-pressure and low-temperature blind fire. The invention comprises following components in percentage by weight percent: 75 to 85 percent of powdered charcoal, 6 to 10 percent of potassium nitrate, 5 to 10 percent of potassium perchlorate, 1 to 5 percent of binding agent, 0 to 2 percent of ammonium nitrate and 0 to 1 percent of burning-smell regulator. The manufacturing process of the fire source fuel is environment friendly and high in safety. Results of on-the-spot tests show that the fire source fuel of the invention can burn in blind fire under conditions of the elevation of 8800m and the temperature of 45 DEG C below zero and can continue to burn for quite a long time, the ignition quality is reliable and stable, the flame can not be extinguished under weathers of gale, rain and snow, the combustion of the fire source fuel is of safety, reliability, no smoke and no toxicity, and the fire source fuel is convenient in carrying and can meet requirements of people who need to carry fire sources while climbing peaks, thereby the invention provides the solid fire source fuel which is convenient in carrying and capable of burning in blind fire for quite a long time for field mountaineering, expedition and field operation training; the invention is wide in use conditions and environments and can be used in all places of the earth, particular in alpine regions for outdoor use (the elevation is more than 3000m and the ambient temperature is less than 0 DEG C), and the invention can be used to the conservation of the fire source for warm-getting, field mountaineering and expedition.

Owner:XIAN NORTH HUIAN CHEM IND CO LTD

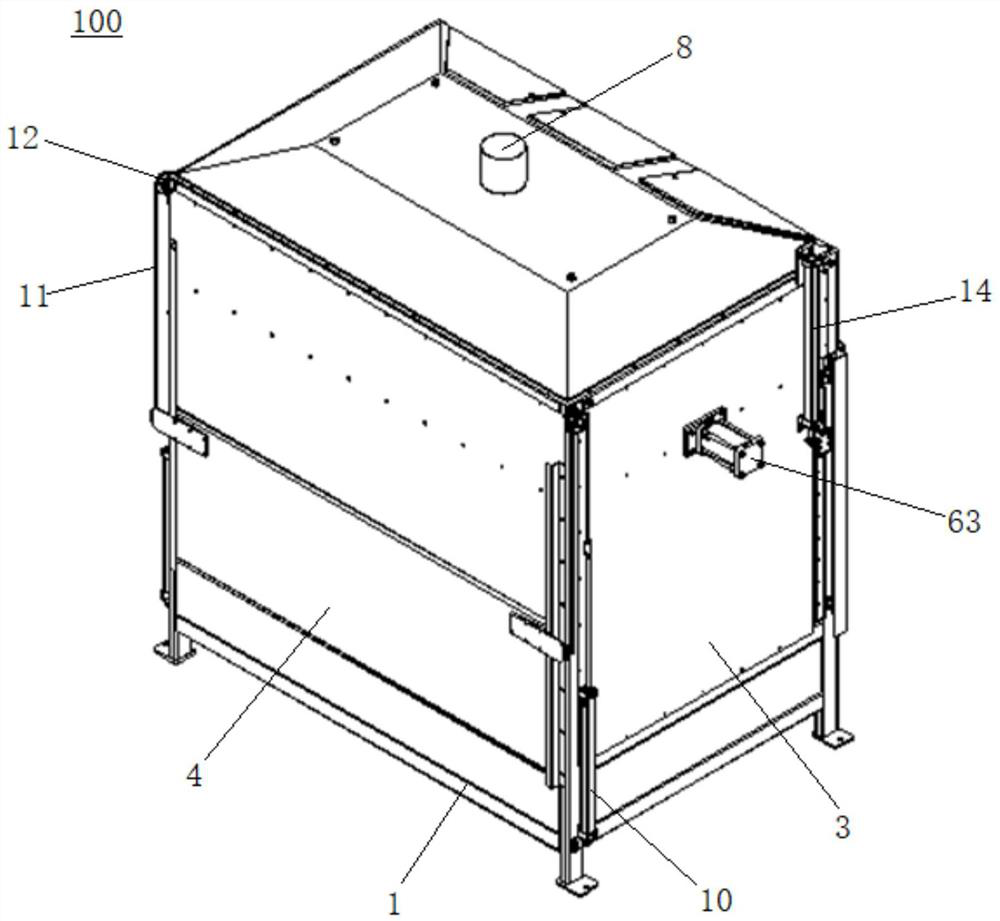

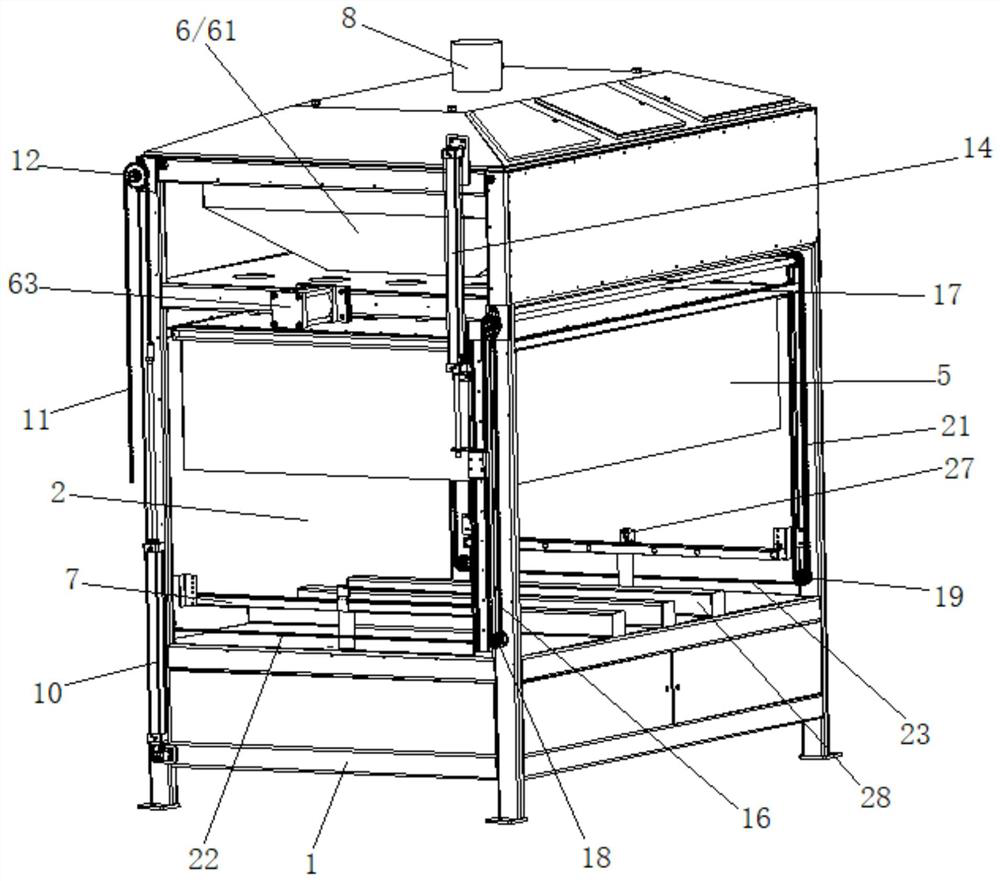

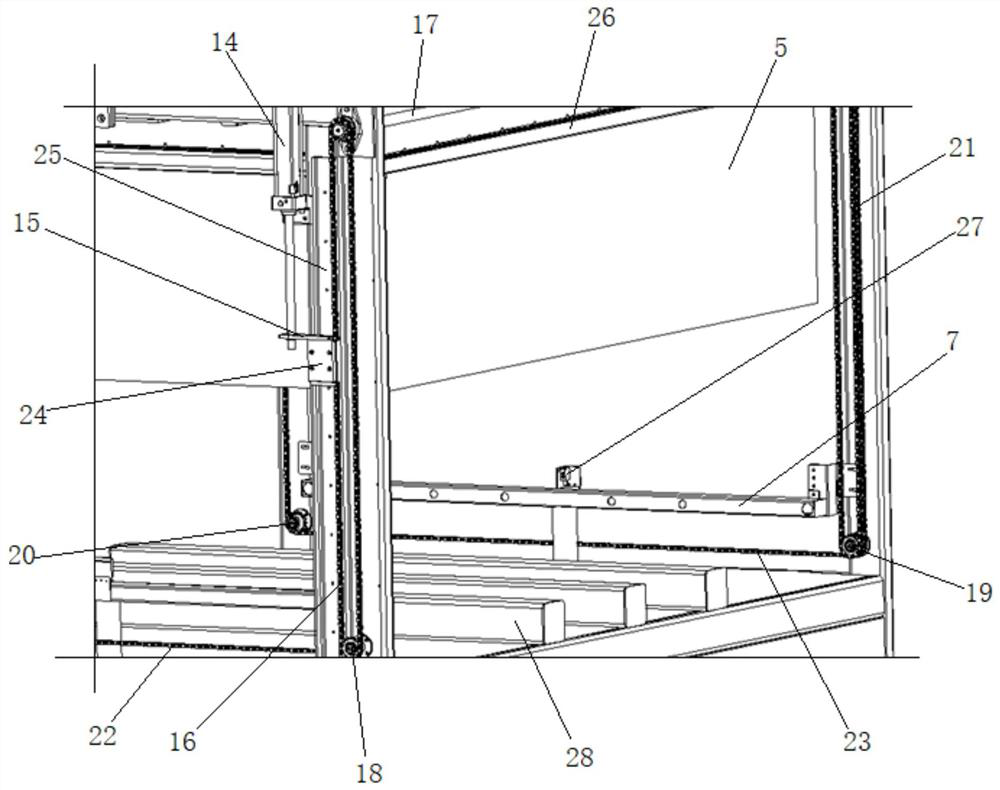

Automatic fire extinguishing device

PendingCN112245835ASo as not to damageGuarantee running stabilityFire rescueAutomatic fire suppressionStructural engineering

The invention discloses an automatic fire extinguishing device. The automatic fire extinguishing device comprises a rack, a fence shell, a sliding door, a fire extinguishing blanket and a sand fallingunit; wherein the fence shell is arranged on the rack and forms a fire extinguishing bin in a surrounding mode; the sliding door is located on one side of the fence shell and closes or opens the fireextinguishing bin through up-down movement; the fire extinguishing blanket is located above the fire extinguishing bin and moves up and down; the sand falling unit is located above the fire extinguishing blanket; an air blowing pipe for blowing air into the fire extinguishing bin is further arranged in the fire extinguishing bin; and an air outlet pipe is arranged at the top of the fire extinguishing bin for communicating with the outside. The automatic fire extinguishing device can automatically extinguish fire of ignited cargoes, does not need manual work to participate in fire extinguishing, reduces the danger of fire extinguishing, can effectively guarantee that kindling is completely extinguished, is high in fire extinguishing efficiency, and saves time and labor.

Owner:健芮智能科技(昆山)有限公司

Embedded lamp

The invention discloses an embedded lamp with a lamp body mounted in a fire-proof cover, the fire-proof cover is composed of a metal layer envelopping a fire-proof heat insulation layer or coated with the fire-proof heat insulation layer, the fire-proof cover can prevent fire propagation from the lamp body to circumambience, and the fire-proof heat insulation layer would not make a temperature of an outer surface of the fire-proof cover be excessive high so as to result burning of some tinder around the fire-proof cover, a cover wall of the fire-proof cover is provided with a heat dispersion opening mounted with an expanded type fire-proof sheet, a heat dispersion hole is arranged at a position of the expanded type fire-proof sheet corresponding to the heat dispersion opening and / or the heat dispersion hole is arranged between an edge of the expanded type fire-proof sheet and an edge of the heat dispersion opening, so that the lamp can performing heat dispersion normally at a common condition, when encountering a fire, the heat dispersion opening can be automatically closed by rapid expansion of the expanded type fire-proof sheet, the fire-proof cover completely insulates the lamp from outside tinder, thereby preventing the tinder propagation from the lamp to outside.

Owner:武良举

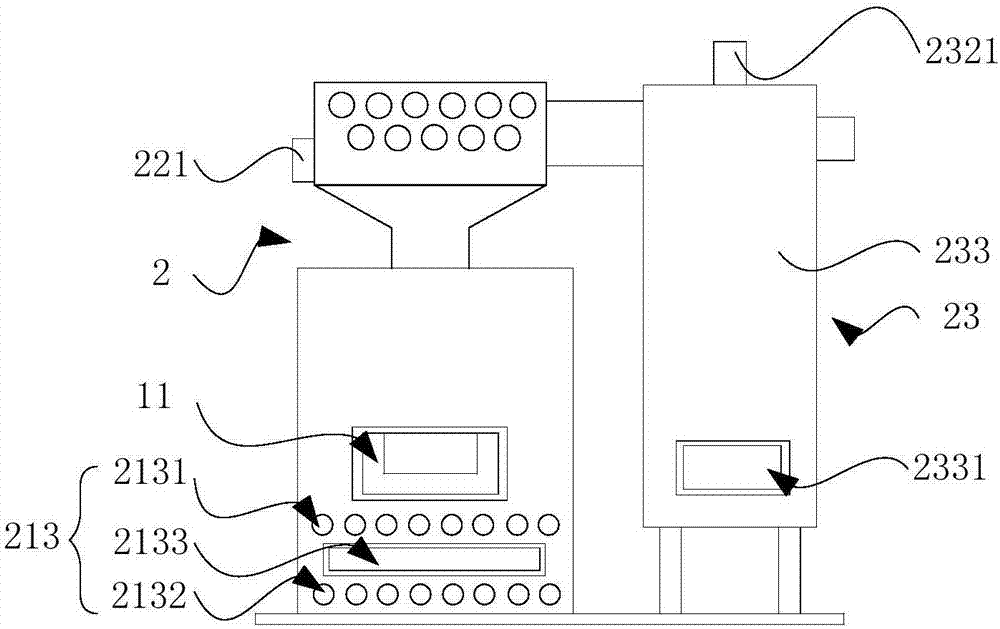

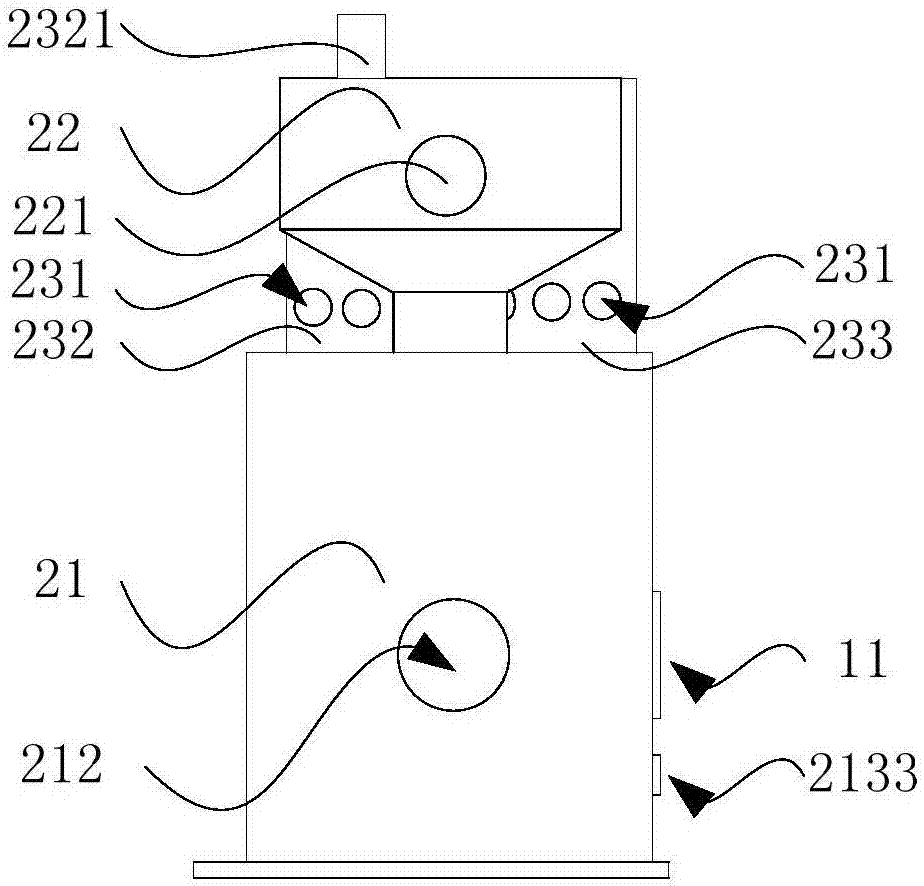

Environment-friendly boiler and heating equipment

ActiveCN107270531AReduce the temperatureReduce the overall heightWater heatersCentral heating systemCoal briquetteProcess engineering

The invention provides an environment-friendly boiler and heating equipment, and relates to the technical field of heating. The environment-friendly boiler comprises a shell and a furnace container arranged inside the shell, a cavity used for flowing of heater water is formed between the shell and the furnace container, and the furnace container comprises a main combustion furnace container, an upper furnace container and a side furnace container, wherein the main combustion furnace container is provided with a coal feeding port which communicates with the external environment of the shell, the upper furnace container at least is partially arranged on the upper portion of the main combustion furnace container and communicates with the main combustion furnace container, the upper furnace container is provided with a putting port used for putting a kindling material and multiple first pipes used for circulation of the heater water, a U-shaped channel used for circulation of soot is formed in the side furnace channel, one side of the upper portion of the side furnace container communicates with the upper furnace container, the other side of the upper portion of the side furnace container communicates with the external environment of the shell for exhausting the soot, and the side furnace container is provided with multiple second pipes used for circulation of the heater water. According to the environment-friendly boiler, coal briquettes can be fully burnt, the heat transfer efficiency is high, and the heating cost is low.

Owner:赵治荣

Ignition, flameout protection and kindling integrated structure with kindling pipe arranged in central hole of ceramic body

PendingCN110440304AIncreased durabilityEasy production and installationDomestic stoves or rangesElectric spark ignitersFailure rateCombustion chamber

The invention relates to the field of commercial kitchen ware, in particular to an ignition, flameout protection and kindling integrated structure with a kindling pipe arranged in a central hole of aceramic body. The structure comprises a combustion chamber head, the ceramic body, the kindling pipe, a kindling spray head, an ignition needle, a flameout protection probe, a sleeve, a sleeving fastening nut and a buckling nut, the whole structure is cylindrical, the combustion chamber head, the sleeve, the ceramic body, the kindling pipe and the kindling spray head are coaxial, the structure iscompact, production and installation of a burner are facilitated, an integrated universal part can be produced in a large scale, and the integrated structure has a wider application space. According to the integrated structure with compact structure, a cover plate with the small size can be used for perfectly protecting various parts inside the lower part and combustion flame, so that the combustion of kindling gas and the stability of flame output can be realized; and the ignition needle electrode is stable in generation of electric sparks, the flameout protection probe detects that a flame signal, so that the effects of being stable and reliable are achieved, then the durability of the ceramic body can be greatly improved, and the overall failure rate is greatly reduced.

Owner:浙江惠厨节能科技有限公司

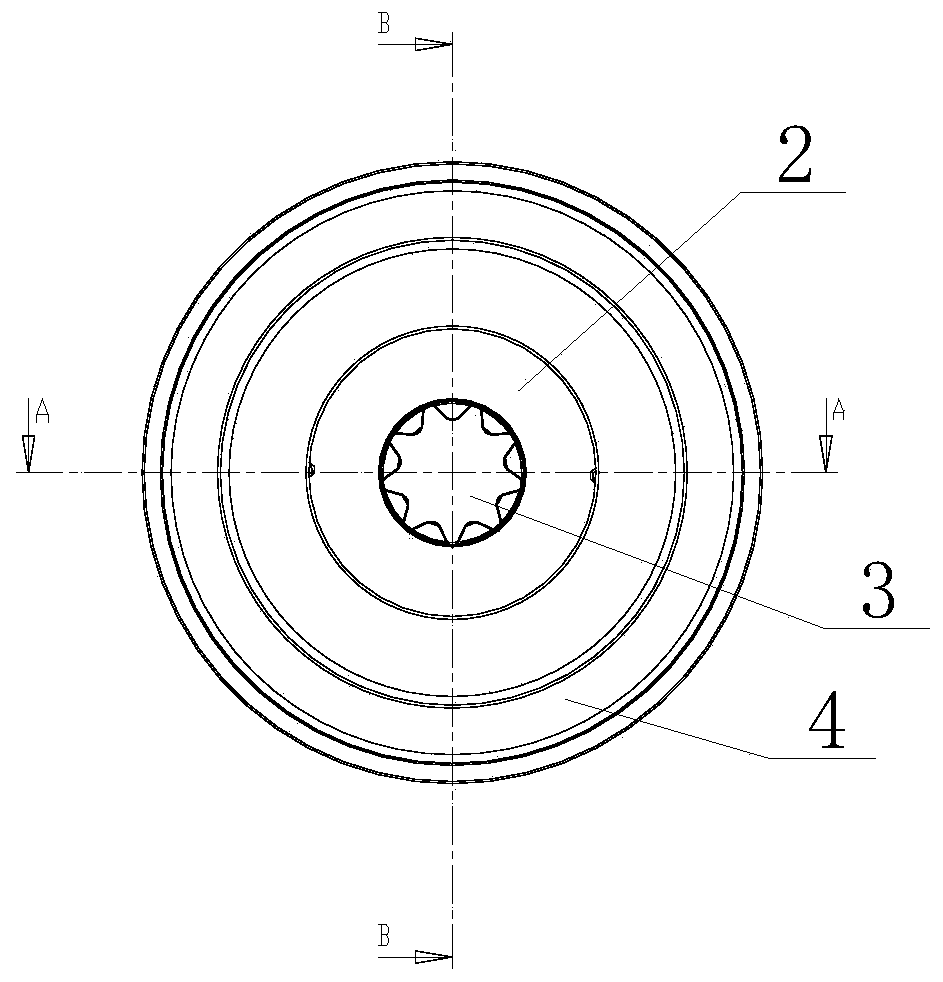

Double Cyclone Burner

The invention discloses a double cyclone burner comprising a burner air box, an outer ring burning core, an inner ring burning core, a kindling burner, an ignition pin and a flame induction pin. The outer ring burning core is arranged in a holding cavity of the burner air box. A plurality of outer helical teeth are distributed outside the outer ring burning core circumferentially. The outer helical teeth and the inner wall of the burner air box form a plurality of outer helical air channels. Each outer helical air channel is provided with a fuel gas outlet discharging fuel gas. The inner ringburning core is arranged in a holding groove formed in a core body of the outer ring burning core from top to bottom. A plurality of inner helical teeth are distributed outside the inner ring burningcore circumferentially. The inner helical teeth and the groove wall of the holding groove form a plurality of inner helical air channels. Each inner helical air channel is provided with a fuel gas outlet discharging fuel gas. An air inlet in the bottom of the burner air box communicates with the outer helical air channels and the inner helical air channels. Through the double cyclone burner provided by the invention, fuel gas can be fully burnt, flame temperature is increased, and use safety is ensured.

Owner:欧华权 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com