High-leg furnace end with uniform gas mixing function

A burner and gas mixing technology, which is used in household stoves/stoves, gaseous heating fuels, household heating, etc., can solve the problems of affecting combustion efficiency, flame drift, flame instability, etc., to increase the heating area and improve the use effect. , The effect of preventing gas backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

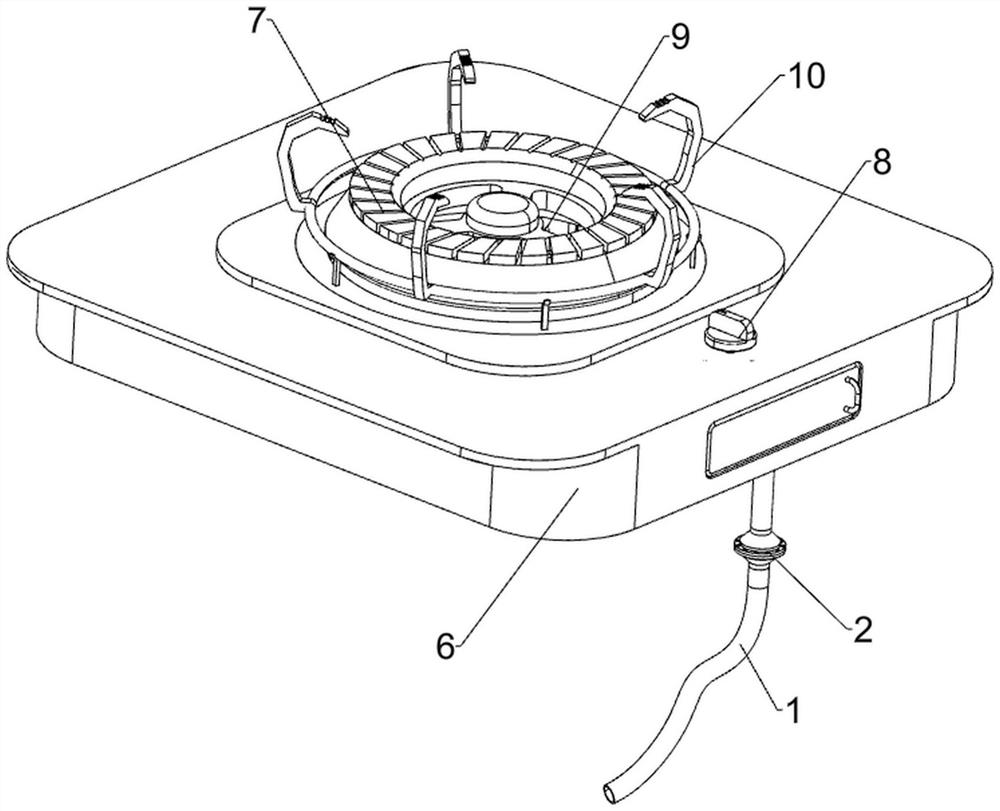

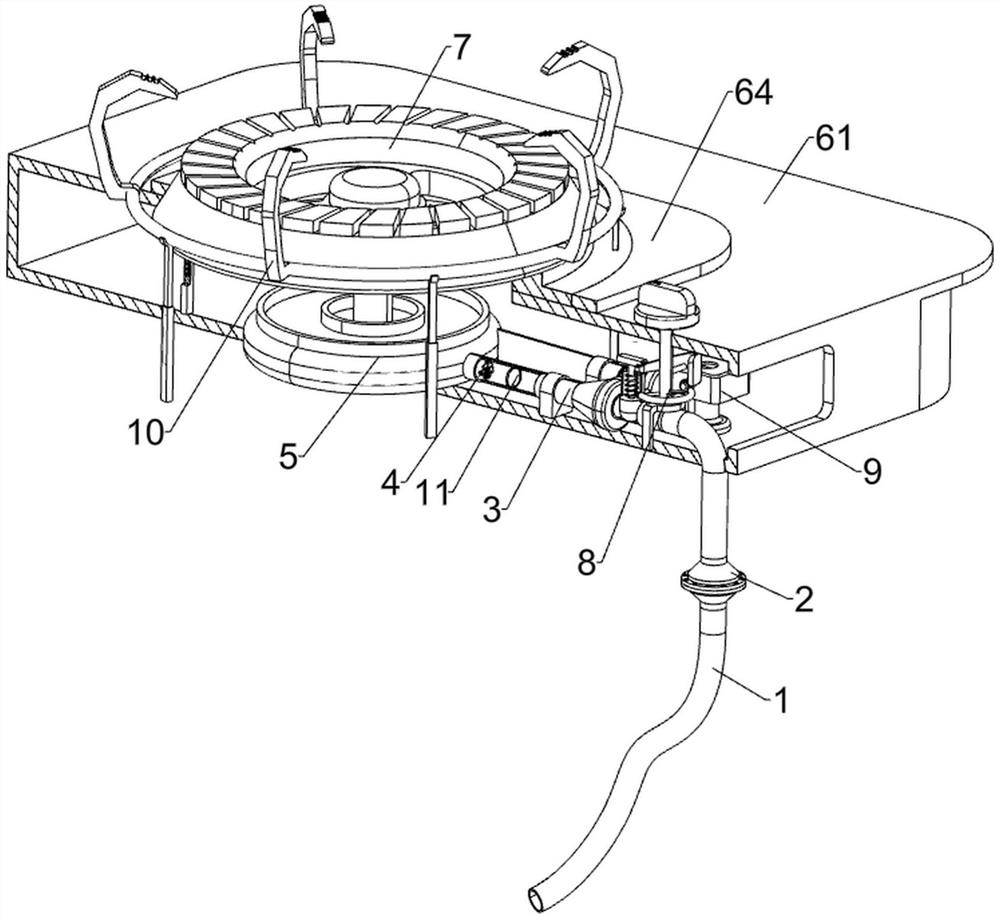

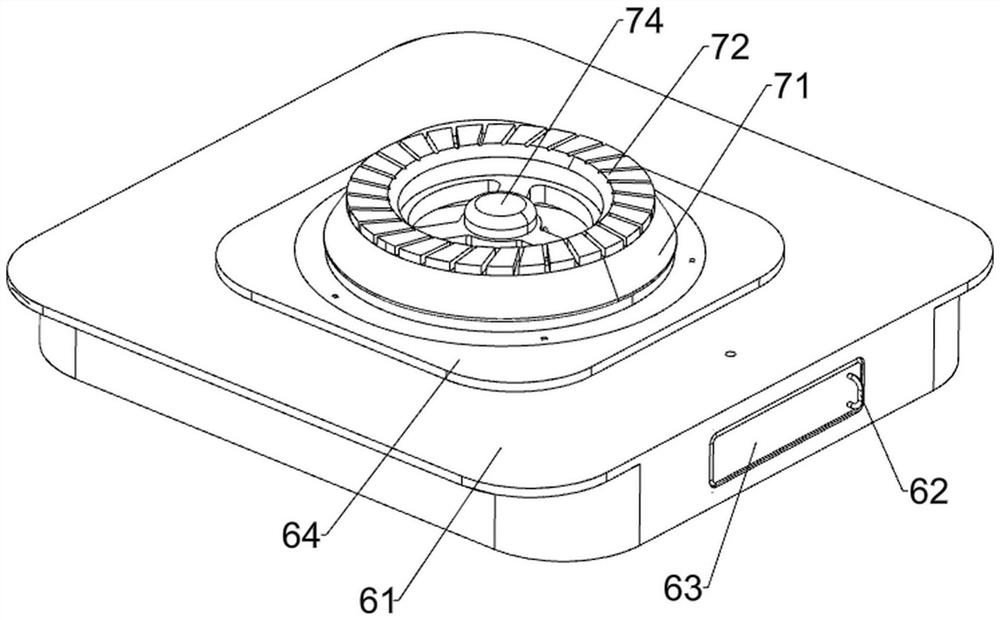

[0026] A tall stove top with a homogeneous gas mixture, such as figure 1 , figure 2 , image 3 and Figure 7 As shown, it includes a gas hose 1, a flame arrester 2, a gas pipeline 3, a turbine 4, a burner 5, a placement mechanism 6 and a stove assembly 7, and a placement mechanism 6 is provided inside the equipment, and a stove is arranged on the top of the placement mechanism 6. Component 7, a furnace head 5 is arranged in the placement mechanism 6, a gas transmission pipeline 3 is connected to the right side of the furnace head 5, a flame arrester 2 is provided at the bottom of the gas transmission pipeline 3, and a gas connection hose 1 is provided at the bottom of the flame arrester 2. A turbine 4 is rotatably arranged between the inner walls of the left part of the pipeline 3 .

[0027] The placement mechanism 6 includes an installation slot plate 61, a handle bar 62, a partition door 63, and an installation plate 64. The top of the installation slot plate 61 is embed...

Embodiment 2

[0031] On the basis of Example 1, such as figure 1 , figure 2 , Figure 4 and Figure 5 As shown, it also includes an air delivery adjustment mechanism 8, and the air delivery adjustment mechanism 8 includes a mounting seat 81, an installation shaft 82, an adjustment knob 83, a first connecting rod 84, a first wedge 85, and a second wedge 86. , the first back-moving spring 87 and the plug post 88, the right side of the bottom of the installation groove plate 61 is provided with an installation seat 81, the top of the installation seat 81 is rotatably provided with an installation shaft 82, the installation shaft 82 passes through the installation groove plate 61, and the installation shaft 82 An adjustment knob 83 is provided on the top, a first connecting rod 84 is provided on the rear side of the middle part of the installation shaft 82, a first wedge-shaped block 85 is provided on the rear side of the first connecting rod 84, and a blocking column 88 is provided slidingl...

Embodiment 3

[0035] On the basis of Example 2, such as figure 1 , figure 2 , Figure 6 and Figure 8 As shown, it also includes a uniform heating mechanism 10 for cooking utensils. The uniform heating mechanism 10 for cooking utensils includes a guide groove plate 101, a placement block 102, a second return spring 103 and a support block 104. The bottom of the inner wall of the installation groove plate 61 is provided with a plurality of guide grooves Plate 101, the guide groove plate 101 is slidably connected with a placement block 102, the placement block 102 is slidably connected with the top of the installation groove plate 61, and a second return spring 103 is connected between the bottom of the placement block 102 and the bottom of the inner wall of the guide groove plate 101, A supporting block 104 is placed between the tops of the placing blocks 102 .

[0036] Also includes a one-way gas transmission mechanism 11, the one-way gas transmission mechanism 11 includes a rotating sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com