Ignition, flameout protection and kindling integrated structure with kindling pipe arranged in central hole of ceramic body

A kind of ignition tube and ceramic body technology, which is applied in the field of commercial kitchen utensils, can solve the problem of reduction, and achieve the effects of improved durability, stable electric spark, and reduced overall failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

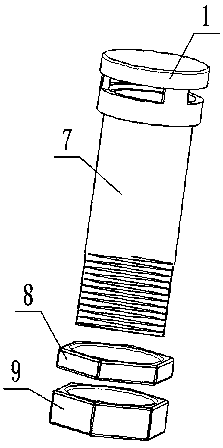

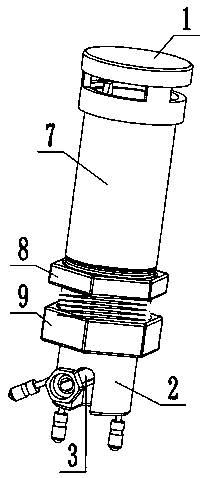

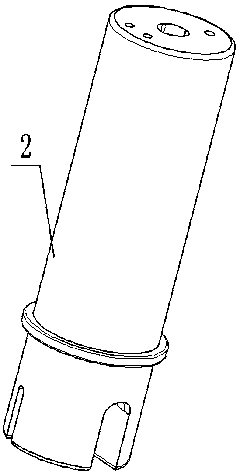

[0015] Combine below Figure 1-5 Describe this embodiment. The present invention relates to the field of commercial kitchen utensils. More specifically, it is an integrated structure of ignition and extinguishing fire with a tinder tube placed in the center hole of a ceramic body, including a combustion chamber head 1, a ceramic body 2, a tinder tube 3, Ignition nozzle 4, ignition needle 5, flameout protection probe 6, sleeve 7, sleeve fastening nut 8, buckle nut 9; ignition tube 3, ceramic body 2, combustion chamber head 1, sleeve 7, ignition nozzle 4 Coaxial, the overall structure is cylindrical, the compact structure is convenient for the production and installation of the burner, and it is conducive to mass production as an integrated general-purpose component, which can make it have a wider application space. The compact integrated structure has a smaller size The small cover plate perfectly protects various internal components and combustion flames below, which can reali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com